ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 621 of 1503

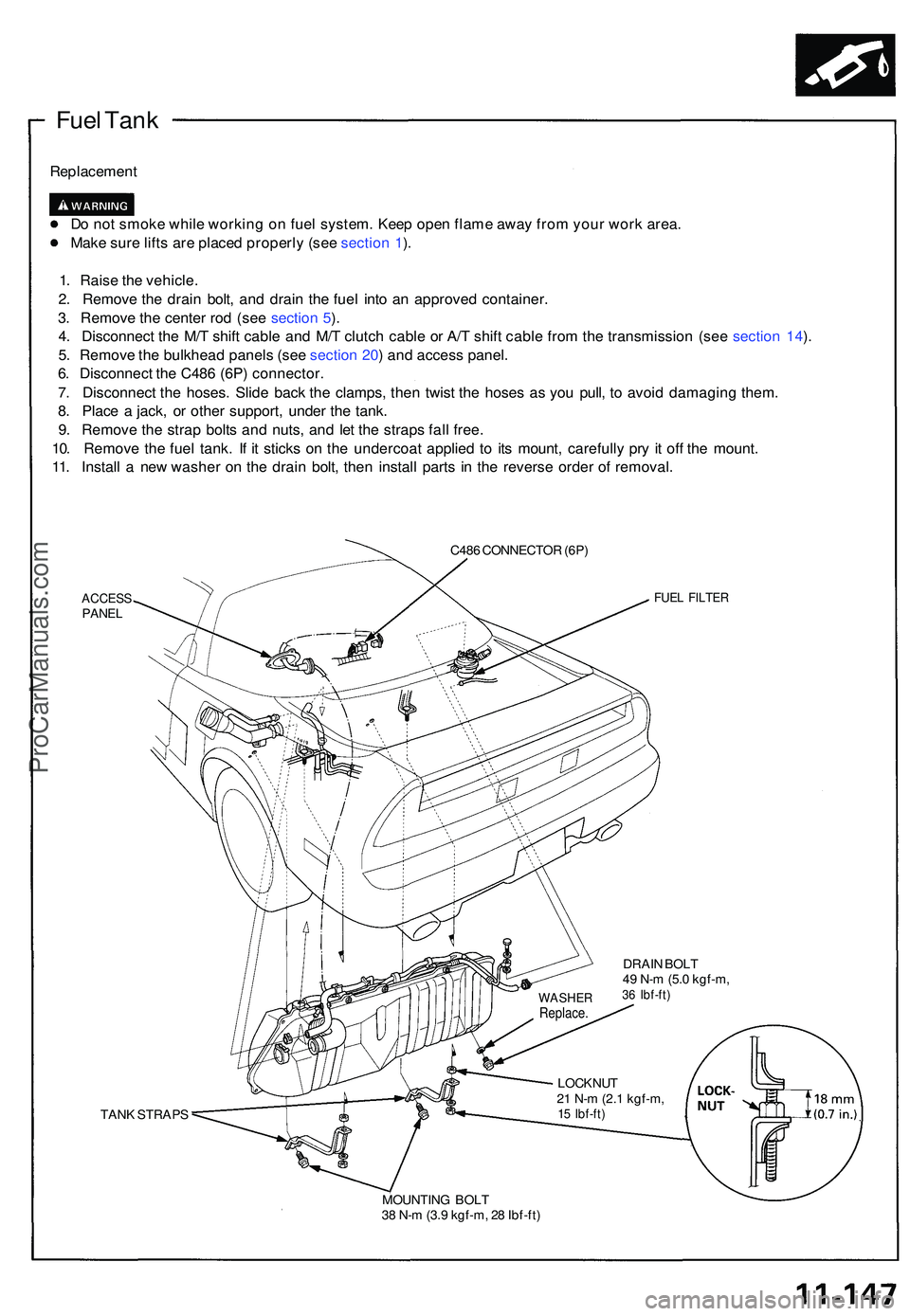

Fuel Tan k

Replacemen t

D o no t smok e whil e workin g o n fue l system . Kee p ope n flam e awa y fro m you r wor k area .

Mak e sur e lift s ar e place d properl y (se e sectio n 1 ).

1 . Rais e th e vehicle .

2 . Remov e th e drai n bolt , an d drai n th e fue l int o a n approve d container .

3 . Remov e th e cente r ro d (se e sectio n 5 ).

4 . Disconnec t th e M/ T shif t cabl e an d M/ T clutc h cabl e o r A/ T shif t cabl e fro m th e transmissio n (se e sectio n 14 ).

5 . Remov e th e bulkhea d panel s (se e sectio n 20 ) an d acces s panel .

6 . Disconnec t th e C48 6 (6P ) connector .

7 . Disconnec t th e hoses . Slid e bac k th e clamps , the n twis t th e hose s a s yo u pull , t o avoi d damagin g them .

8 . Plac e a jack , o r othe r support , unde r th e tank .

9 . Remov e th e stra p bolt s an d nuts , an d le t th e strap s fal l free .

10 . Remov e th e fue l tank . I f i t stick s o n th e undercoa t applie d t o it s mount , carefull y pr y i t of f th e mount .

11 . Instal l a ne w washe r o n th e drai n bolt , the n instal l part s i n th e revers e orde r o f removal .

C486 CONNECTO R (6P )

ACCES SPANELFUEL FILTE R

DRAIN BOL T

4 9 N- m (5. 0 kgf-m ,

36 Ibf-ft )

TANK STRAP S LOCKNU

T

2 1 N- m (2. 1 kgf-m ,15 Ibf-ft )

MOUNTIN G BOL T

3 8 N- m (3. 9 kgf-m , 2 8 Ibf-ft )

WASHE RReplace.

