ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 641 of 1503

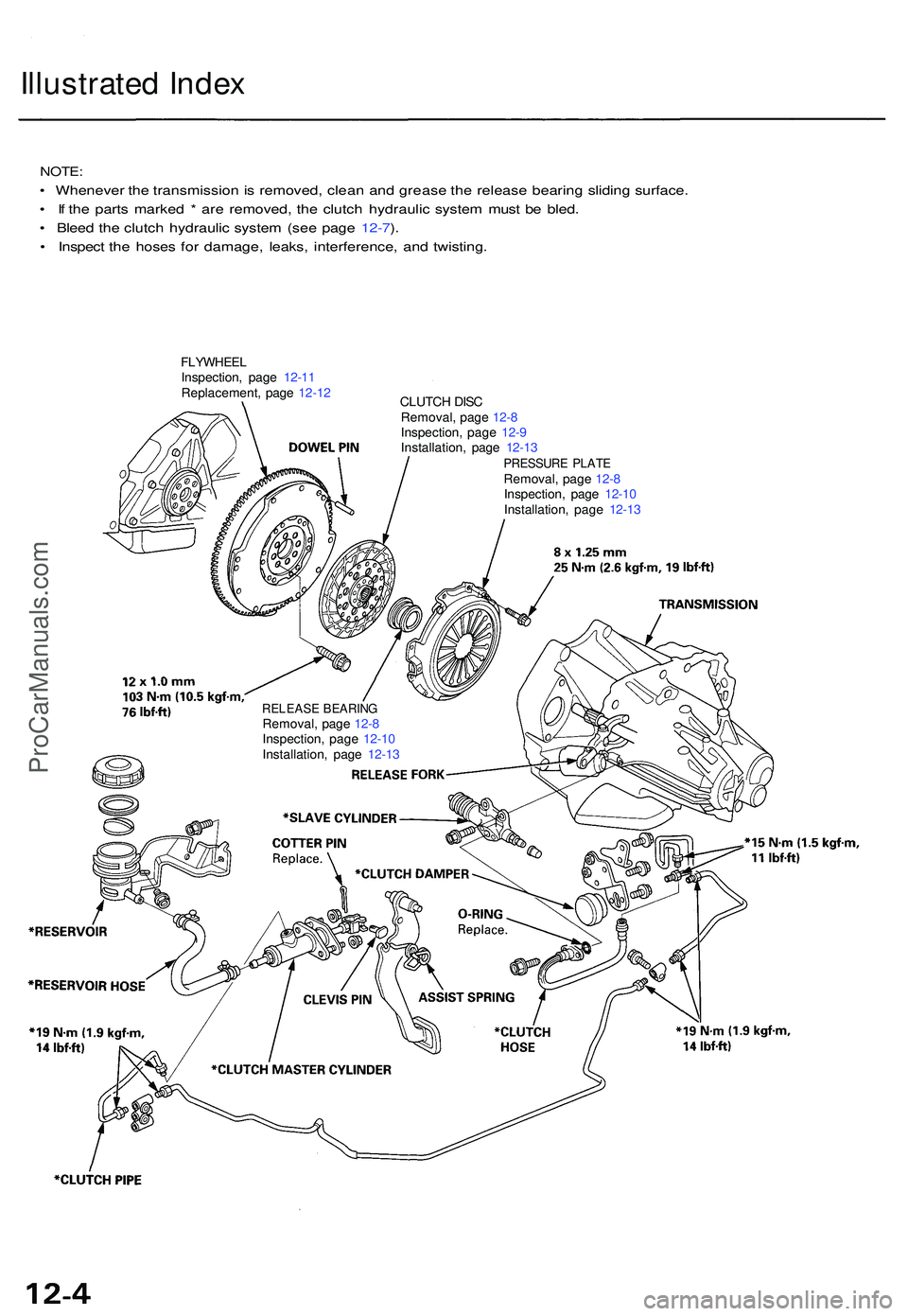

Illustrated Inde x

NOTE :

• Wheneve r th e transmissio n is removed , clea n an d greas e th e releas e bearin g slidin g surface .

• I f th e part s marke d * ar e removed , th e clutc h hydrauli c syste m mus t b e bled .

• Blee d th e clutc h hydrauli c syste m (se e pag e 12-7 ).

• Inspec t th e hose s fo r damage , leaks , interference , an d twisting .

