ACURA TL 1995 Service Repair Manual

Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 891 of 1771

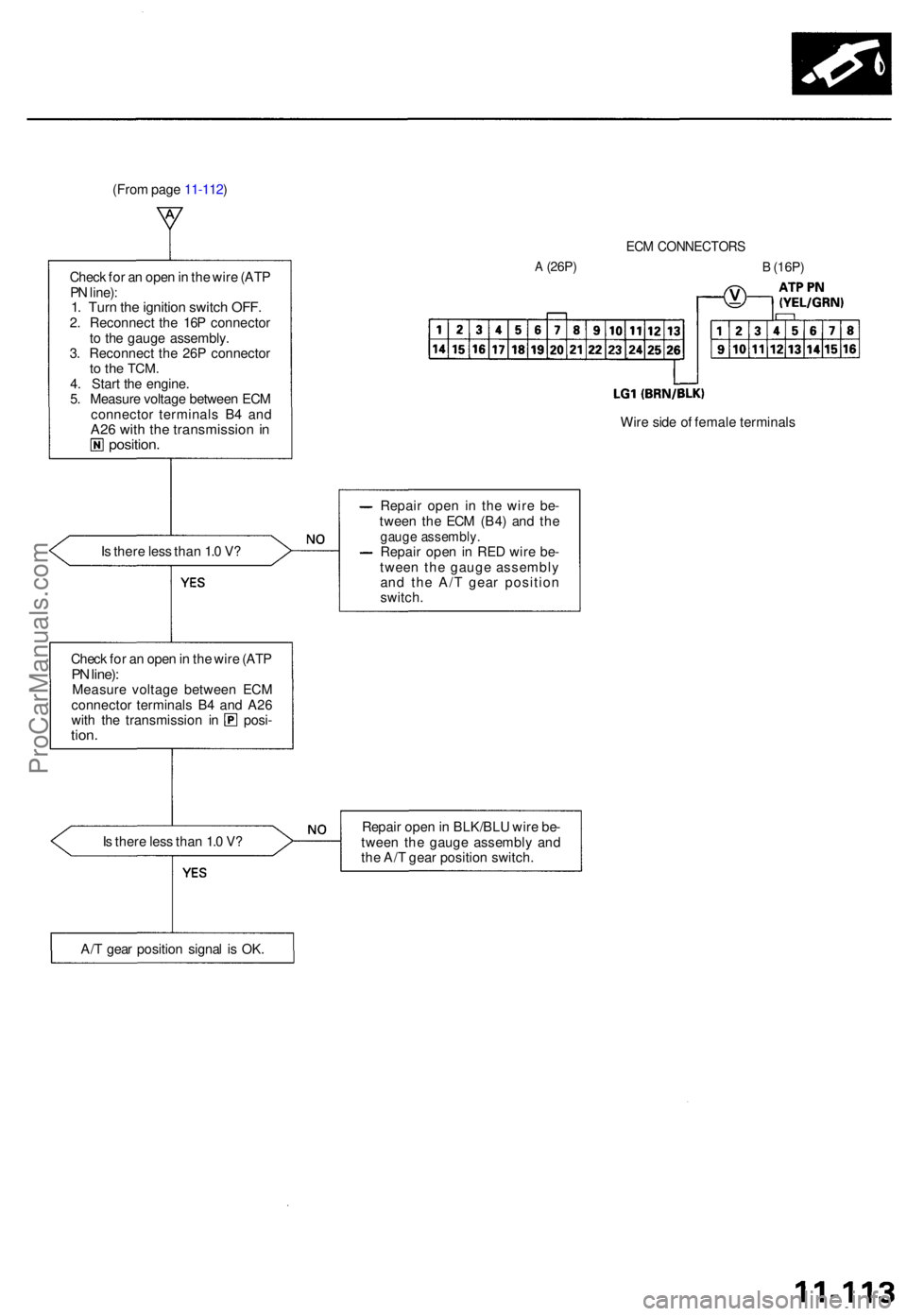

(From pag e 11-112 )

ECM CONNECTOR S

A (26P)

Wire sid e o f femal e terminal s

I s ther e les s tha n 1. 0 V ? Repai

r ope n i n th e wir e be -

twee n th e EC M (B4 ) an d th e

gaug e assembly .Repair ope n in RE D wir e be -

twee n th e gaug e assembl y

an d th e A/ T gea r positio n

switch.

