ACURA TL 1995 Service Repair Manual

Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 861 of 1771

Troubleshooting

Troubleshootin g Procedure s

How T o Begi n Troubleshootin g

Whe n th e Malfunctio n Indicato r Lam p (MIL ) ha s bee n reporte d on , o r ther e i s a driveabilit y problem , us e th e appropri -

at e procedur e belo w to diagnos e an d repai r th e problem .

A . Whe n th e MI L ha s com e on :

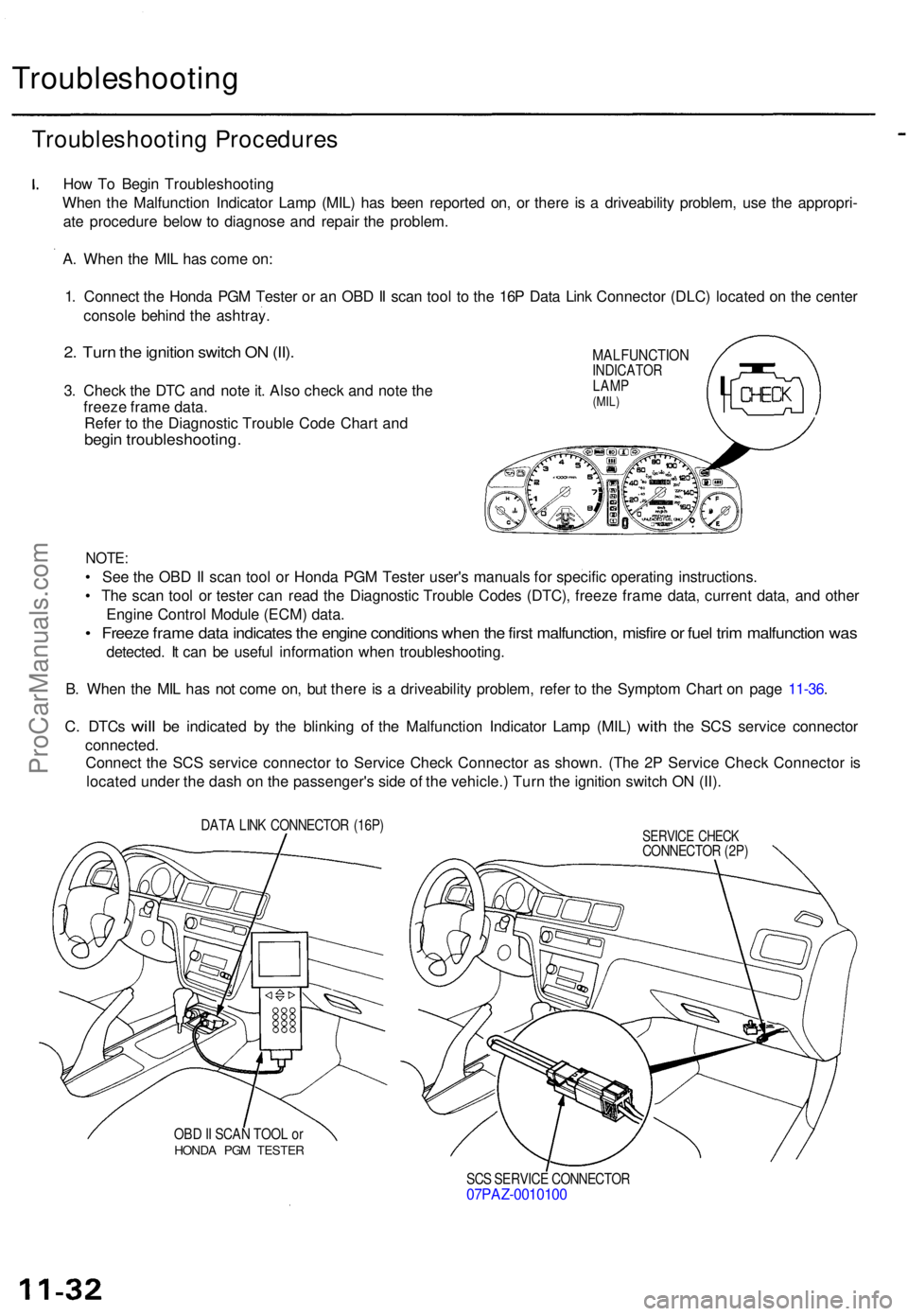

1 . Connec t th e Hond a PG M Teste r o r a n OB D II sca n too l t o th e 16 P Dat a Lin k Connecto r (DLC ) locate d o n th e cente r

consol e behin d th e ashtray .

2. Tur n th e ignitio n switc h O N (II) .

3. Chec k th e DT C an d not e it . Als o chec k an d not e th e

freez e fram e data .

Refe r t o th e Diagnosti c Troubl e Cod e Char t an d

begi n troubleshooting .

MALFUNCTIONINDICATOR

LAM P

(MIL)

NOTE :

• Se e th e OB D II sca n too l o r Hond a PG M Teste r user' s manual s fo r specifi c operatin g instructions .

• Th e sca n too l o r teste r ca n rea d th e Diagnosti c Troubl e Code s (DTC) , freez e fram e data , curren t data , an d othe r

Engin e Contro l Modul e (ECM ) data .

• Freez e fram e dat a indicate s th e engin e condition s whe n th e firs t malfunction , misfir e o r fue l tri m malfunctio n wa s

detected . I t ca n b e usefu l informatio n whe n troubleshooting .

B . Whe n th e MI L ha s no t com e on , bu t ther e i s a driveabilit y problem , refe r t o th e Sympto m Char t o n pag e 11-36 .

C. DTC s will be indicate d by th e blinkin g of th e Malfunctio n Indicato r Lam p (MIL ) with the SC S servic e connecto r

connected .

Connec t th e SC S servic e connecto r t o Servic e Chec k Connecto r a s shown . (Th e 2 P Servic e Chec k Connecto r i s

locate d unde r th e das h o n th e passenger' s sid e o f th e vehicle. ) Tur n th e ignitio n switc h O N (II) .

