ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997,

Model line: NSX,

Model: ACURA NSX 1997

Pages: 1503, PDF Size: 57.08 MB

ACURA NSX 1997 Service Repair Manual

NSX 1997

ACURA

ACURA

https://www.carmanualsonline.info/img/32/56989/w960_56989-0.png

ACURA NSX 1997 Service Repair Manual

Trending: hood release, key battery, lock, seat adjustment, air condition, phone, wheel bolt torque

Page 1121 of 1503

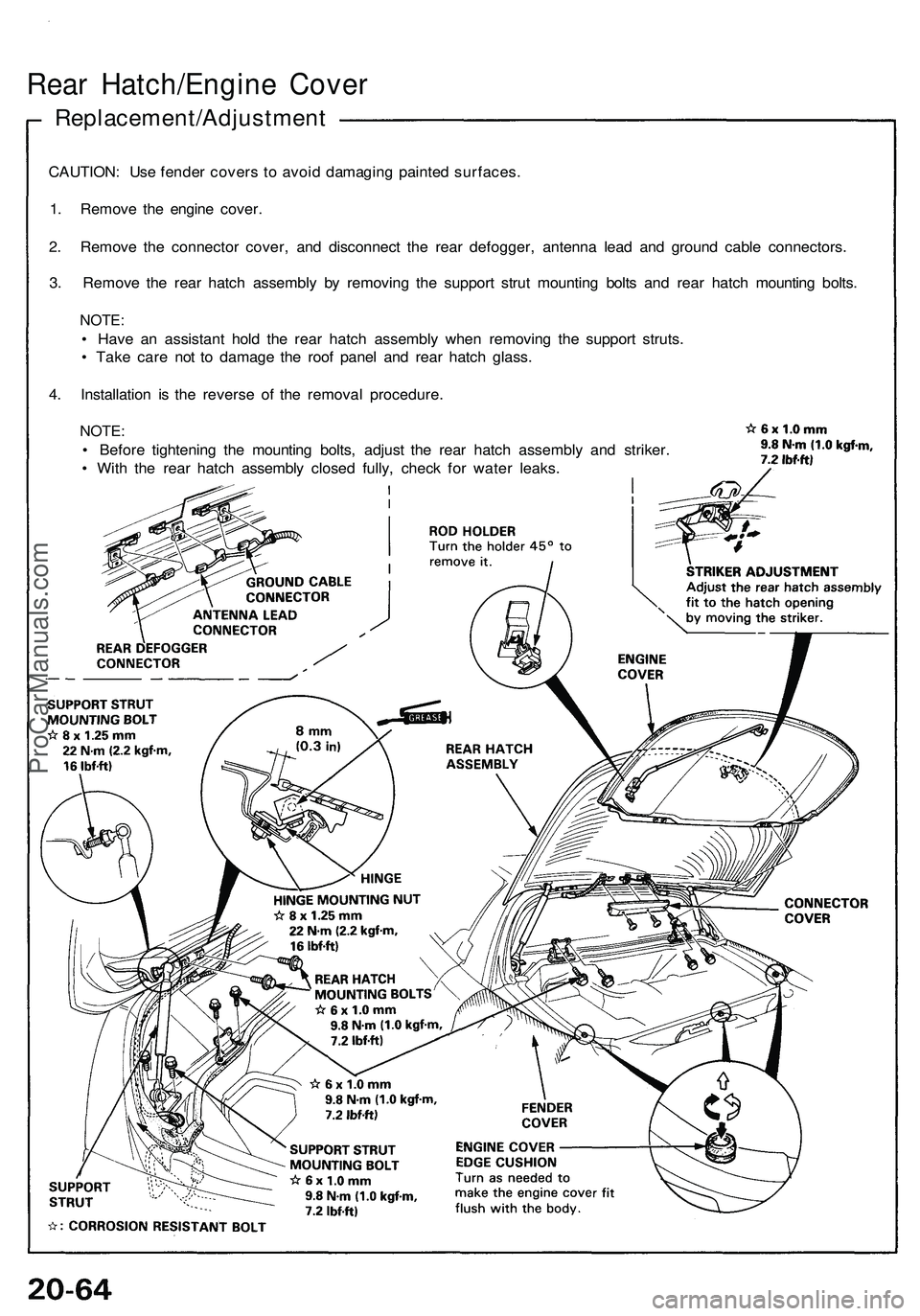

Rear Hatch/Engine Cover

Replacement/Adjustment

CAUTION: Use fender covers to avoid damaging painted surfaces.

1. Remove the engine cover.

2. Remove the connector cover, and disconnect the rear defogger, antenna lead and ground cable connectors.

3. Remove the rear hatch assembly by removing the support strut mounting bolts and rear hatch mounting bolts.

NOTE:

• Have an assistant hold the rear hatch assembly when removing the support struts.

• Take care not to damage the roof panel and rear hatch glass.

4. Installation is the reverse of the removal procedure.

NOTE:

• Before tightening the mounting bolts, adjust the rear hatch assembly and striker.

• With the rear hatch assembly closed fully, check for water leaks.ProCarManuals.com