Check fo r a n ope n in th e wir e (AT PPN line) :Measur e voltag e betwee n EC M

connecto r terminal s B 4 an d A2 6

with th e transmissio n i n posi -tion.

Is ther e les s tha n 1. 0 V ? Repai

r ope n in BLK/BL U wir e be -

twee n th e gaug e assembl y an d

th e A/ T gea r positio n switch .

A/ T gea r positio n signa l i s OK .

Chec

k fo r a n ope n in th e wir e (AT P

P N line) :

1. Tur n th e ignitio n switc h OFF .2. Reconnec t th e 16 P connecto r

t o th e gaug e assembly .

3 . Reconnec t th e 26 P connecto r

to th e TCM .4. Star t th e engine .

5 . Measur e voltag e betwee n EC M

connecto r terminal s B 4 an d

A26 wit h th e transmissio n inposition .

B (16P)

ProCarManuals.com

Page 892 of 1771

Idle Contro l Syste m

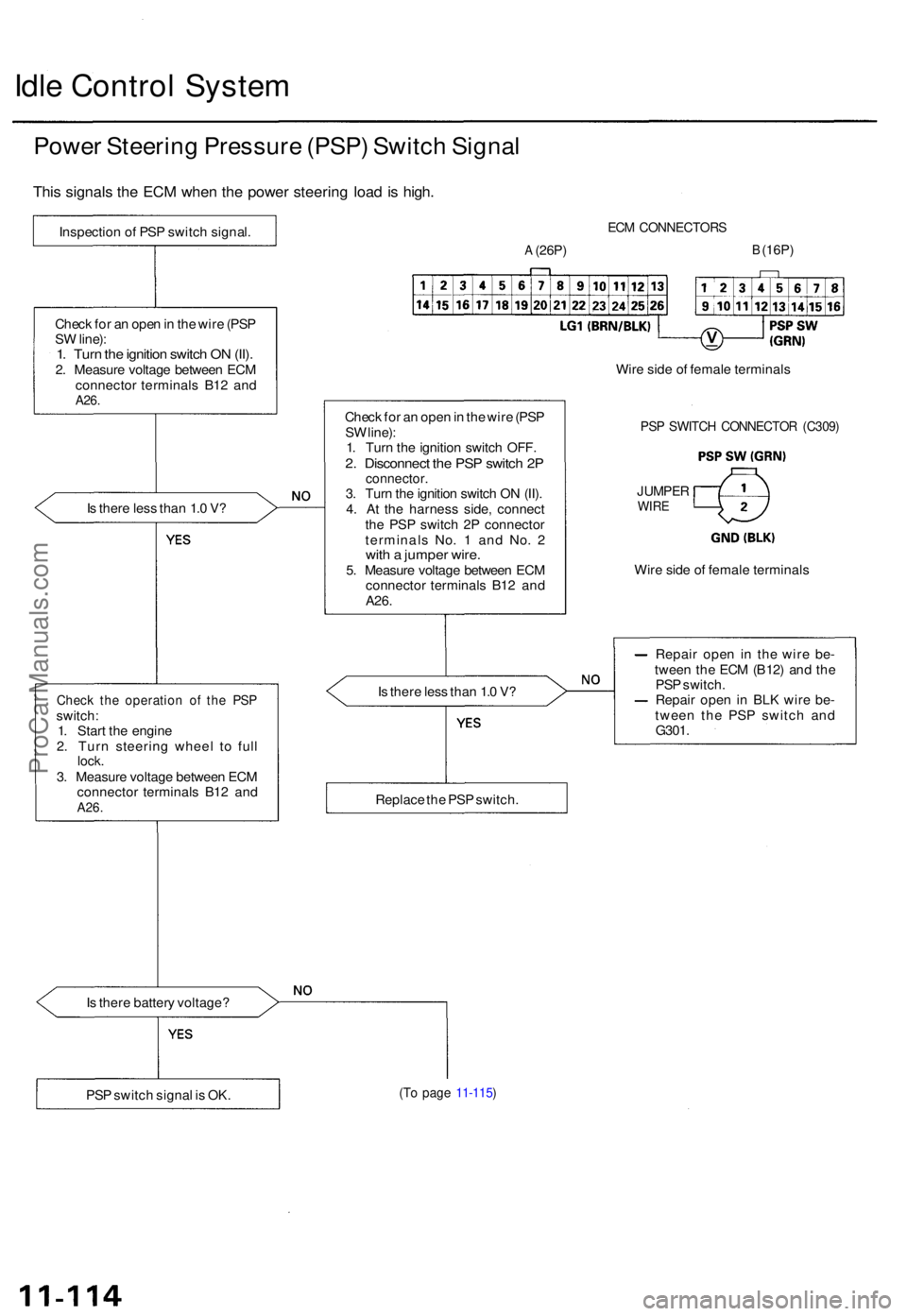

Power Steerin g Pressur e (PSP ) Switc h Signa l

This signal s th e EC M whe n th e powe r steerin g loa d is high .

Is ther e les s tha n 1. 0 V ?

Chec k th e operatio n o f th e PS Pswitch :

1 . Star t th e engin e

2 . Tur n steerin g whee l t o ful l

lock .3. Measur e voltag e betwee n EC M

