ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 631 of 1503

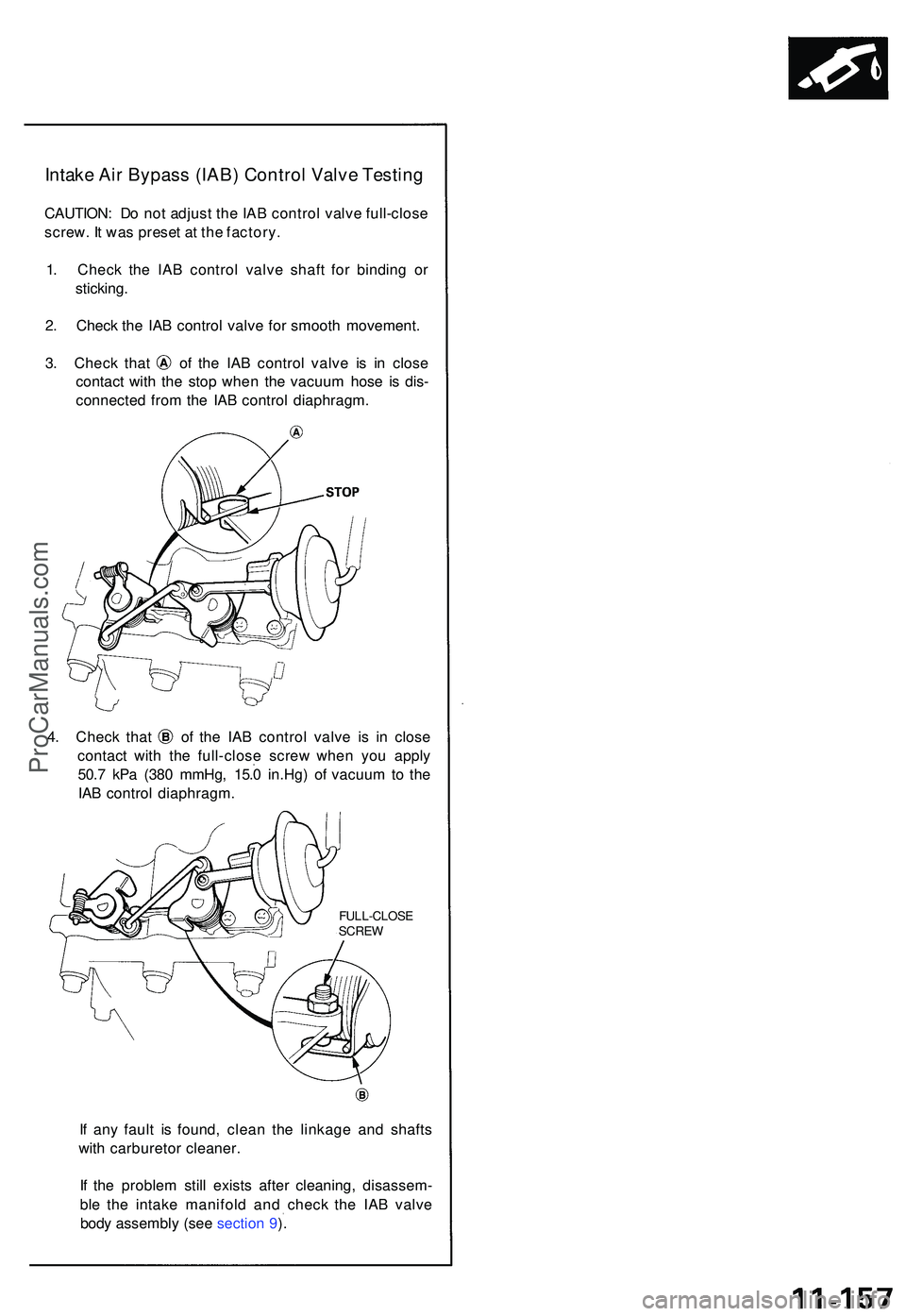

Intake Ai r Bypas s (IAB ) Contro l Valv e Testin g

CAUTION : D o no t adjus t th e IA B contro l valv e full-clos e

screw . I t wa s prese t a t th e factory .

1 . Chec k th e IA B contro l valv e shaf t fo r bindin g o r

sticking .

2 . Chec k th e IA B contro l valv e fo r smoot h movement .

3. Chec k tha t o f th e IA B contro l valv e i s i n clos e

contac t wit h th e sto p whe n th e vacuu m hos e i s dis -

connecte d fro m th e IA B contro l diaphragm .

4. Chec k tha t o f th e IA B contro l valv e i s i n clos e

contac t wit h th e full-clos e scre w whe n yo u appl y

50. 7 kP a (38 0 mmHg , 15. 0 in.Hg ) o f vacuu m to th e

IA B contro l diaphragm .

FULL-CLOS E

SCRE W

If an y faul t i s found , clea n th e linkag e an d shaft s

wit h carbureto r cleaner .

I f th e proble m stil l exist s afte r cleaning , disassem -

bl e th e intak e manifol d an d chec k th e IA B valv e

bod y assembl y (se e sectio n 9 ).

ProCarManuals.com

Page 632 of 1503

Emission Contro l Syste m

System Descriptio n

The emissio n contro l syste m include s tw o Thre e Wa y

Catalyti c Converter s (TWCs) , Exhaus t Ga s Recirculatio n

(EGR ) system , Positiv e Crankcas e Ventilatio n (PCV ) sys -

te m an d Evaporativ e Emissio n (EVAP ) Contro l system .

Th e emissio n contro l syste m is designe d t o mee t federa l

an d stat e emissio n standards .

Tailpipe Emissio n

1. Star t th e engine . Hol d th e engine at 3,00 0 rp m wit h

no loa d (A/ T in o r position , M/ T in neutral ) unti l

th e radiato r fa n come s on , the n le t i t idle .

