ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 1261 of 1503

Description ——————————————————\

——————————————————\

———

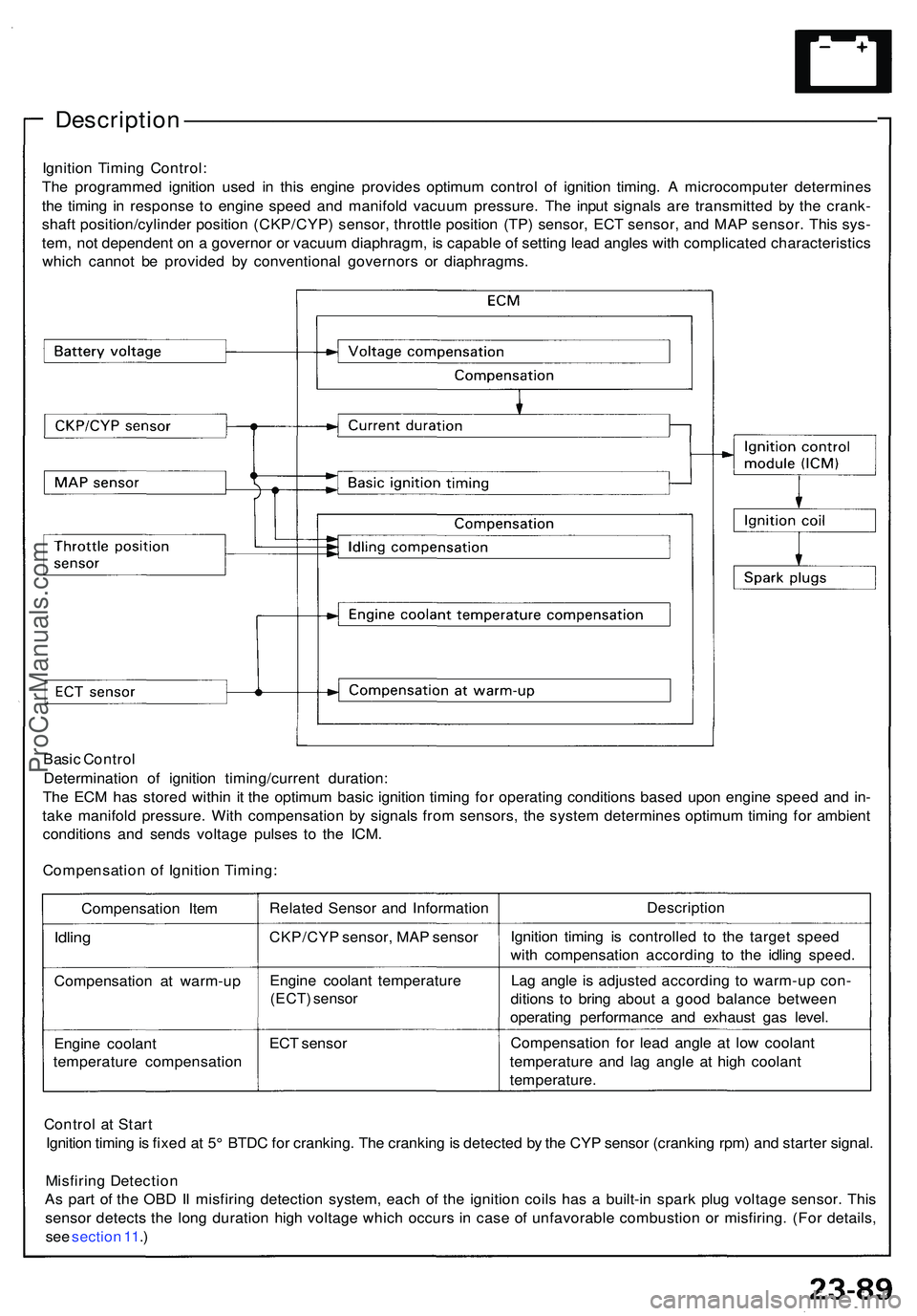

Ignition Timin g Control :

Th e programme d ignitio n use d i n thi s engin e provide s optimu m contro l o f ignitio n timing . A microcompute r determine s

th e timin g i n respons e t o engin e spee d an d manifol d vacuu m pressure . Th e inpu t signal s ar e transmitte d b y th e crank -

shaf t position/cylinde r positio n (CKP/CYP ) sensor , throttl e positio n (TP ) sensor , EC T sensor , an d MA P sensor . Thi s sys -

tem , no t dependen t o n a governo r o r vacuu m diaphragm , i s capabl e o f settin g lea d angle s wit h complicate d characteristic s

whic h canno t b e provide d b y conventiona l governor s o r diaphragms .

Basi c Contro l

Determinatio n of ignitio n timing/curren t duration :

Th e EC M ha s store d withi n i t th e optimu m basi c ignitio n timin g fo r operatin g condition s base d upo n engin e spee d an d in -

tak e manifol d pressure . Wit h compensatio n b y signal s fro m sensors , th e syste m determine s optimu m timin g fo r ambien t

condition s an d send s voltag e pulse s t o th e ICM .

Compensatio n o f Ignitio n Timing :

Compensatio n Ite m

Idlin g

Compensatio n a t warm-u p

Engin e coolan t

temperatur e compensatio nRelate

d Senso r an d Informatio n

CKP/CY P sensor , MA P senso r

Engin e coolan t temperatur e

(ECT) senso r

ECT senso r Descriptio

n

Ignitio n timin g i s controlle d t o th e targe t spee d

wit h compensatio n accordin g t o th e idlin g speed .

La g angl e i s adjuste d accordin g t o warm-u p con -

dition s t o brin g abou t a goo d balanc e betwee n

operatin g performanc e an d exhaus t ga s level .

Compensatio n fo r lea d angl e a t low coolan t

temperatur e an d la g angl e a t hig h coolan t

temperature .

Contro l a t Star t

Ignitio n timin g is fixe d a t 5 ° BTD C fo r cranking . Th e crankin g is detecte d b y th e CY P senso r (crankin g rpm ) an d starte r signal .