DAT A LIN K CONNECTO R (16P )

OB D II SCA N TOO L o r

HOND A PG M TESTE R

SERVICE CHEC KCONNECTO R (2P )

SC S SERVIC E CONNECTO R

07PAZ-001010 0

ProCarManuals.com

Page 862 of 1771

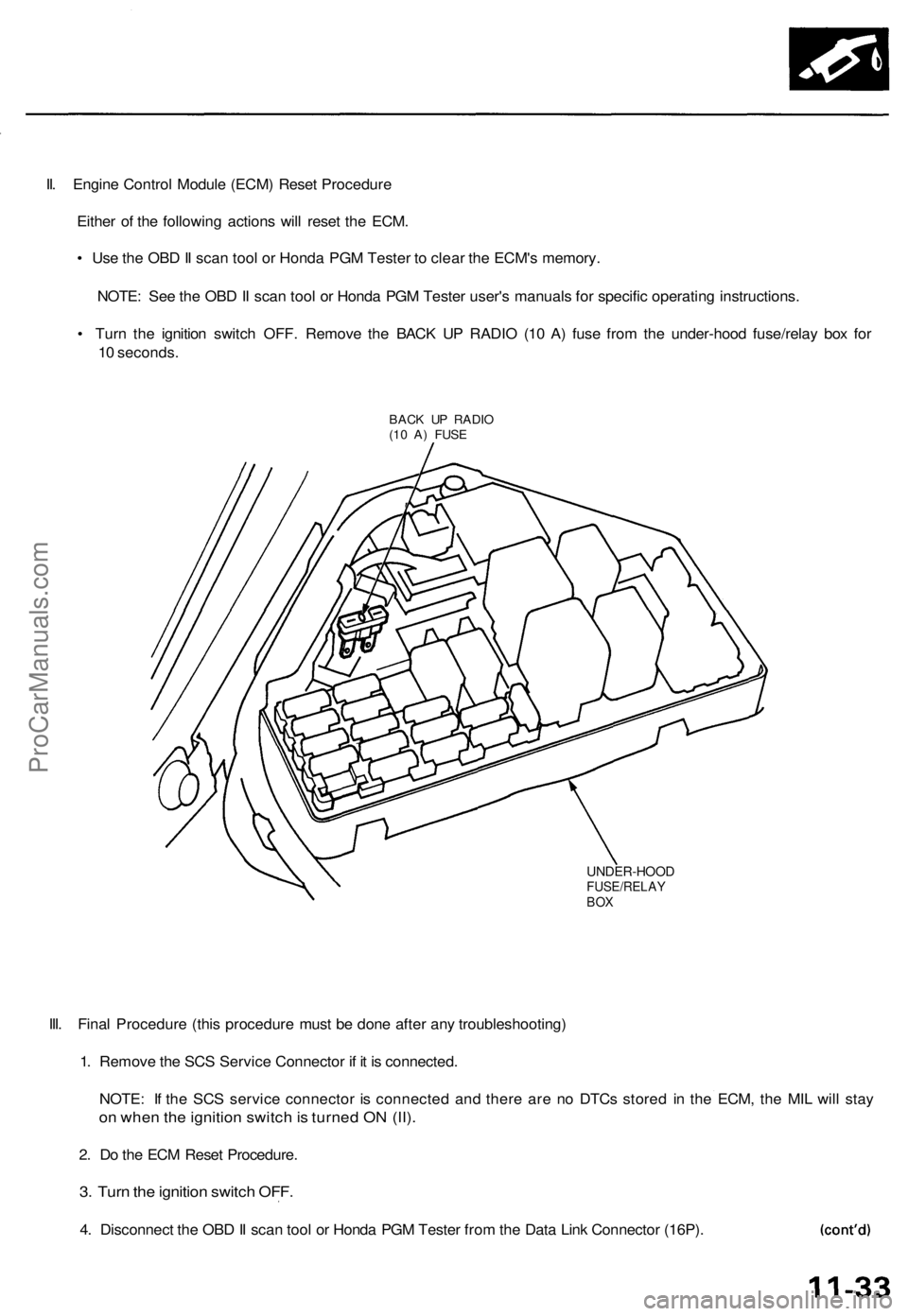

II. Engine Control Module (ECM) Reset Procedure

Either of the following actions will reset the ECM.

• Use the OBD II scan tool or Honda PGM Tester to clear the ECM's memory.

NOTE: See the OBD II scan tool or Honda PGM Tester user's manuals for specific operating instructions.

• Turn the ignition switch OFF. Remove the BACK UP RADIO (10 A) fuse from the under-hood fuse/relay box for

10 seconds.

BACK UP RADIO

(10 A) FUSE

UNDER-HOOD

FUSE/RELAY

BOX

III. Final Procedure (this procedure must be done after any troubleshooting)

1. Remove the SCS Service Connector if it is connected.

NOTE: If the SCS service connector is connected and there are no DTCs stored in the ECM, the MIL will stay

on when the ignition switch is turned ON (II).

2. Do the ECM Reset Procedure.

3. Turn the ignition switch OFF.

4. Disconnect the OBD II scan tool or Honda PGM Tester from the Data Link Connector (16P).ProCarManuals.com

Page 863 of 1771

Troubleshooting

Troubleshooting Procedure s (cont'd )

