ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 711 of 1503

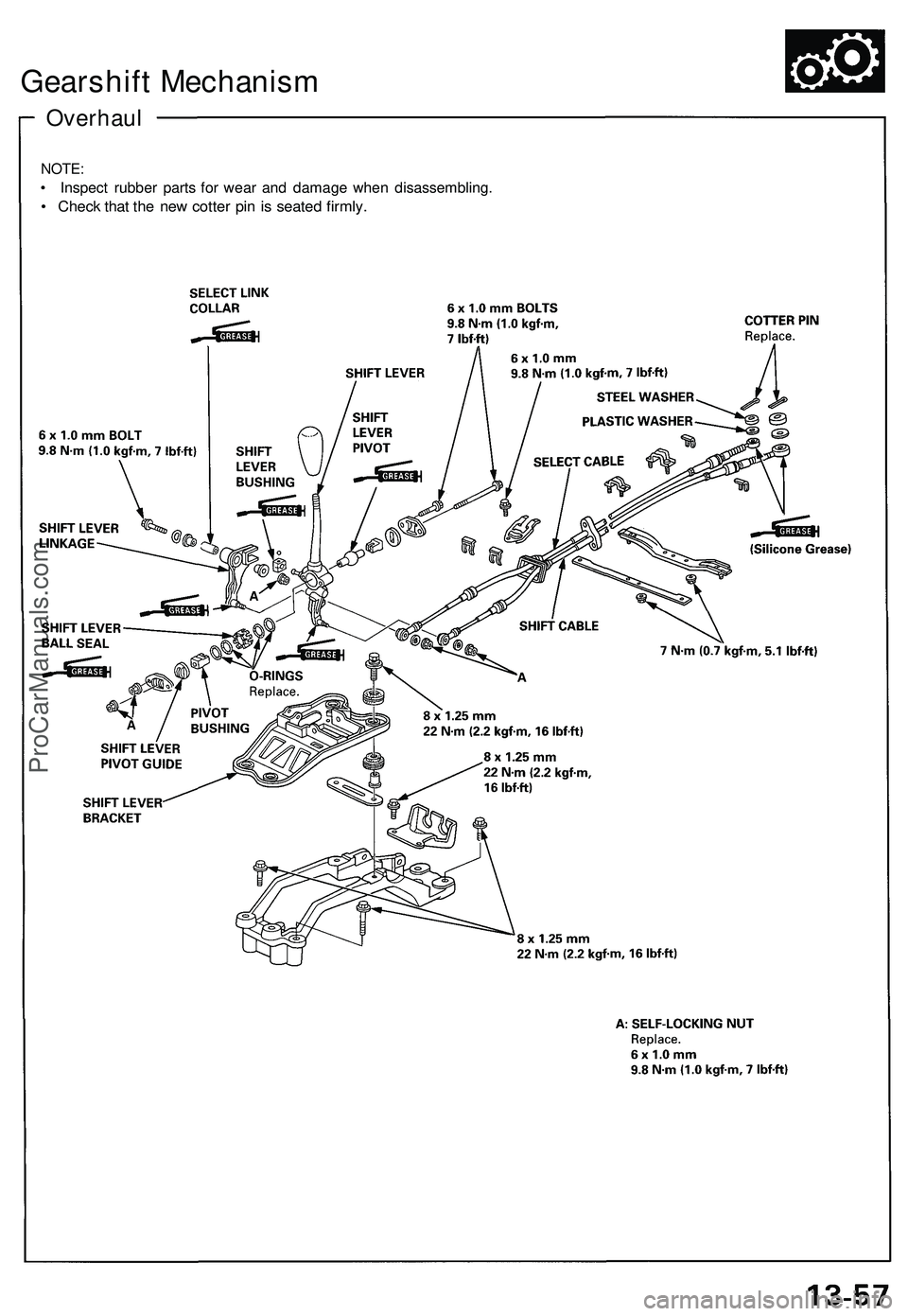

Gearshift Mechanis m

Overhaul

NOTE:

• Inspec t rubbe r part s fo r wea r an d damag e whe n disassembling .

• Chec k tha t th e ne w cotte r pi n i s seate d firmly .

