ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 1271 of 1503

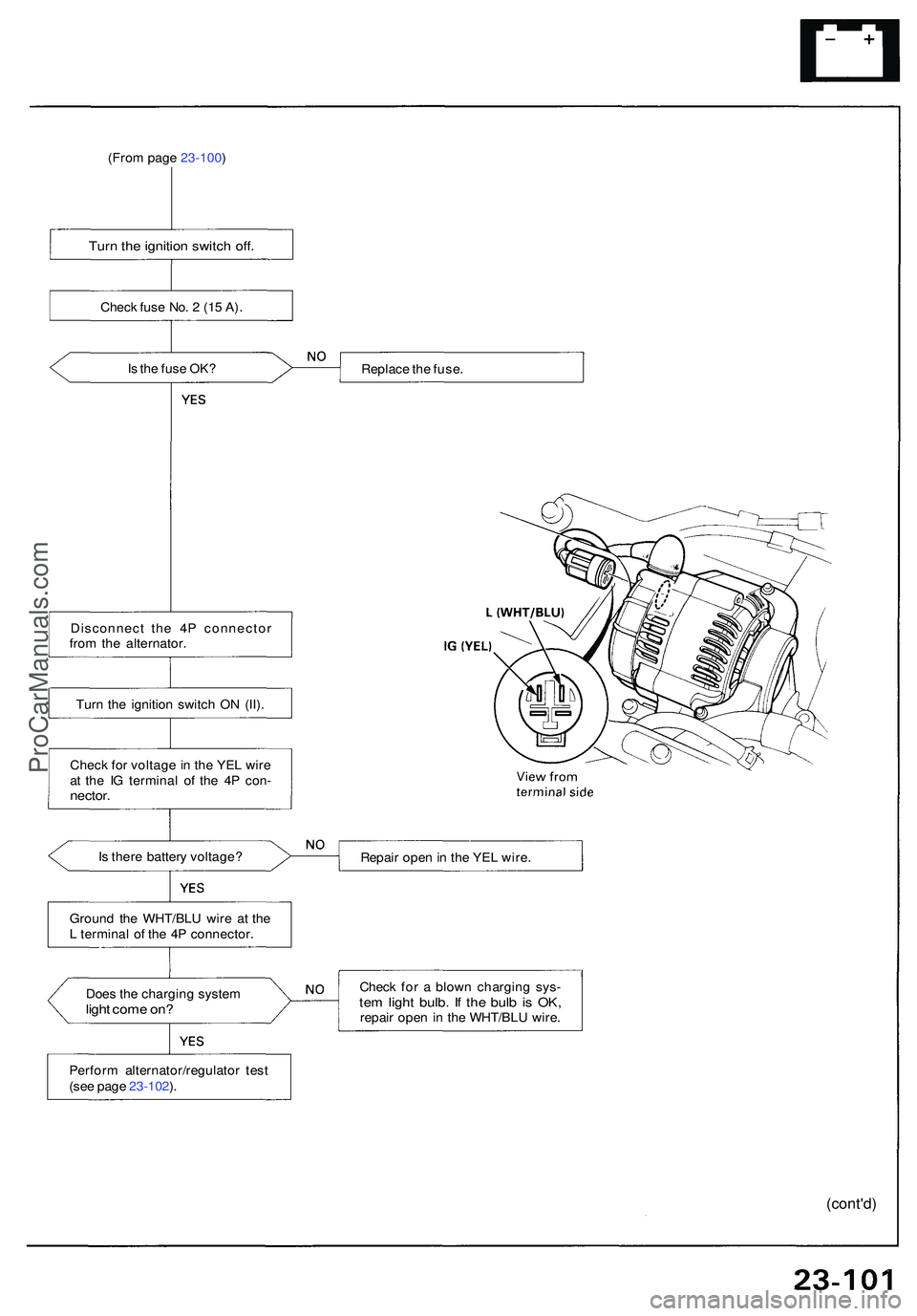

(From page 23-100 )

I s th e fus e OK ?

Disconnec t th e 4 P connecto r

fro m th e alternator .

Tur n th e ignitio n switc h O N (II) .

Chec k fo r voltag e in th e YE L wir e

a t th e I G termina l o f th e 4 P con -

nector .

Is ther e batter y voltage ?

Groun d th e WHT/BL U wir e a t th e

L termina l o f th e 4 P connector .

Doe s th e chargin g syste m

light com e on ?

Perfor m alternator/regulato r tes t

(se e pag e 23-102 ). Replac

e th e fuse .

Repai r ope n in th e YE L wire .

Chec k fo r a blow n chargin g sys -

tem ligh t bulb . I f th e bul b is OK ,repai r ope n in th e WHT/BL U wire .

