ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 131 of 1640

Main Bearing s

Clearanc e

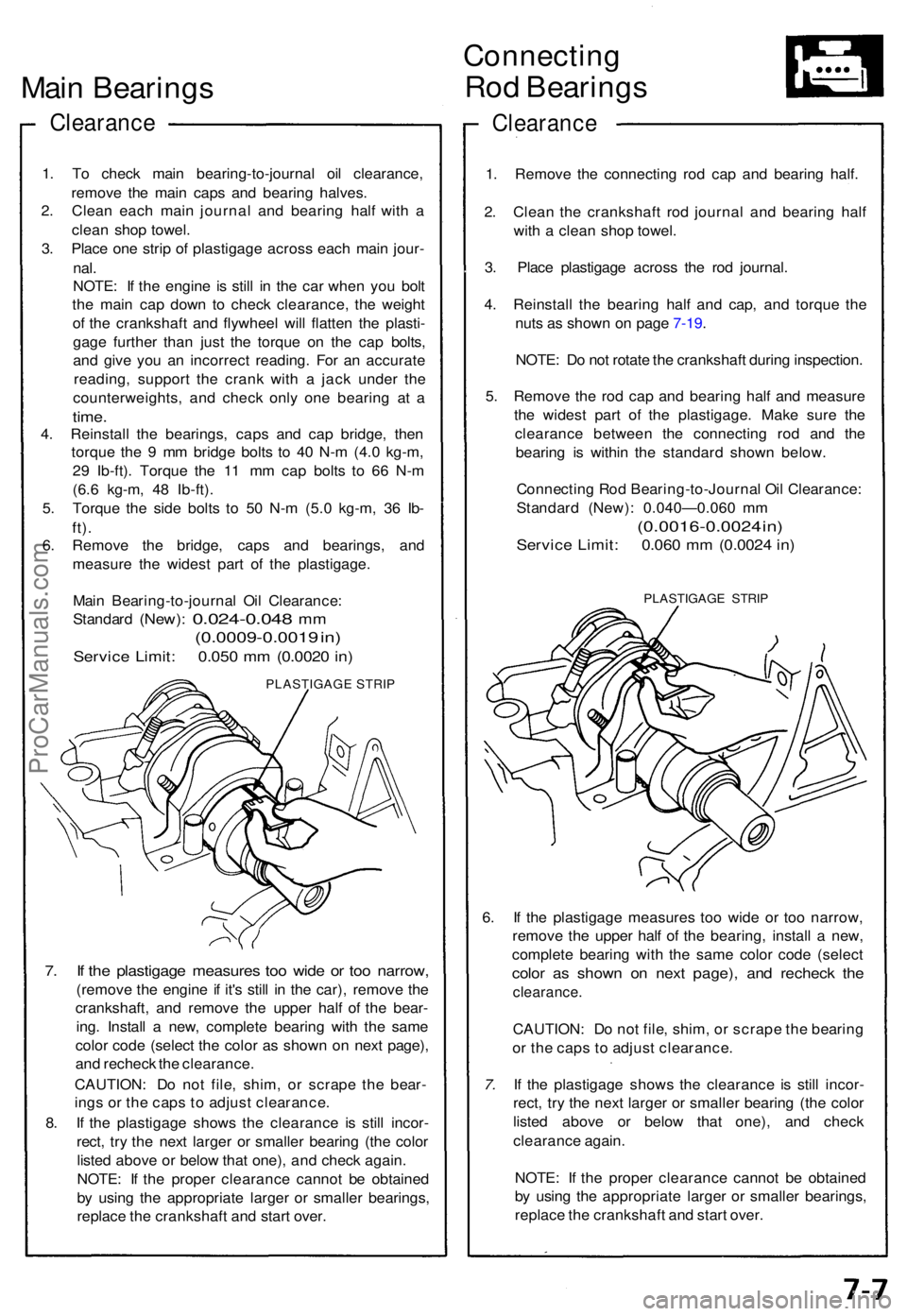

1. T o chec k mai n bearing-to-journa l oi l clearance ,

remov e th e mai n cap s an d bearin g halves .

2 . Clea n eac h mai n journa l an d bearin g hal f wit h a

clea n sho p towel.

3 . Plac e on e stri p o f plastigag e acros s eac h mai n jour -

nal.

NOTE : I f th e engine is stil l i n th e ca r whe n yo u bol t

th e mai n ca p dow n t o chec k clearance , th e weigh t

o f th e crankshaf t an d flywhee l wil l flatte n th e plasti -

gag e furthe r tha n jus t th e torqu e o n th e ca p bolts ,

an d giv e yo u a n incorrec t reading . Fo r a n accurat e

reading , suppor t th e cran k wit h a jac k unde r th e

counterweights , an d chec k onl y on e bearin g a t a

time .

4. Reinstal l th e bearings , cap s an d ca p bridge , the n

torqu e th e 9 m m bridg e bolt s t o 4 0 N- m (4. 0 kg-m ,

2 9 Ib-ft) . Torqu e th e 1 1 m m ca p bolt s t o 6 6 N- m

(6. 6 kg-m , 4 8 Ib-ft) .

5 . Torqu e th e sid e bolt s t o 5 0 N- m (5. 0 kg-m , 3 6 Ib -

ft).

6. Remov e th e bridge , cap s an d bearings , an d

measur e th e wides t par t o f th e plastigage .

Mai n Bearing-to-journa l Oi l Clearance :

Standar d

(New): 0.024-0.04 8 mm

(0.0009-0.001 9 in )

Servic e Limit : 0.05 0 m m (0.002 0 in )

PLASTIGAG E STRI P

7. I f th e plastigag e measure s to o wid e o r to o narrow ,

(remove th e engine if it' s stil l i n th e car) , remov e th e

crankshaft , an d remov e th e uppe r hal f o f th e bear -

ing . Instal l a new , complet e bearin g wit h th e sam e

colo r cod e (selec t th e colo r a s show n o n nex t page) ,

an d rechec k th e clearance .

CAUTION : D o no t file , shim , o r scrap e th e bear -

ing s o r th e cap s t o adjus t clearance .

8 . I f th e plastigag e show s th e clearanc e i s stil l incor -

rect , tr y th e nex t large r o r smalle r bearin g (th e colo r

liste d abov e o r belo w tha t one) , an d chec k again .

NOTE : I f th e prope r clearanc e canno t b e obtaine d

b y usin g th e appropriat e large r o r smalle r bearings ,

replac e th e crankshaf t an d star t over .

Connectin g

Rod Bearing s

Clearanc e

1. Remov e th e connectin g ro d ca p an d bearin g half .

2 . Clea n th e crankshaf t ro d journa l an d bearin g hal f

wit h a clea n sho p towel .

3 . Plac e plastigag e acros s th e ro d journal .

4 . Reinstal l th e bearin g hal f an d cap , an d torqu e th e

nut s a s show n o n pag e 7-19 .

NOTE : D o no t rotat e th e crankshaft during inspection .

