ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 151 of 1640

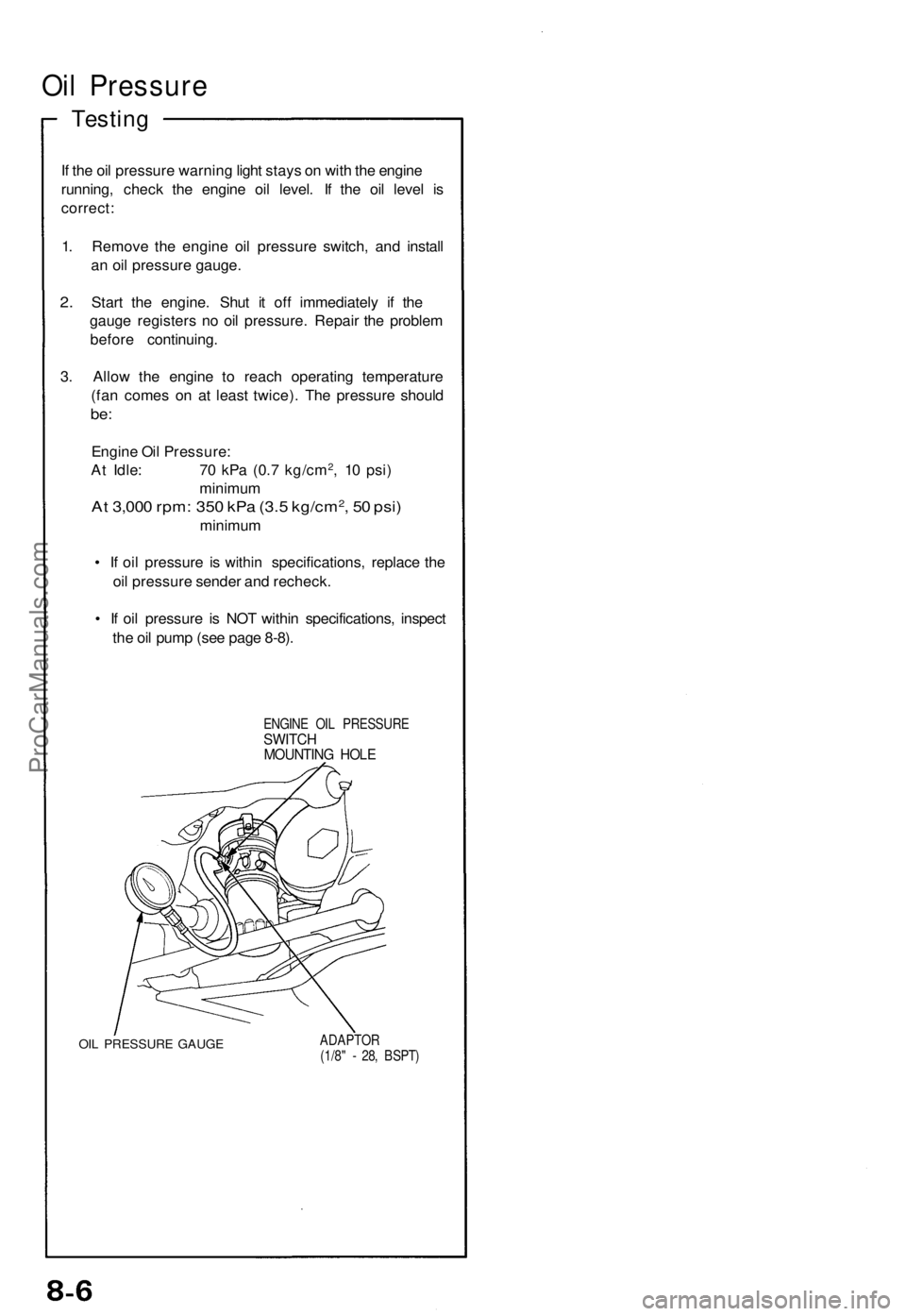

Oil Pressur e

Testing

If th e oi l pressur e warnin g ligh t stay s o n wit h th e engin e

running , chec k th e engin e oi l level . I f th e oi l leve l i s

correct :

1 . Remov e th e engin e oi l pressur e switch , an d instal l

a n oi l pressur e gauge .

2. Star t th e engine . Shu t i t of f immediatel y i f th e

gaug e register s n o oi l pressure . Repai r th e proble m

befor e continuing .

3 . Allo w th e engin e t o reac h operatin g temperatur e

(fa n come s o n a t leas t twice) . Th e pressur e shoul d

be:

Engin e Oi l Pressure :

A t Idle : 7 0 kP a (0. 7 kg/cm2, 1 0 psi )

minimu m

At 3,00 0 rpm : 35 0 kP a (3. 5 kg/cm2, 5 0 psi )

minimu m

• I f oi l pressur e i s

within specifications , replac e th e

oi l pressur e sende r an d recheck .

• I f oi l pressur e i s NO T withi n specifications , inspec t

th e oi l pum p (se e pag e 8-8) .

ENGIN E OI L PRESSUR ESWITCHMOUNTIN G HOL E

OIL PRESSUR E GAUG E ADAPTO R

(1/8 " - 28 , BSPT )