Misfirin g Detectio n

A s par t o f th e OB D II misfirin g detectio n system , eac h o f th e ignitio n coil s ha s a built-i n spar k plu g voltag e sensor . Thi s

senso r detect s th e lon g duratio n hig h voltag e whic h occur s i n cas e o f unfavorabl e combustio n o r misfiring . (Fo r details ,

se e sectio n 11 .)

ProCarManuals.com

Page 1262 of 1503

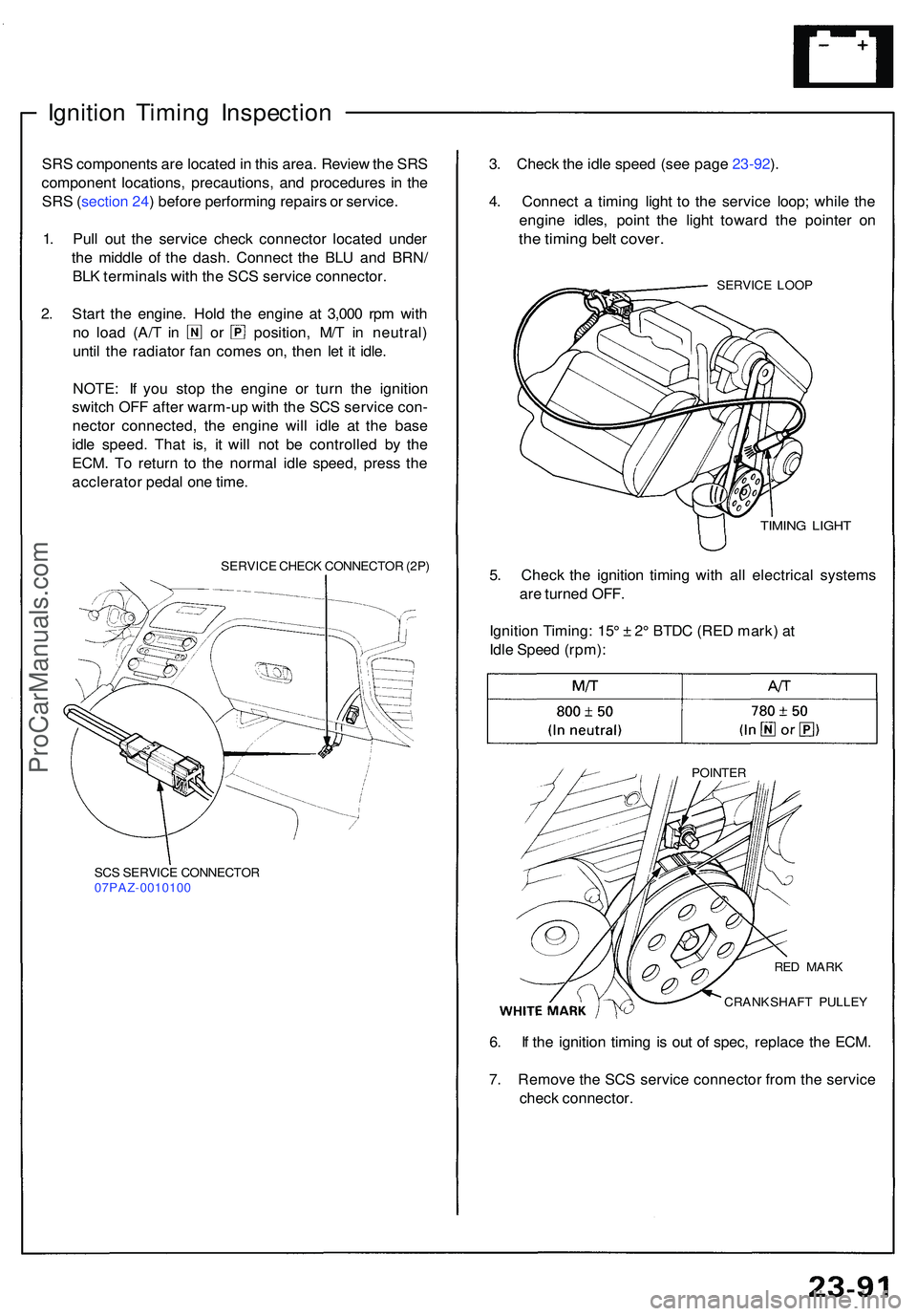

Ignition Timin g Inspectio n

SRS component s ar e locate d in thi s area . Revie w th e SR S

componen t locations , precautions , an d procedure s i n th e

SR S (sectio n 24 ) befor e performin g repair s o r service .

1 . Pul l ou t th e servic e chec k connecto r locate d unde r

th e middl e o f th e dash . Connec t th e BL U an d BRN /

BL K terminal s wit h th e SC S servic e connector .

2 . Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h

no loa d (A/ T i n o r position , M/ T i n neutral )

unti l th e radiato r fa n come s on , the n le t i t idle .

NOTE : I f yo u sto p th e engin e o r tur n th e ignitio n

switc h OF F afte r warm-u p wit h th e SC S servic e con -

necto r connected , th e engin e wil l idl e a t th e bas e

idl e speed . Tha t is , i t wil l no t b e controlle d b y th e

ECM . T o retur n t o th e norma l idl e speed , pres s th e

acclerato r peda l on e time .

SERVIC E CHEC K CONNECTO R (2P )

SC S SERVIC E CONNECTO R

07PAZ-001010 0

3. Chec k th e idl e spee d (se e pag e 23-92 ).

4 . Connec t a timin g ligh t t o th e servic e loop ; whil e th e

engin e idles , poin t th e ligh t towar d th e pointe r o n

the timin g bel t cover .

SERVIC E LOO P

TIMIN G LIGH T

5. Chec k th e ignitio n timin g wit h al l electrica l system s

ar e turne d OFF .

Ignitio n Timing : 15 ° ± 2° BTD C (RE D mark ) a t

Idl e Spee d (rpm) :

POINTE R

6. I f th e ignitio n timin g i s ou t o f spec , replac e th e ECM .

7 . Remov e th e SC S servic e connecto r fro m th e servic e

chec k connector .