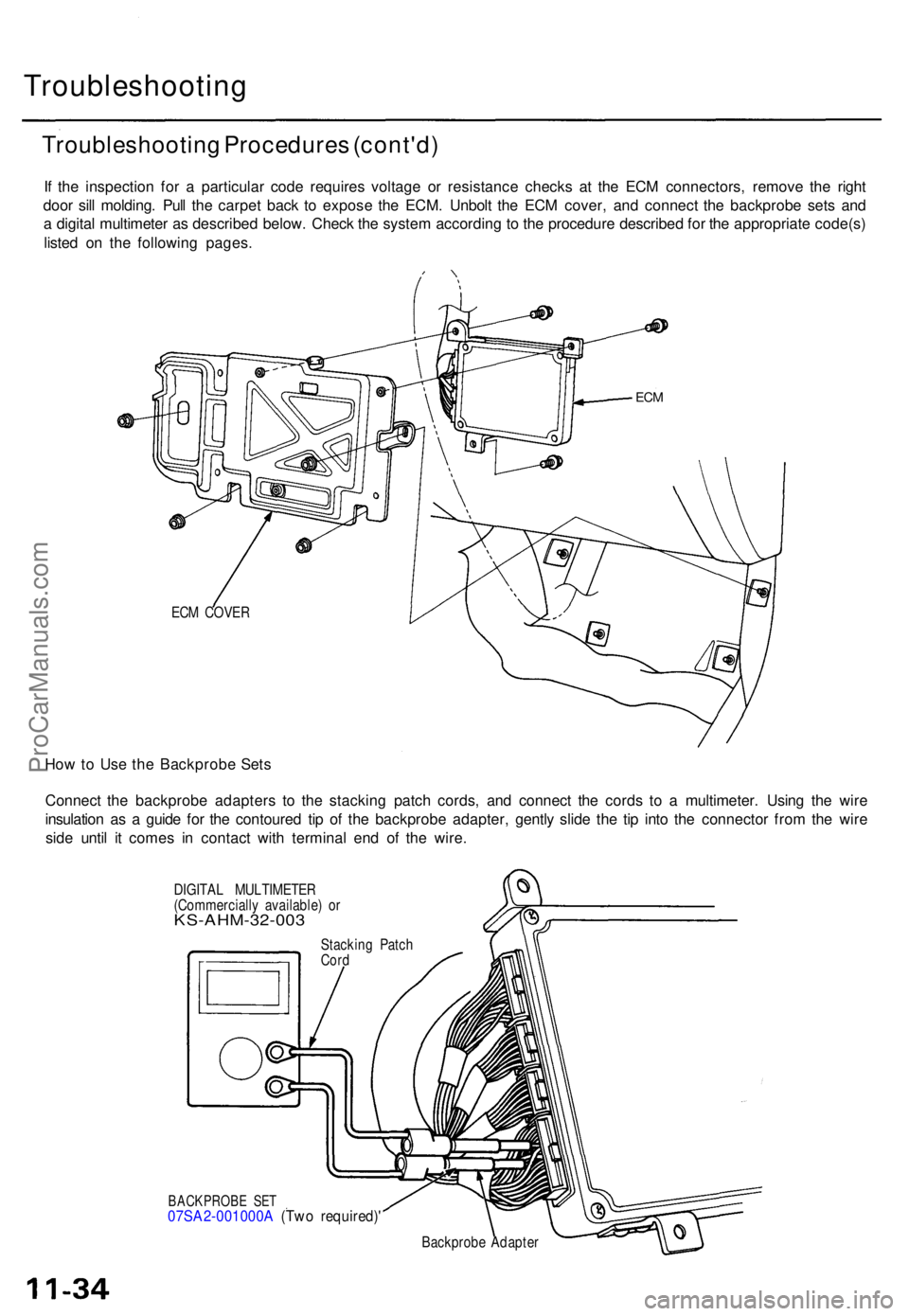

If th e inspectio n fo r a particula r cod e require s voltag e o r resistanc e check s a t th e EC M connectors , remov e th e righ t

doo r sil l molding . Pul l th e carpe t bac k t o expos e th e ECM . Unbol t th e EC M cover , an d connec t th e backprob e set s an d

a digita l multimete r a s describe d below . Chec k th e syste m accordin g t o th e procedur e describe d fo r th e appropriat e code(s )

liste d o n th e followin g pages .

ECM COVE R

How to Us e th e Backprob e Set s

Connec t th e backprob e adapter s t o th e stackin g patc h cords , an d connec t th e cord s t o a multimeter . Usin g th e wir e

insulatio n a s a guid e fo r th e contoure d ti p o f th e backprob e adapter , gentl y slid e th e ti p int o th e connecto r fro m th e wir e

sid e unti l i t come s i n contac t wit h termina l en d o f th e wire .

DIGITA L MULTIMETE R

(Commerciall y available ) o r

KS-AHM-32-00 3

BACKPROBE SE T07SA2-001000 A (Tw o required) '

Backprobe Adapte r

Stackin

g Patc h

Cord

ECM

ProCarManuals.com

Page 864 of 1771

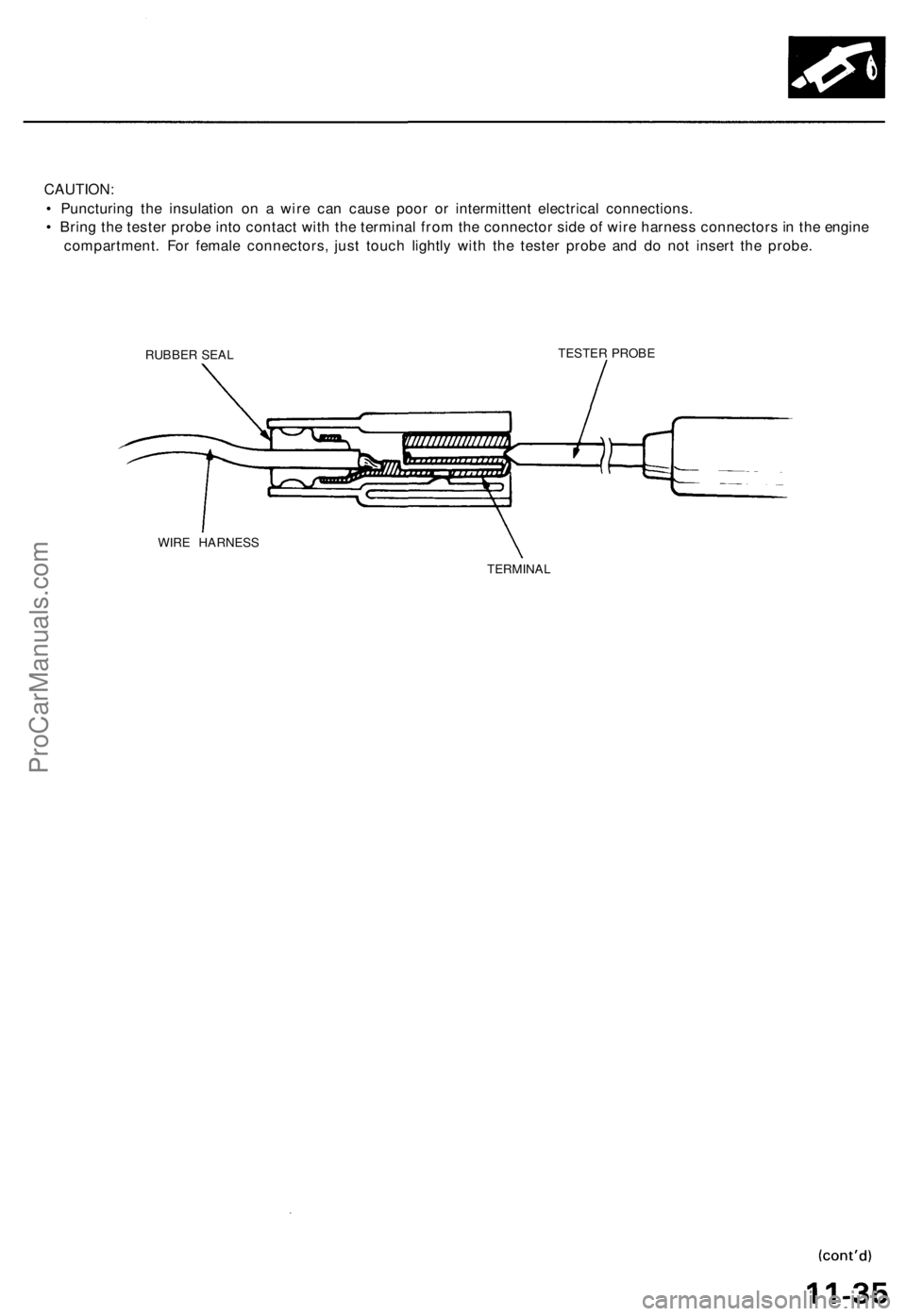

CAUTION:

• Puncturing the insulation on a wire can cause poor or intermittent electrical connections.

• Bring the tester probe into contact with the terminal from the connector side of wire harness connectors in the engine

compartment. For female connectors, just touch lightly with the tester probe and do not insert the probe.