ProCarManuals.com

Page 622 of 1503

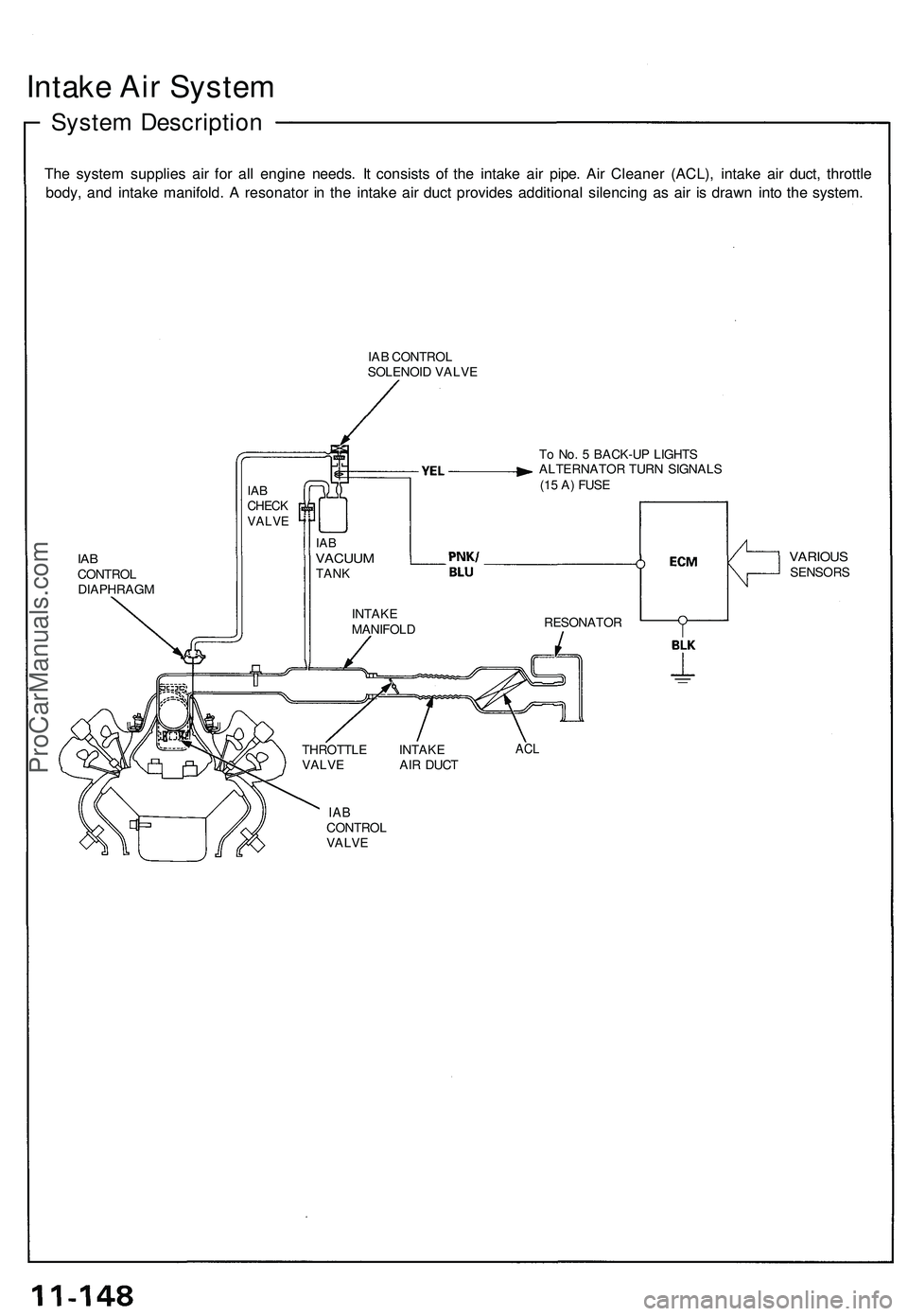

Intake Ai r Syste m

System Descriptio n

The syste m supplie s ai r fo r al l engine needs. I t consist s o f th e intak e ai r pipe . Ai r Cleane r (ACL) , intak e ai r duct , throttl e

body , an d intak e manifold . A resonato r i n th e intak e ai r duc t provide s additiona l silencin g a s ai r i s draw n int o th e system .

