ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997,

Model line: NSX,

Model: ACURA NSX 1997

Pages: 1503, PDF Size: 57.08 MB

ACURA NSX 1997 Service Repair Manual

NSX 1997

ACURA

ACURA

https://www.carmanualsonline.info/img/32/56989/w960_56989-0.png

ACURA NSX 1997 Service Repair Manual

Trending: fuses, oil level, fuel type, start stop button, ignition, high beam, headlight bulb

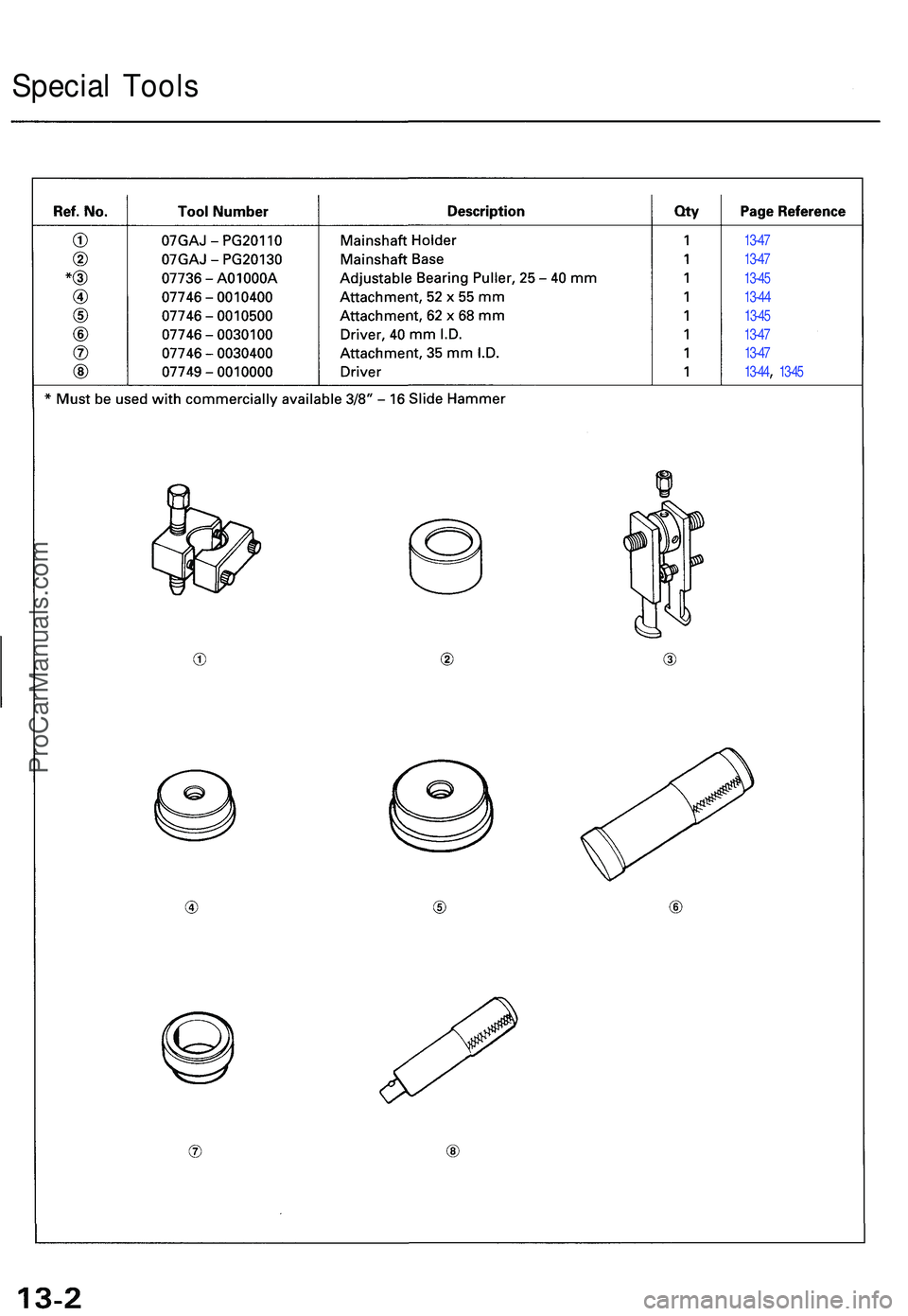

Page 651 of 1503

13-47

13-4 7

13-4 5

13-4 4

13-45

13-47

13-4 7

13-44 , 13-4 5

Specia l Tool s

ProCarManuals.com

Page 652 of 1503

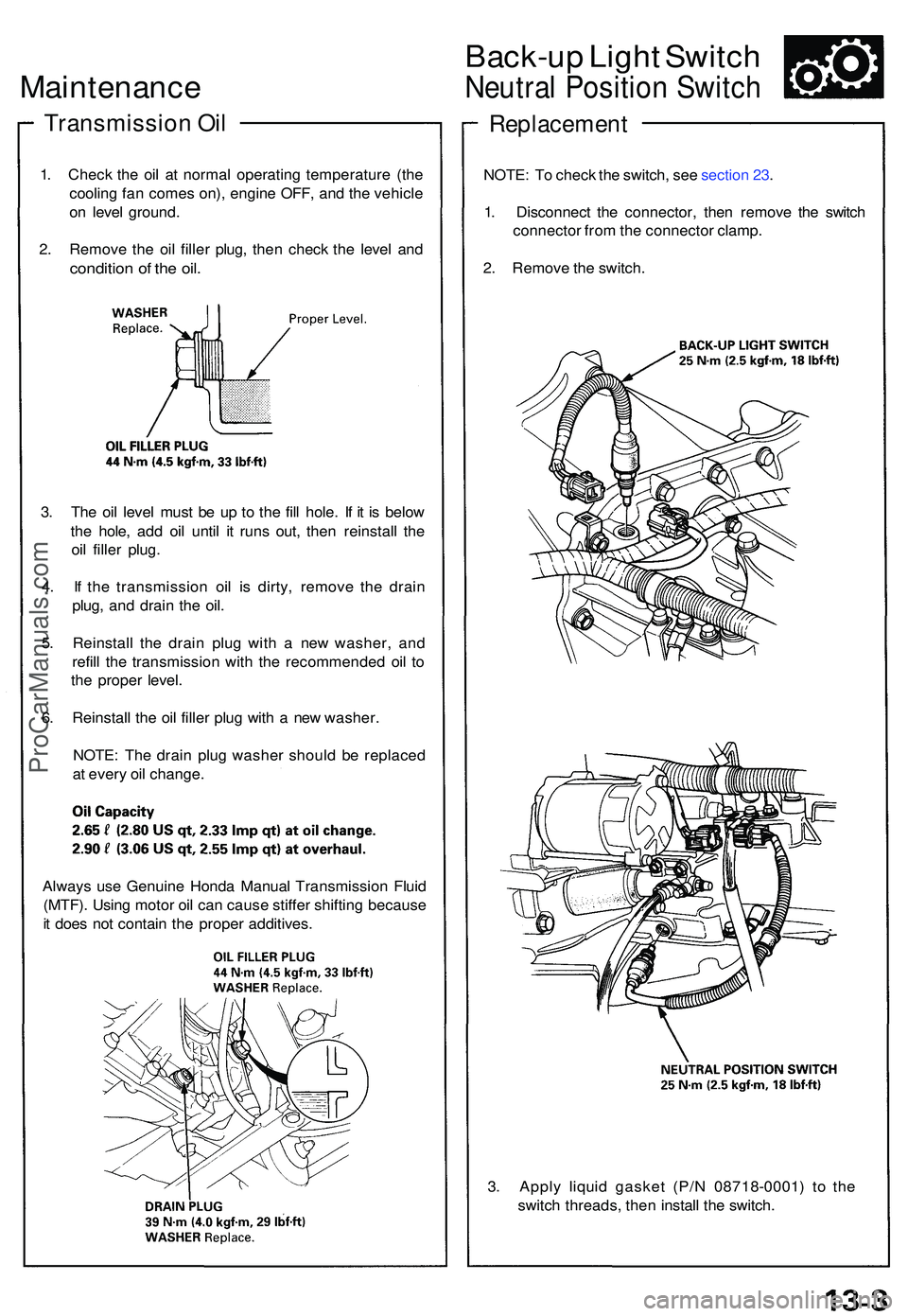

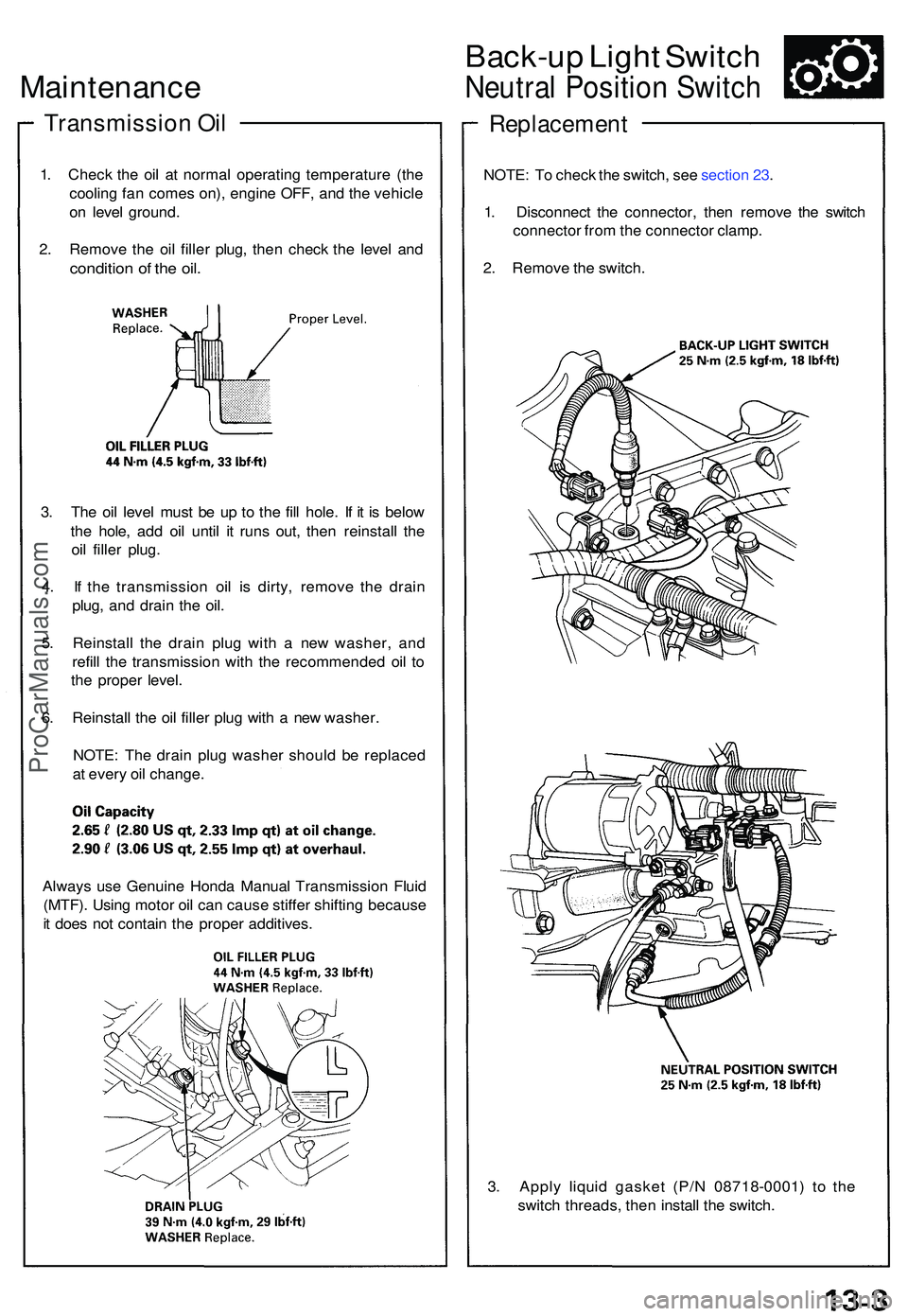

Maintenance

Transmissio n Oi l

1. Chec k th e oi l a t norma l operating temperatur e (th e

coolin g fa n come s on) , engin e OFF , an d th e vehicl e

o n leve l ground .

2 . Remov e th e oi l fille r plug , the n chec k th e leve l an d

conditio n o f th e oil .

3. Th e oi l leve l mus t b e u p t o th e fil l hole . I f i t i s belo w

th e hole , ad d oi l unti l i t run s out , the n reinstal l th e

oi l fille r plug .

4 . I f th e transmissio n oi l i s dirty , remov e th e drai n

plug , an d drai n th e oil .

5 . Reinstal l th e drai n plu g wit h a ne w washer , an d

refil l th e transmissio n wit h th e recommende d oi l t o

th e prope r level .

6 . Reinstal l th e oi l fille r plu g wit h a ne w washer .

NOTE : Th e drai n plu g washe r shoul d b e replace d

a t ever y oi l change .