FLYWHEE LInspection, pag e 12-1 1

Replacement , pag e 12-1 2

CLUTCH DIS C

Removal , pag e 12- 8

Inspection , pag e 12- 9

Installation , pag e 12-1 3

PRESSUR E PLAT ERemoval , pag e 12- 8

Inspection , pag e 12-1 0

Installation , pag e 12-1 3

RELEAS E BEARIN GRemoval , pag e 12- 8

Inspection , pag e 12-1 0

Installation , pag e 12-1 3

ProCarManuals.com

Page 642 of 1503

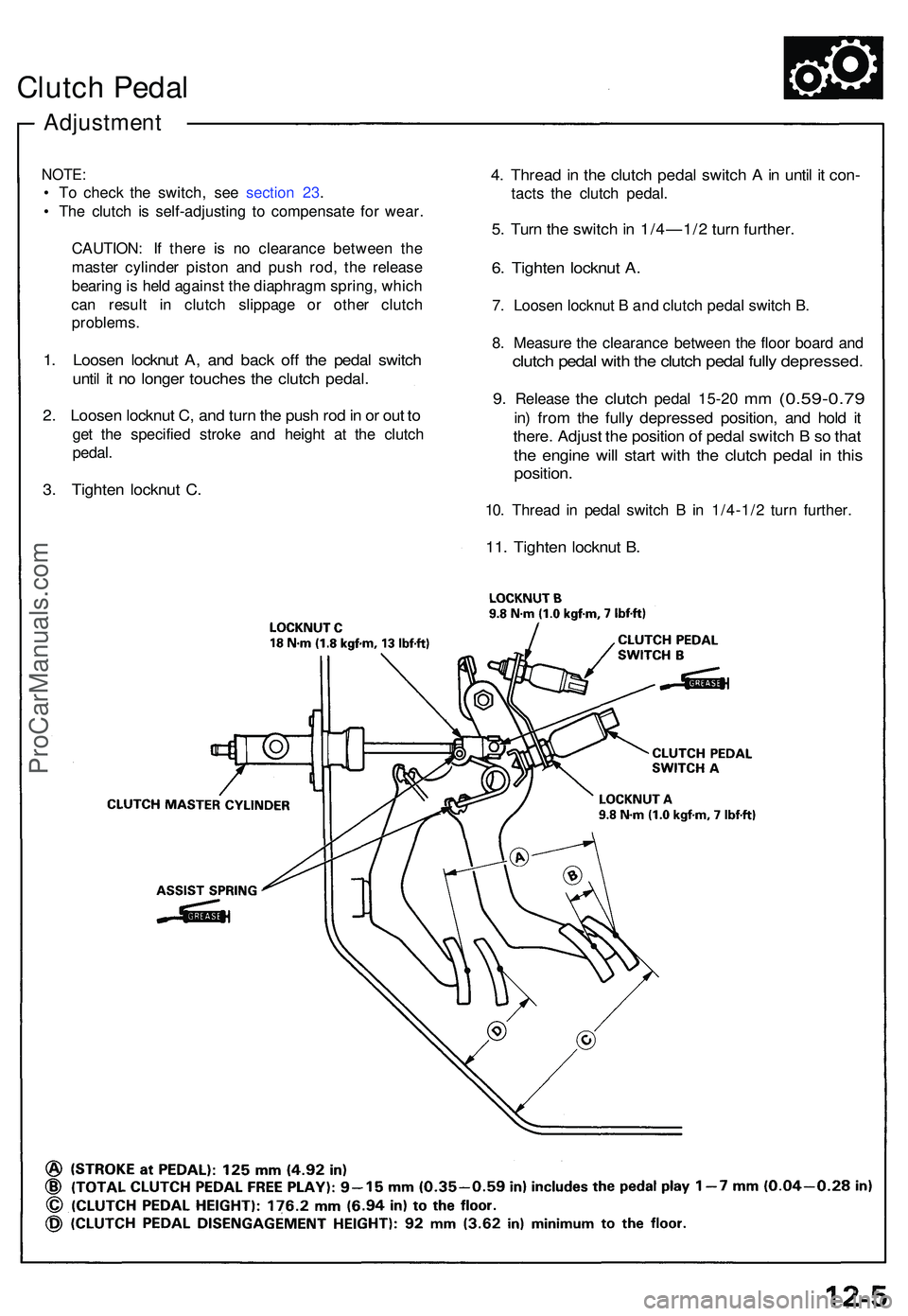

Clutch Peda l

Adjustmen t

NOTE:

• T o chec k th e switch , se e sectio n 23 .

• Th e clutc h i s self-adjustin g t o compensat e fo r wear .

CAUTION : I f ther e i s n o clearanc e betwee n th e

maste r cylinde r pisto n an d pus h rod , th e releas e

bearin g is hel d agains t th e diaphrag m spring , whic h

ca n resul t i n clutc h slippag e o r othe r clutc h

problems .

1. Loose n locknu t A , an d bac k of f th e peda l switc h

until i t n o longe r touche s th e clutc h pedal .

2. Loose n locknu t C , an d tur n th e pus h ro d in o r ou t t o

ge t th e specifie d strok e an d heigh t a t th e clutc h

pedal .

3. Tighte n locknu t C .

4. Threa d in th e clutc h peda l switc h A in unti l i t con -

tacts th e clutc h pedal .

5. Tur n th e switc h in 1/4—1/ 2 tur n further .

6. Tighte n locknu t A .

7. Loose n locknu t B an d clutc h peda l switc h B .

8 . Measur e th e clearanc e betwee n th e floo r boar d an d

clutc h peda l wit h th e clutc h peda l full y depressed .

9. Releas e the clutc h peda l 15-2 0 mm (0.59-0.7 9

in) fro m th e full y depresse d position , an d hol d i t

there . Adjus t th e positio n o f peda l switc h B so tha t

the engin e wil l star t wit h th e clutc h peda l i n thi s

position .