5 . Remov e th e ro d ca p an d bearin g hal f an d measur e

th e wides t par t o f th e plastigage . Mak e sur e th e

clearanc e betwee n th e connectin g ro d an d th e

bearin g i s withi n th e standar d show n below .

Connectin g Ro d Bearing-to-Journa l Oi l Clearance :

Standar d (New) : 0.040—0.06 0 m m

(0.0016-0.002 4 in )

Servic e Limit : 0.06 0 m m (0.002 4 in )

PLASTIGAG E STRI P

6. I f th e plastigag e measure s to o wid e o r to o narrow ,

remov e th e uppe r hal f of the bearing , instal l a new ,

complet e bearin g wit h th e sam e colo r cod e (selec t

color a s show n o n nex t page) , an d rechec k th e

clearance .

CAUTION: D o no t file , shim , o r scrap e th e bearin g

o r th e cap s t o adjus t clearance .

7. I f th e plastigag e show s th e clearanc e i s stil l incor -

rect , tr y th e nex t large r o r smalle r bearin g (th e colo r

liste d abov e o r belo w tha t one) , an d chec k

clearanc e again .

NOTE : I f th e prope r clearanc e canno t b e obtaine d

b y usin g th e appropriat e large r o r smalle r bearings ,

replac e th e crankshaf t an d star t over .

ProCarManuals.com

Page 132 of 1640

Main Bearings

Selection

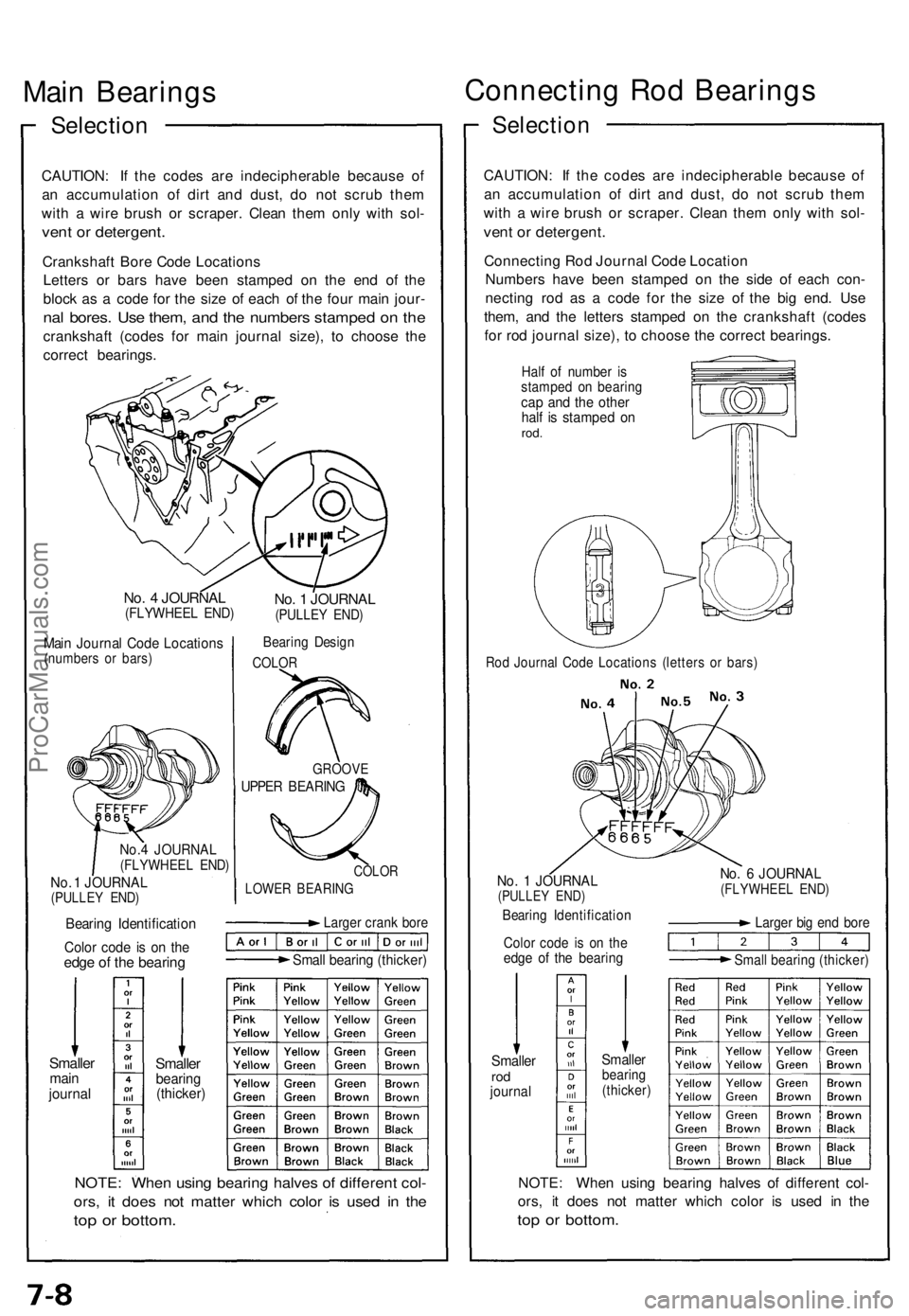

CAUTION: If the codes are indecipherable because of

an accumulation of dirt and dust, do not scrub them

with a wire brush or scraper. Clean them only with sol-

vent or detergent.

Crankshaft Bore Code Locations

Letters or bars have been stamped on the end of the

block as a code for the size of each of the four main jour-

nal bores. Use them, and the numbers stamped on the

crankshaft (codes for main journal size), to choose the

correct bearings.

No. 4 JOURNAL

(FLYWHEEL END)

Main Journal Code Locations

(numbers or bars)

No.4 JOURNAL

(FLYWHEEL END)

No. 1 JOURNAL

(PULLEY END)

No. 1 JOURNAL

(PULLEY END)

Bearing Design

COLOR

GROOVE

UPPER BEARING

COLOR

LOWER BEARING

Bearing Identification

Color code is on the

edge of the bearing

Larger crank bore

Small bearing (thicker)

Smaller

main

journal

Smaller

bearing

(thicker)

NOTE: When using bearing halves of different col-

ors, it does not matter which color is used in the

top or bottom.

Connecting Rod Bearings

Selection

CAUTION: If the codes are indecipherable because of

an accumulation of dirt and dust, do not scrub them

with a wire brush or scraper. Clean them only with sol-

vent or detergent.

Connecting Rod Journal Code Location

Numbers have been stamped on the side of each con-

necting rod as a code for the size of the big end. Use

them, and the letters stamped on the crankshaft (codes

for rod journal size), to choose the correct bearings.

Half of number is

stamped on bearing

cap and the other

half is stamped on

rod.