(cont'd )

Turn th e ignitio n switc h off .

Chec k fus e No . 2 (1 5 A) .

ProCarManuals.com

Page 1272 of 1503

Charging System

Troubleshooting (cont'd)

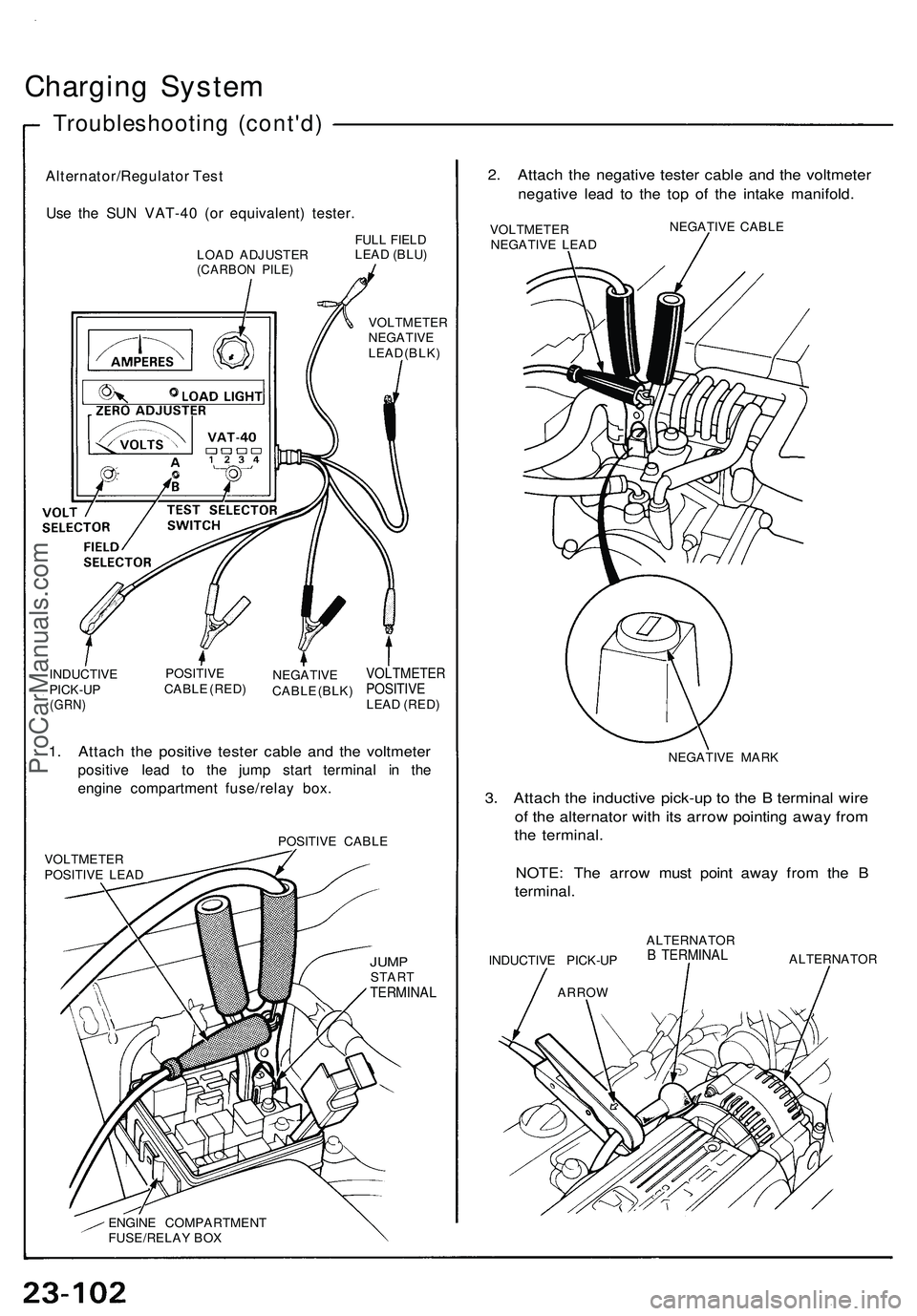

Alternator/Regulator Test

Use the SUN VAT-40 (or equivalent) tester.

LOAD ADJUSTER

(CARBON PILE)

FULL FIELD

LEAD (BLU)

VOLTMETER

NEGATIVE

LEAD (BLK)

INDUCTIVE

PICK-UP

(GRN)

POSITIVE

CABLE (RED)

NEGATIVE

CABLE (BLK)

VOLTMETER

POSITIVE

LEAD (RED)

1. Attach the positive tester cable and the voltmeter

positive lead to the jump start terminal in the

engine compartment fuse/relay box.

