ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 161 of 1640

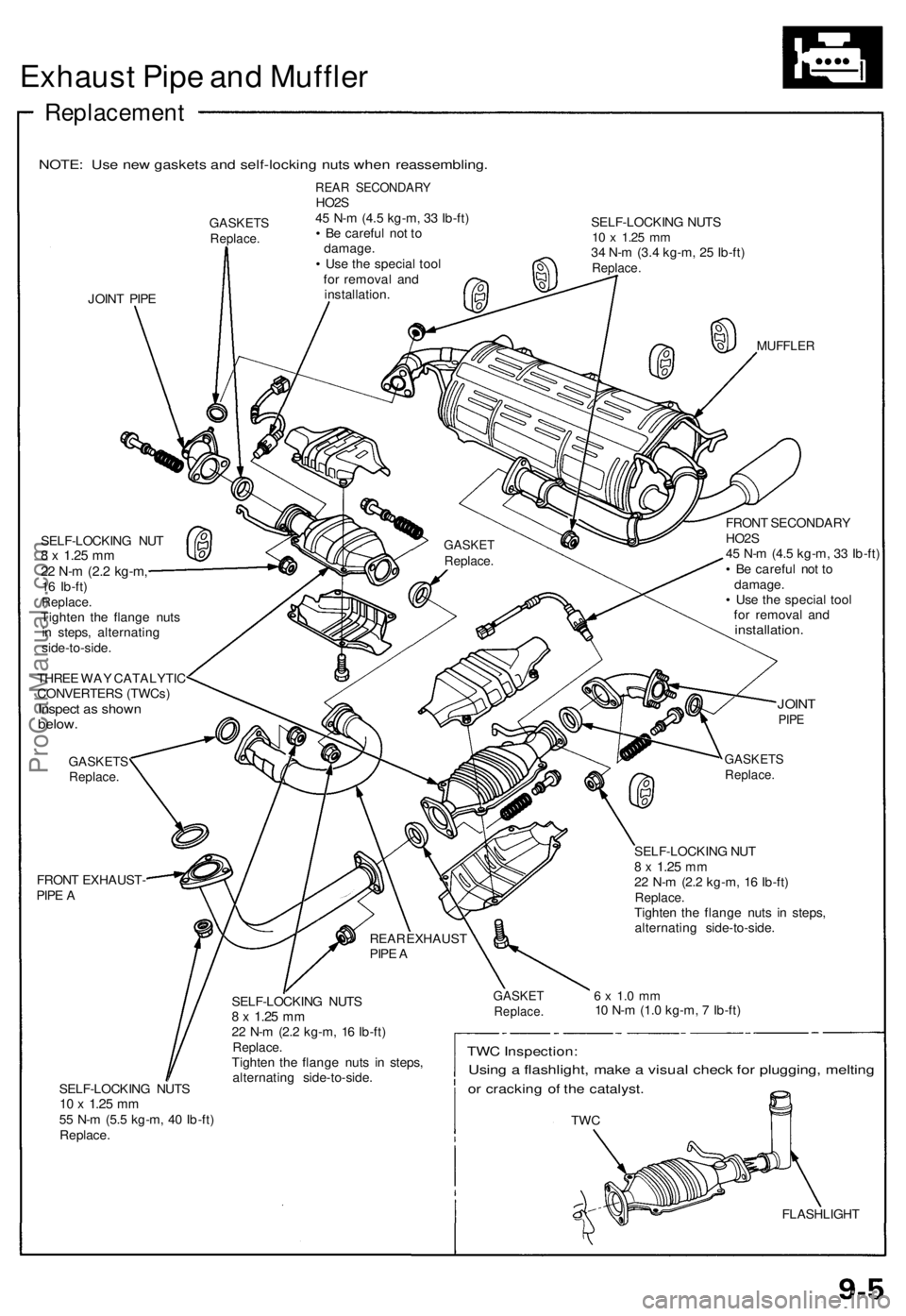

Exhaust Pip e an d Muffle r

Replacemen t

NOTE: Us e ne w gasket s an d self-lockin g nut s whe n reassembling .

GASKETSReplace.

JOINT PIP E

REA R SECONDAR YHO2S

4 5 N- m (4. 5 kg-m , 3 3 Ib-ft )

• B e carefu l no t t o

damage .

• Us e th e specia l too l

fo r remova l an d

installation . SELF-LOCKIN

G NUT S

10 x 1.2 5 mm34 N- m (3. 4 kg-m , 2 5 Ib-ft )Replace .

MUFFLE R

SELF-LOCKIN G NU T8 x 1.2 5 mm22 N- m (2. 2 kg-m ,16 Ib-ft )Replace .Tighten th e flang e nut s

i n steps , alternatin g

side-to-side .

THRE E WA Y CATALYTI C

CONVERTER S (TWCs )

Inspect a s show nbelow.

GASKET SReplace.

FRONT EXHAUST -

PIP E A FRON

T SECONDAR Y

HO2 S

4 5 N- m (4. 5 kg-m , 3 3 Ib-ft )

• B e carefu l no t t o

damage .

• Us e th e specia l too l

fo r remova l an d

installation .

JOINTPIPE

SELF-LOCKIN G NUT S10 x 1.2 5 mm55 N- m (5. 5 kg-m , 4 0 Ib-ft )

Replace . SELF-LOCKIN

G NUT S

8 x 1.2 5 mm22 N- m (2. 2 kg-m , 1 6 Ib-ft )Replace .Tighten th e flang e nut s i n steps ,

alternatin g side-to-side .

GASKETSReplace.

SELF-LOCKIN G NU T8 x 1.2 5 mm22 N- m (2. 2 kg-m , 1 6 Ib-ft )Replace .Tighten th e flang e nut s i n steps ,

alternatin g side-to-side .

6 x 1. 0 m m10 N- m (1. 0 kg-m , 7 Ib-ft )

TWC Inspection :

Using a flashlight , mak e a visua l chec k fo r plugging , meltin g

or crackin g o f th e catalyst .

TWC

FLASHLIGH T

REA

R EXHAUS T

PIP E A

GASKE TReplace .

GASKETReplace .