2 . Connec t a tachometer .

3 . Chec k an d adjus t th e idl e speed , i f necessar y (se e

pag e 11-129 ).

4 . War m u p an d calibrat e th e C O mete r accordin g t o

th e mete r manufacturer' s instructions .

5 . Chec k idl e C O wit h th e headlights , heate r blower ,

rea r windo w defogger , coolin g fan , an d ai r condi -

tione r off .

NOTE : (Canada ) Pul l th e parkin g brak e leve r up .

Star t th e engine , the n chec k tha t th e headlight s ar e

off.

CO mete r shoul d indicat e 0.1 % maximum .

Inspection

any ope n flam e awa y fro m you r wor k area .

D

o no t smok e durin g thi s procedure . Kee p

ProCarManuals.com

Page 633 of 1503

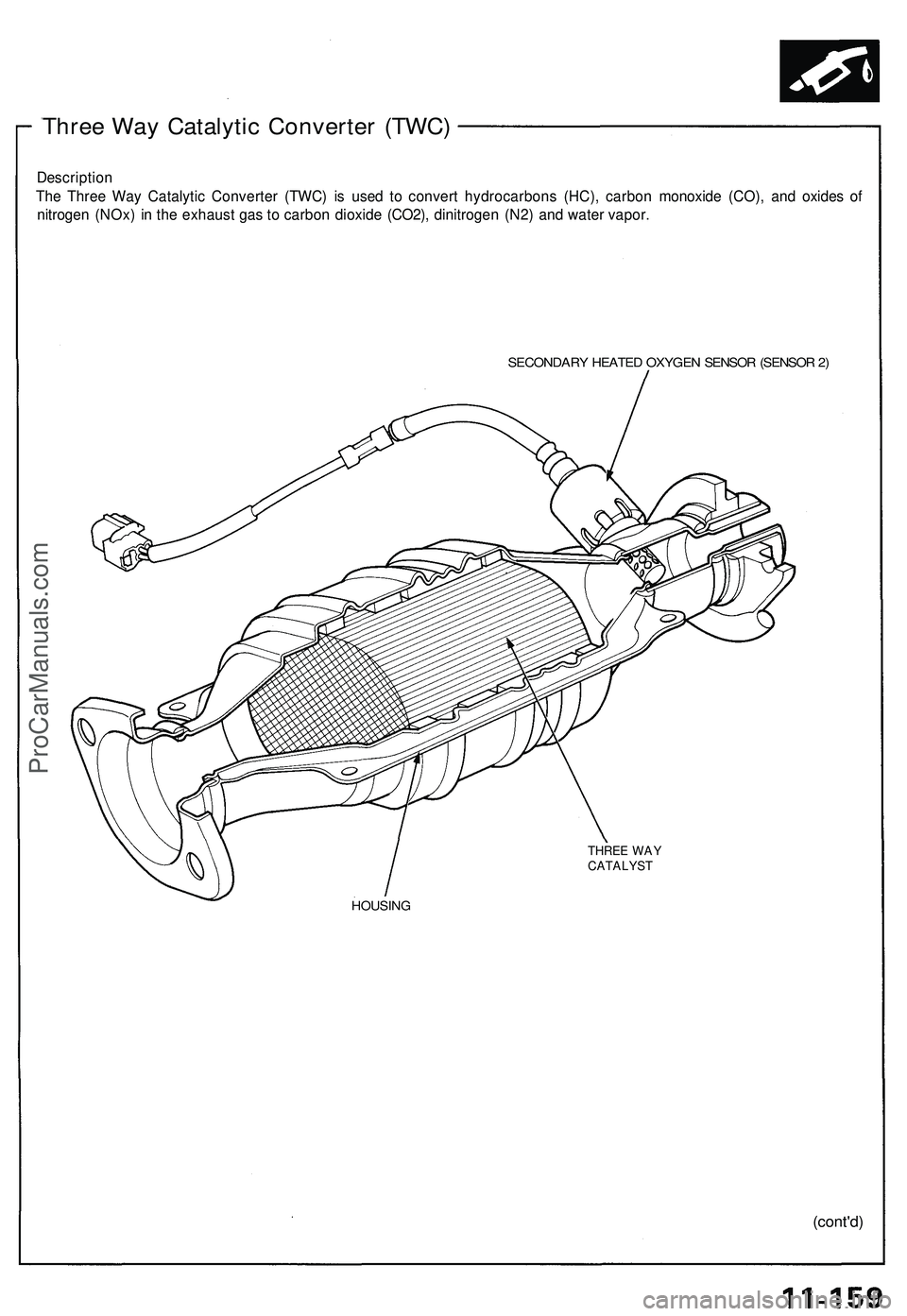

Three Wa y Catalyti c Converte r (TWC)

Descriptio n

Th e Thre e Wa y Catalyti c Converte r (TWC ) i s use d t o conver t hydrocarbon s (HC) , carbo n monoxid e (CO) , an d oxide s o f

nitroge n (NOx ) i n th e exhaus t ga s t o carbo n dioxid e (CO2) , dinitroge n (N2 ) an d wate r vapor .