POSITIVE CABLE

VOLTMETER

POSITIVE LEAD

JUMP

START

TERMINAL

ENGINE COMPARTMENT

FUSE/RELAY BOX

2. Attach the negative tester cable and the voltmeter

negative lead to the top of the intake manifold.

VOLTMETER

NEGATIVE LEAD

NEGATIVE CABLE

NEGATIVE MARK

3. Attach the inductive pick-up to the B terminal wire

of the alternator with its arrow pointing away from

the terminal.

NOTE: The arrow must point away from the B

terminal.

INDUCTIVE PICK-UP

ARROW

ALTERNATOR

B TERMINAL

ALTERNATORProCarManuals.com

Page 1273 of 1503

NOTE: B e sur e th e batter y i s sufficientl y charge d (se e

page 23-68 ).

Connec t th e Su n VAT-4 0 (se e

pag e 23-102 ) an d tur n th e selec -

to r switc h to positio n 1 (starting) .

Star t th e engine , an d le t i t idl e

unti l i t reache s norma l operatin g

temperature .

Rais e th e engin e spee d t o 2,00 0

rpm , an d hol d i t there .

I s th e voltag e ove r 15. 1 V ?

Replace th e voltag e regulator .

Releas e th e accelerato r pedal ,

an d le t th e engin e idle .

Mak e sur e al l accessorie s ar e

turne d off . Tur n th e selecto r

switch to positio n 2 (charging) .

Remove th e inductiv e pick-up ,

an d zer o th e ammeter .

Attac h th e inductiv e pick-u p t o

th e B termina l wir e o f th e alterna -tor wit h it s arro w pointin g awa y

fro m th e terminal .

Rais e th e engin e spee d t o 2,00 0

rpm , an d hol d it there .

I s th e voltag e les s tha n 13. 9 V ?

Test th e batter y (se e pag e 23-68 ).

(T o page 23-104 )

(cont'd)

ProCarManuals.com

Page 1274 of 1503

Charging Syste m

Troubleshootin g (cont'd )

