ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 1251 of 1503

— If the starter still does not crank the engine,

remove the starter and diagnose its internal

problems.

— If the starter cranks the engine, check for an

open in the BLK/WHT wire and connectors be-

tween the starter and ignition switch. Check the

ignition switch.

On cars with automatic transmission, check the

A/T gear position switch (neutral position

switch) and connector.

On cars with manual transmission, check the

starter cut relay, clutch interlock switch and

connectors.

NOTE: Check the No. 29 (50 A) fuse and the

starter cut relay, and inspect the security alarm

system.

3. Check for wear or damage:

The starter should crank the engine smoothly and

steadily.

If the starter engages, but cranks the engine er-

ratically, remove the starter motor. Inspect the

starter, drive gear and flywheel ring gear for

damage.

Check the drive gear overrunning clutch for binding

or slipping when the armature is rotated with the

drive gear held. Replace the gears if damaged.

4. Check cranking voltage and current draw:

Voltage should be no less than 8.5 volts.

Current should be no more than 350 amperes.

If voltage is too low, or current draw too high,

check for:

Low battery.

Open circuit in starter armature commutator

segments.

Starter armature dragging.

Shorted armature winding.

Excessive drag in engine.

5. Check cranking rpm:

Engine speed during cranking should be above 100

rpm.

If speed is too low, check for:

Loose battery or starter terminals.

Excessively worn starter brushes.

Open circuit in commutator segments.

Dirty or damaged helical spline or drive gear.

Defective drive gear overrunning clutch.

6. Check the starter disengagement:

Depress the clutch pedal all the way (M/T) or shift to

or position (A/T), turn the ignition switch to

"Start (III)", and release to ON (II).

The starter drive gear should disengage from the

flywheel ring gear.

If the drive gear hangs up on the flywheel ring gear,

check:

Solenoid plunger and switch for malfunction.

Drive gear assembly for dirt or damaged over-

running clutch.ProCarManuals.com

Page 1252 of 1503

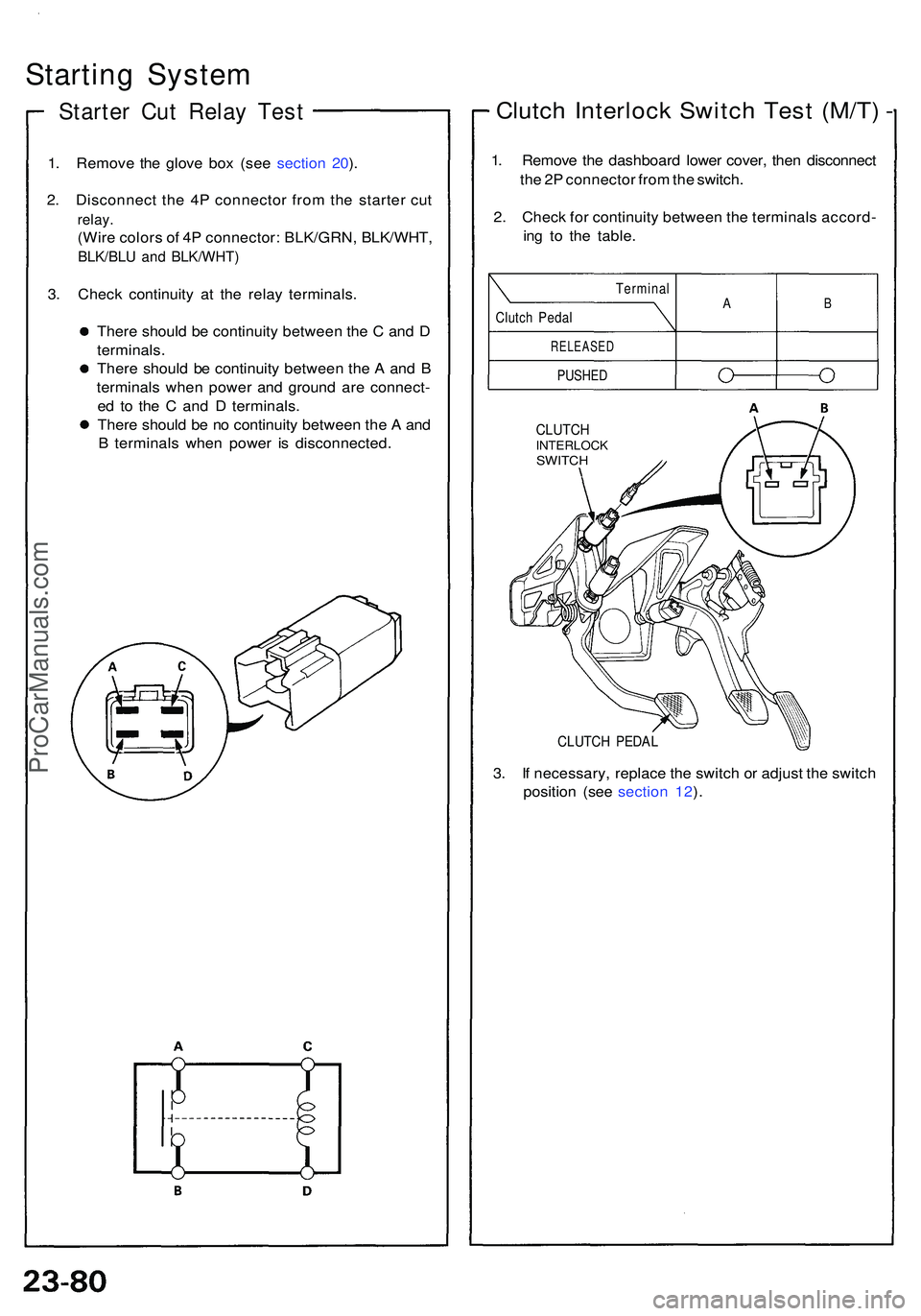

Starting Syste m

Starter Cu t Rela y Tes t

1. Remov e th e glov e bo x (se e sectio n 20 ).

2 . Disconnec t th e 4 P connecto r fro m th e starte r cu t

relay .

