ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 1221 of 1503

Compressor

Replacemen t

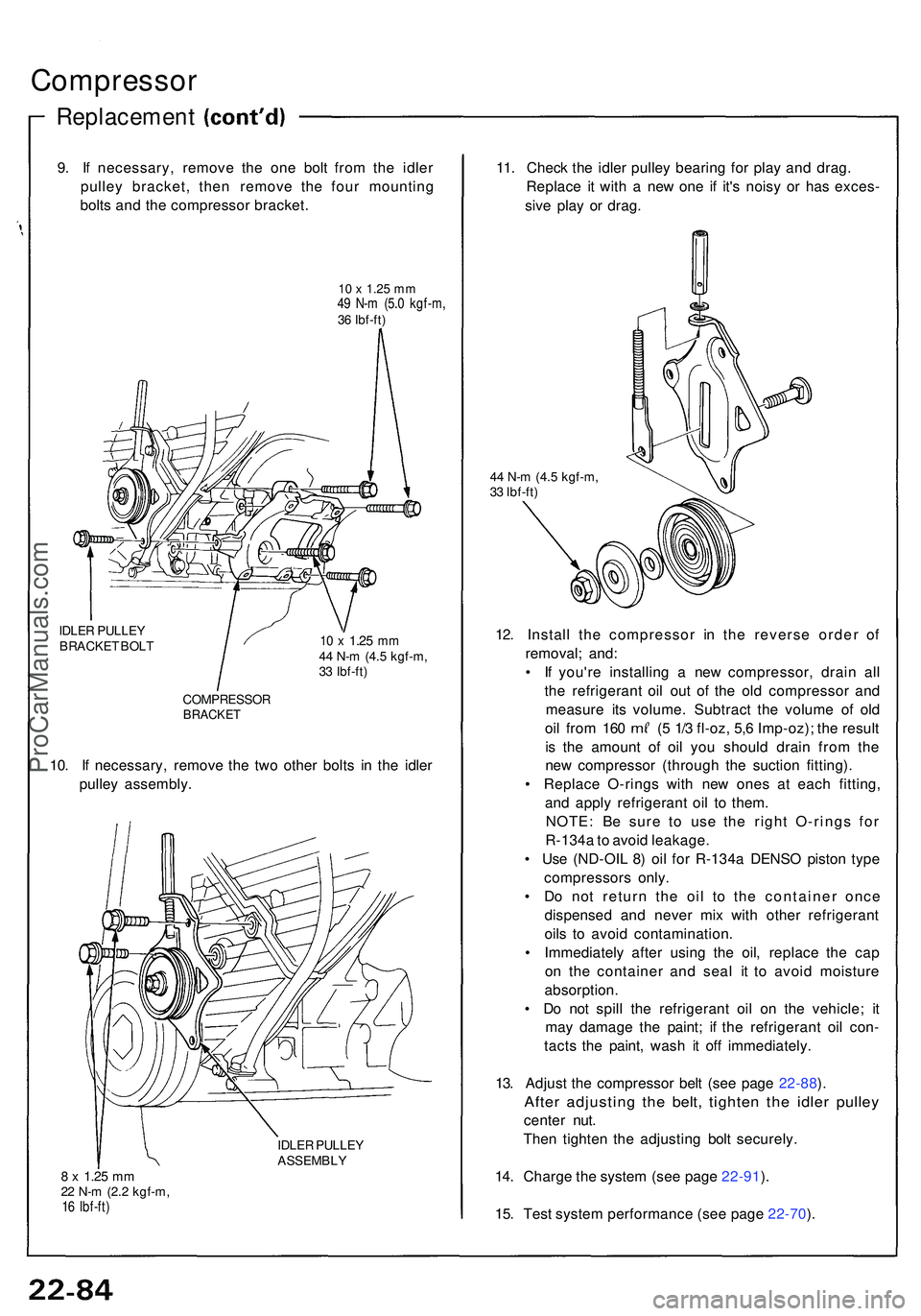

9. I f necessary , remov e th e on e bol t fro m th e idle r

pulle y bracket , the n remov e th e fou r mountin g

bolt s an d th e compresso r bracket .

10 x 1.25 mm49 N- m (5. 0 kgf-m ,36 Ibf-ft )

IDLE R PULLE Y

BRACKE T BOL T

10 x 1.2 5 mm44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

COMPRESSO R

BRACKET

10. I f necessary , remov e th e tw o othe r bolt s i n th e idle r

pulle y assembly .

IDLER PULLE Y

ASSEMBL Y

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,16 Ibf-ft )

11. Chec k th e idle r pulle y bearin g fo r pla y an d drag .

Replac e i t wit h a ne w on e i f it' s nois y o r ha s exces -

siv e pla y o r drag .

44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

12. Instal l th e compresso r i n th e revers e orde r o f

removal ; and :

• I f you'r e installin g a ne w compressor , drai n al l

th e refrigeran t oi l ou t o f th e ol d compresso r an d

measur e it s volume . Subtrac t th e volum e o f ol d

oil fro m 16 0 ( 5 1/ 3 fl-oz , 5, 6 Imp-oz) ; th e resul t

i s th e amoun t o f oi l yo u shoul d drai n fro m th e

ne w compresso r (throug h th e suctio n fitting) .

• Replac e O-ring s wit h ne w one s a t eac h fitting ,

an d appl y refrigeran t oi l t o them .

NOTE : B e sur e t o us e th e righ t O-ring s fo r

R-134 a to avoi d leakage .

• Us e (ND-OI L 8 ) oi l fo r R-134 a DENS O pisto n typ e

compressor s only .

• D o no t retur n th e oi l t o th e containe r onc e

dispense d an d neve r mi x wit h othe r refrigeran t

oil s t o avoi d contamination .

• Immediatel y afte r usin g th e oil, replac e th e ca p

o n th e containe r an d sea l i t t o avoi d moistur e

absorption .

• D o no t spil l th e refrigeran t oi l o n th e vehicle ; i t

ma y damag e th e paint ; i f th e refrigeran t oi l con -

tact s th e paint , was h i t of f immediately .

13 . Adjus t th e compresso r bel t (se e pag e 22-88 ).

Afte r adjustin g th e belt , tighte n th e idle r pulle y

center nut .

The n tighte n th e adjustin g bol t securely .

14 . Charg e th e syste m (se e pag e 22-91 ).

15 . Tes t syste m performanc e (se e pag e 22-70 ).