ProCarManuals.com

Page 712 of 1503

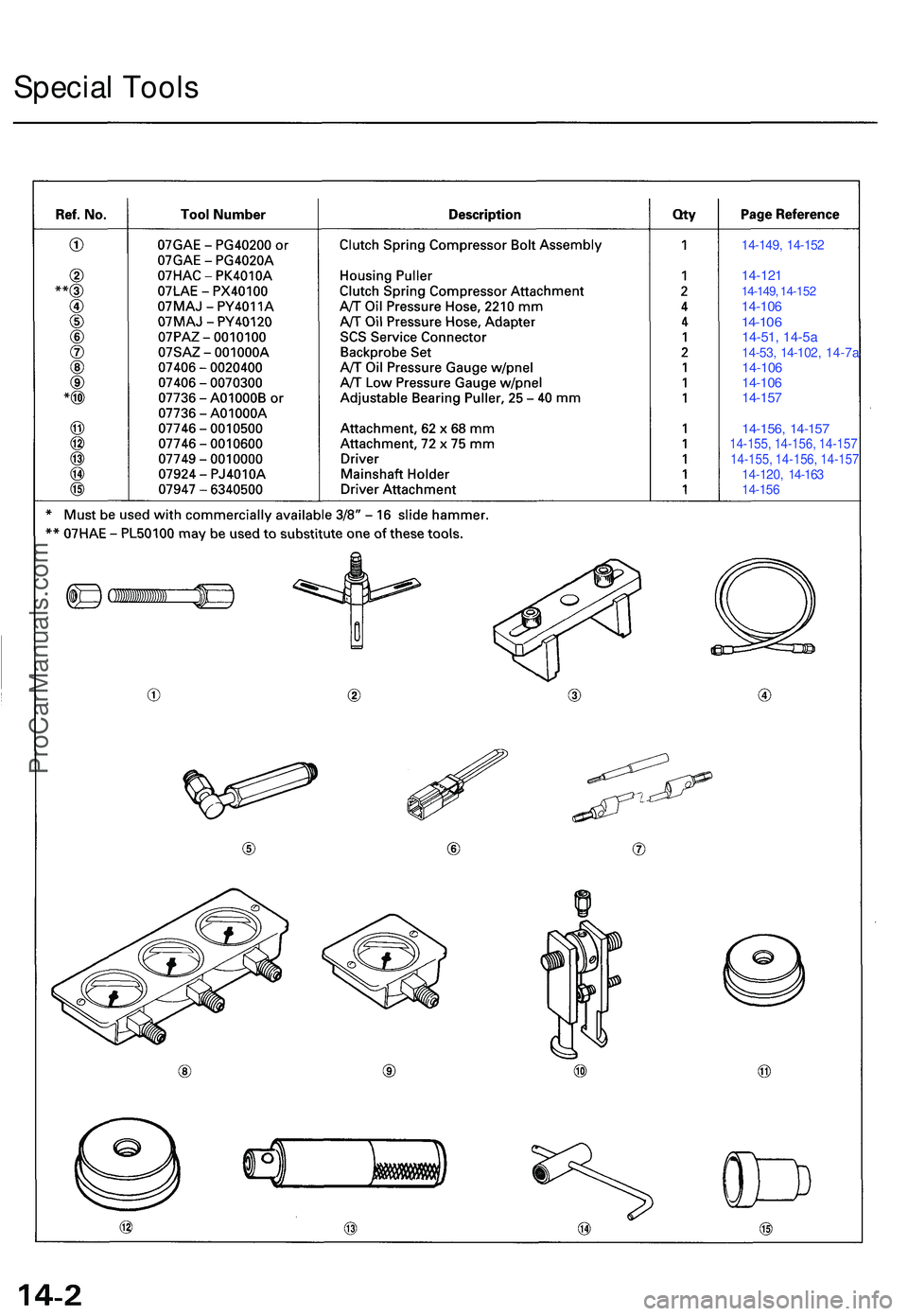

Special Tool s

14-149 , 14-15 2

14-12114-149 , 14-15 214-10614-10614-51 , 14-5a14-53 , 14-10 2, 14-7a14-10 6

14-10 6

14-157

14-156 , 14-15 714-155, 14-156, 14-15714-155, 14-156, 14-15714-120 , 14-16 3

14-15 6

ProCarManuals.com

Page 713 of 1503

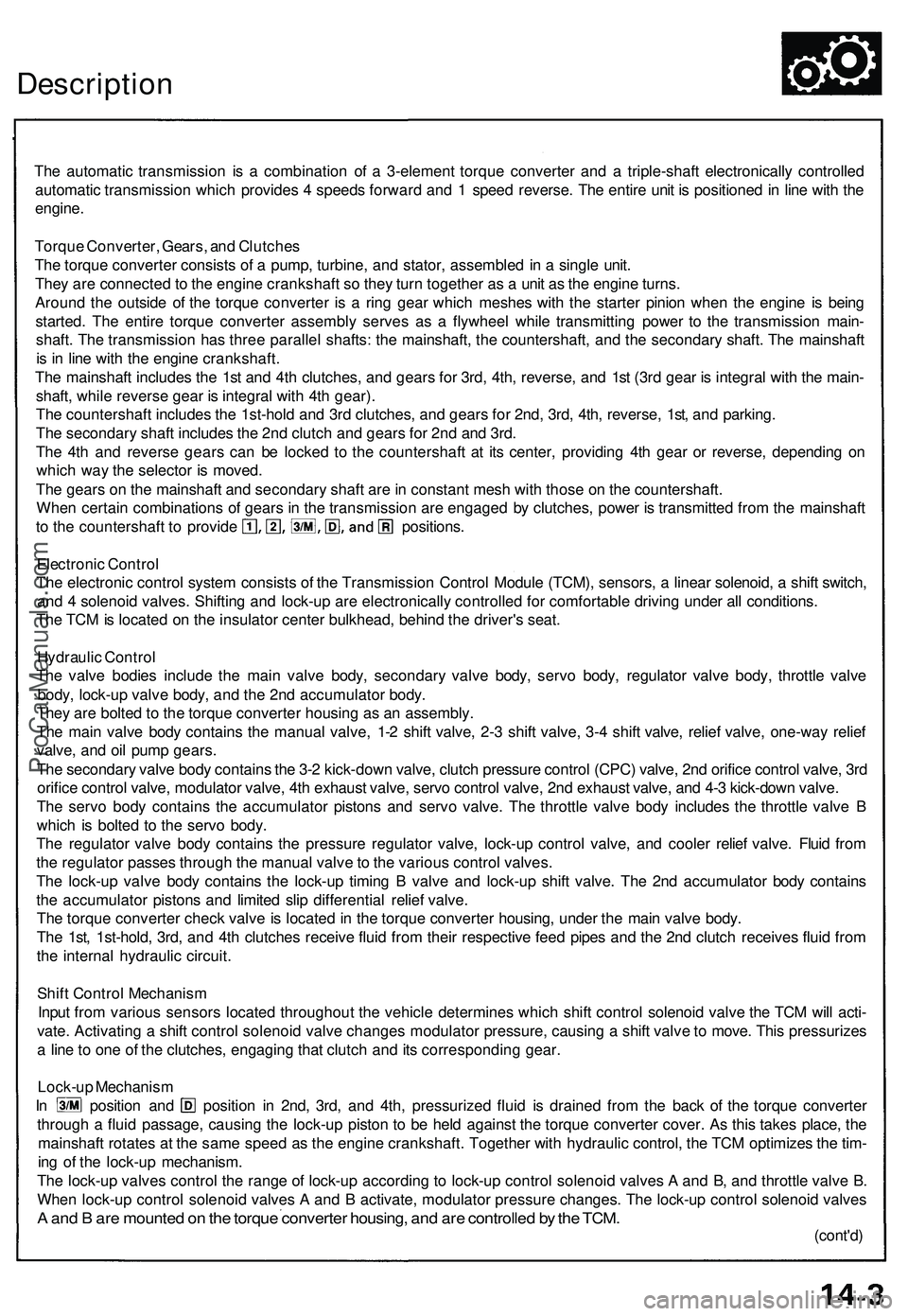

Description

The automatic transmission is a combination of a 3-element torque converter and a triple-shaft electronically controlled

automatic transmission which provides 4 speeds forward and 1 speed reverse. The entire unit is positioned in line with the

engine.