(Wire color s o f 4 P connector : BLK/GRN , BLK/WHT ,

BLK/BLU an d BLK/WHT )

3. Chec k continuit y a t th e rela y terminals .

Ther e shoul d b e continuit y betwee n th e C an d D

terminals .

Ther e shoul d b e continuit y betwee n th e A an d B

terminal s whe n powe r an d groun d ar e connect -

e d t o th e C an d D terminals .

Ther e shoul d b e n o continuit y betwee n th e A an d

B terminal s whe n powe r i s disconnected .

Clutch Interloc k Switc h Tes t (M/T ) -

1 . Remov e th e dashboar d lowe r cover , the n disconnec t

th e 2 P connecto r fro m th e switch .

2 . Chec k fo r continuit y betwee n th e terminal s accord -

in g t o th e table .

CLUTC HINTERLOC KSWITCH

CLUTC H PEDA L

3. I f necessary , replac e th e switc h o r adjus t th e switc h

positio n (se e sectio n 12 ).

RELEASE D

PUSHED

Clutch Peda l

Termina lAB

ProCarManuals.com

Page 1253 of 1503

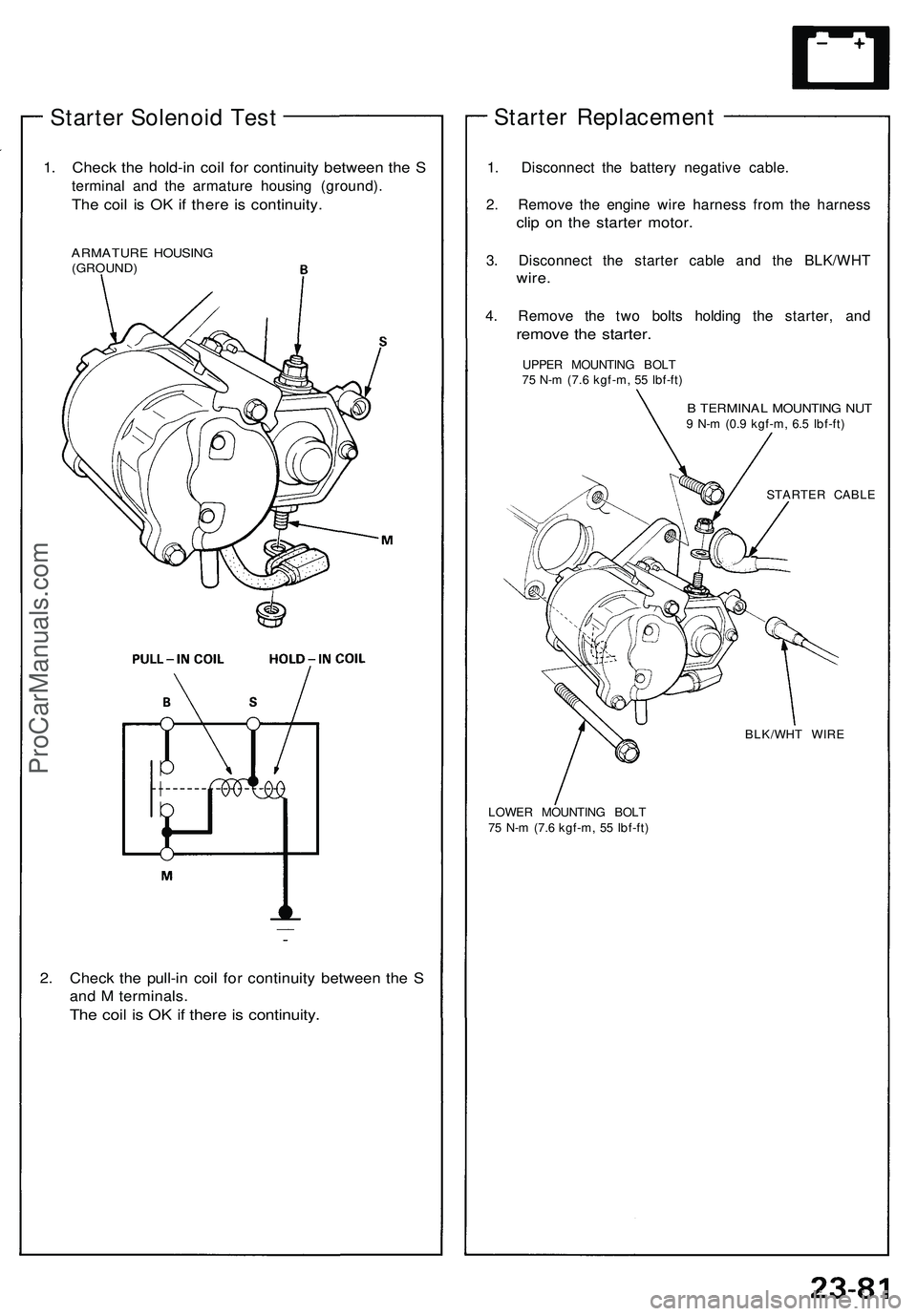

Starter Solenoid Test

1. Check the hold-in coil for continuity between the S

terminal and the armature housing (ground).

The coil is OK if there is continuity.

ARMATURE HOUSING

(GROUND)

2. Check the pull-in coil for continuity between the S

and M terminals.

The coil is OK if there is continuity.

Starter Replacement

1. Disconnect the battery negative cable.

2. Remove the engine wire harness from the harness

clip on the starter motor.

3. Disconnect the starter cable and the BLK/WHT

wire.

4. Remove the two bolts holding the starter, and

remove the starter.

