ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 1281 of 1640

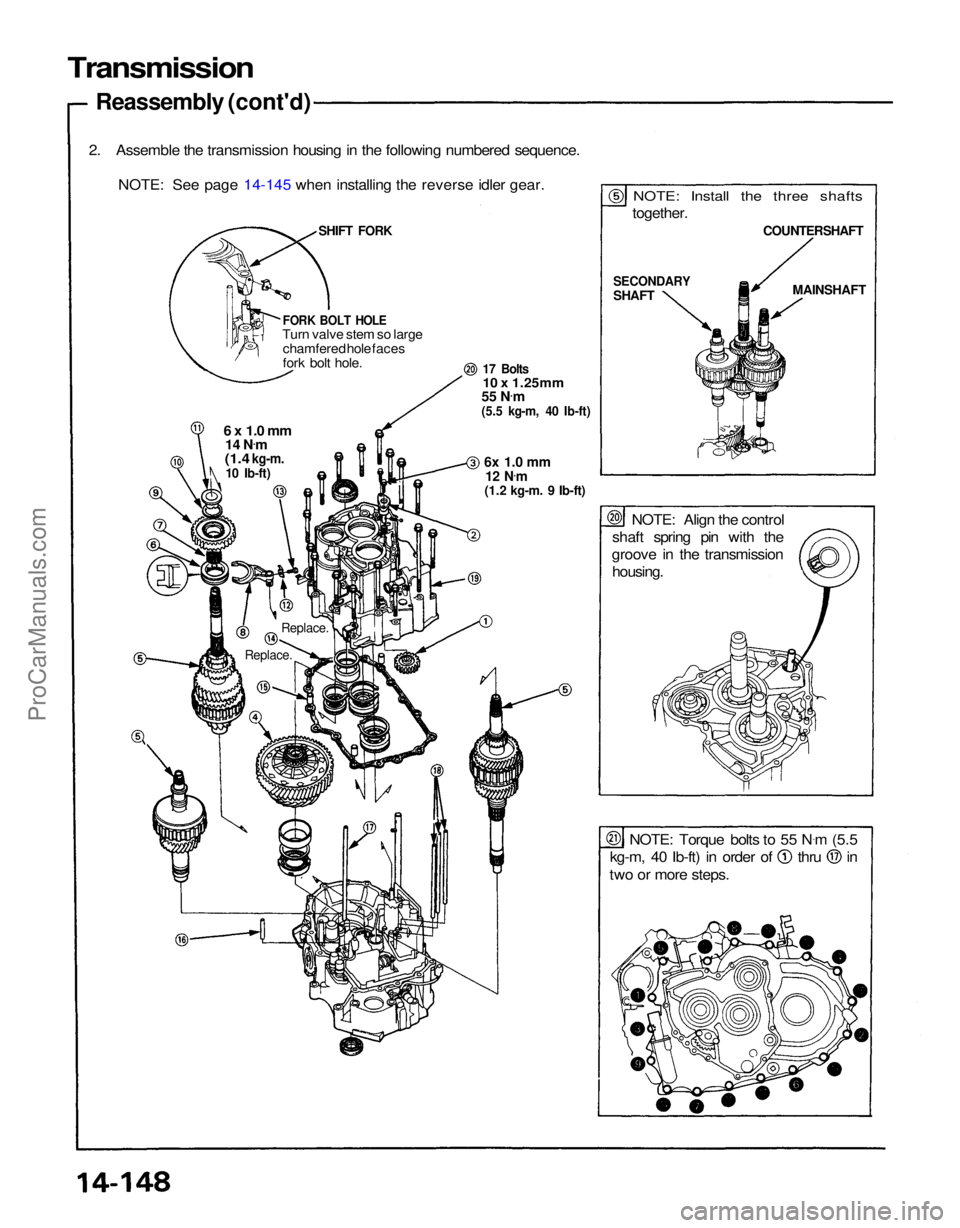

NOTE: Torque bolts to 55 N

.

m (5.5 kg-m, 40 Ib-ft) in order of thru in

two or more steps. NOTE: Align the control

shaft spring pin with the

groove in the transmission housing.

6x 1.0 mm

12 N .

m

(1.2 kg-m. 9 Ib-ft)

Replace.

Replace.

6 x 1.0 mm

14 N .

m

(1.4

kg-m.

10 Ib-ft)

17 Bolts

10 x 1.25mm

55 N .

m

(5.5 kg-m, 40 Ib-ft)

FORK BOLT HOLE

Turn valve stem so large

chamfered hole faces

fork bolt hole.

SHIFT FORK

MAINSHAFT

COUNTERSHAFT

NOTE: Install the three shafts

Transmission

Reassembly (cont'd)

2. Assemble the transmission housing in the following numbered sequence.

NOTE: See page 14-145 when installing the reverse idler gear.