10. Threa d i n peda l switc h B in 1/4-1/ 2 tur n further .

11. Tighte n locknu t B .

ProCarManuals.com

Page 643 of 1503

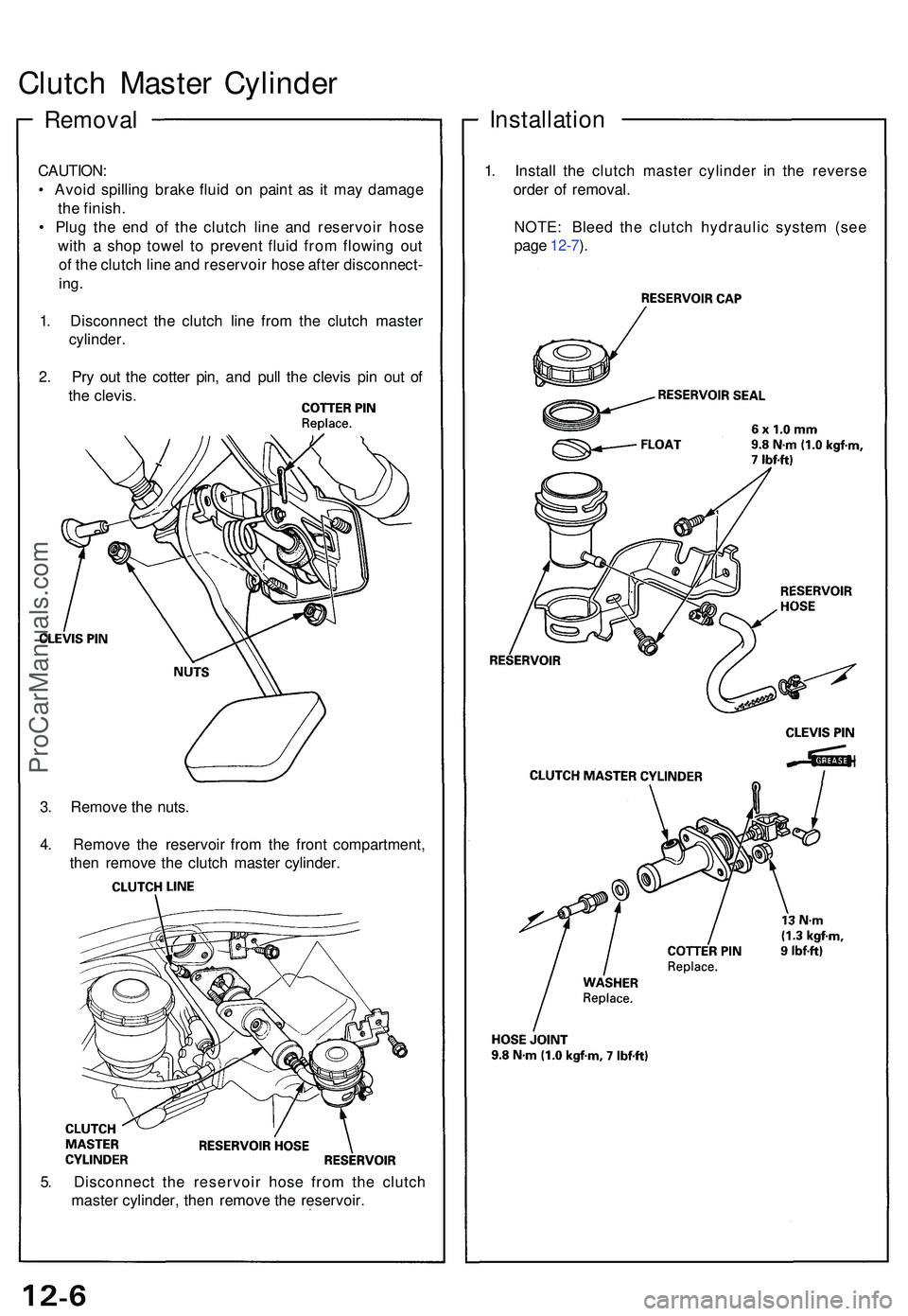

Clutch Maste r Cylinde r

Remova lInstallatio n

CAUTION:

• Avoi d spillin g brak e flui d o n pain t a s i t ma y damag e

th e finish .

• Plu g th e en d o f th e clutc h lin e an d reservoi r hos e

wit h a sho p towe l t o preven t flui d fro m flowin g ou t

o f th e clutc h lin e an d reservoi r hos e afte r disconnect -

ing.

1. Disconnec t th e clutc h lin e fro m th e clutc h maste r

cylinder .

2 . Pr y ou t th e cotte r pin , an d pul l th e clevi s pi n ou t o f

th e clevis .

3 . Remov e th e nuts .

4 . Remov e th e reservoi r fro m th e fron t compartment ,

the n remov e th e clutc h maste r cylinder .

5 . Disconnec t th e reservoi r hos e fro m th e clutc h

maste r cylinder , the n remov e th e reservoir . 1

. Instal l th e clutc h maste r cylinde r i n th e revers e

orde r o f removal .

NOTE : Blee d th e clutc h hydrauli c syste m (se e

pag e 12-7 ).