Page 1122 of 1503

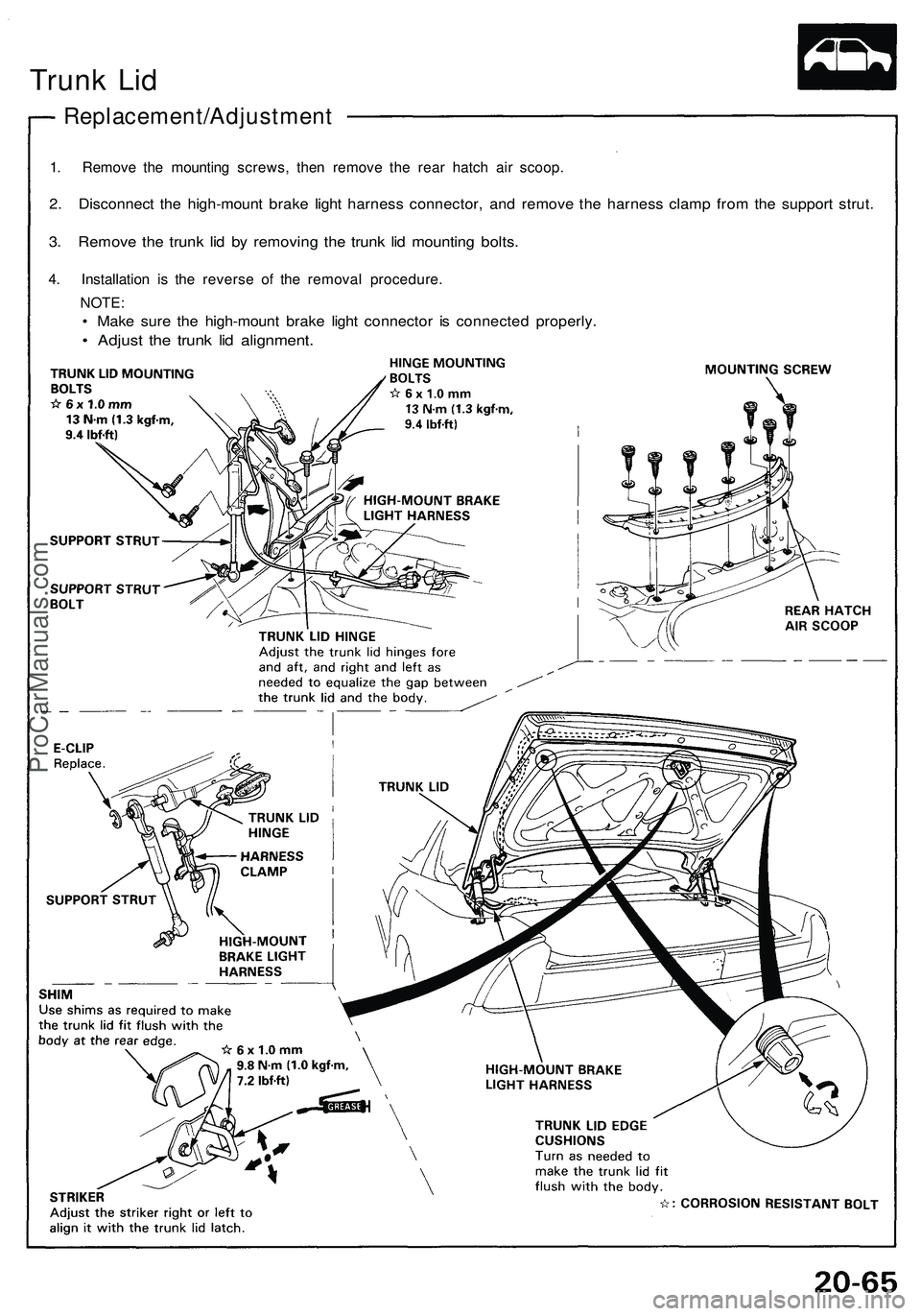

Trunk Lid

Replacement/Adjustment

1. Remove the mounting screws, then remove the rear hatch air scoop.

2. Disconnect the high-mount brake light harness connector, and remove the harness clamp from the support strut.

3. Remove the trunk lid by removing the trunk lid mounting bolts.

4. Installation is the reverse of the removal procedure.

NOTE:

• Make sure the high-mount brake light connector is connected properly.

• Adjust the trunk lid alignment.ProCarManuals.com

Page 1123 of 1503

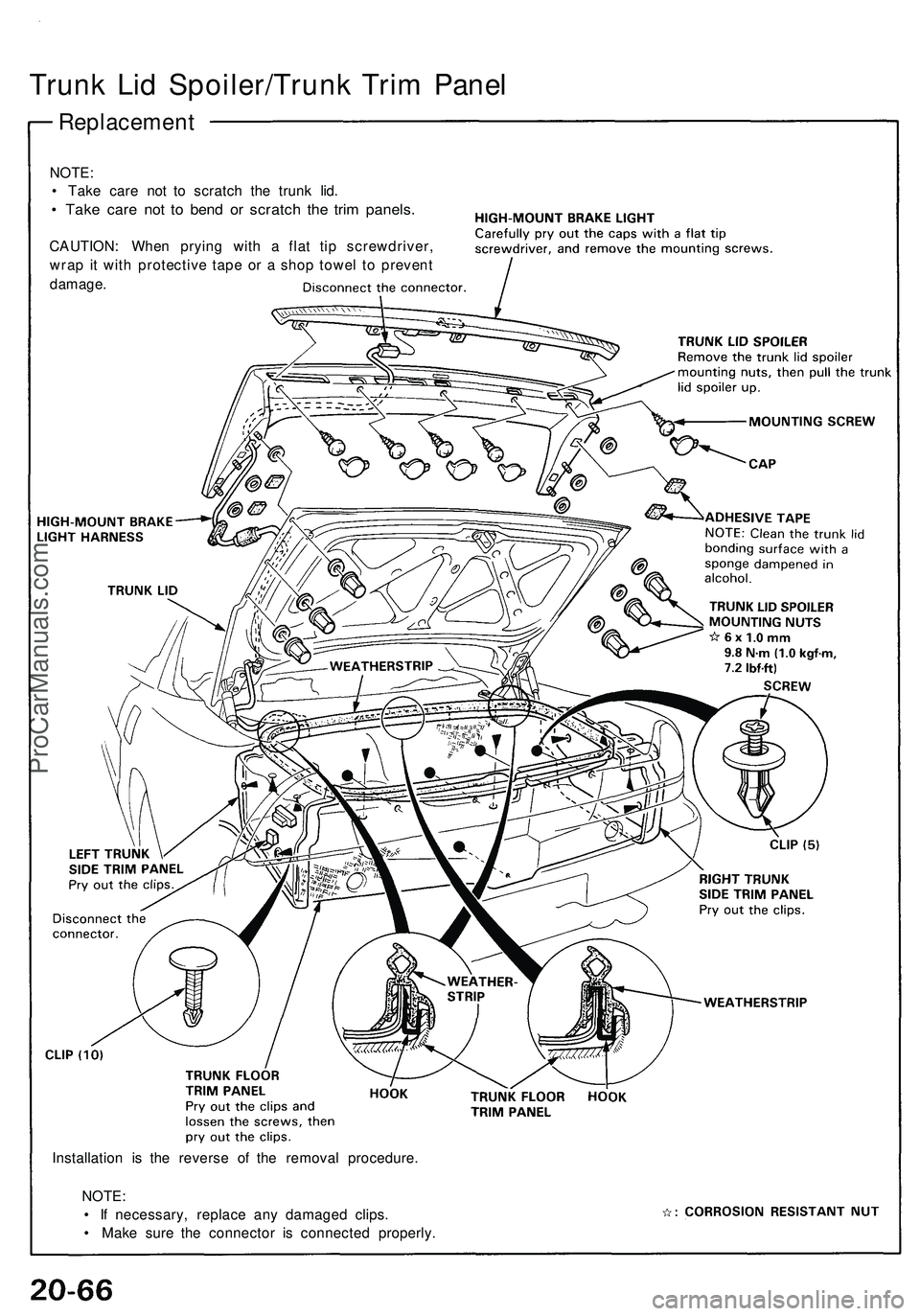

Trunk Lid Spoiler/Trunk Trim Panel

Replacement

NOTE:

• Take care not to scratch the trunk lid.