SECONDARY

SHAFT

together.ProCarManuals.com

Page 1282 of 1640

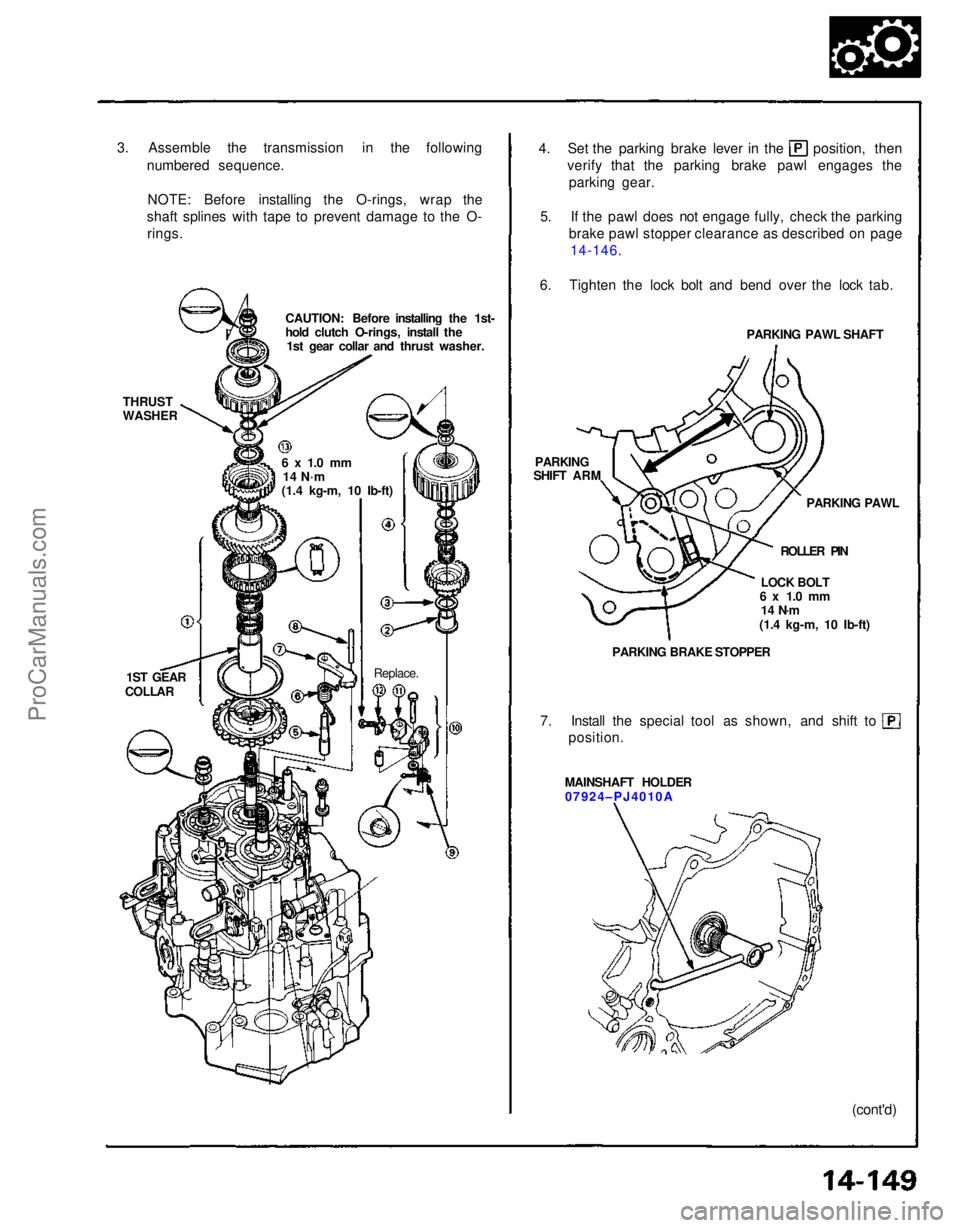

(cont'd)

MAINSHAFT HOLDER

07924–PJ4010A

1ST GEAR

COLLAR

Replace.

PARKING BRAKE STOPPER

7. Install the special tool as shown, and shift to

position. LOCK BOLT

6 x 1.0 mm 14 N·m

(1.4 kg-m, 10 Ib-ft) ROLLER PIN

PARKING PAWL

PARKING

SHIFT ARM PARKING PAWL SHAFT 4. Set the parking brake lever in the position, then

verify that the parking brake pawl engages theparking gear.

5. If the pawl does not engage fully, check the parking brake pawl stopper clearance as described on page14-146.

6. Tighten the lock bolt and bend over the lock tab.

CAUTION: Before installing the 1st-

hold clutch O-rings, install the 1st gear collar and thrust washer.

3. Assemble the transmission in the following

numbered sequence.

NOTE: Before installing the O-rings, wrap the

shaft splines with tape to prevent damage to the O- rings.

THRUST

WASHER

6 x 1.0 mm14 N·m

(1.4 kg-m, 10 Ib-ft)ProCarManuals.com

Page 1283 of 1640

Transmission

Reassembly (cont'd)

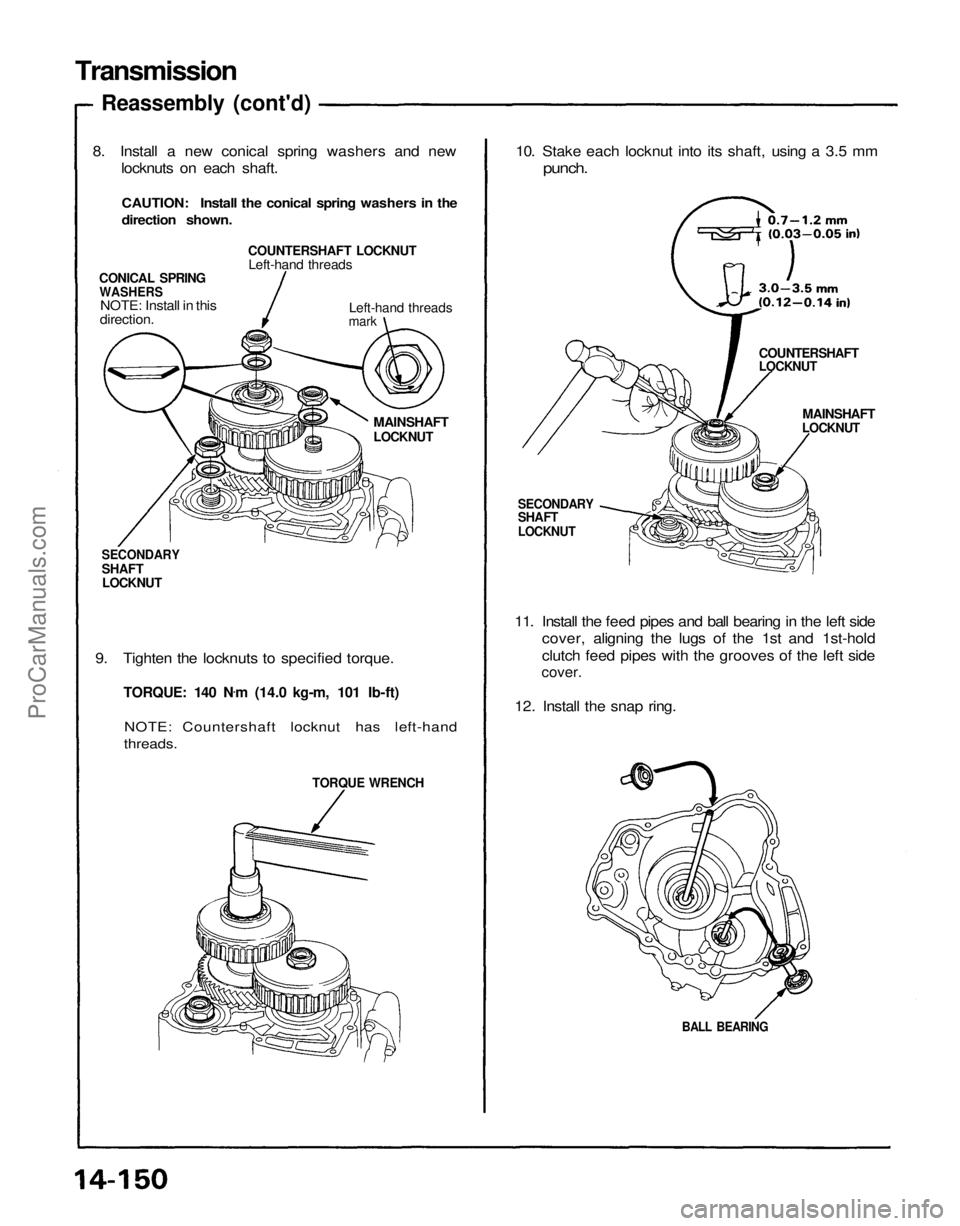

8. Install a new conical spring washers and new locknuts on each shaft.

CAUTION: Install the conical spring washers in the

direction shown.