CRANKSHAF T PULLE Y

RE

D MAR K

ProCarManuals.com

Page 1263 of 1503

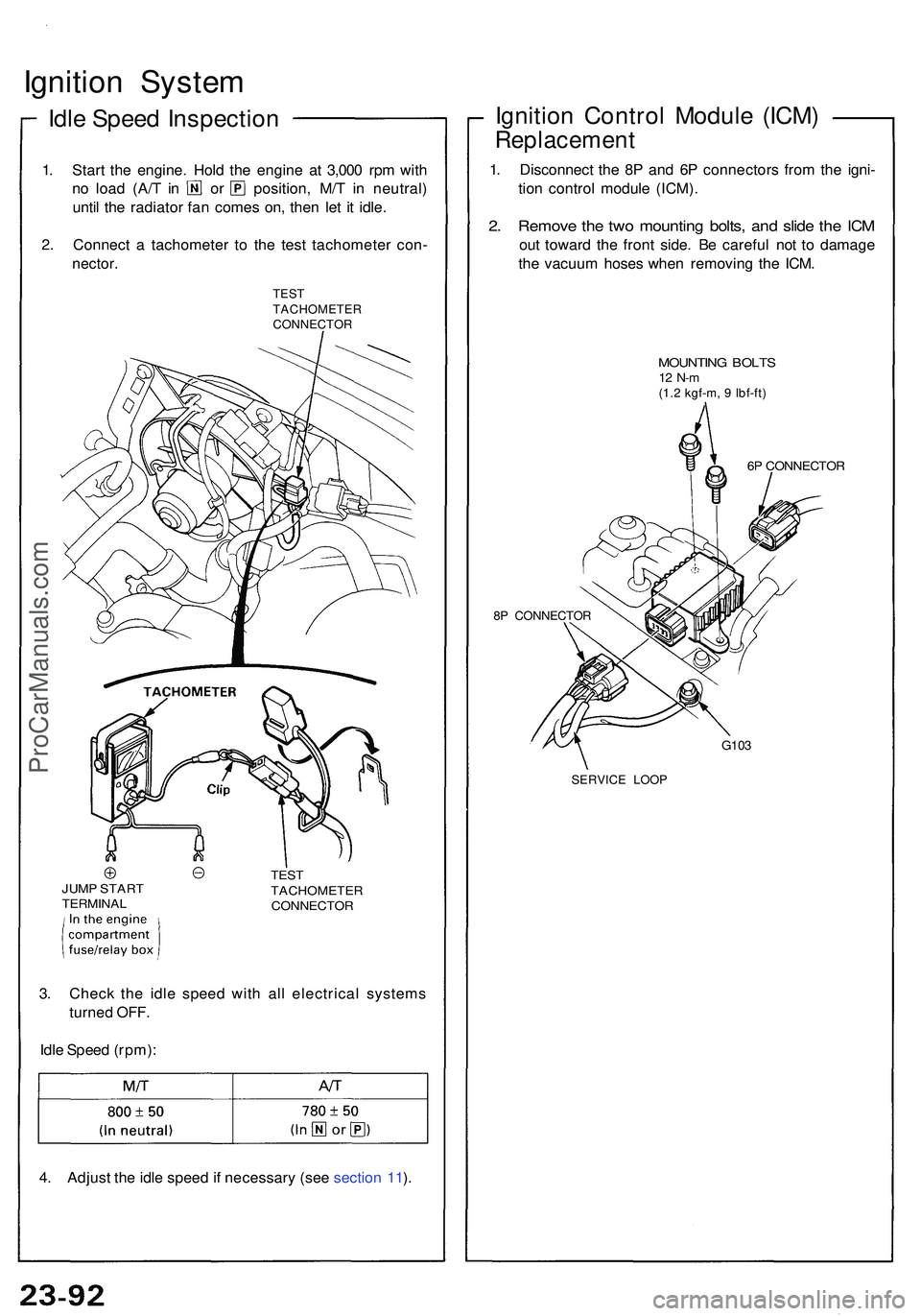

Ignition Syste m

Idle Spee d Inspectio n

1. Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h

no loa d (A/ T i n o r position , M/ T i n neutral )

unti l th e radiato r fa n come s on , the n le t i t idle .

2 . Connec t a tachomete r t o th e tes t tachomete r con -

nector .

TEST

TACHOMETE R

CONNECTO R

3. Chec k th e idl e spee d wit h al l electrica l system s

turne d OFF .

Idl e Spee d (rpm) :

4 . Adjus t th e idl e spee d if necessar y (se e sectio n 11 ).

Ignitio n Contro l Modul e (ICM )

Replacemen t

1. Disconnec t th e 8 P an d 6 P connector s fro m th e igni -

tio n contro l modul e (ICM) .

2. Remov e th e tw o mountin g bolts , an d slid e th e IC M

out towar d th e fron t side . B e carefu l no t t o damag e

th e vacuu m hose s whe n removin g th e ICM .

MOUNTIN G BOLT S12 N- m(1.2 kgf-m , 9 Ibf-ft )