• Take care not to bend or scratch the trim panels.

CAUTION: When prying with a flat tip screwdriver,

wrap it with protective tape or a shop towel to prevent

damage.

Installation is the reverse of the removal procedure.

NOTE:

• If necessary, replace any damaged clips.

• Make sure the connector is connected properly.ProCarManuals.com

Page 1124 of 1503

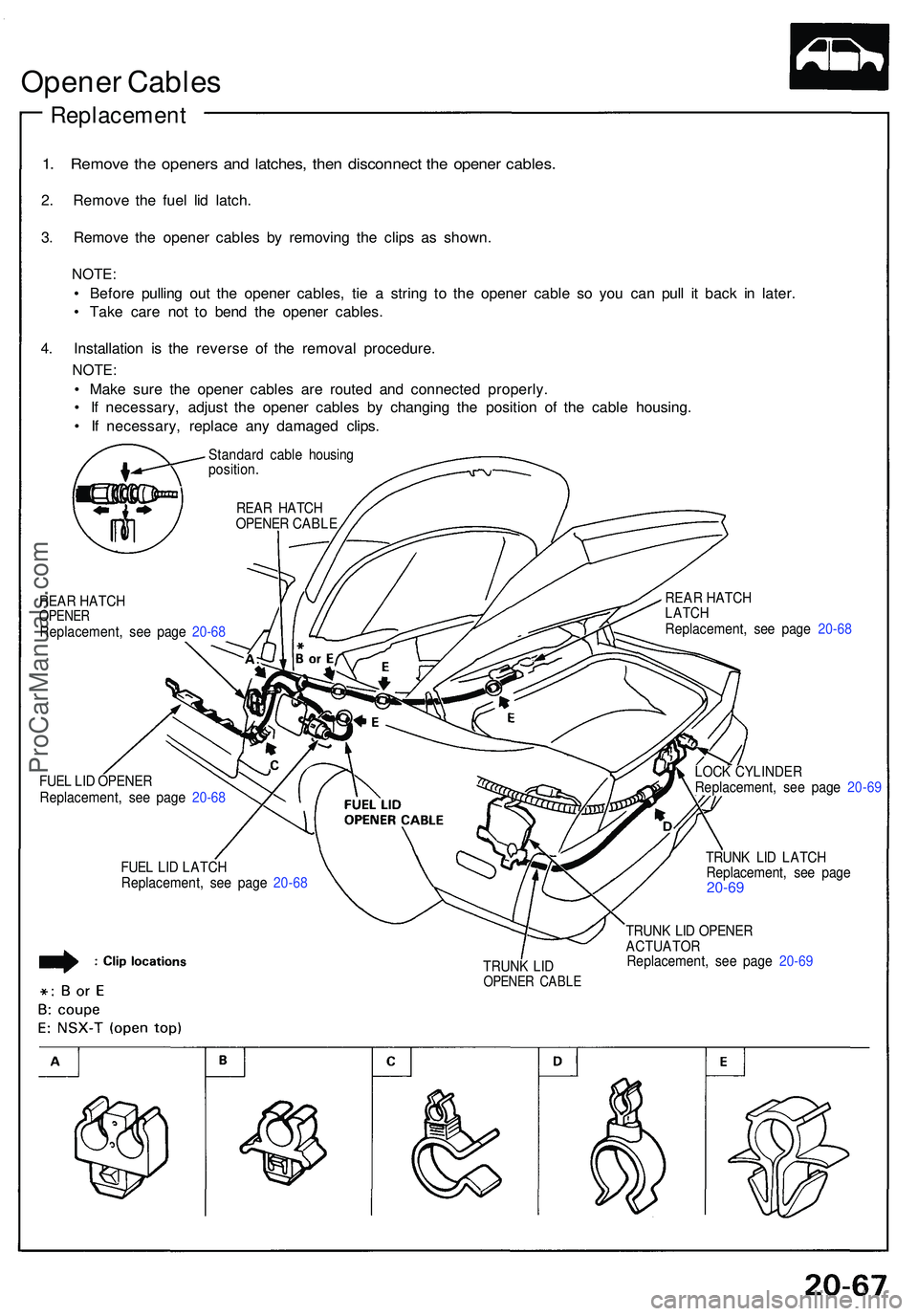

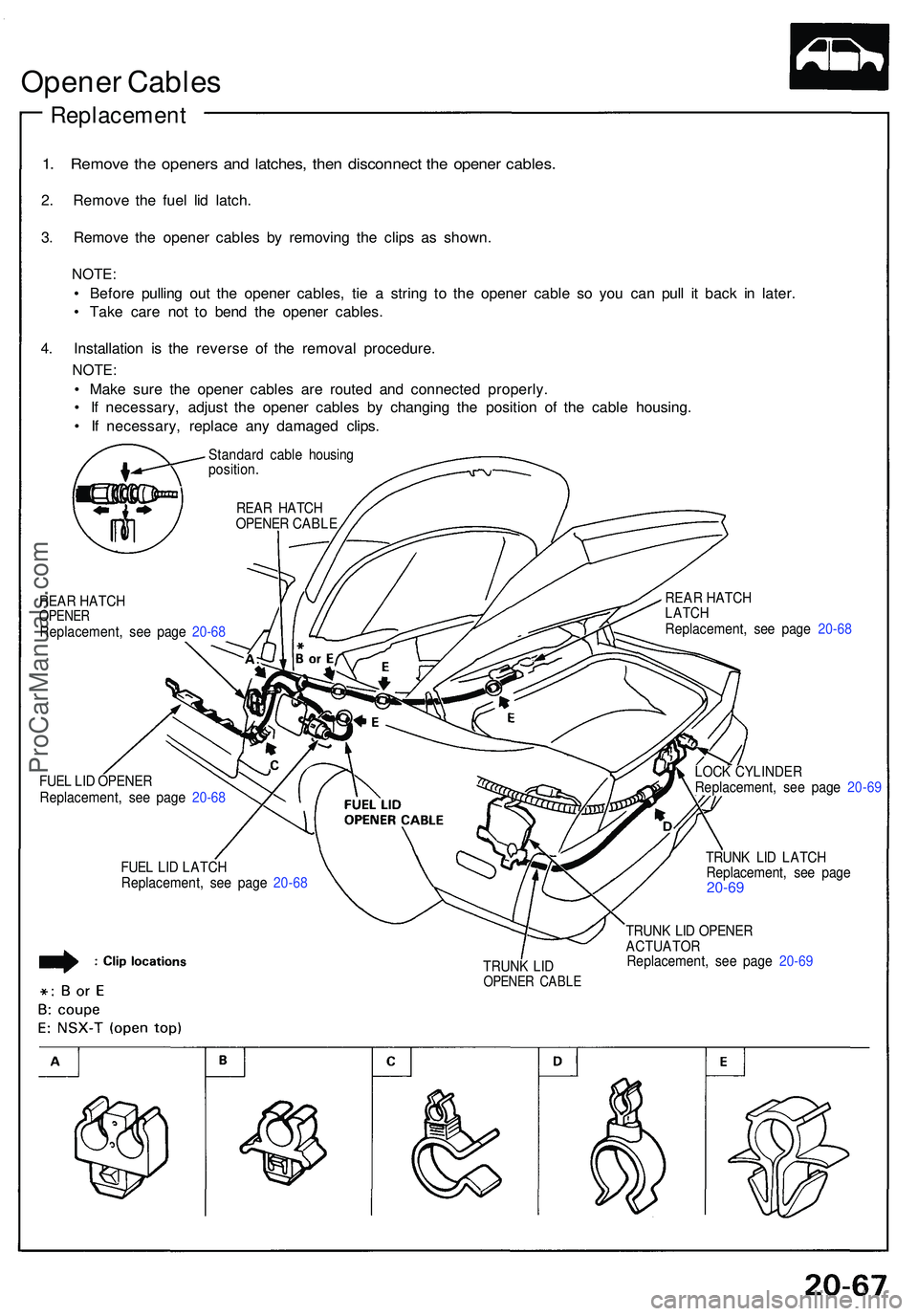

Opener Cable s

Replacemen t

1. Remov e th e opener s an d latches , the n disconnec t th e opene r cables .

2. Remov e th e fue l li d latch .

3 . Remov e th e opene r cable s b y removin g th e clip s a s shown .

NOTE:

• Befor e pullin g ou t th e opene r cables , ti e a strin g t o th e opene r cabl e s o yo u ca n pul l i t bac k i n later .

• Tak e car e no t t o ben d th e opene r cables .

4 . Installatio n i s th e revers e o f th e remova l procedure .

NOTE:

• Mak e sur e th e opene r cable s ar e route d an d connecte d properly .

• I f necessary , adjus t th e opene r cable s b y changin g th e positio n o f th e cabl e housing .

• I f necessary , replac e an y damage d clips .

Standar d cabl e housin g

position .