Back-up Ligh t Switc h

Neutra l Positio n Switc h

Replacemen t

NOTE: T o chec k th e switch , se e sectio n 23 .

1 . Disconnec t th e connector , the n remov e th e switc h

connecto r fro m th e connecto r clamp .

2 . Remov e th e switch .

3 . Appl y liqui d gaske t (P/ N 0871 8-0001 ) t o th e

switc h threads , the n instal l th e switch .

Alway

s us e Genuin e Hond a Manua l Transmissio n Flui d

(MTF) . Usin g moto r oi l ca n caus e stiffe r shiftin g becaus e

i t doe s no t contai n th e prope r additives .

ProCarManuals.com

Page 653 of 1503

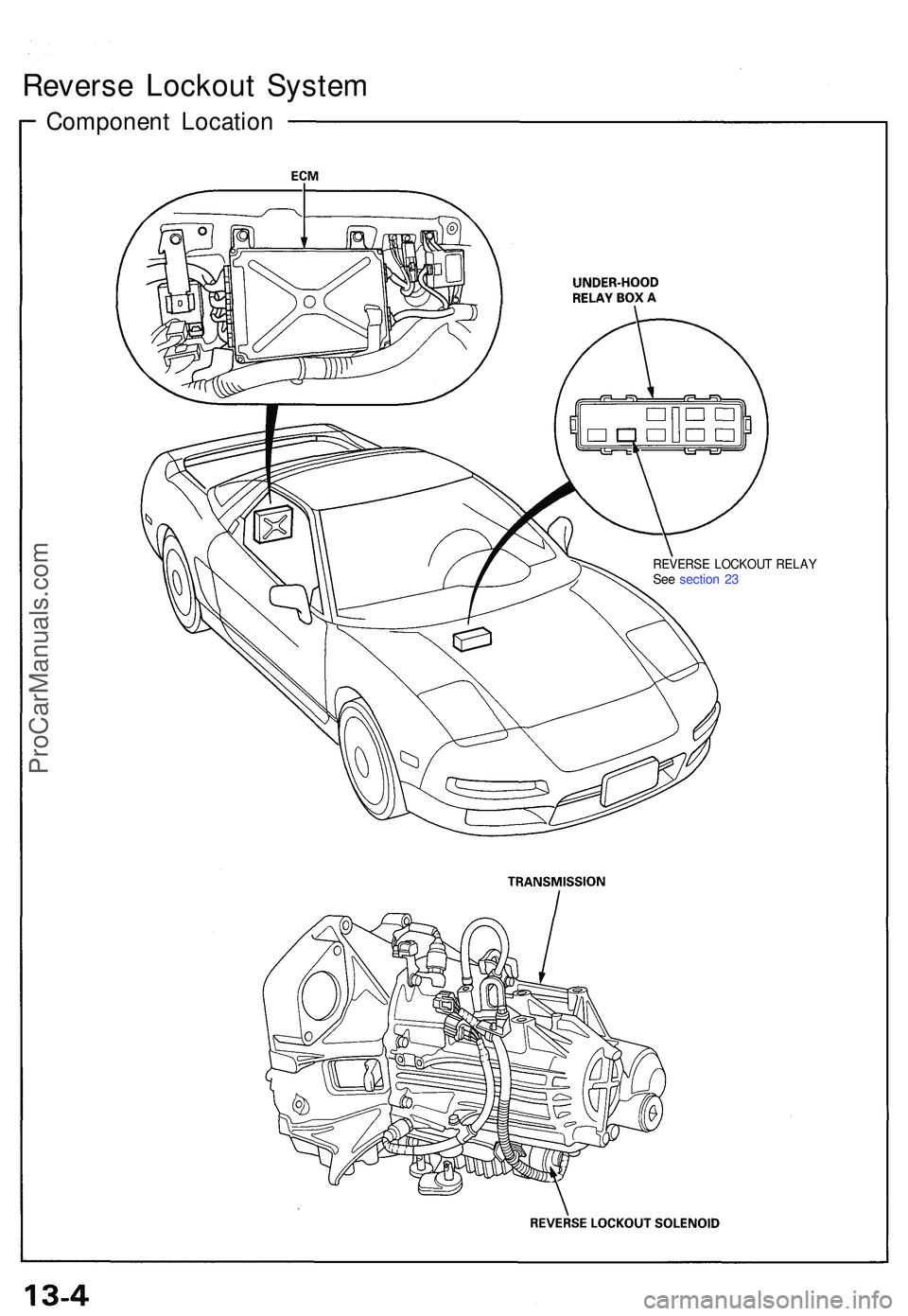

REVERSE LOCKOU T RELA YSee sectio n 2 3

Revers e Lockou t Syste m

Componen t Locatio n

ProCarManuals.com

Page 654 of 1503

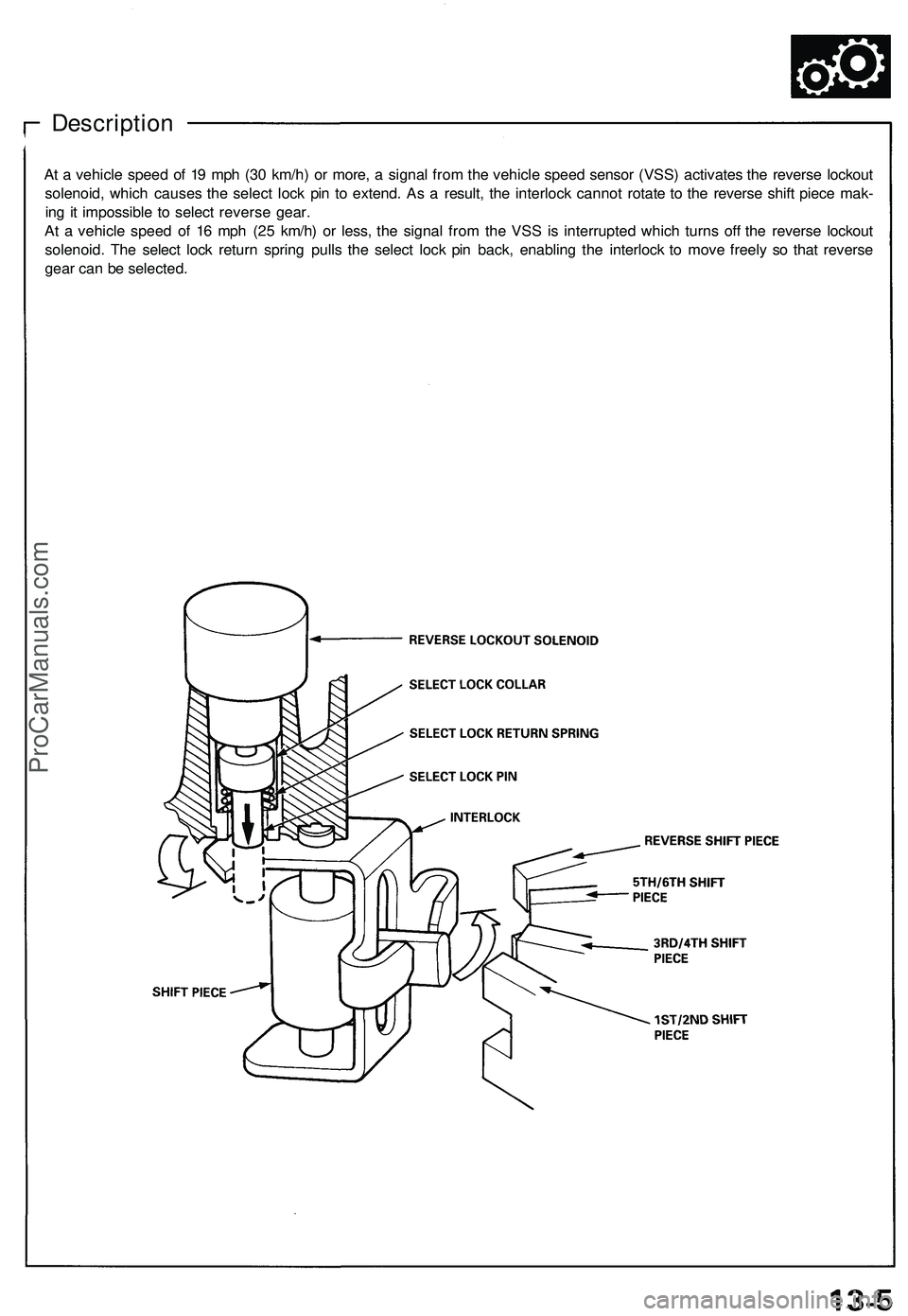