ProCarManuals.com

Page 152 of 1640

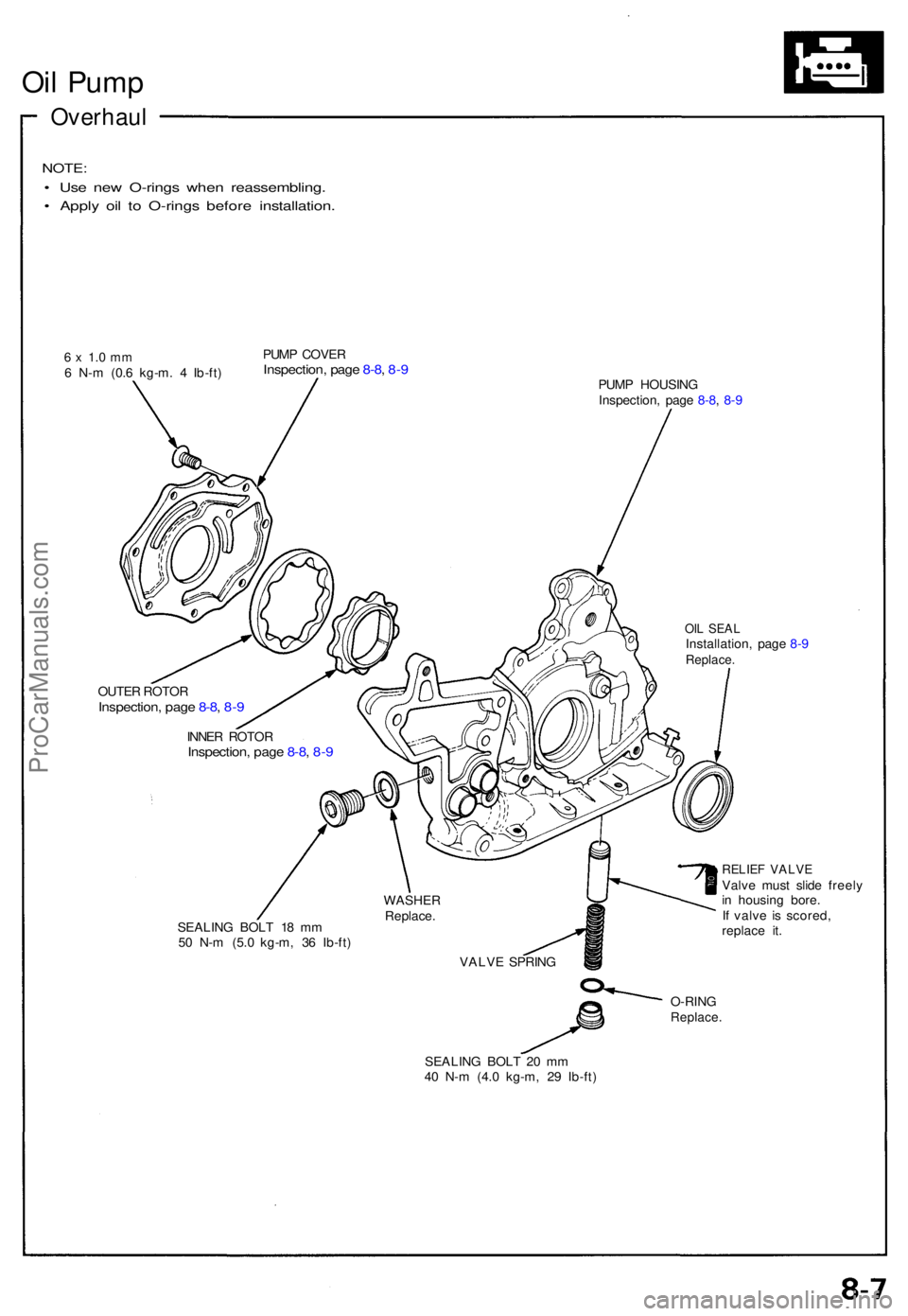

Oil Pum p

Overhau l

NOTE:

• Us e ne w O-ring s whe n reassembling .

• Appl y oi l t o O-ring s befor e installation .

6 x 1. 0 m m6 N- m (0. 6 kg-m . 4 Ib-ft ) PUM

P COVE RInspection , pag e 8-8 , 8-9PUM P HOUSIN G

Inspection , pag e 8-8 , 8-9

OI L SEA LInstallation , pag e 8- 9Replace .

OUTER ROTO RInspection , pag e 8-8 , 8-9

SEALIN G BOL T 1 8 m m

5 0 N- m (5. 0 kg-m , 3 6 Ib-ft )

RELIE F VALV EValve mus t slid e freel y

i n housin g bore .

I f valv e i s scored ,

replac e it .

O-RIN GReplace .

SEALING BOL T 2 0 m m

4 0 N- m (4. 0 kg-m , 2 9 Ib-ft )

INNE

R ROTO R

Inspection , pag e 8-8 , 8-9

WASHE R

Replace .