Torque Converter, Gears, and Clutches

The torque converter consists of a pump, turbine, and stator, assembled in a single unit.

They are connected to the engine crankshaft so they turn together as a unit as the engine turns.

Around the outside of the torque converter is a ring gear which meshes with the starter pinion when the engine is being

started. The entire torque converter assembly serves as a flywheel while transmitting power to the transmission main-

shaft. The transmission has three parallel shafts: the mainshaft, the countershaft, and the secondary shaft. The mainshaft

is in line with the engine crankshaft.

The mainshaft includes the 1st and 4th clutches, and gears for 3rd, 4th, reverse, and 1st (3rd gear is integral with the main-

shaft, while reverse gear is integral with 4th gear).

The countershaft includes the 1st-hold and 3rd clutches, and gears for 2nd, 3rd, 4th, reverse, 1st, and parking.

The secondary shaft includes the 2nd clutch and gears for 2nd and 3rd.

The 4th and reverse gears can be locked to the countershaft at its center, providing 4th gear or reverse, depending on

which way the selector is moved.

The gears on the mainshaft and secondary shaft are in constant mesh with those on the countershaft.

When certain combinations of gears in the transmission are engaged by clutches, power is transmitted from the mainshaft

to the countershaft to provide positions.

Electronic Control

The electronic control system consists of the Transmission Control Module (TCM), sensors, a linear solenoid, a shift switch,

and 4 solenoid valves. Shifting and lock-up are electronically controlled for comfortable driving under all conditions.

The TCM is located on the insulator center bulkhead, behind the driver's seat.

Hydraulic Control

The valve bodies include the main valve body, secondary valve body, servo body, regulator valve body, throttle valve

body, lock-up valve body, and the 2nd accumulator body.

They are bolted to the torque converter housing as an assembly.

The main valve body contains the manual valve, 1-2 shift valve, 2-3 shift valve, 3-4 shift valve, relief valve, one-way relief

valve, and oil pump gears.

The secondary valve body contains the 3-2 kick-down valve, clutch pressure control (CPC) valve, 2nd orifice control valve, 3rd

orifice control valve, modulator valve, 4th exhaust valve, servo control valve, 2nd exhaust valve, and 4-3 kick-down valve.

The servo body contains the accumulator pistons and servo valve. The throttle valve body includes the throttle valve B

which is bolted to the servo body.

The regulator valve body contains the pressure regulator valve, lock-up control valve, and cooler relief valve. Fluid from

the regulator passes through the manual valve to the various control valves.

The lock-up valve body contains the lock-up timing B valve and lock-up shift valve. The 2nd accumulator body contains

the accumulator pistons and limited slip differential relief valve.

The torque converter check valve is located in the torque converter housing, under the main valve body.

The 1st, 1st-hold, 3rd, and 4th clutches receive fluid from their respective feed pipes and the 2nd clutch receives fluid from

the internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the vehicle determines which shift control solenoid valve the TCM will acti-

vate. Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes

a line to one of the clutches, engaging that clutch and its corresponding gear.

Lock-up Mechanism

In position and position in 2nd, 3rd, and 4th, pressurized fluid is drained from the back of the torque converter

through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this takes place, the

mainshaft rotates at the same speed as the engine crankshaft. Together with hydraulic control, the TCM optimizes the tim-

ing of the lock-up mechanism.

The lock-up valves control the range of lock-up according to lock-up control solenoid valves A and B, and throttle valve B.

When lock-up control solenoid valves A and B activate, modulator pressure changes. The lock-up control solenoid valves

A and B are mounted on the torque converter housing, and are controlled by the TCM.

(cont'd)ProCarManuals.com

Page 714 of 1503

(cont'd)