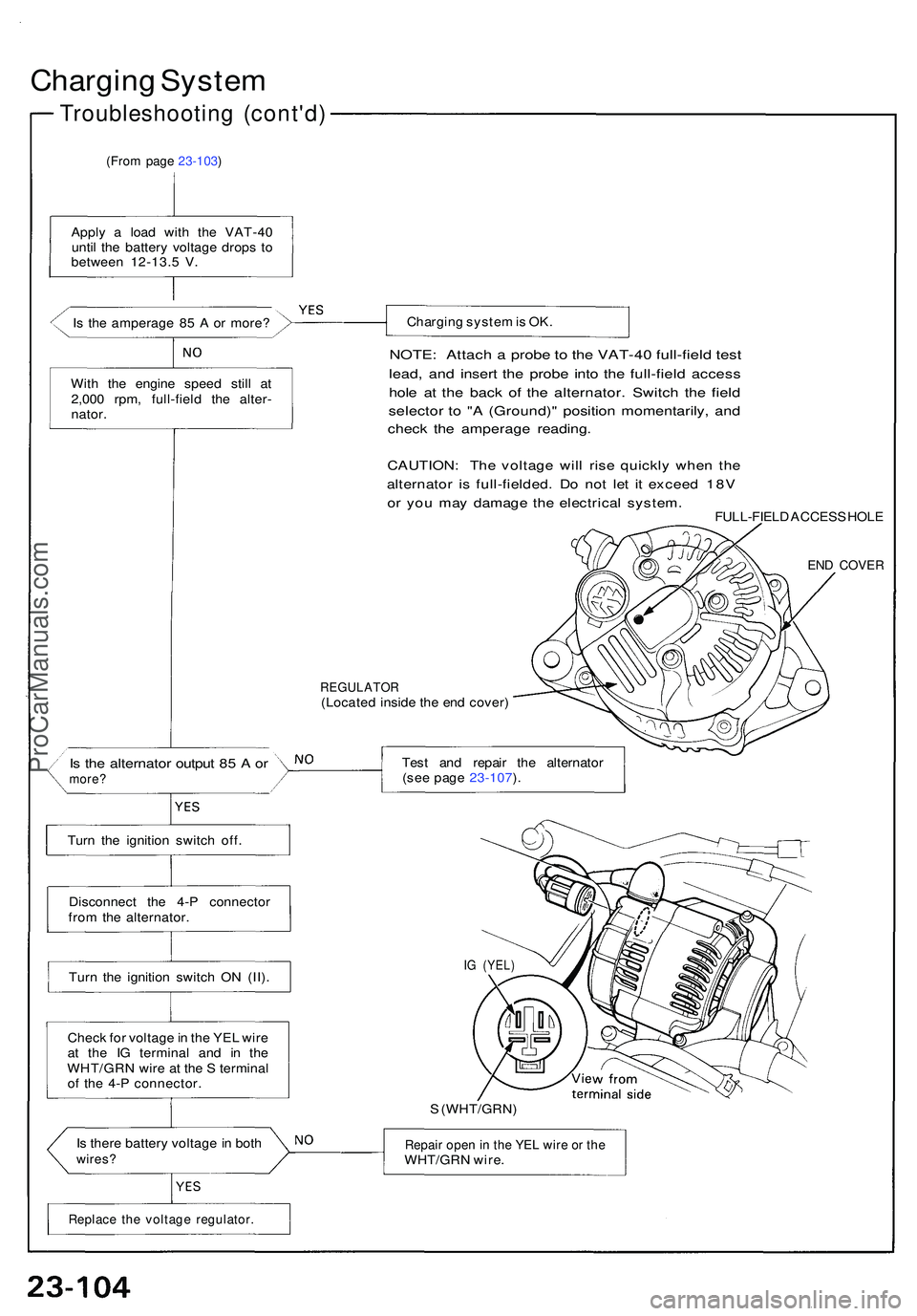

(From page 23-103 )

Apply a loa d wit h th e VAT-4 0

unti l th e batter y voltag e drop s t o

betwee n 12-13. 5 V .

I s th e amperag e 8 5 A or more ?

Wit h th e engin e spee d stil l a t

2,00 0 rpm , full-fiel d th e alter -

nator .

Tur n th e ignitio n switc h off .

Disconnec t th e 4- P connecto r

fro m th e alternator .

Tur n th e ignitio n switc h O N (II) .

Chec k fo r voltag e in th e YE L wir e

a t th e I G termina l an d i n th e

WHT/GR N wir e a t th e S termina l

o f th e 4- P connector .

I s ther e batter y voltag e in bot h

wires ?

Chargin g syste m is OK .

NOTE : Attac h a prob e to th e VAT-4 0 full-fiel d tes t

lead , an d inser t th e prob e int o th e full-fiel d acces s

hole a t th e bac k o f th e alternator . Switc h th e fiel d

selecto r t o " A (Ground) " positio n momentarily , an d

chec k th e amperag e reading .

CAUTION : Th e voltag e wil l ris e quickl y whe n th e

alternato r i s full-fielded . D o no t le t i t excee d 18 V

or yo u ma y damag e th e electrica l system .FULL-FIEL D ACCES S HOL E

END COVE R

REGULATO R(Located insid e th e en d cover )

Tes t an d repai r th e alternato r

(se e pag e 23-107 ).

IG (YEL )

S (WHT/GRN )

Repair ope n in th e YE L wir e o r th eWHT/GR N wire .

Is th e alternato r outpu t 8 5 A ormore ?

Replac e th e voltag e regulator .

