ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 801 of 1640

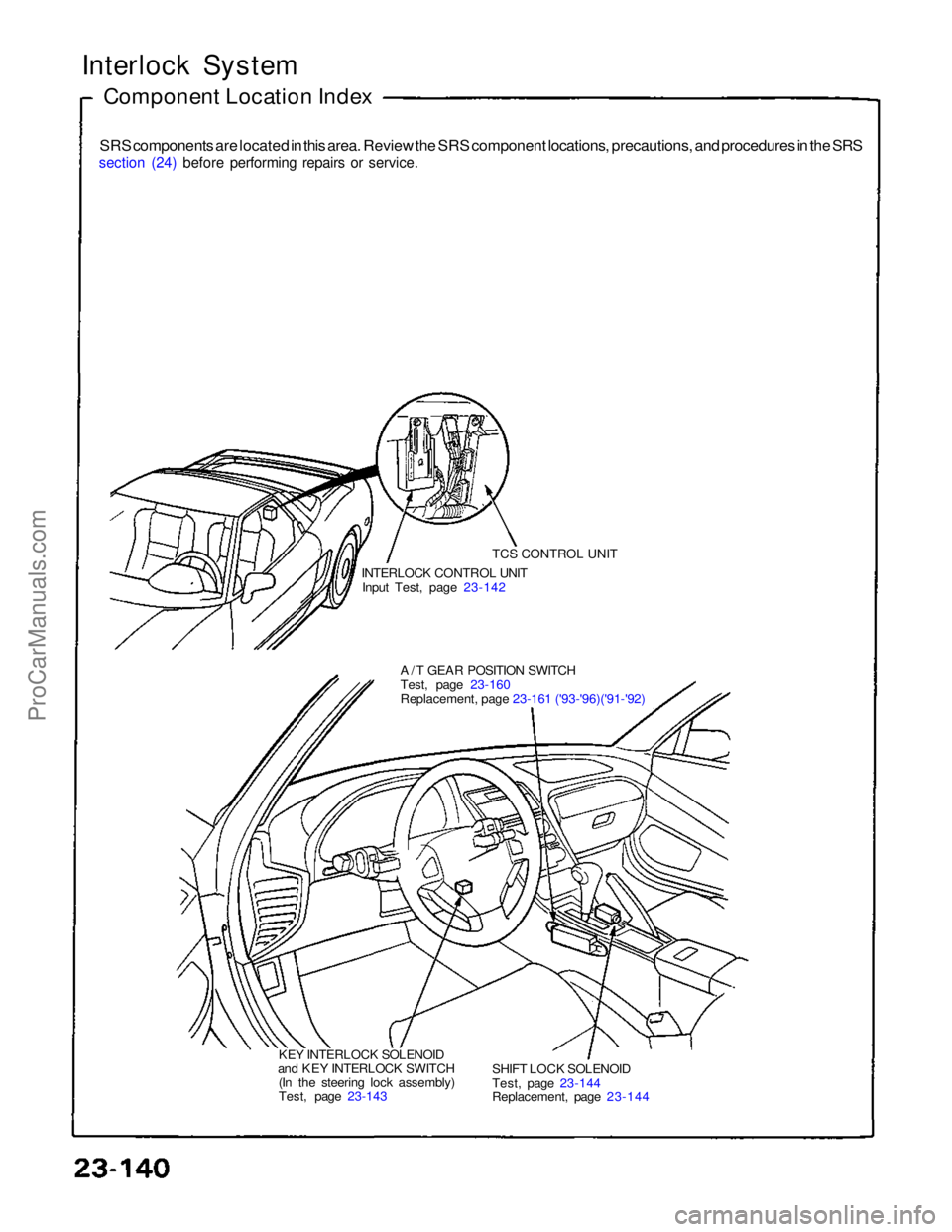

Interlock System

Component Location Index

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section (24) before performing repairs or service.

TCS CONTROL UNIT

INTERLOCK CONTROL UNIT

Input Test, page 23-142

A/T GEAR POSITION SWITCH

Test, page 23-160

Replacement, page 23-161 ('93-'96)('91-'92)

KEY INTERLOCK SOLENOID

and KEY INTERLOCK SWITCH (In the steering lock assembly)