SECONDAR Y HEATE D OXYGE N SENSO R (SENSO R 2 )

THRE E WA Y

CATALYS T

HOUSING

(cont'd)

ProCarManuals.com

Page 634 of 1503

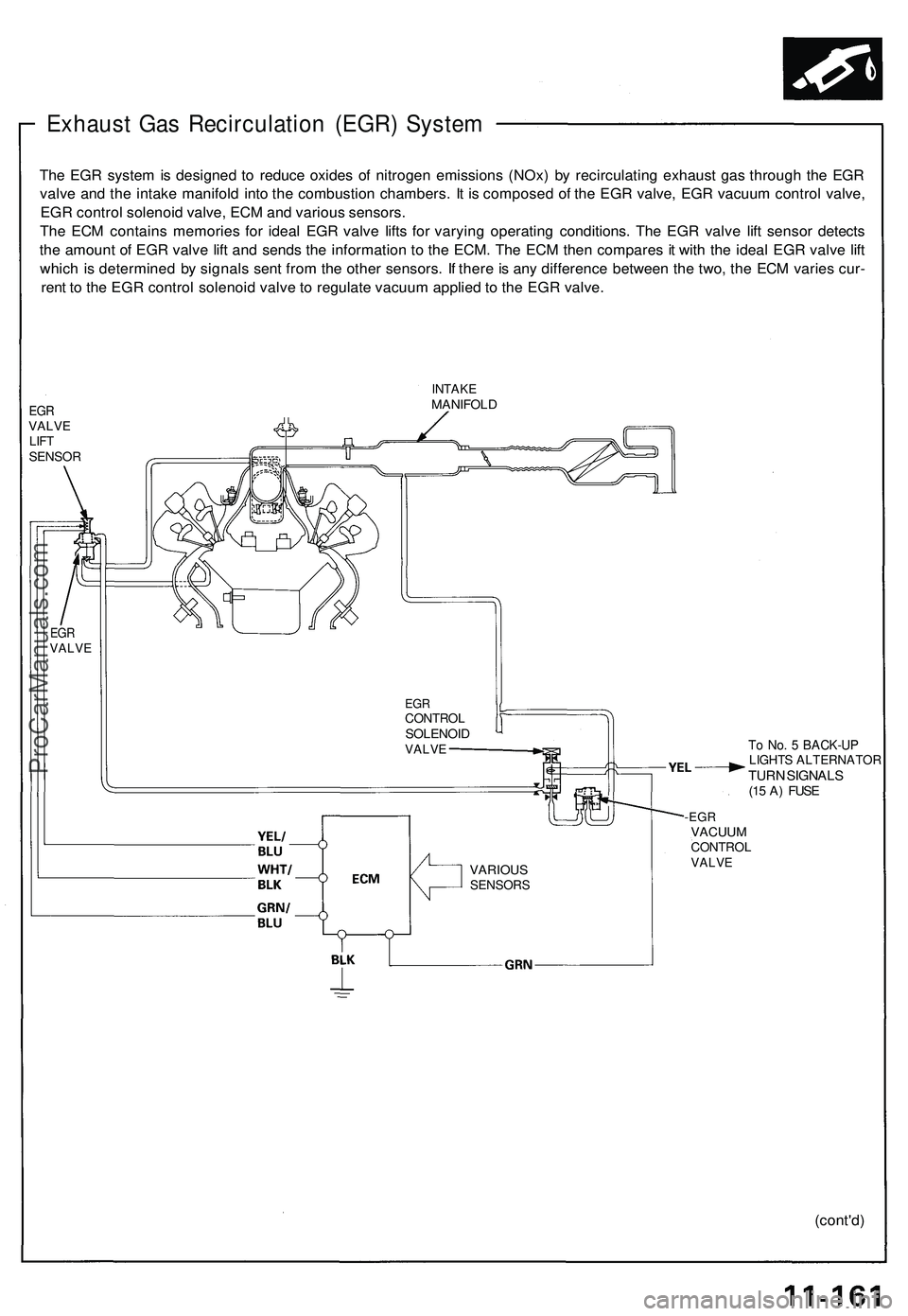

Exhaust Gas Recirculation (EGR) System

The EGR system is designed to reduce oxides of nitrogen emissions (NOx) by recirculating exhaust gas through the EGR

valve and the intake manifold into the combustion chambers. It is composed of the EGR valve, EGR vacuum control valve,

EGR control solenoid valve, ECM and various sensors.

The ECM contains memories for ideal EGR valve lifts for varying operating conditions. The EGR valve lift sensor detects

the amount of EGR valve lift and sends the information to the ECM. The ECM then compares it with the ideal EGR valve lift

which is determined by signals sent from the other sensors. If there is any difference between the two, the ECM varies cur-

rent to the EGR control solenoid valve to regulate vacuum applied to the EGR valve.

EGR

VALVE

LIFT

SENSOR

INTAKE

MANIFOLD

EGR

CONTROL

SOLENOID

VALVE

To No. 5 BACK-UP

LIGHTS ALTERNATOR

TURN SIGNALS

(15 A) FUSE

-EGR

VACUUM

CONTROL

VALVE

(cont'd)