ProCarManuals.com

Page 162 of 1640

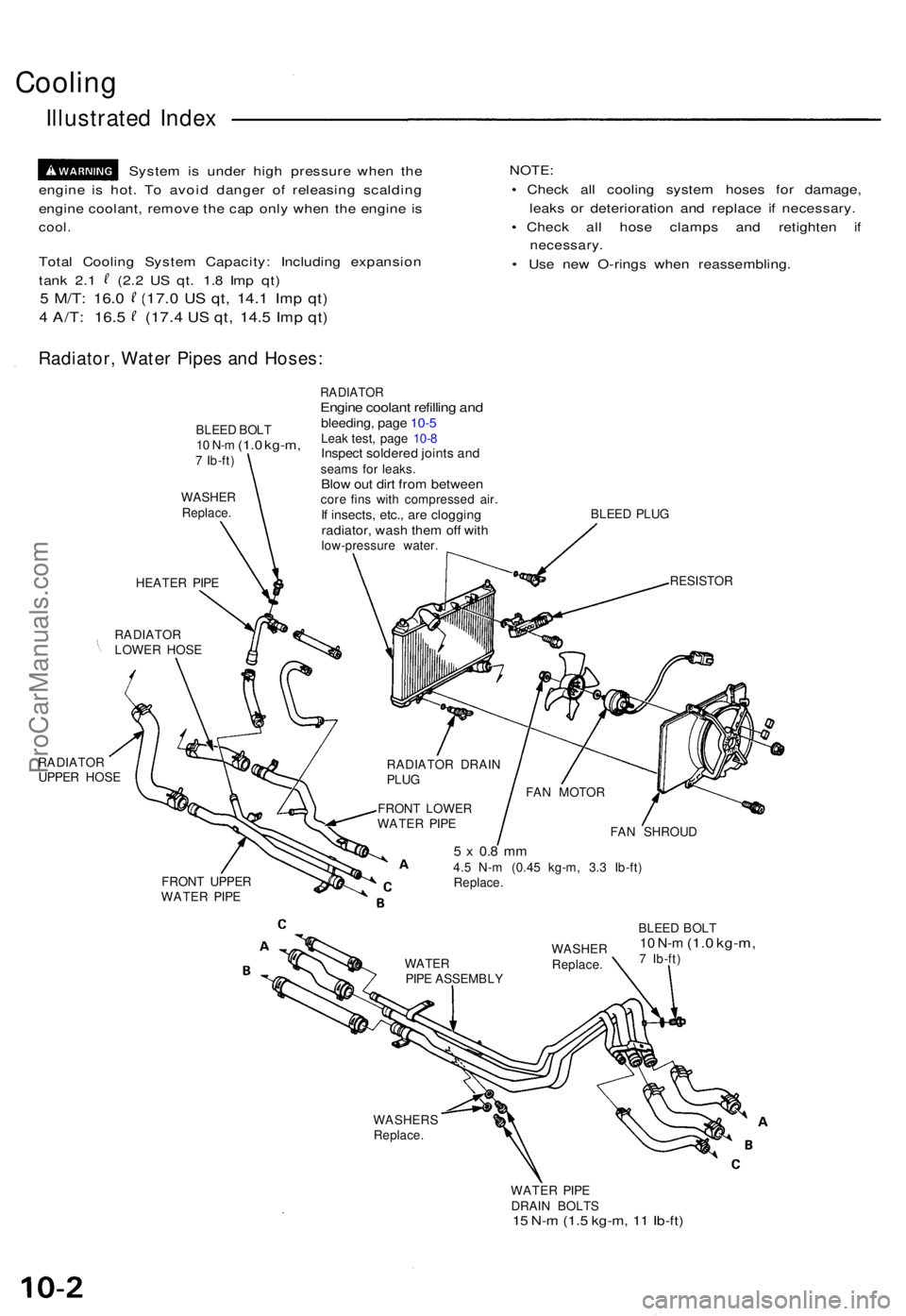

Cooling

Illustrated Index

Syste m is unde r hig h pressur e whe n th e

engin e i s hot . T o avoi d dange r o f releasin g scaldin g

engin e coolant , remov e th e ca p onl y whe n th e engin e i s

cool .

Tota l Coolin g Syste m Capacity : Includin g expansio n

tank 2. 1 (2. 2 U S qt . 1. 8 Im p qt )

5 M/T : 16. 0 (17. 0 US qt , 14. 1 Imp qt )

4 A/T : 16. 5 (17. 4 US qt , 14. 5 Imp qt )

NOTE :

• Chec k al l coolin g syste m hose s fo r damage ,

leak s o r deterioratio n an d replac e i f necessary .

• Chec k al l hos e clamp s an d retighte n i f

necessary .

• Us e ne w O-ring s whe n reassembling .

Radiator, Wate r Pipe s an d Hoses :

BLEED BOL T10 N- m (1. 0 kg-m ,7 Ib-ft )

WASHE RReplace .

HEATER PIP E

RADIATO R

LOWE R HOS E

RADIATO R

UPPE R HOS E

RADIATO REngine coolan t refillin g an dbleeding , pag e 10- 5Leak test , pag e 10- 8Inspec t soldere d joint s an dseam s fo r leaks .Blow ou t dir t fro m betwee ncore fin s wit h compresse d air .If insects , etc. , ar e cloggin gradiator, was h the m of f wit hlow-pressur e water . BLEE

D PLU G

RESISTO R

RADIATO R DRAI N

PLU G

FRON T LOWE R

WATE R PIP E

FRON T UPPE R

WATE R PIP E FA

N SHROU D

5 x 0. 8 m m4.5 N- m (0.4 5 kg-m , 3. 3 Ib-ft )

Replace .

BLEED BOL T

10 N- m (1. 0 kg-m ,7 Ib-ft )

WASHER S

Replace .

WATER PIP E

DRAI N BOLT S

15 N- m (1. 5 kg-m , 1 1 Ib-ft )

WATE RPIPE ASSEMBL YWASHE

RReplace .