Test, page 23-143 SHIFT LOCK SOLENOID

Test, page 23-144

Replacement, page 23-144ProCarManuals.com

Page 802 of 1640

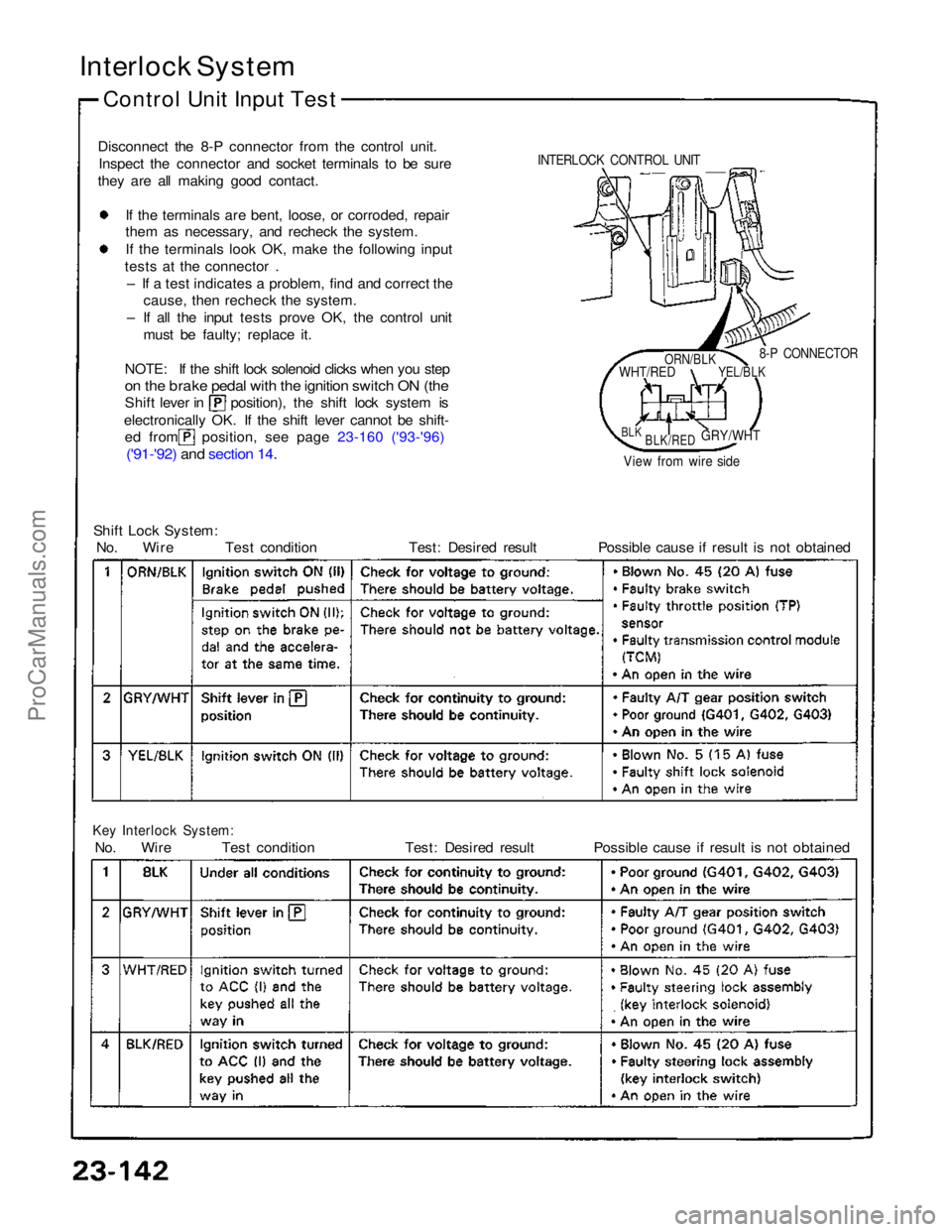

Interlock System

Control Unit Input Test

Disconnect the 8-P connector from the control unit. Inspect the connector and socket terminals to be sure

they are all making good contact.

If the terminals are bent, loose, or corroded, repair

them as necessary, and recheck the system.

I

f

the terminals look OK, make the following input

tests at the connector .

– If a test indicates a problem, find and correct the cause, then recheck the system.

– If all the input tests prove OK, the control unit must be faulty; replace it.

NOTE: If the shift lock solenoid clicks when you step

on the brake pedal with the ignition switch ON (the

Shift lever in position), the shift lock system is

electronically OK. If the shift lever cannot be shift-

ed from position, see page 23-160 ('93-'96)

('91-'92) and section 14

.

Shift Lock System:

No. Wire Test condition Test: Desired result Possible cause if result is not obtained

Key Interlock System:

No. Wire Test condition Test: Desired result Possible cause if result is not obtained

8-P CONNECTOR

View from wire side

INTERLOCK CONTROL UNIT

ORN/BLK

WHT/RED

YEL/BLK

BLK

BLK/RED

GRY/WHTProCarManuals.com

Page 803 of 1640

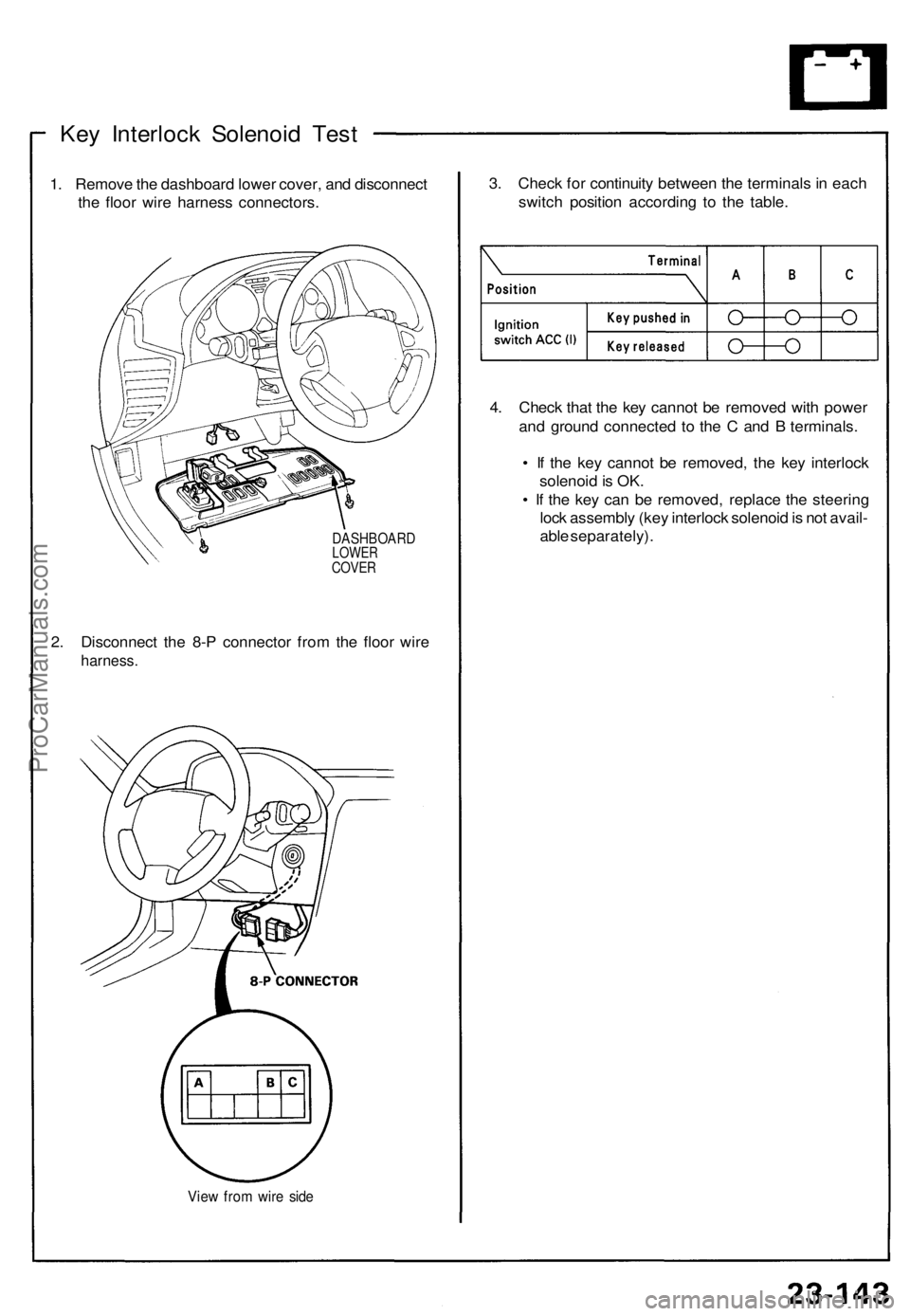

Key Interloc k Solenoi d Tes t

1. Remov e th e dashboard lower cover , an d disconnec t

th e floo r wir e harnes s connectors .