ProCarManuals.com

Page 1222 of 1503

Clutch Inspectio n

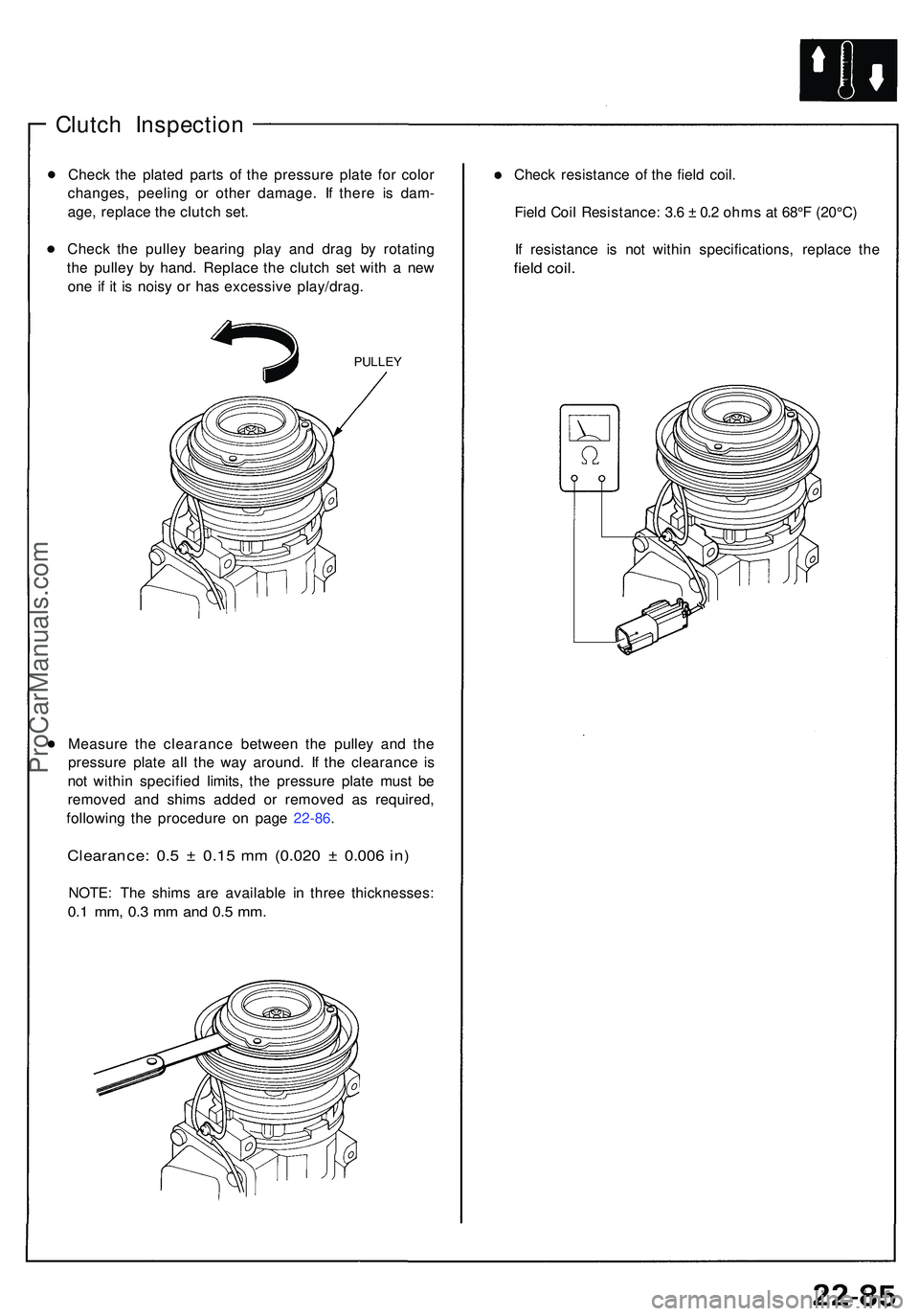

Check th e plate d part s o f th e pressur e plat e fo r colo r

changes , peelin g o r othe r damage . I f ther e i s dam -

age , replac e th e clutc h set .

Chec k th e pulle y bearin g pla y an d dra g b y rotatin g

th e pulle y b y hand . Replac e th e clutc h se t wit h a ne w

on e i f i t i s nois y o r ha s excessiv e play/drag .

PULLEY

Measur e th e clearanc e betwee n th e pulle y an d th e

pressur e plat e al l th e wa y around . I f th e clearanc e i s

no t withi n specifie d limits , th e pressur e plat e mus t b e

remove d an d shim s adde d o r remove d a s required ,

followin g th e procedur e o n pag e 22-86 .

Clearance : 0. 5 ± 0.1 5 m m (0.02 0 ± 0.00 6 in )

NOTE : Th e shim s ar e availabl e i n thre e thicknesses :

0.1 mm , 0. 3 m m an d 0. 5 mm .

Chec k resistanc e o f th e fiel d coil .

Fiel d Coi l Resistance : 3. 6 ± 0. 2 ohm s a t 68° F (20°C )

I f resistanc e i s no t withi n specifications , replac e th e

field coil .