EGR

VALVE

VARIOUS

SENSORSProCarManuals.com

Page 635 of 1503

Emission Control System

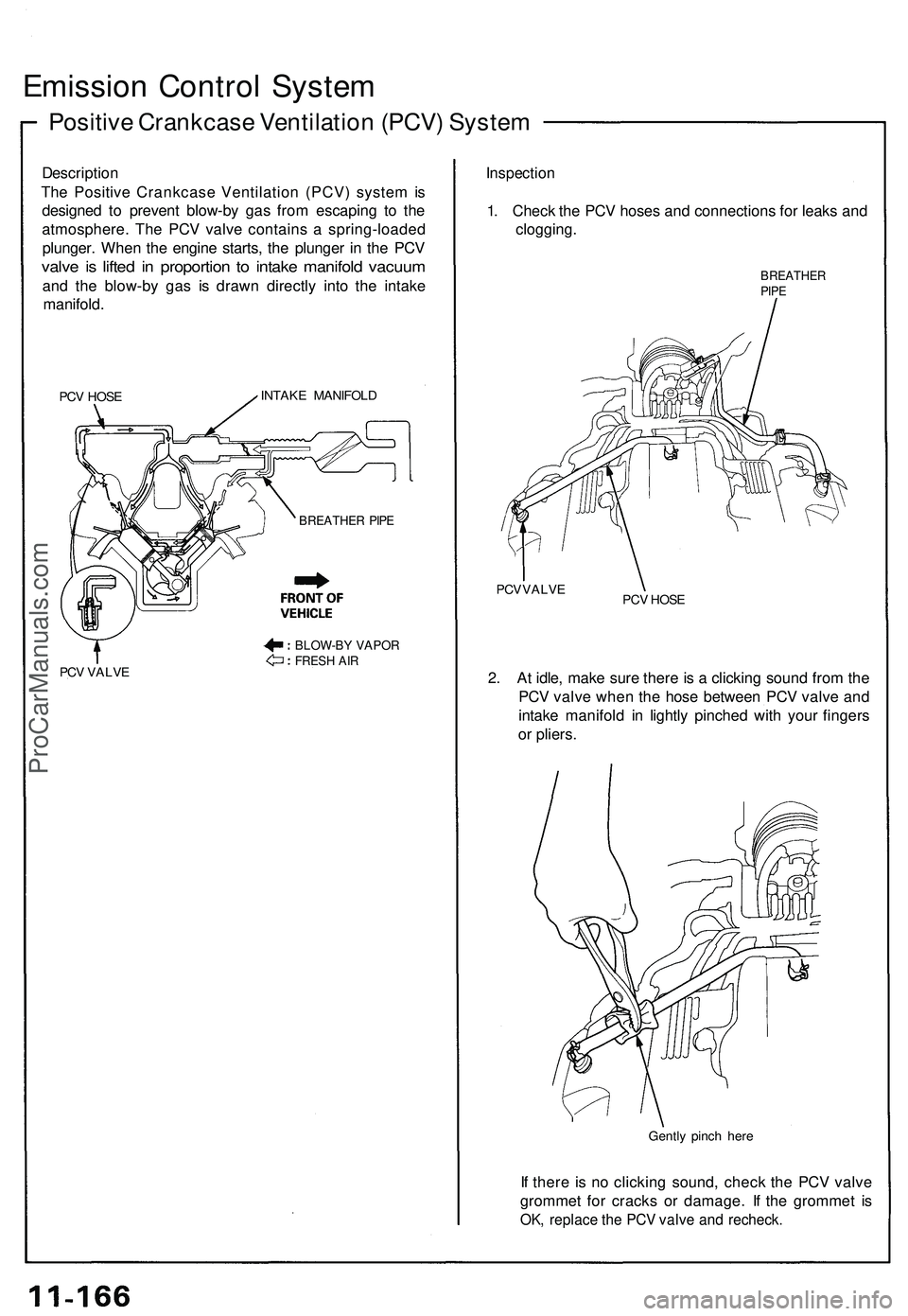

Positive Crankcase Ventilation (PCV) System

Description

The Positive Crankcase Ventilation (PCV) system is

designed to prevent blow-by gas from escaping to the

atmosphere. The PCV valve contains a spring-loaded

plunger. When the engine starts, the plunger in the PCV

valve is lifted in proportion to intake manifold vacuum

and the blow-by gas is drawn directly into the intake

manifold.

PCV HOSE

INTAKE MANIFOLD

PCV VALVE

Inspection

1. Check the PCV hoses and connections for leaks and

clogging.

BREATHER

PIPE

PCV VALVE

PCV HOSE

2. At idle, make sure there is a clicking sound from the

PCV valve when the hose between PCV valve and

intake manifold in lightly pinched with your fingers

or pliers.

Gently pinch here

If there is no clicking sound, check the PCV valve

grommet for cracks or damage. If the grommet is

OK, replace the PCV valve and recheck.