UPPER MOUNTING BOLT

75 N-m (7.6 kgf-m, 55 Ibf-ft)

B TERMINAL MOUNTING NUT

9 N-m (0.9 kgf-m, 6.5 Ibf-ft)

STARTER CABLE

LOWER MOUNTING BOLT

75 N-m (7.6 kgf-m, 55 Ibf-ft)

BLK/WHT WIREProCarManuals.com

Page 1254 of 1503

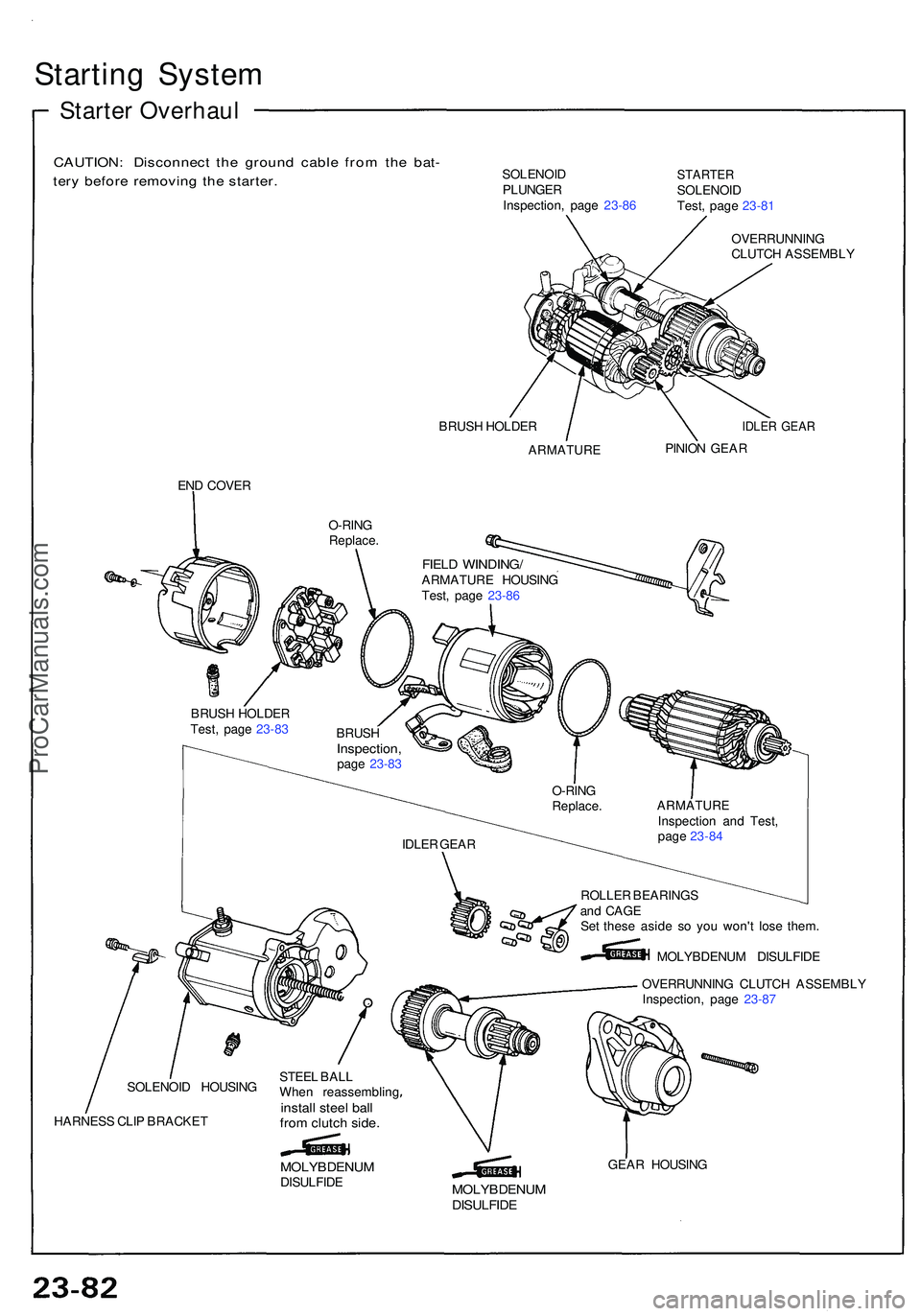

Starting Syste m

Starter Overhau l

CAUTION : Disconnec t th e groun d cabl e fro m th e bat -

tery befor e removin g th e starter .SOLENOI DPLUNGERInspection , pag e 23-8 6

STARTE RSOLENOI D

Test , pag e 23-8 1

OVERRUNNIN G

CLUTC H ASSEMBL Y

BRUS H HOLDE R

ARMATUR E

IDLER GEA R

PINION GEAR

EN D COVE R

O-RING

Replace .

FIELD WINDING /ARMATUR E HOUSIN G

Test , pag e 23-8 6

BRUS H HOLDE R

Test , pag e 23-8 3

BRUSH

Inspection ,page 23-8 3

O-RING

Replace .

ARMATUR EInspection an d Test ,

pag e 23-8 4

HARNES S CLI P BRACKE T STEE

L BAL L

Whe n reassemblin g

install stee l bal lfrom clutc h side .

MOLYBDENU MDISULFIDE ROLLE

R BEARING S

an d CAG E

Se t thes e asid e s o yo u won' t los e them .