Description

At a vehicle speed of 19 mph (30 km/h) or more, a signal from the vehicle speed sensor (VSS) activates the reverse lockout

solenoid, which causes the select lock pin to extend. As a result, the interlock cannot rotate to the reverse shift piece mak-

ing it impossible to select reverse gear.

At a vehicle speed of 16 mph (25 km/h) or less, the signal from the VSS is interrupted which turns off the reverse lockout

solenoid. The select lock return spring pulls the select lock pin back, enabling the interlock to move freely so that reverse

gear can be selected.ProCarManuals.com

Page 655 of 1503

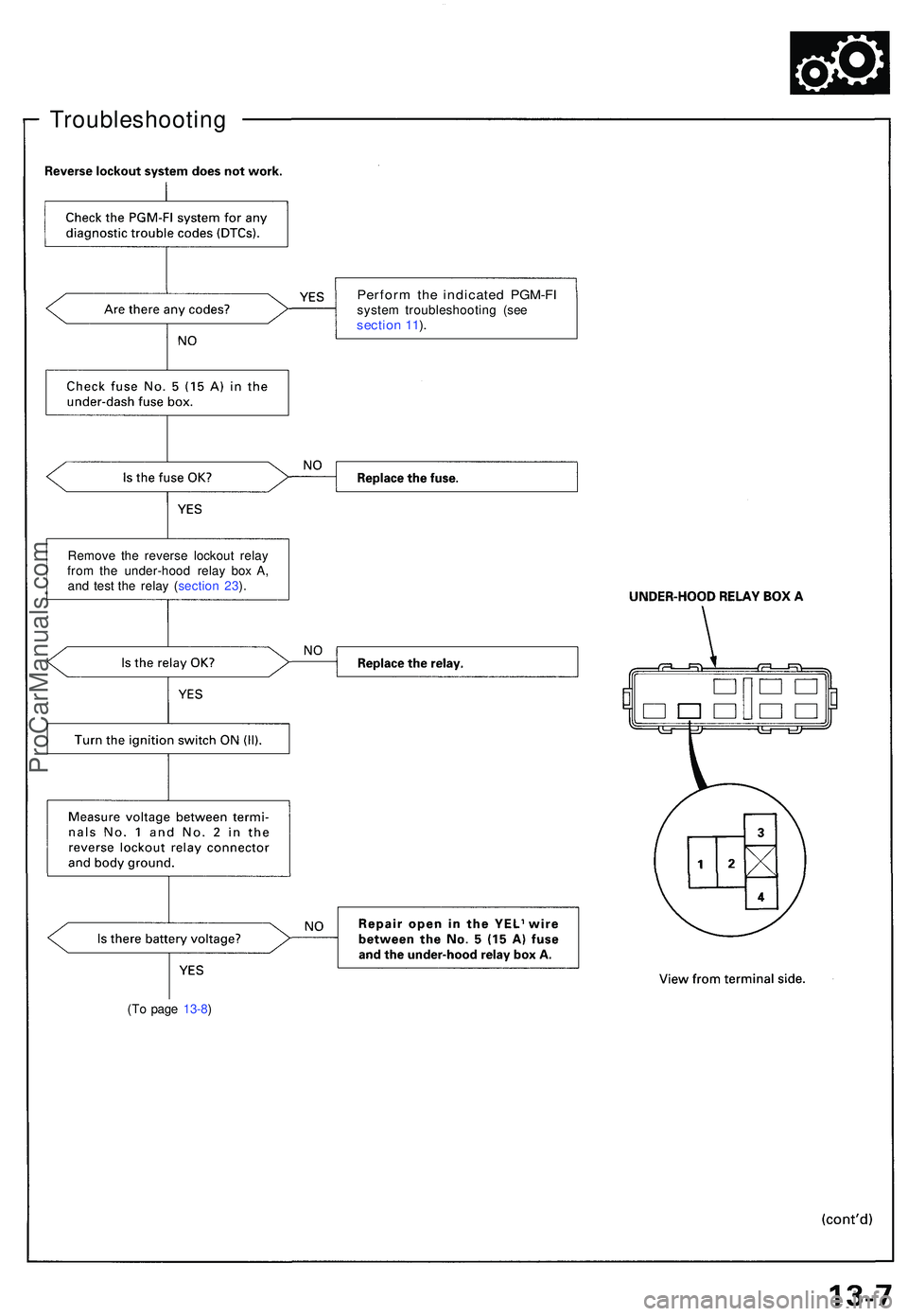

Troubleshooting

(To pag e 13-8 )

Perfor m th e indicate d PGM-F Isystem troubleshootin g (se e sectio n 11 ).