ProCarManuals.com

Page 1223 of 1503

Compressor

Clutch Overhau l

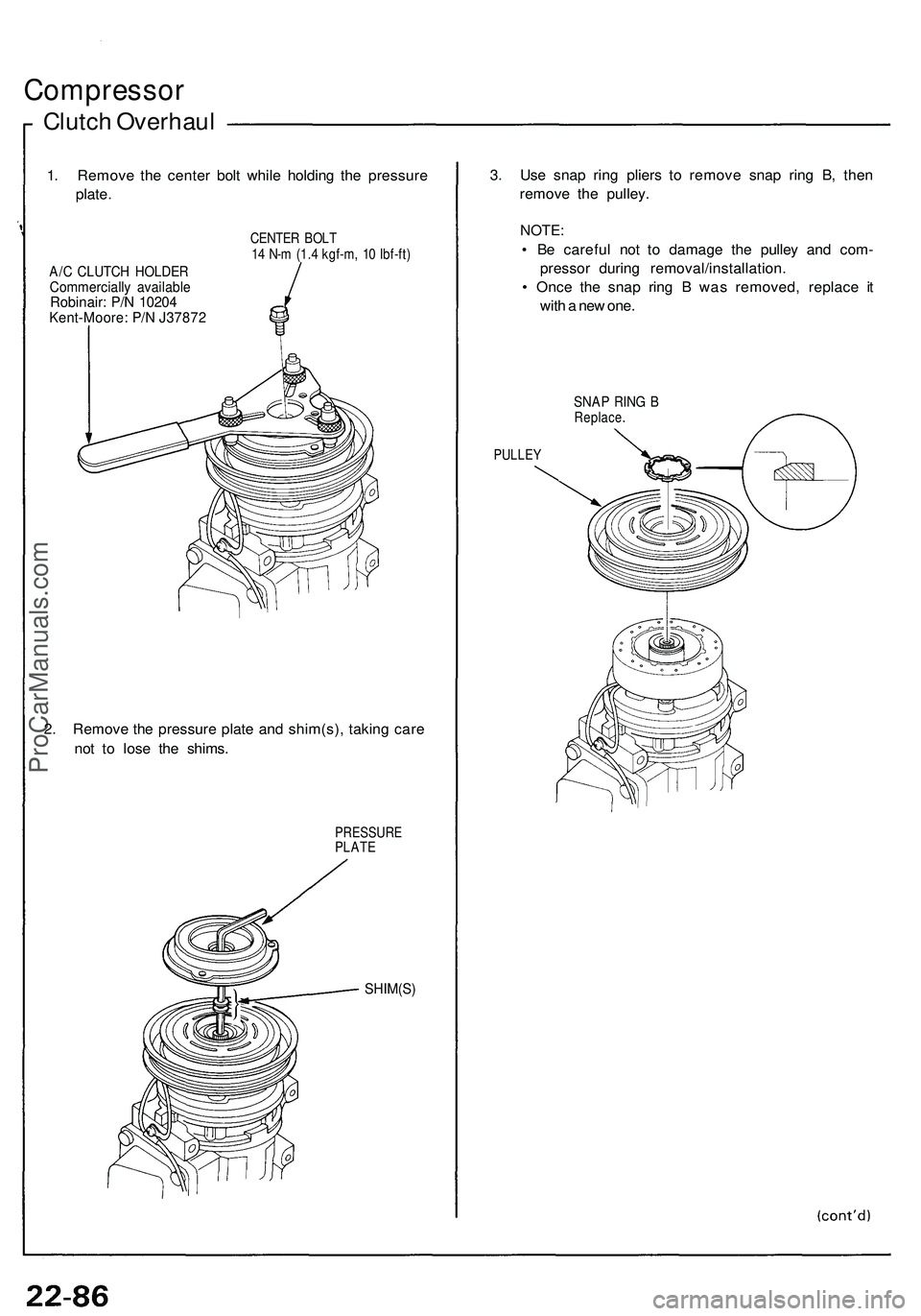

1. Remov e th e cente r bol t whil e holdin g th e pressur e

plate .

CENTE R BOL T14 N- m (1. 4 kgf-m , 1 0 Ibf-ft )

A/C CLUTC H HOLDE RCommerciall y availabl eRobinair: P/ N 1020 4Kent-Moore : P/ N J3787 2

2. Remov e th e pressur e plat e an d shim(s) , takin g car e

no t t o los e th e shims .

PRESSUR EPLATE

SHIM(S )

3. Us e sna p rin g plier s t o remov e sna p rin g B , the n

remov e th e pulley .

NOTE:

• B e carefu l no t t o damag e th e pulle y an d com -

presso r durin g removal/installation .

• Onc e th e sna p rin g B wa s removed , replac e i t

wit h a ne w one .

SNA P RIN G BReplace .

PULLEY

ProCarManuals.com

Page 1224 of 1503

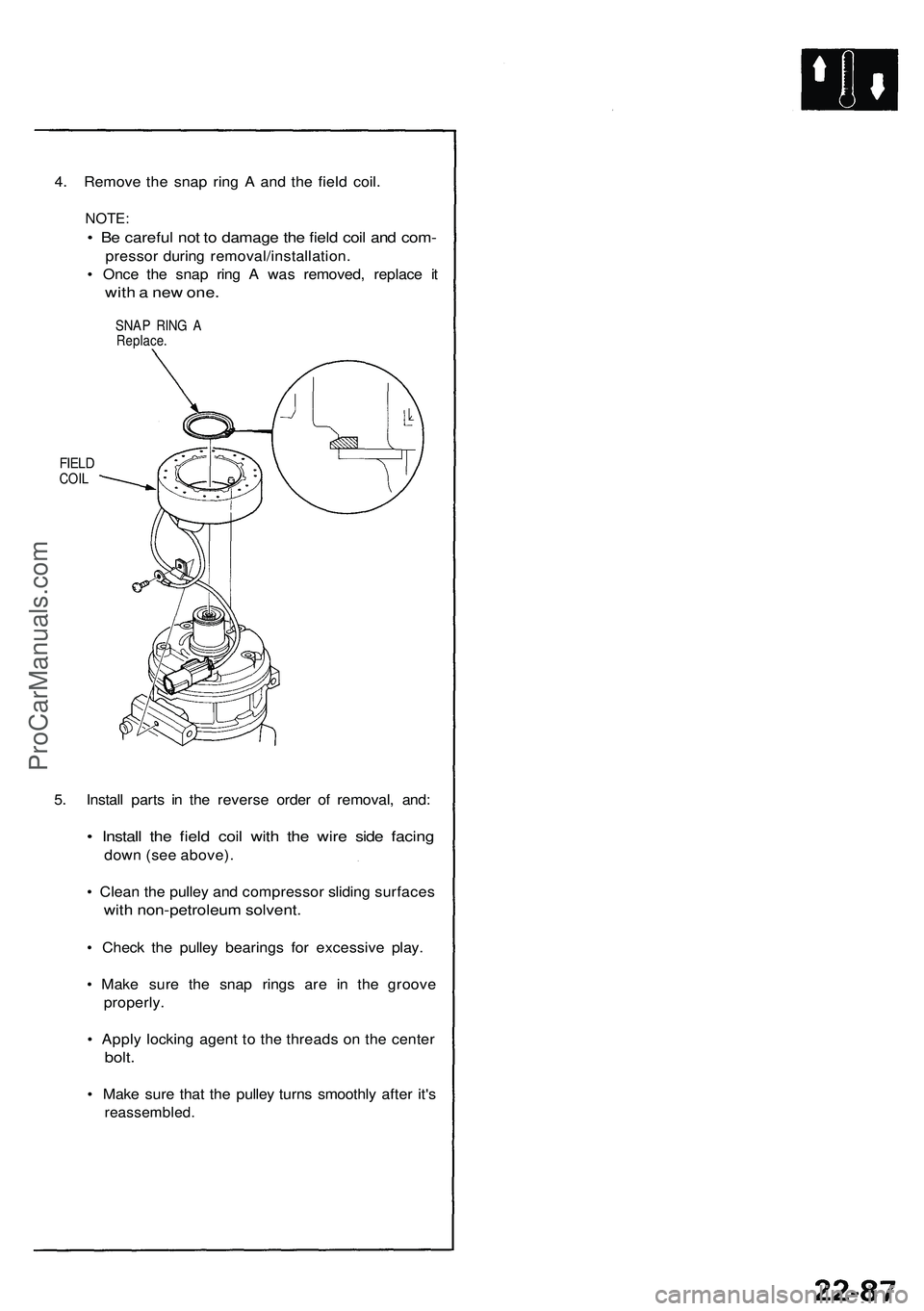

4. Remove the snap ring A and the field coil.

NOTE:

• Be careful not to damage the field coil and com-

pressor during removal/installation.