MOLYBDENU M DISULFID E

OVERRUNNIN G CLUTC H ASSEMBL Y

Inspection , pag e 23-8 7

GEAR HOUSIN GMOLYBDENU MDISULFIDE

SOLENOI D HOUSIN G IDLE

R GEA R

ProCarManuals.com

Page 1255 of 1503

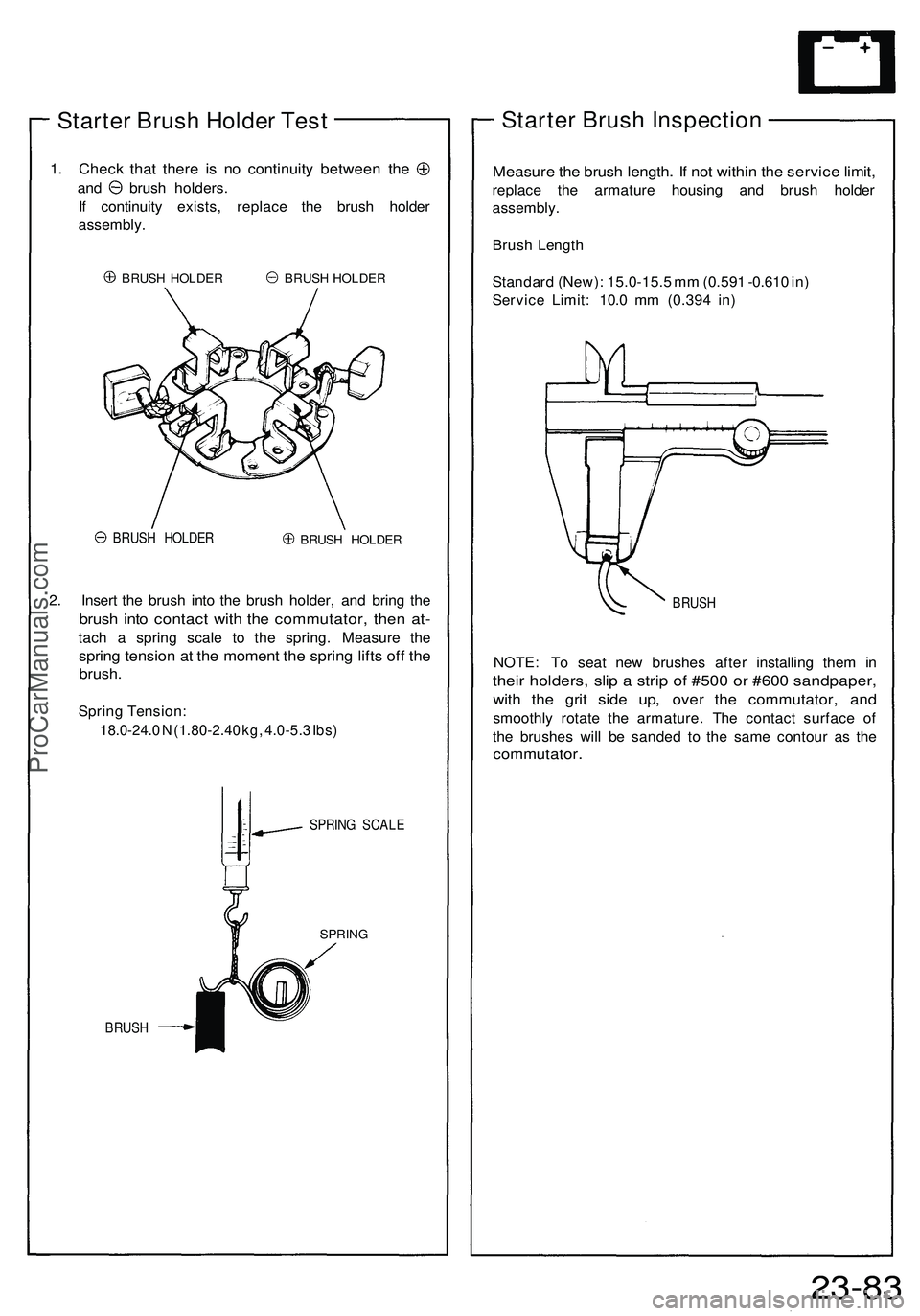

Starter Brus h Holde r Tes t

1. Chec k tha t ther e i s n o continuit y betwee n th e

and brus h holders .

I f continuit y exists , replac e th e brus h holde r

assembly .

BRUSH HOLDE R BRUSH HOLDE R

BRUSH HOLDE RBRUSH HOLDE R

2. Inser t th e brus h int o th e brus h holder , an d brin g th e

brus h int o contac t wit h th e commutator , the n at -

tac h a sprin g scal e t o th e spring . Measur e th e

sprin g tensio n a t th e momen t th e sprin g lift s of f th e

brush .

Spring Tension :

18.0-24.0 N (1.80-2.4 0 kg , 4.0-5. 3 Ibs )

SPRIN G SCAL E

BRUS H

SPRIN G

Starter Brus h Inspectio n

Measure th e brus h length . I f no t withi n th e servic e limit ,

replac e th e armatur e housin g an d brus h holde r

assembly .

Brus h Lengt h

Standar d (New) : 15.0-15. 5 m m (0.59 1 -0.61 0 in )

Servic e Limit : 10. 0 m m (0.39 4 in )

BRUS H

NOTE : T o sea t ne w brushe s afte r installin g the m i n

their holders , sli p a stri p o f #50 0 o r #60 0 sandpaper ,

with th e gri t sid e up , ove r th e commutator , an d

smoothl y rotat e th e armature . Th e contac t surfac e o f

th e brushe s wil l b e sande d t o th e sam e contou r a s th e

commutator .