ProCarManuals.com

Page 1275 of 1503

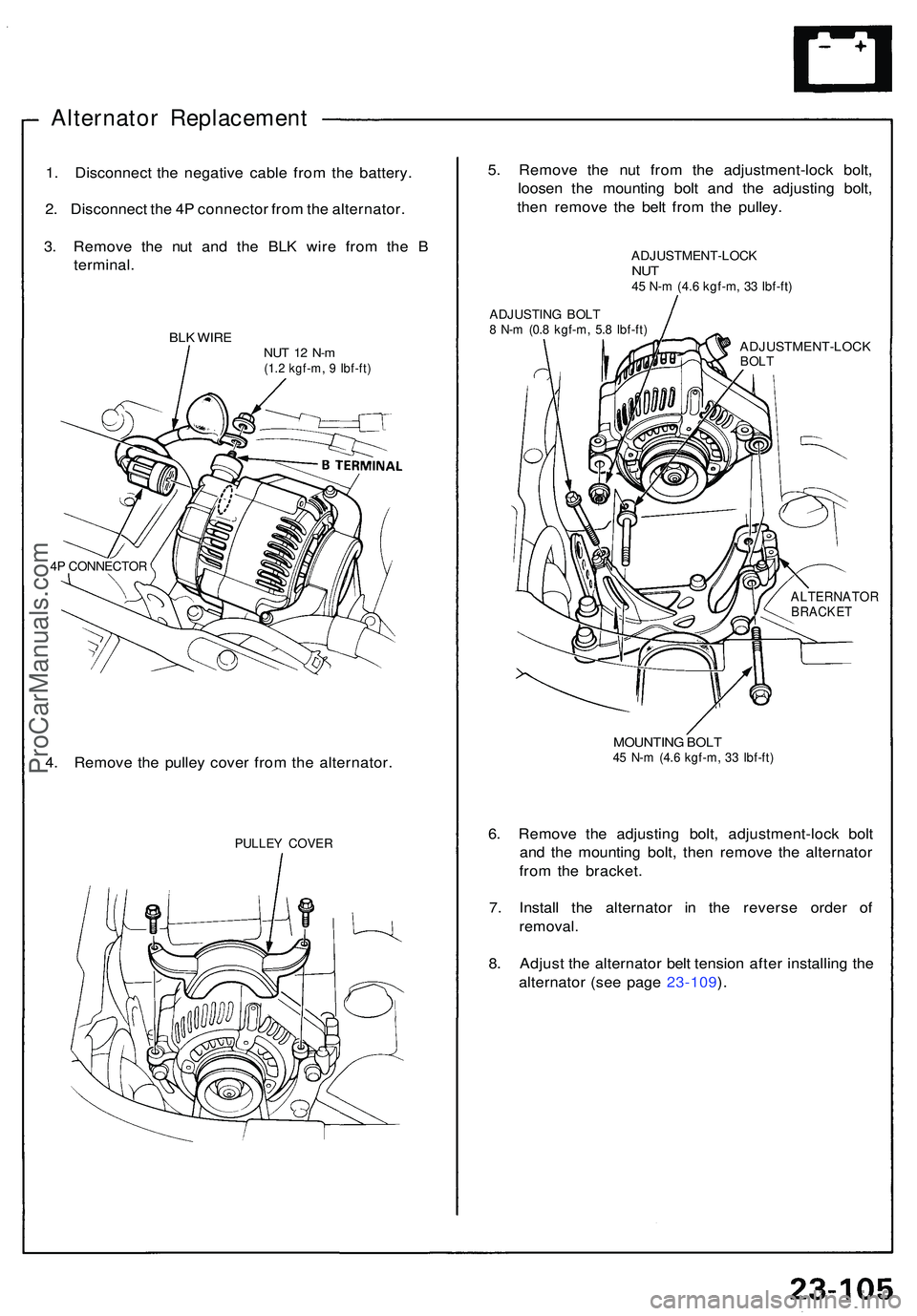

Alternator Replacemen t

1. Disconnec t th e negativ e cabl e fro m th e battery .

2 . Disconnec t th e 4 P connecto r fro m th e alternator .

3 . Remov e th e nu t an d th e BL K wir e fro m th e B

terminal .

BLK WIR ENUT 1 2 N- m(1.2 kgf-m , 9 Ibf-ft )

4P CONNECTO R

4. Remov e th e pulle y cove r fro m th e alternator .

PULLEY COVE R

5. Remov e th e nu t fro m th e adjustment-loc k bolt ,

loose n th e mountin g bol t an d th e adjustin g bolt ,

the n remov e th e bel t fro m th e pulley .

ADJUSTMENT-LOC KNUT45 N- m (4. 6 kgf-m , 3 3 Ibf-ft )

ADJUSTIN G BOL T8 N- m (0. 8 kgf-m , 5. 8 Ibf-ft )

ADJUSTMENT-LOC KBOLT

ALTERNATO RBRACKET

MOUNTIN G BOL T45 N- m (4. 6 kgf-m , 3 3 Ibf-ft )

6. Remov e th e adjustin g bolt , adjustment-loc k bol t

an d th e mountin g bolt , the n remov e th e alternato r

fro m th e bracket .

7 . Instal l th e alternato r i n th e revers e orde r o f

removal .

8. Adjus t th e alternato r bel t tensio n afte r installin g th e

alternato r (se e pag e 23-109 ).