DASHBOAR DLOWERCOVER

2. Disconnec t th e 8- P connecto r fro m th e floo r wir e

harness .

View fro m wir e sid e

3. Chec k fo r continuit y betwee n th e terminal s in eac h

switc h positio n accordin g t o th e table.

4 . Chec k tha t th e ke y canno t b e remove d wit h powe r

an d groun d connecte d t o th e C an d B terminals .

• I f th e ke y canno t b e removed , th e ke y interloc k

solenoi d is OK .

• I f th e ke y ca n b e removed , replac e th e steerin g

loc k assembl y (ke y interloc k solenoi d is no t avail -

abl e separately) .

ProCarManuals.com

Page 804 of 1640

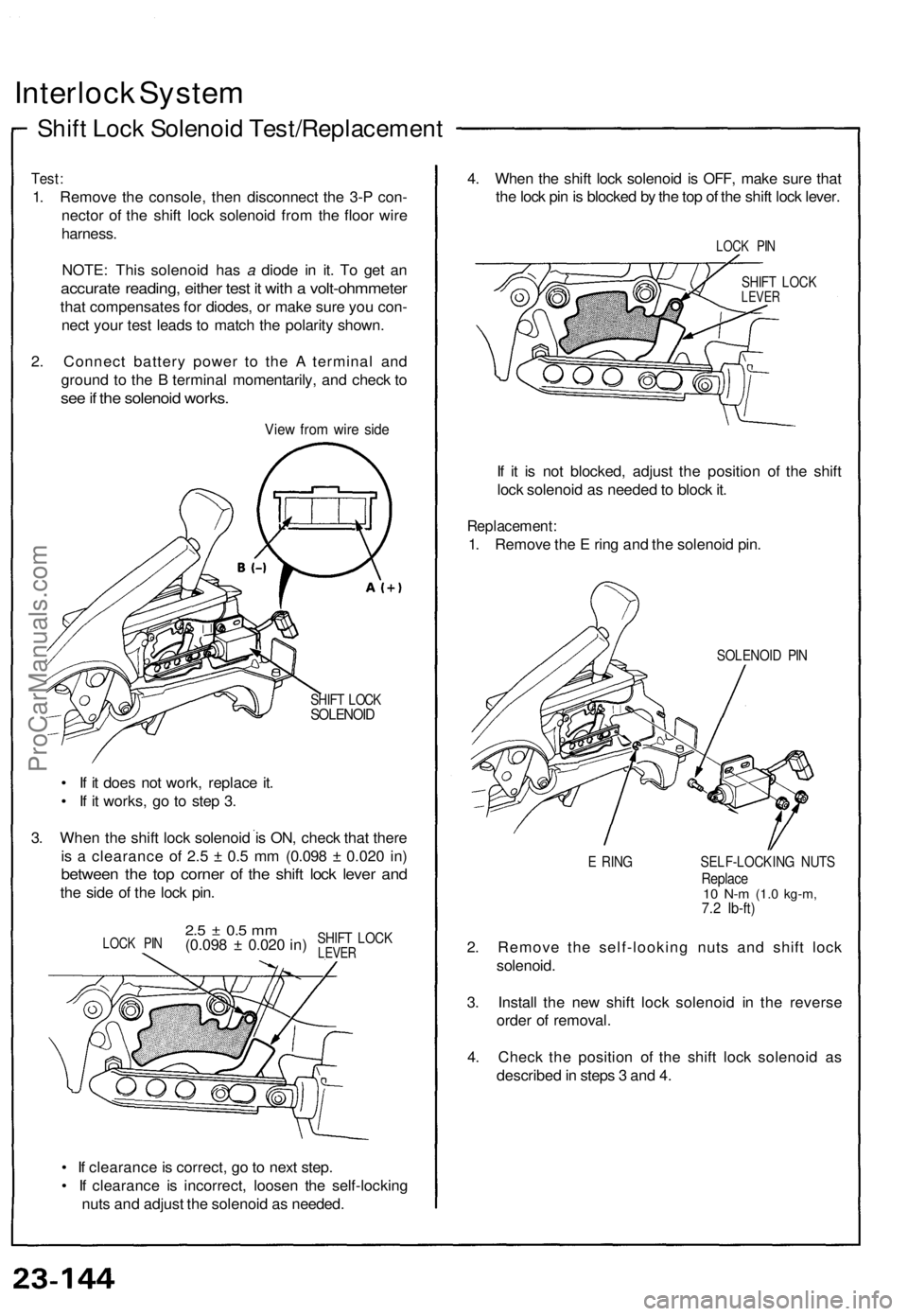

Interlock System

Shift Lock Solenoid Test/Replacement

Test:

1. Remove the console, then disconnect the 3-P con-

nector of the shift lock solenoid from the floor wire

harness.

NOTE: This solenoid has a diode in it. To get an

accurate reading, either test it with a volt-ohmmeter

that compensates for diodes, or make sure you con-

nect your test leads to match the polarity shown.

2. Connect battery power to the A terminal and

ground to the B terminal momentarily, and check to

see if the solenoid works.

View from wire side

SHIFT LOCK

SOLENOID

• If it does not work, replace it.

• If it works, go to step 3.

3. When the shift lock solenoid is ON, check that there

is a clearance of 2.5 ± 0.5 mm (0.098 ± 0.020 in)

between the top corner of the shift lock lever and

the side of the lock pin.