COUNTERSHAFT LOCKNUT

Left-hand threads

CONICAL SPRING

WASHERS

NOTE: Install in this

direction.

Left-hand threads

MAINSHAFT

LOCKNUT

SECONDARY

SHAFT

LOCKNUT

9. Tighten the locknuts to specified torque.

TORQUE: 140 N .

m (14.0 kg-m, 101 Ib-ft)

NOTE: Countershaft locknut has left-hand

threads.

TORQUE WRENCH

10. Stake each locknut into its shaft, using a 3.5 mm

punch.

COUNTERSHAFT

LOCKNUT

MAINSHAFT

LOCKNUT

SECONDARY

SHAFT

LOCKNUT

11. Install the feed pipes and ball bearing in the left side cover, aligning the lugs of the 1st and 1st-hold

clutch feed pipes with the grooves of the left side

cover.

12. Install the snap ring.

BALL BEARING

markProCarManuals.com

Page 1284 of 1640

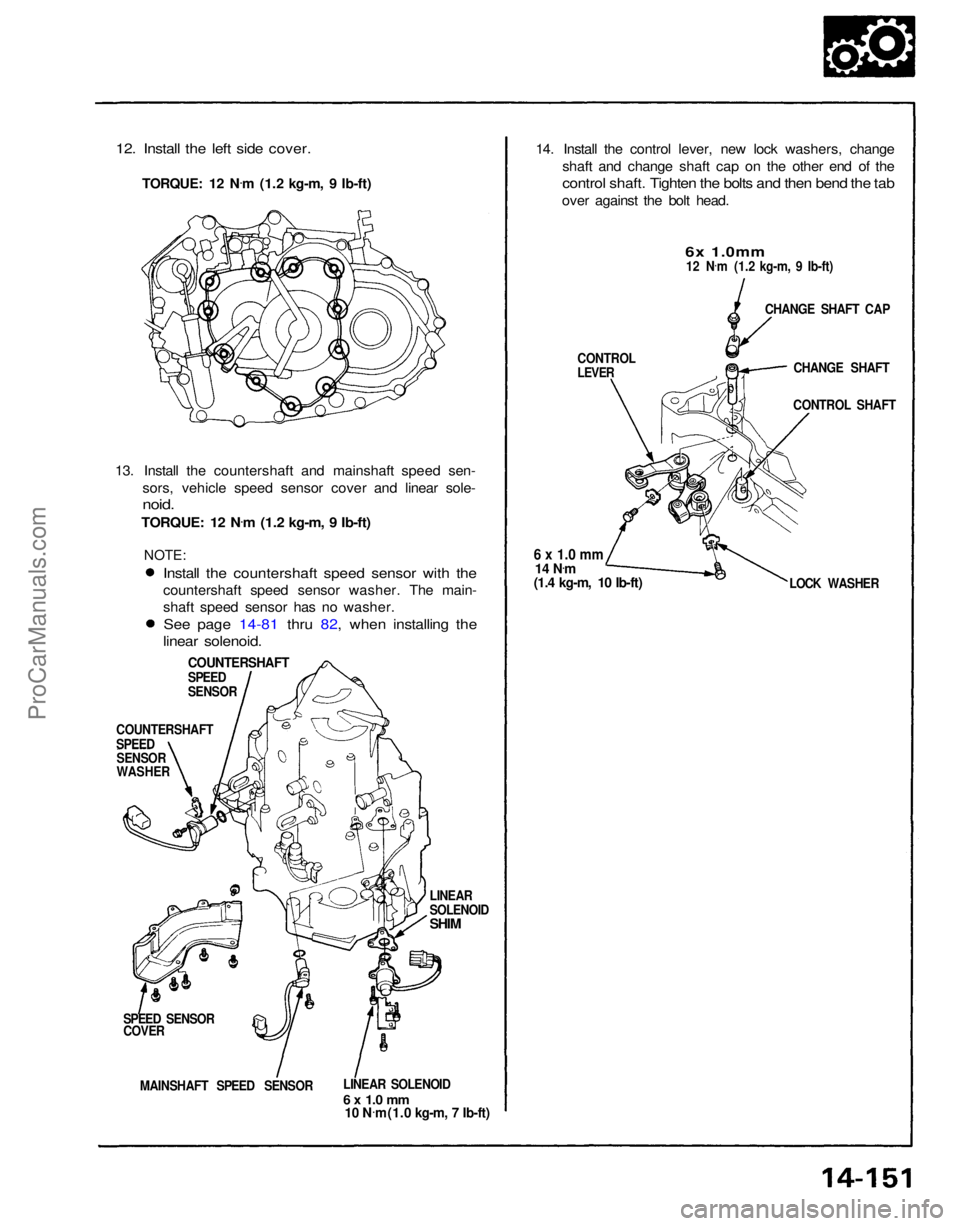

LINEAR SOLENOID

6 x 1.0 mm

10 N .

m(1.0 kg-m, 7 Ib-ft)

MAINSHAFT SPEED SENSOR

SPEED SENSOR

COVER

LINEAR

SOLENOID

SHIM

COUNTERSHAFT

SPEED

LOCK WASHER

6 x 1.0 mm

(1.4 kg-m, 10 Ib-ft)

SPEED

SENSOR

COUNTERSHAFT

Install the countershaft speed sensor with the

countershaft speed sensor washer. The main-

shaft speed sensor has no washer.

See page 14-81 thru 82, when installing the

linear solenoid.

NOTE:

13. Install the countershaft and mainshaft speed sen-

sors, vehicle speed sensor cover and linear sole-

noid.

TORQUE: 12 N .

m (1.2 kg-m, 9 Ib-ft)

CONTROL SHAFT

CHANGE SHAFT

CHANGE SHAFT CAP

6x

1.0mm

12 N

.

m (1.2 kg-m, 9 Ib-ft)

CONTROL

LEVER

14. Install the control lever, new lock washers, change

shaft and change shaft cap on the other end of the

control shaft. Tighten the bolts and then bend the tab

over against the bolt head.

