ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 381 of 1640

Oil Seal

Removal

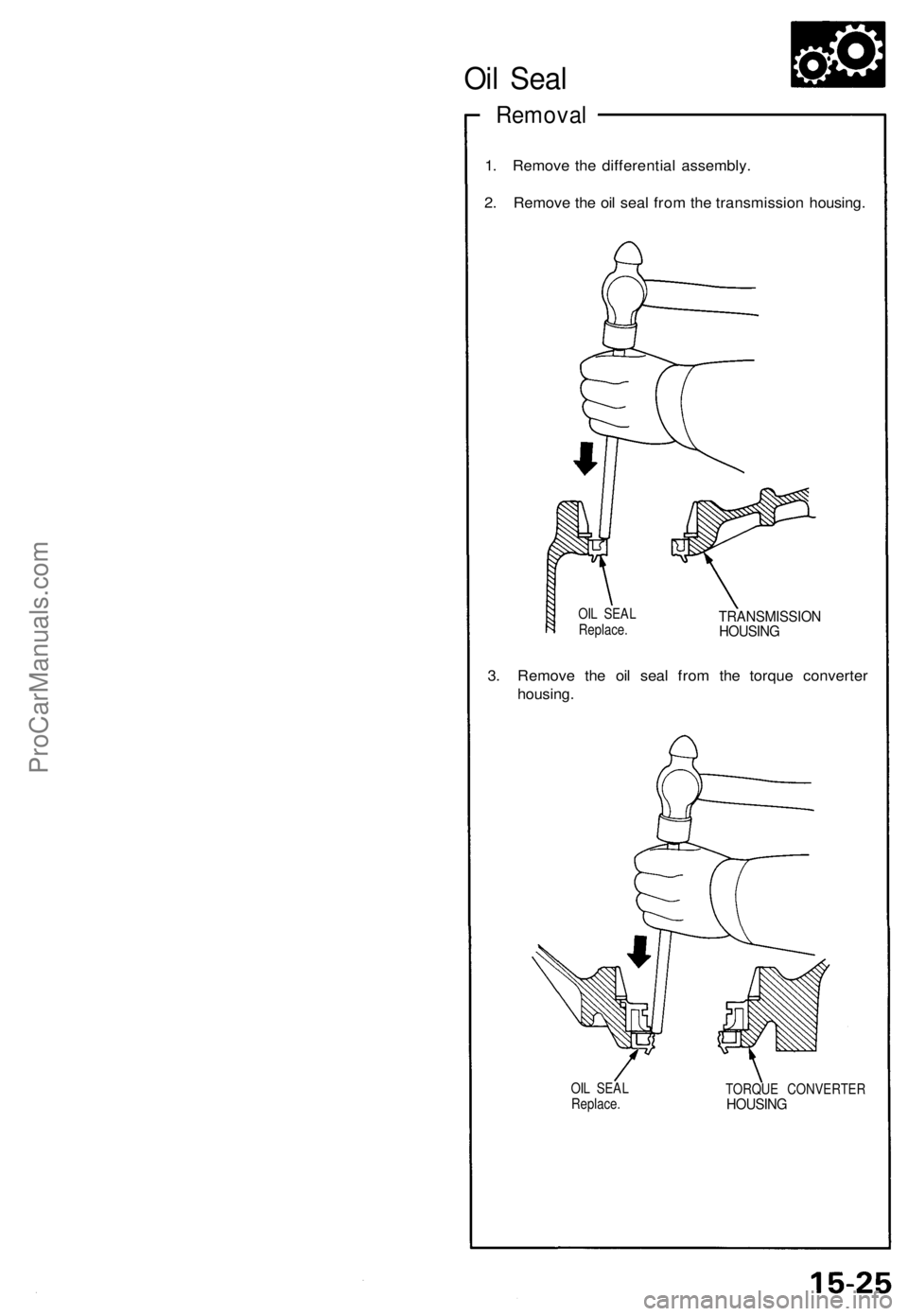

1. Remove the differential assembly.

2. Remove the oil seal from the transmission housing.

OIL SEAL

Replace.

TRANSMISSION

HOUSING

3. Remove the oil seal from the torque converter

housing.

OIL SEAL

Replace.