ProCarManuals.com

Page 644 of 1503

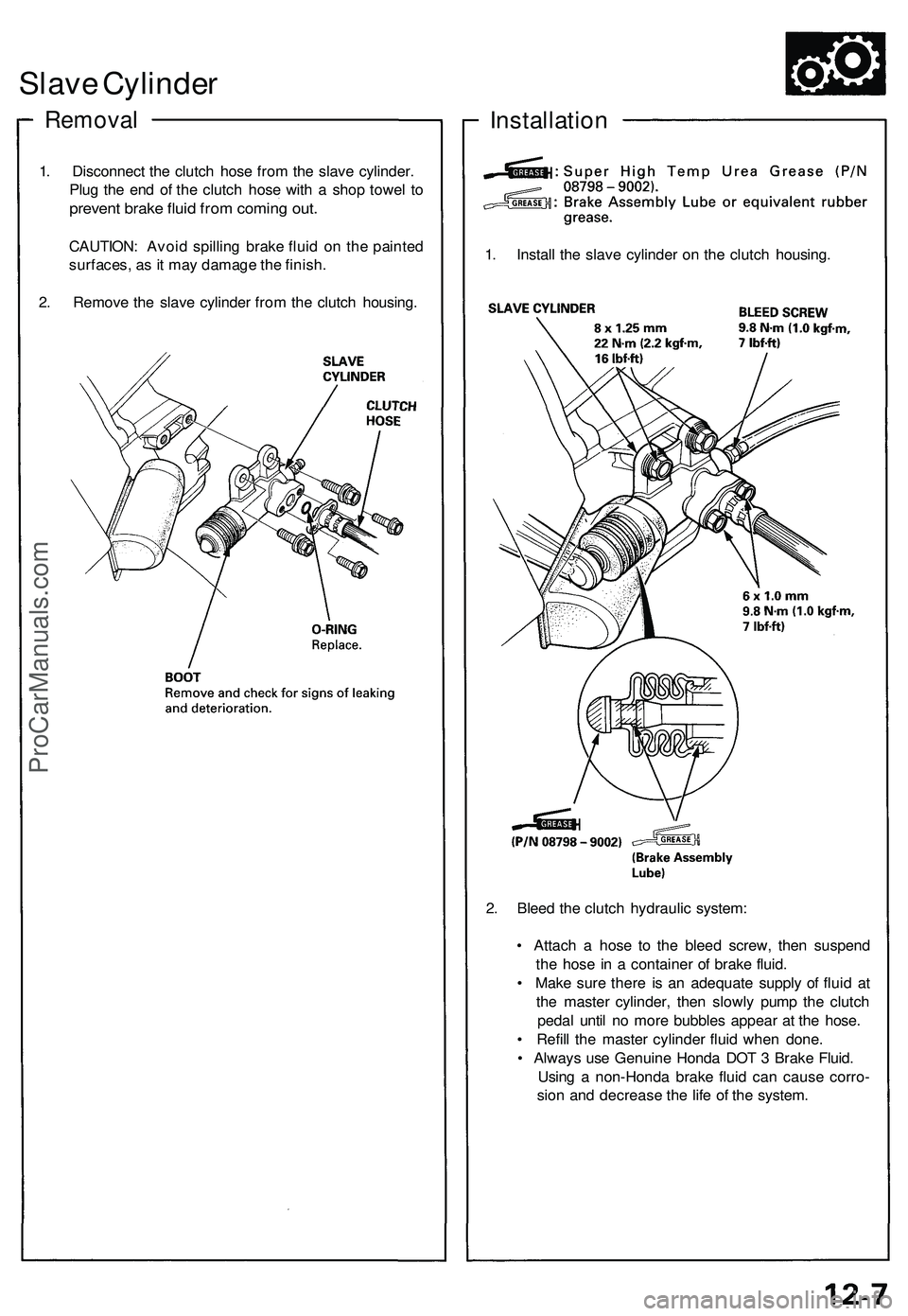

Slave Cylinde r

Remova l

1. Disconnec t th e clutc h hos e fro m th e slav e cylinder .

Plu g th e en d o f th e clutc h hos e wit h a sho p towe l t o

preven t brak e flui d fro m comin g out .

CAUTION : Avoi d spillin g brak e flui d o n th e painte d

surfaces , a s it ma y damag e th e finish .

2 . Remov e th e slav e cylinde r fro m th e clutc h housing . 1

. Instal l th e slav e cylinde r o n th e clutc h housing .

2 . Blee d th e clutc h hydrauli c system :

• Attac h a hos e t o th e blee d screw , the n suspen d

th e hos e i n a containe r o f brak e fluid .

• Mak e sur e ther e i s a n adequat e suppl y o f flui d a t

th e maste r cylinder , the n slowl y pum p th e clutc h

peda l unti l n o mor e bubble s appea r a t th e hose .

• Refil l th e maste r cylinde r flui d whe n done .

• Alway s us e Genuin e Hond a DO T 3 Brak e Fluid .

Usin g a non-Hond a brak e flui d ca n caus e corro -

sio n an d decreas e th e lif e o f th e system .

Installatio n

ProCarManuals.com

Page 645 of 1503

Pressure Plate , Clutc h Dis c

Remova l

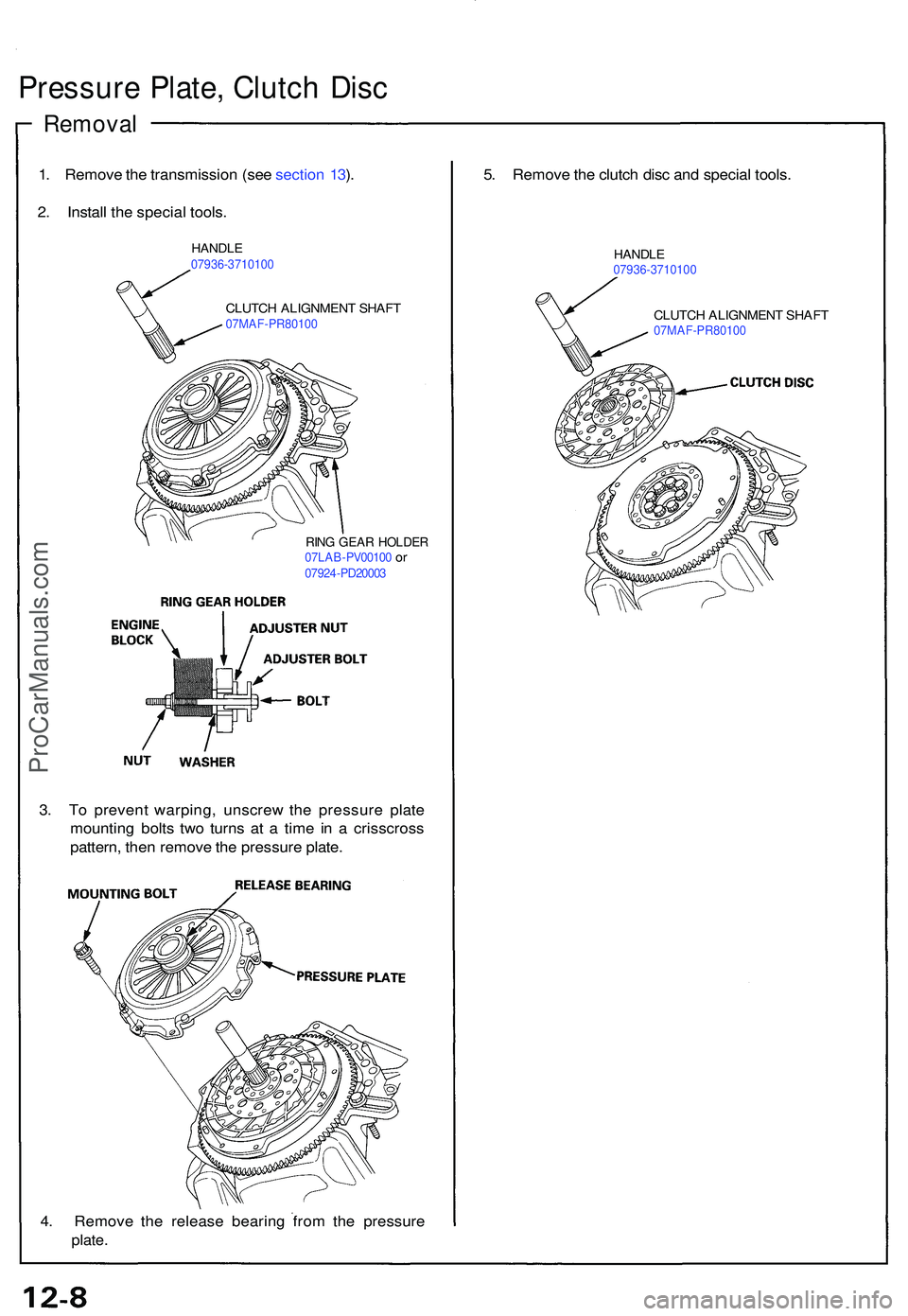

1. Remov e th e transmissio n (se e sectio n 13 ).

2 . Instal l th e specia l tools .