VALV E SPRIN G

ProCarManuals.com

Page 153 of 1640

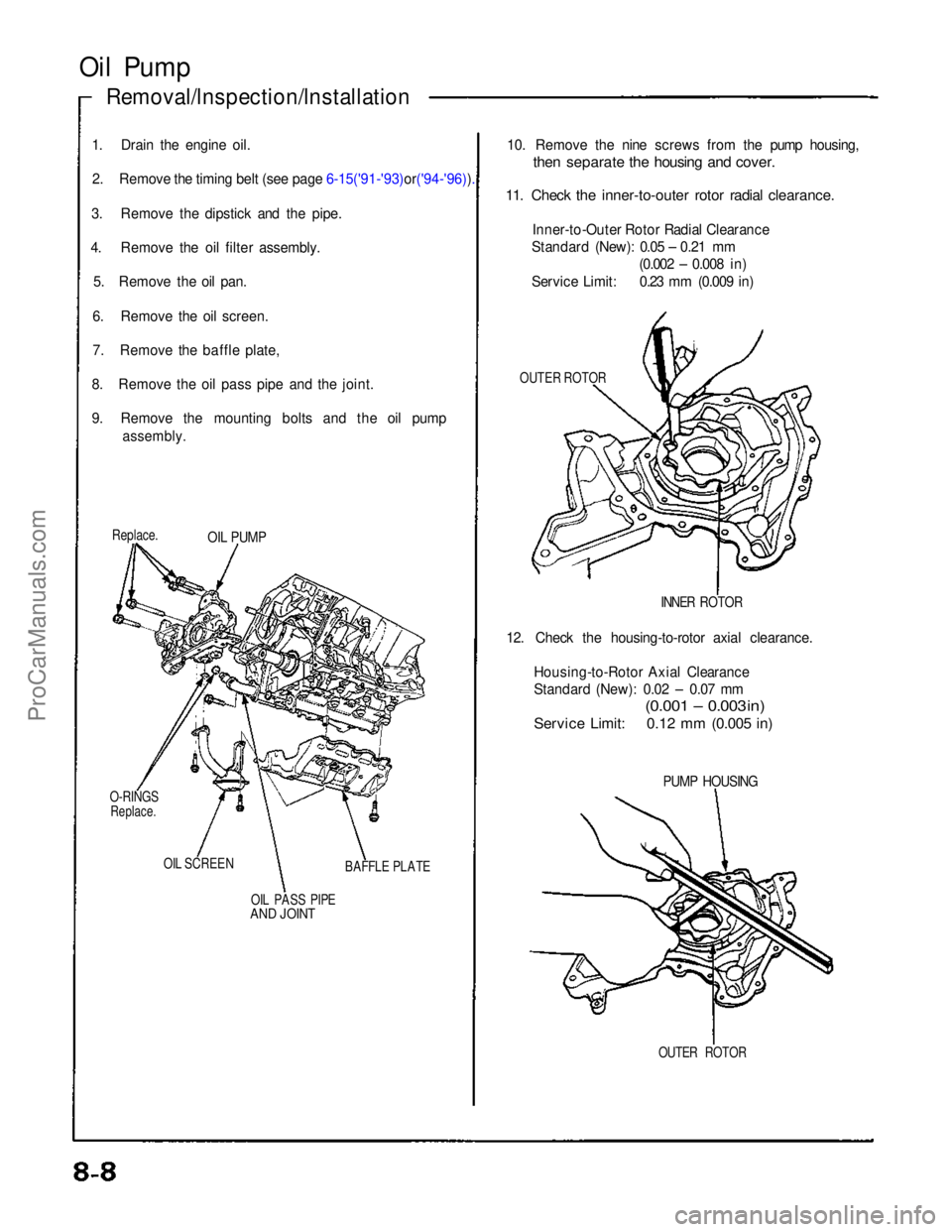

Oil Pump

Removal/lnspection/lnstallation

1. Drain the engine oil. 2. Remove the timing belt (see page 6-15('91-'93)or('94-'96)).

3. Remove the dipstick and the pipe.

4. Remove the oil filter assembly.

5. Remove the oil pan.

6. Remove the oil screen.

7. Remove the baffle plate,

8. Remove the oil pass

pipe and the joint.

9. Remove the mounting bolts and the oil pump

assembly.

Replace.

O-RINGS

Replace.

OIL SCREEN OIL PASS PIPE

AND JOINT

BAFFLE PLATE

OIL PUMP

10. Remove the nine screws from the pump housing,

then separate the housing and cover.

11. Check the inner-to-outer rotor radial clearance.

Inner-to-Outer Rotor Radial Clearance

Standard (New): 0.05 – 0.21 mm (0.002 – 0.008 in)

Service Limit: 0.23 mm (0.009 in)

OUTER ROTOR

INNER ROTOR

12. Check the housing-to-rotor axial clearance. Housing-to-Rotor Axial Clearance

Standard (New): 0.02 – 0.07 mm

(0.001 – 0.003 in)

Service Limit: 0.12 mm (0.005 in)