6P CONNECTO R

8P CONNECTO R

G103

SERVIC E LOO P

JUMP STAR TTERMINA L

TESTTACHOMETE RCONNECTOR

ProCarManuals.com

Page 1264 of 1503

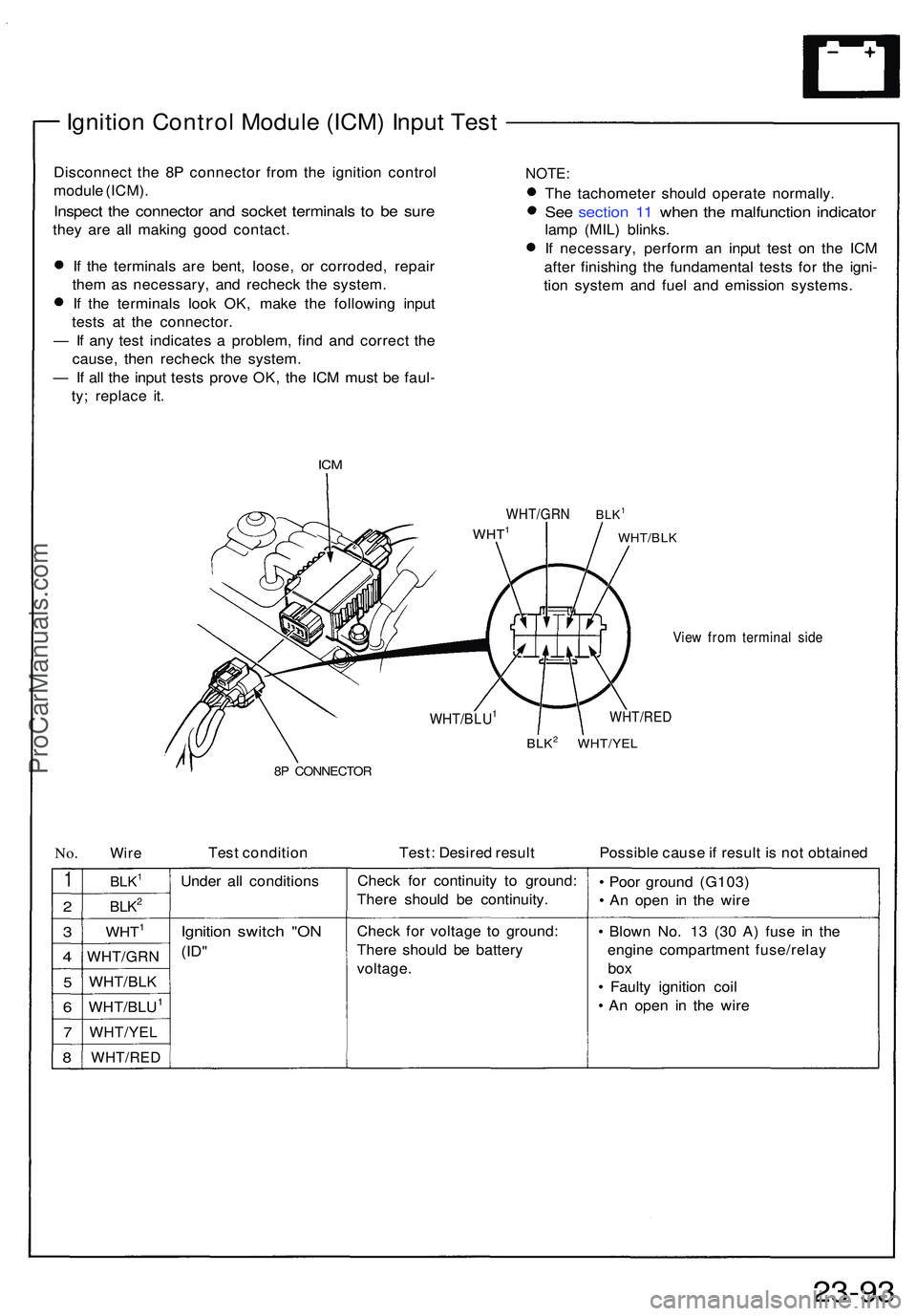

Ignition Contro l Modul e (ICM ) Inpu t Tes t

Disconnec t th e 8 P connecto r fro m th e ignitio n contro l

modul e (ICM) .

Inspec t th e connecto r an d socke t terminal s t o b e sur e

they ar e al l makin g goo d contact .

I f th e terminal s ar e bent , loose , o r corroded , repai r

them as necessary , an d rechec k th e system .

I f th e terminal s loo k OK , mak e th e followin g inpu t

test s a t th e connector .

— If an y tes t indicate s a problem , fin d an d correc t th e

cause , the n rechec k th e system .

— If al l th e inpu t test s prov e OK , th e IC M mus t b e faul -

ty ; replac e it .

IC M

NOTE :

The tachomete r shoul d operat e normally .

See sectio n 1 1 whe n th e malfunctio n indicato r

lamp (MIL ) blinks .

I f necessary , perfor m a n inpu t tes t o n th e IC M

afte r finishin g th e fundamenta l test s fo r th e igni -

tio n syste m an d fue l an d emissio n systems .

WHT/GRN

WHT1BLK1

WHT/BLK

View fro m termina l sid e

WHT/RE D

BLK2 WHT/YE L

8P CONNECTO R

No.Wir eTes t conditio n Test: Desire d resul t Possible caus e if resul t i s no t obtaine d

1

2

3

4

5

6

7

8

BLK1

BLK2

WHT1

WHT/GR N

WHT/BLK

WHT/BLU1

WHT/YE L

WHT/RE D

Under al l condition s

Ignition switc h "O N

(ID"

Chec k fo r continuit y t o ground :

Ther e shoul d b e continuity .

Chec k fo r voltag e t o ground :

Ther e shoul d b e batter y

voltage . •

Poo r groun d (G103 )