HANDL E07936-371010 0

CLUTCH ALIGNMEN T SHAF T07MAF-PR8010 0

RING GEA R HOLDE R07LAB-PV0010 0 or0792 4-PD2000 3

3. T o preven t warping , unscre w th e pressur e plat e

mountin g bolt s tw o turn s a t a tim e i n a crisscros s

pattern , the n remov e th e pressur e plate .

4 . Remov e th e releas e bearin g fro m th e pressur e

plate.

5. Remov e th e clutc h dis c an d specia l tools .

HANDL E07936-371010 0

CLUTCH ALIGNMEN T SHAF T07MAF-PR8010 0

ProCarManuals.com

Page 646 of 1503

Clutch Disc

Inspection

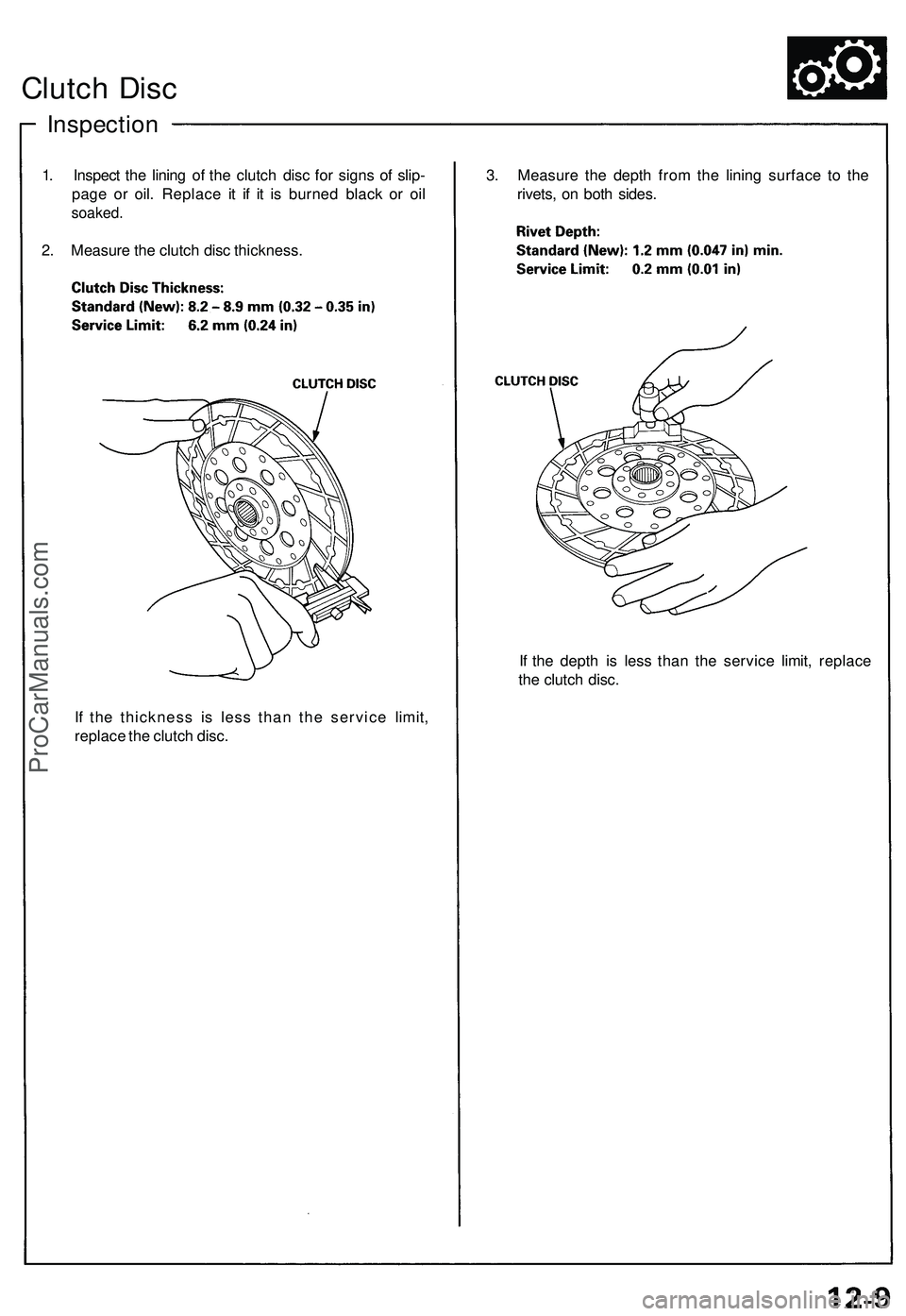

1. Inspect the lining of the clutch disc for signs of slip-

page or oil. Replace it if it is burned black or oil

soaked.

2. Measure the clutch disc thickness.

3. Measure the depth from the lining surface to the

rivets, on both sides.

If the thickness is less than the service limit,

replace the clutch disc.