No. 1 JOURNAL

(PULLEY END)

Bearing Identification

Color code is on the

edge of the bearing

No. 6 JOURNAL

(FLYWHEEL END)

Larger big end bore

Small bearing (thicker)

Smaller

rod

journal

Smaller

bearing

(thicker)

NOTE: When using bearing halves of different col-

ors, it does not matter which color is used in the

top or bottom.

Rod Journal Code Locations (letters or bars)ProCarManuals.com

Page 133 of 1640

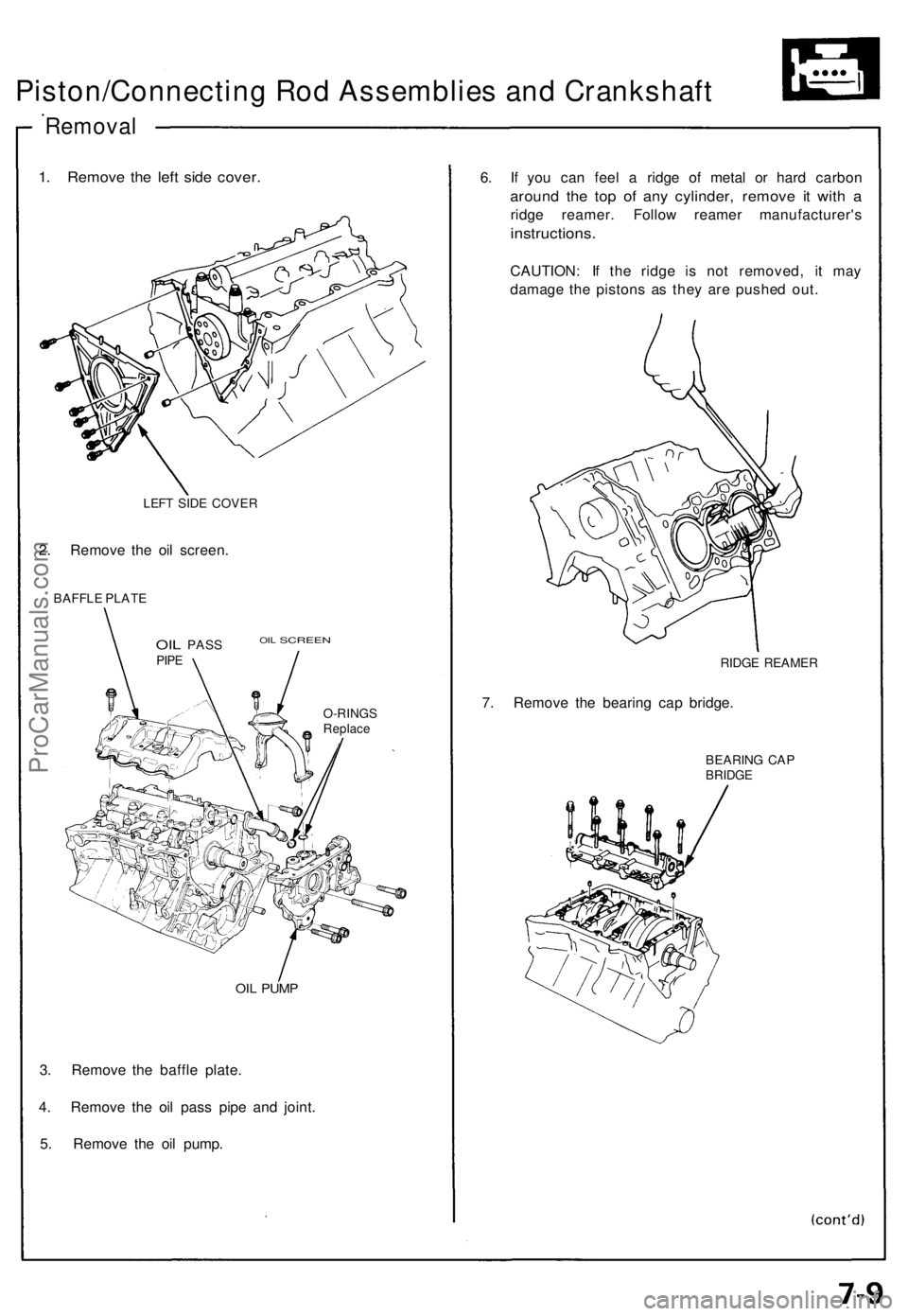

Piston/Connecting Rod Assemblies and Crankshaft

Removal

1. Remov e th e lef t sid e cover .

LEFT SID E COVE R

2. Remov e th e oi l screen .

BAFFLE PLAT E

OIL PAS S OI L SCREEN

PIPE

O-RING SReplace

OIL PUM P

3. Remov e th e baffl e plate .

4 . Remov e th e oi l pas s pip e an d joint .

5 . Remov e th e oi l pump . 6

. I f yo u ca n fee l a ridg e o f meta l o r har d carbo n

around th e to p o f an y cylinder , remov e i t wit h a

ridg e reamer . Follo w reame r manufacturer' s

instructions.

CAUTION: I f th e ridg e i s no t removed , i t ma y

damag e th e piston s a s the y ar e pushe d out .