ProCarManuals.com

Page 1276 of 1503

Charging Syste m

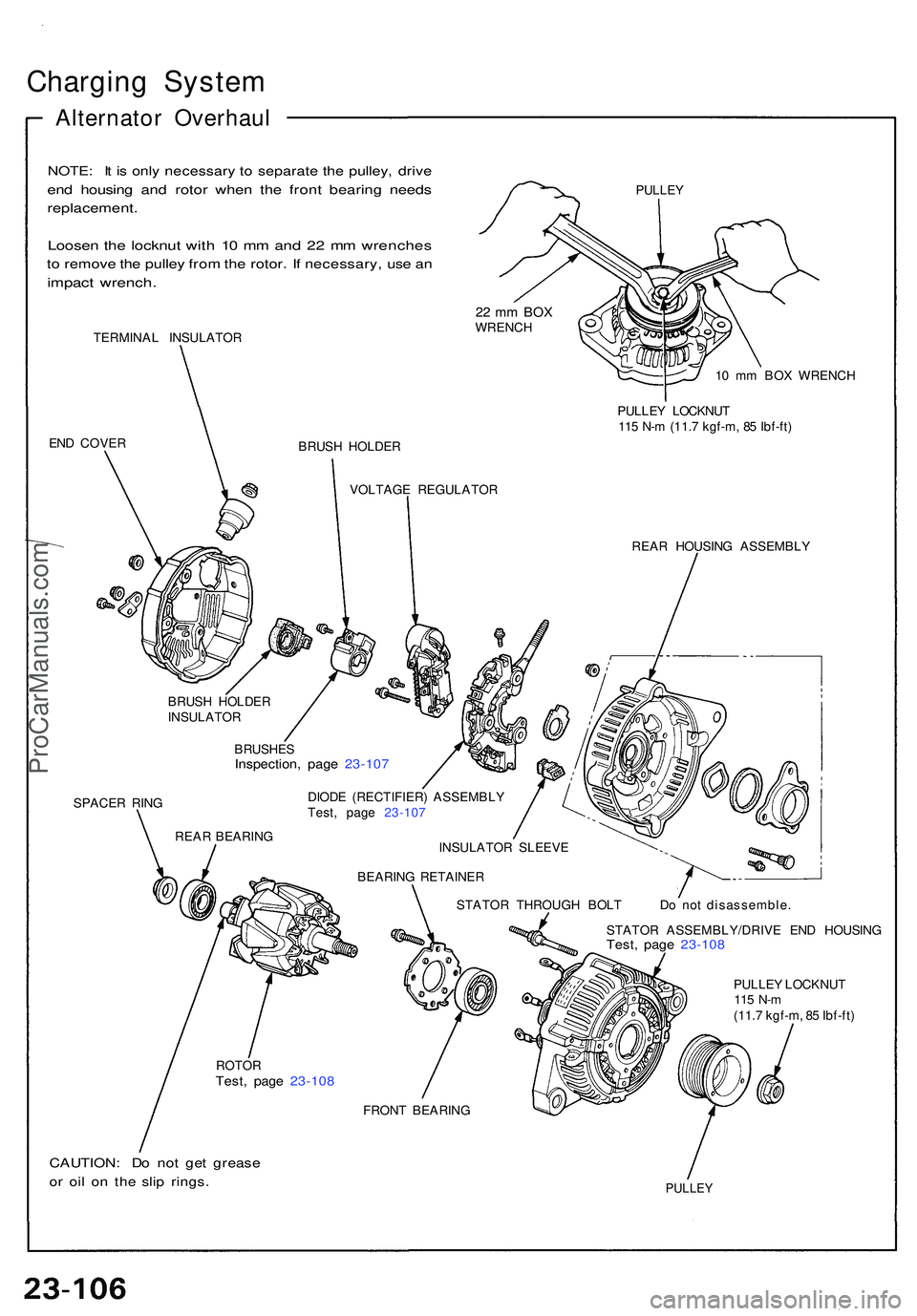

Alternato r Overhau l

NOTE: I t i s onl y necessar y t o separat e th e pulley , driv e

end housin g an d roto r whe n th e fron t bearin g need s

replacement .

Loosen th e locknu t wit h 1 0 m m an d 2 2 m m wrenche s

to remov e th e pulle y fro m th e rotor . I f necessary , us e a n

impac t wrench .

TERMINA L INSULATO R

PULLEY

22 m m BO XWRENC H

10 m m BO X WRENC H

PULLE Y LOCKNU T

11 5 N- m (11. 7 kgf-m , 8 5 Ibf-ft )

EN D COVE R

REAR HOUSIN G ASSEMBL Y

BRUS H HOLDE R

INSULATO R

BRUSHE S

Inspection , pag e 23-10 7

SPACE R RIN G

REA R BEARIN GDIOD

E (RECTIFIER ) ASSEMBL Y

Test , pag e 23-10 7

INSULATO R SLEEV E

BEARIN G RETAINE R

STATO R THROUG H BOL T D o no t disassemble .

STATO R ASSEMBLY/DRIV E EN D HOUSIN G

Test, pag e 23-10 8

PULLE Y LOCKNU T115 N- m(11. 7 kgf-m , 8 5 Ibf-ft )

ROTO RTest, pag e 23-10 8

CAUTION : D o no t ge t greas e

or oi l o n th e sli p rings .