• Once the snap ring A was removed, replace it

with a new one.

SNAP RING A

Replace.

FIELD

COIL

5. Install parts in the reverse order of removal, and:

• Install the field coil with the wire side facing

down (see above).

• Clean the pulley and compressor sliding surfaces

with non-petroleum solvent.

• Check the pulley bearings for excessive play.

• Make sure the snap rings are in the groove

properly.

• Apply locking agent to the threads on the center

bolt.

• Make sure that the pulley turns smoothly after it's

reassembled.ProCarManuals.com

Page 1225 of 1503

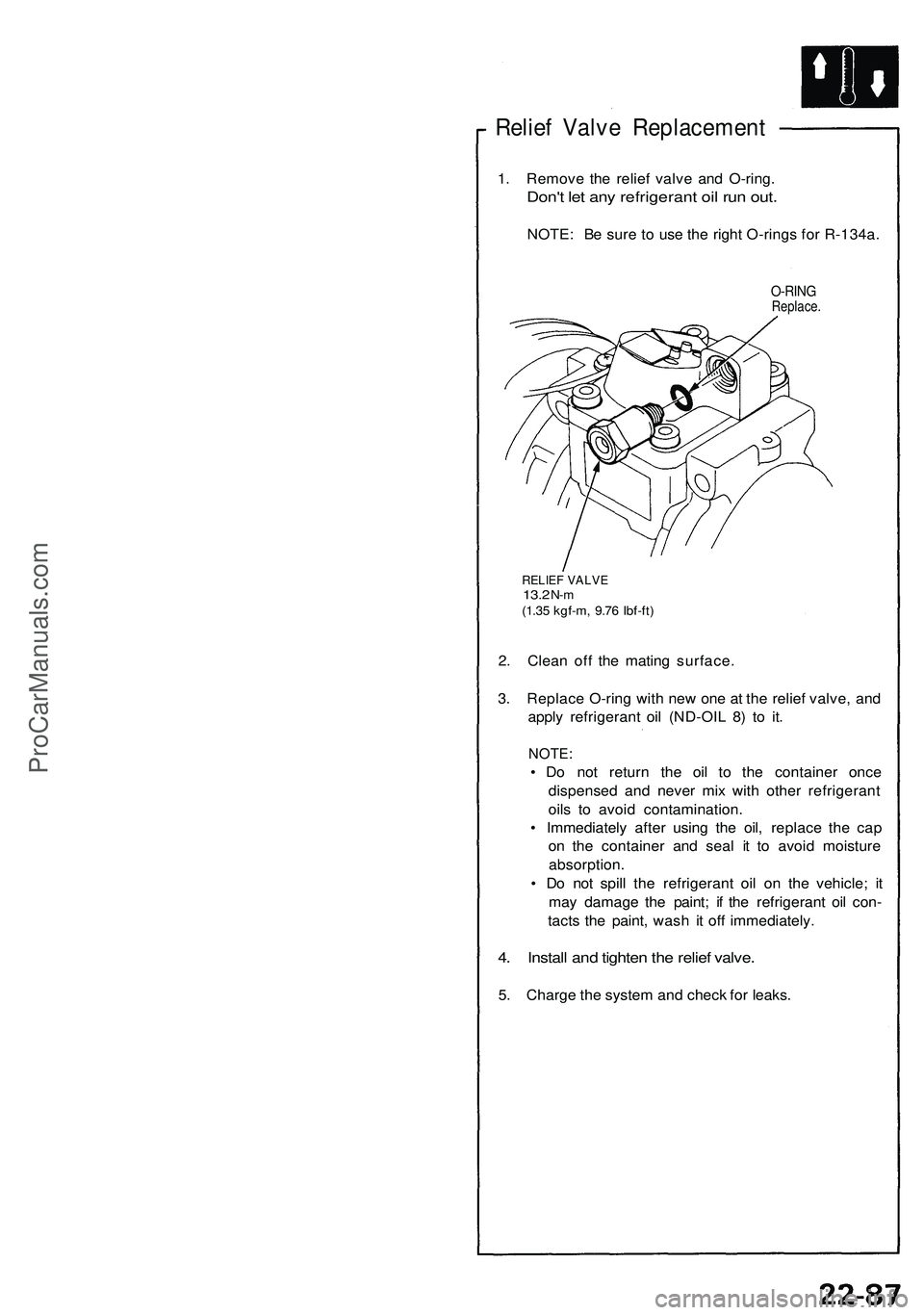

Relief Valve Replacement

1. Remove the relief valve and O-ring.

Don't let any refrigerant oil run out.

NOTE: Be sure to use the right O-rings for R-134a.

O-RING

Replace.

RELIEF VALVE

13.2

N-m

(1.35 kgf-m, 9.76 Ibf-ft)

2. Clean off the mating surface.

3. Replace O-ring with new one at the relief valve, and

apply refrigerant oil (ND-OIL 8) to it.

NOTE:

• Do not return the oil to the container once

dispensed and never mix with other refrigerant

oils to avoid contamination.

• Immediately after using the oil, replace the cap

on the container and seal it to avoid moisture

absorption.

• Do not spill the refrigerant oil on the vehicle; it

may damage the paint; if the refrigerant oil con-

tacts the paint, wash it off immediately.