RIDG E REAME R

7. Remov e th e bearin g ca p bridge .

BEARIN G CA PBRIDG E

ProCarManuals.com

Page 134 of 1640

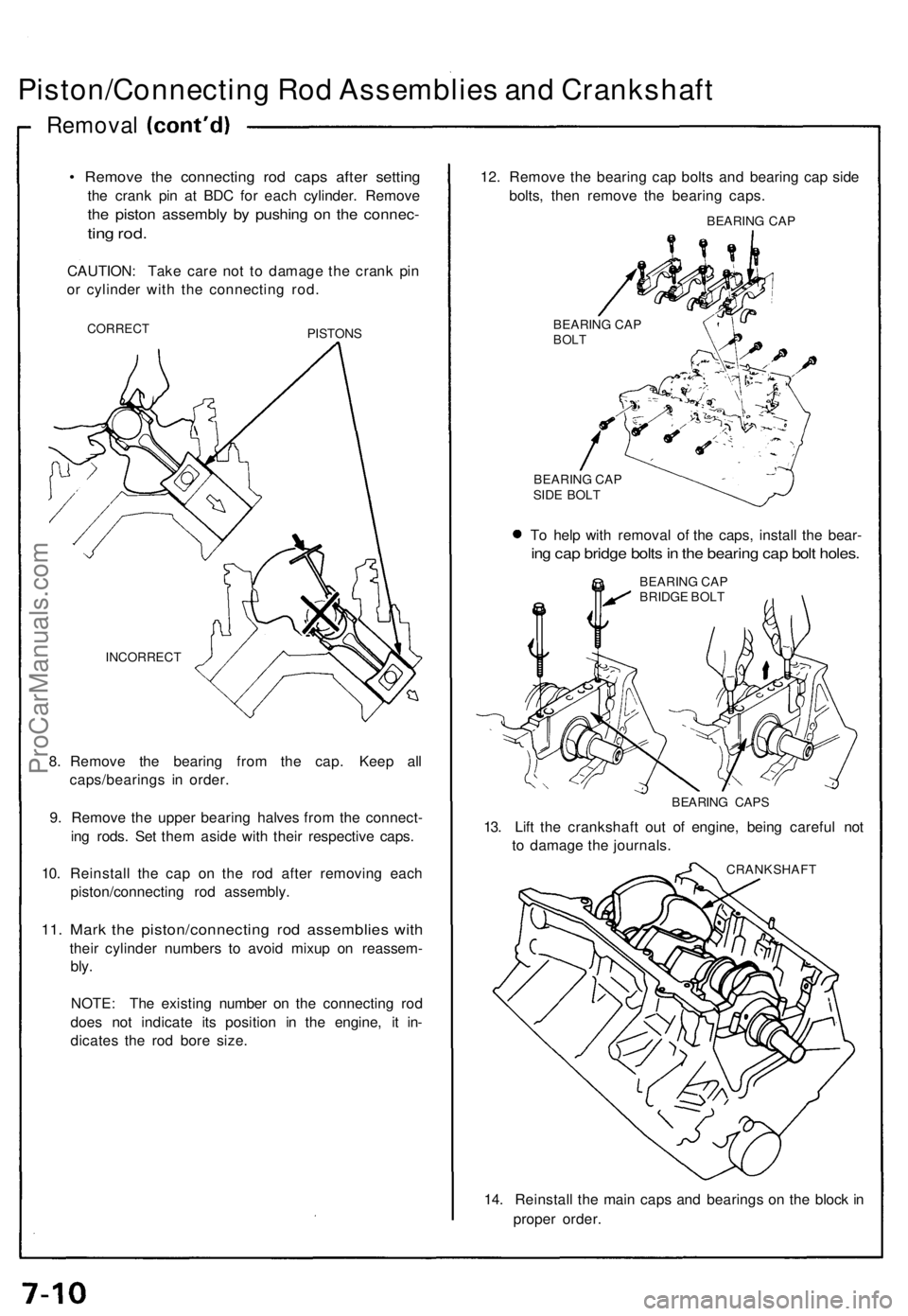

Piston/Connecting Rod Assemblies and Crankshaft

Removal

• Remove the connecting rod caps after setting

the crank pin at BDC for each cylinder. Remove

the piston assembly by pushing on the connec-

ting rod.

CAUTION: Take care not to damage the crank pin

or cylinder with the connecting rod.

CORRECT

PISTONS

INCORRECT

8. Remove the bearing from the cap. Keep all

caps/bearings in order.

9. Remove the upper bearing halves from the connect-

ing rods. Set them aside with their respective caps.

10. Reinstall the cap on the rod after removing each

piston/connecting rod assembly.

11. Mark the piston/connecting rod assemblies with

their cylinder numbers to avoid mixup on reassem-

bly.

NOTE: The existing number on the connecting rod

does not indicate its position in the engine, it in-

dicates the rod bore size.

12. Remove the bearing cap bolts and bearing cap side

bolts, then remove the bearing caps.

BEARING CAP

BEARING CAP

BOLT

BEARING CAP

SIDE BOLT

To help with removal of the caps, install the bear-

ing cap bridge bolts in the bearing cap bolt holes.

BEARING CAP

BRIDGE BOLT

BEARING CAPS

13. Lift the crankshaft out of engine, being careful not

to damage the journals.

CRANKSHAFT

14. Reinstall the main caps and bearings on the block in

proper order.ProCarManuals.com

Page 135 of 1640

Crankshaft

Inspection

• Clea n th e crankshaf t oi l passage s wit h pip e

cleaner s o r a suitabl e brush .

• Chec k th e keywa y an d threads .

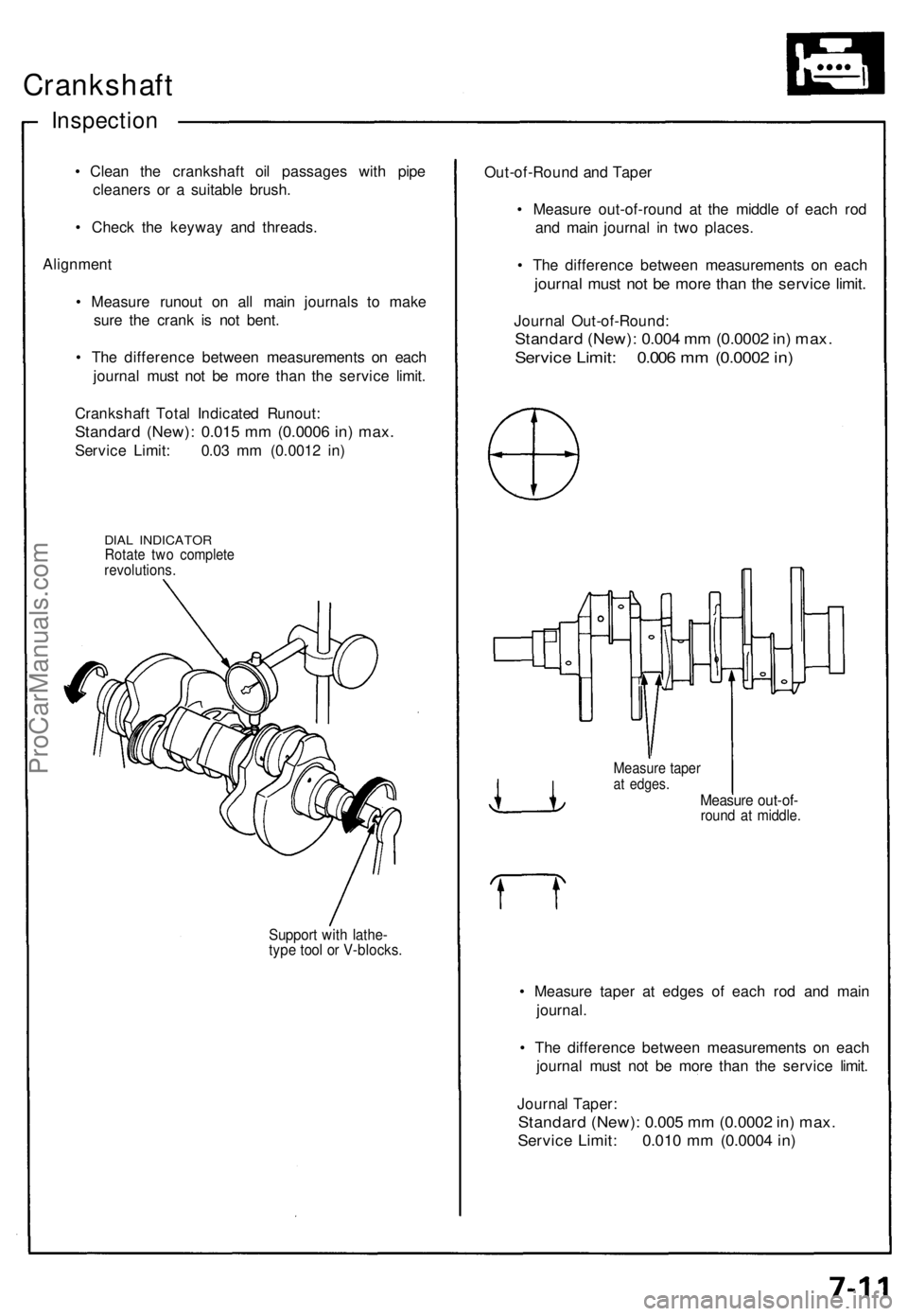

Alignmen t

• Measur e runou t o n al l mai n journal s t o mak e

sur e th e cran k i s no t bent .