RUBBER SEAL

TESTER PROBE

WIRE HARNESS

TERMINALProCarManuals.com

Page 865 of 1771

Troubleshooting

Troubleshooting Procedure s (cont'd )

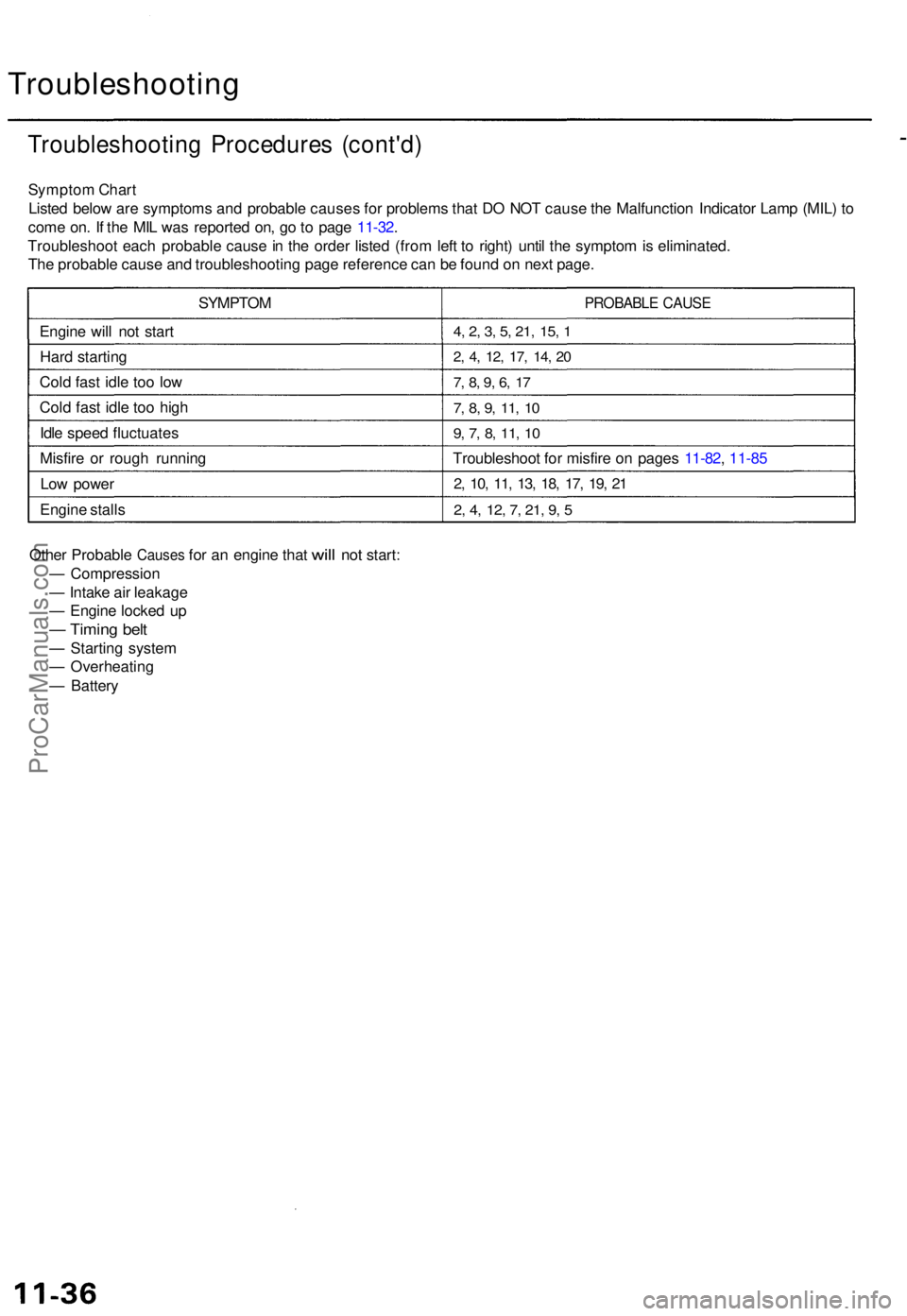

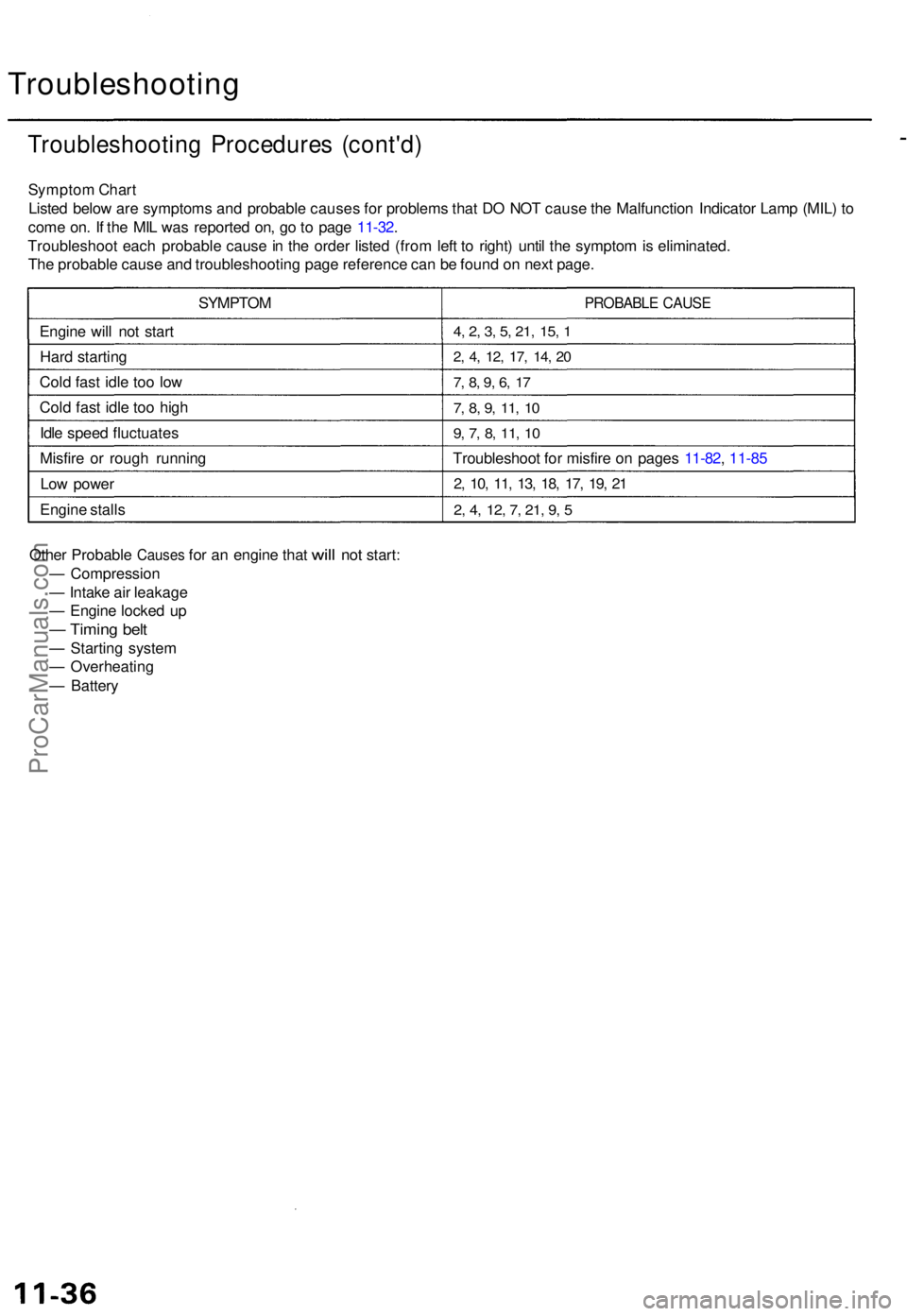

Sympto m Char t

Liste d belo w ar e symptom s an d probabl e cause s fo r problem s tha t D O NO T caus e th e Malfunctio n Indicato r Lam p (MIL ) t o

com e on . I f th e MI L wa s reporte d on , g o to pag e 11-32 .

Troubleshoo t eac h probabl e caus e in th e orde r liste d (fro m lef t t o right ) unti l th e sympto m is eliminated .

Th e probabl e caus e an d troubleshootin g pag e referenc e ca n b e foun d o n nex t page .

SYMPTO M

Engin e wil l no t star t

Har d startin g

Col d fas t idl e to o lo w

Col d fas t idl e to o hig h

Idl e spee d fluctuate s

Misfir e o r roug h runnin g

Lo w powe r

Engin e stall s

PROBABL E CAUS E

4, 2 , 3 , 5 , 21 , 15 , 1

2 , 4 , 12 , 17 , 14 , 2 0

7, 8 , 9 , 6 , 1 7

7, 8 , 9 , 11 , 1 0

9, 7 , 8 , 11 , 1 0

Troubleshoo t fo r misfir e o n page s 11-82 , 11-8 5

2, 10 , 11 , 13 , 18 , 17 , 19 , 2 1

2, 4 , 12 , 7 , 21 , 9 , 5

Othe r Probabl e Causes for a n engin e tha t will no t start :