PUMP HOUSING

OUTER ROTORProCarManuals.com

Page 154 of 1640

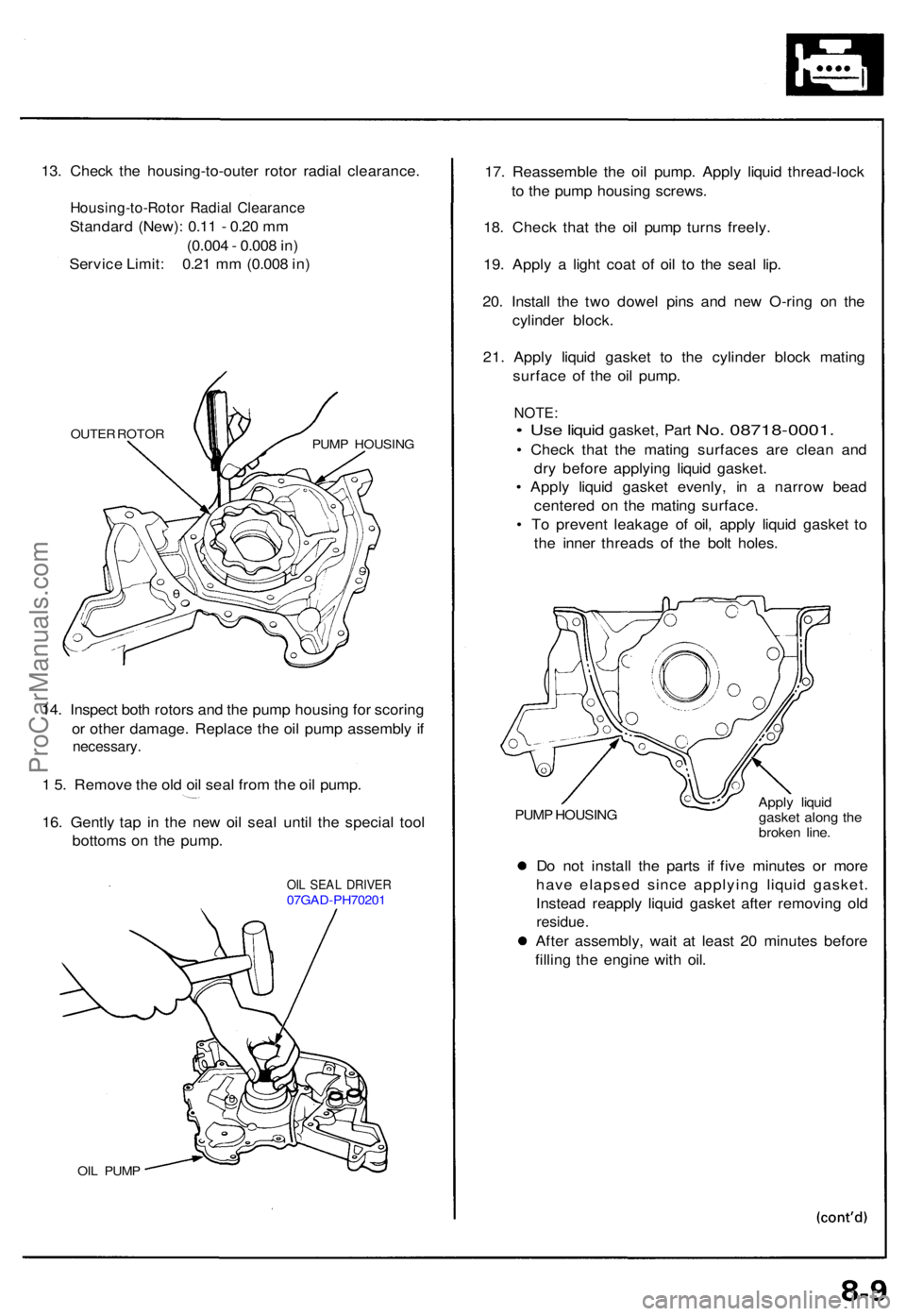

13. Chec k th e housing-to-oute r roto r radia l clearance .

Housing-to-Roto r Radia l Clearanc e

Standard (New) : 0.1 1 - 0.2 0 m m

(0.00 4 - 0.00 8 in )

Servic e Limit : 0.2 1 m m (0.00 8 in )

OUTE R ROTO R

PUMP HOUSIN G

14. Inspec t bot h rotors and th e pum p housin g fo r scorin g

o r othe r damage . Replac e th e oi l pum p assembl y i f

necessary .

1 5 . Remov e th e ol d oi l sea l fro m th e oi l pump .

16 . Gentl y ta p i n th e ne w oi l sea l unti l th e specia l too l

bottom s o n th e pump .

OIL SEA L DRIVE R07GAD-PH7020 1

OIL PUM P

17. Reassembl e th e oi l pump . Appl y liqui d thread-loc k

t o th e pum p housin g screws .

18 . Chec k tha t th e oi l pum p turn s freely .

19 . Appl y a ligh t coa t o f oi l t o th e sea l lip .

20 . Instal l th e tw o dowe l pin s an d ne w O-rin g o n th e

cylinde r block .

21 . Appl y liqui d gaske t t o th e cylinde r bloc k matin g

surfac e o f th e oi l pump .

NOTE:

• Use liqui d gasket , Par t No. 08718-0001 .

• Chec k tha t th e matin g surface s ar e clea n an d

dr y befor e applyin g liqui d gasket .

• Appl y liqui d gaske t evenly , i n a narro w bea d

centere d o n th e matin g surface .

• T o preven t leakag e o f oil , appl y liqui d gaske t t o

th e inne r thread s of the bol t holes .

PUMP HOUSIN G Appl

y liqui d

gaske t alon g th e

broke n line .

Do no t instal l th e part s i f fiv e minute s o r mor e

hav e elapse d sinc e applyin g liqui d gasket .

Instea d reappl y liqui d gaske t afte r removin g ol d

residue .

After assembly , wai t a t leas t 2 0 minute s befor e

fillin g th e engine with oil .