FAN MOTO R

ProCarManuals.com

Page 163 of 1640

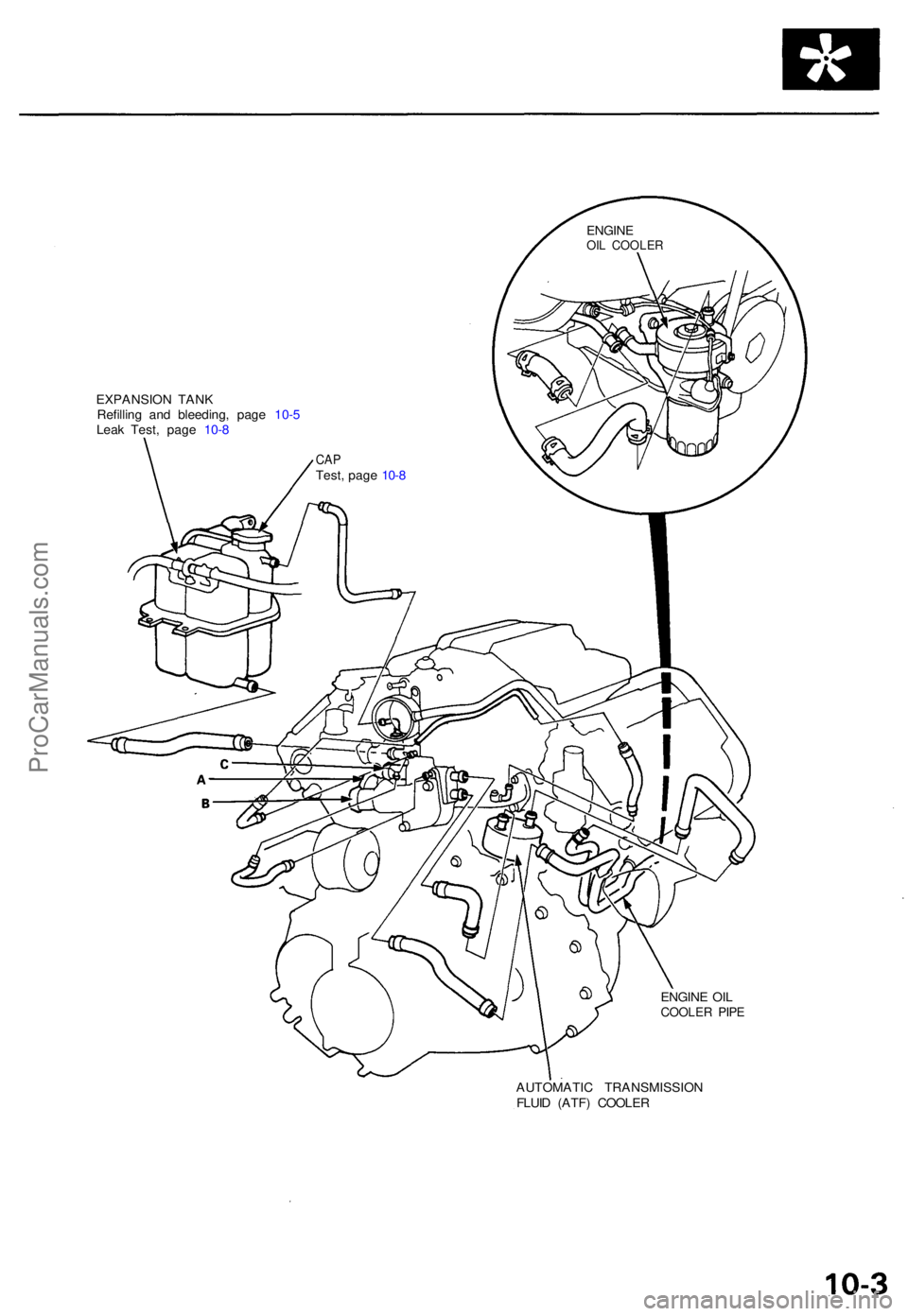

EXPANSION TAN K

Refillin g an d bleeding , pag e 10- 5

Lea k Test , pag e 10- 8

ENGINE OI L

COOLE R PIP E

AUTOMATI C TRANSMISSIO N

FLUI D (ATF ) COOLE R

ENGINEOIL COOLE R

CAPTest , pag e 10- 8

ProCarManuals.com

Page 164 of 1640

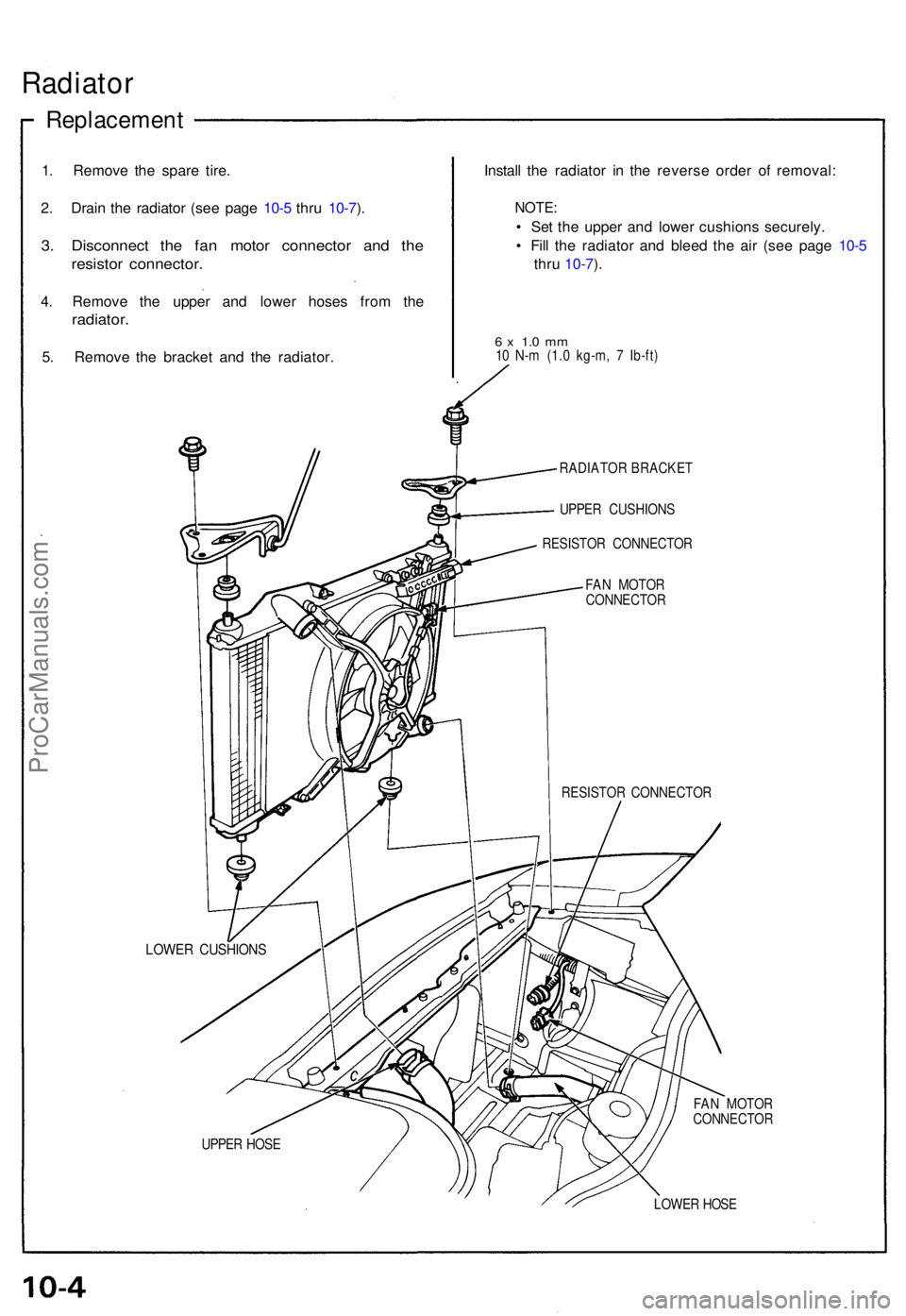

Radiator

Replacemen t

1. Remov e th e spar e tire .

2 . Drai n th e radiato r (se e pag e 10- 5 thr u 10-7 ).

3 . Disconnec t th e fa n moto r connecto r an d th e

resisto r connector .

4. Remov e th e uppe r an d lowe r hose s fro m th e

radiator .