23-83

ProCarManuals.com

Page 1256 of 1503

Starting Syste m

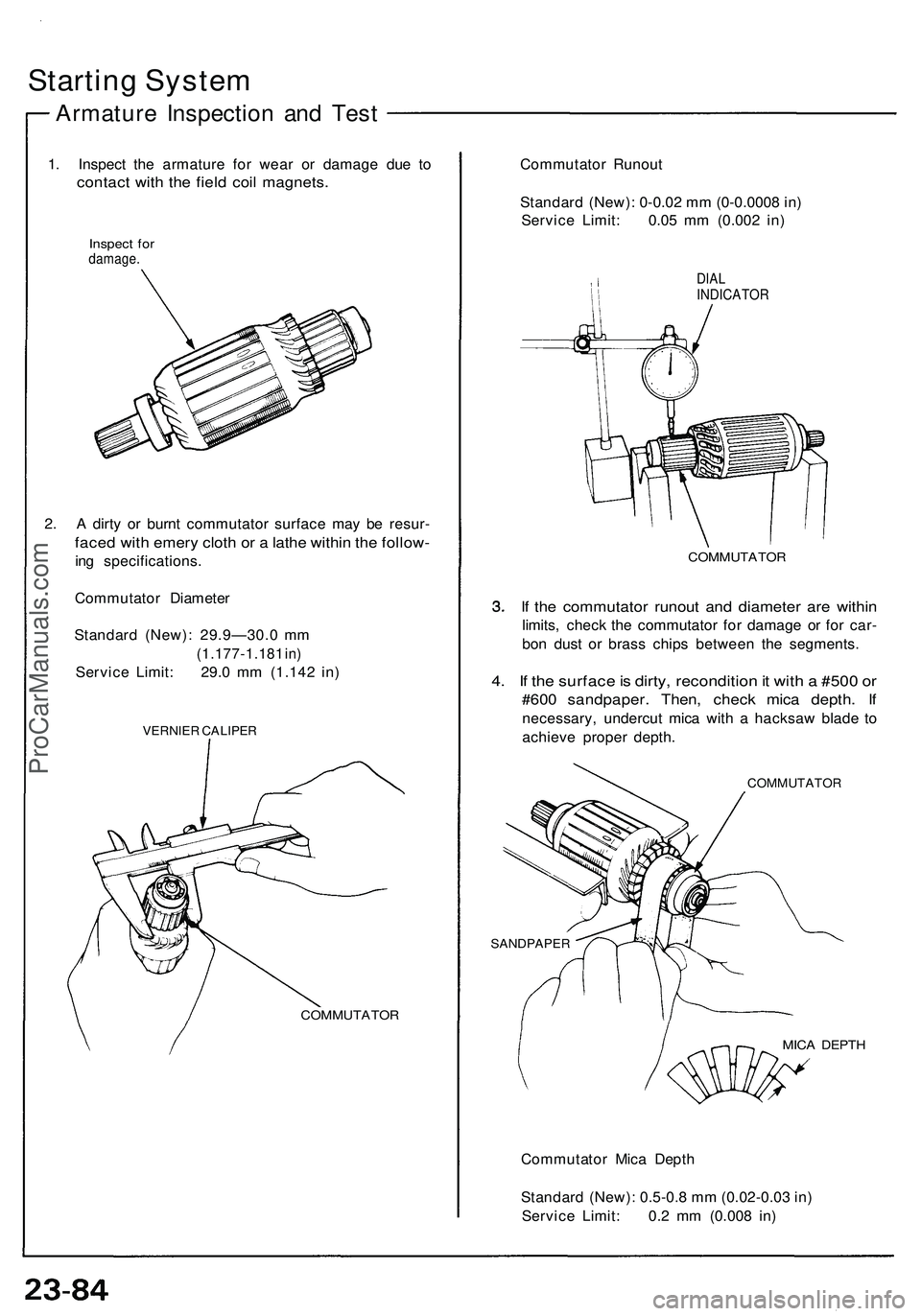

Armatur e Inspectio n an d Tes t

1. Inspec t th e armatur e fo r wea r o r damag e du e t o

contac t wit h th e fiel d coi l magnets .

Inspect fo rdamage .

2. A dirty o r burn t commutato r surfac e ma y b e resur -

faced wit h emer y clot h o r a lath e withi n th e follow -

ing specifications .

Commutato r Diamete r

Standar d (New) : 29.9—30. 0 m m

(1.177-1.18 1 in )

Servic e Limit : 29. 0 m m (1.14 2 in )

VERNIE R CALIPE R

COMMUTATO R

Commutator Runou t

Standar d (New) : 0-0.0 2 m m (0-0.000 8 in )

Servic e Limit : 0.0 5 m m (0.00 2 in )

DIA LINDICATO R

3.

COMMUTATO R

3. I f th e commutato r runou t an d diamete r ar e withi n

limits, chec k th e commutato r fo r damag e o r fo r car -

bo n dus t o r bras s chip s betwee n th e segments .

4. I f th e surfac e is dirty , reconditio n it wit h a #50 0 o r

#60 0 sandpaper . Then , chec k mic a depth . I f

necessary , undercu t mic a wit h a hacksa w blad e t o

achiev e prope r depth .

COMMUTATO R

SANDPAPER

MICA DEPT H

Commutato r Mic a Dept h

Standar d (New) : 0.5-0. 8 m m (0.02-0.0 3 in )

Servic e Limit : 0. 2 m m (0.00 8 in )