ProCarManuals.com

Page 155 of 1640

Oil Pump

Removal/lnspection/lnstallation

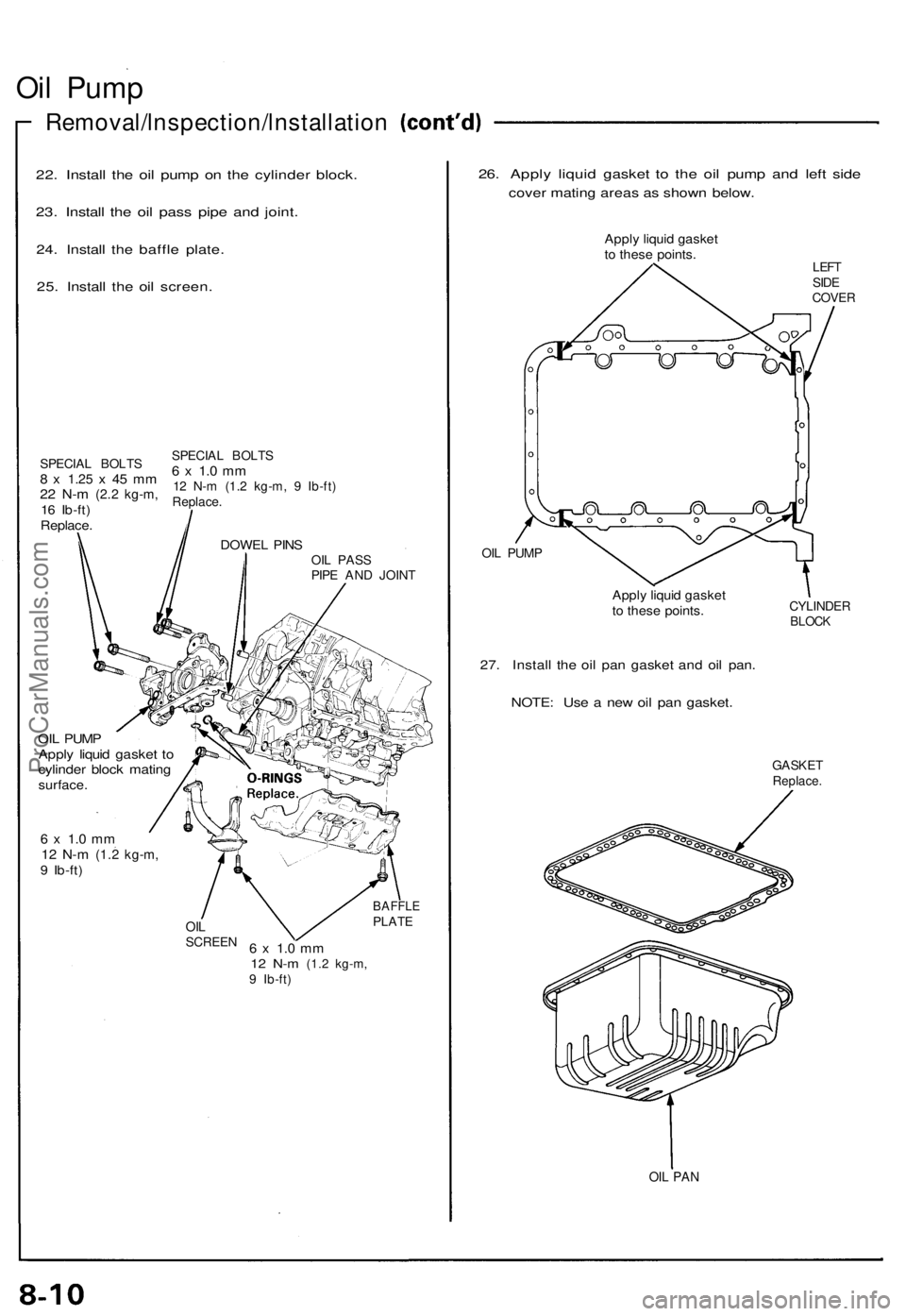

22. Install the oil pump on the cylinder block.

23. Install the oil pass pipe and joint.

24. Install the baffle plate.

25. Install the oil screen.

SPECIAL BOLTS

8 x

1.25

x 45 mm

22 N-m

(2.2 kg-m,

16 Ib-ft)

Replace.

DOWEL PINS

OIL PASS

PIPE AND JOINT

OIL PUMP

Apply liquid gasket to

cylinder block mating

surface.

6 x 1.0 mm

12 N-m

(1.2 kg-m,

9 Ib-ft)

OIL

SCREEN

BAFFLE

PLATE

6 x 1.0 mm

12 N-m

(1.2 kg-m,

9 Ib-ft)

26. Apply liquid gasket to the oil pump and left side

cover mating areas as shown below.

Apply liquid gasket

to these points.

OIL PUMP

Apply liquid gasket

to these points.

27. Install the oil pan gasket and oil pan.

NOTE: Use a new oil pan gasket.

CYLINDER

BLOCK

GASKET

Replace.

OIL PAN

LEFT

SIDE

COVER

SPECIAL BOLTS

6 x 1.0 mm

12 N-m (1.2 kg-m, 9 Ib-ft)

Replace.ProCarManuals.com

Page 156 of 1640

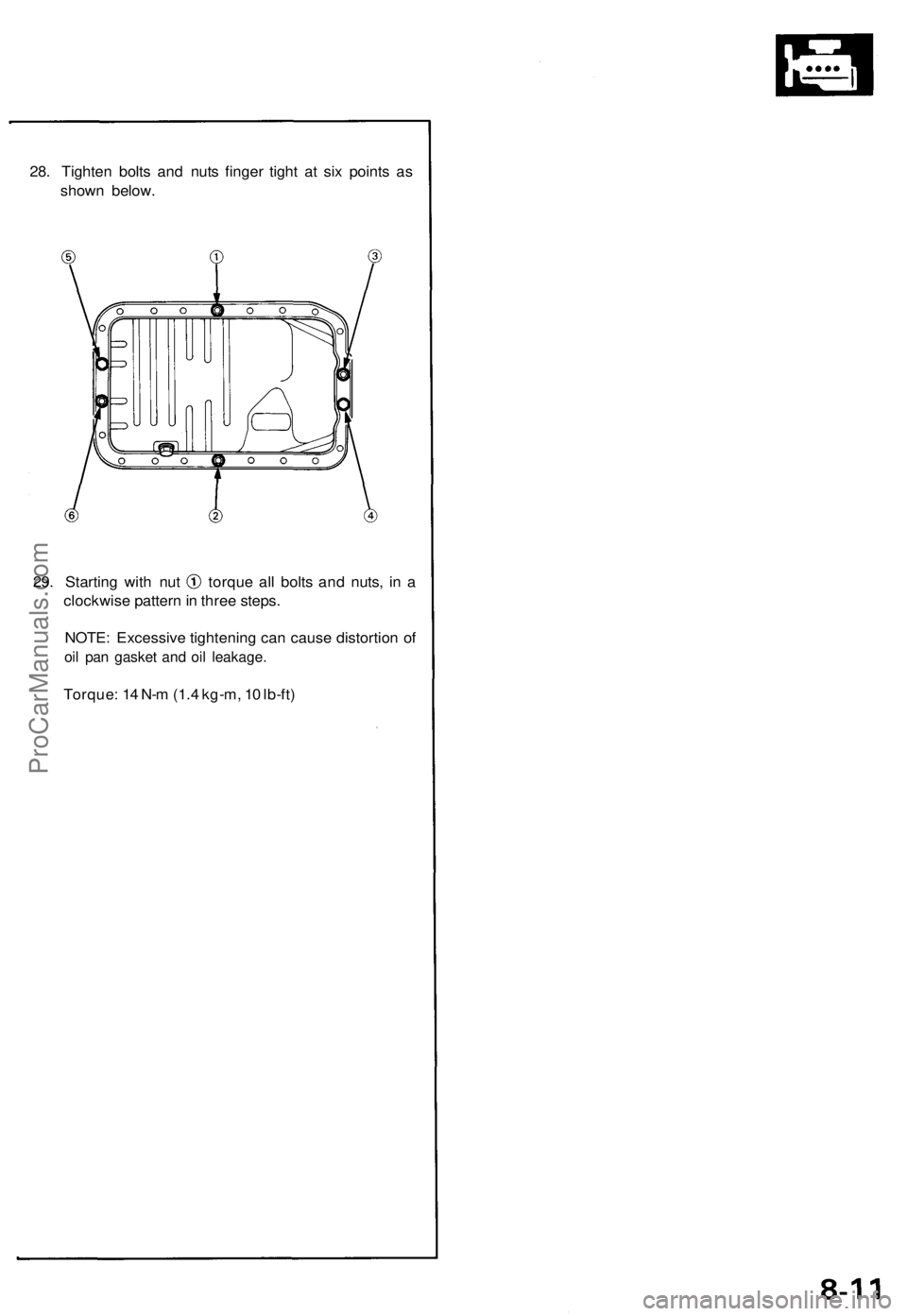

28. Tighten bolts and nuts finger tight at six points as

shown below.