REA R HATC H

OPENE R CABL E

REAR HATC H

LATCHReplacement , se e pag e 20-6 8

REA

R HATC HOPENE RReplacement , se e pag e 20-6 8

FUE L LI D OPENE R

Replacement , se e pag e 20-6 8

FUE L LI D LATC H

Replacement , se e pag e 20-6 8 LOC

K CYLINDE R

Replacement , se e pag e 20-6 9

TRUN K LI D LATC H

Replacement , se e pag e

20-69

TRUN K LI DOPENE R CABL E

TRUNK LI D OPENE RACTUATO RReplacement , se e pag e 20-6 9

ProCarManuals.com

Page 1125 of 1503

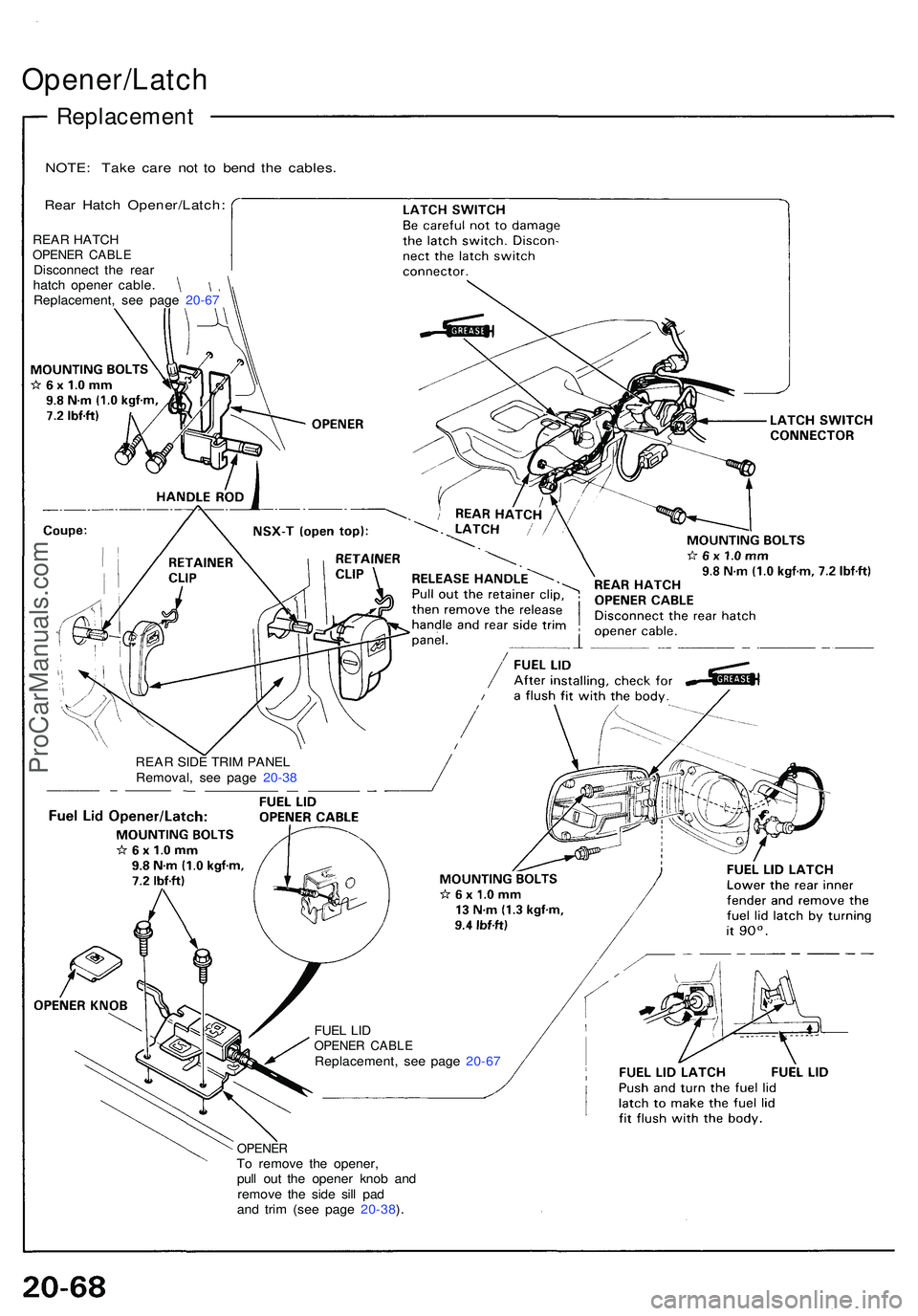

Opener/Latch

Replacement

NOTE: Tak e car e no t t o ben d th e cables .

Rear Hatc h Opener/Latch :

REAR SID E TRI M PANE L