• A n ope n i n th e wir e

• Blow n No . 1 3 (3 0 A ) fus e i n th e

engin e compartmen t fuse/rela y

box

• Fault y ignitio n coi l

• A n ope n i n th e wir e

23-9 3

WHT/BLU1

ProCarManuals.com

Page 1265 of 1503

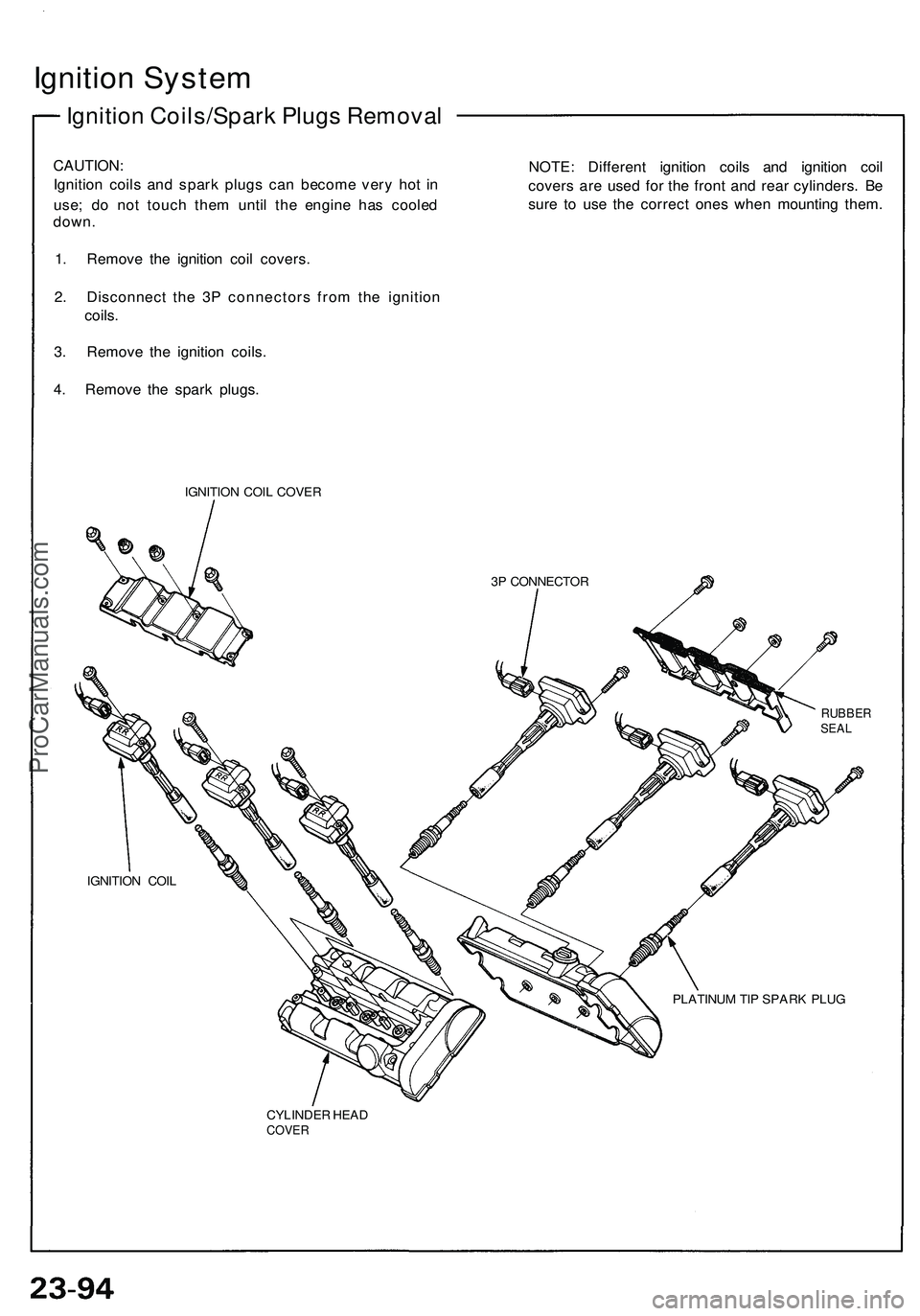

Ignition System

Ignition Coils/Spark Plugs Removal

CAUTION:

Ignition coils and spark plugs can become very hot in

use; do not touch them until the engine has cooled

down.

1. Remove the ignition coil covers.

2. Disconnect the 3P connectors from the ignition

coils.

3. Remove the ignition coils.

4. Remove the spark plugs.

NOTE: Different ignition coils and ignition coil

covers are used for the front and rear cylinders. Be

sure to use the correct ones when mounting them.