• Th e differenc e betwee n measurement s o n eac h

journa l mus t no t b e mor e tha n th e servic e limit .

Crankshaf t Tota l Indicate d Runout :

Standard (New) : 0.01 5 m m (0.000 6 in ) max .

Servic e Limit : 0.0 3 m m (0.001 2 in )

DIA L INDICATO RRotate tw o complet erevolutions .

Support wit h lathe -type too l o r V-blocks .

Out-of-Roun d an d Tape r

• Measur e out-of-roun d a t th e middl e o f eac h ro d

an d mai n journa l i n tw o places .

• Th e differenc e betwee n measurement s o n eac h

journa l mus t no t b e mor e tha n th e servic e limit .

Journa l Out-of-Round :

Standard (New) : 0.00 4 m m (0.000 2 in ) max .

Servic e Limit : 0.00 6 m m (0.000 2 in )

Measur e tape rat edges .Measur e out-of -round a t middle .

• Measur e tape r a t edge s o f eac h ro d an d mai n

journal .

• Th e differenc e betwee n measurement s o n eac h

journa l mus t no t b e mor e tha n th e servic e limit .

Journa l Taper :

Standar d (New) : 0.00 5 m m (0.000 2 in ) max .

Servic e Limit : 0.01 0 m m (0.000 4 in )

ProCarManuals.com

Page 136 of 1640

Cylinder Bloc k

Inspectio n

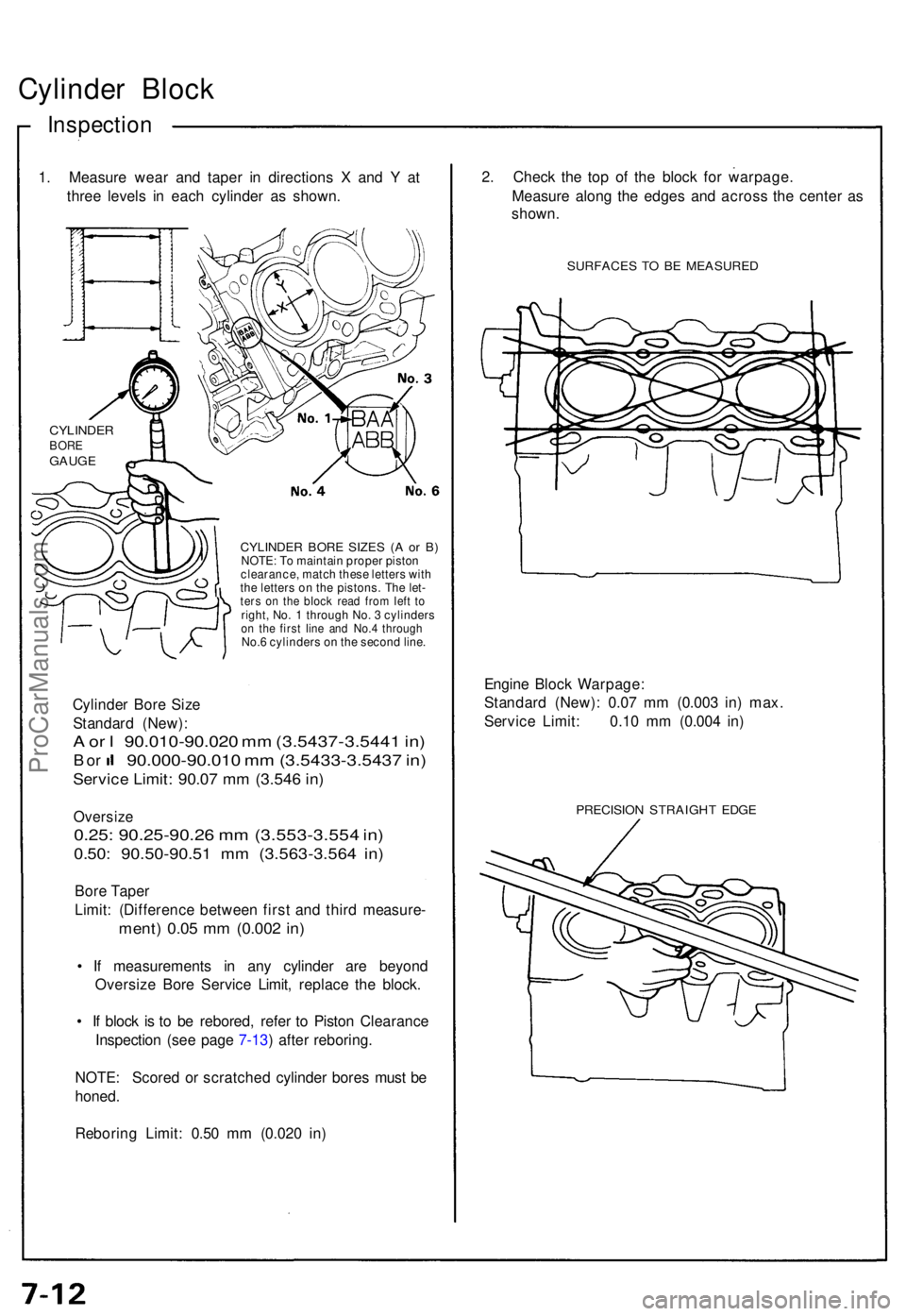

1. Measur e wea r an d tape r i n direction s X an d Y at

thre e level s i n eac h cylinde r a s shown .

CYLINDE R BOR E SIZE S ( A o r B )NOTE : T o maintai n prope r pisto n

clearance , matc h thes e letter s wit h

th e letter s o n th e pistons . Th e let -

ters o n th e bloc k rea d fro m lef t t oright , No . 1 throug h No . 3 cylinder son th e firs t lin e an d No. 4 throug hNo.6 cylinder s o n th e secon d line .

Cylinde r Bor e Siz e

Standar d (New) :

A o r I 90.010-90.02 0 m m (3.5437-3.544 1 in )

B or 90.000-90.01 0 m m (3.5433-3.543 7 in )

Servic e Limit : 90.0 7 m m (3.54 6 in )

Oversiz e

0.25: 90.25-90.2 6 m m (3.553-3.55 4 in )

0.50 : 90.50-90.5 1 m m (3.563-3.56 4 in )

Bor e Tape r

Limit : (Differenc e betwee n firs t an d thir d measure -

ment) 0.0 5 m m (0.00 2 in )

• I f measurement s i n an y cylinde r ar e beyon d

Oversiz e Bor e Servic e Limit , replac e th e block .