Removal , se e pag e 20-3 8

FUE L LI D

OPENE R CABL EReplacement , se e pag e 20-6 7

OPENE RTo remov e th e opener ,

pul l ou t th e opene r kno b an d

remov e th e sid e sil l pa d

an d tri m (se e pag e 20-38 ).

REA

R HATC H

OPENE R CABL EDisconnec t th e rea r

hatc h opene r cable .

Replacement , se e pag e 20-6 7

ProCarManuals.com

Page 1126 of 1503

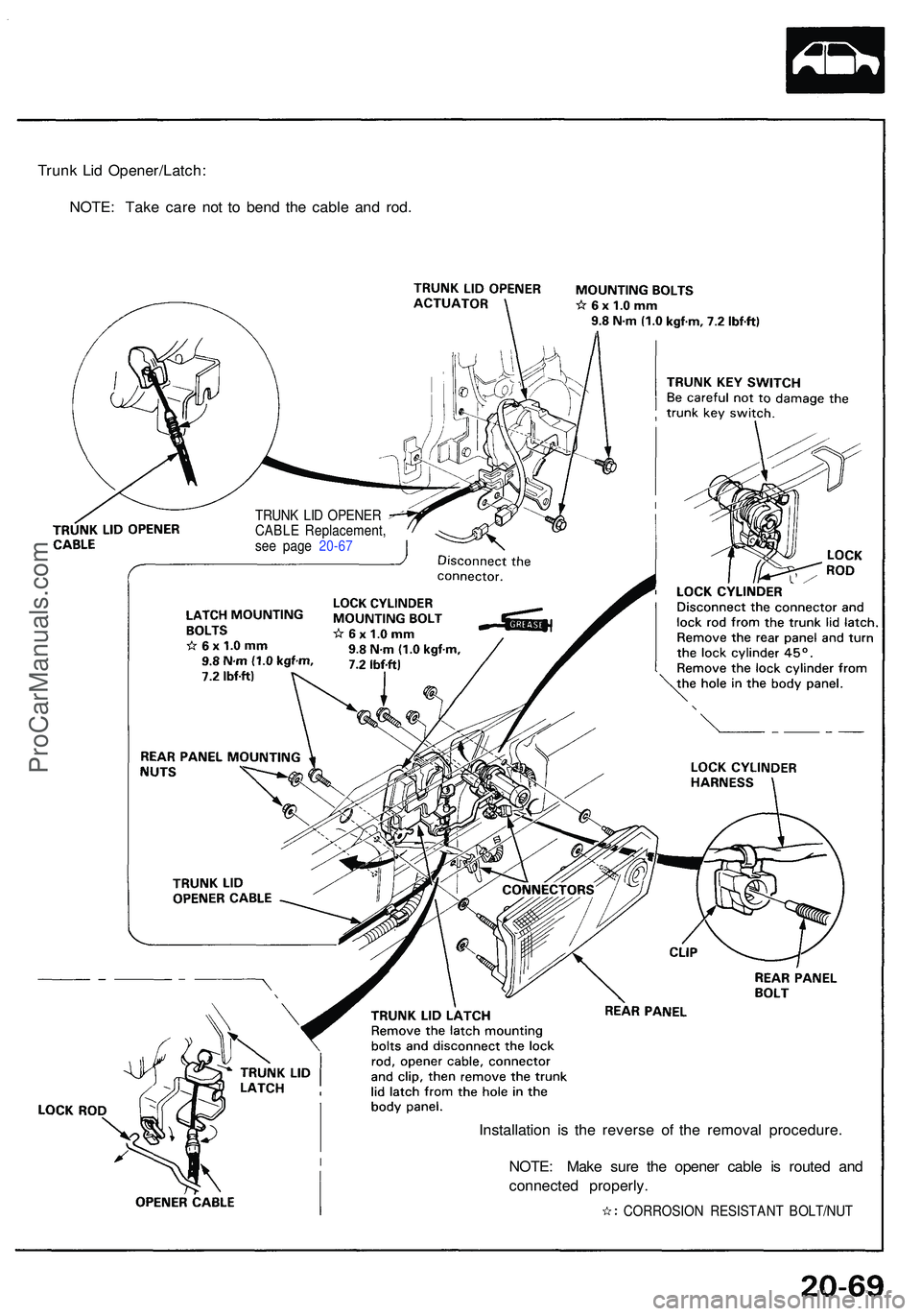

Trunk Li d Opener/Latch :

NOTE : Tak e car e no t t o ben d th e cabl e an d rod .

Installation i s th e revers e o f th e remova l procedure .

NOTE : Mak e sur e th e opene r cabl e i s route d an d

connecte d properly .