4. Install and tighten the relief valve.

5. Charge the system and check for leaks.ProCarManuals.com

Page 1226 of 1503

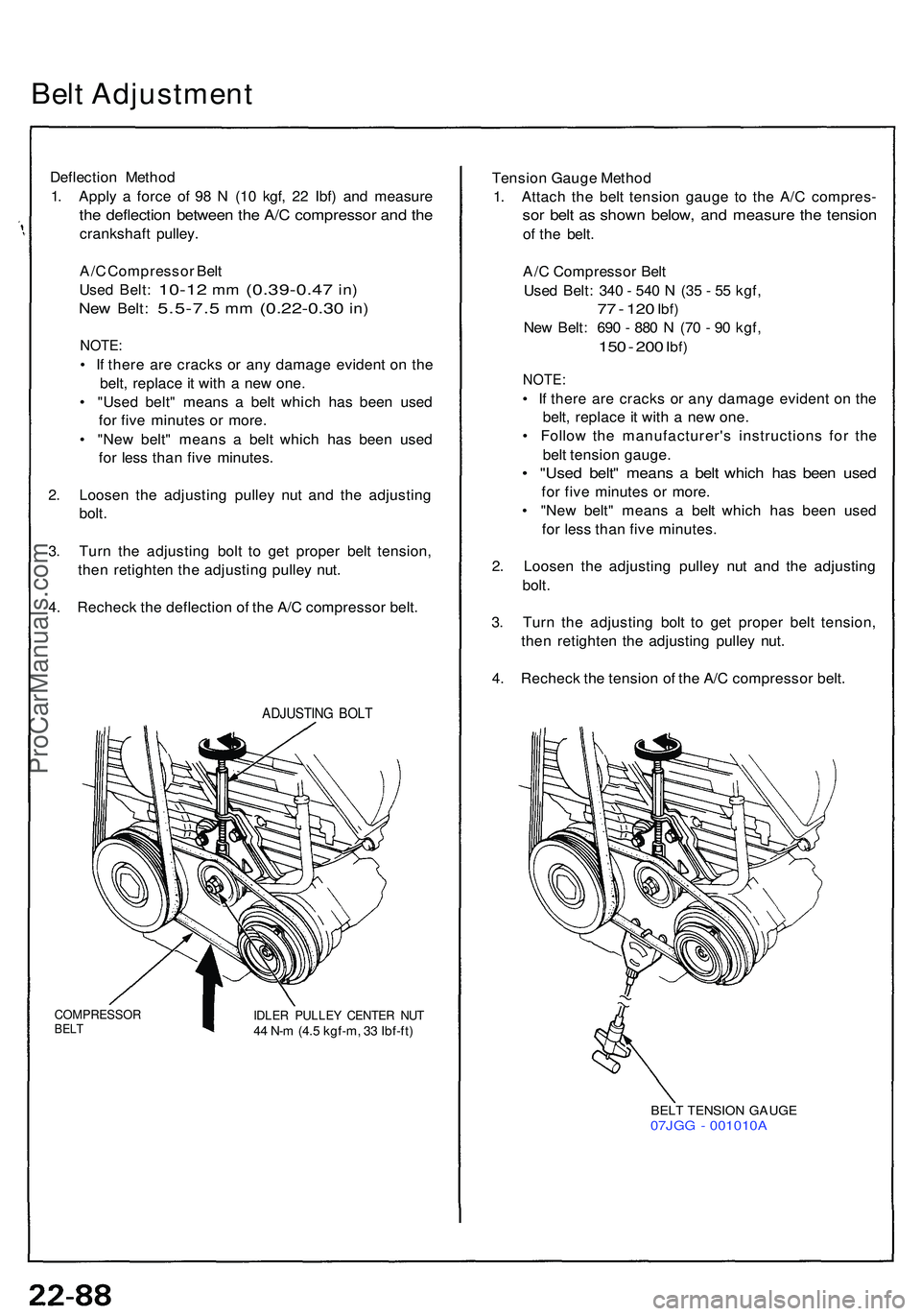

Belt Adjustmen t

Deflection Metho d

1 . Appl y a forc e o f 9 8 N (1 0 kgf , 2 2 Ibf ) an d measur e

the deflectio n betwee n th e A/ C compresso r an d th e

crankshaf t pulley .

A/ C Compresso r Bel t

Use d Belt :

10-1 2 mm (0.39-0.4 7 in)

Ne w Belt : 5.5-7. 5 mm (0.22-0.3 0 in)

NOTE :

• I f ther e ar e crack s o r an y damag e eviden t o n th e

belt , replac e it wit h a ne w one .

• "Use d belt " mean s a bel t whic h ha s bee n use d

fo r fiv e minute s o r more .

• "Ne w belt " mean s a bel t whic h ha s bee n use d

fo r les s tha n fiv e minutes .

2 . Loose n th e adjustin g pulle y nu t an d th e adjustin g

bolt .

3 . Tur n th e adjustin g bol t t o ge t prope r bel t tension ,

the n retighte n th e adjustin g pulle y nut .

4 . Rechec k th e deflectio n o f th e A/ C compresso r belt .

ADJUSTIN G BOL T

COMPRESSO RBELTIDLE R PULLE Y CENTE R NU T44 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

Tensio n Gaug e Metho d

1 . Attac h th e bel t tensio n gaug e t o th e A/ C compres -

sor bel t a s show n below , an d measur e th e tensio n

of th e belt .

A/ C Compresso r Bel t

Use d Belt : 34 0 - 54 0 N (3 5 - 5 5 kgf ,

77 - 12 0 Ibf )

New Belt : 69 0 - 88 0 N (7 0 - 9 0 kgf ,

150 - 20 0 Ibf )

NOTE :

• I f ther e ar e crack s o r an y damag e eviden t o n th e

belt , replac e it wit h a ne w one .

• Follo w th e manufacturer' s instruction s fo r th e

bel t tensio n gauge .

• "Use d belt " mean s a bel t whic h ha s bee n use d

for fiv e minute s o r more .

• "Ne w belt " mean s a bel t whic h ha s bee n use d

fo r les s tha n fiv e minutes .

2 . Loose n th e adjustin g pulle y nu t an d th e adjustin g

bolt .

3 . Tur n th e adjustin g bol t t o ge t prope r bel t tension ,

the n retighte n th e adjustin g pulle y nut .

4 . Rechec k th e tensio n o f th e A/ C compresso r belt .