Remov e th e revers e lockou t rela y

fro m th e under-hoo d rela y bo x A ,

an d tes t th e rela y ( sectio n 23 ).

ProCarManuals.com

Page 656 of 1503

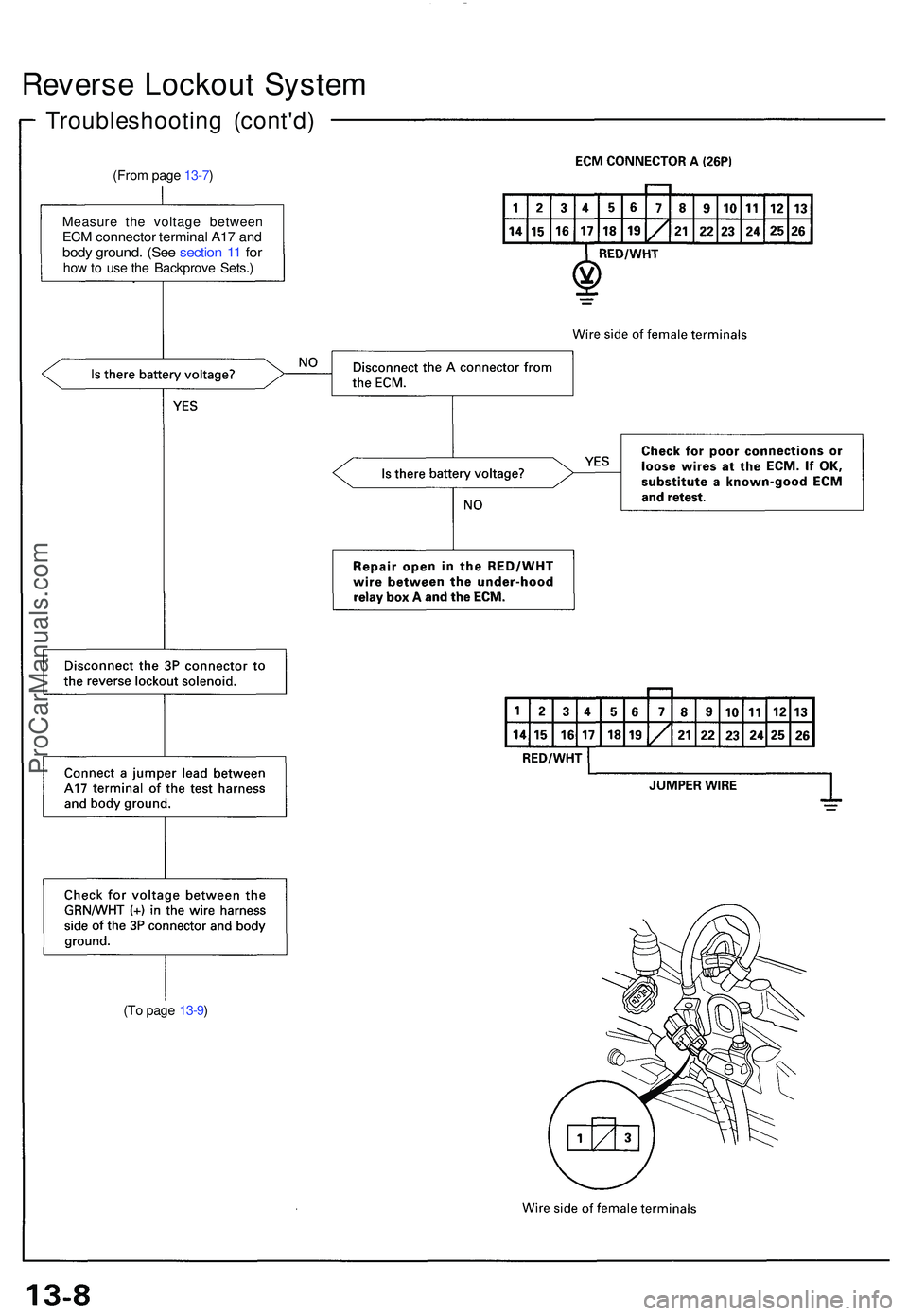

Reverse Lockou t Syste m

Troubleshootin g (cont'd )

(From pag e 13-7 )

Measur e th e voltag e betwee n

ECM connecto r termina l A1 7 an dbod y ground . (Se e sectio n 1 1 fo rhow to us e th e Backprov e Sets. )

(T o pag e 13-9 )