BLOW-BY VAPOR

FRESH AIR

BREATHER PIPEProCarManuals.com

Page 636 of 1503

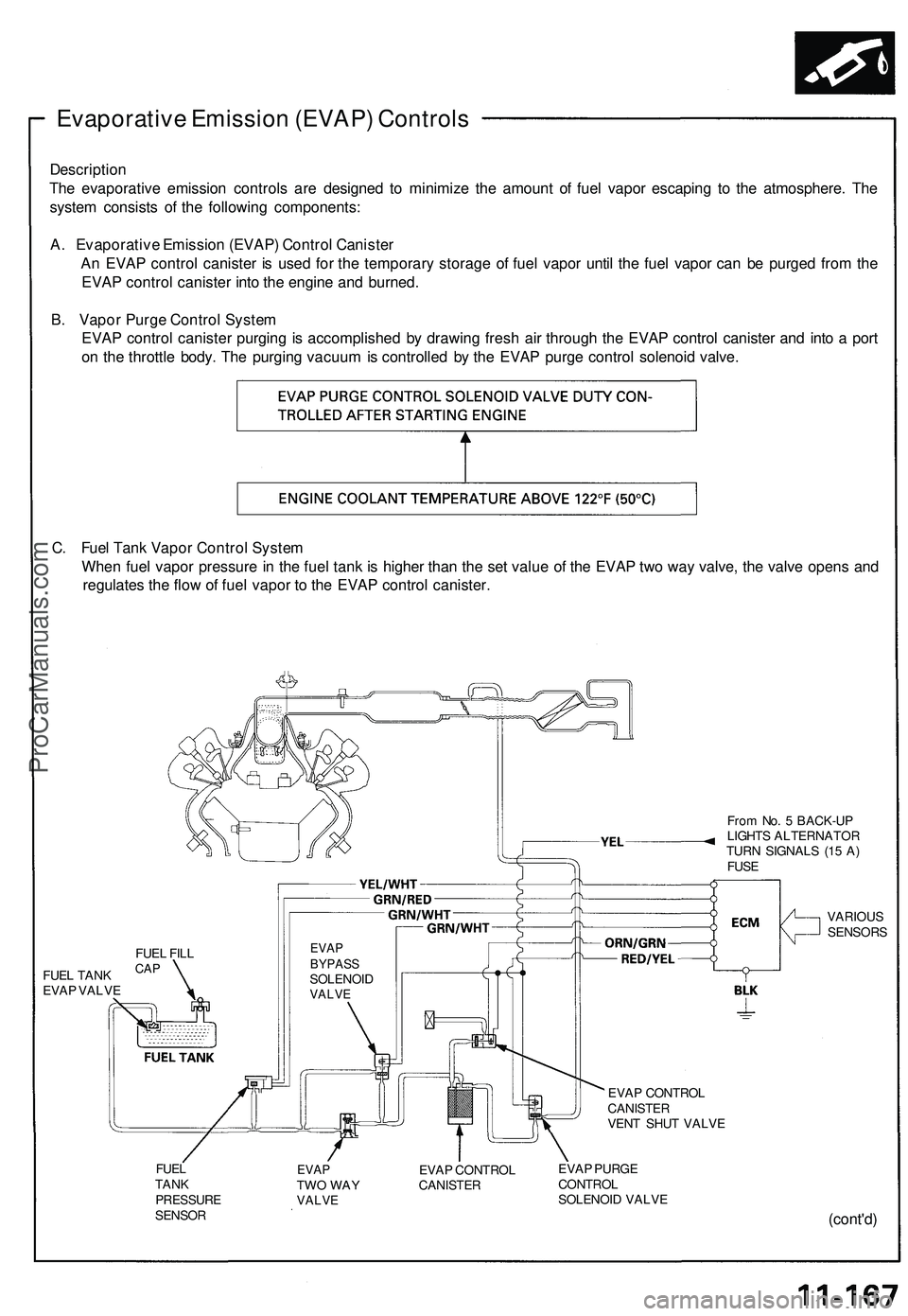

Evaporative Emission (EVAP) Controls

Description

The evaporative emission controls are designed to minimize the amount of fuel vapor escaping to the atmosphere. The

system consists of the following components:

A. Evaporative Emission (EVAP) Control Canister

An EVAP control canister is used for the temporary storage of fuel vapor until the fuel vapor can be purged from the

EVAP control canister into the engine and burned.

B. Vapor Purge Control System

EVAP control canister purging is accomplished by drawing fresh air through the EVAP control canister and into a port

on the throttle body. The purging vacuum is controlled by the EVAP purge control solenoid valve.

C. Fuel Tank Vapor Control System

When fuel vapor pressure in the fuel tank is higher than the set value of the EVAP two way valve, the valve opens and

regulates the flow of fuel vapor to the EVAP control canister.

From No. 5 BACK-UP

LIGHTS ALTERNATOR

TURN SIGNALS (15 A)

FUSE

FUEL TANK

EVAP VALVE

EVAP

BYPASS

SOLENOID

VALVE

VARIOUS

SENSORS

EVAP CONTROL

CANISTER

VENT SHUT VALVE

FUEL

TANK

PRESSURE

SENSOR

EVAP

TWO WAY

VALVE

EVAP CONTROL

CANISTER

EVAP PURGE

CONTROL

SOLENOID VALVE

(cont'd)