TORQUE CONVERTER

HOUSINGProCarManuals.com

Page 382 of 1640

Bearing Preload

Adjustment

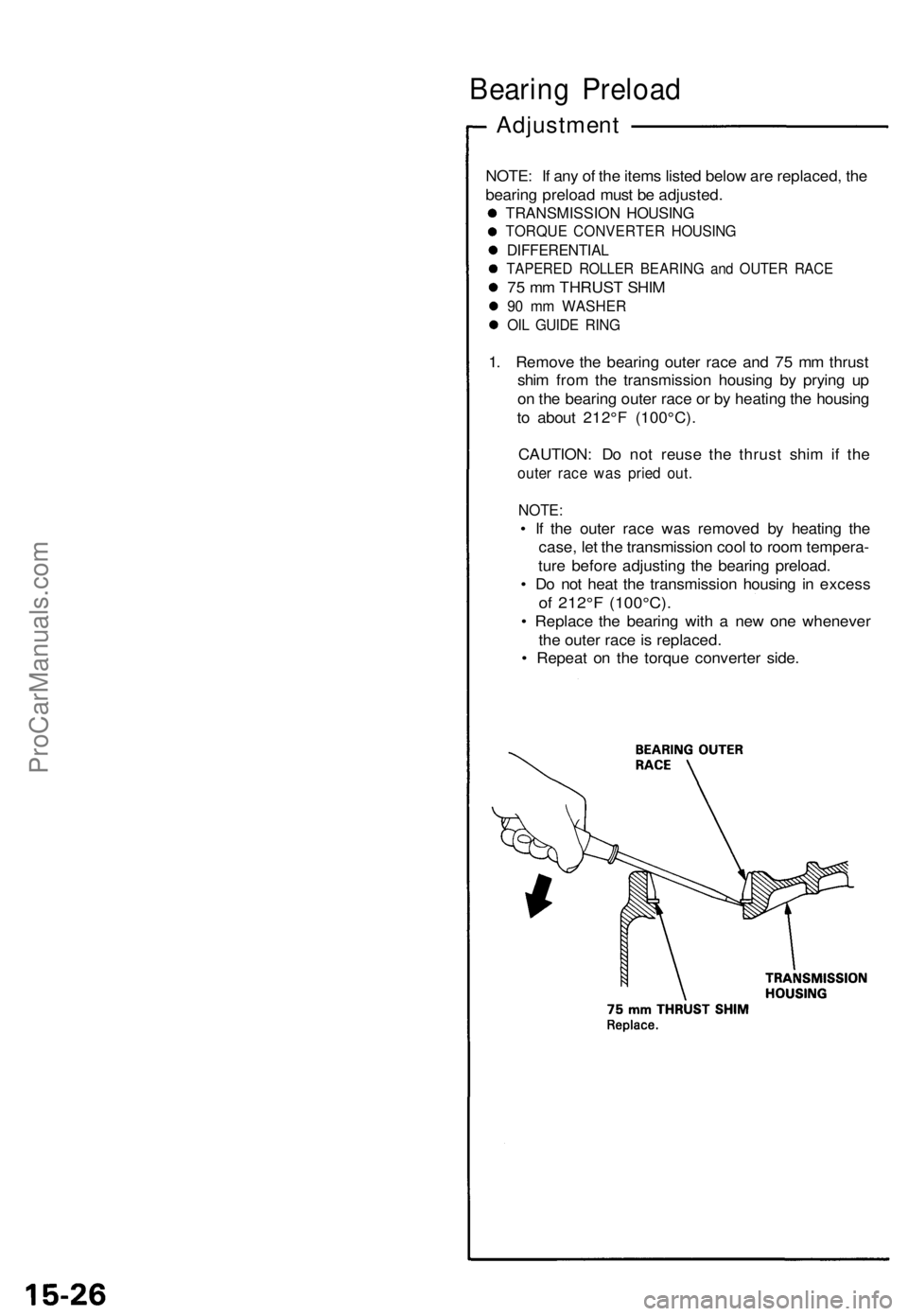

NOTE: If any of the items listed below are replaced, the

bearing preload must be adjusted.

TRANSMISSION HOUSING

TORQUE CONVERTER HOUSING

DIFFERENTIAL

TAPERED ROLLER BEARING and OUTER RACE

75 mm THRUST SHIM

90 mm WASHER

OIL GUIDE RING

1. Remove the bearing outer race and 75 mm thrust

shim from the transmission housing by prying up

on the bearing outer race or by heating the housing

to about 212°F (100°C).

CAUTION: Do not reuse the thrust shim if the

outer race was pried out.

NOTE:

• If the outer race was removed by heating the

case, let the transmission cool to room tempera-

ture before adjusting the bearing preload.

• Do not heat the transmission housing in excess

of 212°F (100°C).

• Replace the bearing with a new one whenever

the outer race is replaced.

• Repeat on the torque converter side.ProCarManuals.com

Page 383 of 1640

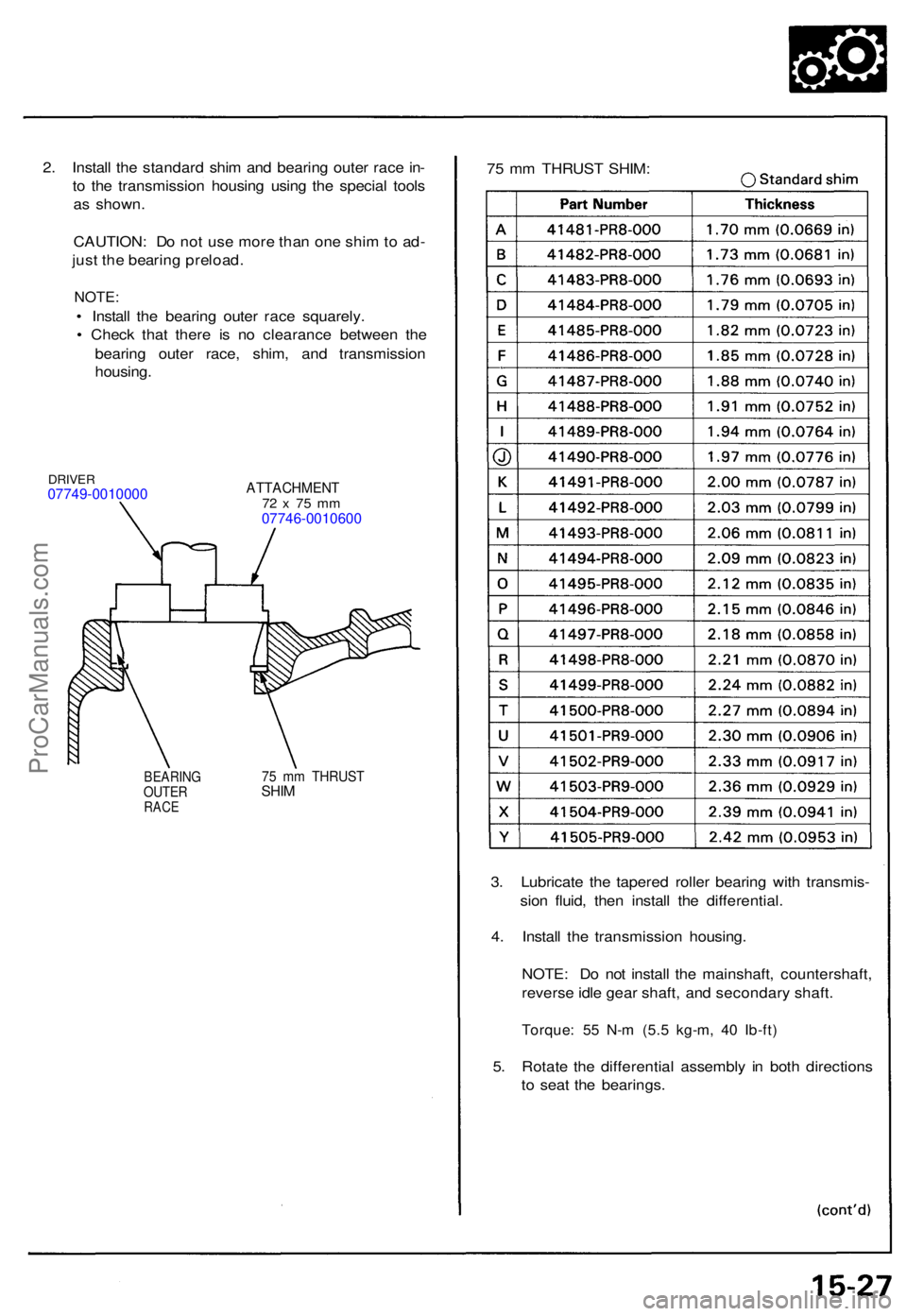

2. Instal l th e standar d shi m an d bearin g oute r rac e in -

t o th e transmissio n housin g usin g th e specia l tool s

a s shown .