FRON T BEARIN G

PULLEY

BRUSH HOLDE R

VOLTAG E REGULATO R

ProCarManuals.com

Page 1277 of 1503

Rectifier Test

NOTE: The diodes are designed to allow current to

pass in one direction while blocking it in the opposite

direction. Since the alternator rectifier is made up of

eight diodes (four pairs), each diode must be tested for

continuity in both directions with an ohmmeter that has

diode checking capability; a total of sixteen checks.

1. Check for continuity in each direction, between the

B and P, and between the E (ground) and P ter-

minals of each diode pair. All diodes should have

continuity in only one direction.

E (GROUND)

2. If any of the eight diodes fails, replace the rectifier

assembly. (Diodes are not available separately.)

Alternator Brush Inspection

1. Remove the end cover, then take out the brush

holder by removing its two screws.

2. Measure the length of the brushes with a vernier

caliper.

Alternator Brush Length:

Standard: 10.5 mm (0.41 in)

Service Limit: 3.5 mm (0.14 in)

ALTERNATOR BRUSHES

VERNIER CALIPER

If the brushes are less than the service limit,

replace the assembly.ProCarManuals.com

Page 1278 of 1503

Charging System

Rotor Slip Ring Test

1. Check that there is continuity between the slip rings.

2. Check that there is no continuity between the slip

rings and the rotor or rotor shaft.

ROTOR SHAFT

SLIP RINGS

ROTOR

3. If the rotor fails either continuity check, replace the

alternator.

Stator Test

1. Check that there is continuity between each pair of

leads.

2. Check that there is no continuity between each lead

and the coil core.

LEADS

COIL CORE

3. If the coil fails either continuity check, replace the

alternator.ProCarManuals.com

Page 1279 of 1503

Alternator Bel t Adjustmen t

Deflection Method :

1 . Appl y a forc e o f 9 8 N (1 0 kgf , 2 2 Ibf ) betwee n th e

alternato r an d crankshaf t pulley , an d measur e it s

deflection .

Deflection : 11-13. 5 m m (0.43-0.5 3 in )

NOTE : O n a brand-ne w belt , th e deflectio n shoul d

be 6- 8 m m (0.24-0.3 1 in ) befor e th e bel t ha s

had an y runnin g tim e o n th e engine .

ADJUSTIN G BOL T8 N- m (0. 8 kgf-m , 5. 8 Ibf-ft )

MOUNTIN G BOL T45 N- m (4. 6 kgf-m , 3 3 Ibf-ft )

ADJUSTMENT-LOC KNUT45 N- m (4. 6 kgf-m , 3 3 Ibf-ft )CRANKSHAF T PULLE Y

2. I f bel t deflectio n i s incorrect , loose n th e

adjustment-loc k nu t an d th e mountin g bolt .

3 . Tur n th e adjustin g bol t unti l bel t deflectio n i s cor -

rect , the n retighte n th e nu t an d bolt .

4 . Rechec k th e bel t tension . Tensio

n Gaug e Method :

1 . Attac h th e bel t tensio n gaug e t o th e belt , an d mea -

sur e bel t tension .

Tension : 45 0 - 65 0 N (4 5 - 6 5 kgf , 99-14 3 Ibf )

NOTE : O n a brand-ne w belt , th e tensio n shoul d b e

90 0 - 110 0 N (9 0 - 11 0 kgf , 19 8 - 24 3 Ibf ) befor e th e

bel t ha s ha d an y runnin g tim e o n th e engine .

MOUNTIN G BOL T45 N- m (4. 6 kgf-m , 3 3 Ibf-ft )

ADJUSTIN G BOL T8 N- m (0. 8 kgf-m , 5. 8 Ibf-ft )BELT TENSIO N GAUG E07JGG-001010 A

ADJUSTMENT-LOC KNUT45 N- m (4. 6 kgf-m ,33 Ibf-ft )CRANKSHAF T PULLE Y

2. I f bel t tensio n i s incorrect , loose n th e adjustment -

loc k nu t an d th e mountin g bolt .

3 . Tur n th e adjustin g bol t unti l bel t tensio n i s correct ,

the n retighte n th e nu t an d bolt .

4 . Rechec k th e bel t tension .