IAB CONTRO L

SOLENOI D VALV E

To No . 5 BACK-U P LIGHT S

ALTERNATO R TUR N SIGNAL S

(1 5 A ) FUS E

IABCONTRO L

DIAPHRAG M

THROTTLE INTAK E

VALV E AI R DUC T

VARIOU SSENSOR S

ACL

IABCONTRO LVALVE

INTAK E

MANIFOL DRESONATO R

IABCHEC KVALV E

IABVACUU MTANK

ProCarManuals.com

Page 623 of 1503

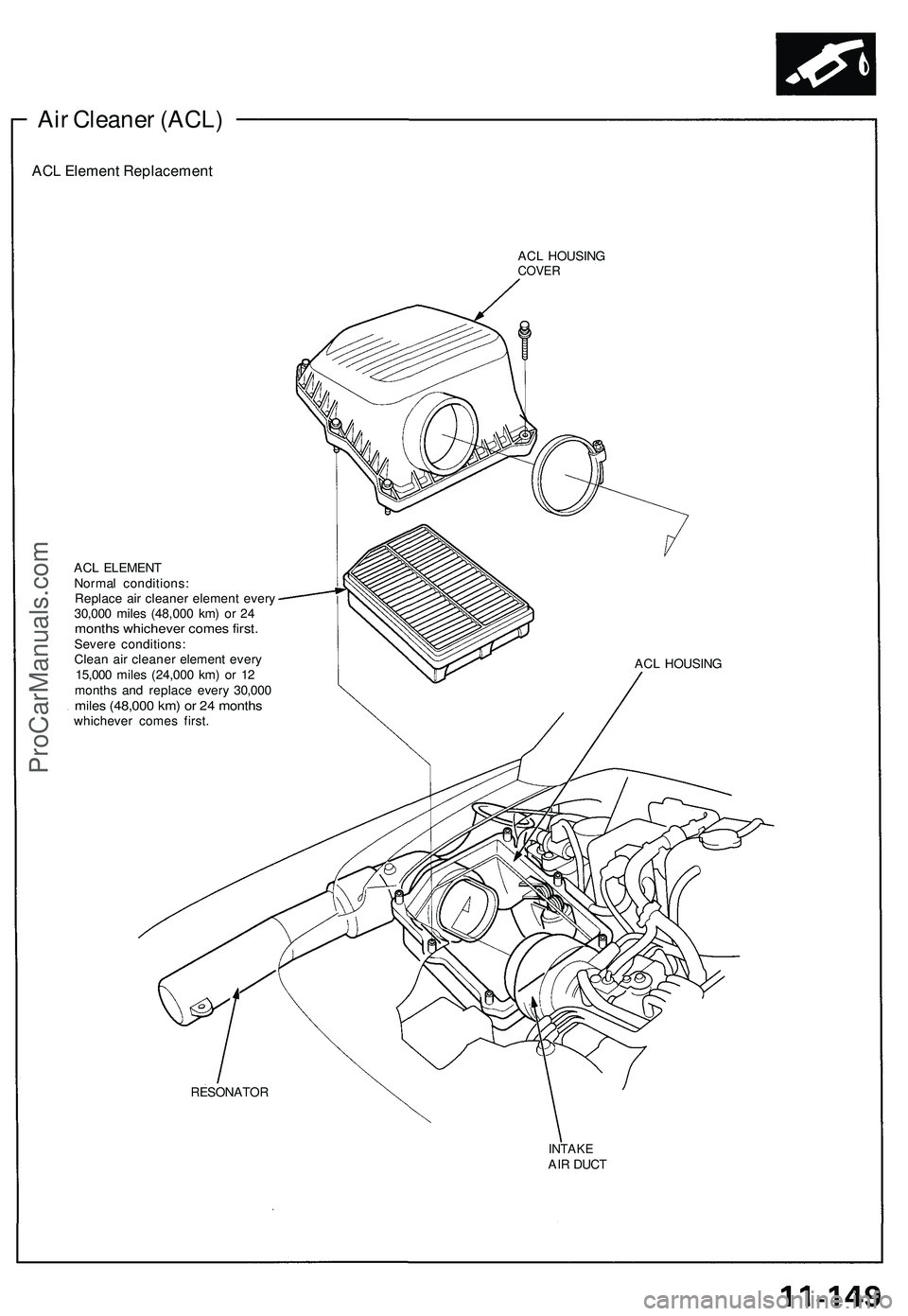

Air Cleaner (ACL)

ACL Element Replacement

ACL HOUSING

COVER

ACL ELEMENT

Normal conditions:

Replace air cleaner element every

30,000 miles (48,000 km) or 24

months whichever comes first.

Severe conditions:

Clean air cleaner element every

15,000 miles (24,000 km) or 12

months and replace every 30,000

miles (48,000 km) or 24 months

whichever comes first.

ACL HOUSING

RESONATOR

INTAKE

AIR DUCTProCarManuals.com

Page 624 of 1503

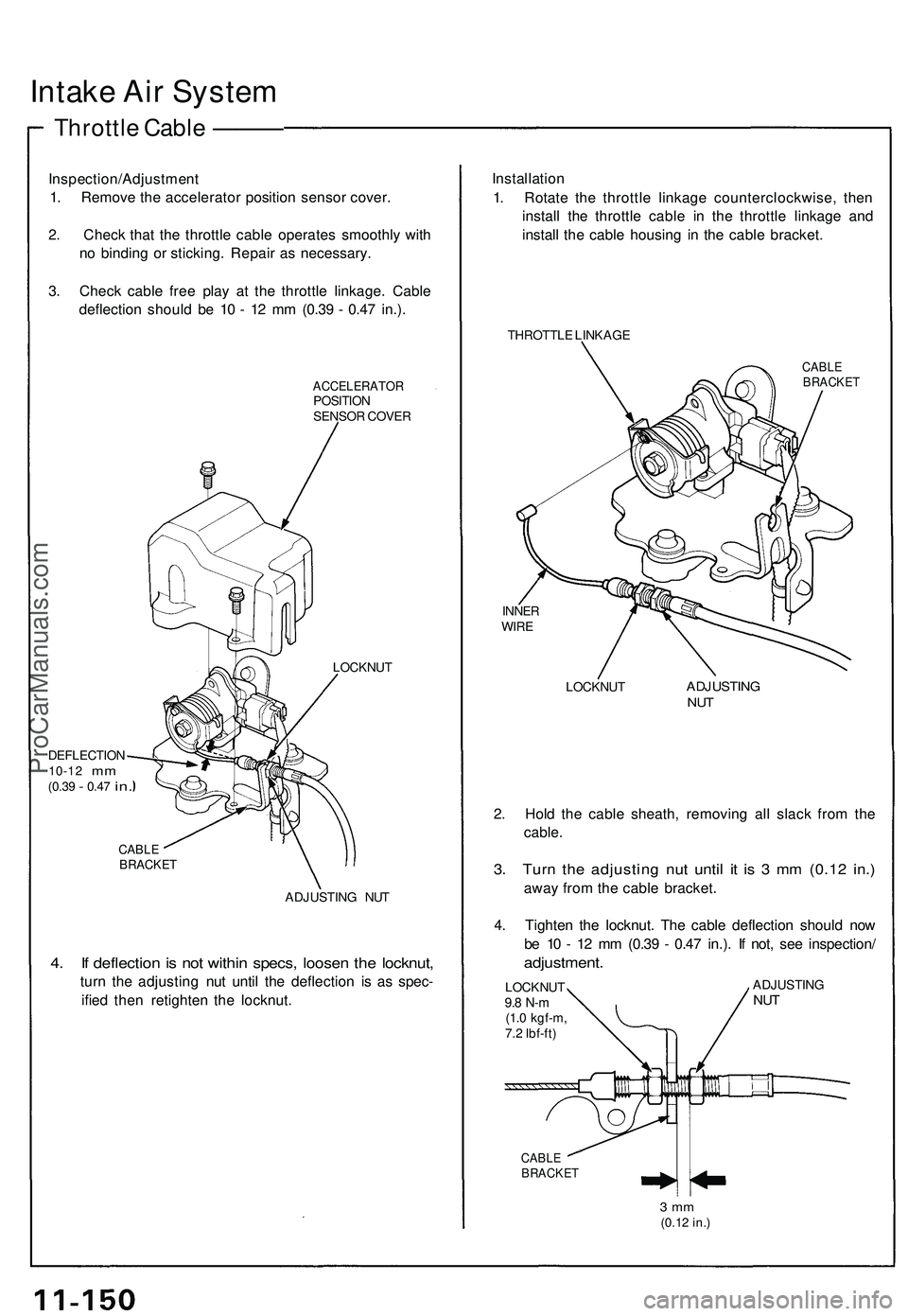

Intake Air System

Throttle Cable ———

Inspection/Adjustment

1. Remove the accelerator position sensor cover.

2. Check that the throttle cable operates smoothly with

no binding or sticking. Repair as necessary.