29. Starting with nut torque all bolts and nuts, in a

clockwise pattern in three steps.

NOTE: Excessive tightening can cause distortion of

oil pan gasket and oil leakage.

Torque: 14 N-m (1.4 kg-m, 10 lb-ft)ProCarManuals.com

Page 157 of 1640

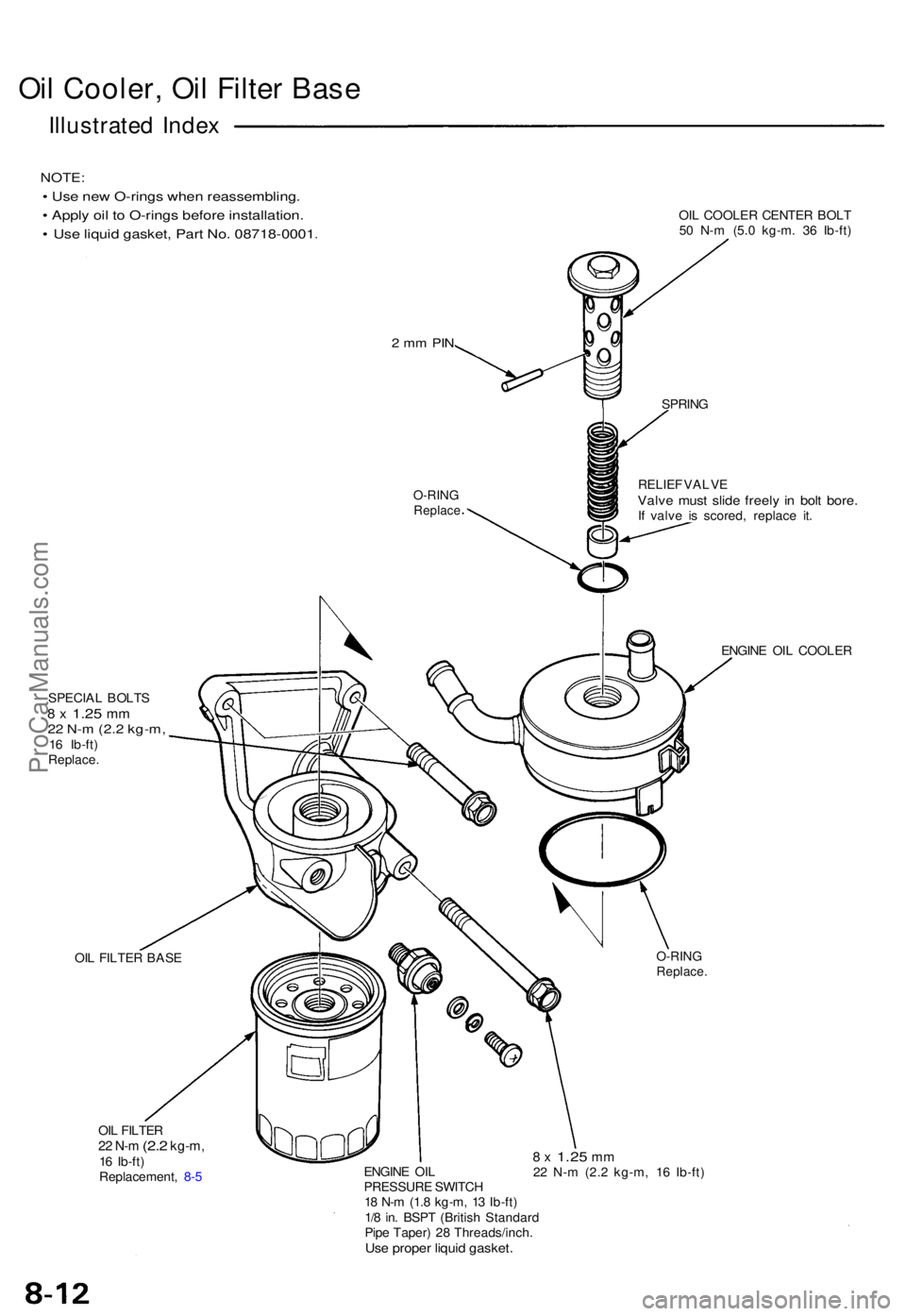

Oil Cooler , Oi l Filte r Bas e

Illustrate d Inde x

NOTE :

• Use new O-rings when reassembling.

• Apply oil to O-rings before installation.

• Use liquid gasket, Part No. 08718-0001

.

OI L COOLE R CENTE R BOL T

5 0 N- m (5. 0 kg-m . 3 6 Ib-ft )

2 m m PI N

O-RIN GReplac e

SPECIA L BOLT S8 x 1.2 5 mm22 N- m (2. 2 kg-m ,16 Ib-ft )

Replace .

OI L FILTE R BAS E SPRIN

G

RELIE F VALV E

Valve mus t slid e freel y i n bol t bore .If valv e i s scored , replac e it .

ENGIN E OI L COOLE R

O-RINGReplace .

OIL FILTE R22 N- m (2. 2 kg-m ,16 Ib-ft )

Replacement , 8- 5 ENGIN

E OI L

PRESSUR E SWITC H

1 8 N- m (1. 8 kg-m , 1 3 Ib-ft )

1/ 8 in . BSP T (Britis h Standar d

Pip e Taper ) 2 8 Threads/inch .

Use prope r liqui d gasket .