Description

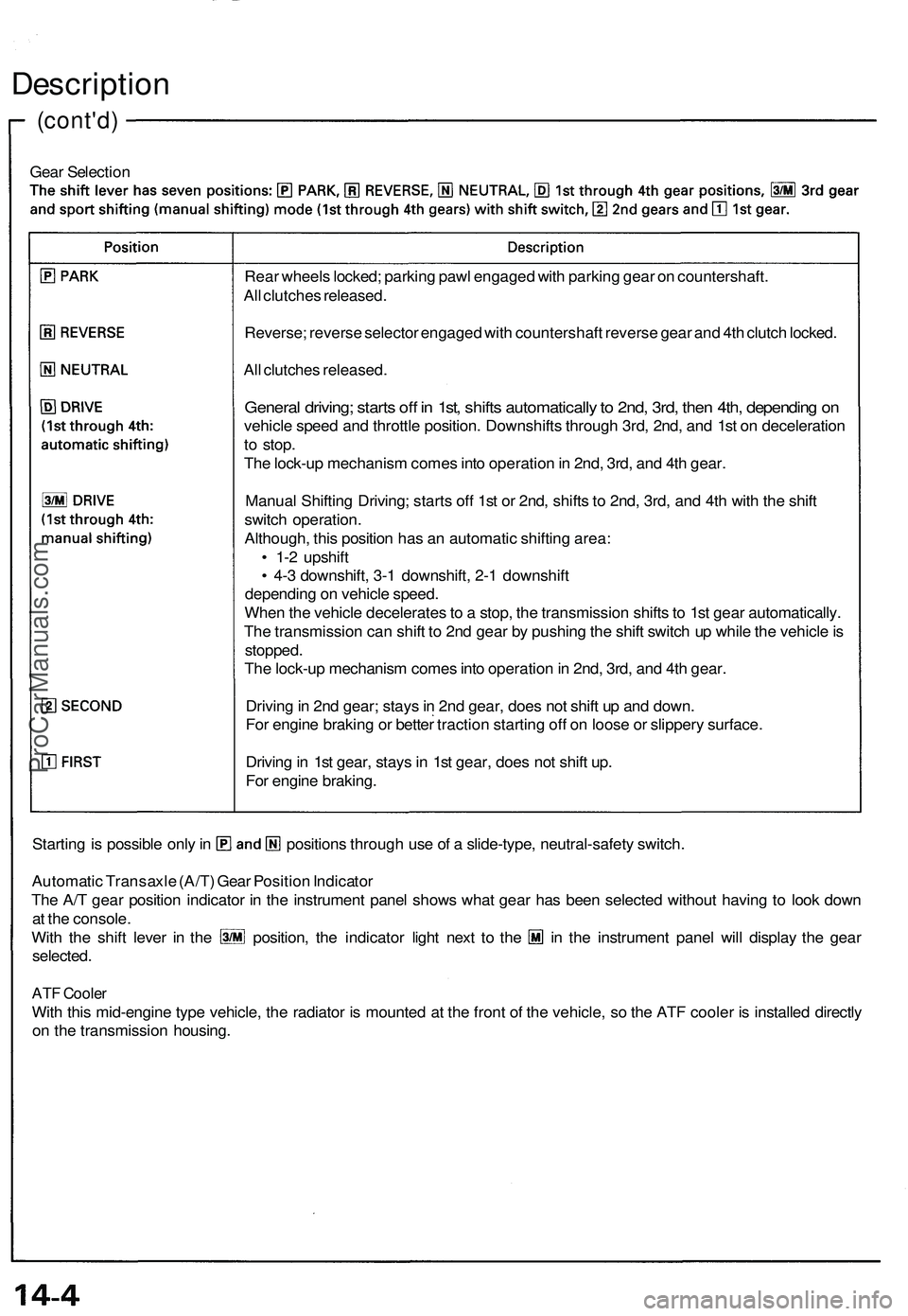

Gear Selection

Starting is possible only in positions through use of a slide-type, neutral-safety switch.

Automatic Transaxle (A/T) Gear Position Indicator

The A/T gear position indicator in the instrument panel shows what gear has been selected without having to look down

at the console.

With the shift lever in the position, the indicator light next to the in the instrument panel will display the gear

selected.

ATF Cooler

With this mid-engine type vehicle, the radiator is mounted at the front of the vehicle, so the ATF cooler is installed directly

on the transmission housing.

Rear wheels locked; parking pawl engaged with parking gear on countershaft.

All clutches released.

Reverse; reverse selector engaged with countershaft reverse gear and 4th clutch locked.

All clutches released.

General driving; starts off in 1st, shifts automatically to 2nd, 3rd, then 4th, depending on

vehicle speed and throttle position. Downshifts through 3rd, 2nd, and 1st on deceleration

to stop.

The lock-up mechanism comes into operation in 2nd, 3rd, and 4th gear.

Manual Shifting Driving; starts off 1st or 2nd, shifts to 2nd, 3rd, and 4th with the shift

switch operation.

Although, this position has an automatic shifting area:

• 1-2 upshift

• 4-3 downshift, 3-1 downshift, 2-1 downshift

depending on vehicle speed.

When the vehicle decelerates to a stop, the transmission shifts to 1st gear automatically.

The transmission can shift to 2nd gear by pushing the shift switch up while the vehicle is

stopped.

The lock-up mechanism comes into operation in 2nd, 3rd, and 4th gear.

Driving in 2nd gear; stays in 2nd gear, does not shift up and down.

For engine braking or better traction starting off on loose or slippery surface.

Driving in 1st gear, stays in 1st gear, does not shift up.

For engine braking.ProCarManuals.com

Page 715 of 1503

![ACURA NSX 1997 Service Repair Manual

TORQUE CONVERTER

LOCK-UP CONTROL

SOLENOID VALVE

ASSEMBLY

4TH CLUTCH

1ST CLUTCH

1ST-HOLD CLUTCH

ATF COOLER

DIFFERENTIAL ASSEMBLY

[LIMITED SLIP DIFFERENTIAL (LSD)]

2ND CLUTCH

3RD CLUTCHProCa ACURA NSX 1997 Service Repair Manual

TORQUE CONVERTER

LOCK-UP CONTROL

SOLENOID VALVE

ASSEMBLY

4TH CLUTCH

1ST CLUTCH

1ST-HOLD CLUTCH

ATF COOLER

DIFFERENTIAL ASSEMBLY

[LIMITED SLIP DIFFERENTIAL (LSD)]

2ND CLUTCH

3RD CLUTCHProCa](/img/32/56989/w960_56989-714.png)

TORQUE CONVERTER

LOCK-UP CONTROL

SOLENOID VALVE

ASSEMBLY

4TH CLUTCH

1ST CLUTCH

1ST-HOLD CLUTCH

ATF COOLER

DIFFERENTIAL ASSEMBLY

[LIMITED SLIP DIFFERENTIAL (LSD)]