connecto r terminal s B1 2 an d

A26 .

Is ther e batter y voltage ?

ECM CONNECTOR S

A (26P)B (16P)

Chec k fo r a n ope n in th e wir e (PS P

S W line) :

1 . Tur n th e ignitio n switc h OFF .

2. Disconnec t th e PS P switc h 2 Pconnector .3. Tur n th e ignitio n switc h O N (II) .

4 . A t th e harnes s side , connec t

th e PS P switc h 2 P connecto r

terminal s No . 1 an d No . 2

wit h a jumpe r wire .5. Measur e voltag e betwee n EC M

connecto r terminal s B1 2 an d

A26 .

Is ther e les s tha n 1. 0 V ? Repai

r ope n i n th e wir e be -

twee n th e EC M (B12 ) an d th e

PS P switch .

Repai r ope n in BL K wir e be -

twee n th e PS P switc h an d

G301 .

(To pag e 11-115 )PSP switc h signa l i s OK . Replac

e th e PS P switch . Wir

e sid e o f femal e terminal s

JUMPERWIRE

PSP SWITC H CONNECTO R (C309 )

Wire side of femal e terminal s

Chec

k fo r a n ope n in th e wir e (PS P

S W line) :1. Tur n th e ignitio n switc h O N (II) .2. Measur e voltag e betwee n EC M

connecto r terminal s B1 2 an d

A26 .

Inspectio n o f PS P switc h signal .