• I f bloc k i s t o b e rebored , refe r t o Pisto n Clearanc e

Inspectio n (se e pag e 7-13 ) afte r reboring .

NOTE : Score d o r scratche d cylinde r bore s mus t b e

honed .

Reborin g Limit : 0.5 0 m m (0.02 0 in ) 2

. Chec k th e to p o f th e bloc k fo r warpage .

Measur e alon g th e edge s an d acros s th e cente r a s

shown .

SURFACE S T O B E MEASURE D

Engine Bloc k Warpage :

Standar d (New) : 0.0 7 m m (0.00 3 in ) max .

Servic e Limit : 0.1 0 m m (0.00 4 in )

PRECISIO N STRAIGH T EDG E

CYLINDE RBOREGAUG E

ProCarManuals.com

Page 137 of 1640

Piston/Connecting Rod

Assemblies

Inspection

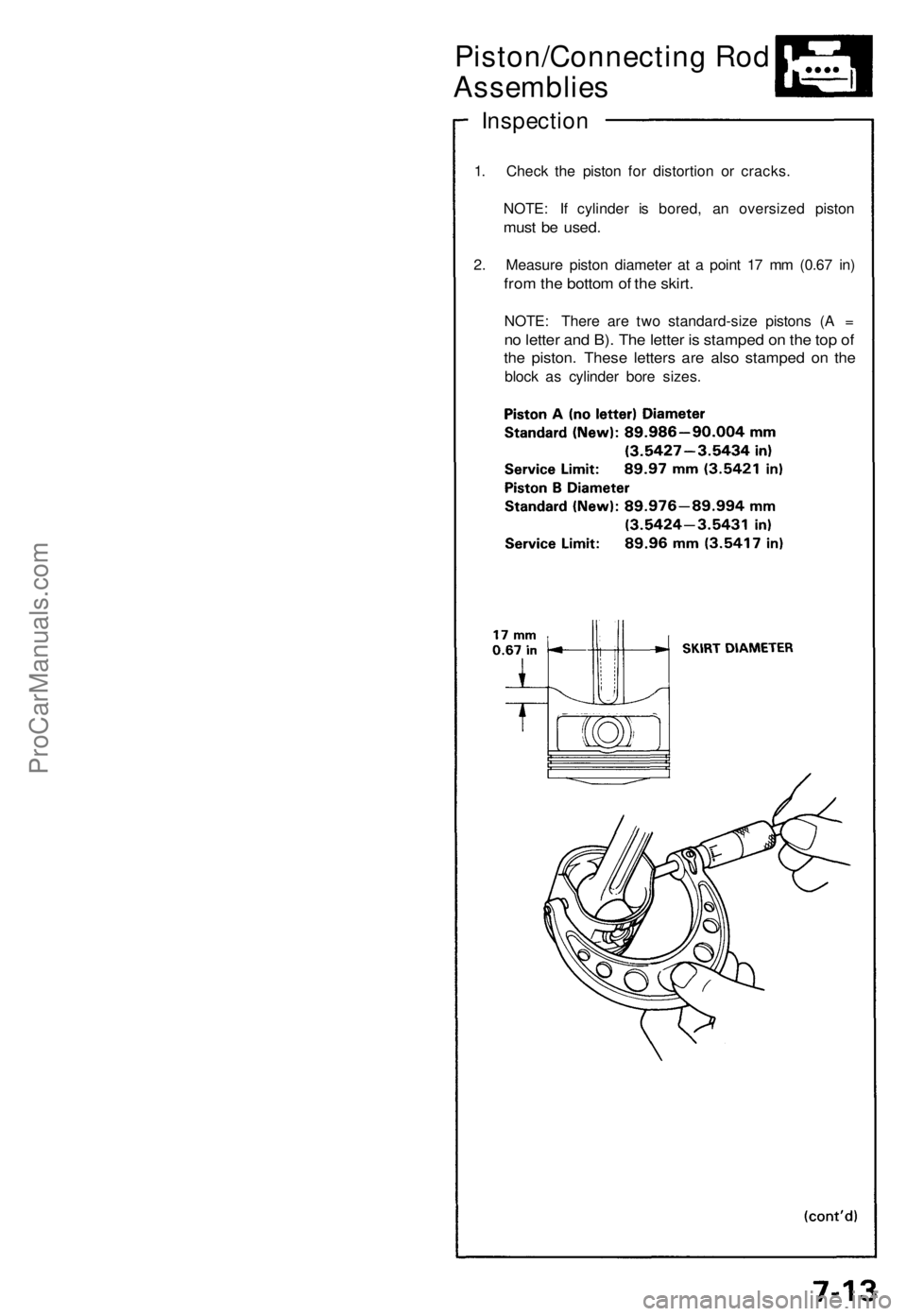

1. Check the piston for distortion or cracks.

NOTE: If cylinder is bored, an oversized piston

must be used.

2. Measure piston diameter at a point 17 mm (0.67 in)

from the bottom of the skirt.