12. Install the left side cover.

TORQUE: 12 N .

m (1.2 kg-m, 9 Ib-ft)

SENSOR

WASHER

14 N

.

mProCarManuals.com

Page 1285 of 1640

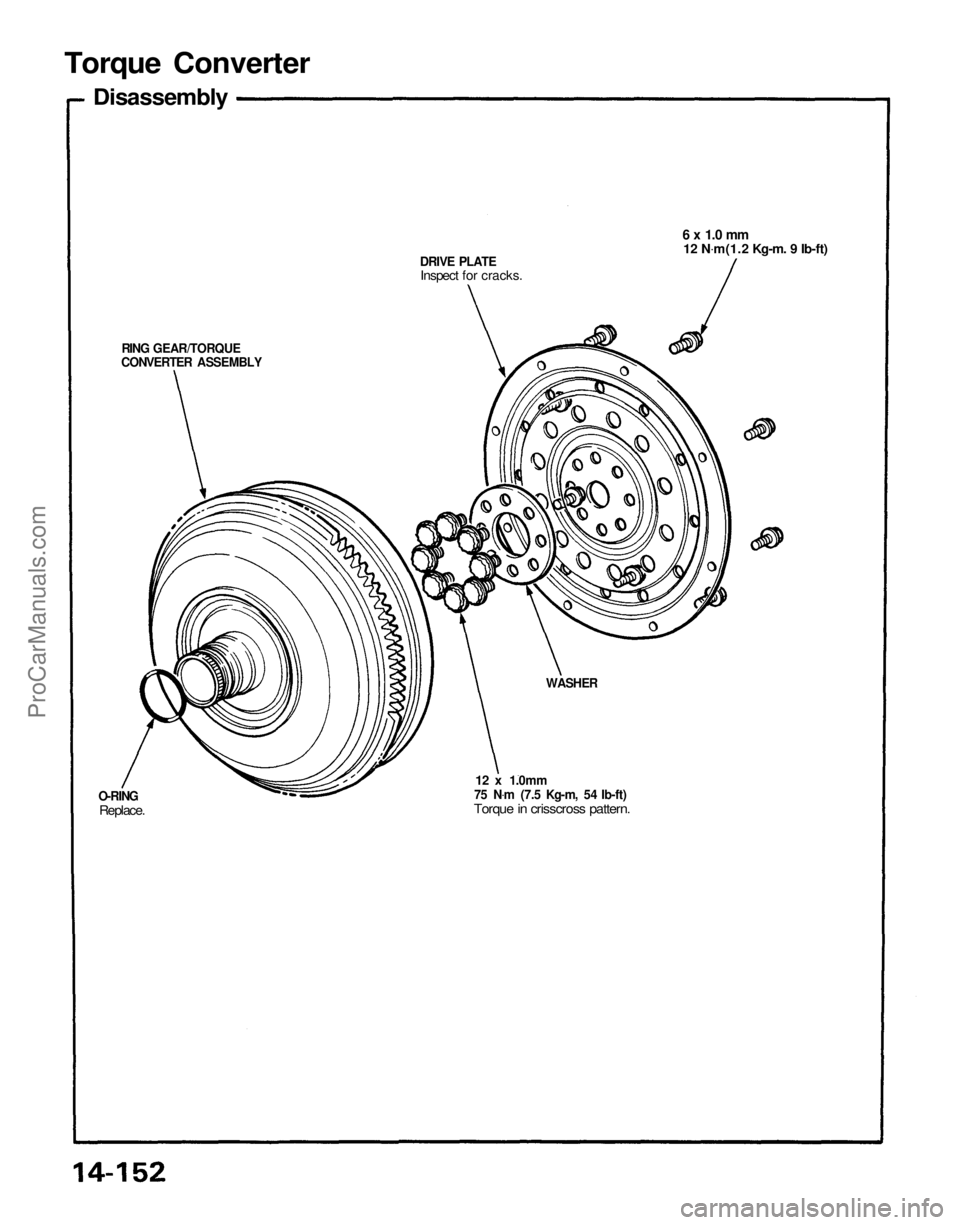

Torque Converter

Disassembly

6 x 1.0 mm

12 N .

m(1.2 Kg-m. 9 Ib-ft)

DRIVE PLATE

Inspect for cracks.

RING GEAR/TORQUE

CONVERTER ASSEMBLY

WASHER

12 x

1.0mm

75 N .

m (7.5 Kg-m, 54 Ib-ft)

Torque in crisscross pattern.