— Compressio n

— Intak e ai r leakag e

— Engin e locke d u p

— Timin g bel t

— Startin g syste m

— Overheatin g

— Batter y

ProCarManuals.com

Page 866 of 1771

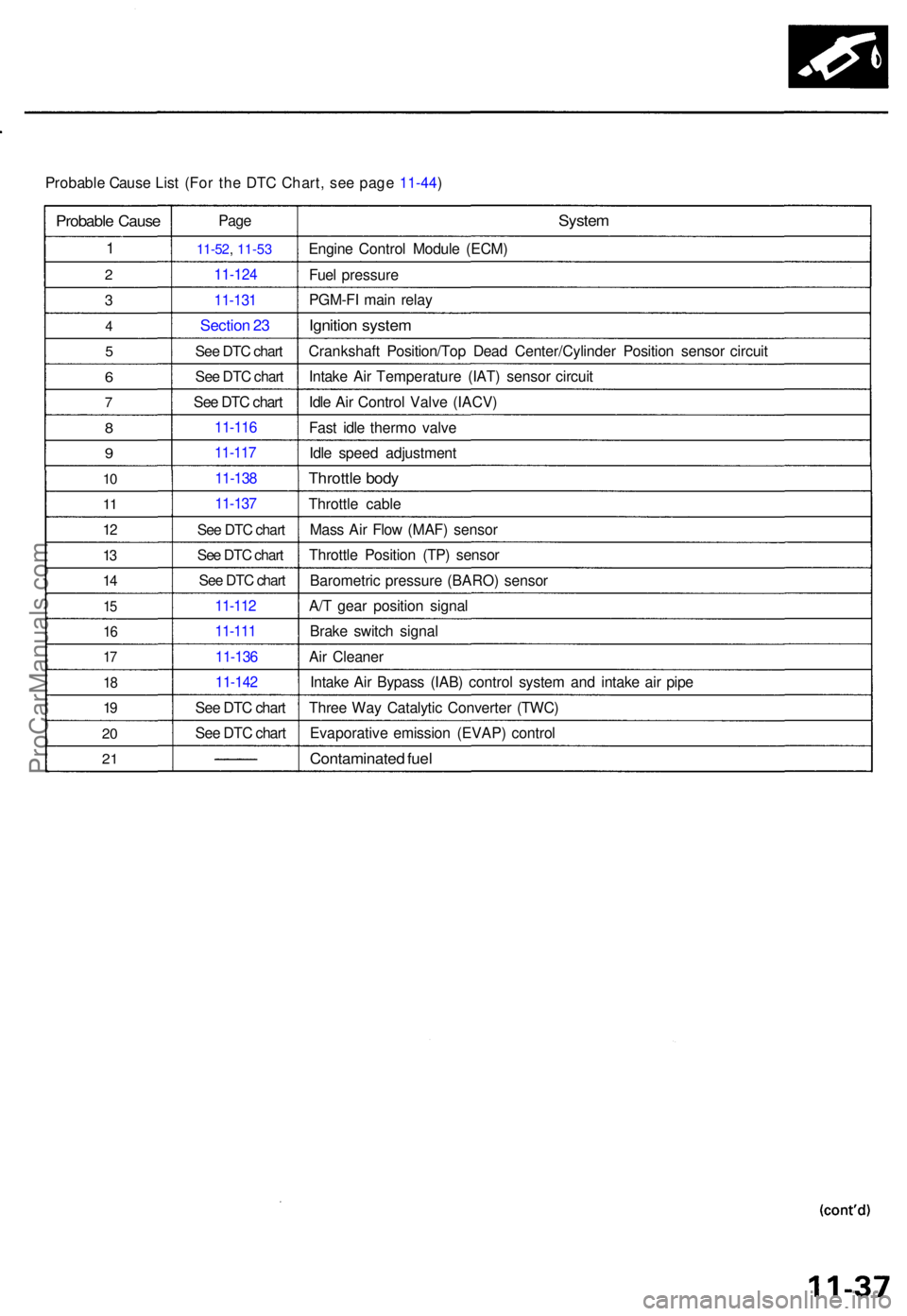

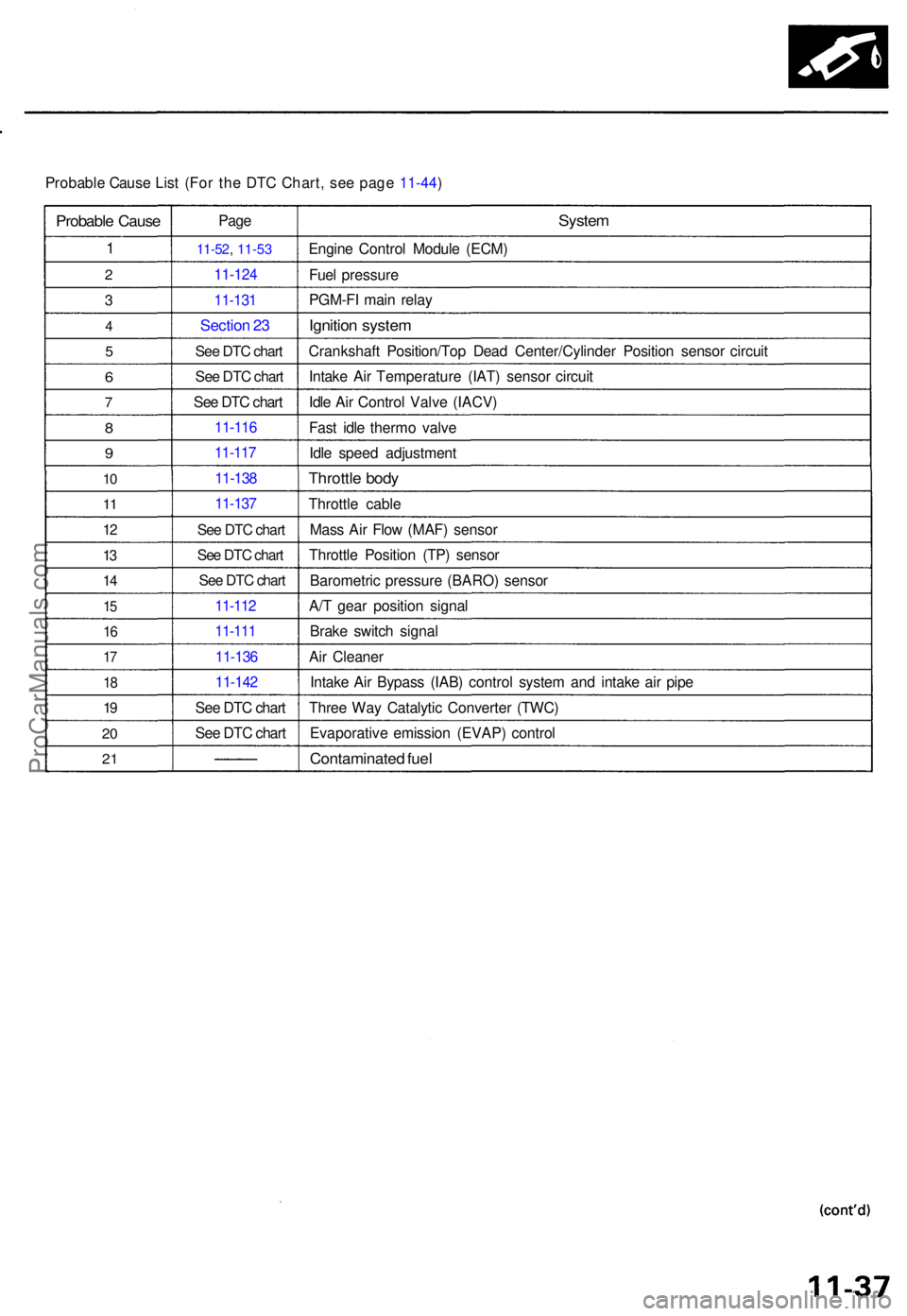

Probable Caus e Lis t (For the DTC Chart, see page 11-44)

Probabl e Caus e

1

2

3

4

5

6

7

8

9

10

1 1

12

13

1 4

15

1 6

17

1 8

19

2 0

2 1

Pag e

11-5 2, 11-53

11-12 4

11-131

Sectio n 2 3

See DTC chart

See DTC chart

See DTC chart

11-11 6

11-11 7

11-13 8

11-13 7

See DTC chart

See DTC chart

See DTC chart

11-11 2

11-11 1

11-13 6

11-14 2

See DTC chart

See DTC chart

System

Engin e Contro l Modul e (ECM )

Fue l pressur e

PGM-F I mai n rela y

Ignitio n syste m

Crankshaf t Position/To p Dea d Center/Cylinde r Positio n senso r circui t

Intak e Ai r Temperatur e (IAT ) senso r circui t

Idl e Ai r Contro l Valv e (IACV )

Fas t idl e therm o valv e

Idl e spee d adjustmen t

Throttle bod y

Throttl e cabl e

Mas s Ai r Flo w (MAF ) senso r

Throttl e Positio n (TP ) senso r

Barometri c pressur e (BARO ) senso r

A/ T gea r positio n signa l

Brak e switc h signa l

Ai r Cleane r

Intak e Ai r Bypas s (IAB ) contro l syste m an d intak e ai r pip e

Thre e Wa y Catalyti c Converte r (TWC )

Evaporativ e emissio n (EVAP ) contro l

Contaminate d fue l

ProCarManuals.com

Page 867 of 1771

Troubleshooting

Troubleshooting Procedures (cont'd)