BELT TENSIO N GAUG E07JGG - 001010 A

ProCarManuals.com

Page 1227 of 1503

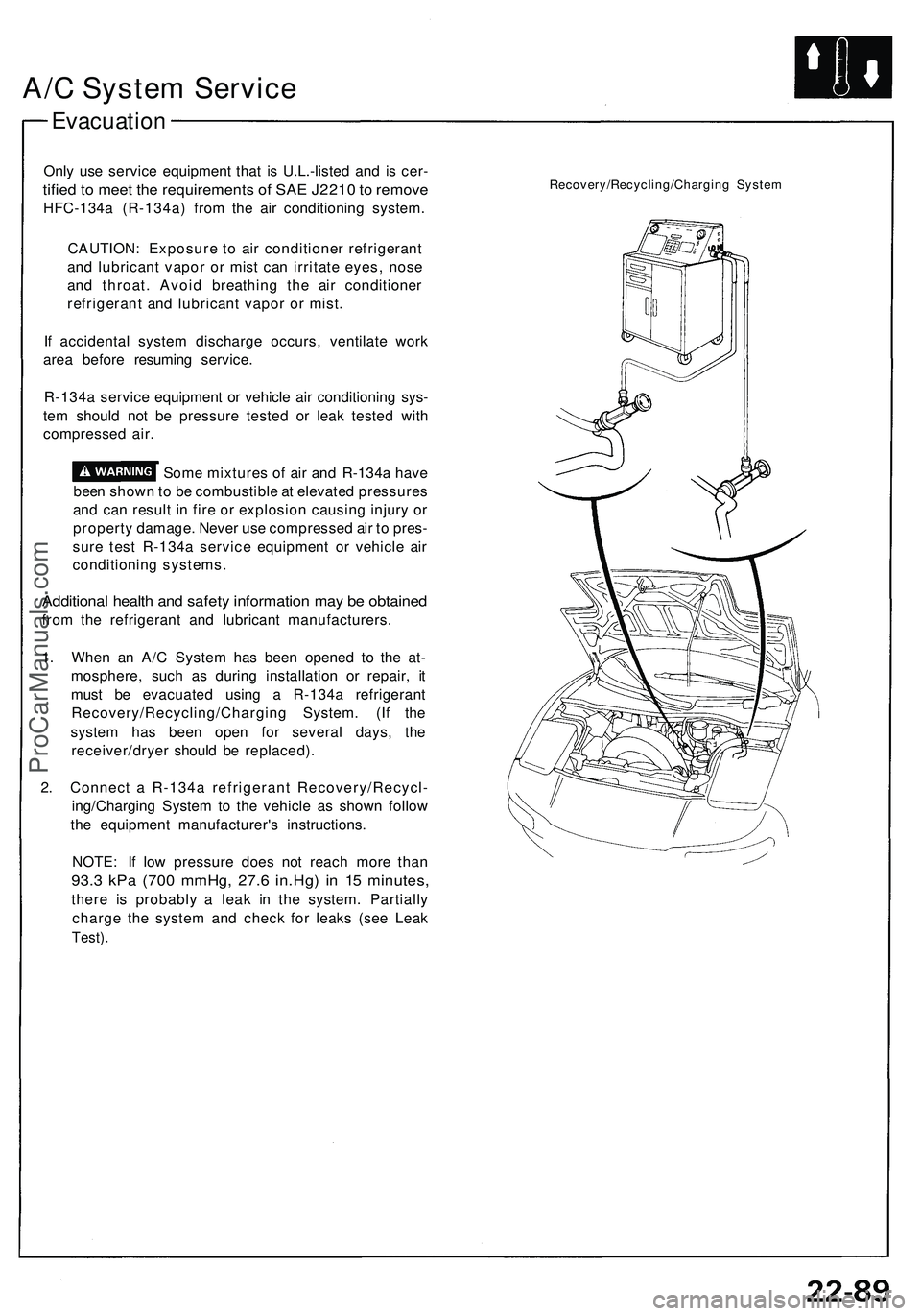

A/C System Service

Evacuation

Only use service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioning system.

CAUTION: Exposure to air conditioner refrigerant

and lubricant vapor or mist can irritate eyes, nose

and throat. Avoid breathing the air conditioner

refrigerant and lubricant vapor or mist.

If accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioning sys-

tem should not be pressure tested or leak tested with

compressed air.

Some mixtures of air and R-134a have

been shown to be combustible at elevated pressures

and can result in fire or explosion causing injury or

property damage. Never use compressed air to pres-

sure test R-134a service equipment or vehicle air

conditioning systems.

Additional health and safety information may be obtained

from the refrigerant and lubricant manufacturers.

1. When an A/C System has been opened to the at-

mosphere, such as during installation or repair, it

must be evacuated using a R-134a refrigerant

Recovery/Recycling/Charging System. (If the

system has been open for several days, the

receiver/dryer should be replaced).

2. Connect a R-134a refrigerant Recovery/Recycl-

ing/Charging System to the vehicle as shown follow

the equipment manufacturer's instructions.

NOTE: If low pressure does not reach more than

93.3 kPa (700 mmHg, 27.6 in.Hg) in 15 minutes,

there is probably a leak in the system. Partially

charge the system and check for leaks (see Leak

Test).