2ND CLUTCH

3RD CLUTCHProCarManuals.com

Page 716 of 1503

Clutches

Description

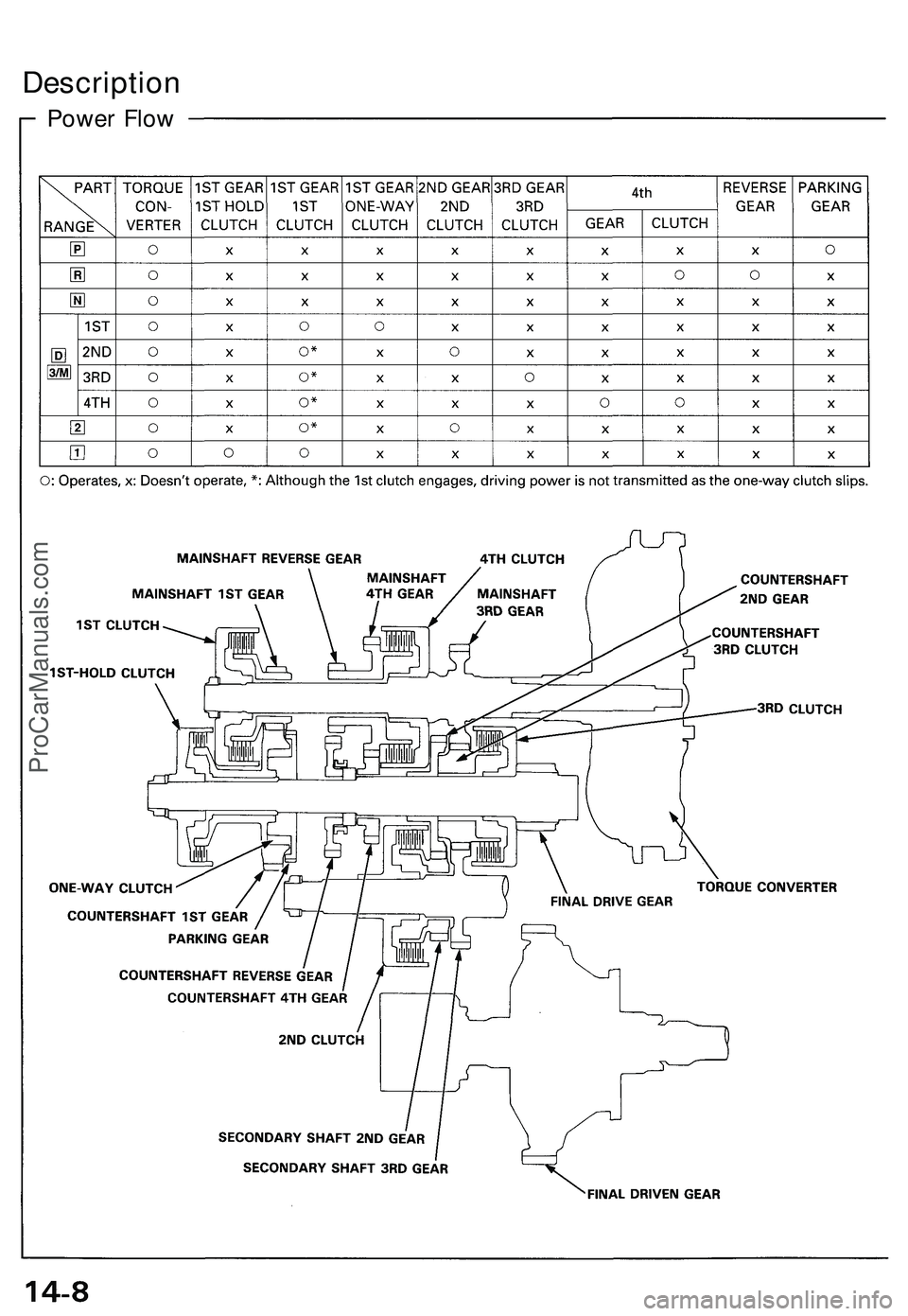

The four-speed automatic transmission uses hydraulically-actuated clutches to engage or disengage the transmission

gears. When hydraulic pressure is introduced into the clutch drum, the clutch piston is applied. This presses the friction

discs and steel plates together, locking them so they don't slip. Power is then transmitted through the engaged clutch pack

to its hub-mounted gear.

When hydraulic pressure is bled from the clutch pack, the piston releases the friction discs and the steel plates, and they

are free to slide past each other. This allows the gear to spin independently of its shaft, transmitting no power.