5. Remov e th e bracke t an d th e radiator . Instal

l th e radiato r i n th e revers e orde r o f removal :

NOTE:

• Se t th e uppe r an d lowe r cushion s securely .

• Fil l th e radiato r an d blee d th e ai r (se e pag e 10- 5

thr u 10-7 ).

6 x 1. 0 m m10 N- m (1. 0 kg-m , 7 Ib-ft )

RADIATO R BRACKE T

UPPE R CUSHION S

RESISTO R CONNECTO R

FA N MOTO R

CONNECTO R

RESISTO R CONNECTO R

LOWER CUSHION S

FAN MOTO R

CONNECTO R

UPPE R HOS E

LOWER HOS E

ProCarManuals.com

Page 165 of 1640

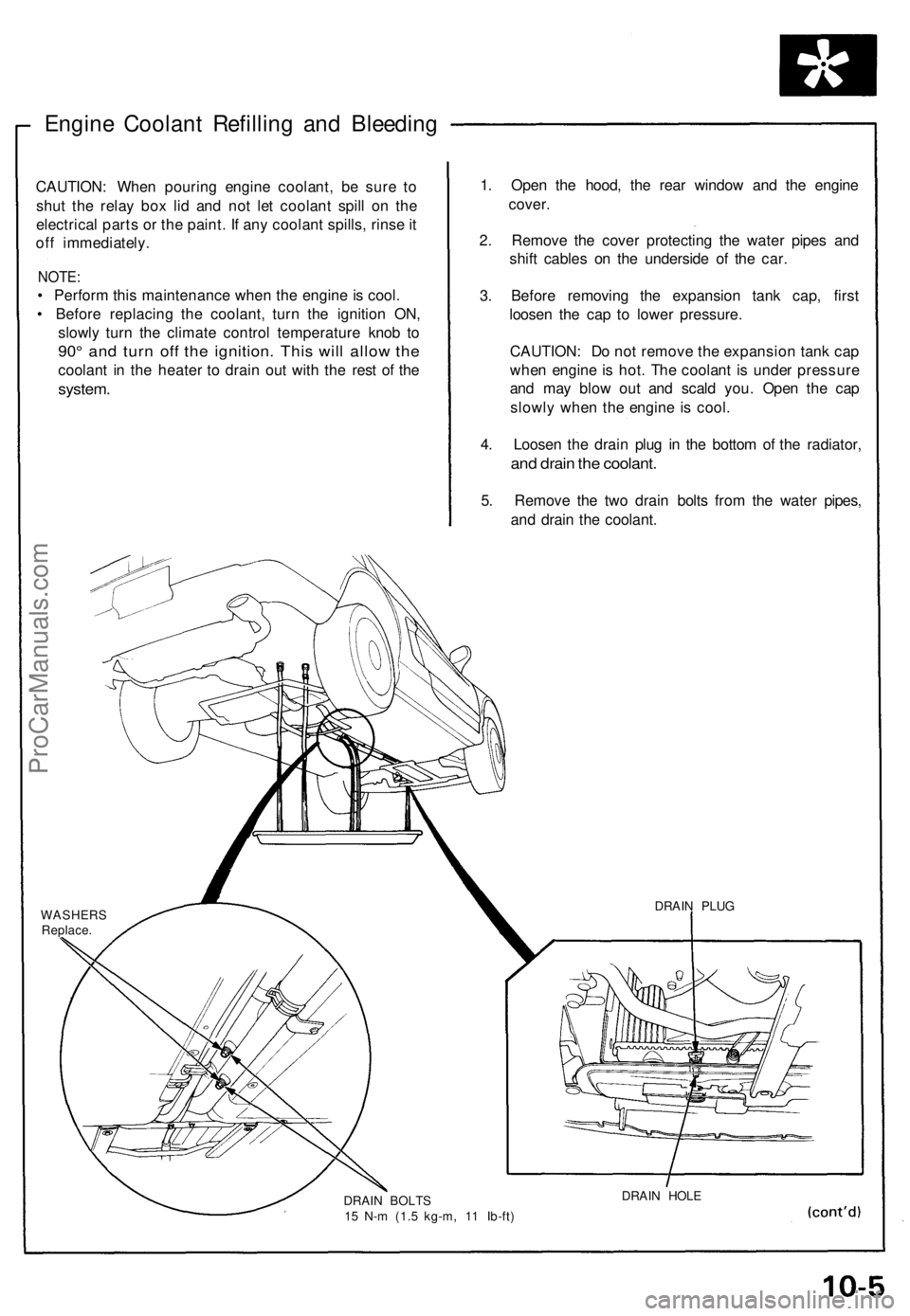

Engine Coolant Refilling and Bleeding

CAUTION: When pouring engine coolant, be sure to

shut the relay box lid and not let coolant spill on the

electrical parts or the paint. If any coolant spills, rinse it

off immediately.

NOTE:

• Perform this maintenance when the engine is cool.

• Before replacing the coolant, turn the ignition ON,

slowly turn the climate control temperature knob to

90° and turn off the ignition. This will allow the

coolant in the heater to drain out with the rest of the

system.

1. Open the hood, the rear window and the engine

cover.

2. Remove the cover protecting the water pipes and

shift cables on the underside of the car.

3. Before removing the expansion tank cap, first

loosen the cap to lower pressure.

CAUTION: Do not remove the expansion tank cap

when engine is hot. The coolant is under pressure

and may blow out and scald you. Open the cap

slowly when the engine is cool.

4. Loosen the drain plug in the bottom of the radiator,

and drain the coolant.

5. Remove the two drain bolts from the water pipes,

and drain the coolant.

WASHERS

Replace.