FUEL FILL

CAPProCarManuals.com

Page 637 of 1503

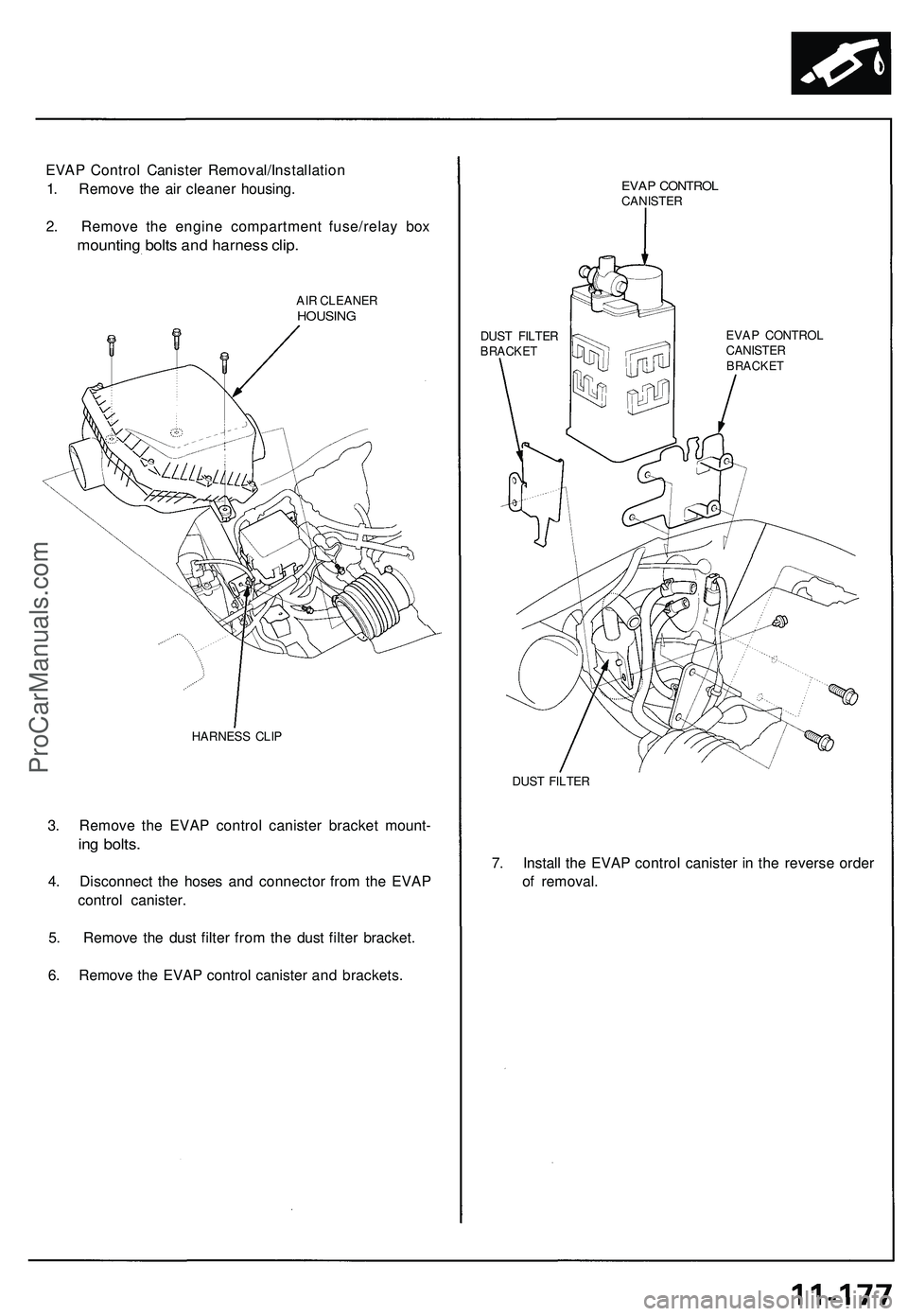

EVAP Control Canister Removal/Installation

1. Remove the air cleaner housing.

2. Remove the engine compartment fuse/relay box

mounting bolts and harness clip.

AIR CLEANER

HOUSING

HARNESS CLIP

3. Remove the EVAP control canister bracket mount-

ing bolts.

4. Disconnect the hoses and connector from the EVAP

control canister.

5. Remove the dust filter from the dust filter bracket.

6. Remove the EVAP control canister and brackets.

EVAP CONTROL

CANISTER

DUST FILTER

BRACKET

EVAP CONTROL

CANISTER

BRACKET

DUST FILTER

7. Install the EVAP control canister in the reverse order

of removal.ProCarManuals.com

Page 638 of 1503

Emission Contro l Syste m

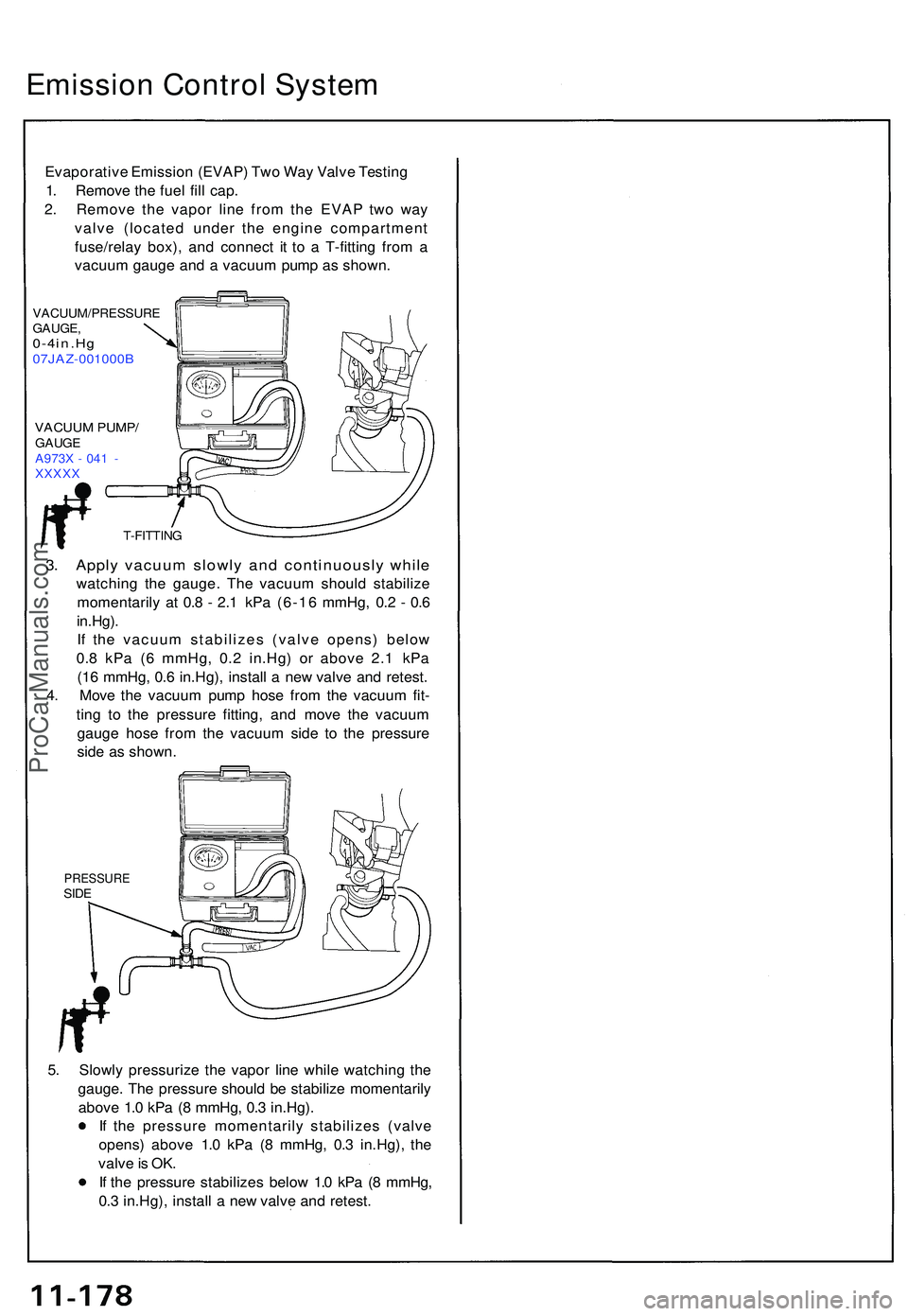

Evaporativ e Emissio n (EVAP ) Tw o Wa y Valv e Testin g

1 . Remov e th e fue l fil l cap .