8 x 1.2 5 mm22 N- m (2. 2 kg-m , 1 6 Ib-ft )

ProCarManuals.com

Page 158 of 1640

Special Tools

Ref.

No.

Tool Number Description

Qty

Page Reference

9-4('91-'93) or ('94-'96),

5 ('94-'96),

O

2

Sensor Socket Wrench

07LAA – PT50101

1ProCarManuals.com

Page 159 of 1640

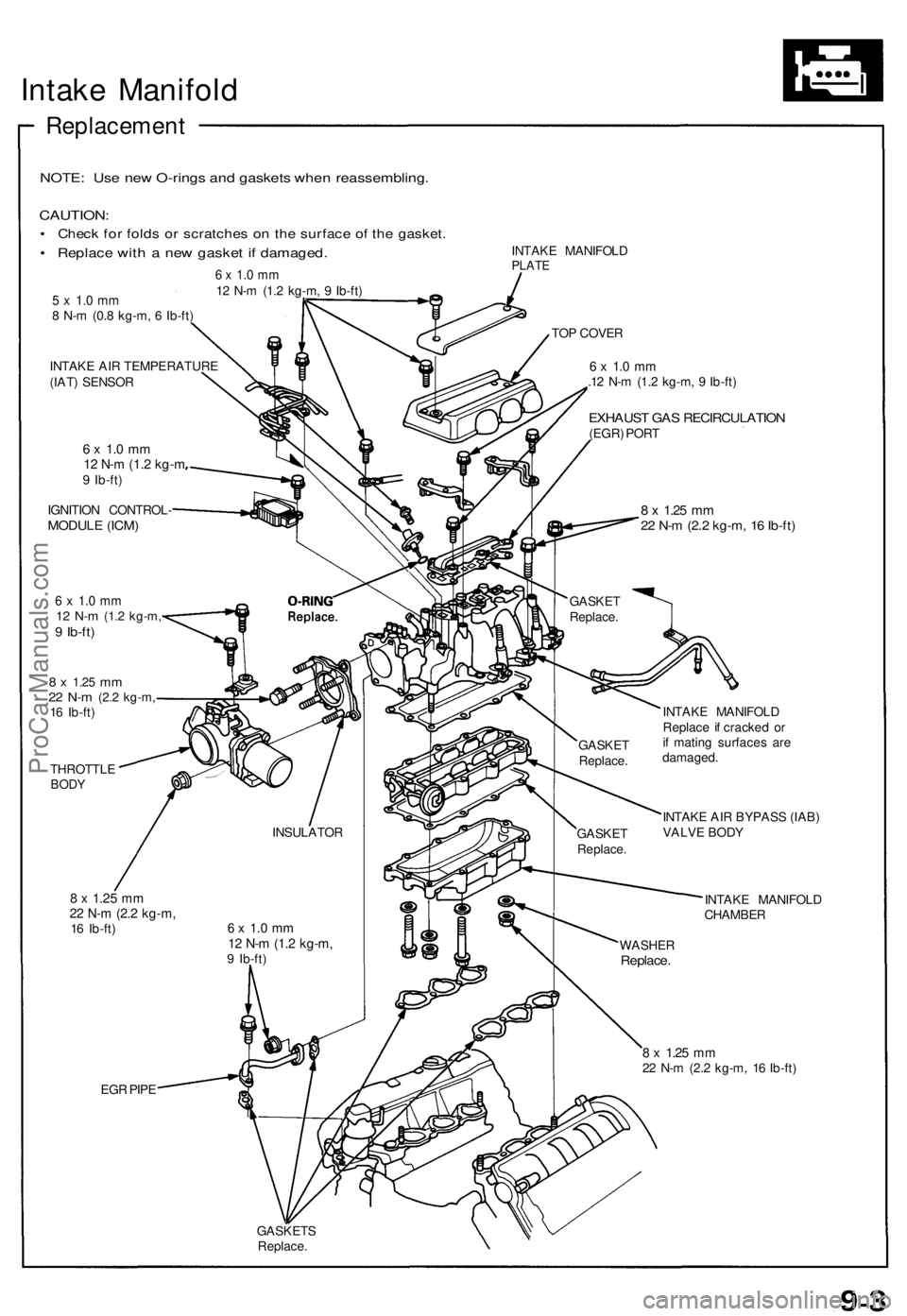

Intake Manifol d

Replacemen t

NOTE: Us e ne w O-ring s an d gasket s whe n reassembling .

CAUTION:

• Chec k fo r fold s o r scratche s o n th e surfac e o f th e gasket .

• Replac e wit h a ne w gaske t i f damaged .

6 x 1. 0 m m12 N- m (1. 2 kg-m , 9 Ib-ft )5 x 1. 0 m m8 N- m (0. 8 kg-m , 6 Ib-ft )

INTAK E AI R TEMPERATUR E

(IAT ) SENSO R

6 x 1. 0 m m12 N- m (1. 2 kg- m9 Ib-ft )

IGNITIO N CONTROL -

MODULE (ICM )

6 x 1. 0 m m12 N- m (1. 2 kg-m ,9 Ib-ft )

8 x 1.2 5 mm22 N- m (2. 2 kg-m ,16 Ib-ft )

THROTTL EBODY

INTAK E MANIFOL DPLATE

TOP COVE R

6 x 1. 0 m m.12 N- m (1. 2 kg-m , 9 Ib-ft )

EXHAUS T GA S RECIRCULATIO N(EGR) POR T

8 x 1.2 5 mm22 N- m (2. 2 kg-m , 1 6 Ib-ft )

INTAK E MANIFOL D

Replac e i f cracke d o r

i f matin g surface s ar e

damaged .

8 x 1.2 5 mm22 N- m (2. 2 kg-m ,16 Ib-ft ) INTAK

E AI R BYPAS S (IAB )

VALV E BOD Y

INTAK E MANIFOL D

CHAMBE R

8 x 1.2 5 mm22 N- m (2. 2 kg-m , 1 6 Ib-ft )

EG R PIP E

GASKET SReplace.