ProCarManuals.com

Page 893 of 1771

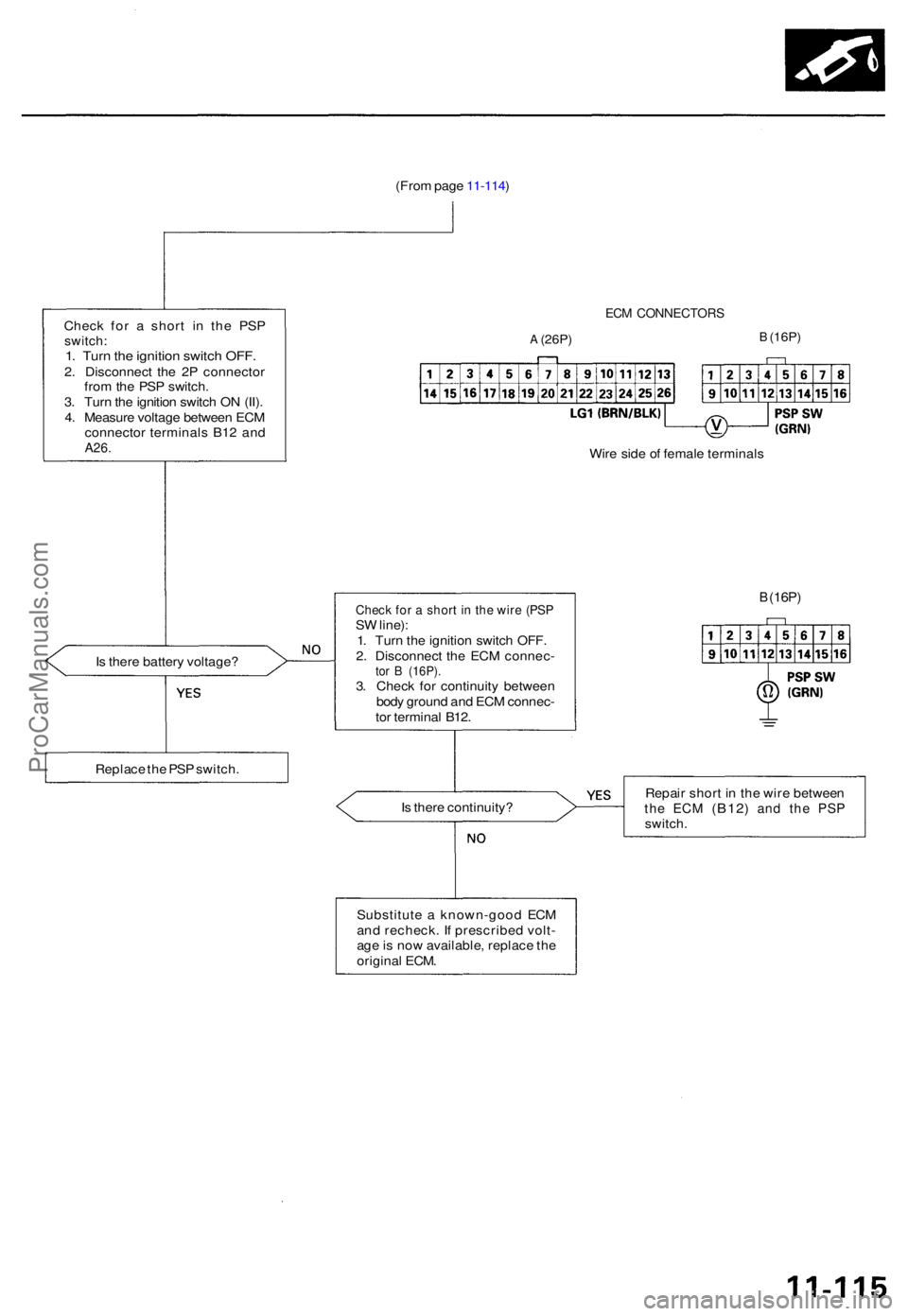

(From pag e 11-114 )

Chec k fo r a shor t i n th e PS P

switch :1. Tur n th e ignitio n switc h OFF .2. Disconnec t th e 2 P connecto r

fro m th e PS P switch .

3 . Tur n th e ignitio n switc h O N (II) .

4 . Measur e voltag e betwee n EC M

connecto r terminal s B1 2 an d

A26 .

ECM CONNECTOR S

A (26P)B (16P)

Wire sid e o f femal e terminal s

I s ther e batter y voltage ?

B (16P)

Is ther e continuity ? Repai

r shor t i n th e wir e betwee nthe EC M (B12 ) and th e PS Pswitch .

Substitut e a known-goo d EC M

an d recheck . I f prescribe d volt -

ag e is no w available , replac e th e

origina l ECM .

Replac

e th e PS P switch .

Check fo r a shor t i n th e wir e (PS PSW line) :

1 . Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e EC M connec -

tor B (16P) .3. Chec k fo r continuit y betwee n

bod y groun d an d EC M connec -

to r termina l B12 .