O-RING

Replace.ProCarManuals.com

Page 1286 of 1640

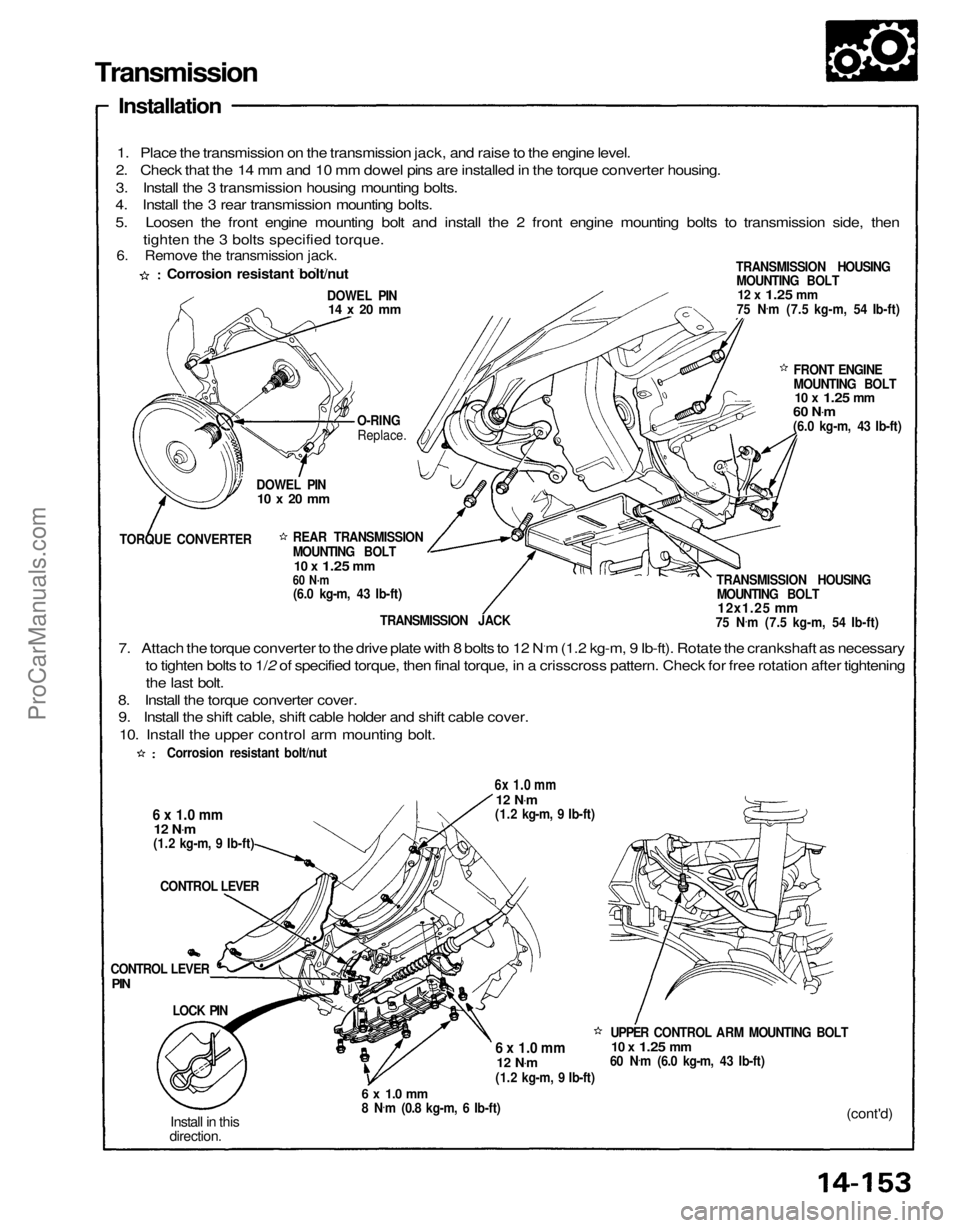

Transmission

Installation

1. Place the transmission on the transmission jack, and raise to the engine level.

2. Check that the 14 mm and 10 mm dowel pins are installed in the torque converter housing.

3. Install the 3 transmission housing mounting bolts.

4. Install the 3 rear transmission mounting bolts.

5. Loosen the front engine mounting bolt and install the 2 front engine mounting bolts to transmission side, then

tighten the 3 bolts specified torque.

TRANSMISSION HOUSINGMOUNTING BOLT

12 x

1.25

mm

75 N .

m (7.5 kg-m, 54 Ib-ft)

DOWEL PIN

14 x 20 mm

FRONT ENGINE

MOUNTING BOLT

10 x

1.25

mm

60 N .

m

(6.0 kg-m, 43 Ib-ft)

TRANSMISSION HOUSING MOUNTING BOLT

12x1.25 mm

75 N .

m (7.5 kg-m, 54 Ib-ft)

O-RING

Replace.

DOWEL PIN

10 x 20 mm

TORQUE CONVERTER REAR TRANSMISSION

MOUNTING BOLT

10 x

1.25

mm

60 N·m

(6.0 kg-m, 43 Ib-ft)

TRANSMISSION JACK

7. Attach the torque converter to the drive plate with 8 bolts to 12 N.m (1.2 kg-m, 9 Ib-ft). Rotate the crankshaft as necessary to tighten bolts to 1/2 of specified torque, then final torque, in a crisscross pattern. Check for free rotation after tighteningthe last bolt.

8. Install the torque converter cover. 9. Install the shift cable, shift cable holder and shift cable cover.

10. Install the upper control arm mounting bolt.

6x 1.0 mm

12 N

.

m

(1.2 kg-m, 9 Ib-ft)

6 x 1.0 mm

12 N

.

m

(1.2 kg-m, 9 Ib-ft)

CONTROL LEVER

UPPER CONTROL ARM MOUNTING BOLT

10 x

1.25

mm

60 N .

m (6.0 kg-m, 43 Ib-ft)

6 x 1.0 mm

12 N

.

m

(1.2 kg-m, 9 Ib-ft)

(cont'd)

6 x 1.0 mm

8 N

.

m (0.8 kg-m, 6 Ib-ft)

Install in this

direction.