TRUNK LI D OPENE R

CABL E Replacement ,

se e pag e 20-6 7

CORROSION RESISTAN T BOLT/NU T

ProCarManuals.com

Page 1127 of 1503

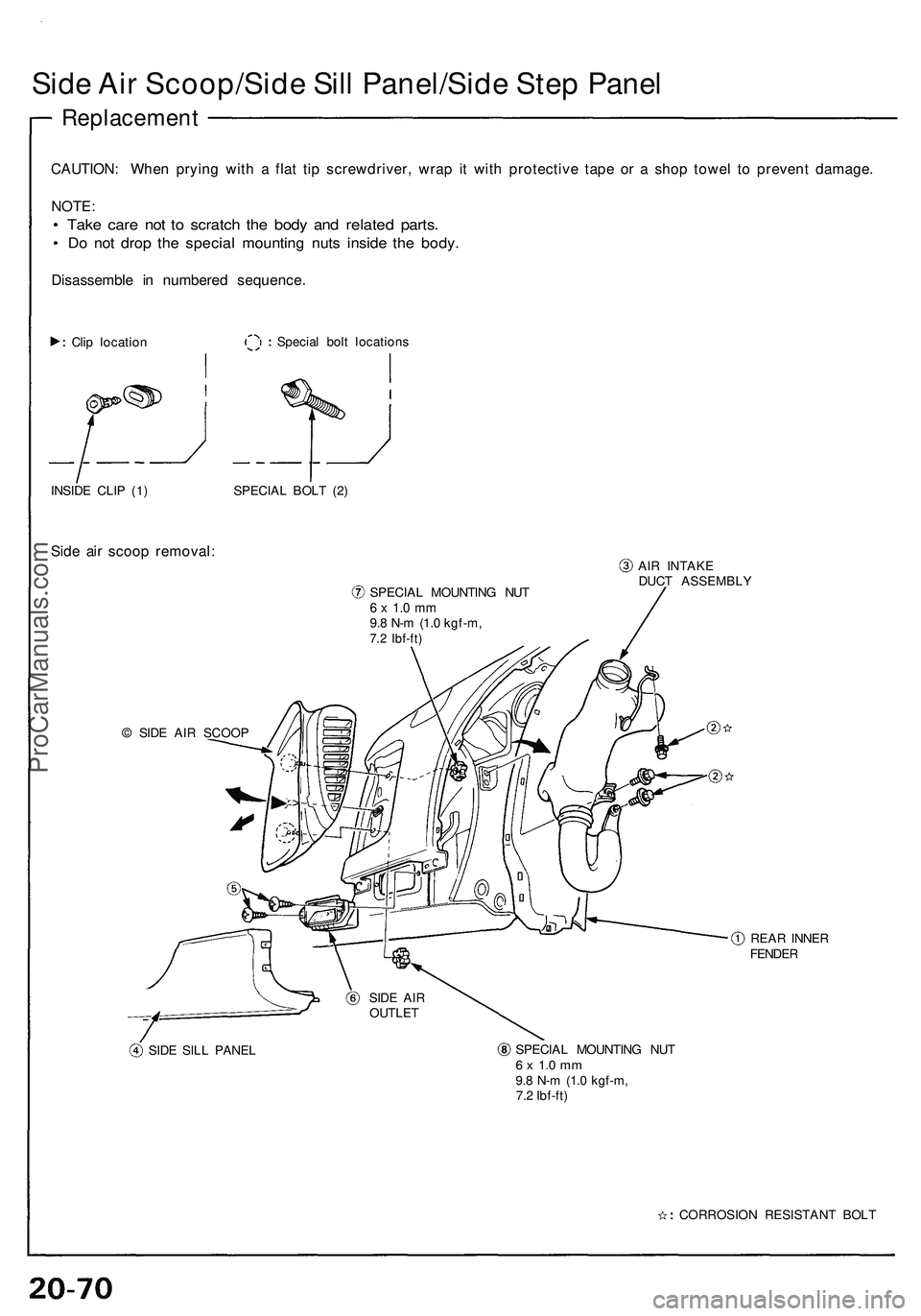

Side Air Scoop/Side Sill Panel/Side Step Panel

Replacement

CAUTION: When prying with a flat tip screwdriver, wrap it with protective tape or a shop towel to prevent damage.

NOTE:

• Take care not to scratch the body and related parts.

• Do not drop the special mounting nuts inside the body.

Disassemble in numbered sequence.

Clip location

Special bolt locations

INSIDE CLIP (1)

Side air scoop removal:

SPECIAL BOLT (2)