ProCarManuals.com

Page 657 of 1503

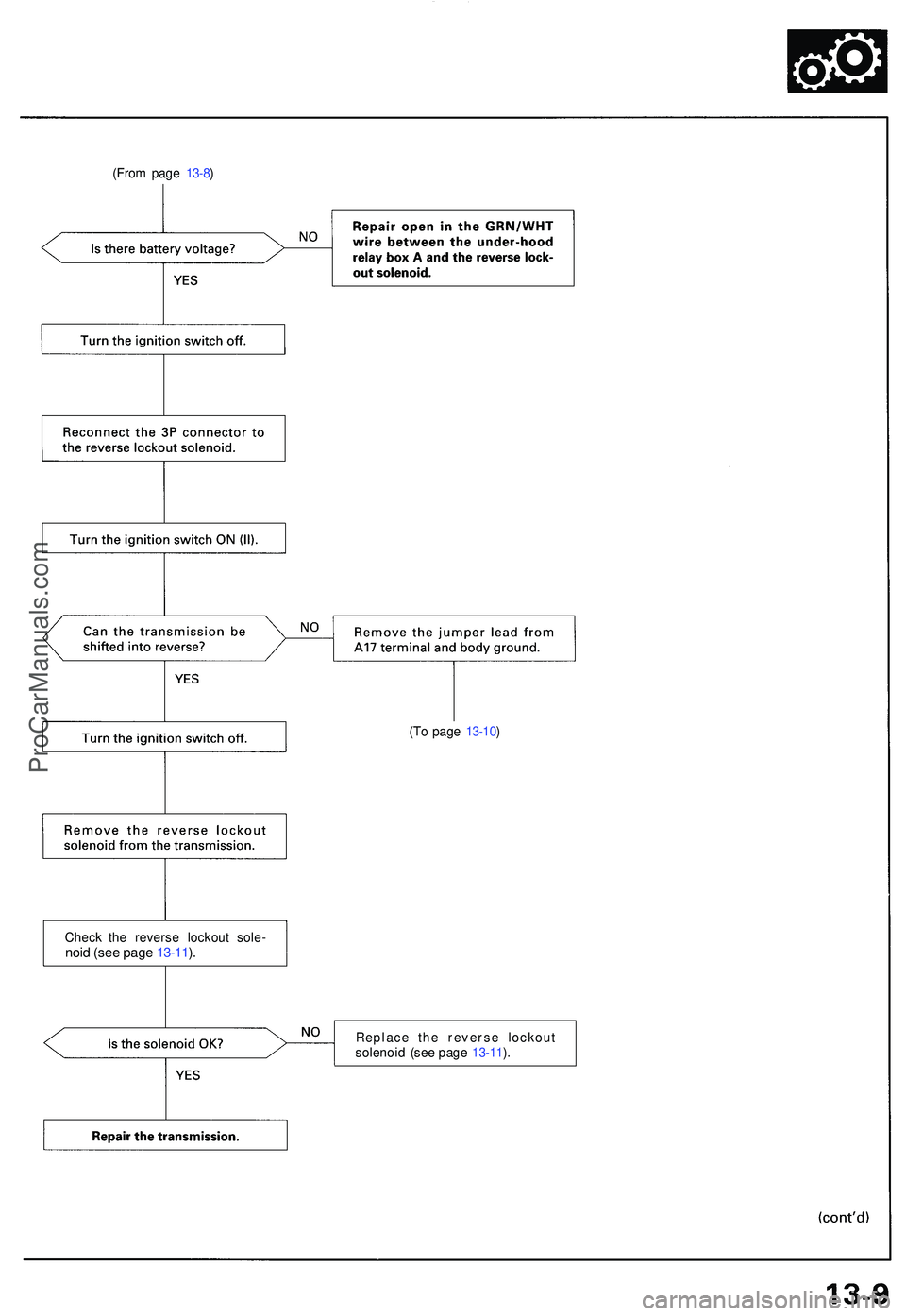

(From pag e 13-8 )

(To pag e 13-10 )

Chec k th e revers e lockou t sole -

noid (se e pag e 13-11 ).

Replac e th e revers e lockou t

solenoi d (se e pag e 13-11 ).

ProCarManuals.com

Page 658 of 1503

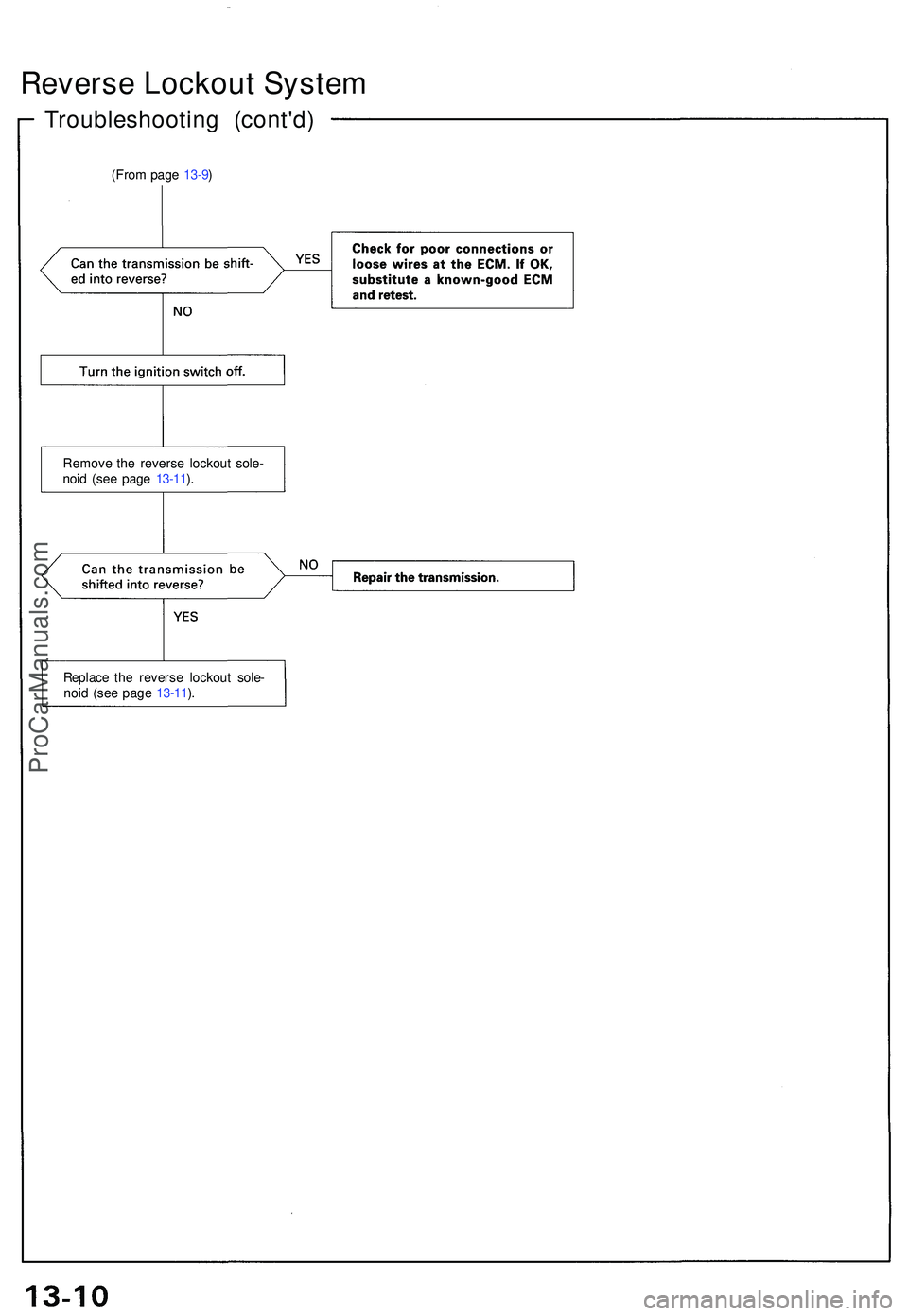

Reverse Lockou t Syste m

Troubleshootin g (cont'd )

(From pag e 13-9 )

Remov e th e revers e lockou t sole -

noi d (se e pag e 13-11 ).

Replac e th e revers e lockou t sole -

noi d (se e pag e 13-11 ).