ProCarManuals.com

Page 894 of 1771

Idle Contro l Syste m

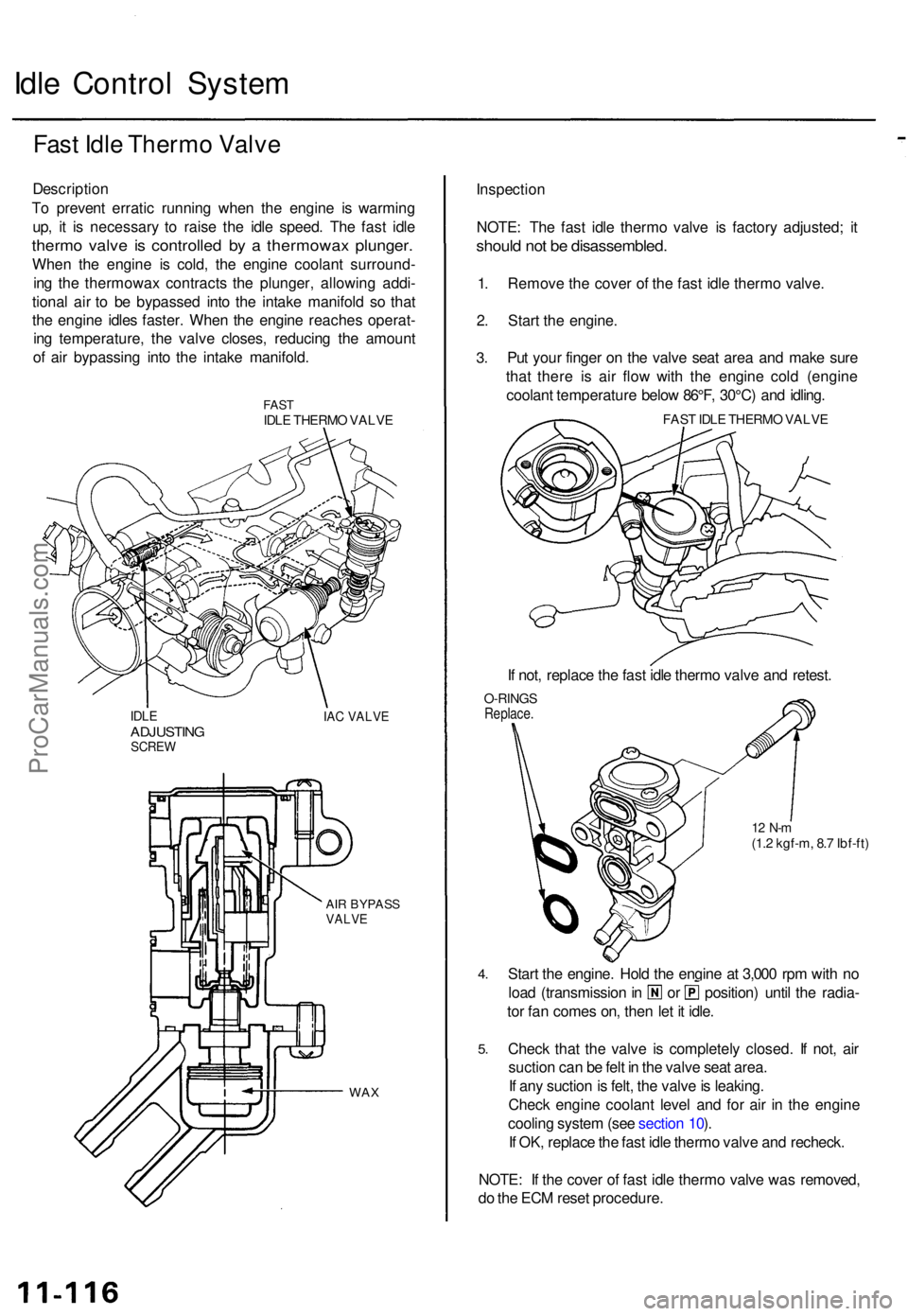

Fast Idl e Therm o Valv e

Descriptio n

T o preven t errati c runnin g whe n th e engin e i s warmin g

up , i t i s necessar y t o rais e th e idl e speed . Th e fas t idl e

therm o valv e i s controlle d b y a thermowa x plunger .

When th e engin e i s cold , th e engin e coolan t surround -

in g th e thermowa x contract s th e plunger , allowin g addi -

tiona l ai r t o b e bypasse d int o th e intak e manifol d s o tha t

th e engin e idle s faster . Whe n th e engin e reache s operat -

in g temperature , th e valv e closes , reducin g th e amoun t

o f ai r bypassin g int o th e intak e manifold .

FASTIDLE THERM O VALV E

IDLEADJUSTIN GSCREW

IAC VALV E

AIR BYPAS SVALVE

WAX

Inspectio n

NOTE : Th e fas t idl e therm o valv e i s factor y adjusted ; i t

shoul d no t b e disassembled .