If the depth is less than the service limit, replace

the clutch disc.ProCarManuals.com

Page 647 of 1503

Pressure Plat e

Inspectio n

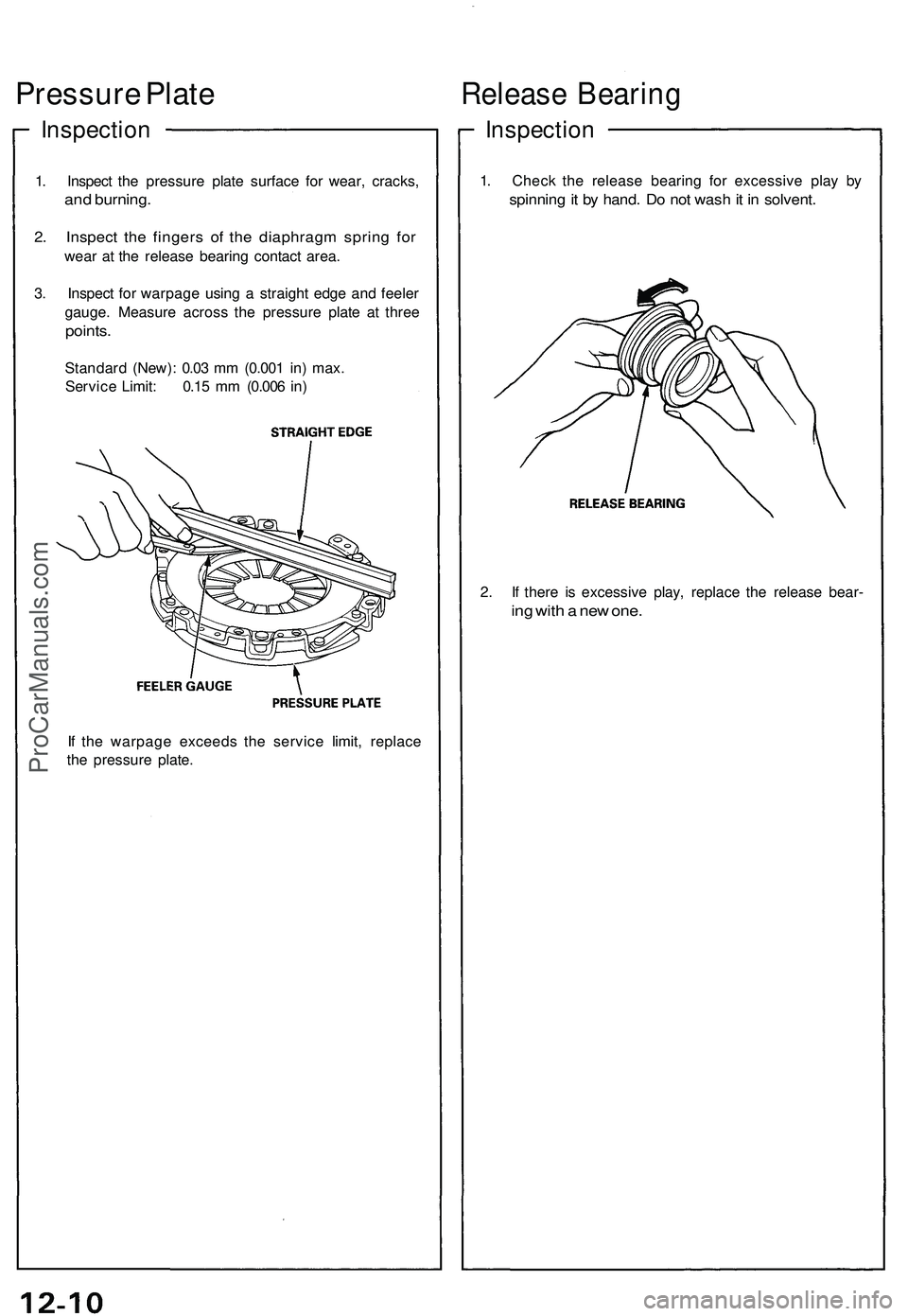

1. Inspec t th e pressur e plat e surfac e fo r wear , cracks ,

and burning .

2. Inspec t th e finger s o f th e diaphrag m sprin g fo r

wea r a t th e releas e bearin g contac t area .

3 . Inspec t fo r warpag e usin g a straigh t edg e an d feele r

gauge . Measur e acros s th e pressur e plat e a t thre e

points .

Standar d (New) : 0.0 3 m m (0.00 1 in ) max .

Servic e Limit : 0.1 5 m m (0.00 6 in )

I f th e warpag e exceed s th e servic e limit , replac e

th e pressur e plate . 1

. Chec k th e releas e bearin g fo r excessiv e pla y b y

spinnin g it b y hand . D o no t was h it i n solvent .

Release Bearin g

Inspectio n

2. I f ther e i s excessiv e play , replac e th e releas e bear -

ing wit h a ne w one .