• If clearance is correct, go to next step.

• If clearance is incorrect, loosen the self-locking

nuts and adjust the solenoid as needed.

4. When the shift lock solenoid is OFF, make sure that

the lock pin is blocked by the top of the shift lock lever.

LOCK PIN

SHIFT LOCK

LEVER

If it is not blocked, adjust the position of the shift

lock solenoid as needed to block it.

Replacement:

1. Remove the E ring and the solenoid pin.

SOLENOID PIN

E RING SELF-LOCKING NUTS

Replace

10 N-m

(1.0 kg-m,

7.2 Ib-ft)

2. Remove the self-looking nuts and shift lock

solenoid.

3. Install the new shift lock solenoid in the reverse

order of removal.

4. Check the position of the shift lock solenoid as

described in steps 3 and 4.

LOCK PIN

2.5 ± 0.5 mm

(0.098 ± 0.020 in)

SHIFT LOCK

LEVERProCarManuals.com

Page 805 of 1640

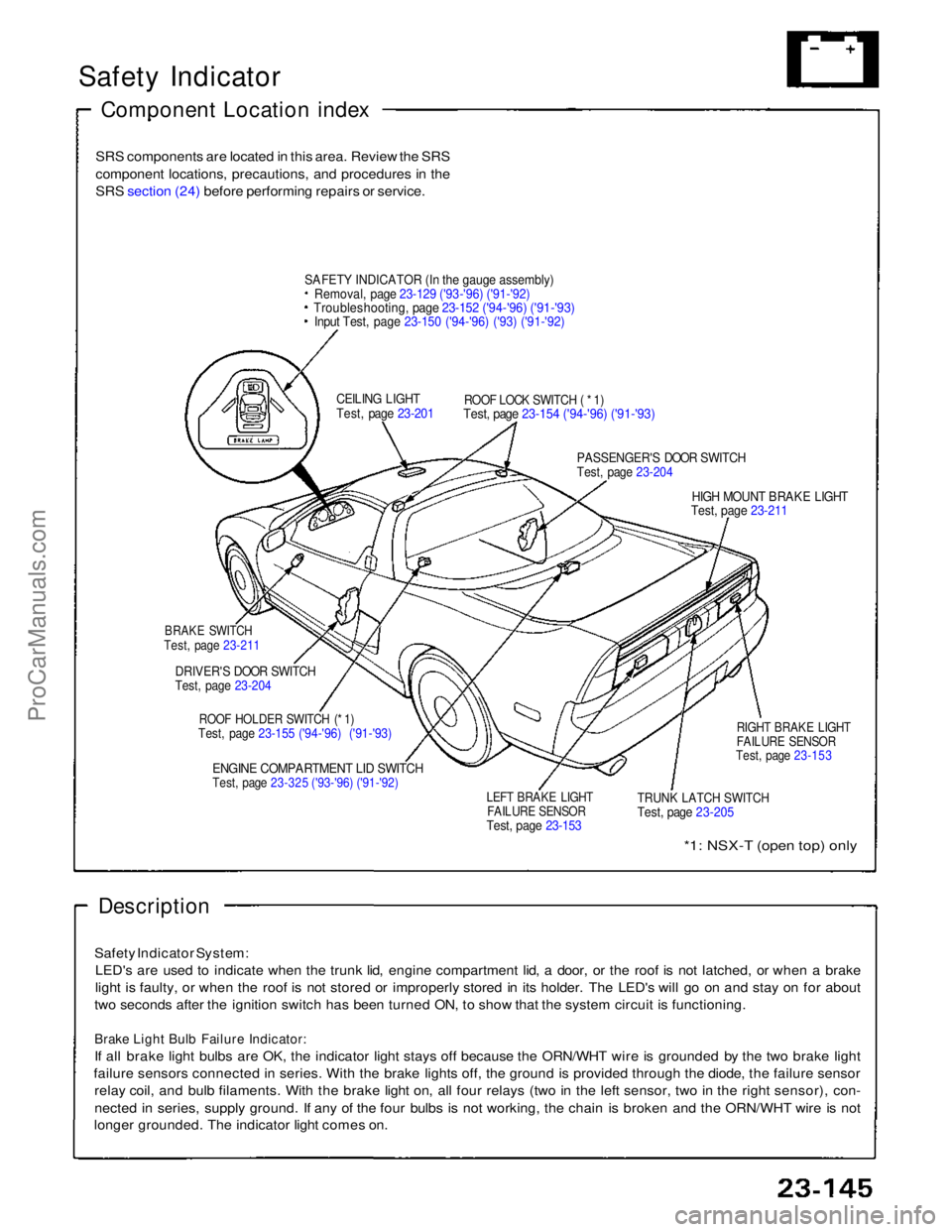

Safety Indicator

Component Location index

SRS components are located in this area. Review the SRS

component locations, precautions, and procedures in the

SRS section (24) before performing repairs or service.

SAFET

Y

INDICATOR (In the gauge assembly)

Removal, page 23-129 ('93-'96) ('91-'92)

Troubleshooting, page 23-152 ('94-'96) ('91-'93)

Input Test, page 23-150 ('94-'96) ('93) ('91-'92)

CEILING LIGHT

Test, page 23-201

ROOF LOCK SWITCH ( * 1)

Test, page 23-154 ('94-'96) ('91-'93)

PASSENGER'S DOOR SWITCH

Test, page 23-204

HIGH MOUNT BRAKE LIGHT

Test, page 23-211

BRAKE SWITCH

Test, page 23-211

DRIVER'S DOOR SWITCH

Test, page 23-204

ROOF HOLDER SWITCH (* 1)

Test, page 23-155 ('94-'96) ('91-'93)

ENGINE COMPARTMENT LID SWITCH

Test, page 23-325 ('93-'96) ('91-'92)

LEFT BRAKE LIGHT

FAILURE SENSOR

Test, page 23-153

TRUNK LATCH SWITCH

Test, page 23-205

RIGHT BRAKE LIGHT

FAILURE SENSOR

Test, page 23-153

*1: NSX-T (open top) only

Description

Safety Indicator System: LED's are used to indicate when the trunk lid, engine compartment lid, a door, or the roof is not latched, or when a brake

light is faulty, or when the roof is not stored or improperly stored in its holder. The LED's will go on and stay on for about

two seconds after the ignition switch has been turned ON, to show that the system circuit is functioning.