1. Remov e th e cove r o f th e fas t idl e therm o valve .

2 . Star t th e engine .

3.Pu t you r finge r o n th e valv e sea t are a an d mak e sur e

tha t ther e i s ai r flo w wit h th e engin e col d (engin e

coolan t temperatur e belo w 86°F , 30°C ) an d idling .

FAST IDL E THERM O VALV E

If not , replac e th e fas t idl e therm o valv e an d retest .

O-RING SReplace .

12 N- m(1.2 kgf-m , 8. 7 Ibf-ft )

4.

5 .

Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h n o

loa d (transmissio n in o r position ) unti l th e radia -

to r fa n come s on , the n le t i t idle .

Chec k tha t th e valv e i s completel y closed . I f not , ai r

suctio n ca n b e fel t i n th e valv e sea t area .

I f an y suctio n is felt , th e valv e is leaking .

Chec k engin e coolan t leve l an d fo r ai r i n th e engin e

coolin g syste m (se e sectio n 10 ).

I f OK , replac e th e fas t idl e therm o valv e an d recheck .

NOTE : I f th e cove r o f fas t idl e therm o valv e wa s removed ,

d o th e EC M rese t procedure .

ProCarManuals.com

Page 895 of 1771

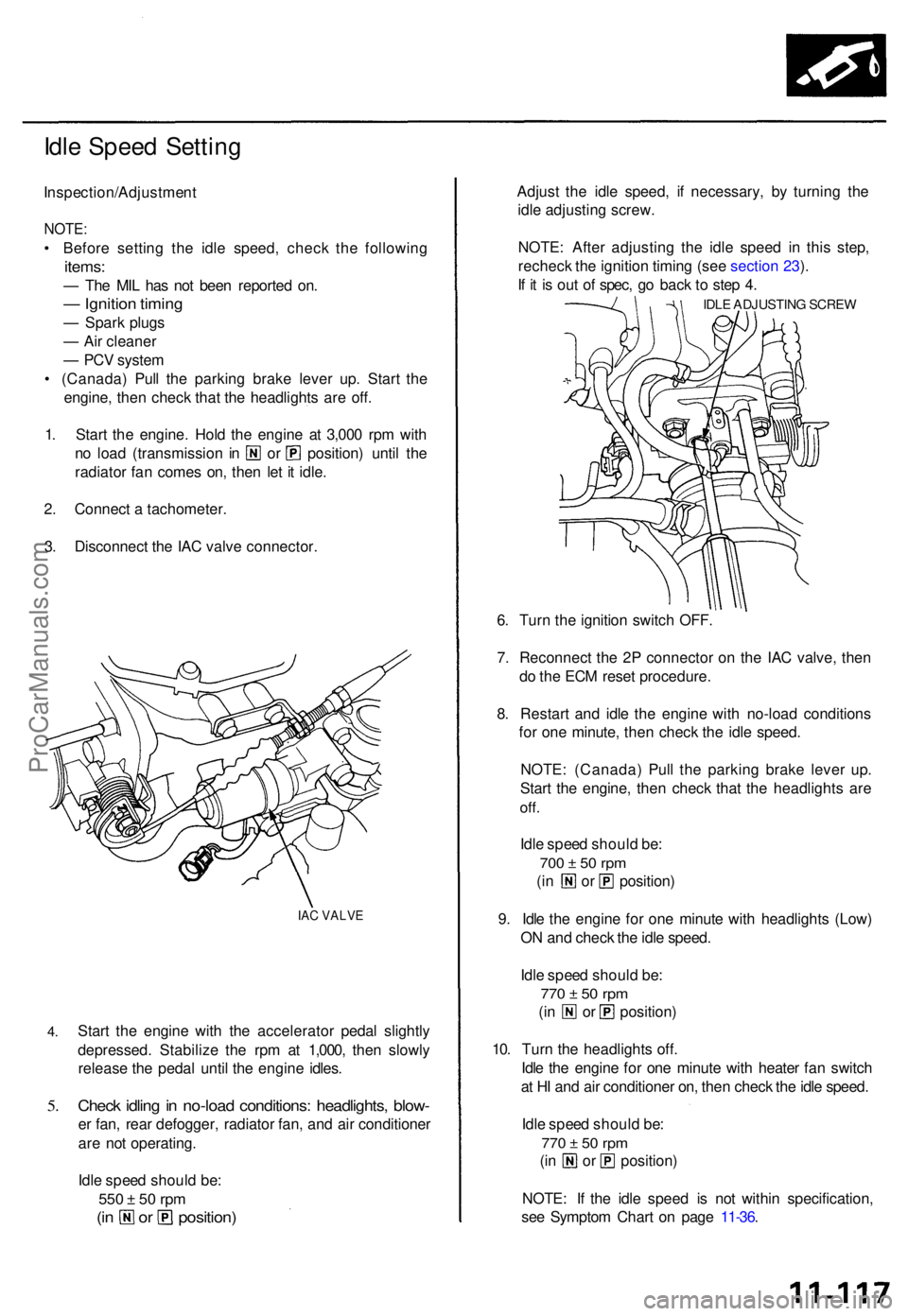

Idle Spee d Settin g

Inspection/Adjustmen t

NOTE:

• Befor e settin g th e idl e speed , chec k th e followin g

items:

— Th e MI L ha s no t bee n reporte d on .

— Ignitio n timin g

— Spar k plug s

— Ai r cleane r

— PC V syste m

• (Canada ) Pul l th e parkin g brak e leve r up . Star t th e

engine , the n chec k tha t th e headlight s ar e off .

1 . Star t th e engine . Hol d th e engine at 3,00 0 rp m wit h

no loa d (transmissio n i n o r position ) unti l th e

radiato r fa n come s on , the n le t i t idle .

2 . Connec t a tachometer .