3. Check cable free play at the throttle linkage. Cable

deflection should be 10 - 12 mm (0.39 - 0.47 in.).

ACCELERATOR

POSITION

SENSOR COVER

DEFLECTION

10-12

mm

(0.39

-

0.47

in.

LOCKNUT

CABLE

BRACKET

ADJUSTING NUT

4. If deflection is not within specs, loosen the locknut,

turn the adjusting nut until the deflection is as spec-

ified then retighten the locknut.

Installation

1. Rotate the throttle linkage counterclockwise, then

install the throttle cable in the throttle linkage and

install the cable housing in the cable bracket.

THROTTLE LINKAGE

CABLE

BRACKET

INNER

WIRE

LOCKNUT

ADJUSTING

NUT

2. Hold the cable sheath, removing all slack from the

cable.

3. Turn the adjusting nut until it is 3 mm (0.12 in.)

away from the cable bracket.

4. Tighten the locknut. The cable deflection should now

be 10 - 12 mm (0.39 - 0.47 in.). If not, see inspection/

adjustment.

LOCKNUT

9.8 N-m

(1.0 kgf-m,

7.2 Ibf-ft)

ADJUSTING

NUT

CABLE

BRACKET

3 mm

(0.12 in.)ProCarManuals.com

Page 625 of 1503

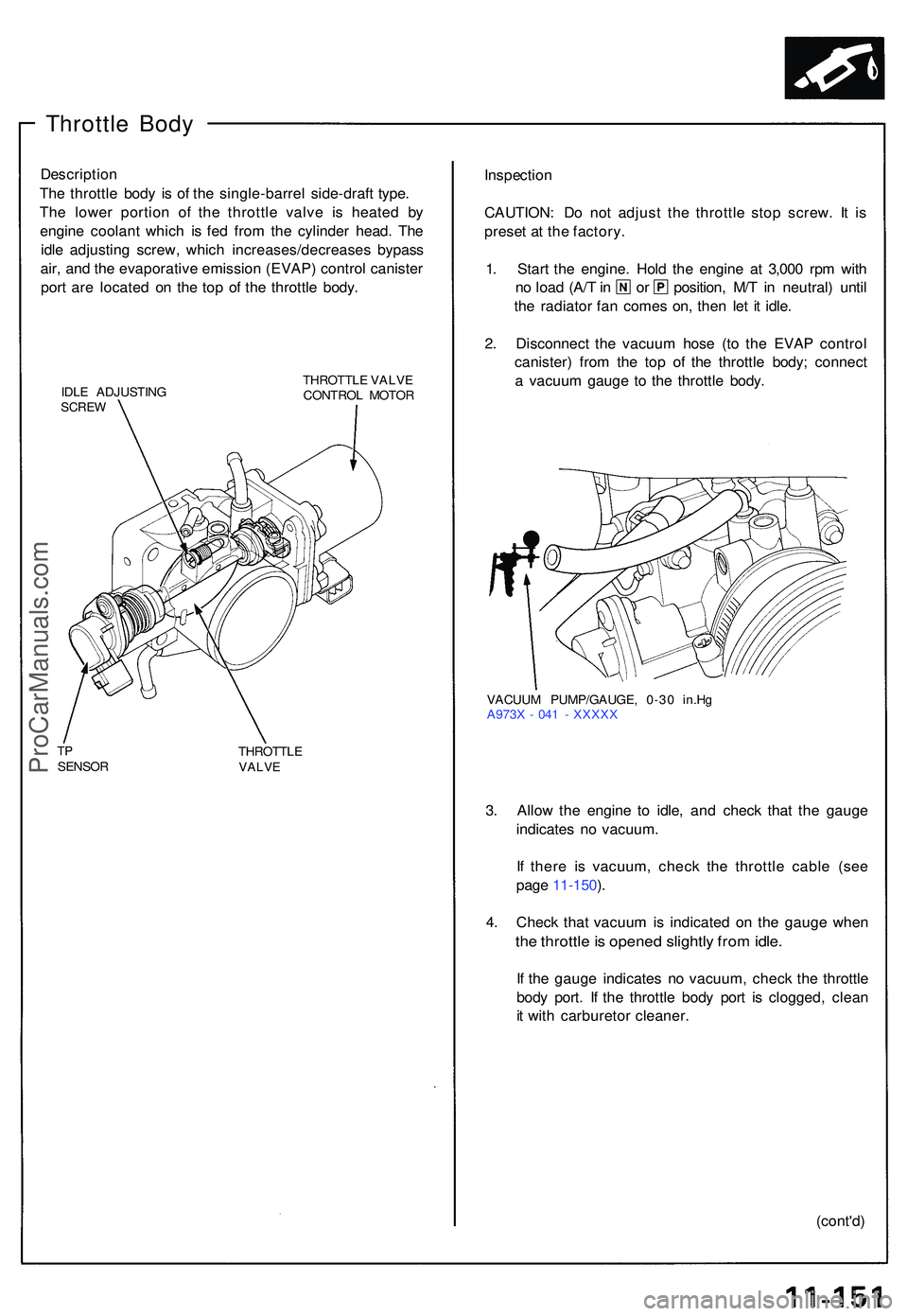

Throttle Bod y

Descriptio n

Th e throttl e bod y i s o f th e single-barre l side-draf t type .

Th e lowe r portio n o f th e throttl e valv e i s heate d b y

engine coolan t whic h i s fe d fro m th e cylinde r head . Th e

idl e adjustin g screw , whic h increases/decrease s bypas s

air , an d th e evaporativ e emissio n (EVAP ) contro l caniste r

por t ar e locate d o n th e to p o f th e throttl e body .

IDLE ADJUSTIN GSCREW

THROTTL E VALV E

CONTRO L MOTO R

TPSENSO R THROTTL

EVALVE

Inspectio n

CAUTION : D o no t adjus t th e throttl e sto p screw . I t i s

prese t a t th e factory .

1 . Star t th e engine . Hol d th e engine at 3,00 0 rp m wit h

no loa d (A/ T in o r position , M/ T i n neutral ) unti l

th e radiato r fa n come s on , the n le t i t idle .

2 . Disconnec t th e vacuu m hos e (t o th e EVA P contro l

canister ) fro m th e to p o f th e throttl e body ; connec t

a vacuu m gaug e t o th e throttl e body .