Brake Light Bulb Failure Indicator:

If all brake light bulbs are OK, the indicator light stays off because the ORN/WHT wire is grounded by the two brake light

failure sensors connected in series. With the brake lights off, the ground is provided through the diode, the failure sensor relay coil, and bulb filaments. With the brake light on, all four relays (two in the left sensor, two in the right sensor), con-

nected in series, supply ground. If any of the four bulbs is not working, the chain is broken and the ORN/WHT wire is not

longer grounded. The indicator light comes on.ProCarManuals.com

Page 806 of 1640

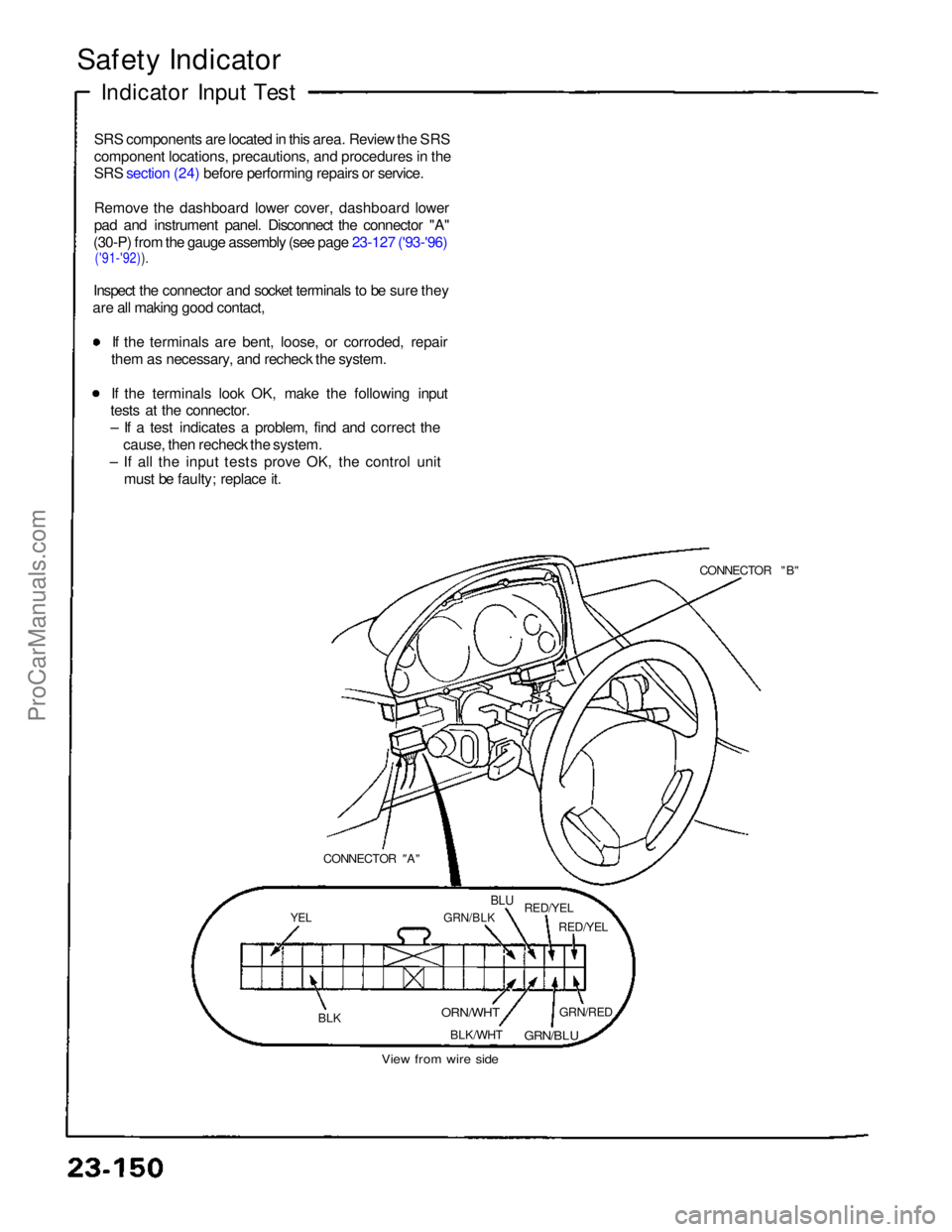

Safety Indicator

Indicator Input Test

SRS components are located in this area. Review the SRS

component locations, precautions, and procedures in the

SRS section (24) before performing repairs or service.

Remove the dashboard lower cover, dashboard lower

pad and instrument panel. Disconnect the connector "A"

(30-P) from the gauge assembly (see page 23-127 ('93-'96)

('91-'92)).

Inspect the connector and socket terminals to be sure they

are all making good contact,

If the terminals are bent, loose, or corroded, repair

them as necessary, and recheck the system. If the terminals look OK, make the following input

tests at the connector.

– If a test indicates a problem, find and correct the

cause, then recheck the system.

– If all the input tests prove OK, the control unit must be faulty; replace it.

CONNECTOR "B"

CONNECTOR "

A"