CAUTION : D o no t us e mor e tha n on e shi m to ad -

jus t th e bearin g preload .

NOTE:

• Instal l th e bearin g oute r rac e squarely .

• Chec k tha t ther e i s n o clearanc e betwee n th e

bearin g oute r race , shim , an d transmissio n

housing .

DRIVER07749-0010000 ATTACHMEN T72 x 7 5 m m07746-0010600

BEARIN GOUTERRACE

75 m m THRUS TSHIM

3. Lubricat e th e tapere d rolle r bearin g wit h transmis -

sio n fluid , the n instal l th e differential .

4 . Instal l th e transmissio n housing .

NOTE : D o no t instal l th e mainshaft , countershaft ,

revers e idl e gea r shaft , an d secondar y shaft .

Torque : 5 5 N- m (5. 5 kg-m , 4 0 Ib-ft )

5. Rotat e th e differentia l assembl y i n bot h direction s

t o sea t th e bearings .

7

5 m m THRUS T SHIM :

ProCarManuals.com

Page 384 of 1640

Bearing Preloa d

Adjustmen t

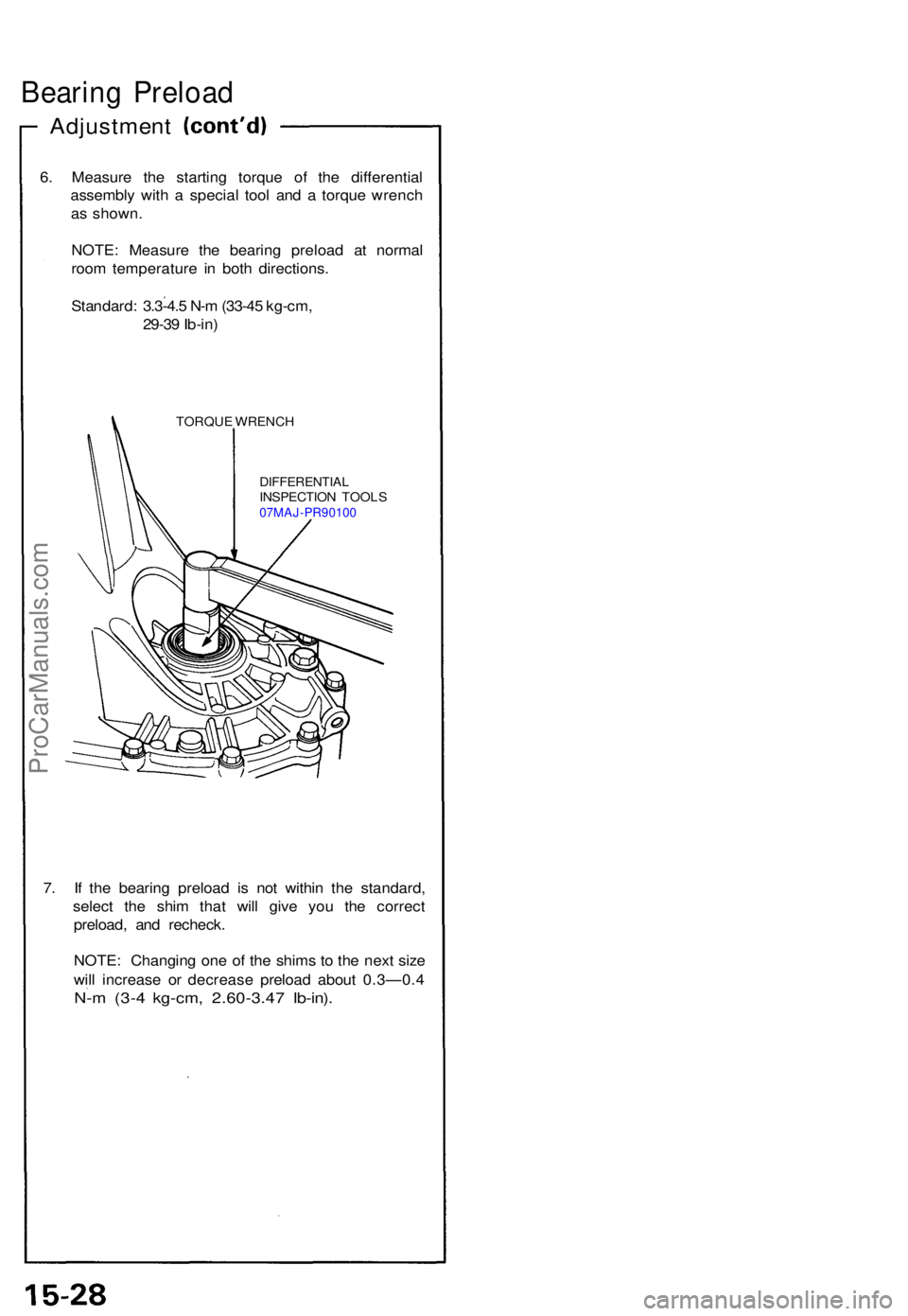

6. Measur e th e startin g torqu e o f th e differentia l

assembl y wit h a specia l too l an d a torqu e wrenc h

a s shown .

NOTE : Measur e th e bearin g preloa d a t norma l

roo m temperatur e i n bot h directions .

Standard:

3.3-4.5 N-m (33-45 kg-cm, 29-39 Ib-in)

TORQU E WRENC H

DIFFERENTIA LINSPECTION TOOL S07MAJ-PR90100

7. I f th e bearin g preloa d i s no t withi n th e standard ,

selec t th e shi m tha t wil l giv e yo u th e correc t

preload , an d recheck .

NOTE : Changin g on e o f th e shim s t o th e nex t siz e

wil l increas e o r decreas e preloa d abou t 0.3—0. 4

N-m (3- 4 kg-cm , 2.60-3.4 7 Ib-in) .