IGNITION COIL COVER

RUBBER

SEAL

PLATINUM TIP SPARK PLUG

CYLINDER HEAD

COVER

3P CONNECTOR

IGNITION COILProCarManuals.com

Page 1266 of 1503

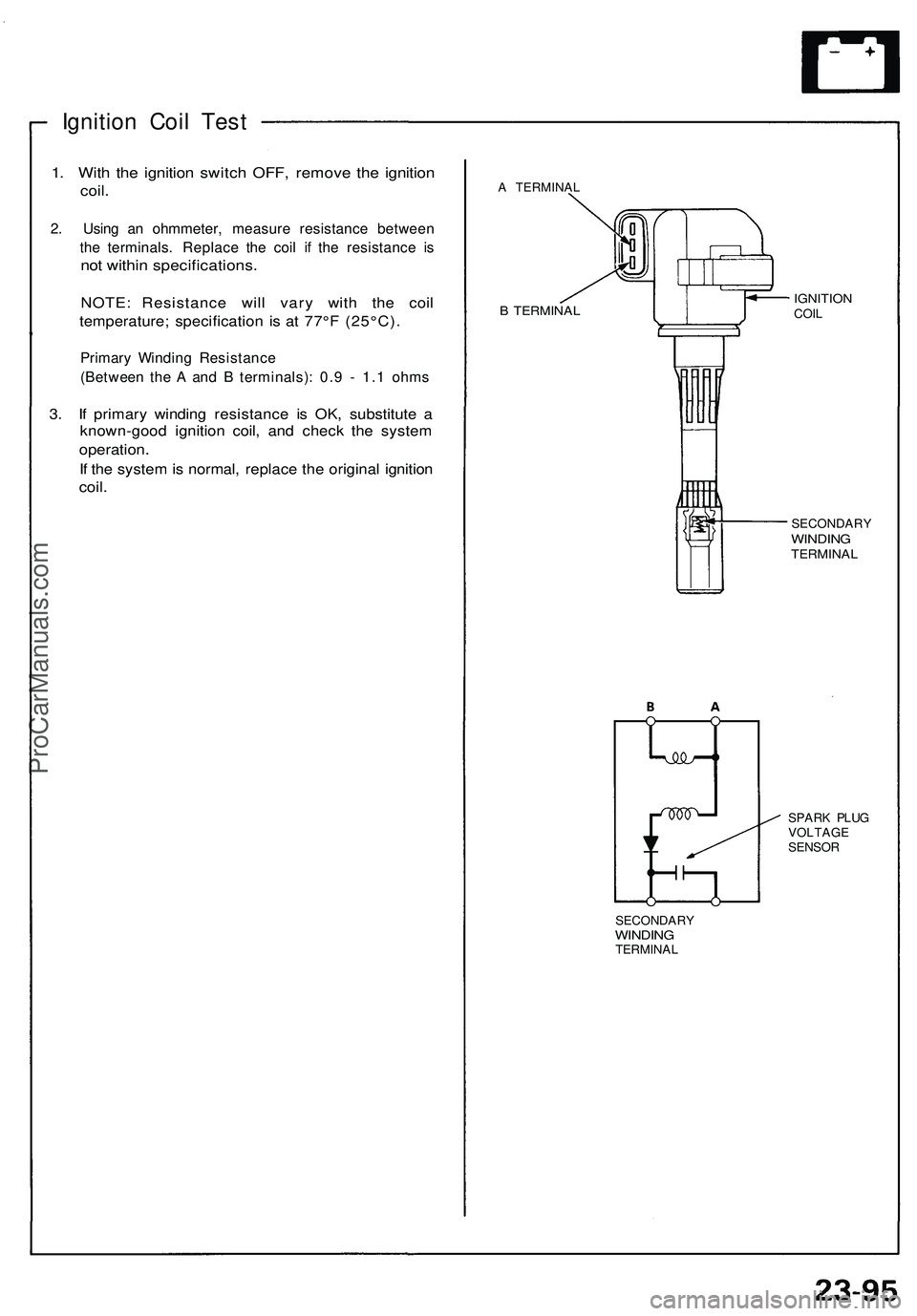

Ignition Coi l Tes t

1. Wit h th e ignitio n switc h OFF , remov e th e ignitio n

coil.

2. Usin g a n ohmmeter , measur e resistanc e betwee n

th e terminals . Replac e th e coi l i f th e resistanc e i s

no t withi n specifications .

NOTE: Resistanc e wil l var y wit h th e coi l

temperature ; specificatio n i s a t 77° F (25°C) .

Primary Windin g Resistanc e

(Betwee n th e A an d B terminals) : 0.9 - 1. 1 ohm s

3. I f primar y windin g resistanc e i s OK , substitut e aknown-goo d ignitio n coil , an d chec k th e syste m

operation .

If th e syste m is normal , replac e th e origina l ignitio n

coil.

A TERMINA L

B TERMINA LIGNITIONCOIL

SECONDAR Y

WINDINGTERMINA L

SPARK PLU G

VOLTAG E

SENSO R

SECONDAR Y

WINDINGTERMINA L

ProCarManuals.com

Page 1267 of 1503

Ignition System

Spark Plug Inspection

1. Inspect the electrodes and ceramic insulator for:

Worn or deformed

electrodes

Cracked

insulator

Burned or worn electrodes may be caused by:

Advanced ignition timing

Loose spark plug

Plug heat range too hot

Insufficient cooling

Fouled plug may be caused by:

Retarded ignition timing

Oil in combustion chamber

Incorrect spark plug gap

Plug heat range too cold

Excessive idling/low speed running

Clogged air cleaner element

Deteriorated ignition coil

2. Replace the plug if it is fouled or worn. Do not use

spark plugs other than those listed below.

Spark Plug:

PFR6L-11 (NGK)

PK20PR-L11 (DENSO)

3. Make sure that the 1.3 mm (0.051 in) plug gauge

does not go into the gap for the platinum tip plug. If

the gauge goes into the gap, do not attempt to

adjust the side electrode; replace the plug with a

new

one.

Electrode Gap:

Platinum tip plug:

Check and confirm that the

1.3 mm (0.051 in) plug

gauge does not go into the

gap.

Anti-seize compound

applied to threads

4. Apply a small quantity of anti-seize compound to

the plug threads before installing each plug. Screw

the plugs into the cylinder head finger-tight, then

torque them to 18 N-m (1.8 kgf-m, 13 Ibf-ft).