YEL

GRN/BLK

BLU

RED/YEL

RED/YEL

BLK

ORN/WHT

BLK/WHT GRN/RED

GRN/BLU

View from wire sideProCarManuals.com

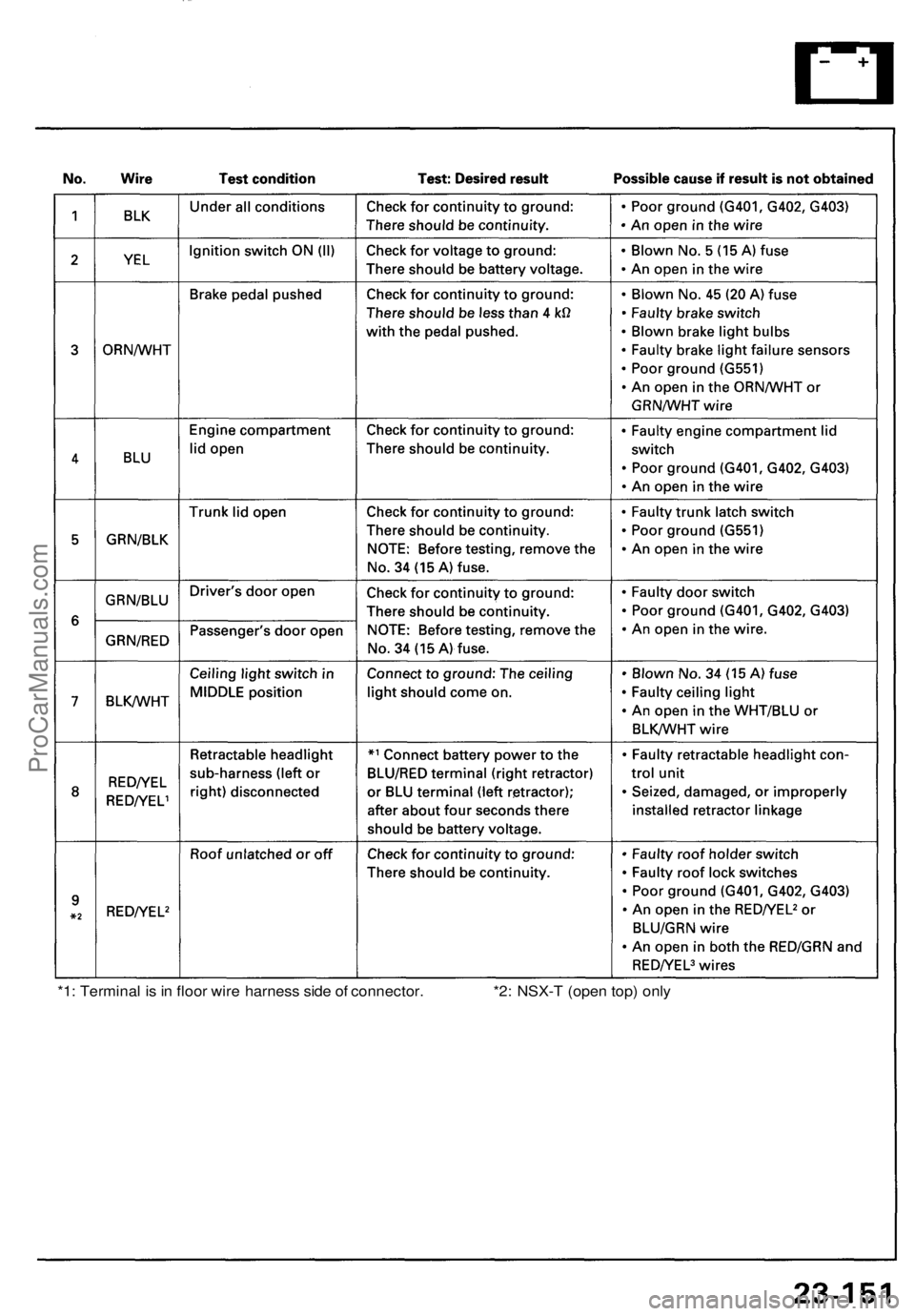

Page 807 of 1640

*1: Terminal is in floor wire harness side of connector. *2: NSX-T (open top) onlyProCarManuals.com