ProCarManuals.com

Page 385 of 1640

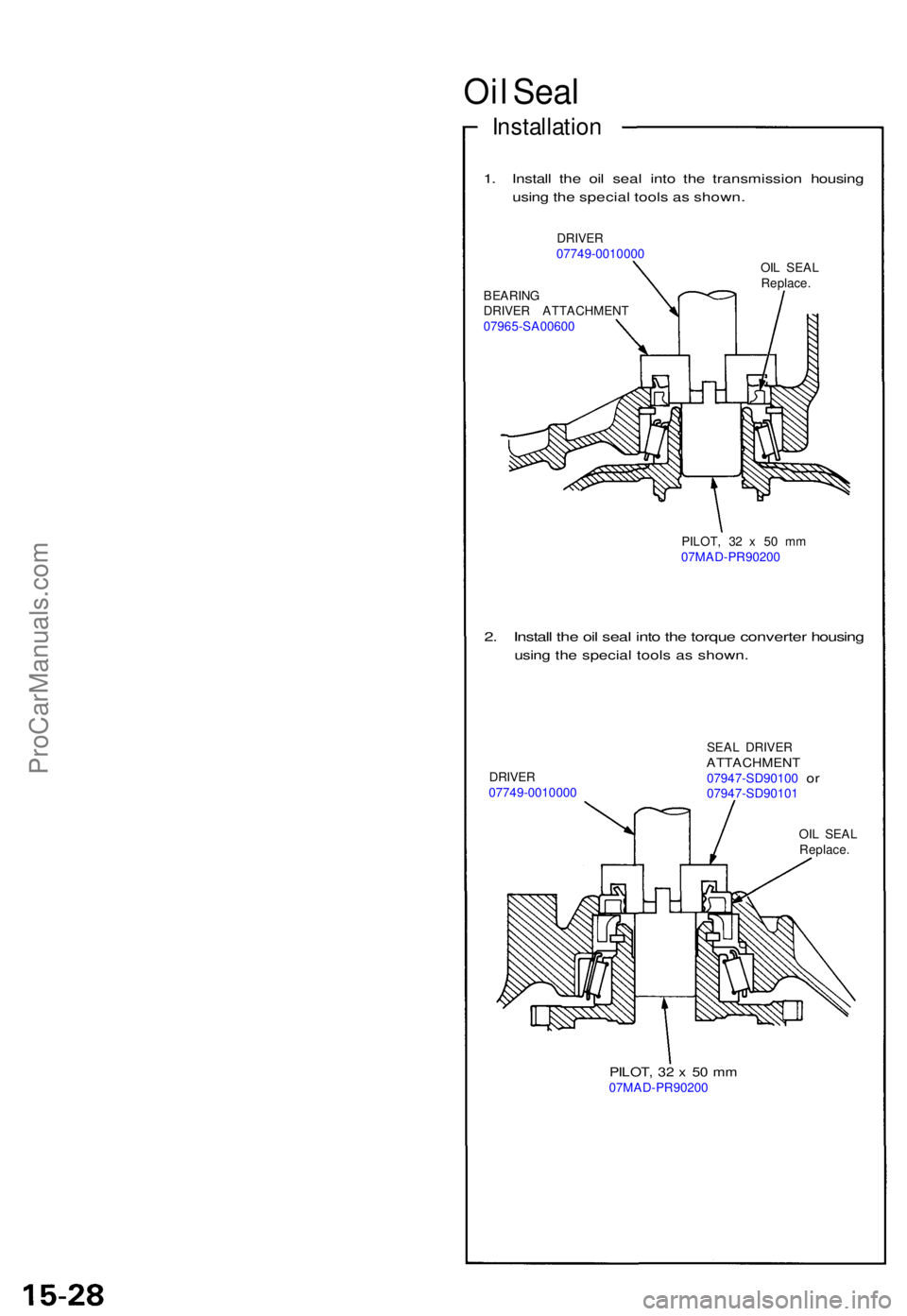

Oil Sea l

Installatio n

1. Instal l th e oi l sea l int o th e transmissio n housin g

usin g th e specia l tool s a s shown .

DRIVER07749-0010000

BEARIN G

DRIVE R ATTACHMEN T

07965-SA00600 OI

L SEA L

Replace .

PILOT , 3 2 x 5 0 m m

07MAD-PR90200

2 . Instal l th e oi l sea l int o th e torqu e converte r housin g

using th e specia l tool s a s shown .

DRIVER

07749-0010000 SEA

L DRIVE RATTACHMEN T07947-SD90100 or07947-SD90101

OIL SEA L

Replace .