DRAIN BOLTS

15 N-m (1.5 kg-m, 11 Ib-ft)

DRAIN HOLE

DRAIN PLUGProCarManuals.com

Page 166 of 1640

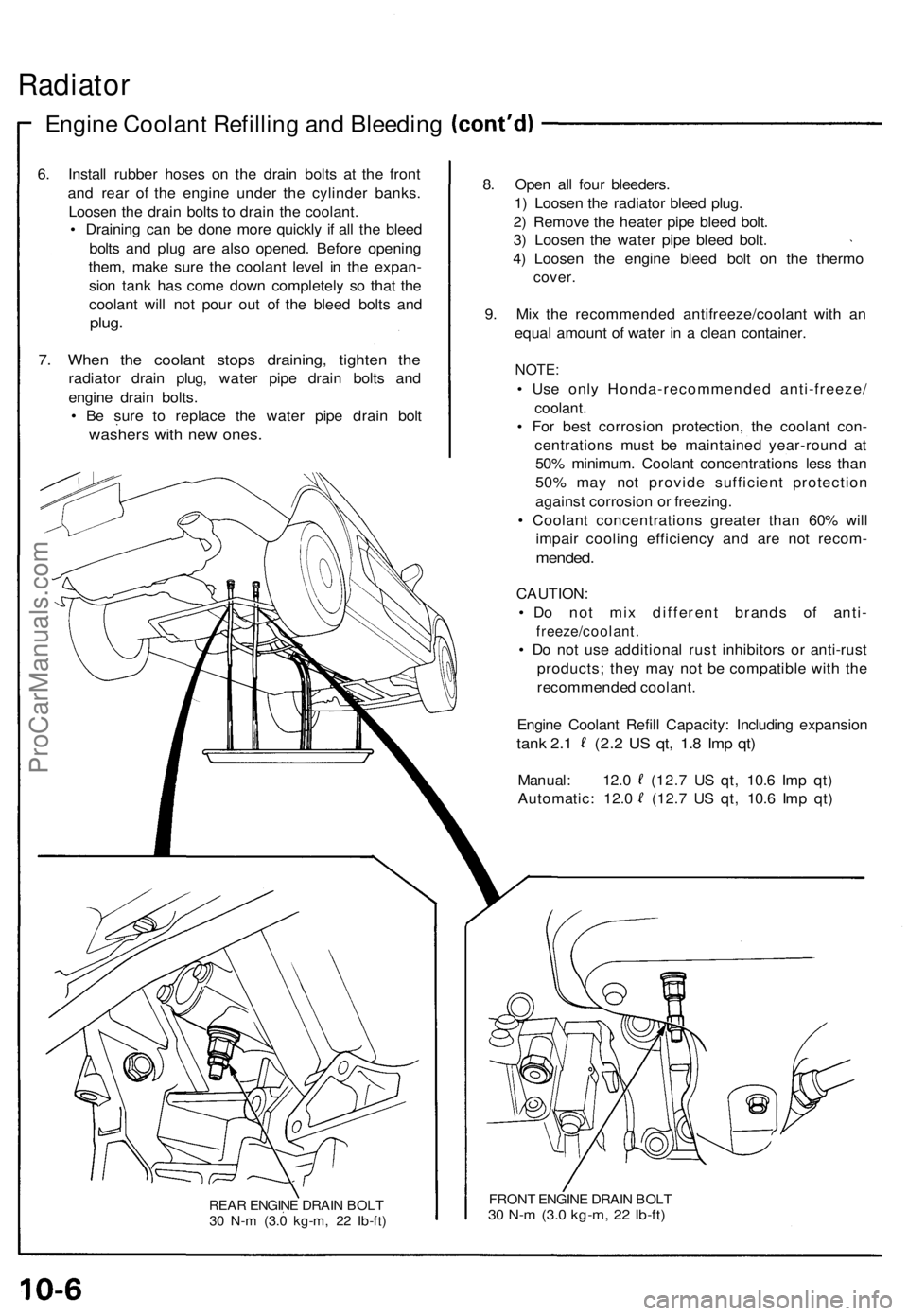

Radiator

Engine Coolan t Refillin g an d Bleedin g

6. Instal l rubbe r hose s o n th e drai n bolt s a t th e fron t

an d rea r of the engin e unde r th e cylinde r banks .

Loose n th e drai n bolt s t o drai n th e coolant .

• Drainin g ca n b e don e mor e quickl y i f al l th e blee d

bolt s an d plu g ar e als o opened . Befor e openin g

them , mak e sur e th e coolan t leve l i n th e expan -

sio n tan k ha s com e dow n completel y s o tha t th e

coolan t wil l no t pou r ou t o f th e blee d bolt s an d

plug .

7. Whe n th e coolan t stop s draining , tighte n th e

radiato r drai n plug , wate r pip e drai n bolt s an d

engin e drai n bolts .

• B e sur e t o replac e th e wate r pip e drai n bol t

washer s wit h ne w ones .

REAR ENGIN E DRAI N BOL T

3 0 N- m (3. 0 kg-m , 2 2 Ib-ft )

8. Ope n al l fou r bleeders .

1 ) Loose n th e radiato r blee d plug .

2 ) Remov e th e heate r pip e blee d bolt .

3 ) Loose n th e wate r pip e blee d bolt .

4 ) Loose n th e engin e blee d bol t o n th e therm o

cover.

9. Mi x th e recommende d antifreeze/coolan t wit h a n

equa l amoun t o f wate r i n a clea n container .

NOTE:

• Us e onl y Honda-recommende d anti-freeze /

coolant.

• Fo r bes t corrosio n protection , th e coolan t con -

centration s mus t b e maintaine d year-roun d a t

50 % minimum . Coolan t concentration s les s tha n

50 % ma y no t provid e sufficien t protectio n

agains t corrosio n o r freezing .

• Coolan t concentration s greate r tha n 60 % wil l

impai r coolin g efficienc y an d ar e no t recom -

mended.

CAUTION :

• D o no t mi x differen t brand s o f anti -

freeze/coolant .

• D o no t us e additiona l rus t inhibitor s o r anti-rus t

products ; the y ma y no t b e compatibl e wit h th e

recommende d coolant .

Engin e Coolan t Refil l Capacity : Includin g expansio n

tank 2. 1 (2. 2 U S qt , 1. 8 Im p qt )

Manual : 12. 0 (12. 7 U S qt , 10. 6 Im p qt )

Automatic : 12. 0 (12. 7 U S qt , 10. 6 Im p qt )

FRON T ENGIN E DRAI N BOL T30 N- m (3. 0 kg-m , 2 2 Ib-ft )