Recovery/Recycling/Charging SystemProCarManuals.com

Page 1228 of 1503

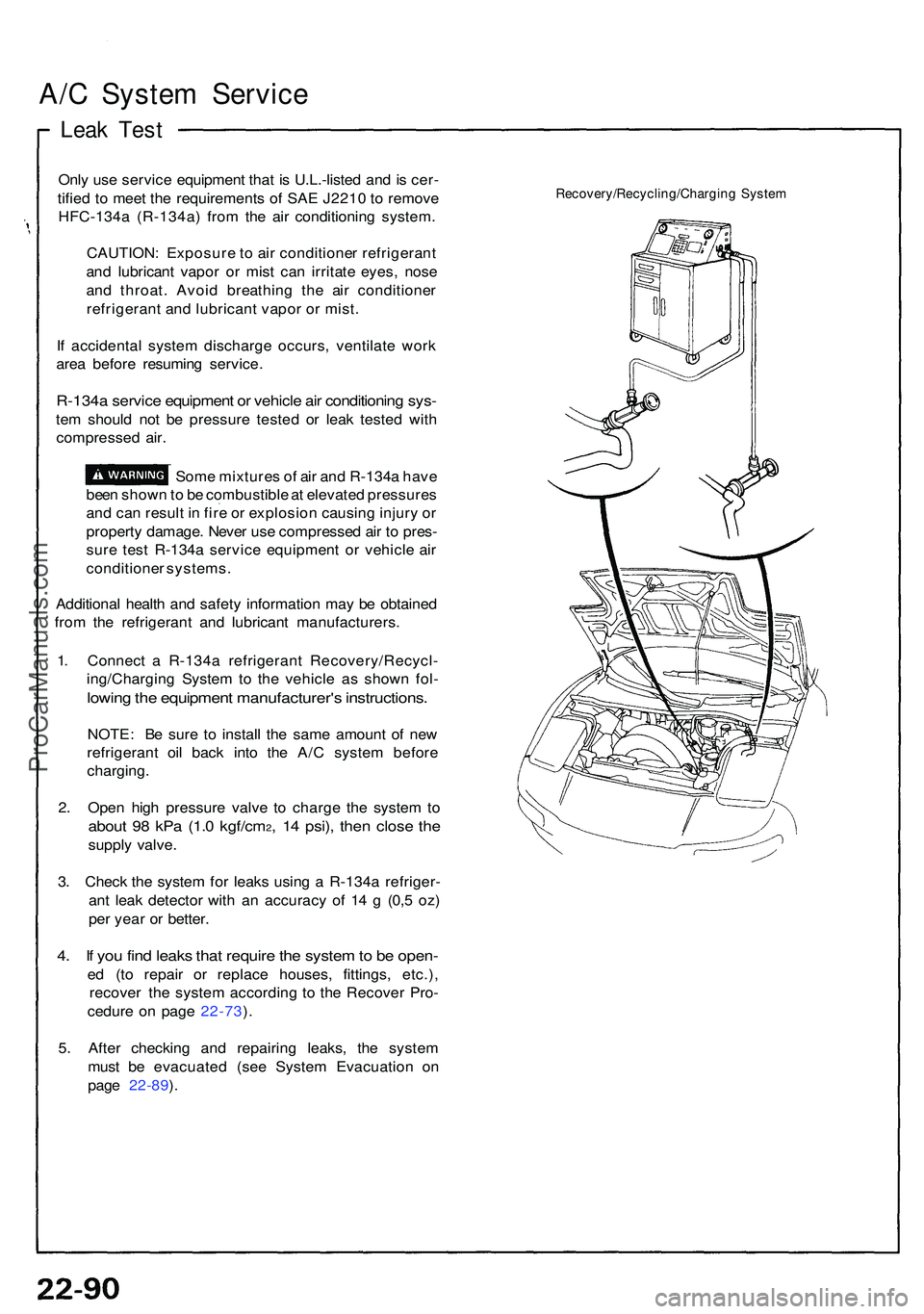

A/C Syste m Servic e

Leak Tes t

Only us e servic e equipmen t tha t i s U.L.-liste d an d is cer -

tifie d t o mee t th e requirement s o f SA E J221 0 t o remov e

HFC-134 a (R-134a ) fro m th e ai r conditionin g system .

CAUTION : Exposur e t o ai r conditione r refrigeran t

an d lubrican t vapo r o r mis t ca n irritat e eyes , nos e

an d throat . Avoi d breathin g th e ai r conditione r

refrigeran t an d lubrican t vapo r o r mist .

I f accidenta l syste m discharg e occurs , ventilat e wor k

are a befor e resumin g service .

R-134a servic e equipmen t o r vehicl e ai r conditionin g sys -

tem shoul d no t b e pressur e teste d o r lea k teste d wit h

compresse d air .

Som e mixture s o f ai r an d R-134 a hav e

bee n show n to b e combustibl e a t elevate d pressure s

an d ca n resul t i n fir e o r explosio n causin g injur y o r

propert y damage . Neve r us e compresse d ai r t o pres -

sur e tes t R-134 a servic e equipmen t o r vehicl e ai r

conditione r systems.

Additiona l healt h an d safet y informatio n ma y b e obtaine d

fro m th e refrigeran t an d lubrican t manufacturers .

1 . Connec t a R-134 a refrigeran t Recovery/Recycl -

ing/Chargin g Syste m to th e vehicl e a s show n fol -

lowin g th e equipmen t manufacturer' s instructions .

NOTE: B e sur e t o instal l th e sam e amoun t o f ne w

refrigeran t oi l bac k int o th e A/ C syste m befor e

charging .

2 . Ope n hig h pressur e valv e t o charg e th e syste m to

abou t 9 8 kP a (1. 0 kgf/cm2, 1 4 psi) , the n clos e th e

suppl y valve .

3 . Chec k th e syste m fo r leak s usin g a R-134 a refriger -

an t lea k detecto r wit h a n accurac y o f 1 4 g (0, 5 oz )

pe r yea r o r better .

4. I f yo u fin d leak s tha t requir e th e syste m to b e open -

ed (t o repai r o r replac e houses , fittings , etc.) ,

recove r th e syste m accordin g t o th e Recove r Pro -

cedur e o n pag e 22-73 ).

5 . Afte r checkin g an d repairin g leaks , th e syste m

mus t b e evacuate d (se e Syste m Evacuatio n o n

pag e 22-89 ).