VACUU M PUMP/GAUGE , 0-3 0 in.H g

A973 X - 04 1 - XXXX X

3. Allo w th e engine to idle , an d chec k tha t th e gaug e

indicate s n o vacuum .

I f ther e i s vacuum , chec k th e throttl e cabl e (se e

pag e 11-150 ).

4 . Chec k tha t vacuu m is indicate d o n th e gaug e whe n

the throttl e is opene d slightl y fro m idle .

If th e gaug e indicate s n o vacuum , chec k th e throttl e

bod y port . I f th e throttl e bod y por t i s clogged , clea n

i t wit h carbureto r cleaner .

(cont'd)

ProCarManuals.com

Page 626 of 1503

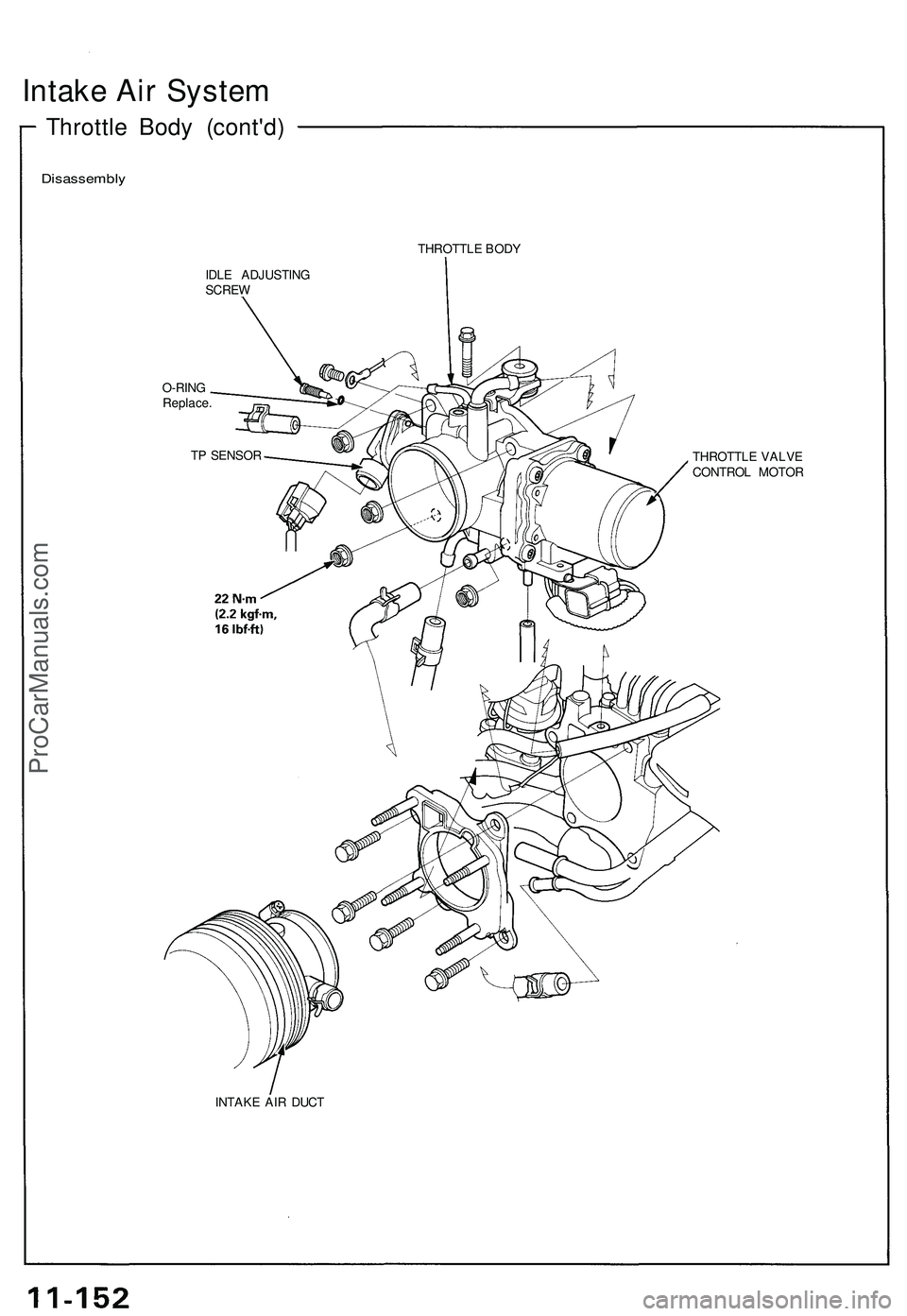

Intake Air System

Throttle Body (cont'd)

Disassembly

THROTTLE BODY

IDLE ADJUSTING

SCREW

O-RING

Replace.