LOCK PIN

CONTROL LEVER

PIN

Corrosion resistant bolt/nut

Corrosion resistant bolt/nut

6. Remove the transmission jack.ProCarManuals.com

Page 1287 of 1640

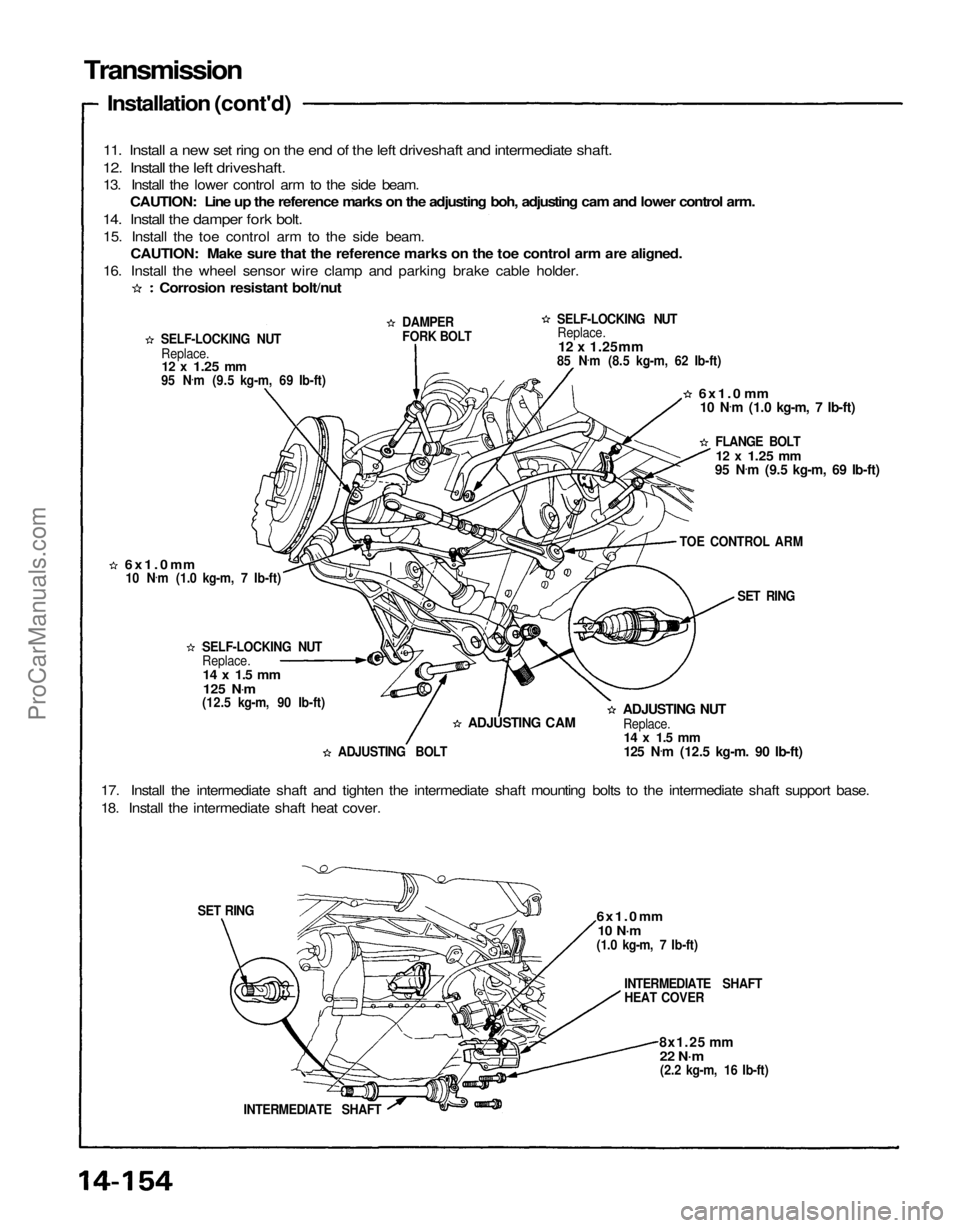

Transmission

Installation (cont'd)

11. Install a new set ring on the end of the left driveshaft and intermediate shaft.

12. Install the left driveshaft.

13. Install the lower control arm to the side beam. CAUTION: Line up the reference marks on the adjusting boh, adjusting cam and lower control arm.

14. Install the damper fork bolt.

15. Install the toe control arm to the side beam. CAUTION: Make sure that the reference marks on the toe control arm are aligned.

16. Install the wheel sensor wire clamp and parking brake cable holder.

SELF-LOCKING NUTReplace.

12 x

1.25

mm

95 N .

m (9.5 kg-m, 69 Ib-ft) DAMPER

FORK BOLT

SELF-LOCKING NUT

Replace.

12 x 1.25mm

85 N .

m (8.5 kg-m, 62 Ib-ft)

6x1.0

mm

10 N .

m (1.0 kg-m, 7 Ib-ft)

FLANGE BOLT

12 x

1.25

mm

95 N .

m (9.5 kg-m, 69 Ib-ft)

TOE CONTROL ARM SET RING

6x1.0

mm

Replace. SELF-LOCKING NUT

ADJUSTING NUT

Replace.

14 x 1.5 mm

125 N .

m (12.5 kg-m. 90 Ib-ft)

ADJUSTING CAM

ADJUSTING BOLT

17. Install the intermediate shaft and tighten the intermediate shaft mounting bolts to the intermediate shaft support base.

18. Install the intermediate shaft heat cover.

6x1.0

mm

10 N·m

(1.0 kg-m, 7 Ib-ft)

INTERMEDIATE SHAFT

HEAT COVER

8x1.25 mm

22 N·m

(2.2 kg-m, 16 Ib-ft)

INTERMEDIATE SHAFT

SET RING

Corrosion resistant bolt/nut

10 N .

m (1.0 kg-m, 7 Ib-ft)

14 x 1.5 mm

125 N .

m

(12.5 kg-m, 90 Ib-ft)ProCarManuals.com

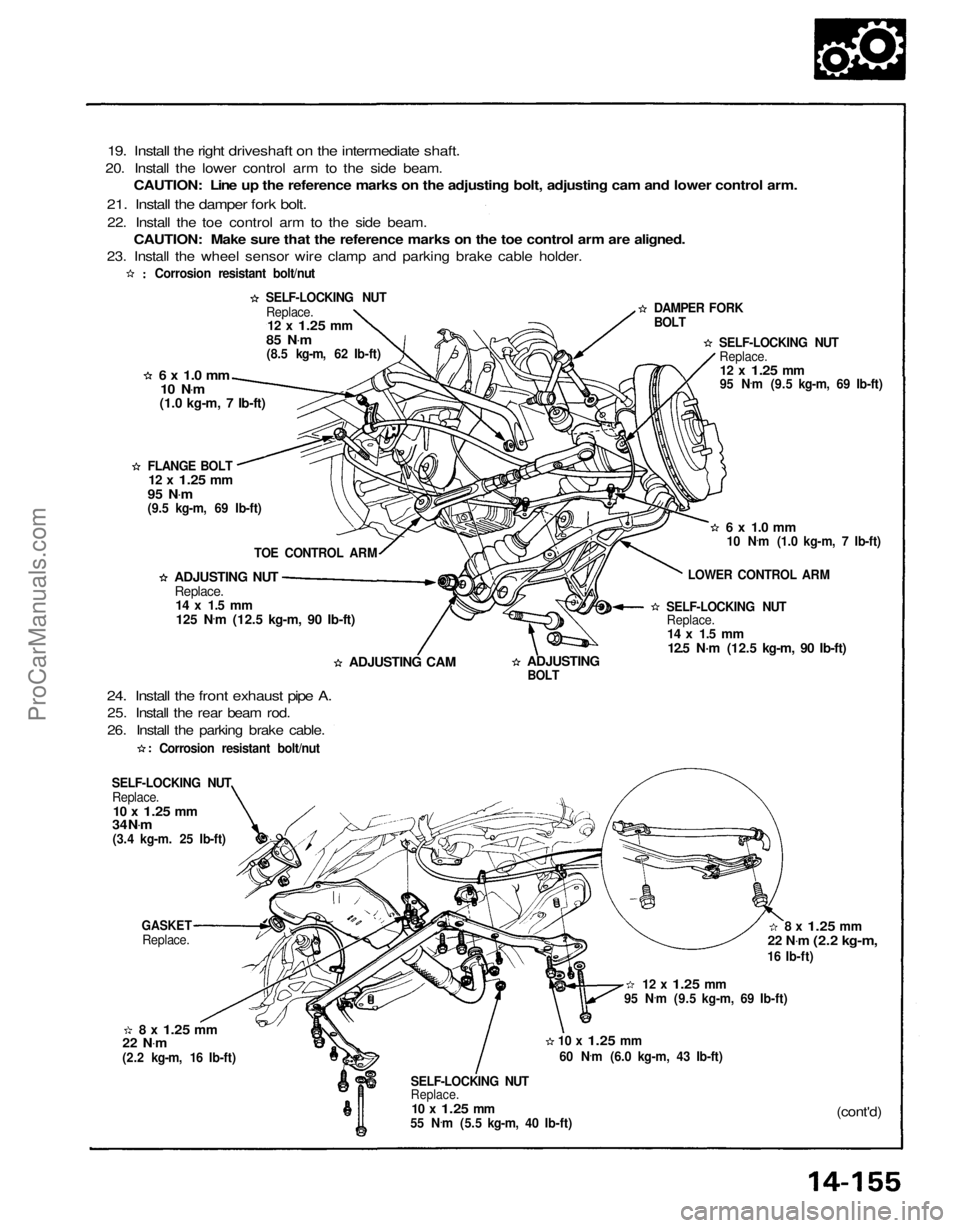

Page 1288 of 1640

19. Install the right driveshaft on the intermediate shaft.

20. Install the lower control arm to the side beam. CAUTION: Line up the reference marks on the adjusting bolt, adjusting cam and lower control arm.