SPECIAL MOUNTING NUT

6 x 1.0 mm

9.8 N-m (1.0 kgf-m,

7.2 Ibf-ft)

AIR INTAKE

DUCT ASSEMBLY

© SIDE AIR SCOOP

REAR INNER

FENDER

SIDE SILL PANEL

SPECIAL MOUNTING NUT

6 x 1.0 mm

9.8 N-m (1.0 kgf-m,

7.2 Ibf-ft)

CORROSION RESISTANT BOLT

SIDE AIR

OUTLETProCarManuals.com

Page 1128 of 1503

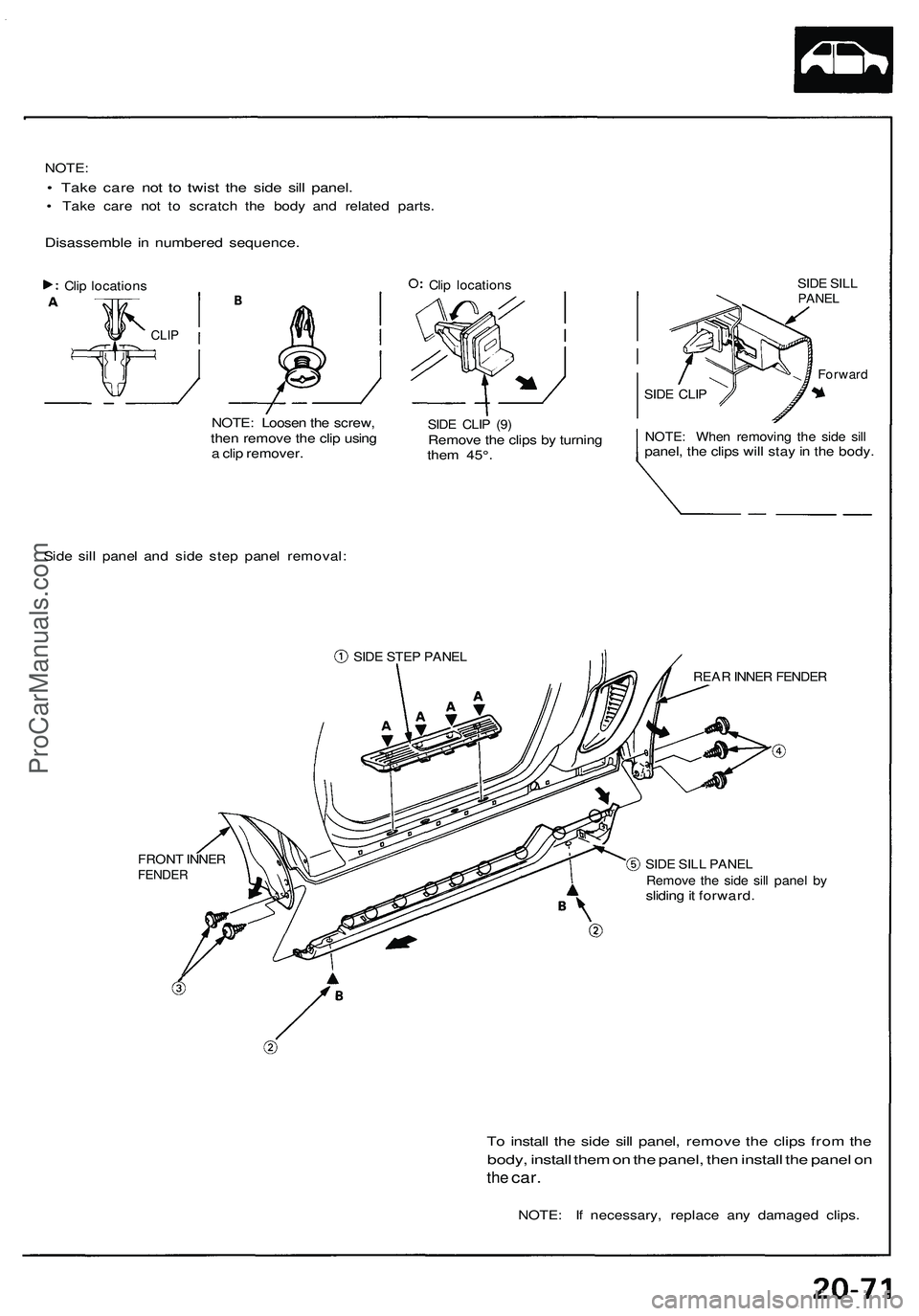

NOTE:

• Take care not to twist the side sill panel.

• Take care not to scratch the body and related parts.

Disassemble in numbered sequence.

NOTE: Loosen the screw,

then remove the clip using

a clip remover.

Clip locations

SIDE SILL

PANEL

SIDE CLIP (9)

Remove the clips by turning

them 45°.

SIDE CLIP

NOTE: When removing the side sill

panel, the clips will stay in the body.

Side sill panel and side step panel removal:

SIDE STEP PANEL

FRONT INNER

FENDER

REAR INNER FENDER

SIDE SILL PANEL

Remove the side sill panel by

sliding it forward.

To install the side sill panel, remove the clips from the

body, install them on the panel, then install the panel on

the

car.

NOTE: If necessary, replace any damaged clips.