ProCarManuals.com

Page 1280 of 1503

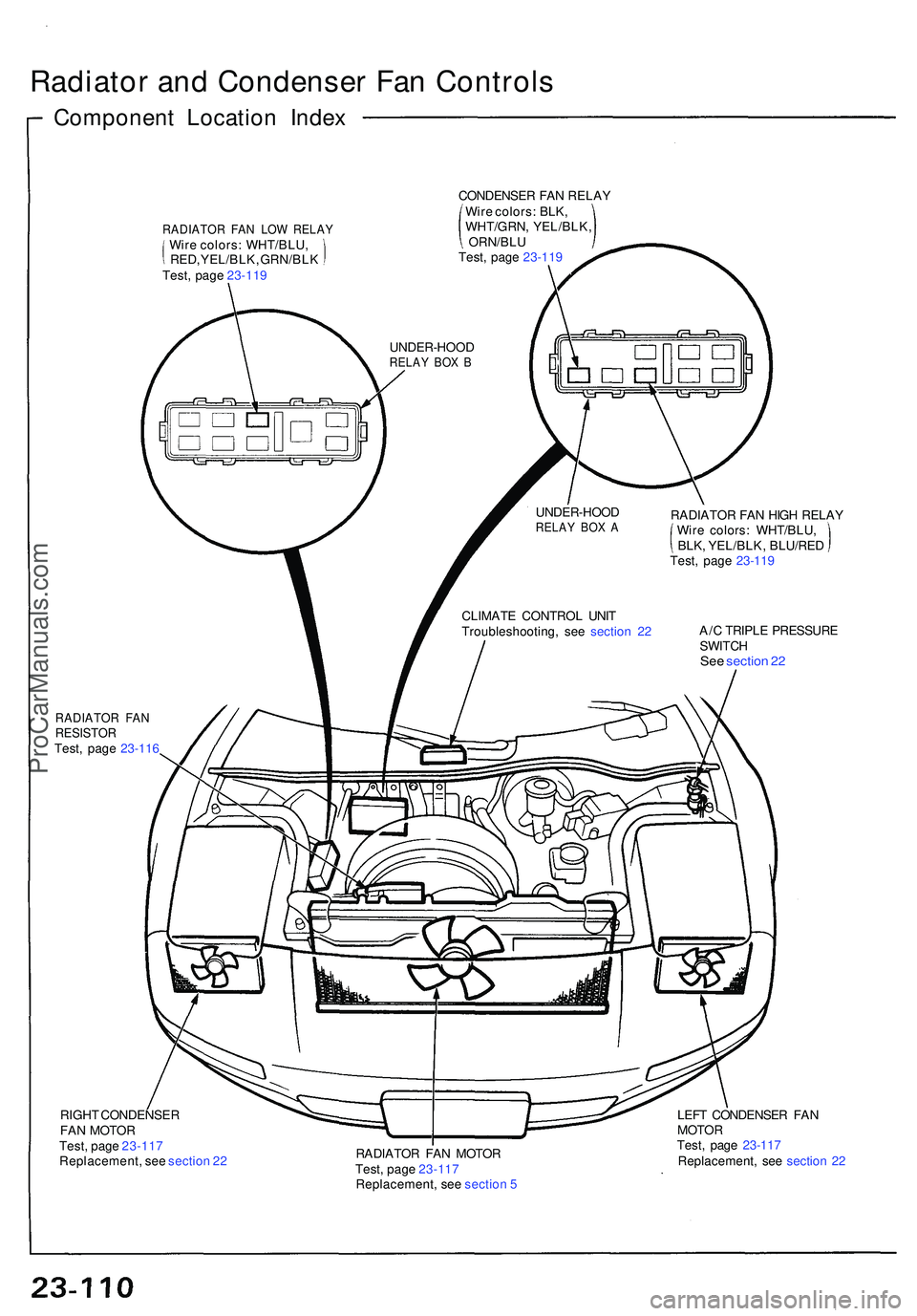

Radiator an d Condense r Fa n Control s

Componen t Locatio n Inde x

RADIATO R FA N LO W RELA YWire colors : WHT/BLU ,RED, YEL/BLK , GRN/BL K

Test , pag e 23-11 9

A/C TRIPL E PRESSUR E

SWITC H

See sectio n 2 2

RADIATO R FA NRESISTO RTest, pag e 23-11 6 UNDER-HOO

D

RELAY BO X B

UNDER-HOO DRELAY BO X A

CLIMAT E CONTRO L UNI T

Troubleshooting , se e sectio n 2 2

RIGH T CONDENSE R

FA N MOTO R

Test , pag e 23-11 7

Replacement , se e sectio n 2 2 RADIATO

R FA N MOTO R

Test , pag e 23-11 7

Replacement , se e sectio n 5 LEF

T CONDENSE R FA N

MOTO R

Test , pag e 23-11 7

Replacement , se e sectio n 2 2

CONDENSE

R FA N RELA Y

Wir e colors : BLK ,

WHT/GRN , YEL/BLK ,

ORN/BLU

Test , pag e 23-11 9

RADIATOR FA N HIG H RELA Y

Wir e colors : WHT/BLU ,

BLK, YEL/BLK , BLU/RE D

Test , pag e 23-11 9

ProCarManuals.com