21. Install the damper fork bolt.

22. Install the toe control arm to the side beam. CAUTION: Make sure that the reference marks on the toe control arm are aligned.

23. Install the wheel sensor wire clamp and parking brake cable holder.

Corrosion resistant bolt/nut

SELF-LOCKING NUT DAMPER FORK

BOLT

SELF-LOCKING NUTReplace.

12 x

1.25

mm

95 N .

m (9.5 kg-m, 69 Ib-ft)

6 x 1.0 mm

FLANGE BOLT

(cont'd)

SELF-LOCKING NUT

Replace.

10 x

1.25

mm

55 N .

m (5.5 kg-m, 40 Ib-ft)

10 x

1.25

mm

60 N .

m (6.0 kg-m, 43 Ib-ft) 95 N

.

m (9.5 kg-m, 69 Ib-ft)

12 x

1.25

mm

22 N

.

m

(2.2 kg-m,

16 Ib-ft)

8 x

1.25

mm

22 N .

m

(2.2 kg-m, 16 Ib-ft)

8 x

1.25

mm

GASKET

Replace.

SELF-LOCKING NUT

Replace.

10 x

1.25

mm

34 N .

m

(3.4 kg-m. 25 Ib-ft)

24. Install the front exhaust pipe A.

25. Install the rear beam rod.

26. Install the parking brake cable.

ADJUSTING CAM

125 N

.

m (12.5 kg-m, 90 Ib-ft)

ADJUSTING NUT

Replace.

14 x 1.5 mm

TOE CONTROL ARM

95 N

.

m

(9.5 kg-m, 69 Ib-ft) Replace.

12 x

1.25

mm

85 N .

m

(8.5 kg-m, 62 Ib-ft)

10 N .

m

(1.0 kg-m, 7 Ib-ft)

12 x

1.25

mm

Corrosion resistant bolt/nut

ADJUSTING

BOLT

SELF-LOCKING NUT

Replace.

14 x 1.5 mm

12.5 N·m (12.5 kg-m, 90 Ib-ft)

LOWER CONTROL ARM

6 x 1.0 mm

10 N .

m (1.0 kg-m, 7 Ib-ft)ProCarManuals.com

Page 1289 of 1640

Transmission

Installation (cont'd)

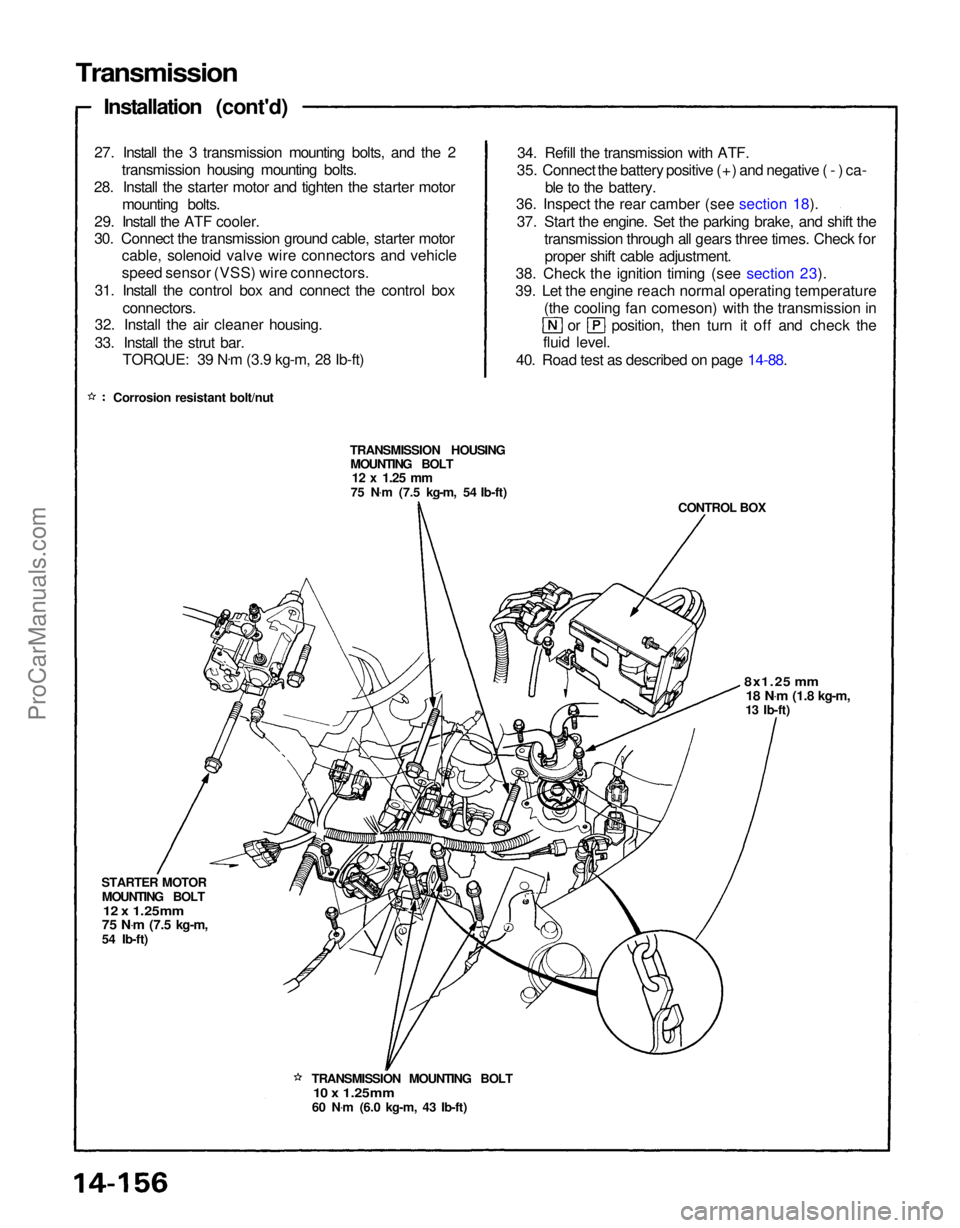

27. Install the 3 transmission mounting bolts, and the 2 transmission housing mounting bolts.

28. Install the starter motor and tighten the starter motor mounting bolts.

29. Install the ATF cooler.

30. Connect the transmission ground cable, starter motor cable, solenoid valve wire connectors and vehicle

speed sensor (VSS) wire connectors.