ProCarManuals.com

Page 659 of 1503

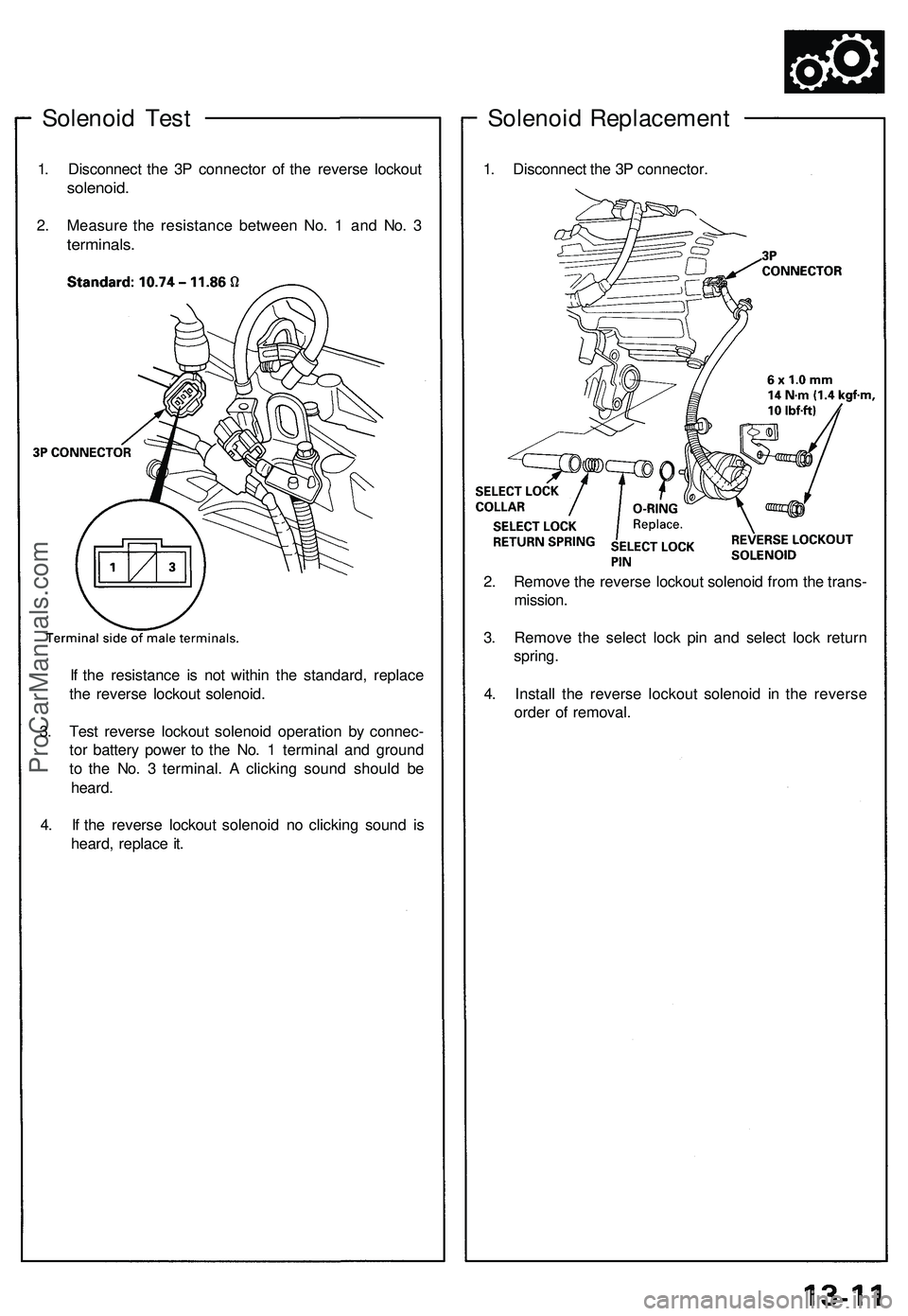

Solenoid Test

1. Disconnect the 3P connector of the reverse lockout

solenoid.

2. Measure the resistance between No. 1 and No. 3

terminals.

If the resistance is not within the standard, replace

the reverse lockout solenoid.

3. Test reverse lockout solenoid operation by connec-

tor battery power to the No. 1 terminal and ground

to the No. 3 terminal. A clicking sound should be

heard.

4. If the reverse lockout solenoid no clicking sound is

heard, replace it.

Solenoid Replacement

1. Disconnect the 3P connector.

2. Remove the reverse lockout solenoid from the trans-

mission.

3. Remove the select lock pin and select lock return

spring.