ProCarManuals.com

Page 167 of 1640

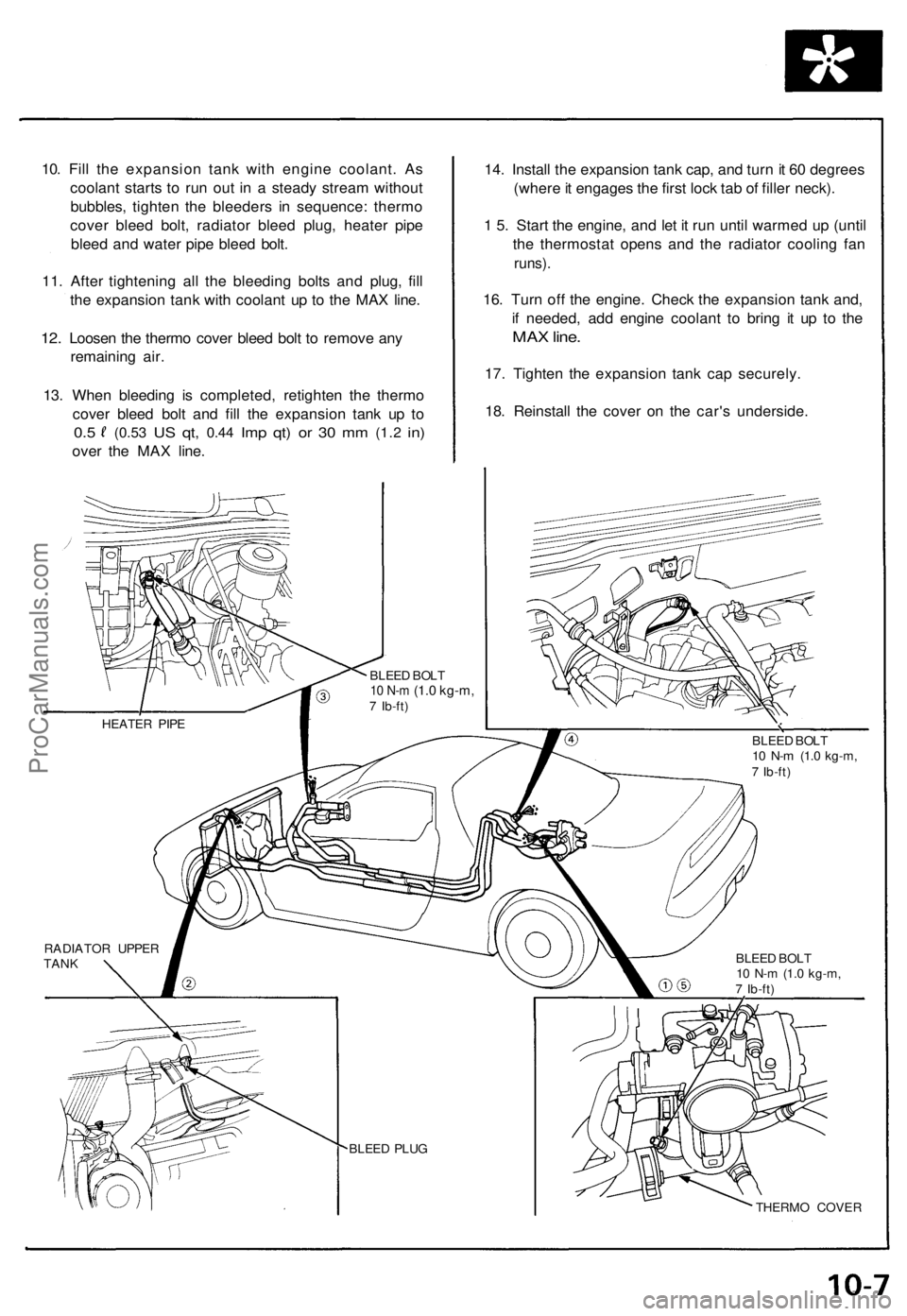

10. Fil l th e expansio n tan k wit h engin e coolant . A s

coolan t start s t o ru n ou t i n a stead y strea m withou t

bubbles , tighte n th e bleeder s i n sequence : therm o

cove r blee d bolt , radiato r blee d plug , heate r pip e

blee d an d wate r pip e blee d bolt .

11 . Afte r tightenin g al l th e bleedin g bolt s an d plug , fil l

th e expansio n tan k wit h coolan t u p t o th e MA X line .

12. Loose n th e therm o cove r blee d bol t t o remov e an y

remainin g air .

13 . Whe n bleedin g i s completed , retighte n th e therm o

cove r blee d bol t an d fill the expansio n tan k u p t o

0. 5 (0.5 3 US qt , 0.4 4 Imp qt ) o r 3 0 m m (1. 2 in)

ove r th e MA X line . 14

. Instal l th e expansio n tan k cap , an d tur n it 6 0 degree s

(wher e it engage s th e firs t loc k ta b o f fille r neck) .

1 5 . Star t th e engine , an d le t i t ru n unti l warme d u p (unti l

th e thermosta t open s an d th e radiato r coolin g fa n

runs) .

16. Tur n of f th e engine . Chec k th e expansio n tan k and ,

i f needed , ad d engin e coolan t t o brin g i t u p t o th e

MA X line .

17. Tighte n th e expansio n tan k ca p securely .

18 . Reinstal l th e cove r o n th e car' s underside .