6 x 1. 0 m m12 N- m (1. 2 kg-m ,9 Ib-ft )INSULATO

R

WASHERReplace.

GASKE TReplace .

GASKETReplace .

GASKETReplace .

ProCarManuals.com

Page 160 of 1640

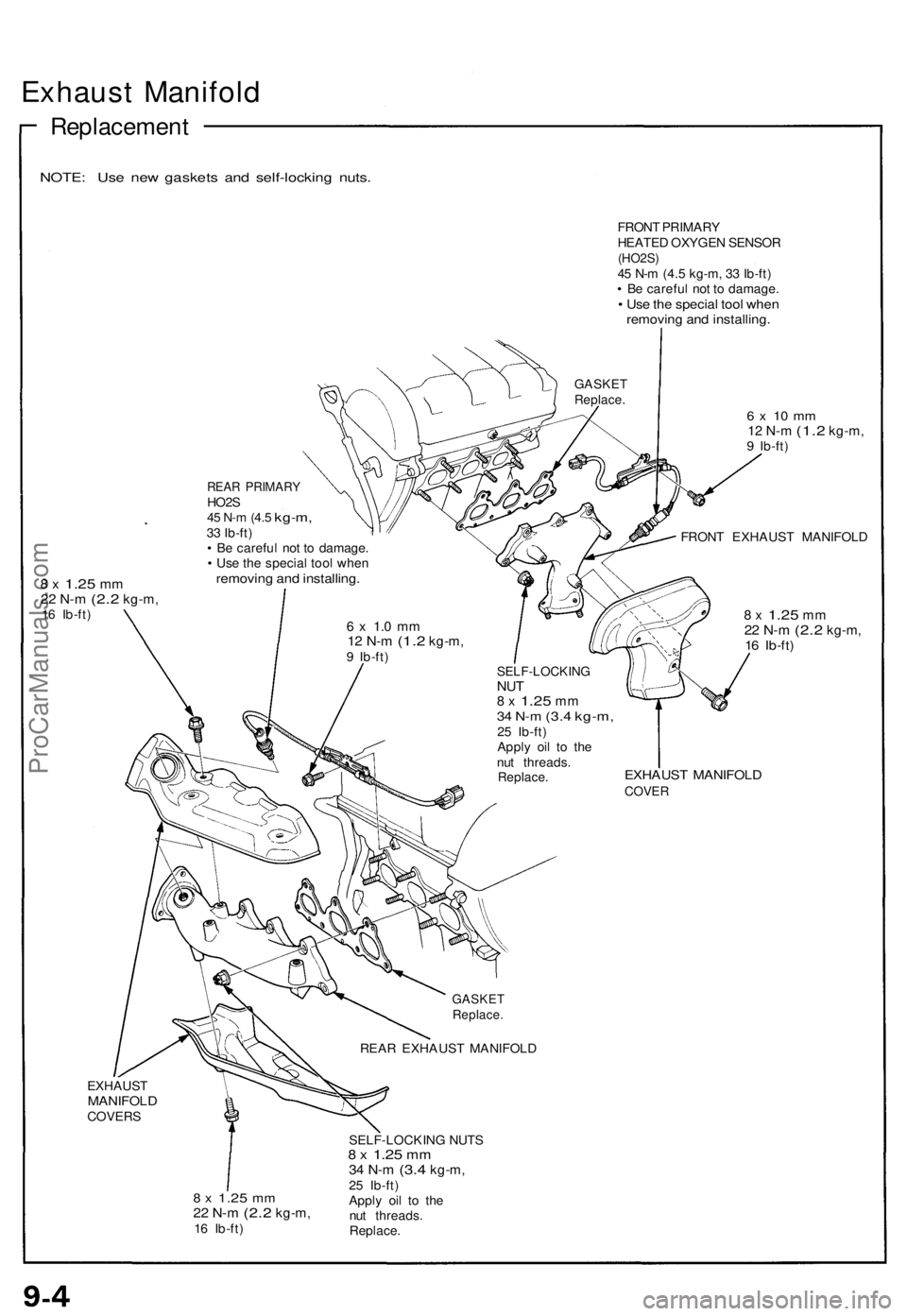

Exhaust Manifol d

Replacemen t

NOTE: Us e ne w gasket s an d self-lockin g nuts .

FRON T PRIMAR Y

HEATE D OXYGE N SENSO R

(HO2S)45 N- m (4. 5 kg-m , 3 3 Ib-ft )

• B e carefu l no t t o damage .

• Us e th e specia l too l whe nremovin g an d installing .

8 x 1.2 5 mm22 N- m (2. 2 kg-m ,16 Ib-ft )

REAR PRIMAR YHO2S45 N- m (4. 5 kg-m ,33 Ib-ft )

• B e carefu l no t t o damage .

• Us e th e specia l too l whe n

removin g an d installing .

6 x 1 0 m m12 N- m (1. 2 kg-m ,9 Ib-ft )

SELF-LOCKIN GNUT8 x 1.2 5 mm34 N- m (3. 4 kg-m ,25 Ib-ft )

Appl y oi l t o th e

nu t threads .

Replace.

FRONT EXHAUS T MANIFOL D

8 x 1.2 5 mm22 N- m (2. 2 kg-m ,16 Ib-ft )

EXHAUS T MANIFOL DCOVER

EXHAUS TMANIFOL DCOVERS

8 x 1.2 5 mm22 N- m (2. 2 kg-m ,16 Ib-ft )

GASKE TReplace .

REAR EXHAUS T MANIFOL D

SELF-LOCKIN G NUT S

8 x 1.2 5 mm34 N- m (3. 4 kg-m ,25 Ib-ft )

Appl y oi l t o th e

nu t threads .

Replace.

6 x 1. 0 m m12 N- m (1. 2 kg-m ,9 Ib-ft )

GASKE TReplace .

ProCarManuals.com