ProCarManuals.com

Page 1257 of 1503

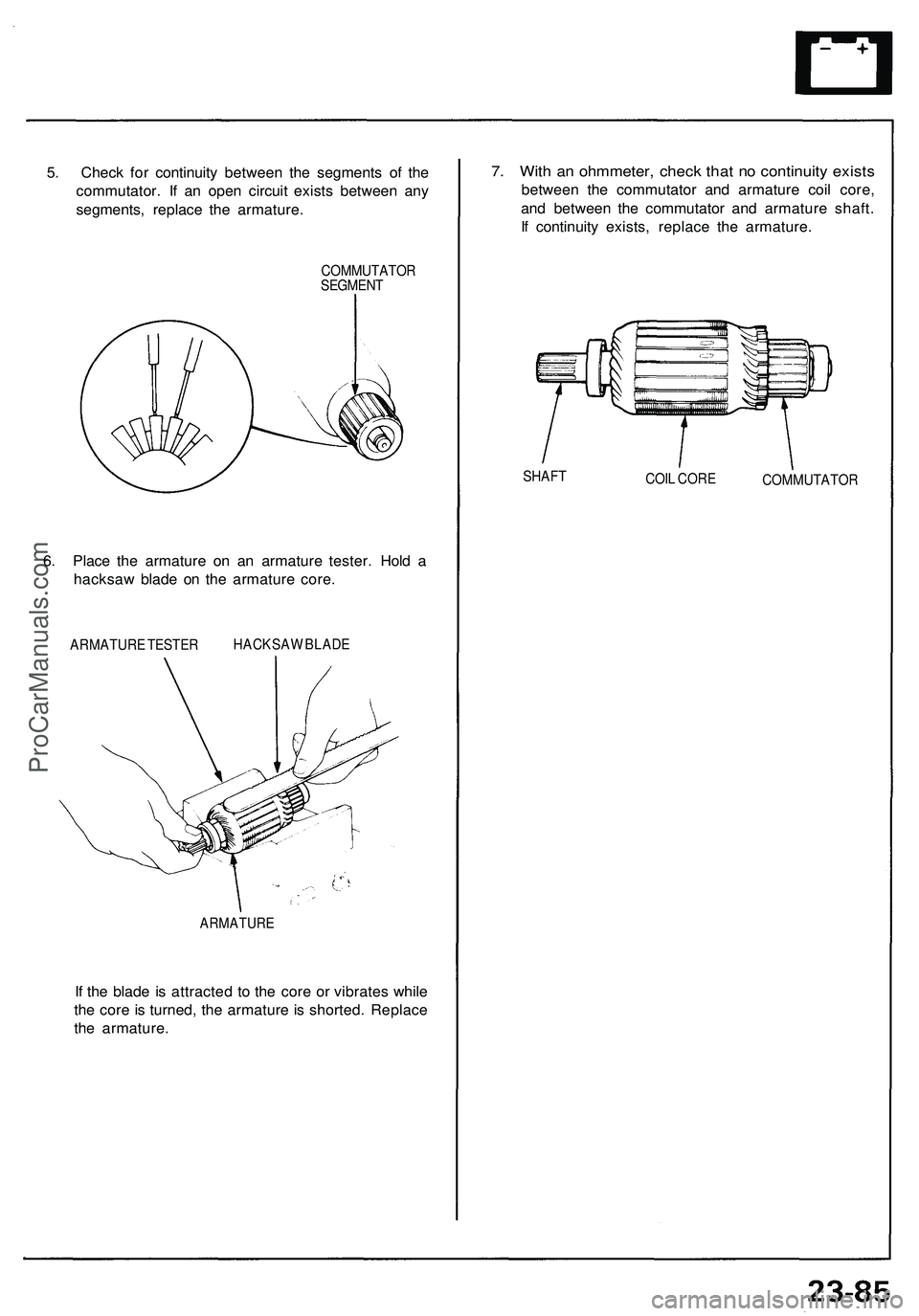

5. Check for continuity between the segments of the

commutator. If an open circuit exists between any

segments, replace the armature.

COMMUTATOR

SEGMENT

6. Place the armature on an armature tester. Hold a

hacksaw blade on the armature core.

ARMATURE TESTER

HACKSAW BLADE

ARMATURE

If the blade is attracted to the core or vibrates while

the core is turned, the armature is shorted. Replace

the armature.

7. With an ohmmeter, check that no continuity exists

between the commutator and armature coil core,

and between the commutator and armature shaft.

If continuity exists, replace the armature.