31. Install the control box and connect the control box connectors.

32. Install the air cleaner housing.

33. Install the strut bar.

TORQUE: 39 N .

m (3.9 kg-m, 28 Ib-ft)

Corrosion resistant bolt/nut 34. Refill the transmission with ATF.

35. Connect the battery positive (+) and negative (-) ca- ble to the battery.

36. Inspect the rear camber (see section 18).

37. Start the engine. Set the parking brake, and shift the transmission through all gears three times. Check forproper shift cable adjustment.

38. Check the ignition timing (see section 23).

39. Let the engine reach normal operating temperature (the cooling fan comeson) with the transmission in or position, then turn it off and check the

fluid level.

40. Road test as described on page 14-88.

TRANSMISSION HOUSING MOUNTING BOLT

12 x

1.25

mm

75 N .

m (7.5 kg-m, 54 Ib-ft)

CONTROL BOX

8x1.25 mm

18 N .

m

(1.8 kg-m,

13 Ib-ft)

TRANSMISSION MOUNTING BOLT

10 x 1.25mm

60 N .

m (6.0 kg-m, 43 Ib-ft)

STARTER MOTOR

MOUNTING BOLT

12 x 1.25mm

75 N .

m

(7.5 kg-m,

54 Ib-ft)ProCarManuals.com

Page 1290 of 1640

Shift Cable

Adjustment

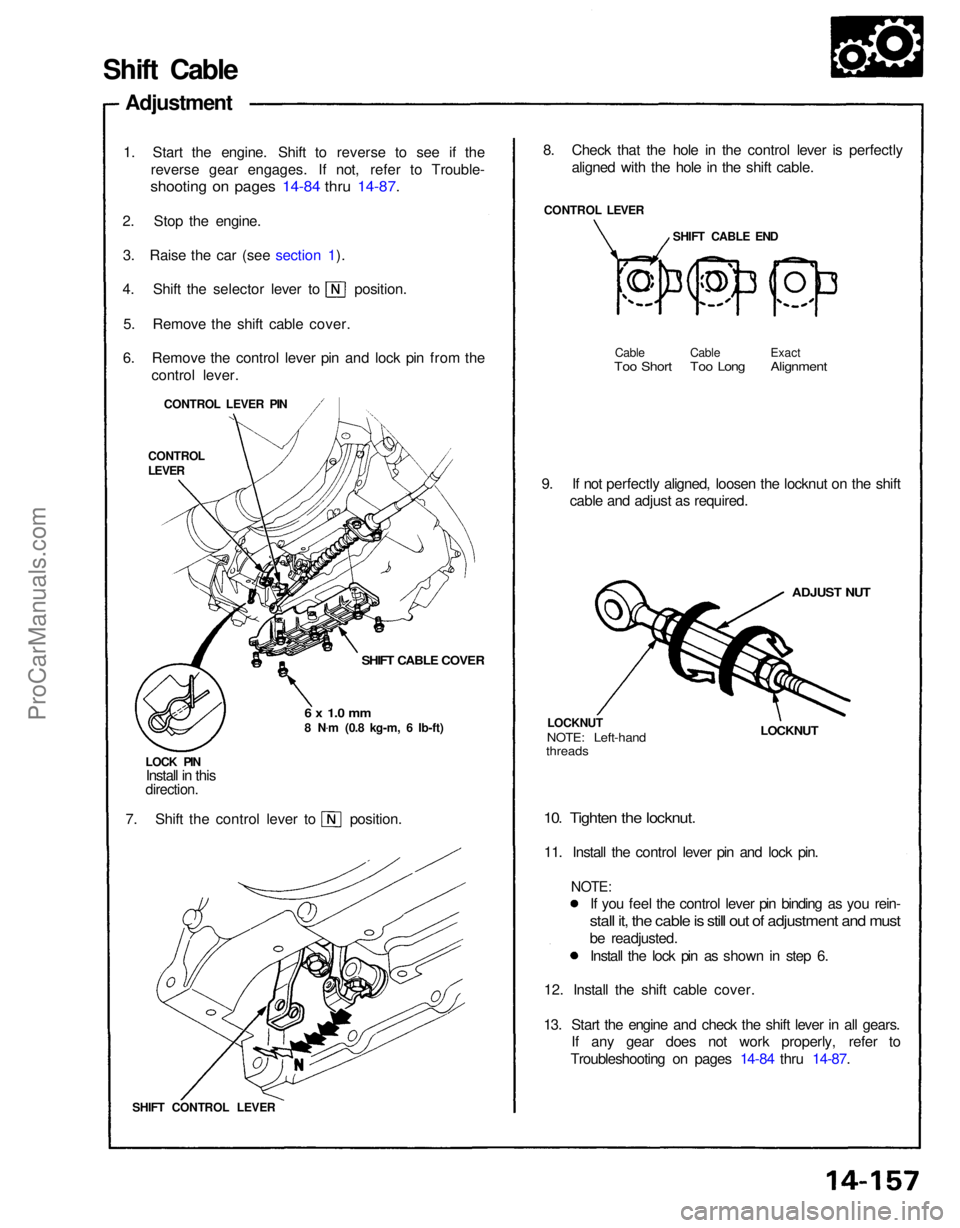

1. Start the engine. Shift to reverse to see if the reverse gear engages. If not, refer to Trouble-

shooting on pages 14-84 thru 14-87.

2. Stop the engine. 3. Raise the car (see section 1). 4. Shift the selector lever to position.

5. Remove the shift cable cover.

6. Remove the control lever pin and lock pin from the control lever.

CONTROL LEVER PIN

CONTROL

LEVER

SHIFT CABLE COVER

6 x 1.0 mm

8 N .

m (0.8 kg-m, 6 Ib-ft)

LOCK PIN Install in this

direction.

7. Shift the control lever to position.

SHIFT CONTROL LEVER 12. Install the shift cable cover.

13. Start the engine and check the shift lever in all gears. If any gear does not work properly, refer to

Troubleshooting on pages 14-84 thru 14-87. If you feel the control lever pin binding as you rein-

stall it, the cable is still out of adjustment and must

be readjusted.

Install the lock pin as shown in step 6.

10. Tighten the locknut.

11. Install the control lever pin and lock pin.

NOTE:

LOCKNUT

LOCKNUT

NOTE: Left-hand

threads

ADJUST NUT

9. If not perfectly aligned, loosen the locknut on the shift

cable and adjust as required. Cable Cable Exact

Too Short Too Long Alignment

SHIFT CABLE END

CONTROL LEVER

8. Check that the hole in the control lever is perfectly

aligned with the hole in the shift cable.ProCarManuals.com