Page 808 of 1640

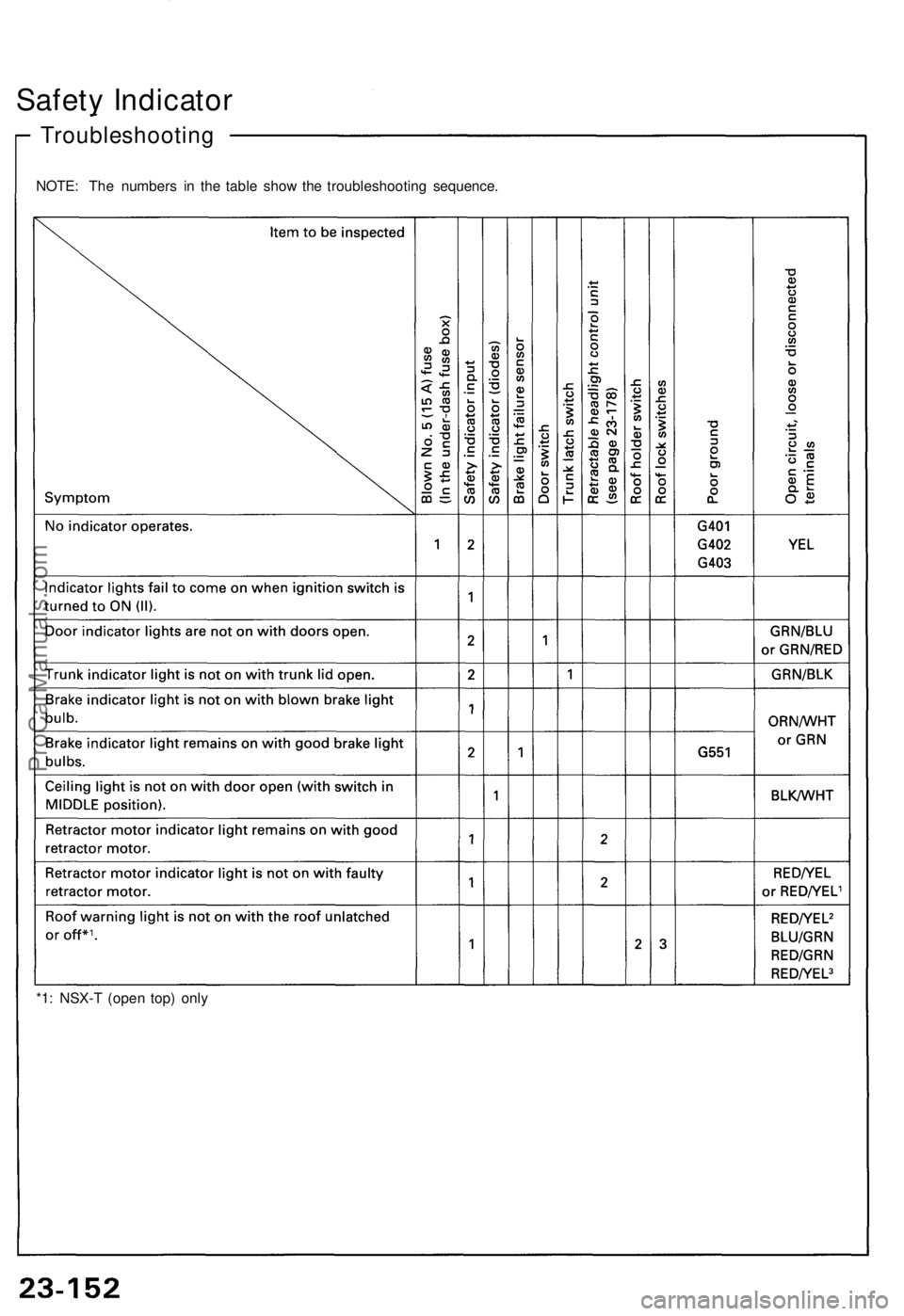

Safety Indicato r

*1: NSX- T (ope n top ) onl y

Troubleshootin g

NOTE: Th e number s i n th e tabl e sho w th e troubleshootin g sequence .

ProCarManuals.com

Page 809 of 1640

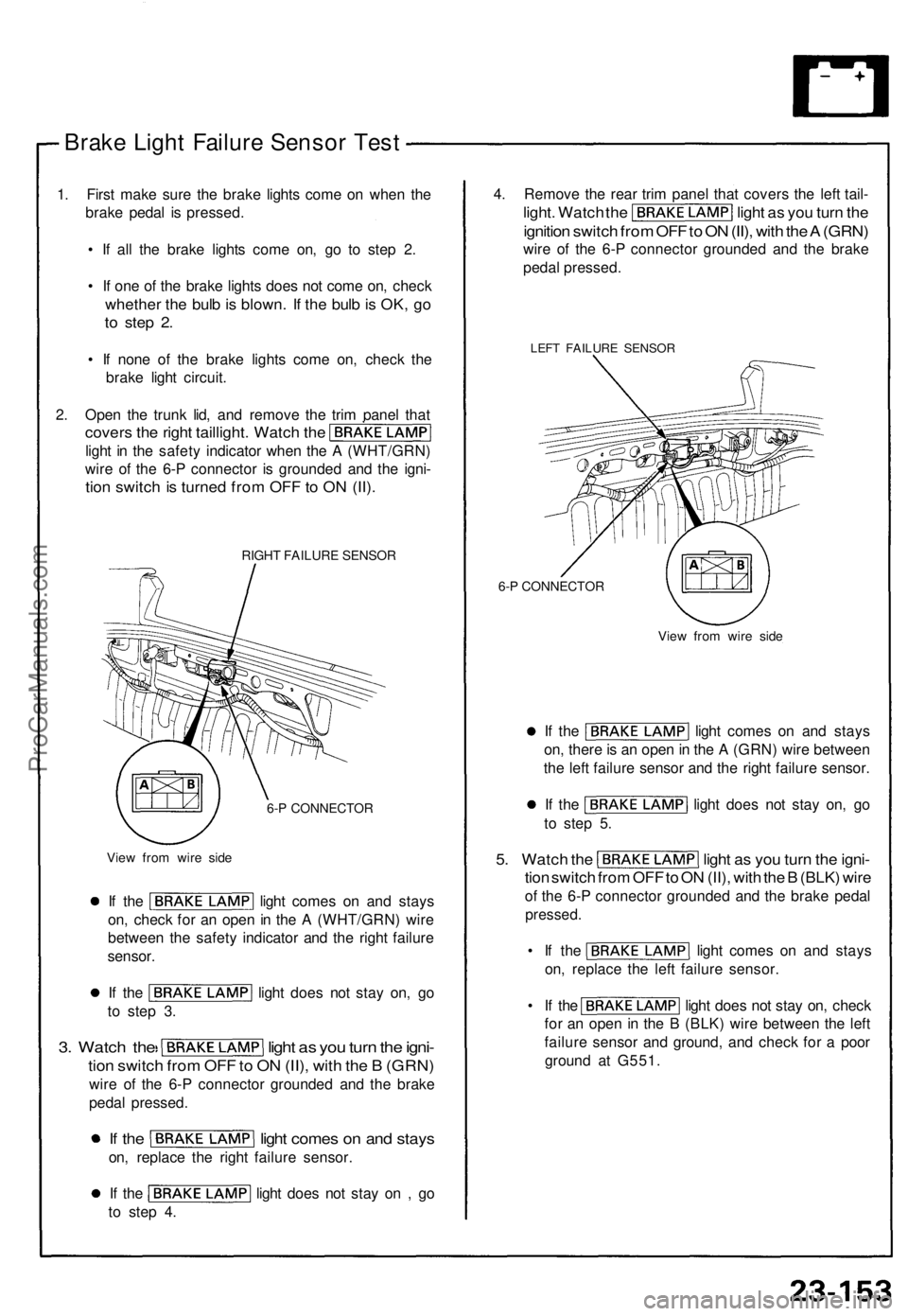

Brake Ligh t Failur e Senso r Tes t

1. Firs t mak e sur e th e brak e light s com e o n whe n th e

brak e peda l i s pressed .

• I f al l th e brak e light s com e on , g o t o ste p 2 .

• I f on e o f th e brak e light s doe s no t com e on , chec k

whethe r th e bul b is blown . I f th e bul b is OK , g o

to ste p 2 .

• I f non e of the brak e light s com e on , chec k th e

brak e ligh t circui t.

2 . Ope n th e trun k lid , an d remov e th e tri m pane l tha t

cover s th e righ t taillight . Watc h th e

ligh t i n th e safet y indicato r whe n th e A (WHT/GRN )

wir e o f th e 6- P connecto r i s grounde d an d th e igni -

tion switc h is turne d fro m OF F to O N (II) .

RIGH T FAILUR E SENSO R

6- P CONNECTO R

Vie w fro m wir e sid e

If th e ligh t come s o n an d stay s

on , chec k fo r a n ope n in th e A (WHT/GRN ) wir e

betwee n th e safet y indicato r an d th e righ t failur e

sensor .