SHAFT

COIL CORE

COMMUTATORProCarManuals.com

Page 1258 of 1503

Starting System

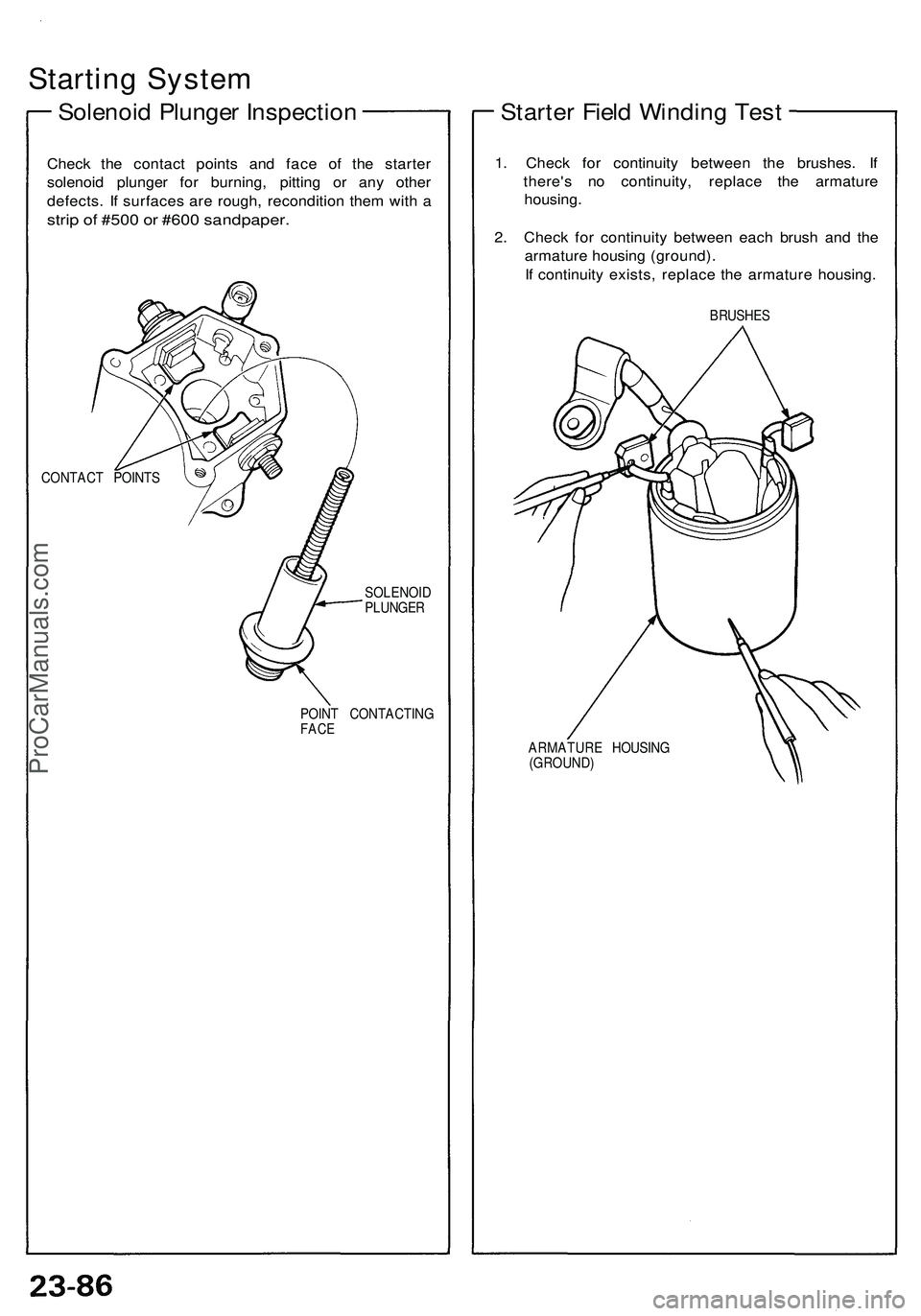

Solenoid Plunger Inspection

Check the contact points and face of the starter

solenoid plunger for burning, pitting or any other

defects. If surfaces are rough, recondition them with a

strip of #500 or #600 sandpaper.

CONTACT POINTS

SOLENOID

PLUNGER

POINT CONTACTING

FACE

Starter Field Winding Test

1. Check for continuity between the brushes. If

there's no continuity, replace the armature

housing.

2. Check for continuity between each brush and the

armature housing (ground).

If continuity exists, replace the armature housing.

BRUSHES

ARMATURE HOUSING

(GROUND)ProCarManuals.com

Page 1259 of 1503

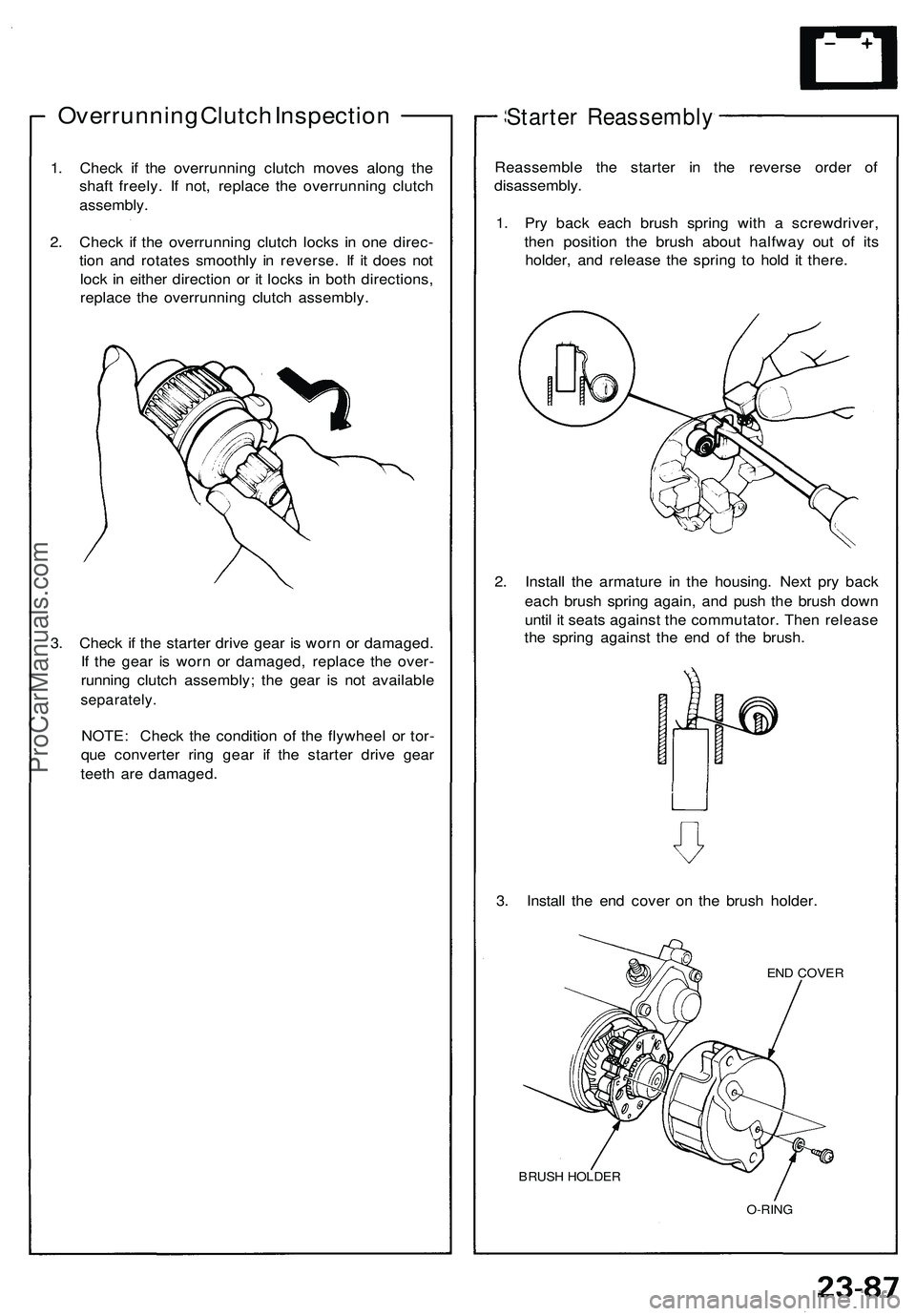

Overrunning Clutch Inspection

1. Check if the overrunning clutch moves along the

shaft freely. If not, replace the overrunning clutch

assembly.