Clip locations

CLIP

ForwardProCarManuals.com

Page 1129 of 1503

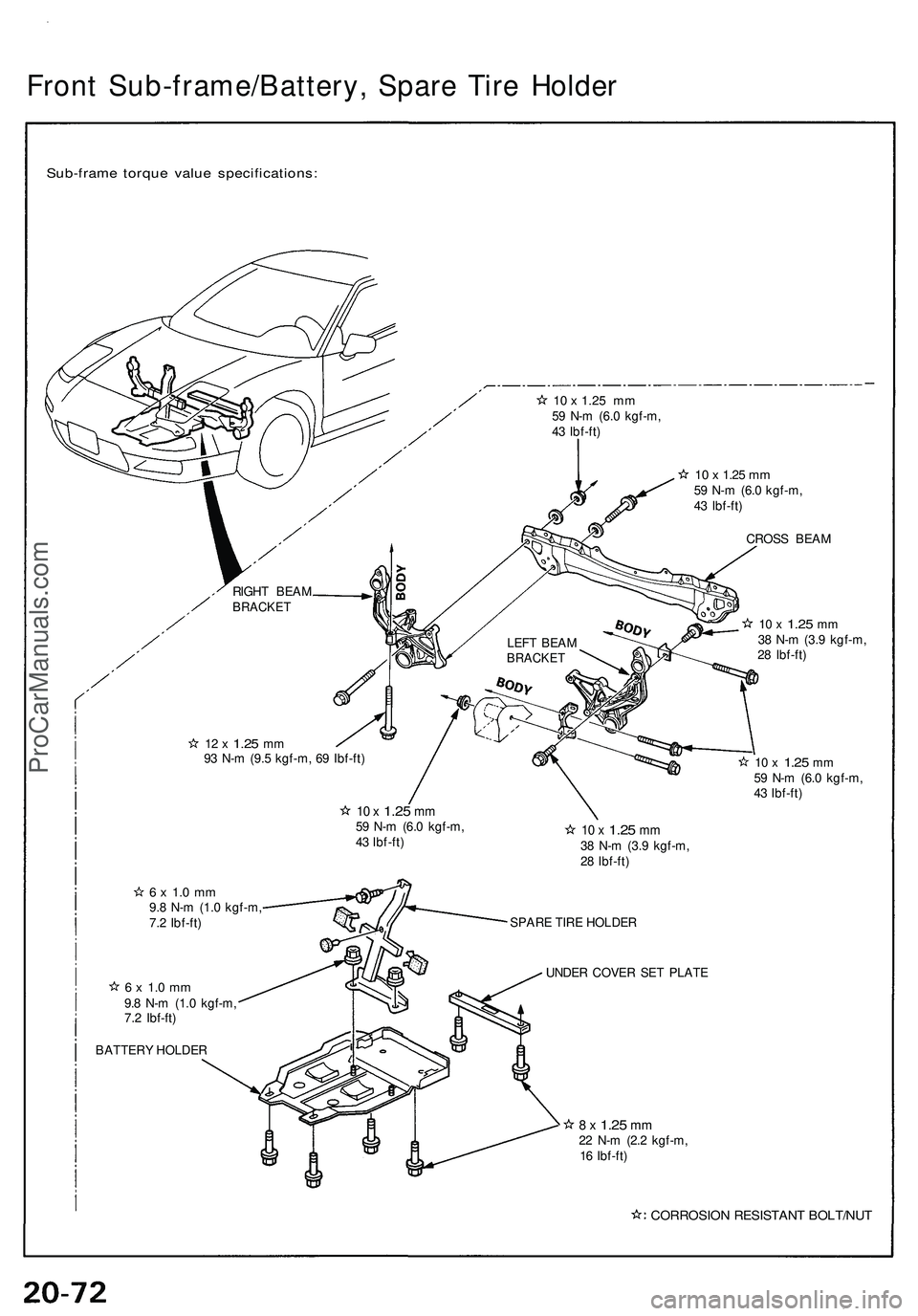

Front Sub-frame/Battery , Spar e Tir e Holde r

Sub-fram e torqu e valu e specifications :

10 x 1.25 mm59 N- m (6. 0 kgf-m ,

4 3 Ibf-ft )

10 x 1.2 5 m m59 N- m (6. 0 kgf-m ,

4 3 Ibf-ft )

CROS S BEA M

10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,

2 8 Ibf-ft )

12 x 1.2 5 mm93 N- m (9. 5 kgf-m , 6 9 Ibf-ft )10 x 1.2 5 mm59 N- m (6. 0 kgf-m ,

4 3 Ibf-ft )

10 x 1.2 5 mm59 N- m (6. 0 kgf-m ,

4 3 Ibf-ft )10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,

2 8 Ibf-ft )

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft ) SPAR

E TIR E HOLDE R

UNDE R COVE R SE T PLAT E

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

CORROSIO N RESISTAN T BOLT/NU T

RlGHT BEA MBRACKE T

BATTERY HOLDE R LEF

T BEA M

BRACKE T

ProCarManuals.com

Page 1130 of 1503

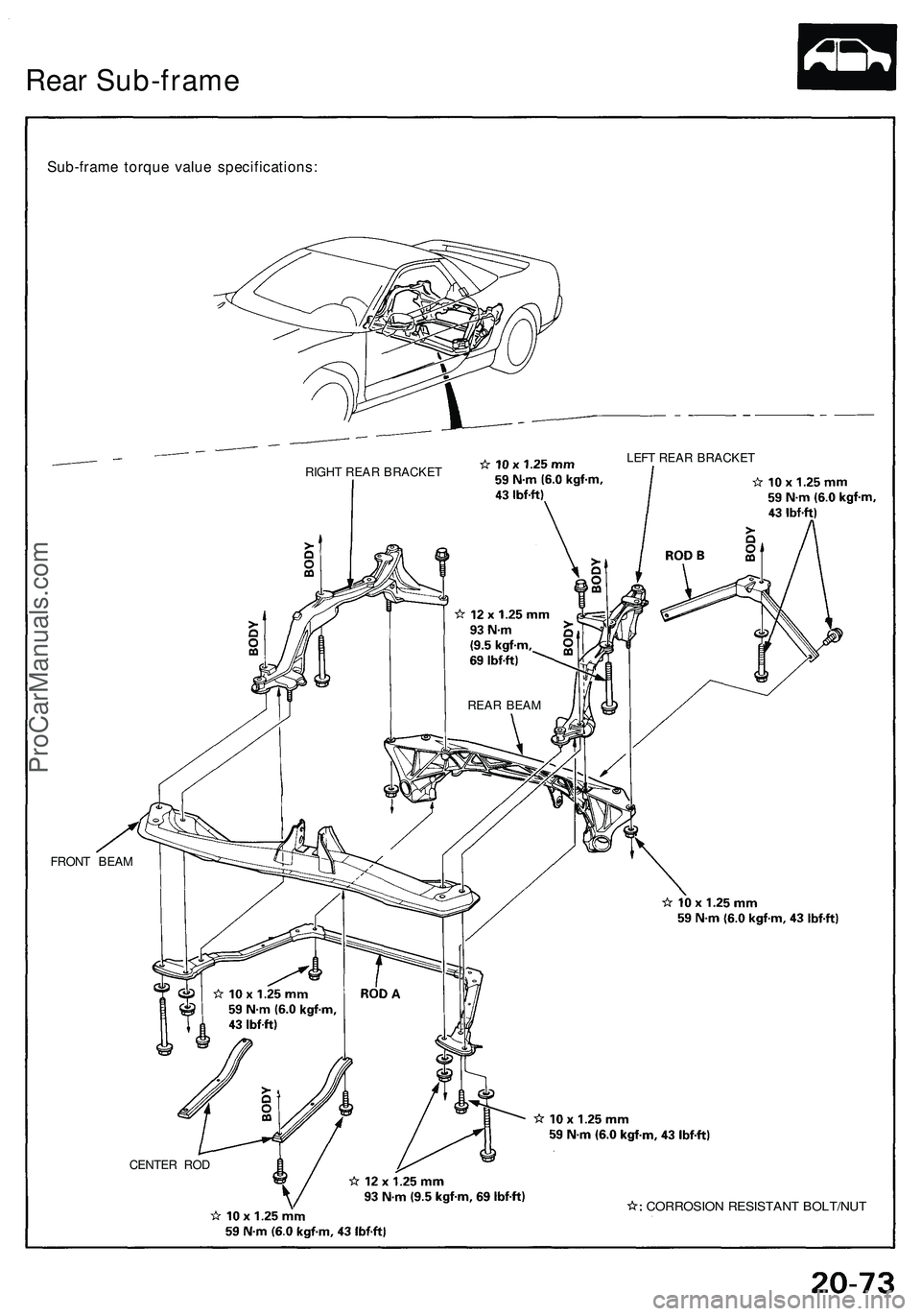

Rear Sub-frame

Sub-frame torque value specifications:

RIGHT REAR BRACKET

LEFT REAR BRACKET

FRONT BEAM

CENTER ROD

CORROSION RESISTANT BOLT/NUT

REAR BEAMProCarManuals.com

Trending: oil level, clutch, seats, radio controls, maintenance, fuel type, change wheel