2 . Remov e th e vapo r lin e fro m th e EVA P tw o wa y

valv e (locate d unde r th e engin e compartmen t

fuse/rela y box) , an d connec t i t t o a T-fittin g fro m a

vacuu m gaug e an d a vacuu m pum p a s shown .

VACUUM/PRESSUR E

GAUGE ,

0-4in.H g07JAZ-001000 B

VACUUM PUMP /GAUGE

A973 X - 04 1 -

XXXX X

3. Appl y vacuu m slowl y an d continuousl y whil e

watchin g th e gauge . Th e vacuu m shoul d stabiliz e

momentaril y a t 0. 8 - 2. 1 kP a (6-1 6 mmHg , 0. 2 - 0. 6

in.Hg) .

I f th e vacuu m stabilize s (valv e opens ) belo w

0. 8 kP a ( 6 mmHg , 0. 2 in.Hg ) o r abov e 2. 1 kP a

(1 6 mmHg , 0. 6 in.Hg) , instal l a ne w valv e an d retest .

4 . Mov e th e vacuu m pum p hos e fro m th e vacuu m fit -

tin g t o th e pressur e fitting , an d mov e th e vacuu m

gaug e hos e fro m th e vacuu m sid e t o th e pressur e

sid e a s shown .

PRESSUR ESIDE

5. Slowl y pressuriz e th e vapo r lin e whil e watchin g th e

gauge . Th e pressur e shoul d b e stabiliz e momentaril y

abov e 1. 0 kP a ( 8 mmHg , 0. 3 in.Hg) .

I f th e pressur e momentaril y stabilize s (valv e

opens ) abov e 1. 0 kP a ( 8 mmHg , 0. 3 in.Hg) , th e

valv e is OK .

I f th e pressur e stabilize s belo w 1. 0 kP a ( 8 mmHg ,

0. 3 in.Hg) , instal l a ne w valv e an d retest .