INTAKE AIR DUCT

THROTTLE VALVE

CONTROL MOTOR

TP SENSORProCarManuals.com

Page 627 of 1503

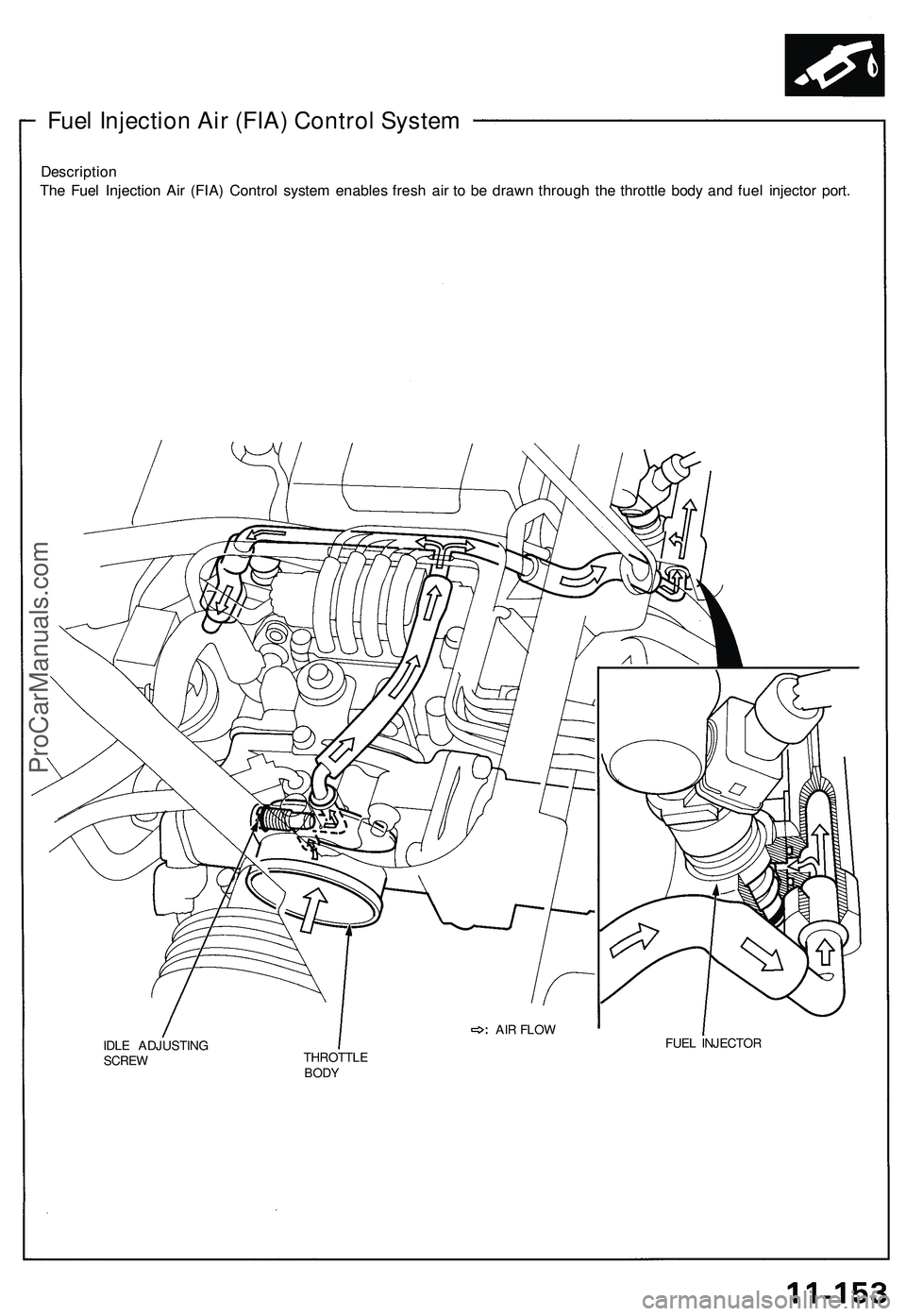

Description

The Fuel Injection Air (FIA) Control system enables fresh air to be drawn through the throttle body and fuel injector port.

IDLE ADJUSTING

SCREW

FUEL INJECTOR

THROTTLE

BODY

AIR FLOW

Fuel Injection Air (FIA) Control SystemProCarManuals.com

Page 628 of 1503

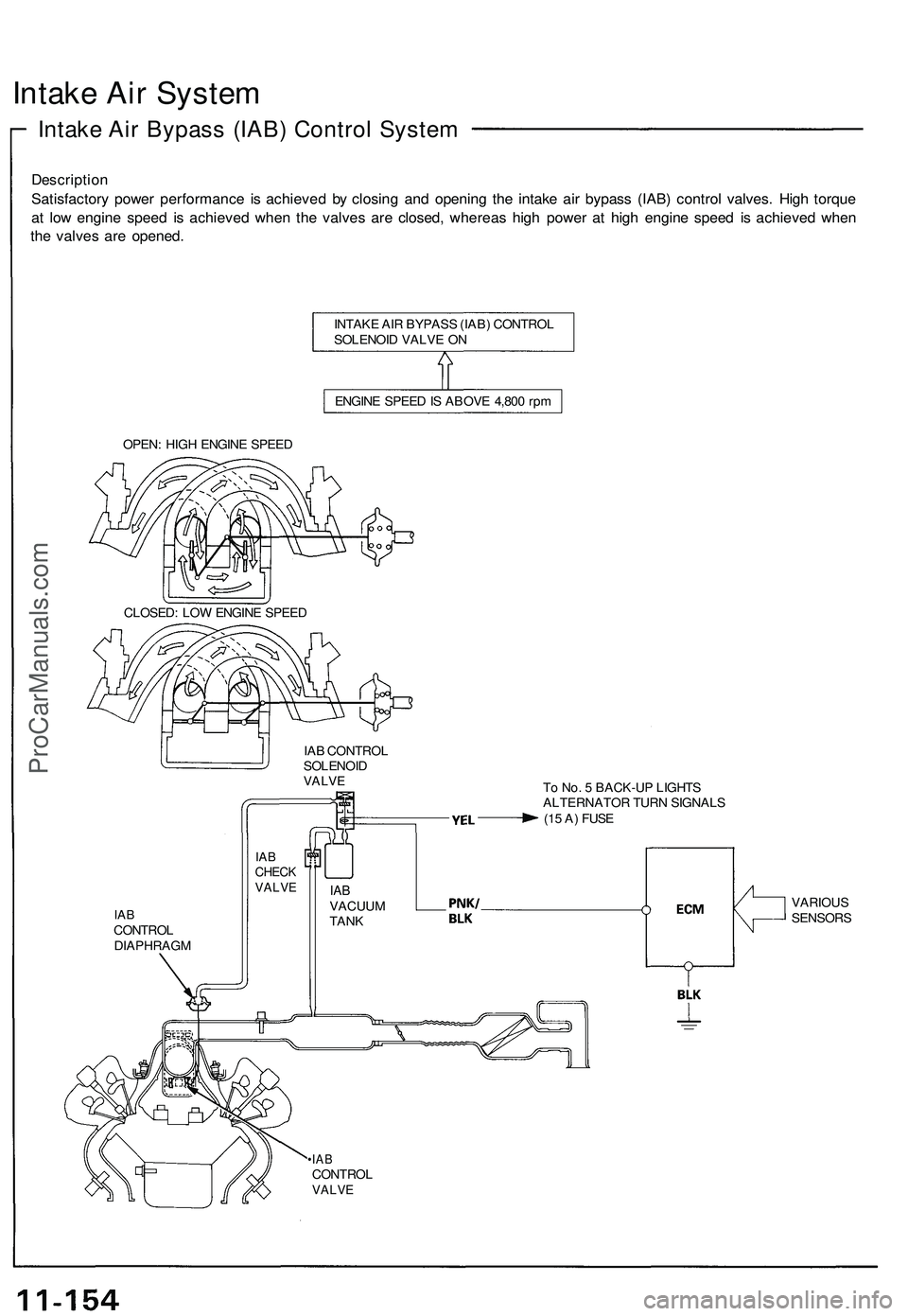

Intake Air System

Intake Air Bypass (IAB) Control System

Description

Satisfactory power performance is achieved by closing and opening the intake air bypass (IAB) control valves. High torque

at low engine speed is achieved when the valves are closed, whereas high power at high engine speed is achieved when

the valves are opened.