THERMO COVE R

BLEE

D PLU G

RADIATO

R UPPE R

TAN K HEATE

R PIP E

BLEED BOL T

10 N- m (1. 0 kg-m ,7 Ib-ft )

BLEE

D BOL T

10 N- m (1. 0 kg-m ,7 Ib-ft )

BLEE

D BOL T

10 N- m (1. 0 kg-m ,7 Ib-ft )

ProCarManuals.com

Page 168 of 1640

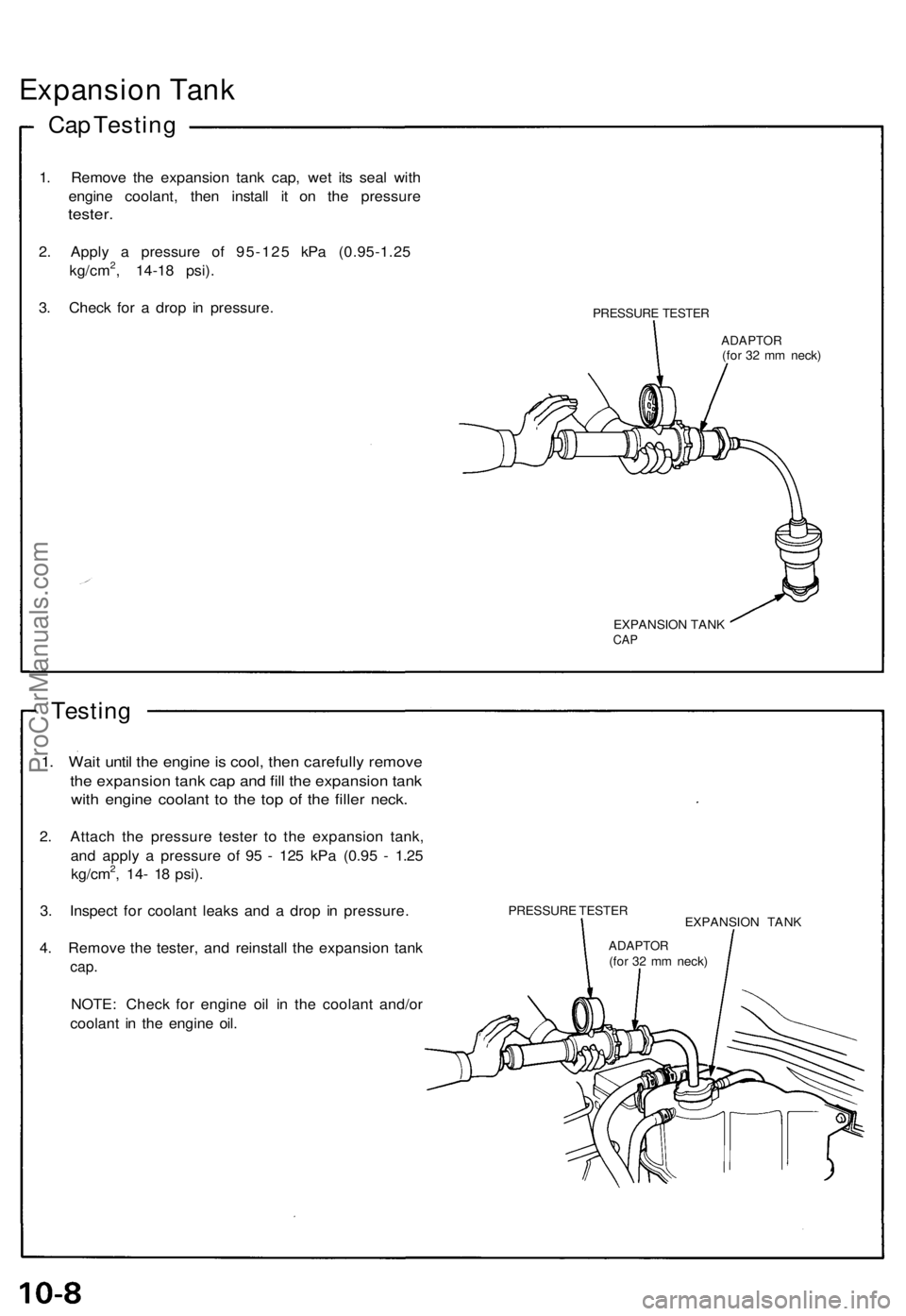

Expansion Tan k

Cap Testin g

1. Remov e th e expansio n tan k cap , we t it s sea l wit h

engin e coolant , the n instal l i t o n th e pressur e

tester.

2. Appl y a pressur e o f 95-12 5 kP a (0.95-1.2 5

kg/cm2, 14-1 8 psi) .

3 . Chec k fo r a dro p i n pressure .

PRESSUR E TESTE R

ADAPTO R(for 3 2 m m neck )

EXPANSIO N TAN K

CAP

Testin g

1. Wai t unti l th e engin e is cool , the n carefull y remov e

the expansio n tan k ca p an d fil l th e expansio n tan k

with engin e coolan t t o th e to p o f th e fille r neck .

2. Attac h th e pressur e teste r t o th e expansio n tank ,

an d appl y a pressur e o f 9 5 - 12 5 kP a (0.9 5 - 1.2 5

kg/cm

2, 14 - 1 8 psi) .

3 . Inspec t fo r coolan t leak s an d a dro p i n pressure .

4 . Remov e th e tester , an d reinstal l th e expansio n tan k

cap.

NOTE : Chec k fo r engin e oi l i n th e coolan t and/o r

coolan t i n th e engin e oil .

PRESSUR E TESTE R

EXPANSION TAN K

ADAPTO R(for 3 2 m m neck )

ProCarManuals.com

Page 169 of 1640

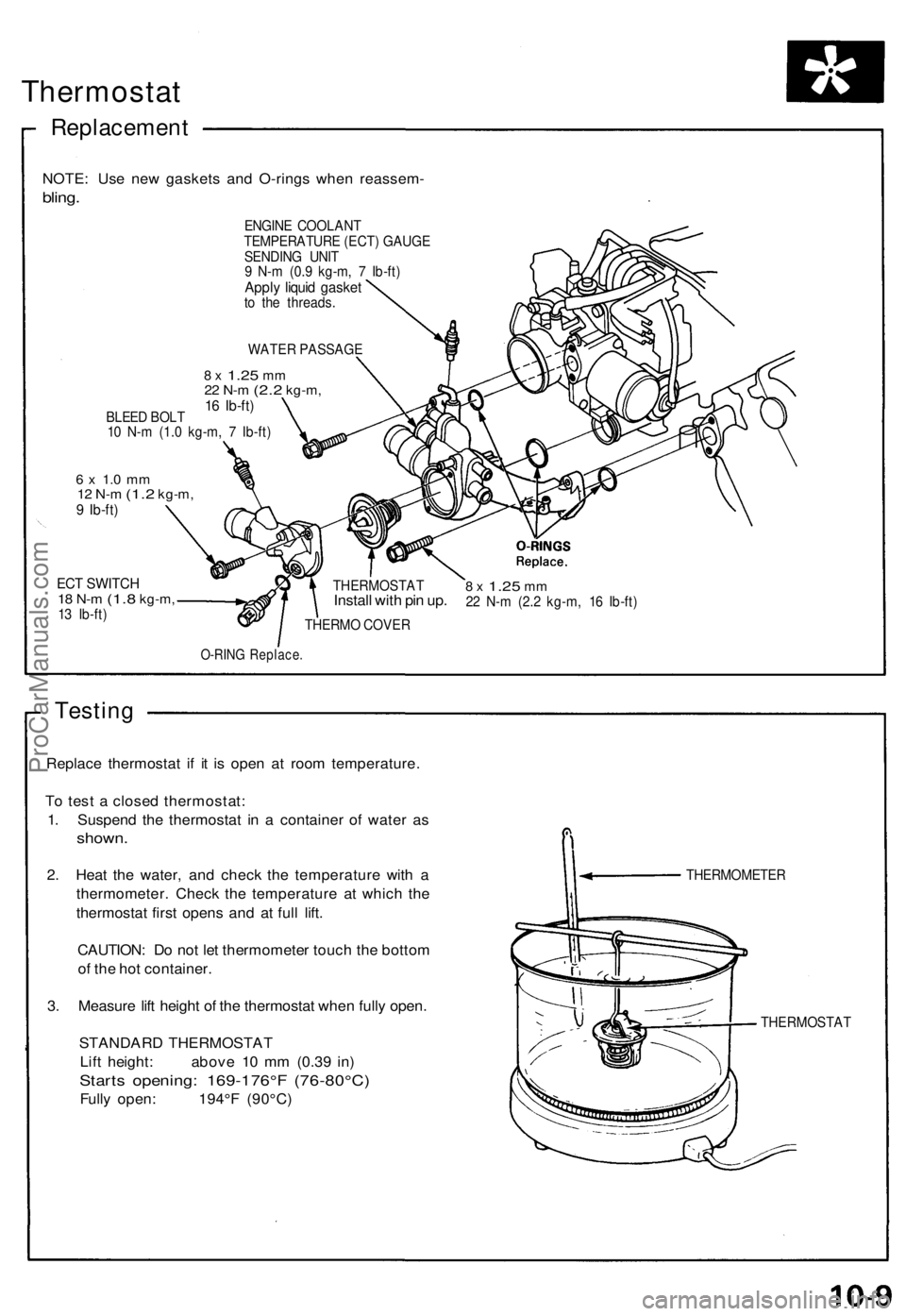

Thermostat

Replacemen t

NOTE: Us e ne w gasket s an d O-ring s whe n reassem -

bling.

ENGIN E COOLAN T

TEMPERATUR E (ECT ) GAUG E

SENDIN G UNI T

9 N- m (0. 9 kg-m , 7 Ib-ft )

Apply liqui d gaske tto th e threads .