NOTE: There are two standard-size pistons (A =

no letter and B). The letter is stamped on the top of

the piston. These letters are also stamped on the

block as cylinder bore sizes.ProCarManuals.com

Page 138 of 1640

Piston/Connecting Ro d

Assemblie s

Inspection

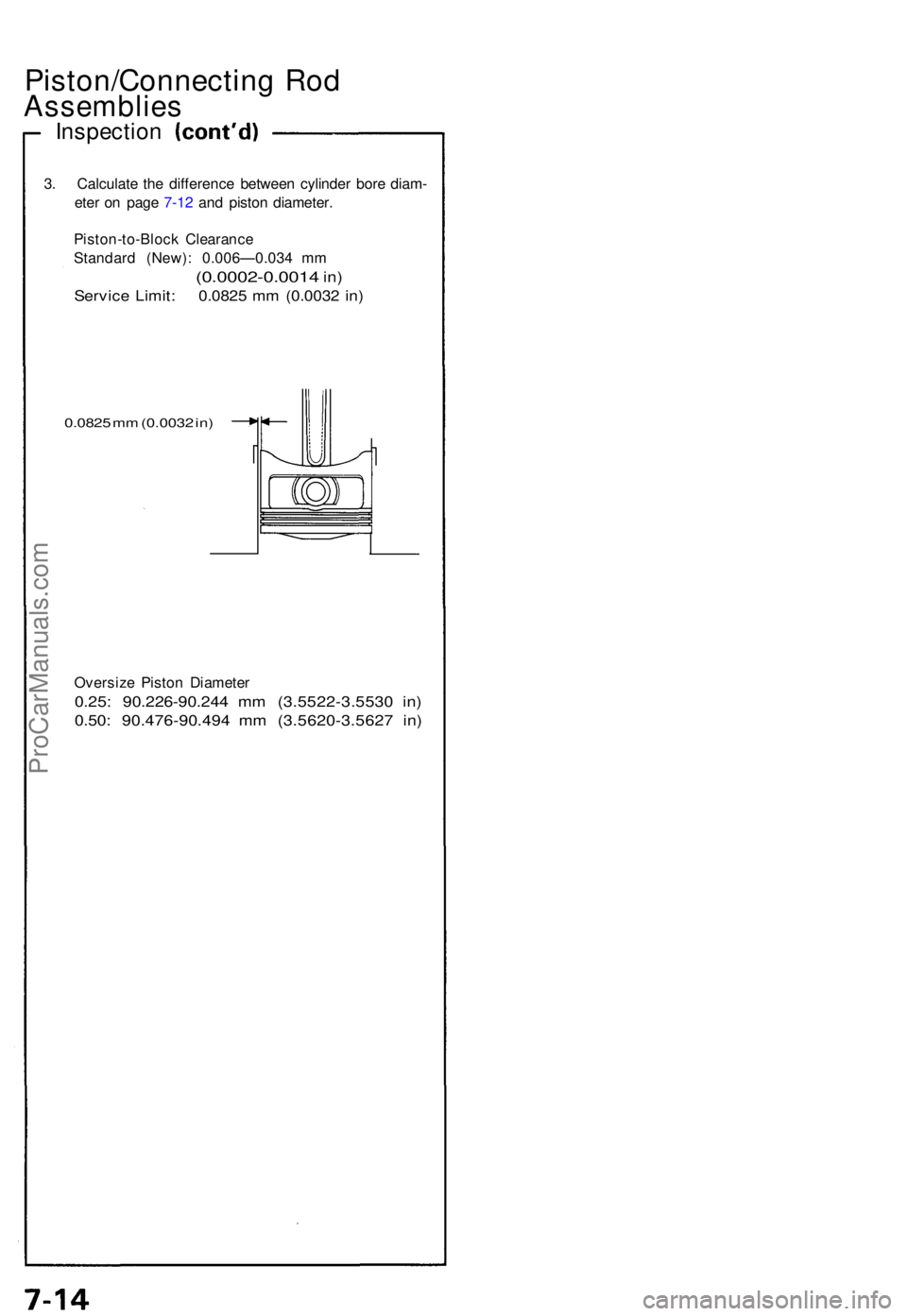

3. Calculat e th e differenc e betwee n cylinde r bor e diam -

ete r o n pag e 7-1 2 an d pisto n diameter .

Piston-to-Bloc k Clearanc e

Standar d (New) : 0.006—0.03 4 m m

(0.0002-0.001 4 in)

Servic e Limit : 0.082 5 m m (0.003 2 in )

0.082 5 m m (0.003 2 in )

Oversiz e Pisto n Diamete r

0.25: 90.226-90.24 4 m m (3.5522-3.553 0 in )

0.50 : 90.476-90.49 4 m m (3.5620-3.562 7 in )

ProCarManuals.com

Page 139 of 1640

Connecting Rod s

Selectio n

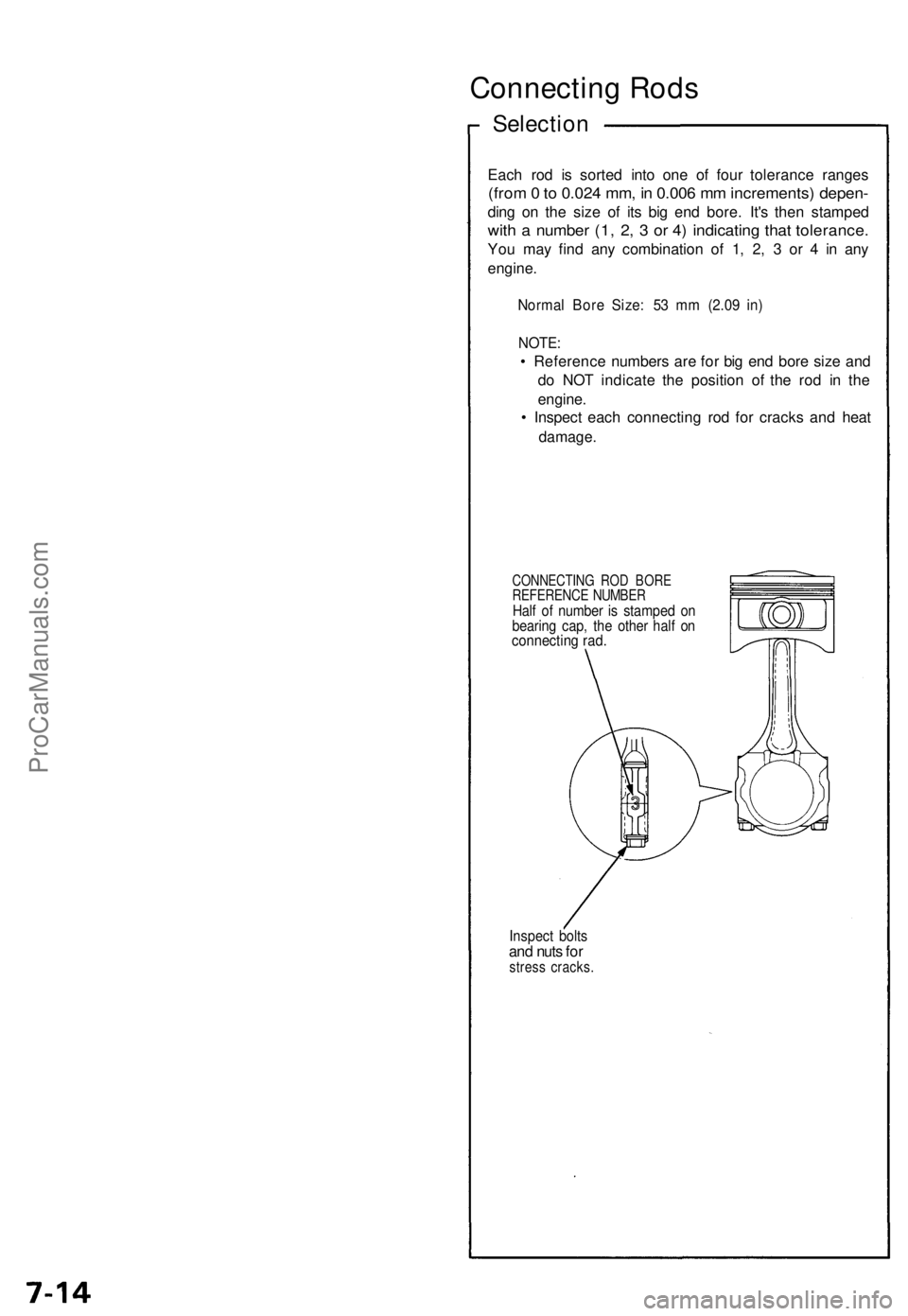

Each ro d i s sorte d int o on e o f fou r toleranc e range s

(from 0 to 0.02 4 mm , i n 0.00 6 m m increments ) depen -

ding o n th e siz e o f it s bi g en d bore . It' s the n stampe d

with a numbe r (1 , 2 , 3 or 4 ) indicatin g tha t tolerance .