3 . Disconnec t th e IA C valv e connector .

IAC VALV E

4.

5.

Star t th e engin e wit h th e accelerato r peda l slightl y

depressed . Stabiliz e th e rp m a t 1,000 , the n slowl y

releas e th e peda l unti l th e engin e idles .

Check idlin g in no-loa d conditions : headlights , blow -

er fan , rea r defogger , radiato r fan , an d ai r conditione r

ar e no t operating .

Idl e spee d shoul d be :

550 ± 5 0 rp m

(in o r position )

Adjust th e idl e speed , i f necessary, by turnin g th e

idl e adjustin g screw .

NOTE : Afte r adjustin g th e idl e spee d i n thi s step ,

rechec k th e ignitio n timin g (se e sectio n 23 ).

I f i t i s ou t o f spec , g o bac k t o ste p 4 .

IDL E ADJUSTIN G SCRE W

6. Tur n th e ignitio n switc h OFF .

7 . Reconnec t th e 2 P connecto r o n th e IA C valve , the n

d o th e EC M rese t procedure .

8 . Restar t an d idl e th e engine with no-loa d condition s

fo r on e minute , the n chec k th e idl e speed .

NOTE : (Canada ) Pul l th e parkin g brak e leve r up .

Star t th e engine , the n chec k tha t th e headlight s ar e

off.

Idle spee d shoul d be :

700 ± 5 0 rp m

(in o r position )

9 . Idl e th e engin e fo r on e minut e wit h headlight s (Low )

O N an d chec k th e idl e speed .

Idl e spee d shoul d be :

770 ± 5 0 rp m

(in o r position )

10 . Tur n th e headlight s off .

Idl e th e engin e fo r on e minut e wit h heate r fa n switc h

a t H I an d ai r conditione r on , the n chec k th e idl e speed .

Idl e spee d shoul d be :

770 ± 5 0 rp m

(in o r position )

NOTE : I f th e idl e spee d i s no t withi n specification ,

se e Sympto m Char t o n pag e 11-36 .