ProCarManuals.com

Page 648 of 1503

Flywheel, Flywhee l Bearin g

Inspectio n

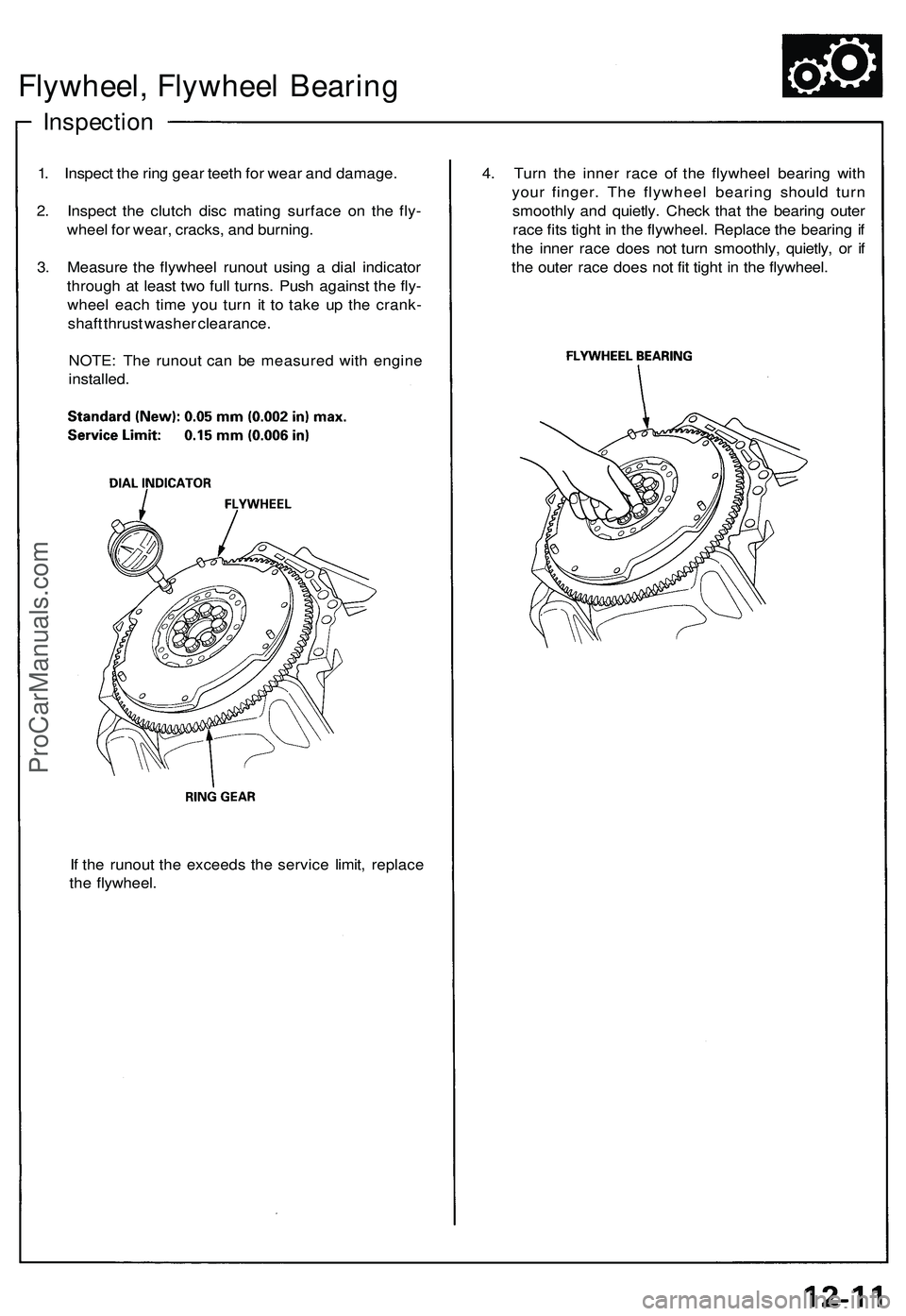

1. Inspec t th e rin g gea r teet h fo r wea r an d damage .

2 . Inspec t th e clutc h dis c matin g surfac e o n th e fly -

whee l fo r wear , cracks , an d burning .

3 . Measur e th e flywhee l runou t usin g a dia l indicato r

throug h a t leas t tw o ful l turns . Pus h agains t th e fly -

whee l eac h tim e yo u tur n i t t o tak e u p th e crank -

shaf t thrus t washe r clearance .

NOTE : Th e runou t ca n b e measure d wit h engin e

installed . 4

. Tur n th e inne r rac e o f th e flywhee l bearin g with

you r finger . Th e flywhee l bearin g shoul d tur n

smoothl y an d quietly . Chec k tha t th e bearin g oute r

rac e fit s tigh t i n th e flywheel . Replac e th e bearin g if

th e inne r rac e doe s no t tur n smoothly , quietly , o r i f

th e oute r rac e doe s no t fi t tigh t i n th e flywheel .

I f th e runou t th e exceed s th e servic e limit , replac e

th e flywheel .

ProCarManuals.com

Page 649 of 1503

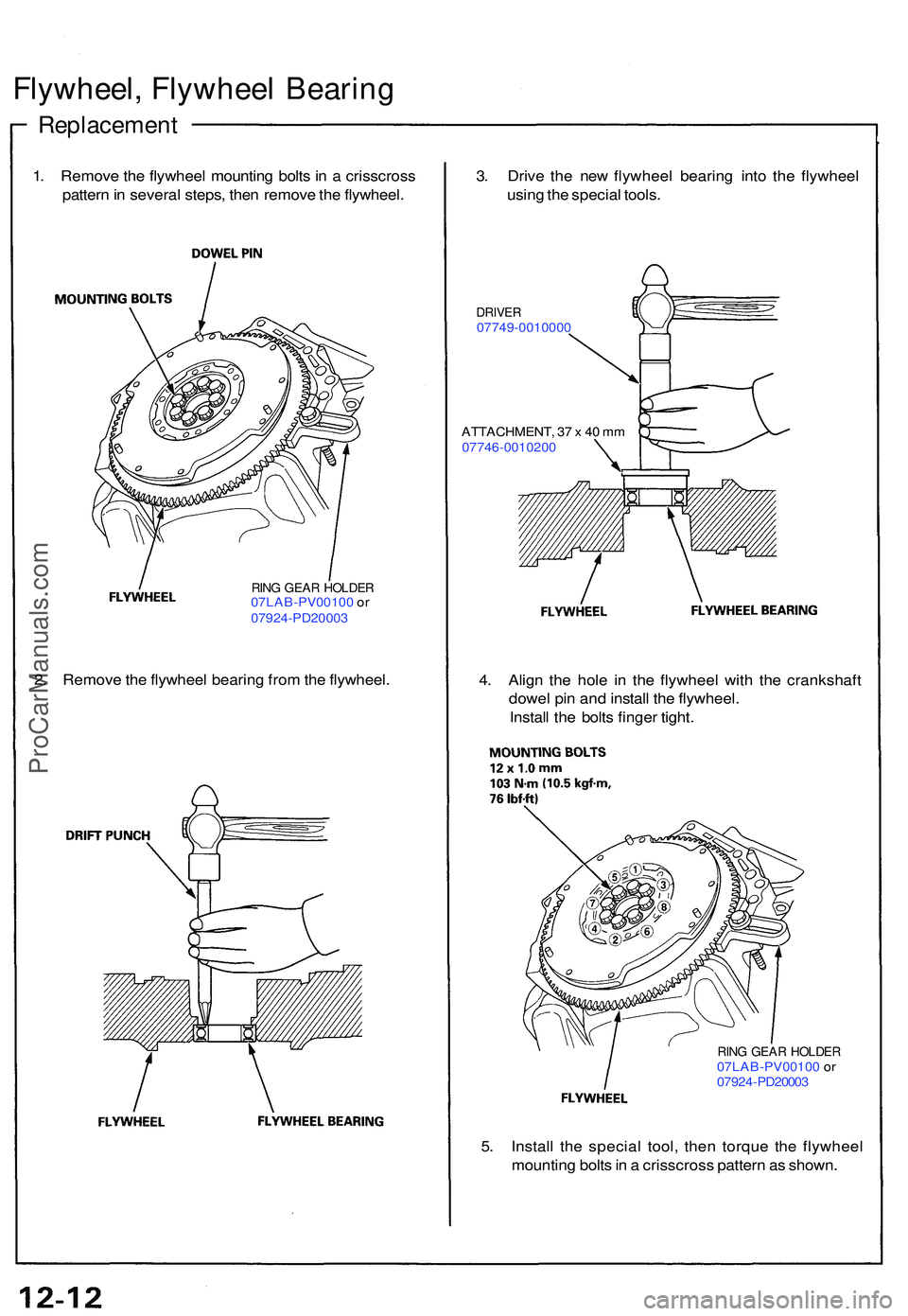

Flywheel, Flywhee l Bearin g

Replacemen t

1. Remov e th e flywhee l mountin g bolt s in a crisscros s

patter n in severa l steps , the n remov e th e flywheel . 3

. Driv e th e ne w flywhee l bearin g int o th e flywhee l

usin g th e specia l tools .