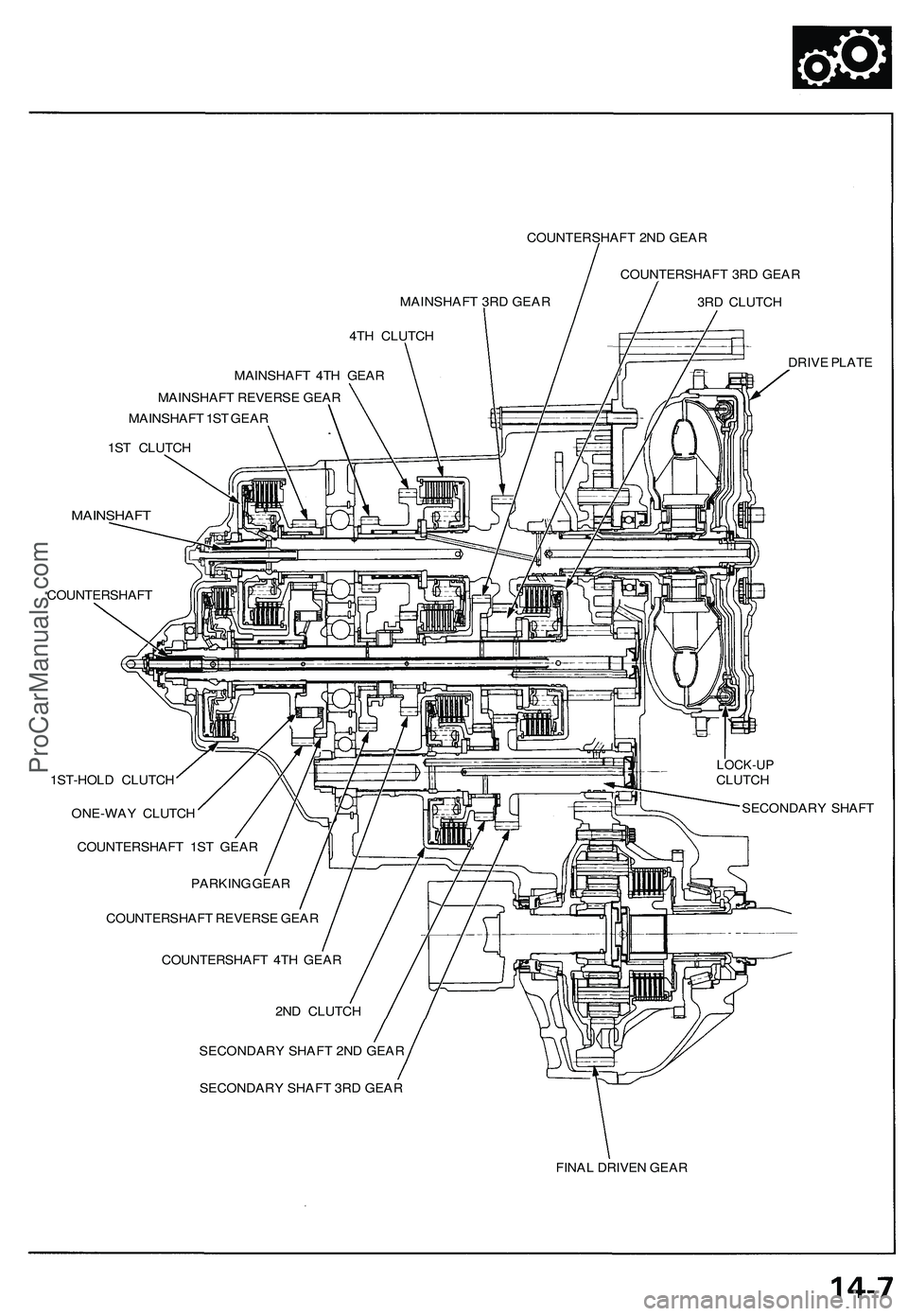

1st Clutch

The 1st clutch engages/disengages 1st gear, and is located at the end of the mainshaft, just behind the left side cover.

The 1st clutch is supplied hydraulic pressure by its ATF feed pipe within the mainshaft.

1st-hold Clutch

The 1st-hold clutch engages/disengages 1st-hold or position, and is located at the end of the countershaft, just behind

the left side cover. The 1st-hold clutch is supplied hydraulic pressure by its ATF feed pipe within the countershaft.

2nd Clutch

The 2nd clutch engages/disengages 2nd gear, and is located on the secondary shaft. The 2nd clutch is supplied hydraulic

pressure through the secondary shaft by a circuit connected to the 2nd accumulator body.

3rd Clutch

The 3rd clutch engages/disengages 3rd gear, and is located at the end of the countershaft, opposite the left side cover.

The 3rd clutch is supplied hydraulic pressure by its ATF feed pipe within the countershaft.

4th Clutch

The 4th clutch engages/disengages 4th gear, as well as reverse gear, and is located at the center of the mainshaft. The 4th

clutch is supplied hydraulic pressure by its ATF feed pipe within the mainshaft.

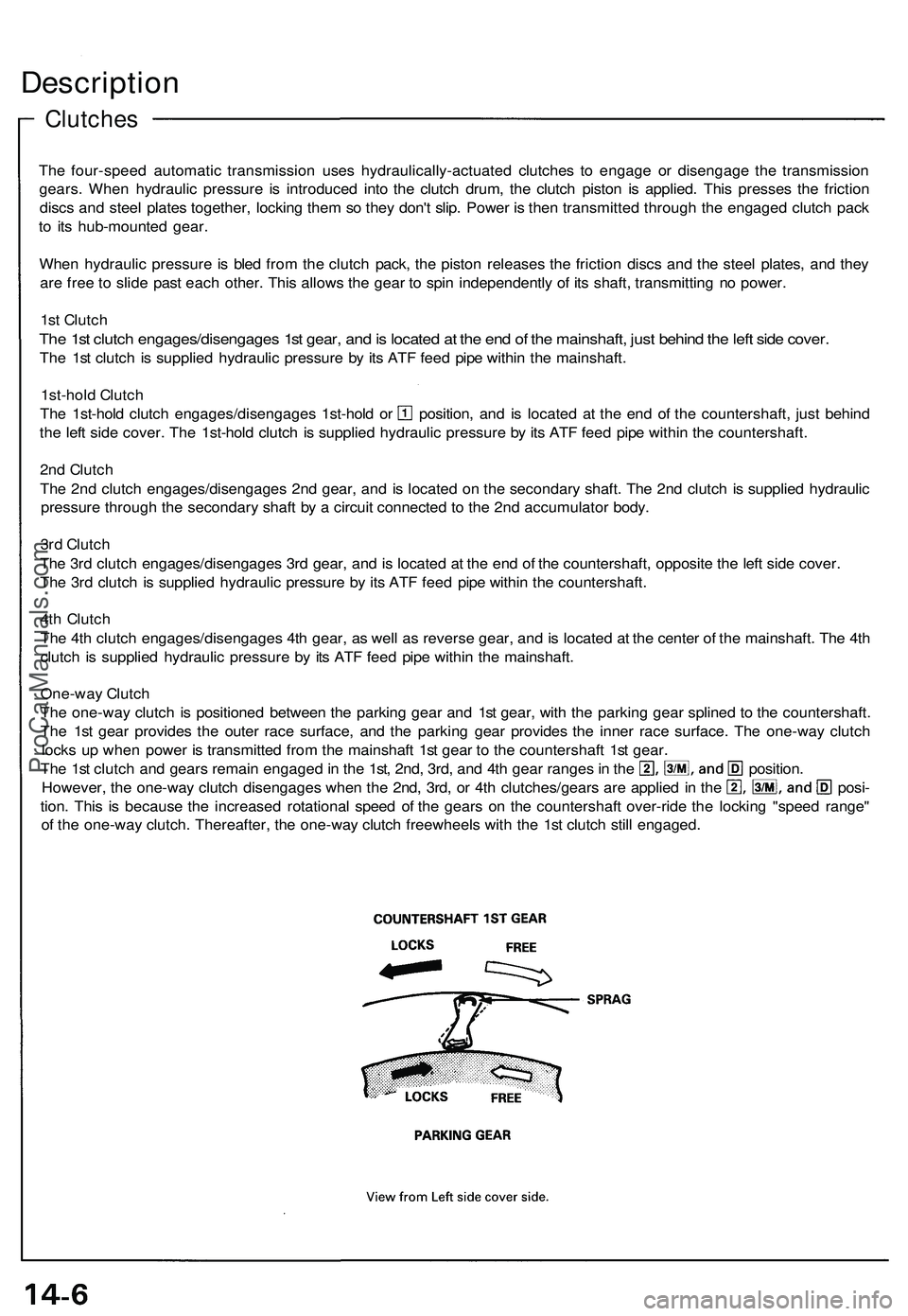

One-way Clutch

The one-way clutch is positioned between the parking gear and 1st gear, with the parking gear splined to the countershaft.