PILOT, 3 2 x 5 0 m m07MAD-PR90200

ProCarManuals.com

Page 386 of 1640

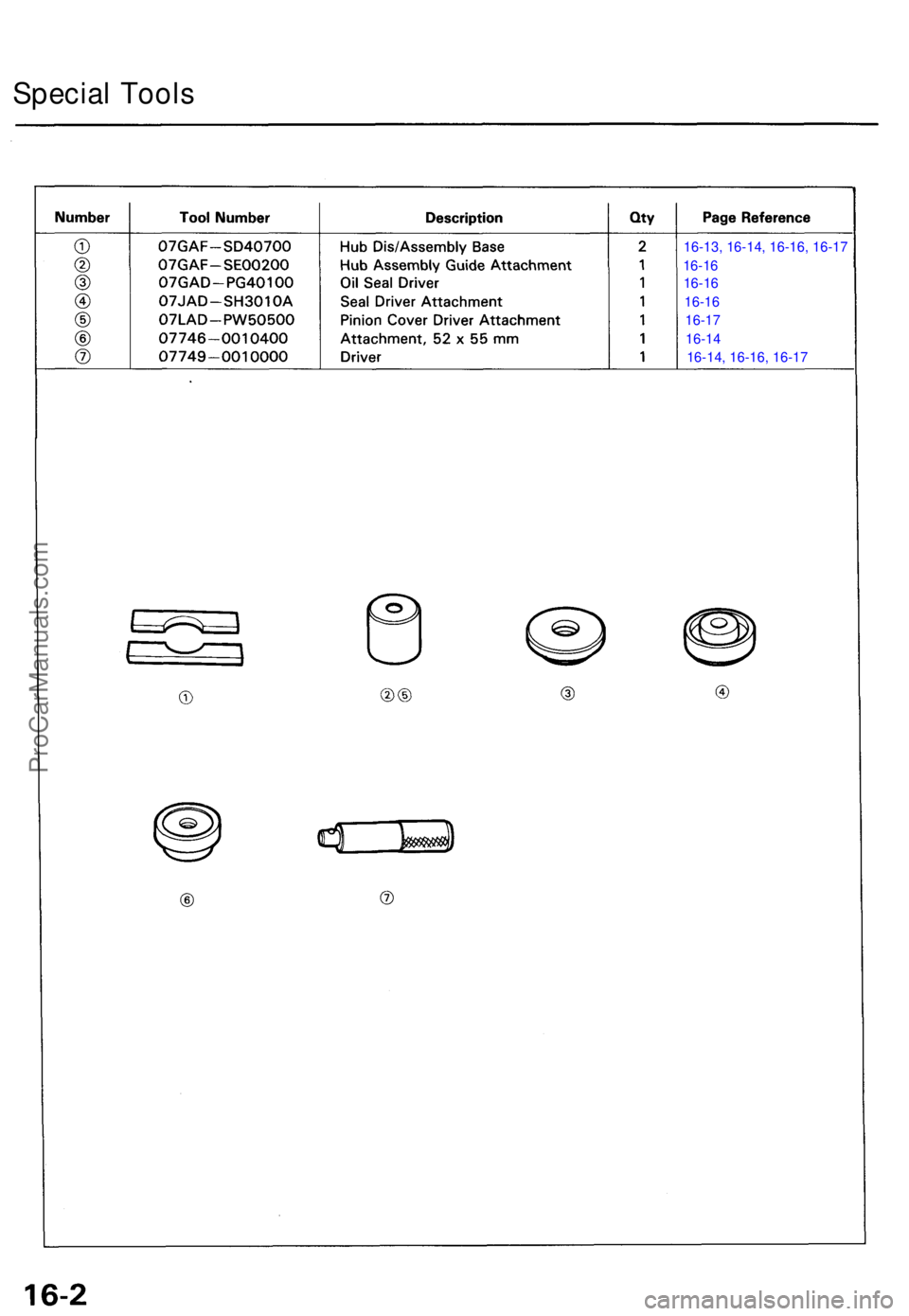

Special Tool s

16-13, 16-14, 16-16, 16-1 7

16-16 16-16

16-1616-17

16-14 16-14, 16-16, 16-17

ProCarManuals.com

Page 387 of 1640

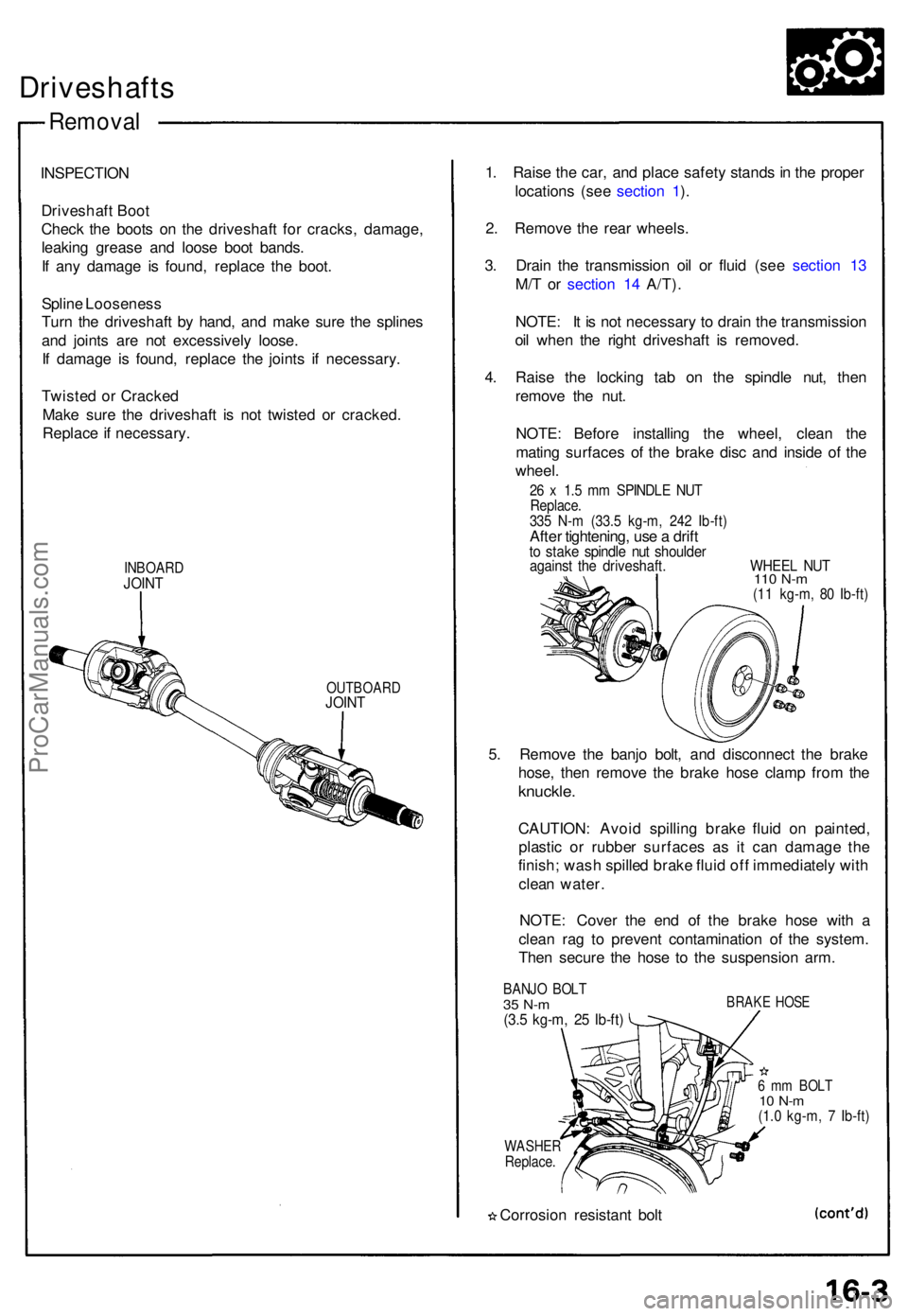

Driveshafts

Removal

INSPECTIO N

Driveshaf t Boo t

Chec k th e boot s o n th e driveshaf t fo r cracks , damage ,

leakin g greas e an d loos e boo t bands .