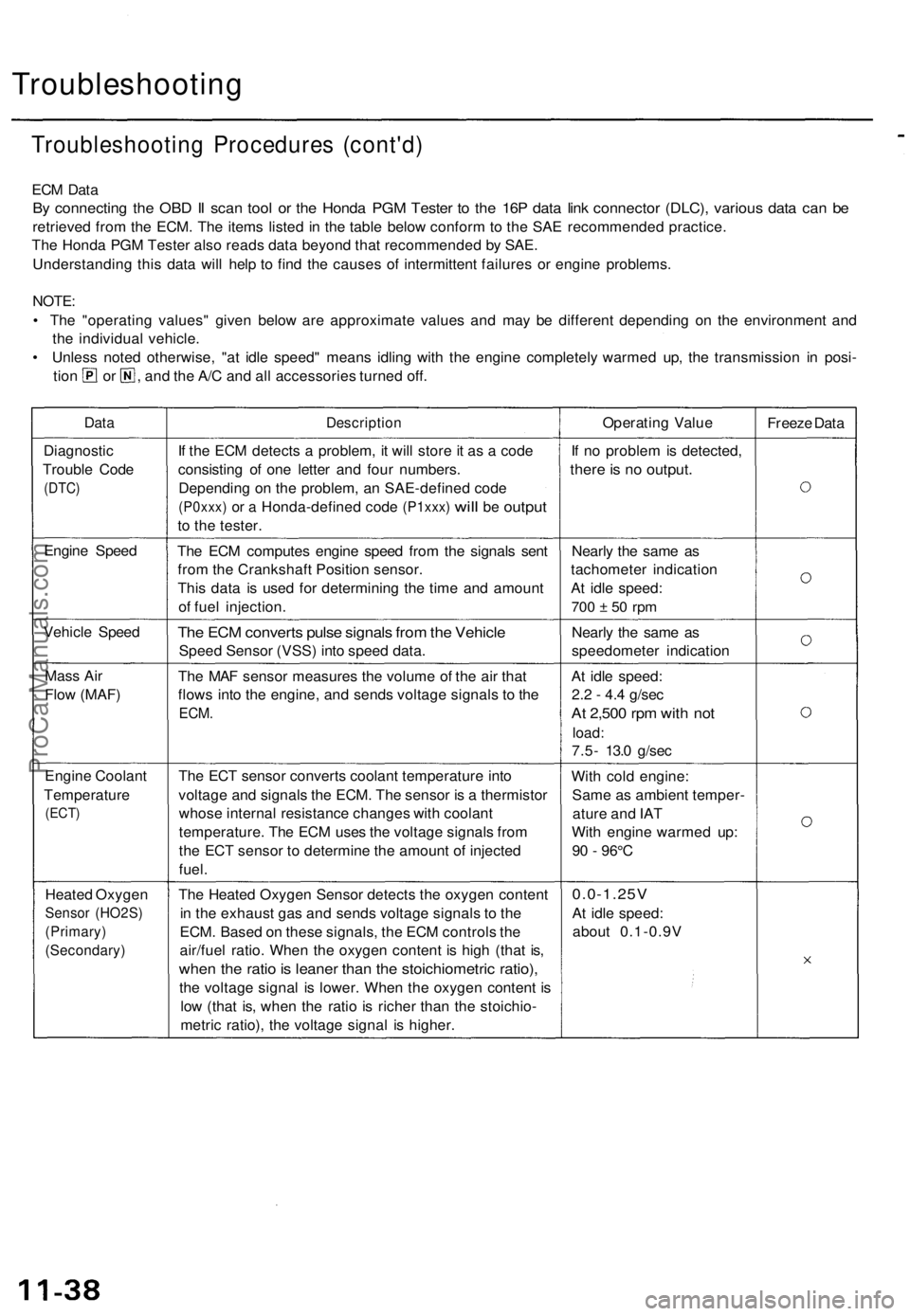

ECM Data

By connecting the OBD II scan tool or the Honda PGM Tester to the 16P data link connector (DLC), various data can be

retrieved from the ECM. The items listed in the table below conform to the SAE recommended practice.

The Honda PGM Tester also reads data beyond that recommended by SAE.

Understanding this data will help to find the causes of intermittent failures or engine problems.

NOTE:

• The "operating values" given below are approximate values and may be different depending on the environment and

the individual vehicle.

• Unless noted otherwise, "at idle speed" means idling with the engine completely warmed up, the transmission in posi-

tion or , and the A/C and all accessories turned off.

Data

Description

Operating Value

Freeze Data

Diagnostic

Trouble Code

(DTC)

If the ECM detects a problem, it will store it as a code

consisting of one letter and four numbers.

Depending on the problem, an SAE-defined code

(P0xxx)

or a

Honda-defined code

(P1xxx)

will

be

output

to the tester.

If no problem is detected,

there is no output.

Engine Speed

The ECM computes engine speed from the signals sent

from the Crankshaft Position sensor.

This data is used for determining the time and amount

of fuel injection.

Nearly the same as

tachometer indication

At idle speed:

700 ± 50 rpm

Vehicle Speed

The ECM converts pulse signals from the Vehicle

Speed Sensor (VSS) into speed data.

Nearly the same as

speedometer indication

Mass Air

Flow (MAF)

The MAF sensor measures the volume of the air that

flows into the engine, and sends voltage signals to the

ECM.

At idle speed:

2.2 - 4.4 g/sec

At 2,500 rpm with not

load:

7.5- 13.0 g/sec

Engine Coolant

Temperature

(ECT)

The ECT sensor converts coolant temperature into

voltage and signals the ECM. The sensor is a thermistor

whose internal resistance changes with coolant

temperature. The ECM uses the voltage signals from

the ECT sensor to determine the amount of injected

fuel.

With cold engine:

Same as ambient temper-

ature and IAT

With engine warmed up:

90 - 96°C

Heated Oxygen

Sensor (HO2S)

(Primary)

(Secondary)

The Heated Oxygen Sensor detects the oxygen content

in the exhaust gas and sends voltage signals to the

ECM. Based on these signals, the ECM controls the

air/fuel ratio. When the oxygen content is high (that is,

when the ratio is leaner than the stoichiometric ratio),

the voltage signal is lower. When the oxygen content is

low (that is, when the ratio is richer than the stoichio-

metric ratio), the voltage signal is higher.

0.0-1.25V

At idle speed:

about 0.1-0.9VProCarManuals.com

Page 868 of 1771

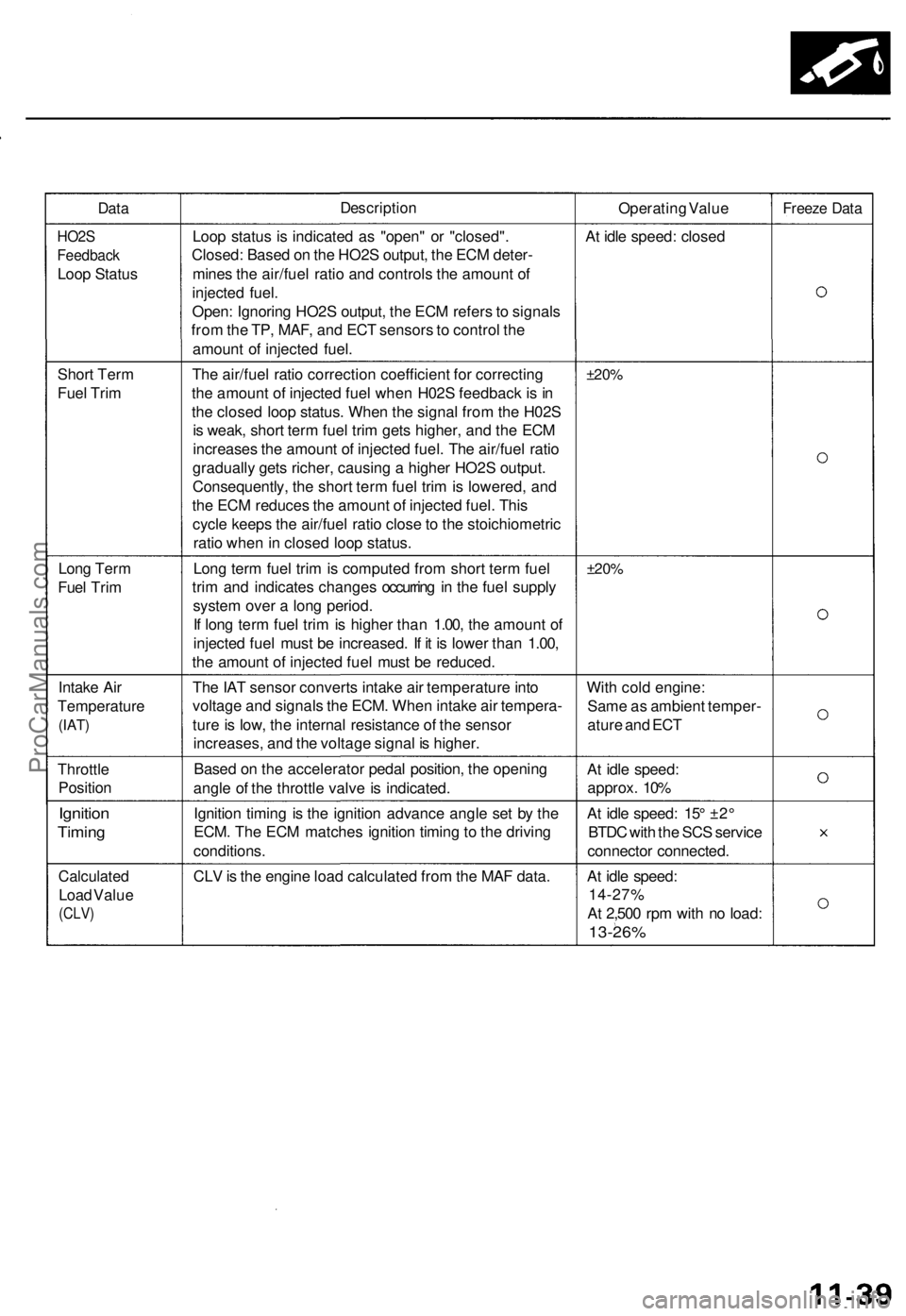

Data

Description

Operating Value

Freeze Data

HO2S

Feedback

Loop Status

Loop status is indicated as "open" or "closed".

Closed: Based on the HO2S output, the ECM deter-

mines the air/fuel ratio and controls the amount of

injected fuel.

Open: Ignoring HO2S output, the ECM refers to signals

from the TP, MAF, and ECT sensors to control the

amount of injected fuel.

At idle speed: closed

Short Term

Fuel Trim

The air/fuel ratio correction coefficient for correcting

the amount of injected fuel when H02S feedback is in

the closed loop status. When the signal from the H02S

is weak, short term fuel trim gets higher, and the ECM

increases the amount of injected fuel. The air/fuel ratio

gradually gets richer, causing a higher HO2S output.

Consequently, the short term fuel trim is lowered, and

the ECM reduces the amount of injected fuel. This

cycle keeps the air/fuel ratio close to the stoichiometric

ratio when in closed loop status.

±20%

Long Term

Fuel Trim

Long term fuel trim is computed from short term fuel

trim and indicates changes occurring in the fuel supply

system over a long period.

If long term fuel trim is higher than 1.00, the amount of

injected fuel must be increased. If it is lower than 1.00,

the amount of injected fuel must be reduced.

±20%

Intake Air

Temperature

(IAT)

The IAT sensor converts intake air temperature into

voltage and signals the ECM. When intake air tempera-

ture is low, the internal resistance of the sensor

increases, and the voltage signal is higher.

With cold engine:

Same as ambient temper-

ature and ECT

Throttle

Position

Based on the accelerator pedal position, the opening

angle of the throttle valve is indicated.

At idle speed:

approx. 10%

Ignition

Timing

Ignition timing is the ignition advance angle set by the

ECM. The ECM matches ignition timing to the driving

conditions.

At idle speed: 15° ±2°

BTDC with the SCS service

connector connected.

Calculated

Load Value

(CLV)

CLV is the engine load calculated from the MAF data.

At idle speed:

14-27%

At 2,500 rpm with no load:

13-26%ProCarManuals.com

Page 869 of 1771

Troubleshooting

Troubleshooting Procedure s (cont'd )

Sympto m Char t

Liste d belo w ar e symptom s an d probabl e cause s fo r problem s tha t D O NO T caus e th e Malfunctio n Indicato r Lam p (MIL ) t o

com e on . I f th e MI L wa s reporte d on , g o to pag e 11-32 .

Troubleshoo t eac h probabl e caus e in th e orde r liste d (fro m lef t t o right ) unti l th e sympto m is eliminated .

Th e probabl e caus e an d troubleshootin g pag e referenc e ca n b e foun d o n nex t page .

SYMPTO M

Engin e wil l no t star t

Har d startin g

Col d fas t idl e to o lo w

Col d fas t idl e to o hig h

Idl e spee d fluctuate s

Misfir e o r roug h runnin g

Lo w powe r

Engin e stall s

PROBABL E CAUS E

4, 2 , 3 , 5 , 21 , 15 , 1

2 , 4 , 12 , 17 , 14 , 2 0

7, 8 , 9 , 6 , 1 7

7, 8 , 9 , 11 , 1 0

9, 7 , 8 , 11 , 1 0

Troubleshoo t fo r misfir e o n page s 11-82 , 11-8 5

2, 10 , 11 , 13 , 18 , 17 , 19 , 2 1

2, 4 , 12 , 7 , 21 , 9 , 5

Othe r Probabl e Causes for a n engin e tha t will no t start :

— Compressio n

— Intak e ai r leakag e

— Engin e locke d u p

— Timin g bel t

— Startin g syste m

— Overheatin g

— Batter y

ProCarManuals.com

Page 870 of 1771

Probable Caus e Lis t (For the DTC Chart, see page 11-44)

Probabl e Caus e

1

2

3

4

5

6

7

8

9

10

1 1

12

13

1 4

15

1 6

17

1 8

19

2 0

2 1

Pag e

11-5 2, 11-53

11-12 4

11-131

Sectio n 2 3

See DTC chart

See DTC chart

See DTC chart

11-11 6

11-11 7

11-13 8

11-13 7

See DTC chart

See DTC chart

See DTC chart

11-11 2

11-11 1

11-13 6

11-14 2

See DTC chart

See DTC chart

System

Engin e Contro l Modul e (ECM )

Fue l pressur e

PGM-F I mai n rela y

Ignitio n syste m

Crankshaf t Position/To p Dea d Center/Cylinde r Positio n senso r circui t

Intak e Ai r Temperatur e (IAT ) senso r circui t

Idl e Ai r Contro l Valv e (IACV )

Fas t idl e therm o valv e

Idl e spee d adjustmen t

Throttle bod y

Throttl e cabl e

Mas s Ai r Flo w (MAF ) senso r

Throttl e Positio n (TP ) senso r

Barometri c pressur e (BARO ) senso r

A/ T gea r positio n signa l

Brak e switc h signa l

Ai r Cleane r

Intak e Ai r Bypas s (IAB ) contro l syste m an d intak e ai r pip e

Thre e Wa y Catalyti c Converte r (TWC )

Evaporativ e emissio n (EVAP ) contro l

Contaminate d fue l

ProCarManuals.com