2. Check if the overrunning clutch locks in one direc-

tion and rotates smoothly in reverse. If it does not

lock in either direction or it locks in both directions,

replace the overrunning clutch assembly.

3. Check if the starter drive gear is worn or damaged.

If the gear is worn or damaged, replace the over-

running clutch assembly; the gear is not available

separately.

NOTE: Check the condition of the flywheel or tor-

que converter ring gear if the starter drive gear

teeth are damaged.

Starter Reassembly

Reassemble the starter in the reverse order of

disassembly.

1. Pry back each brush spring with a screwdriver,

then position the brush about halfway out of its

holder, and release the spring to hold it there.

2. Install the armature in the housing. Next pry back

each brush spring again, and push the brush down

until it seats against the commutator. Then release

the spring against the end of the brush.

3. Install the end cover on the brush holder.

END COVER

BRUSH HOLDER

O-RINGProCarManuals.com

Page 1260 of 1503

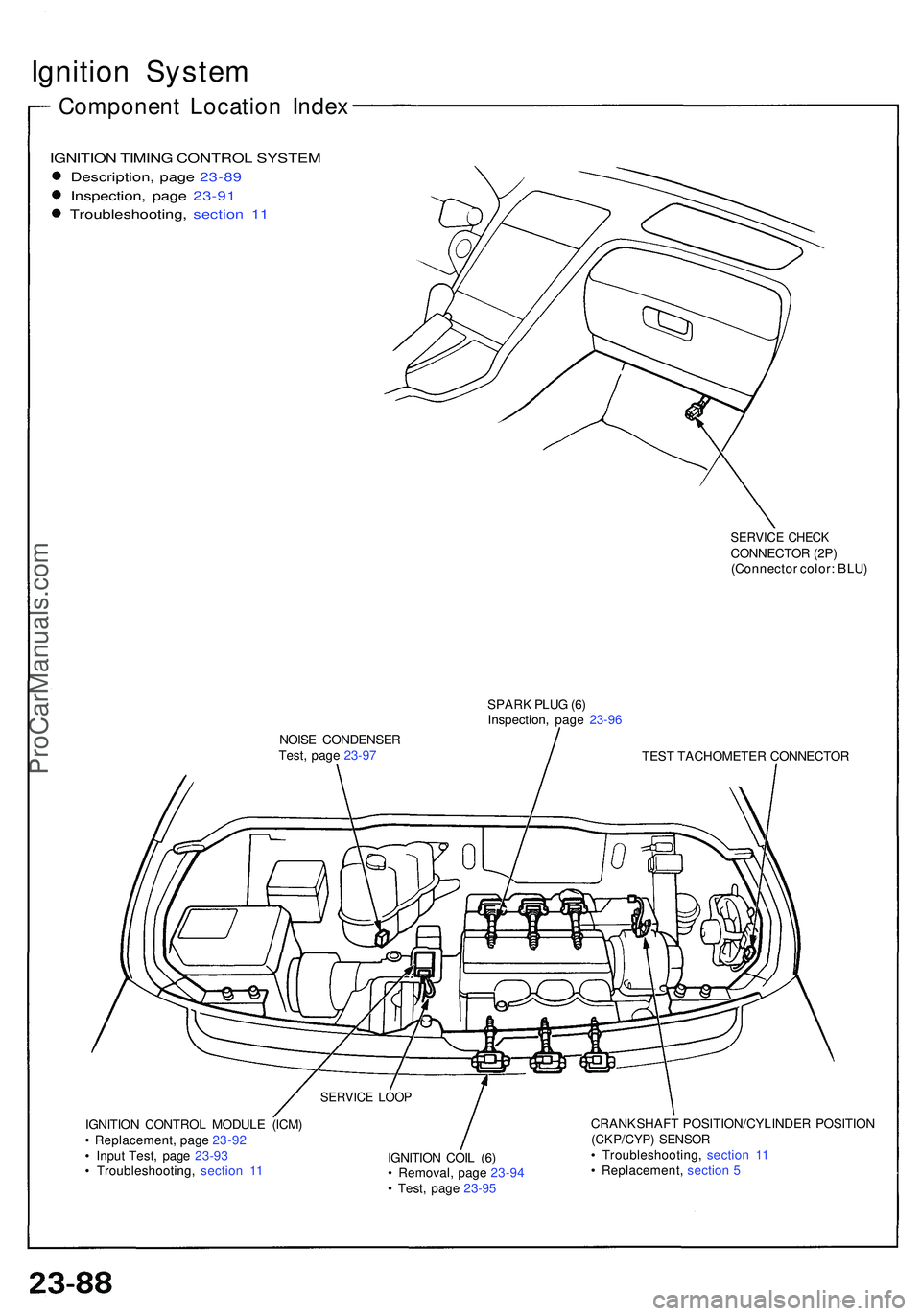

Ignition Syste m

Componen t Locatio n Inde x

IGNITIO N TIMIN G CONTRO L SYSTE M

Description , pag e 23-8 9

Inspection , pag e 23-9 1

Troubleshooting , sectio n 1 1

SERVIC E CHEC KCONNECTO R (2P )

(Connecto r color : BLU )

SPAR K PLU G (6 )

Inspection , pag e 23-9 6

NOIS E CONDENSE R

Test , pag e 23-9 7

TEST TACHOMETE R CONNECTO R

IGNITIO N CONTRO L MODUL E (ICM )

• Replacement , pag e 23-9 2

• Inpu t Test , pag e 23-9 3

• Troubleshooting , sectio n 1 1 IGNITIO

N COI L (6 )

• Removal , pag e 23-9 4

• Test , pag e 23-9 5 CRANKSHAF

T POSITION/CYLINDE R POSITIO N

(CKP/CYP ) SENSO R• Troubleshooting , sectio n 1 1

• Replacement , sectio n 5

SERVIC E LOO P

ProCarManuals.com