I f an y damag e i s found , replac e th e boot .

Splin e Loosenes s

Tur n th e driveshaf t b y hand , an d mak e sur e th e spline s

an d joint s ar e no t excessivel y loose .

I f damag e i s found , replac e th e joint s i f necessary .

Twiste d o r Cracke d

Mak e sur e th e driveshaf t i s no t twiste d o r cracked .

Replac e if necessary .

INBOARDJOINT

OUTBOAR DJOINT

1. Rais e th e car , an d plac e safet y stand s in th e prope r

location s (se e sectio n 1 ).

2 . Remov e th e rea r wheels .

3 . Drai n th e transmissio n oi l o r flui d (se e sectio n 1 3

M/ T o r sectio n 1 4 A/T) .

NOTE : I t i s no t necessar y t o drai n th e transmissio n

oi l whe n th e righ t driveshaf t i s removed .

4 . Rais e th e lockin g ta b o n th e spindl e nut , the n

remov e th e nut .

NOTE : Befor e installin g th e wheel , clea n th e

matin g surface s of the brak e dis c an d insid e of the

wheel .

26 x 1. 5 m m SPINDL E NU TReplace .335 N- m (33. 5 kg-m , 24 2 Ib-ft )After tightening , us e a drif tto stak e spindl e nu t shoulde ragainst th e driveshaft . WHEE L NU T110 N- m(11 kg-m , 8 0 Ib-ft )

5. Remov e th e banj o bolt , an d disconnec t th e brak e

hose , the n remov e th e brak e hos e clam p fro m th e

knuckle .

CAUTION : Avoi d spillin g brak e flui d o n painted ,

plasti c o r rubbe r surface s a s i t ca n damag e th e

finish ; was h spille d brak e flui d of f immediatel y wit h

clea n water .

NOTE : Cove r th e en d o f th e brak e hos e wit h a

clea n ra g t o preven t contaminatio n of the system.

The n secur e th e hos e t o th e suspensio n arm .

BANJ O BOL T35 N- m(3.5 kg-m , 2 5 Ib-ft )

BRAK E HOS E

WASHE RReplace.

Corrosio n resistan t bol t

6 m m BOL T10 N- m(1.0 kg-m , 7 Ib-ft )

ProCarManuals.com

Page 388 of 1640

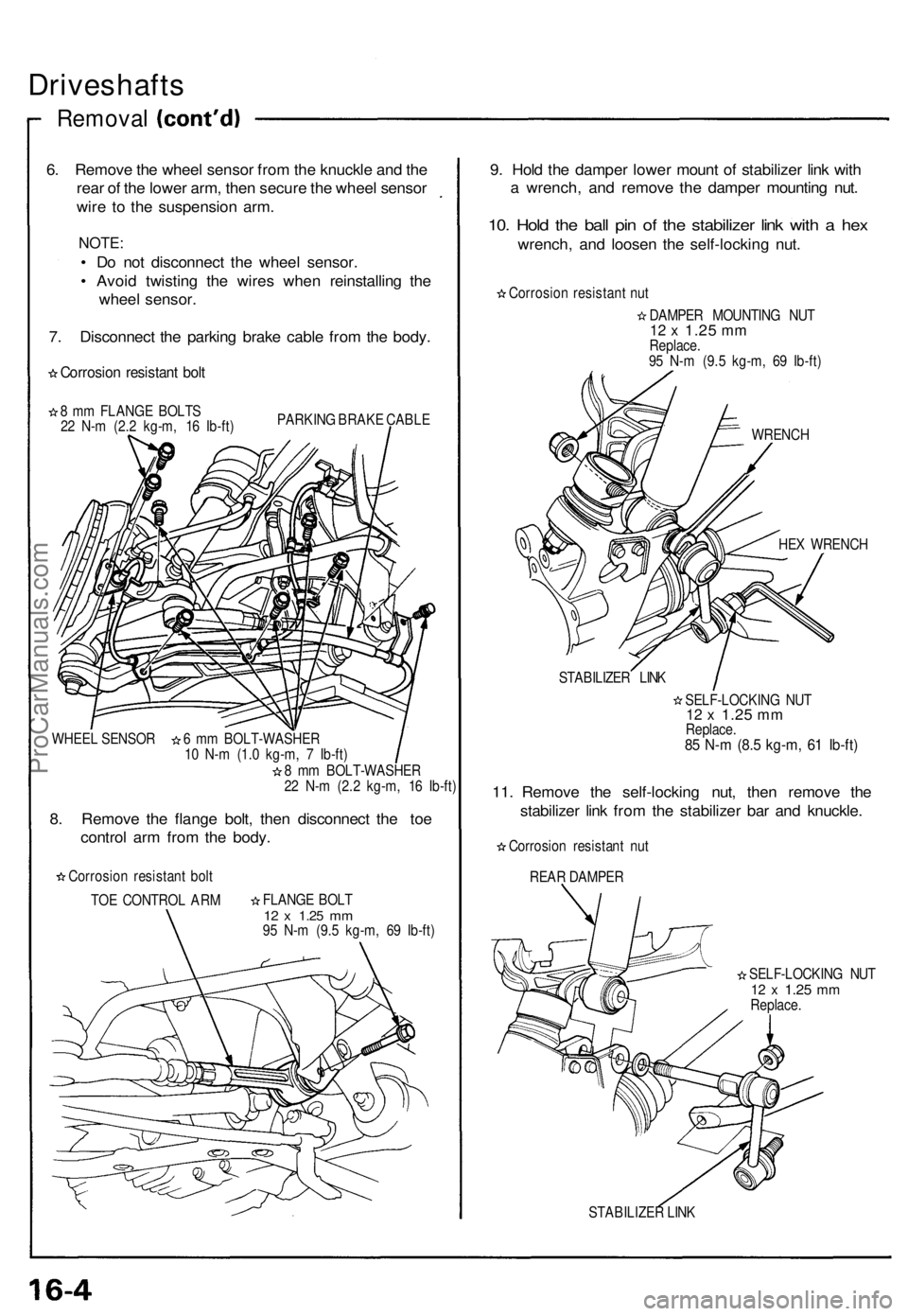

Driveshafts

Removal

6. Remov e th e whee l senso r fro m th e knuckl e an d th e

rea r o f th e lowe r arm , the n secur e th e whee l senso r

wir e t o th e suspensio n arm .