WATE R PASSAG E

8 x 1.2 5 mm22 N- m (2. 2 kg-m ,16 Ib-ft )BLEE D BOL T

1 0 N- m (1. 0 kg-m , 7 Ib-ft )

6 x 1. 0 m m12 N- m (1. 2 kg-m ,9 Ib-ft )

ECT SWITC H18 N- m (1. 8 kg-m ,13 Ib-ft )

8 x 1.2 5 mm22 N- m (2. 2 kg-m , 1 6 Ib-ft )

THERM O COVE R

O-RING Replace .

Testing

Replac e thermosta t i f i t i s ope n a t roo m temperature .

T o tes t a close d thermostat :

1 . Suspen d th e thermosta t i n a containe r o f wate r a s

shown .

2. Hea t th e water , an d chec k th e temperatur e wit h a

thermometer . Chec k th e temperatur e a t whic h th e

thermosta t firs t open s an d a t ful l lift .

CAUTION : D o no t le t thermomete r touc h th e botto m

o f th e ho t container .

3 . Measur e lif t heigh t o f th e thermosta t whe n full y open .

STANDAR D THERMOSTA T

Lif t height : abov e 1 0 m m (0.3 9 in )

Start s opening : 169-176° F (76-80°C )

Fully open : 194° F (90°C )

THERMOMETE R

THERMOSTA T

THERMOSTA

T

Install wit h pi n up .

ProCarManuals.com

Page 170 of 1640

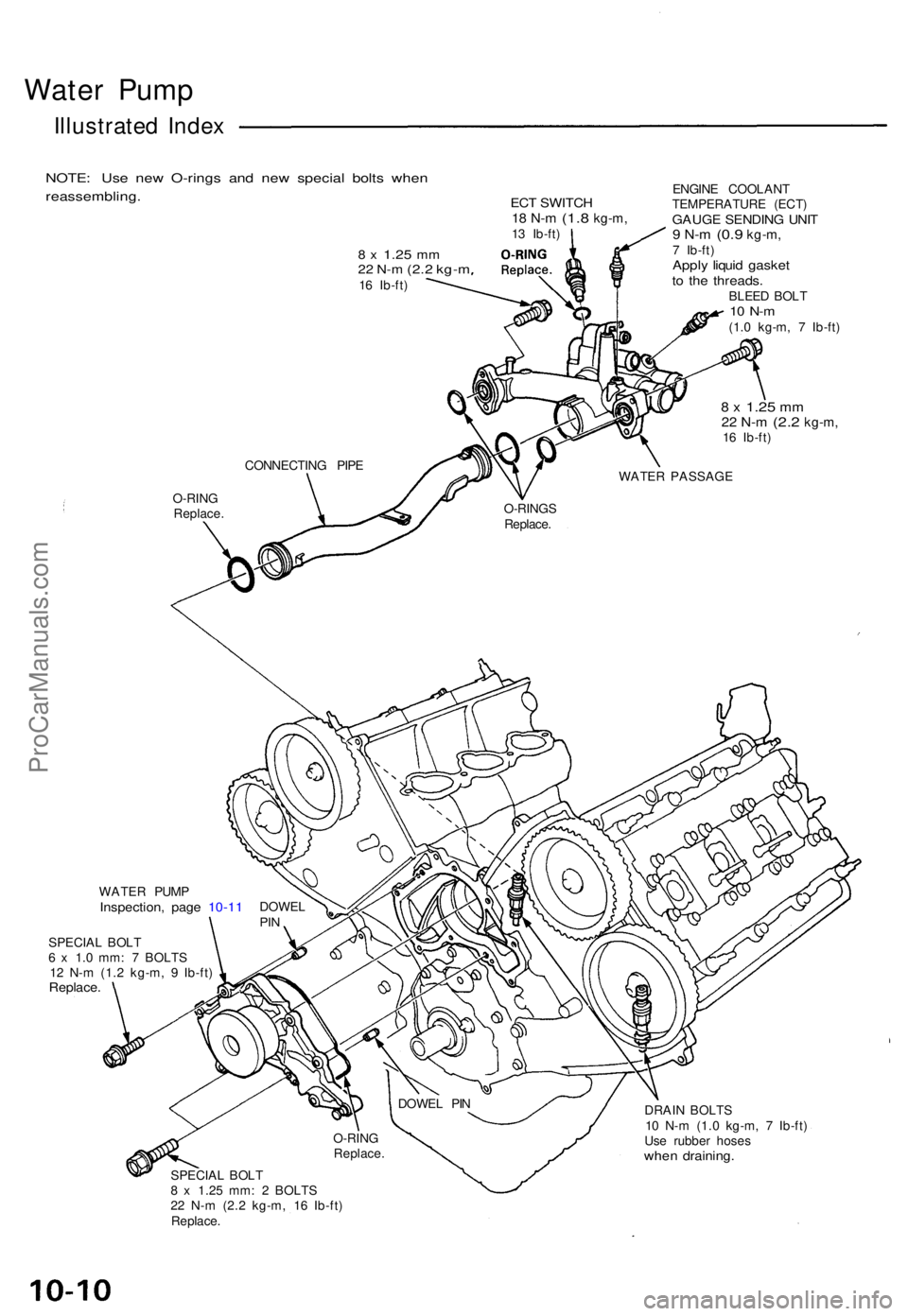

Water Pum p

Illustrate d Inde x

NOTE : Us e ne w O-ring s an d ne w specia l bolt s whe n

reassembling .

8 x 1.2 5 mm22 N- m (2. 2 kg- m16 Ib-ft )

ECT SWITC H18 N- m (1. 8 kg-m ,13 Ib-ft ) ENGIN

E COOLAN T

TEMPERATUR E (ECT )GAUG E SENDIN G UNI T9 N- m (0. 9 kg-m ,7 Ib-ft )Apply liqui d gaske tto th e threads .BLEED BOL T10 N- m(1.0 kg-m , 7 Ib-ft )

8 x 1.2 5 mm22 N- m (2. 2 kg-m ,16 Ib-ft )

O-RIN G

Replace .

DRAIN BOLT S

1 0 N- m (1. 0 kg-m , 7 Ib-ft )

Us e rubbe r hose s

when draining .

SPECIAL BOL T

8 x 1.2 5 mm : 2 BOLT S

2 2 N- m (2. 2 kg-m , 1 6 Ib-ft )

Replace . DOWE

L PI N

O-RIN G

Replace .

WATER PUM PInspection , pag e 10-1 1 DOWE LPIN

SPECIA L BOL T

6 x 1. 0 mm : 7 BOLT S

1 2 N- m (1. 2 kg-m , 9 Ib-ft )

Replace .

WATER PASSAG E

O-RING S

Replace .

CONNECTIN

G PIP E

ProCarManuals.com