4. Install the reverse lockout solenoid in the reverse

order of removal.ProCarManuals.com

Page 660 of 1503

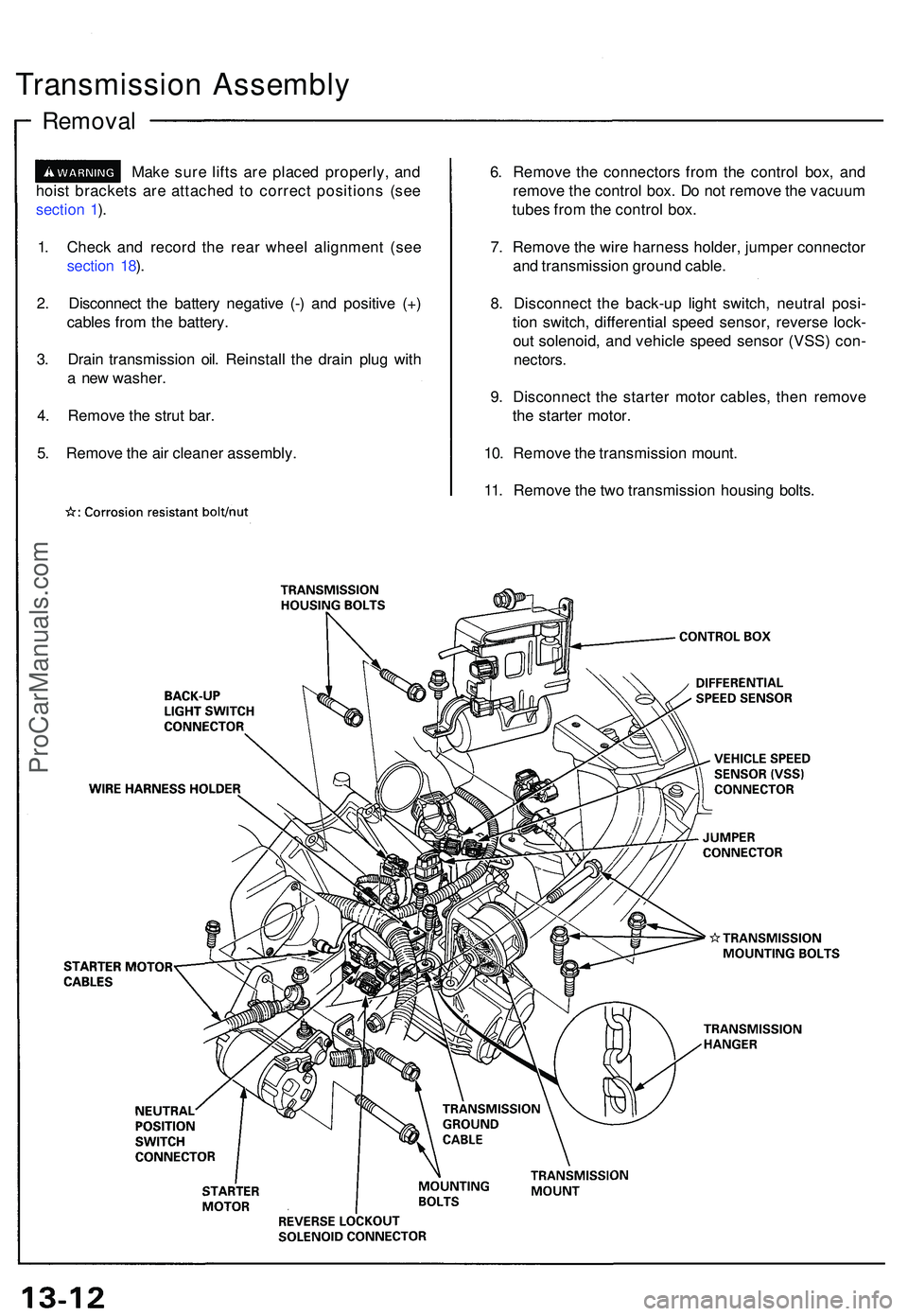

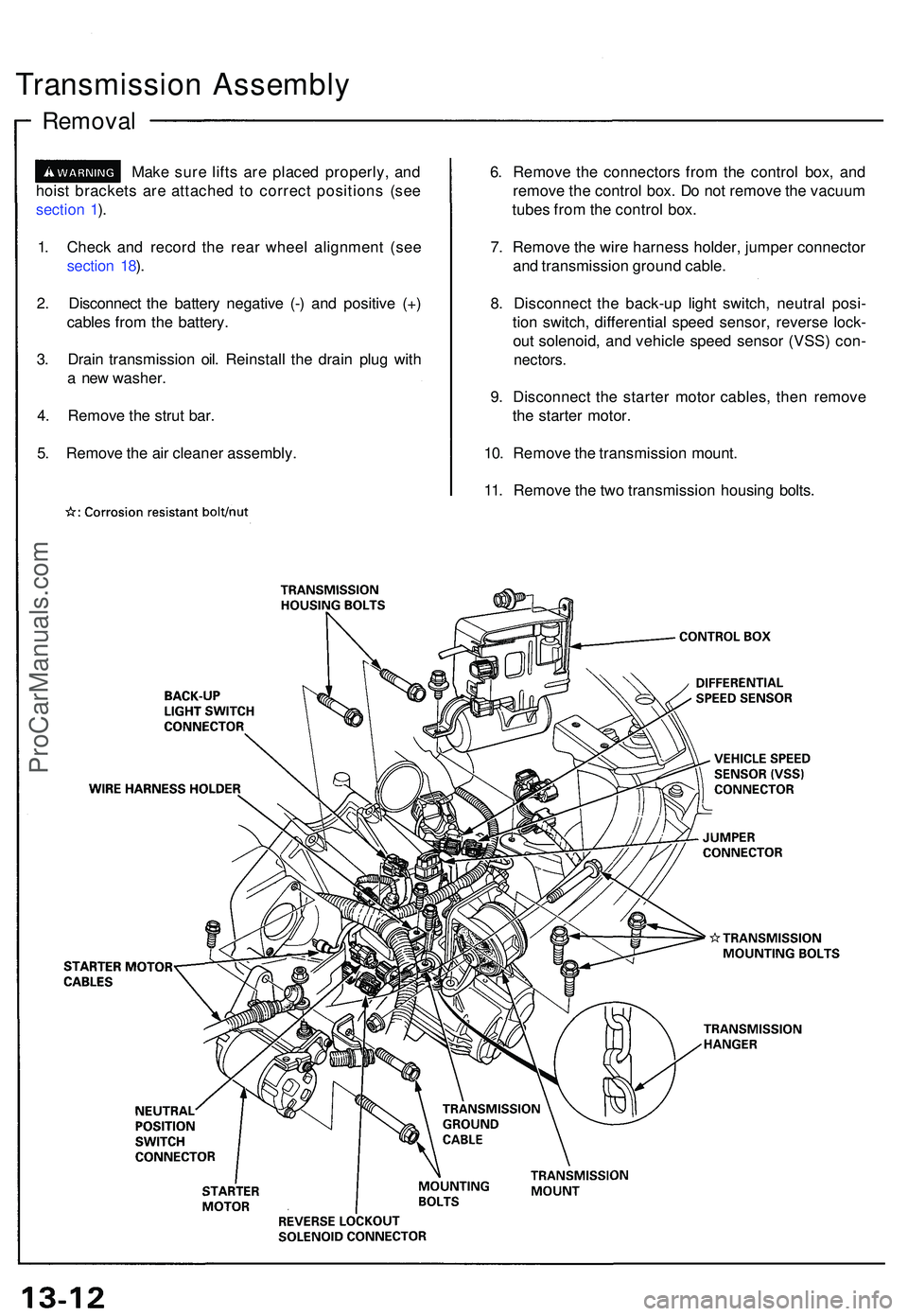

Transmission Assembl y

Removal

Make sur e lift s ar e place d properly , an d

hois t bracket s ar e attache d t o correc t position s (se e

sectio n 1 ).

1 . Chec k an d recor d th e rea r whee l alignmen t (se e

sectio n 18 ).

2 . Disconnec t th e batter y negativ e (- ) an d positiv e (+ )

cable s fro m th e battery .

3 . Drai n transmissio n oil . Reinstal l th e drai n plu g wit h

a ne w washer .

4 . Remov e th e stru t bar .

5 . Remov e th e ai r cleane r assembly . 6

. Remov e th e connector s fro m th e contro l box , an d

remov e th e contro l box . D o no t remov e th e vacuu m

tube s fro m th e contro l box .

7 . Remov e th e wir e harnes s holder , jumpe r connecto r

an d transmissio n groun d cable .

8 . Disconnec t th e back-u p ligh t switch , neutra l posi -

tio n switch , differentia l spee d sensor , revers e lock -

ou t solenoid , an d vehicl e spee d senso r (VSS ) con -

nectors .

9. Disconnec t th e starte r moto r cables , the n remov e

th e starte r motor .

10 . Remov e th e transmissio n mount .

11 . Remov e th e tw o transmissio n housin g bolts .

ProCarManuals.com

Trending: oil filter, clock, water pump, height, check engine, child restraint, parking sensors