If th e ligh t doe s no t sta y on , g o

t o ste p 3 .

3. Watc h th e ligh t a s yo u tur n th e igni -

tion switc h fro m OF F to O N (II) , wit h th e B (GRN )

wire o f th e 6- P connecto r grounde d an d th e brak e

peda l pressed .

If th e ligh t come s o n an d stay s

on, replac e th e righ t failur e sensor .

If th e ligh t doe s no t sta y o n , g o

t o ste p 4 . 4

. Remov e th e rea r tri m pane l tha t cover s th e lef t tail -

light . Watc h th e ligh t a s yo u tur n th e

ignitio n switc h fro m OF F to O N (II) , wit h th e A (GRN )

wire o f th e 6- P connecto r grounde d an d th e brak e

peda l pressed .

LEFT FAILUR E SENSO R

6-P CONNECTO R

View fro m wir e sid e

If th e ligh t come s o n an d stay s

on , ther e is a n ope n in th e A (GRN ) wir e betwee n

th e lef t failur e senso r an d th e righ t failur e sensor .

If th e ligh t doe s no t sta y on , g o

t o ste p 5 .

5. Watc h th e ligh t a s yo u tur n th e igni -

tion switc h fro m OF F to O N (II) , wit h th e B (BLK ) wir e

of th e 6- P connecto r grounde d an d th e brak e peda l

pressed .

• I f th e ligh t come s o n an d stay s

on , replac e th e lef t failur e sensor .

• I f th e ligh t doe s no t sta y on , chec k

fo r a n ope n in th e B (BLK ) wir e betwee n th e lef t

failur e senso r an d ground , an d chec k fo r a poo r

groun d a t G551 .

ProCarManuals.com

Page 810 of 1640

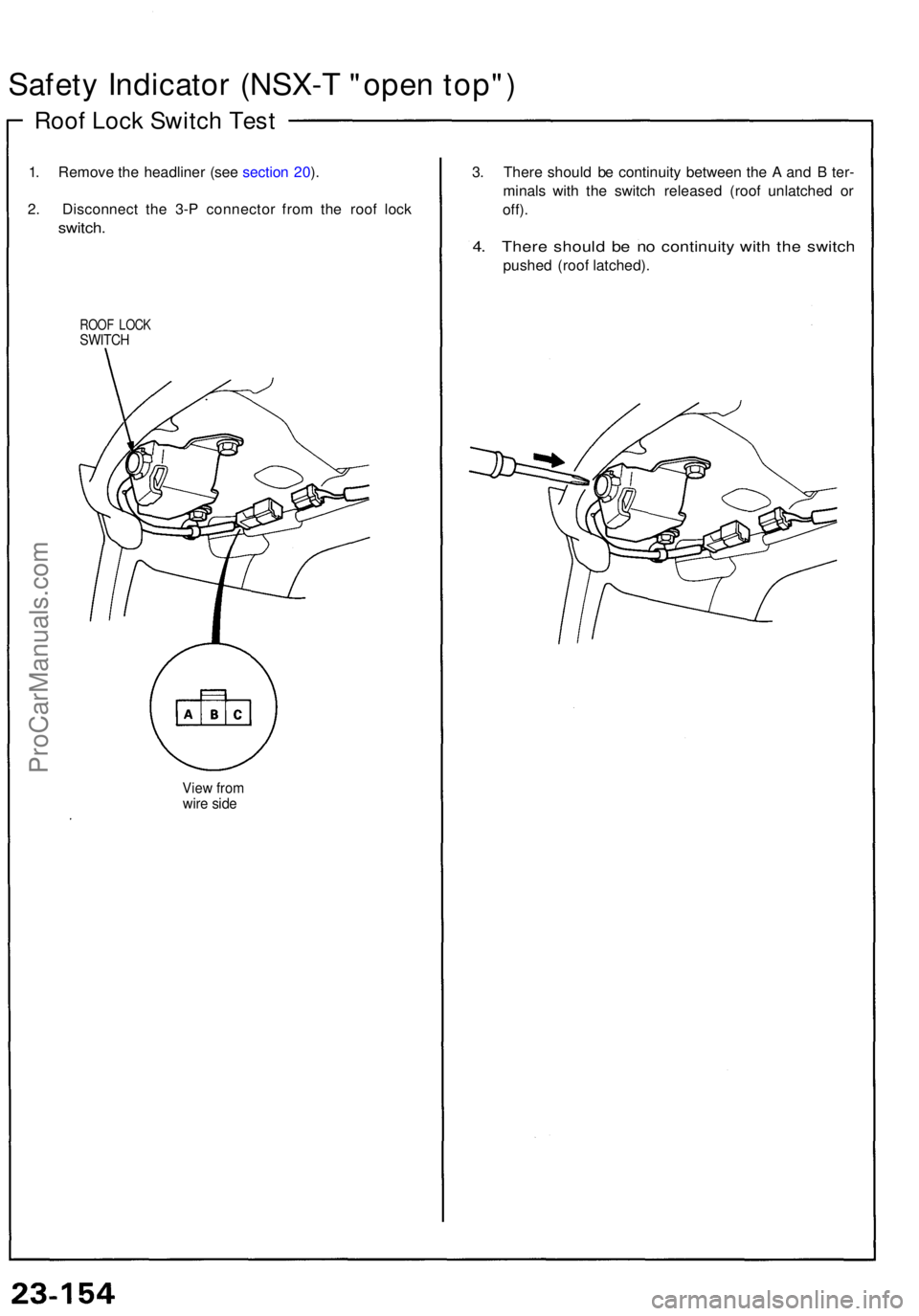

Safety Indicato r (NSX- T "ope n top" )

Roof Loc k Switc h Tes t

1. Remov e th e headline r (se e sectio n 20 ).

2 . Disconnec t th e 3- P connecto r fro m th e roo f loc k

switch .

ROOF LOC KSWITC H

View fro mwire sid e

3. Ther e shoul d b e continuit y betwee n th e A an d B ter -

minal s wit h th e switc h release d (roo f unlatche d o r

off) .

4. Ther e shoul d b e n o continuit y wit h th e switc h

pushe d (roo f latched) .

ProCarManuals.com