Improper gap

Oil-fouling

Carbon deposits

Cracked center

electrode insulator

Damaged

gasketProCarManuals.com

Page 1268 of 1503

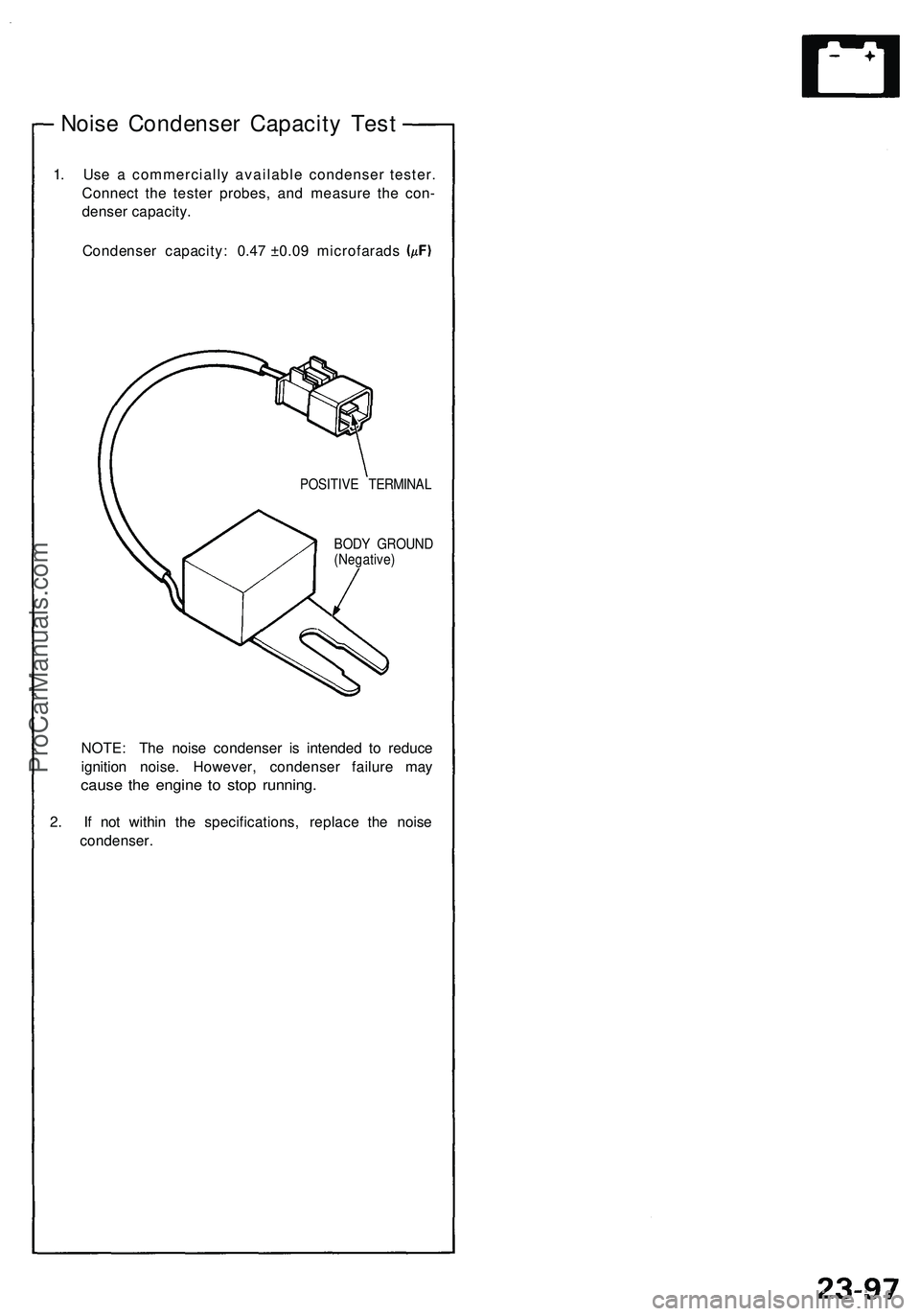

Noise Condenser Capacity Test

1. Use a commercially available condenser tester.

Connect the tester probes, and measure the con-

denser capacity.

Condenser capacity: 0.47 ±0.09 microfarads

POSITIVE TERMINAL

BODY GROUND

(Negative)

NOTE: The noise condenser is intended to reduce

ignition noise. However, condenser failure may

cause the engine to stop running.

2. If not within the specifications, replace the noise

condenser.ProCarManuals.com

Page 1269 of 1503

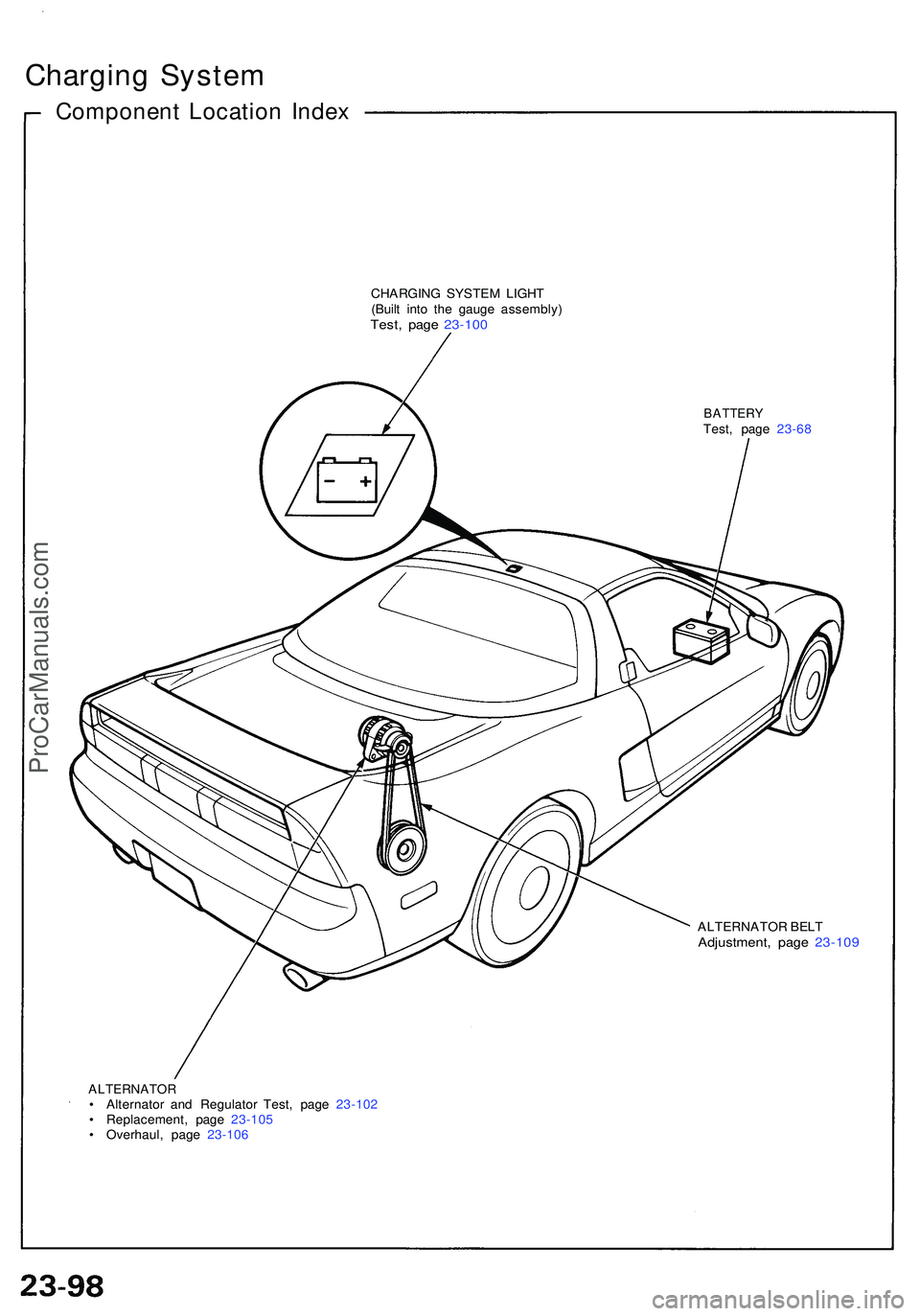

Charging Syste m

Componen t Locatio n Inde x

CHARGIN G SYSTE M LIGH T

(Buil t int o th e gaug e assembly )