Recovery/Recycling/Chargin g Syste m

ProCarManuals.com

Page 1229 of 1503

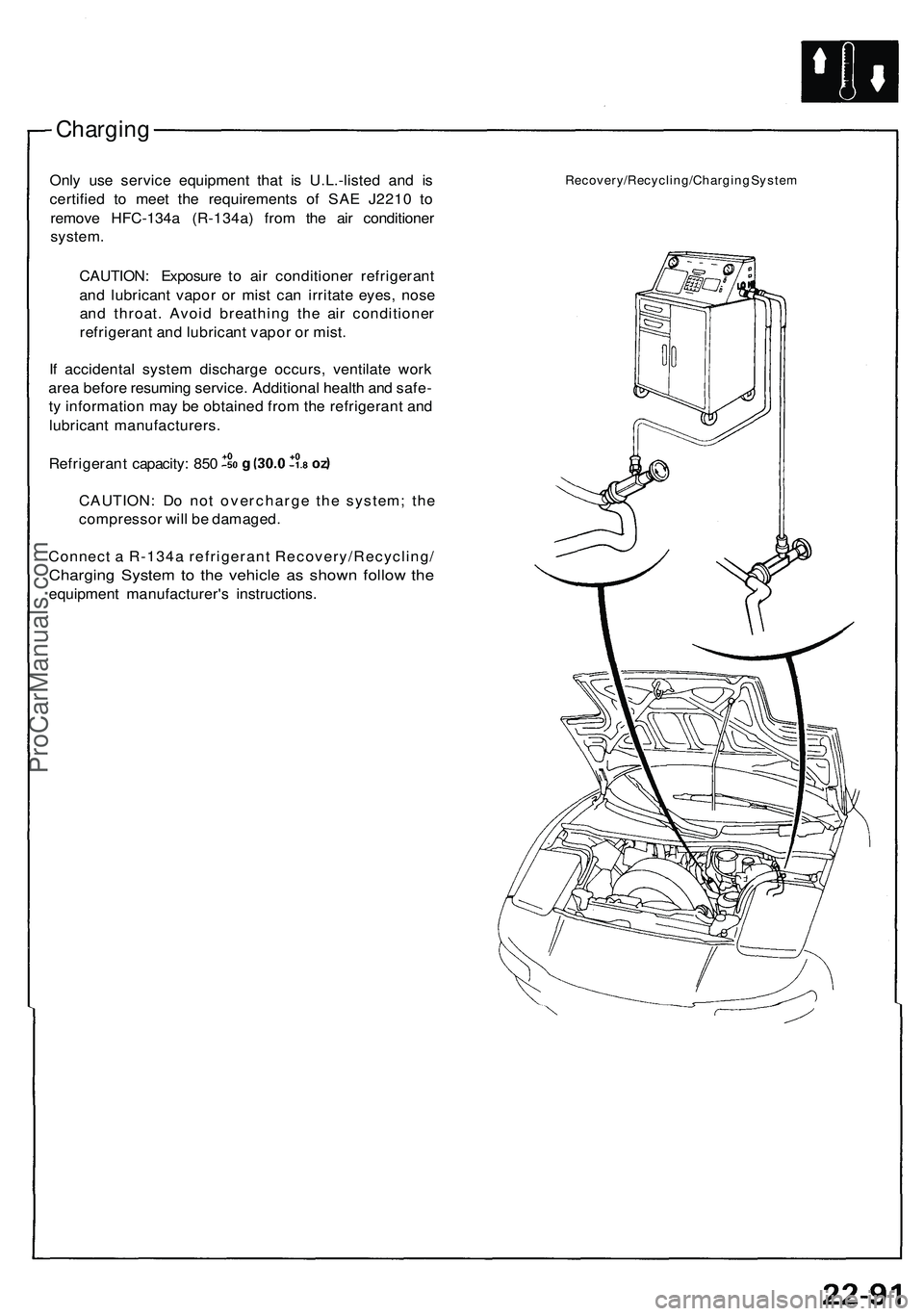

Charging

Only use service equipment that is U.L.-listed and is

certified to meet the requirements of SAE J2210 to

remove HFC-134a (R-134a) from the air conditioner

system.

CAUTION: Exposure to air conditioner refrigerant

and lubricant vapor or mist can irritate eyes, nose

and throat. Avoid breathing the air conditioner

refrigerant and lubricant vapor or mist.

If accidental system discharge occurs, ventilate work

area before resuming service. Additional health and safe-

ty information may be obtained from the refrigerant and

lubricant manufacturers.

Refrigerant capacity: 850

CAUTION: Do not overcharge the system; the

compressor will be damaged.

Connect a R-134a refrigerant Recovery/Recycling/

Charging System to the vehicle as shown follow the

equipment manufacturer's instructions.

Recovery/Recycling/Charging SystemProCarManuals.com

Page 1230 of 1503

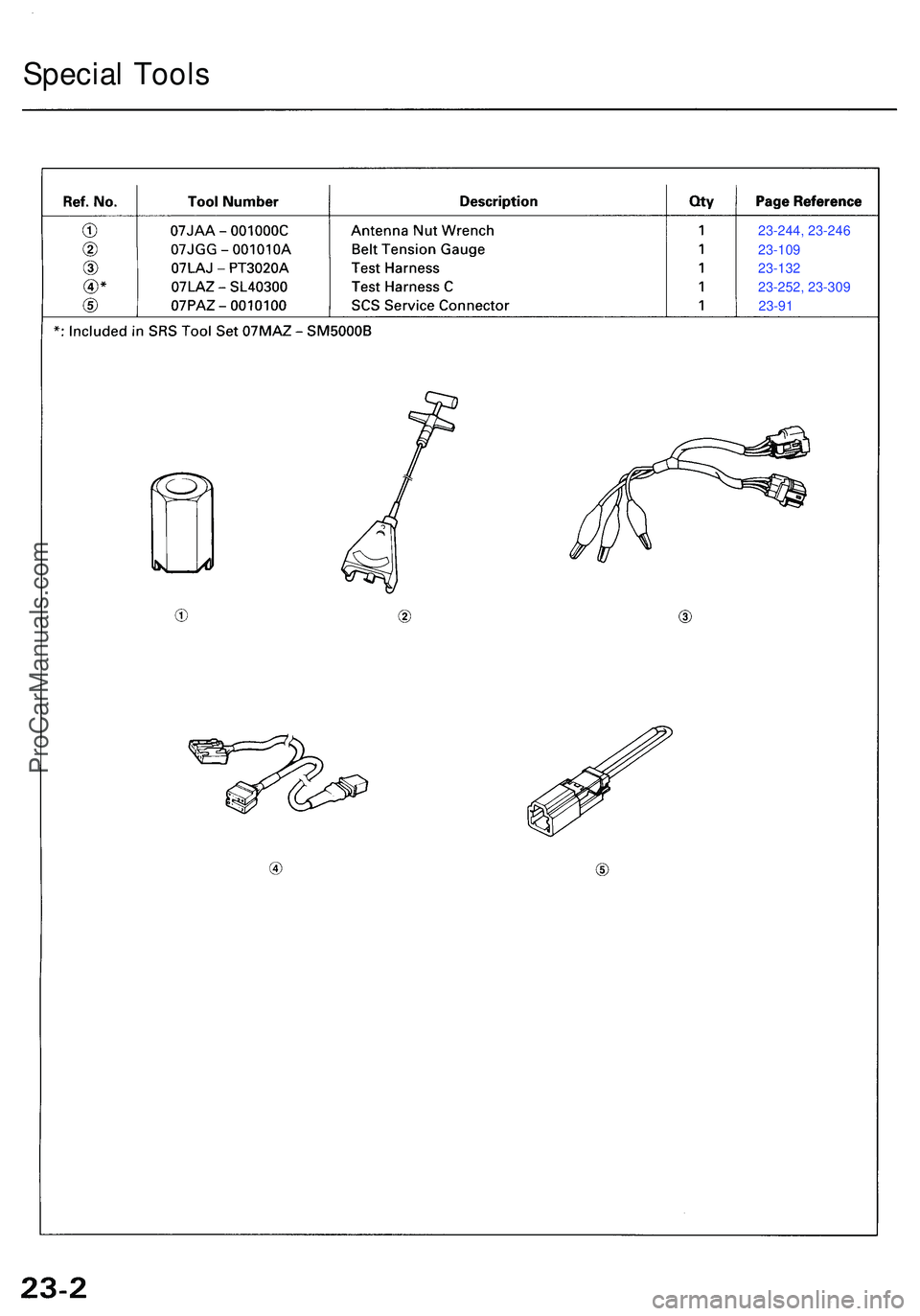

Special Tool s

23-244, 23-246

23-109

23-132

23-252, 23-309

23-91

ProCarManuals.com