The 1st gear provides the outer race surface, and the parking gear provides the inner race surface. The one-way clutch

locks up when power is transmitted from the mainshaft 1st gear to the countershaft 1st gear.

The 1st clutch and gears remain engaged in the 1st, 2nd, 3rd, and 4th gear ranges in the position.

However, the one-way clutch disengages when the 2nd, 3rd, or 4th clutches/gears are applied in the posi-

tion. This is because the increased rotational speed of the gears on the countershaft over-ride the locking "speed range"

of the one-way clutch. Thereafter, the one-way clutch freewheels with the 1st clutch still engaged.ProCarManuals.com

Page 717 of 1503

COUNTERSHAFT 2ND GEAR

MAINSHAFT 3RD GEAR

4TH CLUTCH

COUNTERSHAFT 3RD GEAR

3RD CLUTCH

MAINSHAFT 4TH GEAR

MAINSHAFT REVERSE GEAR

MAINSHAFT 1ST GEAR

1ST CLUTCH

MAINSHAFT

COUNTERSHAFT

DRIVE PLATE

1ST-HOLD CLUTCH

ONE-WAY CLUTCH

COUNTERSHAFT 1ST GEAR

PARKING GEAR

COUNTERSHAFT REVERSE GEAR

COUNTERSHAFT 4TH GEAR

2ND CLUTCH

SECONDARY SHAFT 2ND GEAR

SECONDARY SHAFT 3RD GEAR

SECONDARY SHAFT

FINAL DRIVEN GEAR

LOCK-UP

CLUTCHProCarManuals.com

Page 718 of 1503

Power Flow

DescriptionProCarManuals.com

Page 719 of 1503

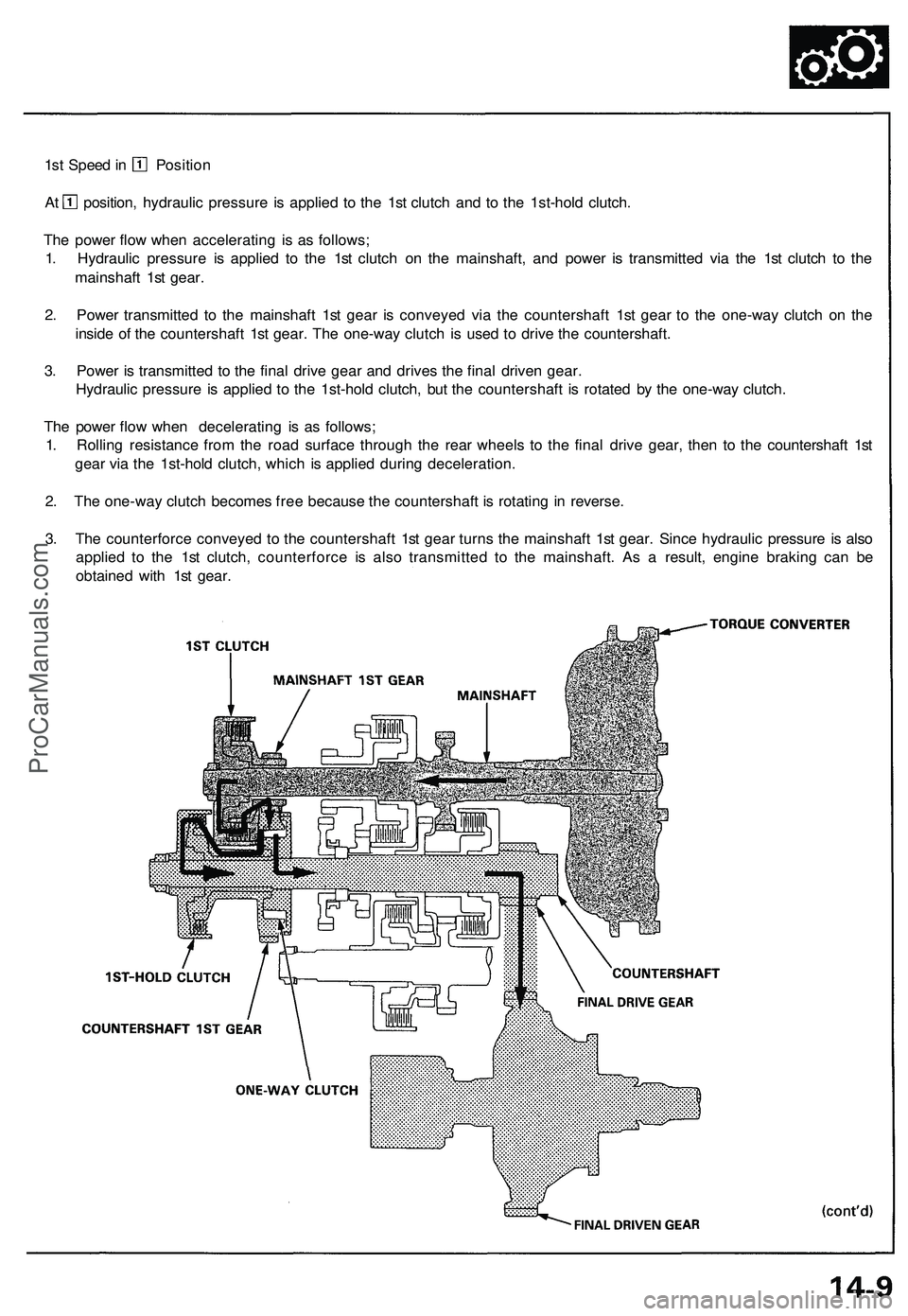

1st Speed in Position

At position, hydraulic pressure is applied to the 1st clutch and to the 1st-hold clutch.