NOTE :

• D o no t disconnec t th e whee l sensor .

• Avoi d twistin g th e wire s whe n reinstallin g th e

whee l sensor .

7 . Disconnec t th e parkin g brak e cabl e fro m th e body .

Corrosio n resistan t bol t

8 m m FLANG E BOLT S

2 2 N- m (2. 2 kg-m , 1 6 Ib-ft ) PARKIN

G BRAK E CABL E

WHEE L SENSO R 6 mm BOLT-WASHE R

1 0 N- m (1. 0 kg-m , 7 Ib-ft )

8 m m BOLT-WASHE R

2 2 N- m (2. 2 kg-m , 1 6 Ib-ft )

Corrosio n resistan t bol t

TO E CONTRO L AR M FLANG

E BOL T

12 x 1.2 5 mm95 N- m (9. 5 kg-m , 6 9 Ib-ft )

9. Hol d th e dampe r lowe r moun t o f stabilize r lin k wit h

a wrench , an d remov e th e dampe r mountin g nut .

10. Hol d th e bal l pi n o f th e stabilize r lin k wit h a he x

wrench , an d loose n th e self-lockin g nut .

Corrosio n resistan t nu t

DAMPE R MOUNTIN G NU T

12 x 1.2 5 mmReplace .

9 5 N- m (9. 5 kg-m , 6 9 Ib-ft )

WRENC H

HE X WRENC H

STABILIZE R LIN K

SELF-LOCKIN G NU T

12 x 1.2 5 mmReplace .85 N- m (8. 5 kg-m , 6 1 Ib-ft )

11. Remov e th e self-lockin g nut , the n remov e th e

stabilize r lin k fro m th e stabilize r ba r an d knuckle .

Corrosio n resistan t nu t

REA R DAMPE R

SELF-LOCKING NU T

12 x 1.2 5 mmReplace .

STABILIZE R LIN K

8. Remov e th e flang e bolt , the n disconnec t th e to e

contro l ar m fro m th e body .

ProCarManuals.com

Page 389 of 1640

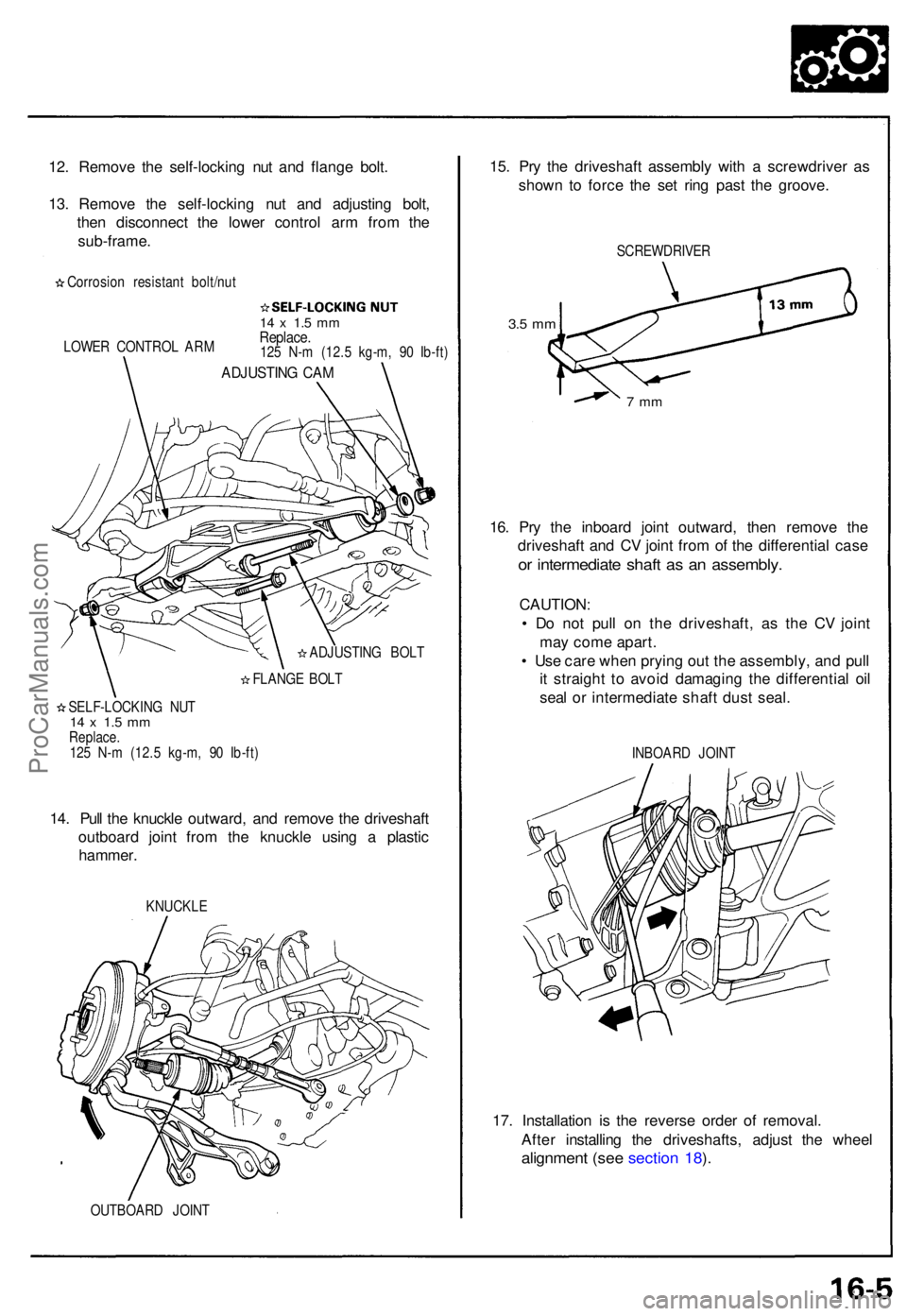

12. Remov e th e self-lockin g nu t an d flang e bolt .

13 . Remov e th e self-lockin g nu t an d adjustin g bolt ,

the n disconnec t th e lowe r contro l ar m fro m th e

sub-frame .