INTAKE AIR BYPASS (IAB) CONTROL

SOLENOID VALVE ON

ENGINE SPEED IS ABOVE 4,800 rpm

OPEN: HIGH ENGINE SPEED

CLOSED: LOW ENGINE SPEED

IAB CONTROL

SOLENOID

VALVE

To No. 5 BACK-UP LIGHTS

ALTERNATOR TURN SIGNALS

(15 A) FUSE

IAB

CONTROL

DIAPHRAGM

•IAB

CONTROL

VALVE

IAB

CHECK

VALVE

IAB

VACUUM

TANK

VARIOUS

SENSORSProCarManuals.com

Page 629 of 1503

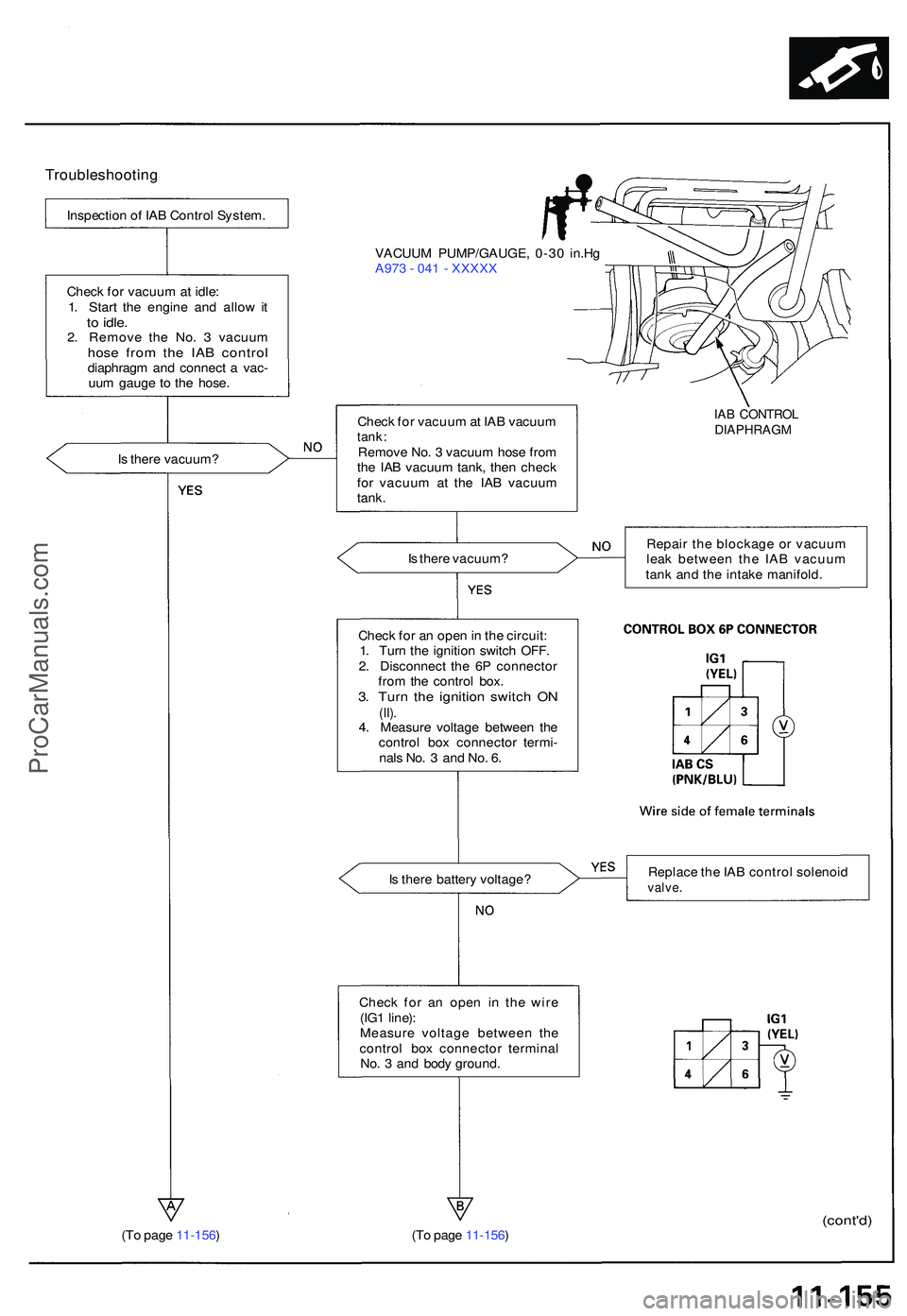

Troubleshooting

Inspection o f IA B Contro l System .

Chec k fo r vacuu m at idle :

1 . Star t th e engin e an d allo w it

to idle .2. Remov e th e No . 3 vacuu mhose fro m th e IA B contro ldiaphrag m an d connec t a vac -

uu m gaug e t o th e hose . VACUU

M PUMP/GAUGE , 0-3 0 in.H g

A97 3 - 04 1 - XXXX X

I s ther e vacuum ? Chec

k fo r vacuu m at IA B vacuu m

tank:Remov e No . 3 vacuu m hos e fro m

th e IA B vacuu m tank , the n chec k

fo r vacuu m a t th e IA B vacuu m

tank.

IAB CONTRO LDIAPHRAG M

Is ther e vacuum ?

Chec k fo r a n ope n in th e circuit :

1 . Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e 6 P connecto r

fro m th e contro l box .

3. Tur n th e ignitio n switc h O N(II).4. Measur e voltag e betwee n th e

contro l bo x connecto r termi -

nal s No . 3 an d No . 6 .

I s ther e batter y voltage ? Replac

e th e IA B contro l solenoi d

valve.

Check fo r a n ope n i n th e wir e

(IG 1 line) :

Measur e voltag e betwee n th e

contro l bo x connecto r termina l

No . 3 an d bod y ground .