DRIVE R07749-001000 0

ATTACHMENT , 3 7 x 40 m m

07746-001020 0

4. Alig n th e hol e i n th e flywhee l wit h th e crankshaf t

dowe l pi n an d instal l th e flywheel .

Instal l th e bolt s finge r tight .

5 . Instal l th e specia l tool , the n torqu e th e flywhee l

mountin g bolt s in a crisscros s patter n a s shown .

RING GEA R HOLDE R07LAB-PV0010 0 o r

0792 4-PD2000 3

RING GEA R HOLDE R07LAB-PV0010 0 o r

07924-PD2000 3

2. Remov e th e flywhee l bearin g fro m th e flywheel .

ProCarManuals.com

Page 650 of 1503

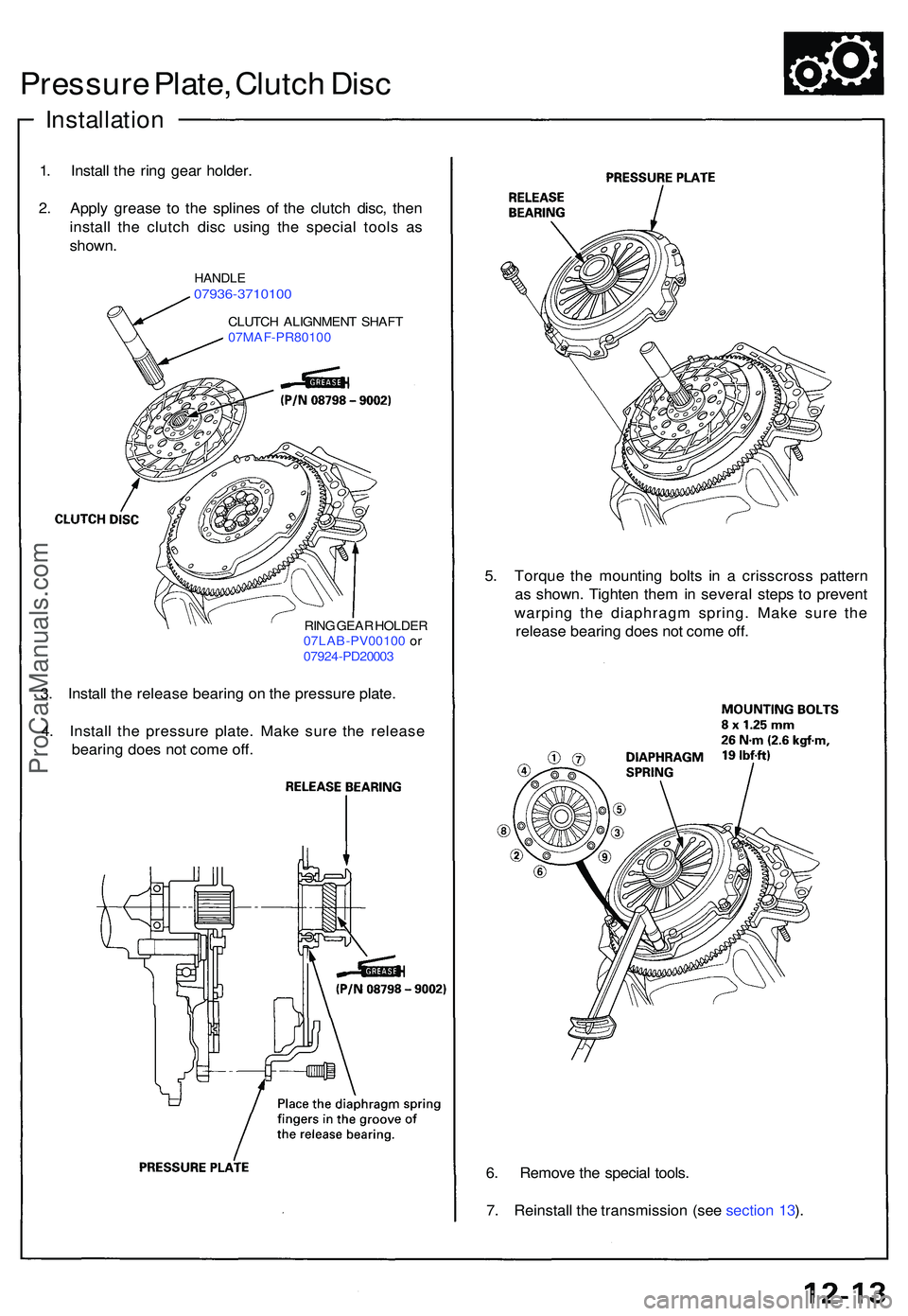

Pressure Plate , Clutc h Dis c

Installatio n

1. Instal l th e rin g gea r holder .

2 . Appl y greas e t o th e spline s o f th e clutc h disc , the n

instal l th e clutc h dis c usin g th e specia l tool s a s

shown .

HANDL E07936-371010 0

CLUTCH ALIGNMEN T SHAF T

07MAF-PR8010 0

RIN G GEA R HOLDE R

07LAB-PV0010 0 o r

0792 4-PD2000 3

3. Instal l th e releas e bearin g o n th e pressur e plate .

4 . Instal l th e pressur e plate . Mak e sur e th e releas e

bearin g doe s no t com e off .

6. Remov e th e specia l tools .

7 . Reinstal l th e transmissio n (se e sectio n 13 ).

5

. Torqu e th e mountin g bolt s i n a crisscros s patter n

a s shown . Tighte n the m in severa l step s t o preven t

warpin g th e diaphrag m spring . Mak e sur e th e

releas e bearin g doe s no t com e off .

ProCarManuals.com