Corrosion resistan t bolt/nu t

LOWE R CONTRO L AR M

14 x 1. 5 m mReplace .125 N- m (12. 5 kg-m , 9 0 Ib-ft )

ADJUSTIN G CA M

ADJUSTIN G BOL T

FLANG E BOL T

SELF-LOCKIN G NU T

14 x 1. 5 m mReplace .

12 5 N- m (12. 5 kg-m , 9 0 Ib-ft )

14. Pul l th e knuckl e outward , an d remov e th e driveshaf t

outboar d join t fro m th e knuckl e usin g a plasti c

hammer .

KNUCKL E

OUTBOAR D JOIN T

15. Pr y th e driveshaf t assembl y wit h a screwdrive r a s

show n t o forc e th e se t rin g pas t th e groove .

SCREWDRIVE R

3.5 m m

7 m m

16. Pr y th e inboar d join t outward , the n remov e th e

driveshaf t an d C V join t fro m o f th e differentia l cas e

or intermediat e shaf t a s a n assembly .

CAUTION :

• D o no t pul l o n th e driveshaft , a s th e C V join t

ma y com e apart .

• Us e car e whe n pryin g ou t th e assembly , an d pul l

i t straigh t t o avoi d damagin g th e differentia l oi l

sea l o r intermediat e shaf t dus t seal .

INBOAR D JOIN T

17. Installatio n i s th e revers e orde r of removal .

Afte r installin g th e driveshafts , adjus t th e whee l

alignmen t (se e sectio n 18 ).

ProCarManuals.com

Page 390 of 1640

Driveshafts

Disassembly

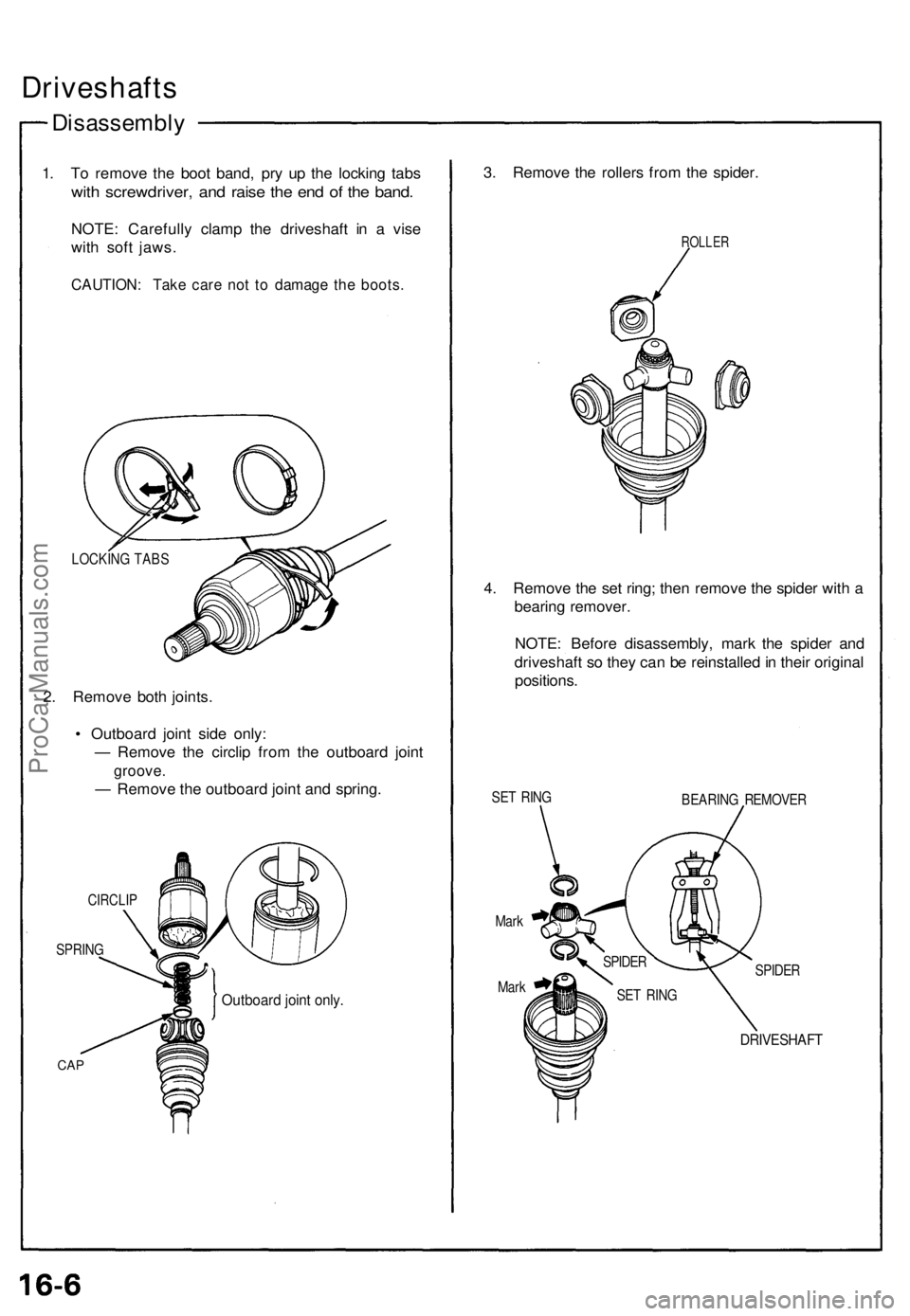

1. To remove the boot band, pry up the locking tabs

with screwdriver, and raise the end of the band.

NOTE: Carefully clamp the driveshaft in a vise

with soft jaws.

CAUTION: Take care not to damage the boots.

LOCKING TABS

2. Remove both joints.

• Outboard joint side only:

— Remove the circlip from the outboard joint

groove.

— Remove the outboard joint and spring.

CIRCLIP

SPRING

CAP

Outboard joint only.

3. Remove the rollers from the spider.

ROLLER

4. Remove the set ring; then remove the spider with a

bearing remover.

NOTE: Before disassembly, mark the spider and

driveshaft so they can be reinstalled in their original

positions.

SET RING

BEARING REMOVER

Mark

Mark

SPIDER

DRIVESHAFT

SPIDER

SET RINGProCarManuals.com