T-FITTIN G

ProCarManuals.com

Page 639 of 1503

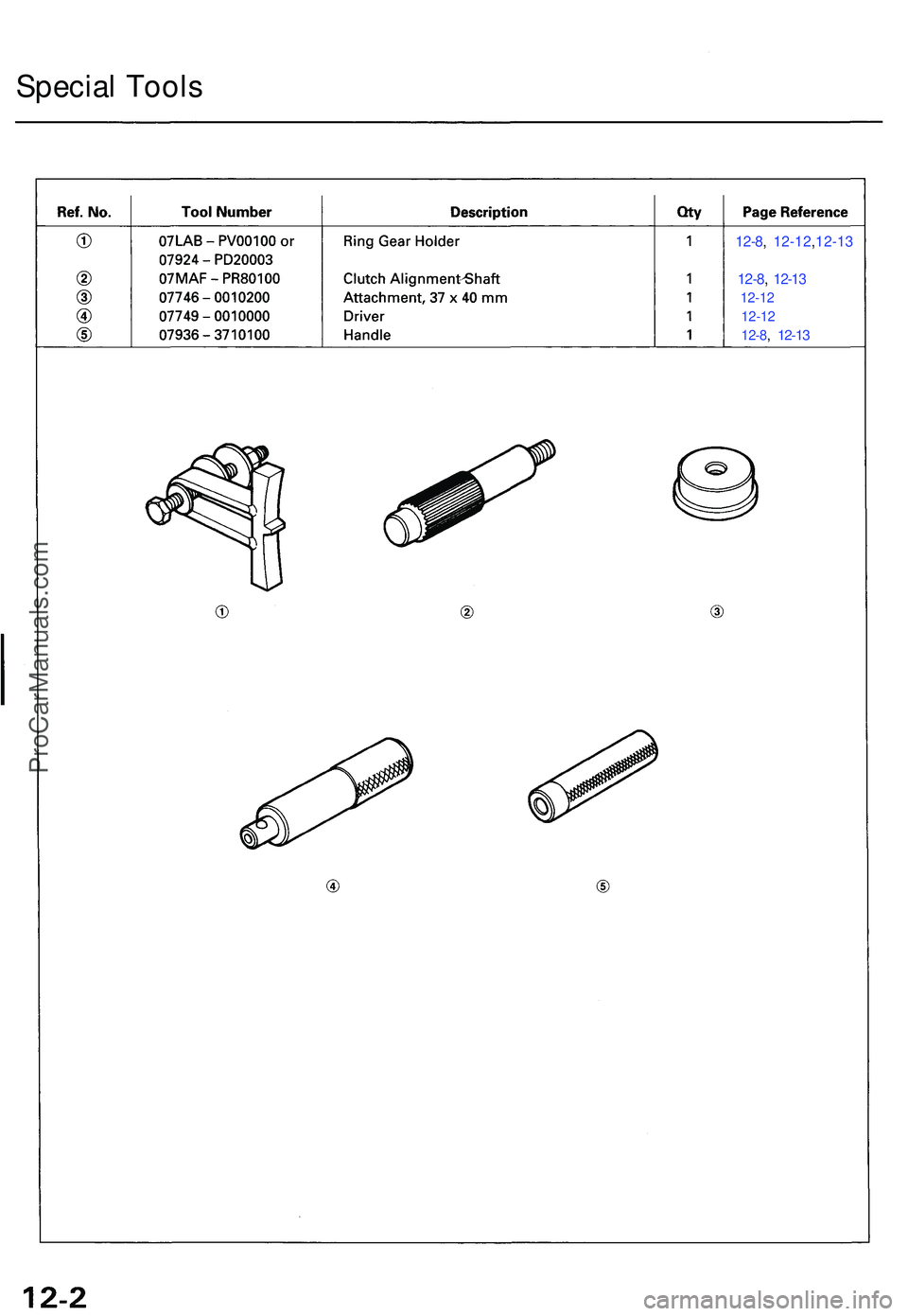

Special Tool s

12-8, 12-12 ,12-1 3

12-8 ,

12-1 3

12-1 2

12-1 2

12-8 ,

12-1 3

ProCarManuals.com

Page 640 of 1503

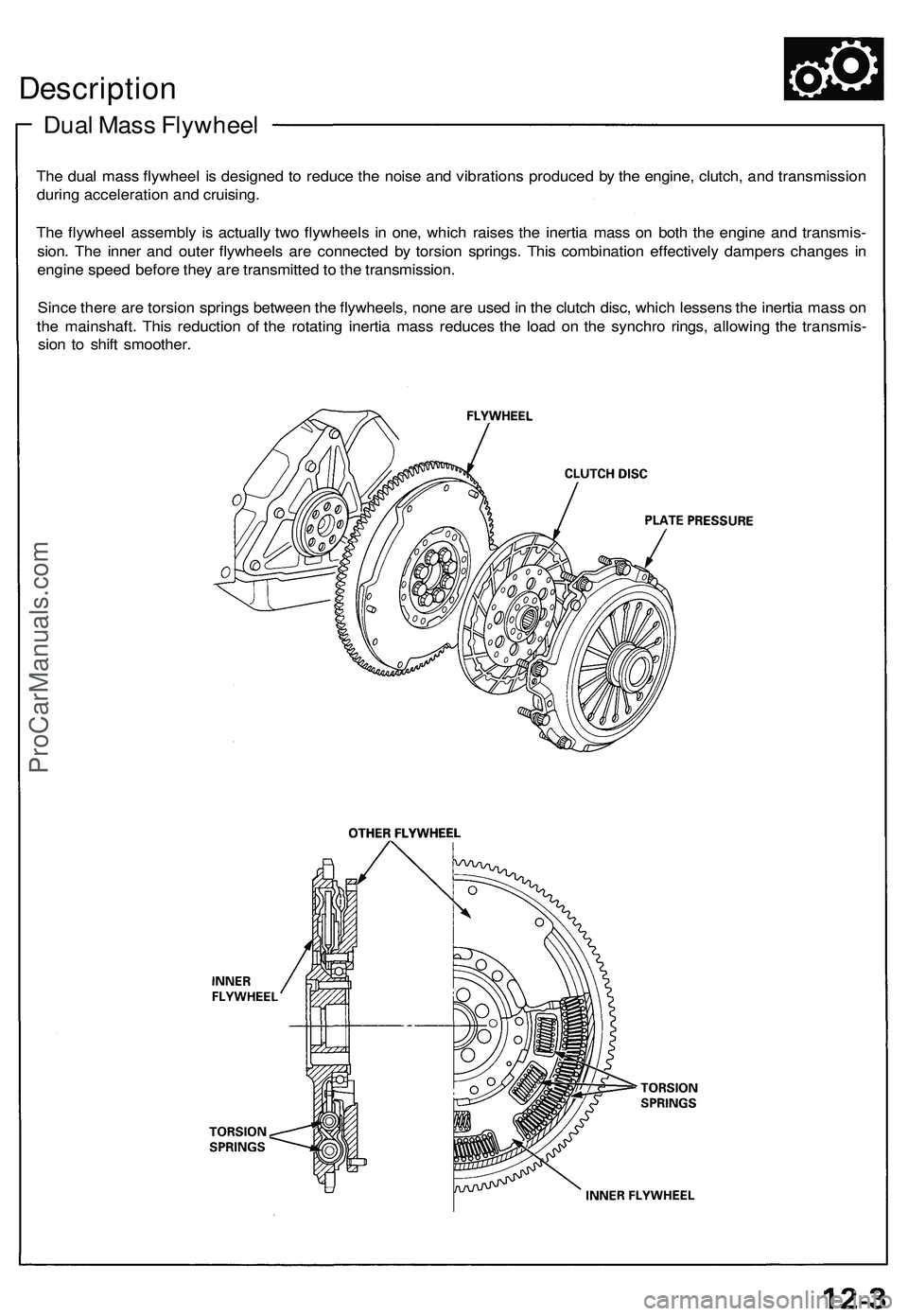

Description

Dual Mas s Flywhee l

The dua l mas s flywhee l i s designe d t o reduc e th e nois e an d vibration s produce d b y th e engine , clutch , an d transmissio n

durin g acceleratio n an d cruising .

Th e flywhee l assembl y i s actuall y tw o flywheel s i n one , whic h raise s th e inerti a mas s o n bot h th e engin e an d transmis -

sion . Th e inne r an d oute r flywheel s ar e connecte d b y torsio n springs . Thi s combinatio n effectivel y damper s change s i n

engin e spee d befor e the y ar e transmitte d to th e transmission .

Sinc e ther e ar e torsio n spring s betwee n th e flywheels , non e ar e use d in th e clutc h disc , whic h lessen s th e inerti a mas s o n

th e mainshaft . Thi s reductio n o f th e rotatin g inerti a mas s reduce s th e loa d o n th e synchr o rings , allowin g th e transmis -

sio n t o shif t smoother .

ProCarManuals.com