The power flow when accelerating is as follows;

1. Hydraulic pressure is applied to the 1st clutch on the mainshaft, and power is transmitted via the 1st clutch to the

mainshaft 1st gear.

2. Power transmitted to the mainshaft 1st gear is conveyed via the countershaft 1st gear to the one-way clutch on the

inside of the countershaft 1st gear. The one-way clutch is used to drive the countershaft.

3. Power is transmitted to the final drive gear and drives the final driven gear.

Hydraulic pressure is applied to the 1st-hold clutch, but the countershaft is rotated by the one-way clutch.

The power flow when decelerating is as follows;

1. Rolling resistance from the road surface through the rear wheels to the final drive gear, then to the countershaft 1st

gear via the 1st-hold clutch, which is applied during deceleration.

2. The one-way clutch becomes free because the countershaft is rotating in reverse.

3. The counterforce conveyed to the countershaft 1st gear turns the mainshaft 1st gear. Since hydraulic pressure is also

applied to the 1st clutch, counterforce is also transmitted to the mainshaft. As a result, engine braking can be

obtained with 1st gear.ProCarManuals.com

Page 720 of 1503

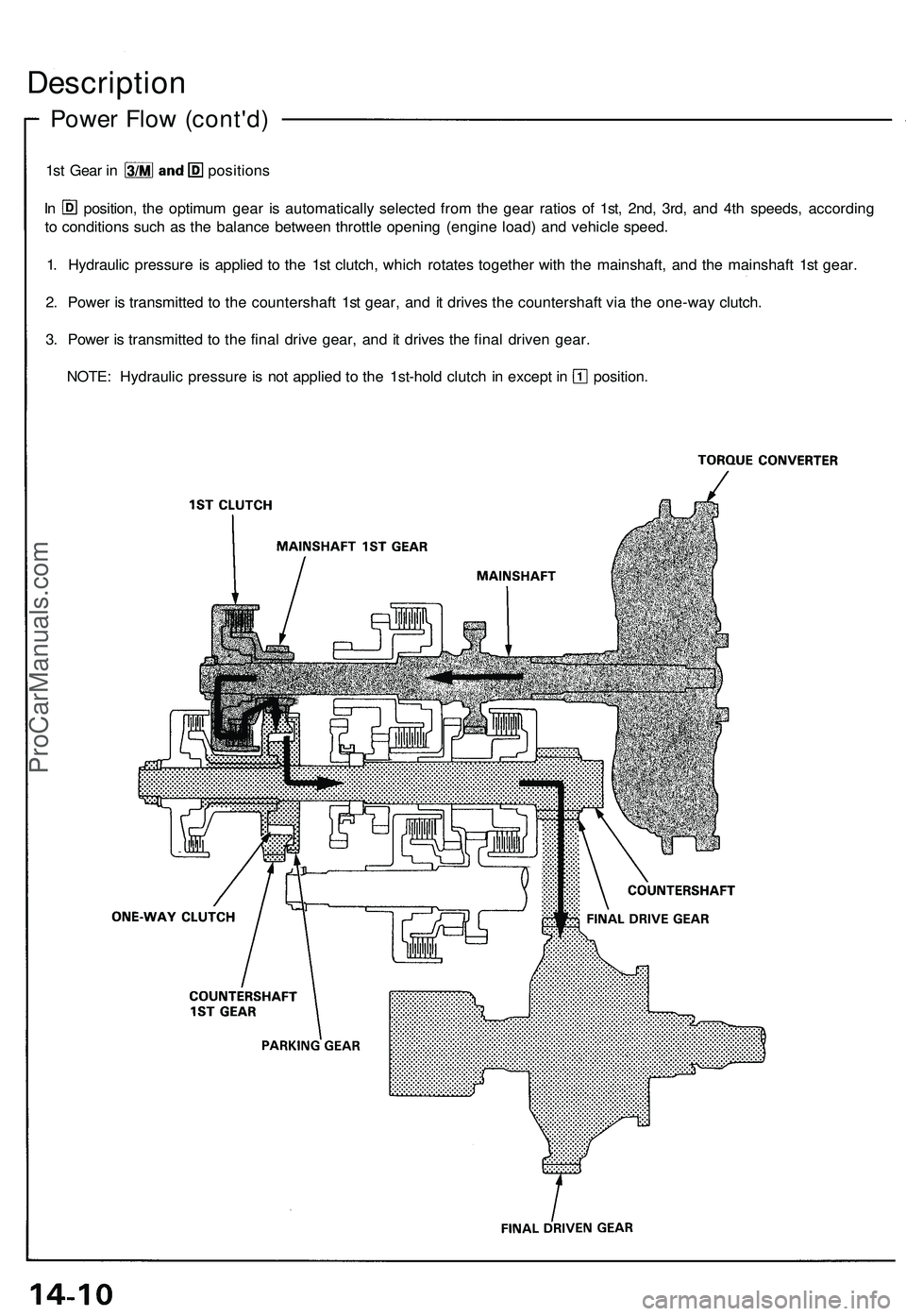

Power Flow (cont'd)

Description

1st Gear in positions

In position, the optimum gear is automatically selected from the gear ratios of 1st, 2nd, 3rd, and 4th speeds, according

to conditions such as the balance between throttle opening (engine load) and vehicle speed.

1. Hydraulic pressure is applied to the 1st clutch, which rotates together with the mainshaft, and the mainshaft 1st gear.

2. Power is transmitted to the countershaft 1st gear, and it drives the countershaft via the one-way clutch.

3. Power is transmitted to the final drive gear, and it drives the final driven gear.

NOTE: Hydraulic pressure is not applied to the 1st-hold clutch in except in position.ProCarManuals.com