Test, pag e 23-10 0

BATTER YTest, pag e 23-6 8

ALTERNATO R BEL T

Adjustment , pag e 23-10 9

ALTERNATO R• Alternato r an d Regulato r Test , pag e 23-10 2

• Replacement , pag e 23-10 5

• Overhaul , pag e 23-10 6

ProCarManuals.com

Page 1270 of 1503

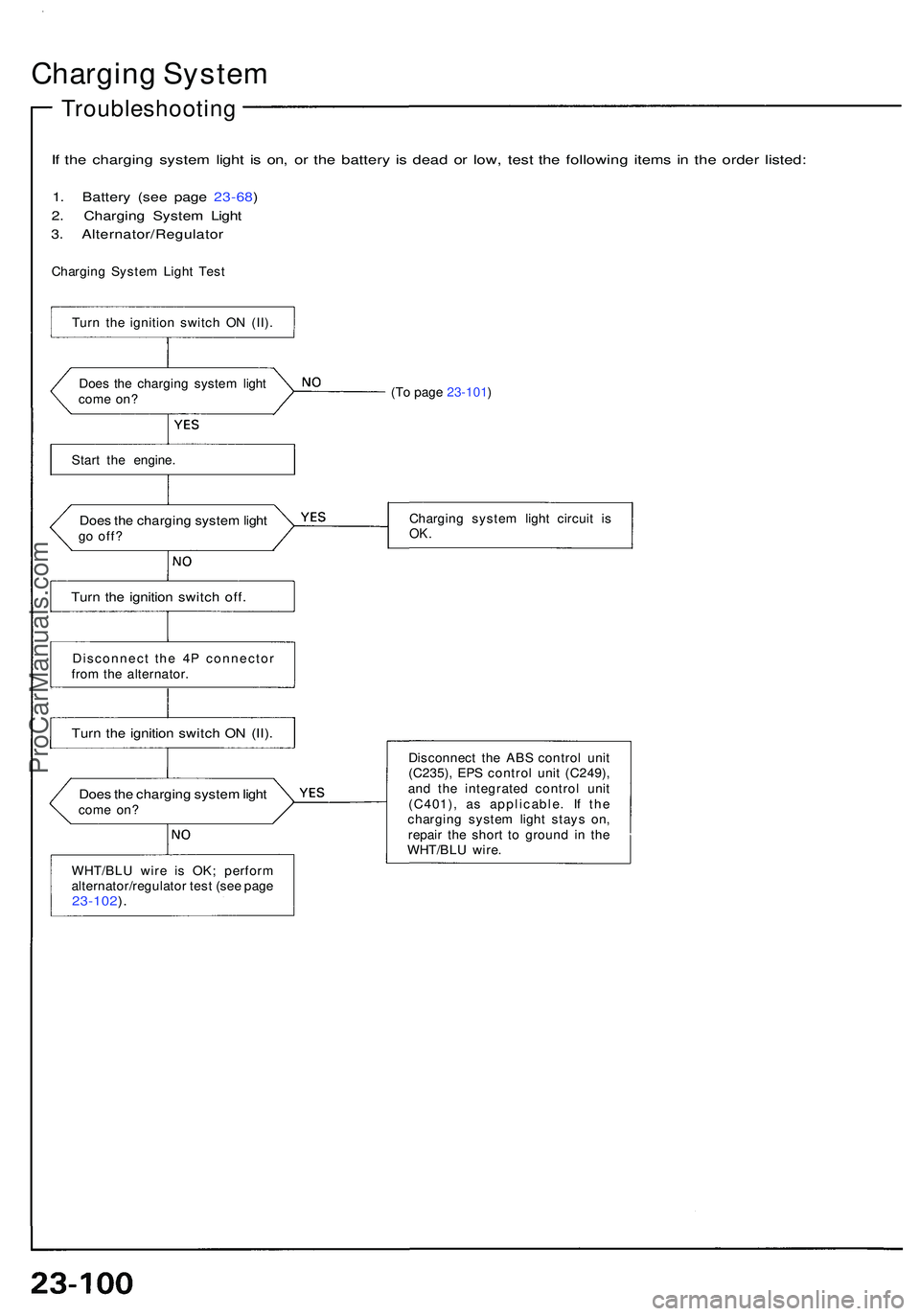

Charging Syste m

Troubleshootin g

If th e chargin g syste m ligh t i s on , o r th e batter y i s dea d o r low , tes t th e followin g item s i n th e orde r listed :

1. Batter y (se e pag e 23-68 )

2 . Chargin g Syste m Ligh t

3 . Alternator/Regulato r

Charging Syste m Ligh t Tes t

Doe s th e chargin g syste m ligh t

com e on ?

Star t th e engine .

Does th e chargin g syste m ligh tgo off ?

Turn th e ignitio n switc h off .

Disconnec t th e 4 P connecto r

fro m th e alternator .

Turn th e ignitio n switc h O N (II) .

WHT/BL U wir e i s OK ; perfor m

alternator/regulato r tes t (se e pag e

23-102 ).

(T o page 23-101 )

Chargin g syste m ligh t circui t i s

OK .

Disconnec t th e AB S contro l uni t

(C235) , EP S contro l uni t (C249) ,

an d th e integrate d contro l uni t

(C401) , a s applicable . I f th e

chargin g syste m ligh t stay s on ,

repai r th e shor t t o groun d i n th e

WHT/BL U wire .

Does th e chargin g syste m ligh tcom e on ?

Tur

n th e ignitio n switc h O N (II) .

ProCarManuals.com