You ma y fin d an y combinatio n o f 1 , 2 , 3 or 4 in an y

engine .

Norma l Bor e Size : 5 3 m m (2.0 9 in )

NOTE :

• Referenc e number s ar e fo r bi g en d bor e siz e an d

d o NO T indicat e th e positio n of the ro d i n th e

engine .

• Inspec t eac h connectin g ro d fo r crack s an d hea t

damage .

CONNECTIN G RO D BOR EREFERENC E NUMBE RHalf o f numbe r i s stampe d o nbearin g cap , th e othe r hal f o nconnectin g rad .

Inspec t bolt sand nut s fo rstres s cracks .

ProCarManuals.com

Page 140 of 1640

Piston Ring s

End Ga p

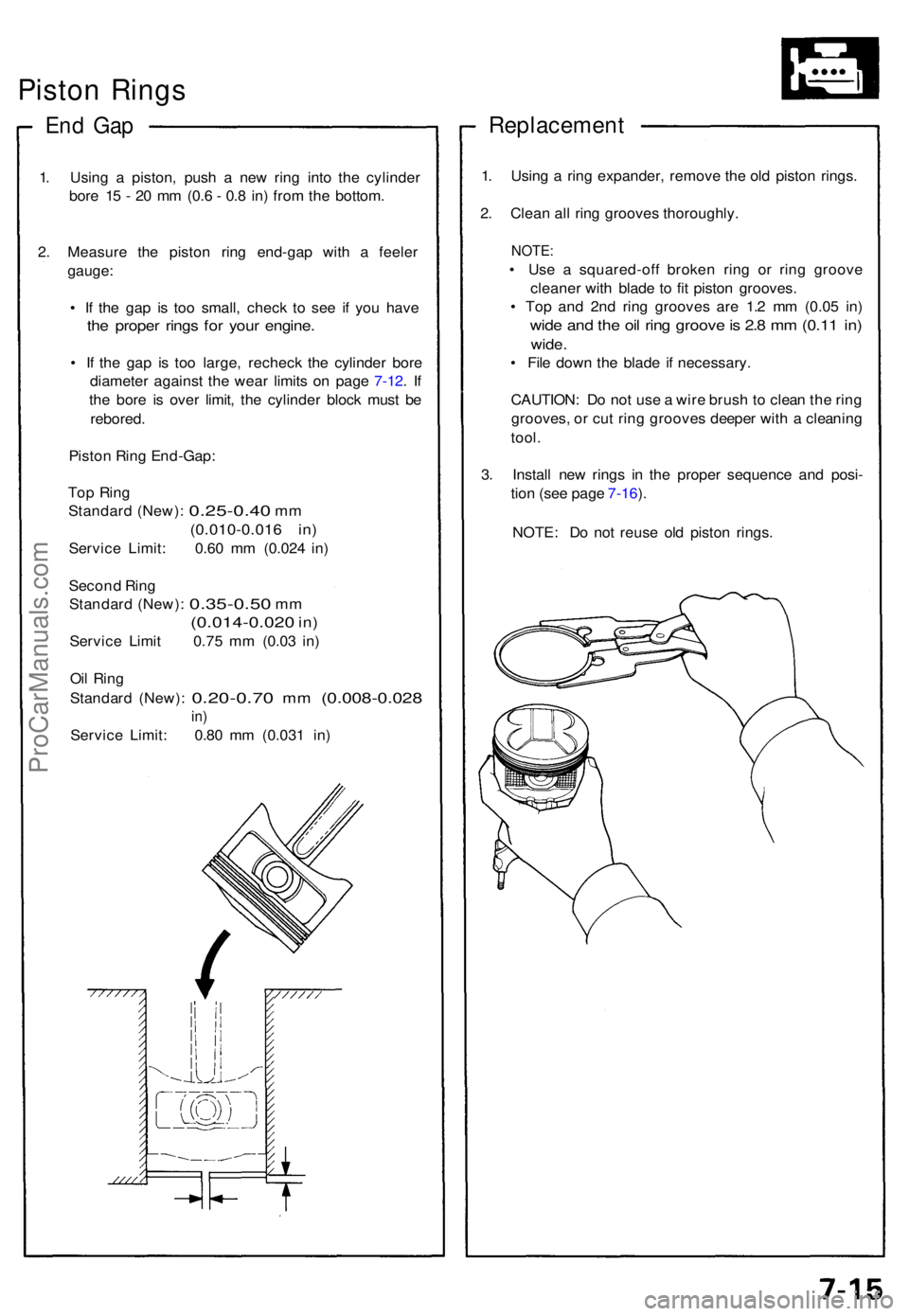

1. Usin g a piston , pus h a ne w rin g int o th e cylinde r

bor e 1 5 - 2 0 m m (0. 6 - 0. 8 in ) fro m th e bottom .

2 . Measur e th e pisto n rin g end-ga p wit h a feele r

gauge :

• I f th e ga p i s to o small , chec k t o se e i f yo u hav e

the prope r ring s fo r you r engine .

• I f th e ga p i s to o large , rechec k th e cylinde r bor e

diameter against th e wea r limit s o n pag e 7-12 . I f

th e bor e i s ove r limit , th e cylinde r bloc k mus t b e

rebored .

Pisto n Rin g End-Gap :

To p Rin g

Standar d (New) :

0.25-0.4 0 mm

(0.010-0.01 6 in )

Servic e Limit : 0.6 0 m m (0.02 4 in )

Secon d Rin g

Standar d (New) :

0.35-0.5 0 mm

(0.014-0.02 0 in)

Servic e Limi t 0.7 5 m m (0.0 3 in )

Oi l Rin g

Standar d (New) :

0.20-0.7 0 mm (0.008-0.02 8

in)

Servic e Limit : 0.8 0 m m (0.03 1 in )

Replacemen t

1. Usin g a rin g expander , remov e th e ol d pisto n rings .

2 . Clea n al l rin g groove s thoroughly .

NOTE:

• Us e a squared-of f broke n rin g o r rin g groov e

cleane r wit h blad e t o fi t pisto n grooves .

• To p an d 2n d rin g groove s ar e 1. 2 m m (0.0 5 in )

wid e an d th e oi l rin g groov e is 2. 8 m m (0.1 1 in )

wide .

• Fil e dow n th e blad e i f necessary .

CAUTION : D o no t us e a wir e brus h to clea n th e rin g

grooves , o r cu t rin g groove s deepe r wit h a cleanin g

tool .

3 . Instal l ne w ring s i n th e prope r sequenc e an d posi -

tio n (se e pag e 7-16 ).

NOTE : D o no t reus e ol d pisto n rings .

ProCarManuals.com