(T o pag e 11-156 )

(cont'd)(To pag e 11-156 ) Repai

r th e blockag e o r vacuu m

lea k betwee n th e IA B vacuu m

tan k an d th e intak e manifold .

ProCarManuals.com

Page 630 of 1503

Intake Ai r Syste m

Intake Ai r Bypas s (IAB ) Contro l Syste m (cont'd )

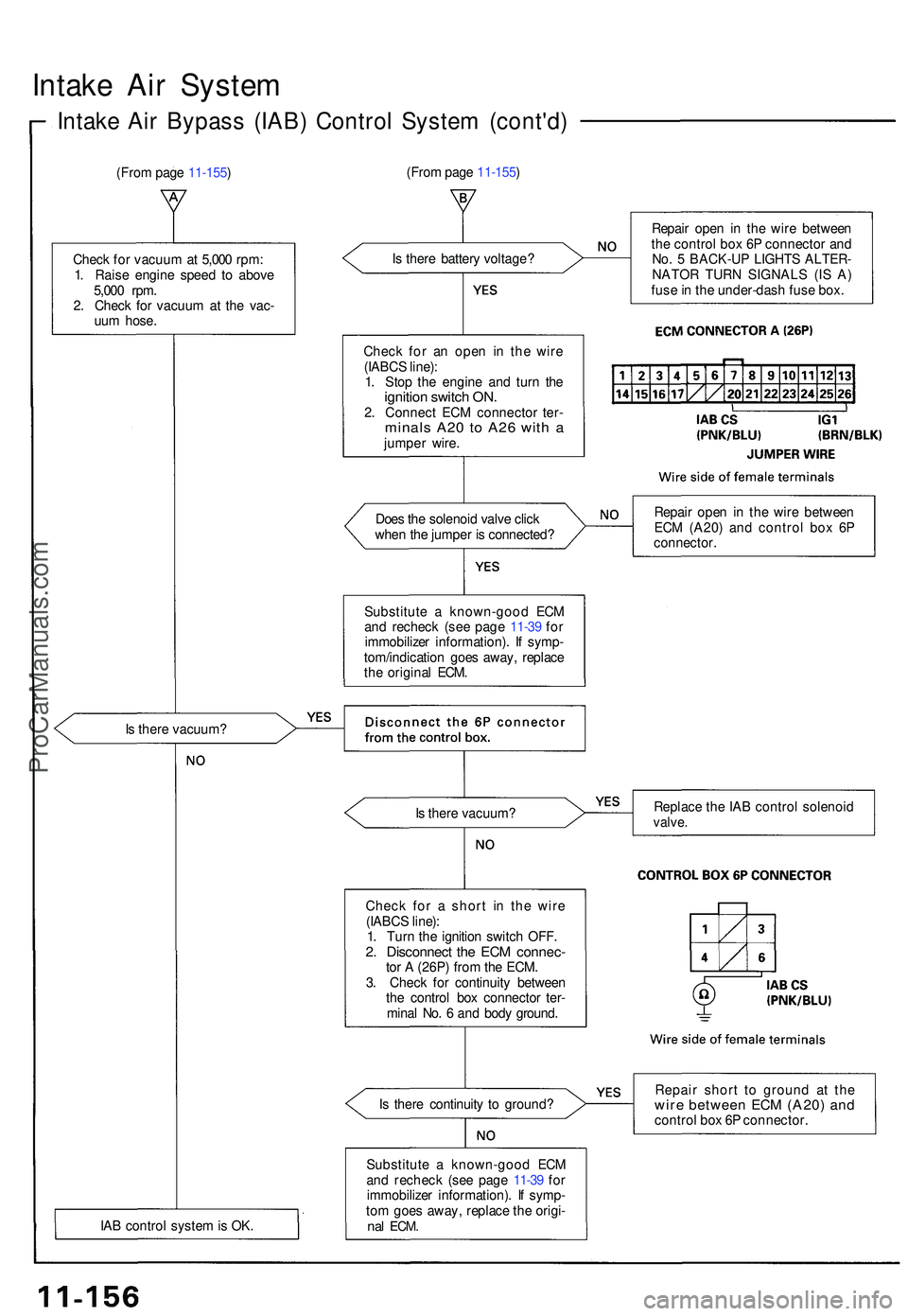

(From pag e 11-155 )

Chec k fo r vacuu m at 5,00 0 rpm :

1 . Rais e engin e spee d t o abov e

5,00 0 rpm .

2 . Chec k fo r vacuu m a t th e vac -

uu m hose .

I s ther e vacuum ?

IA B contro l syste m is OK . I

s ther e batter y voltage ?

Chec k fo r a n ope n i n th e wir e

(IABC S line) :

1 . Sto p th e engin e an d tur n th e

ignitio n switc h ON .2. Connec t EC M connecto r ter -minal s A2 0 t o A2 6 wit h ajumpe r wire .

Doe s th e solenoi d valv e clic k

whe n th e jumpe r i s connected ?

Substitut e a known-goo d EC M

an d rechec k (se e pag e 11-3 9 fo r

immobilize r information) . I f symp -

tom/indicatio n goe s away , replac e

th e origina l ECM .

I s ther e vacuum ?

Chec k fo r a shor t i n th e wir e

(IABC S line) :

1 . Tur n th e ignitio n switc h OFF .

2. Disconnec t th e EC M connec -tor A (26P ) fro m th e ECM .

3 . Chec k fo r continuit y betwee n

th e contro l bo x connecto r ter -

mina l No . 6 an d bod y ground .

I s ther e continuit y t o ground ?

Substitut e a known-goo d EC M

an d rechec k (se e pag e 11-3 9 fo r

immobilize r information) . I f symp -

to m goe s away , replac e th e origi -

nal ECM .

Repai r ope n i n th e wir e betwee n

th e contro l bo x 6 P connecto r an d

No . 5 BACK-U P LIGHT S ALTER -

NATO R TUR N SIGNAL S (I S A )

fus e in th e under-das h fus e box .

Repai r ope n i n th e wir e betwee n

EC M (A20 ) an d contro l bo x 6 P

connector .

Replac e th e IA B contro l solenoi d

valve.

Repai r shor t t o groun d a t th ewir e betwee n EC M (A20 ) an dcontro l bo x 6 P connector .

(Fro

m pag e 11-155 )

ProCarManuals.com