ProCarManuals.com

Page 896 of 1771

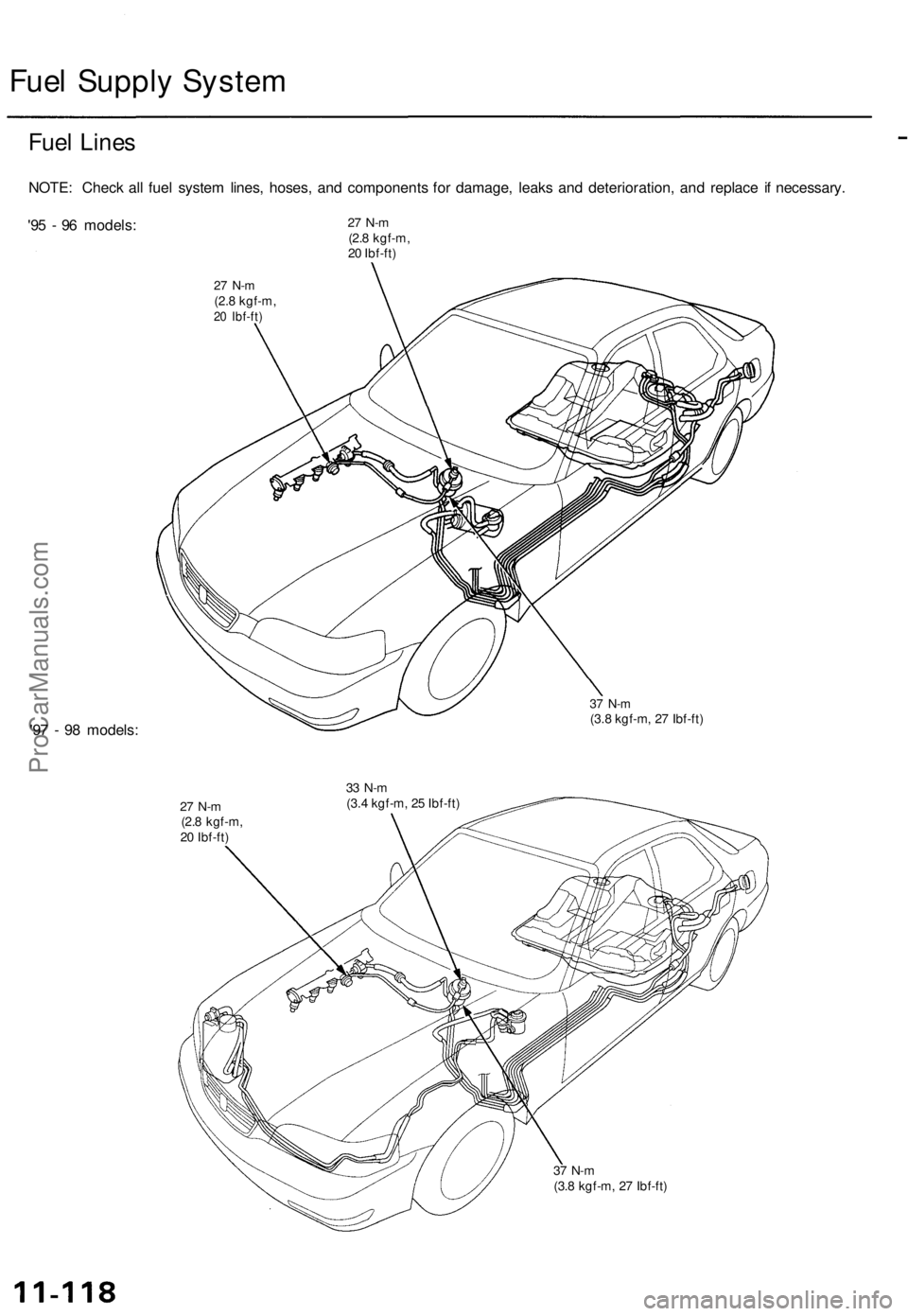

Fuel Supply System

Fuel Lines

NOTE: Check all fuel system lines, hoses, and components for damage, leaks and deterioration, and replace if necessary.

'95 - 96 models:

27 N-m

(2.8 kgf-m,

20 Ibf-ft)

27 N-m

(2.8 kgf-m,

20 Ibf-ft)

'97 - 98 models:

37 N-m

(3.8 kgf-m, 27 Ibf-ft)

27 N-m

(2.8 kgf-m,

20 Ibf-ft)

33 N-m

(3.4 kgf-m, 25 Ibf-ft)

37 N-m

(3.8 kgf-m, 27 Ibf-ft)ProCarManuals.com

Page 897 of 1771

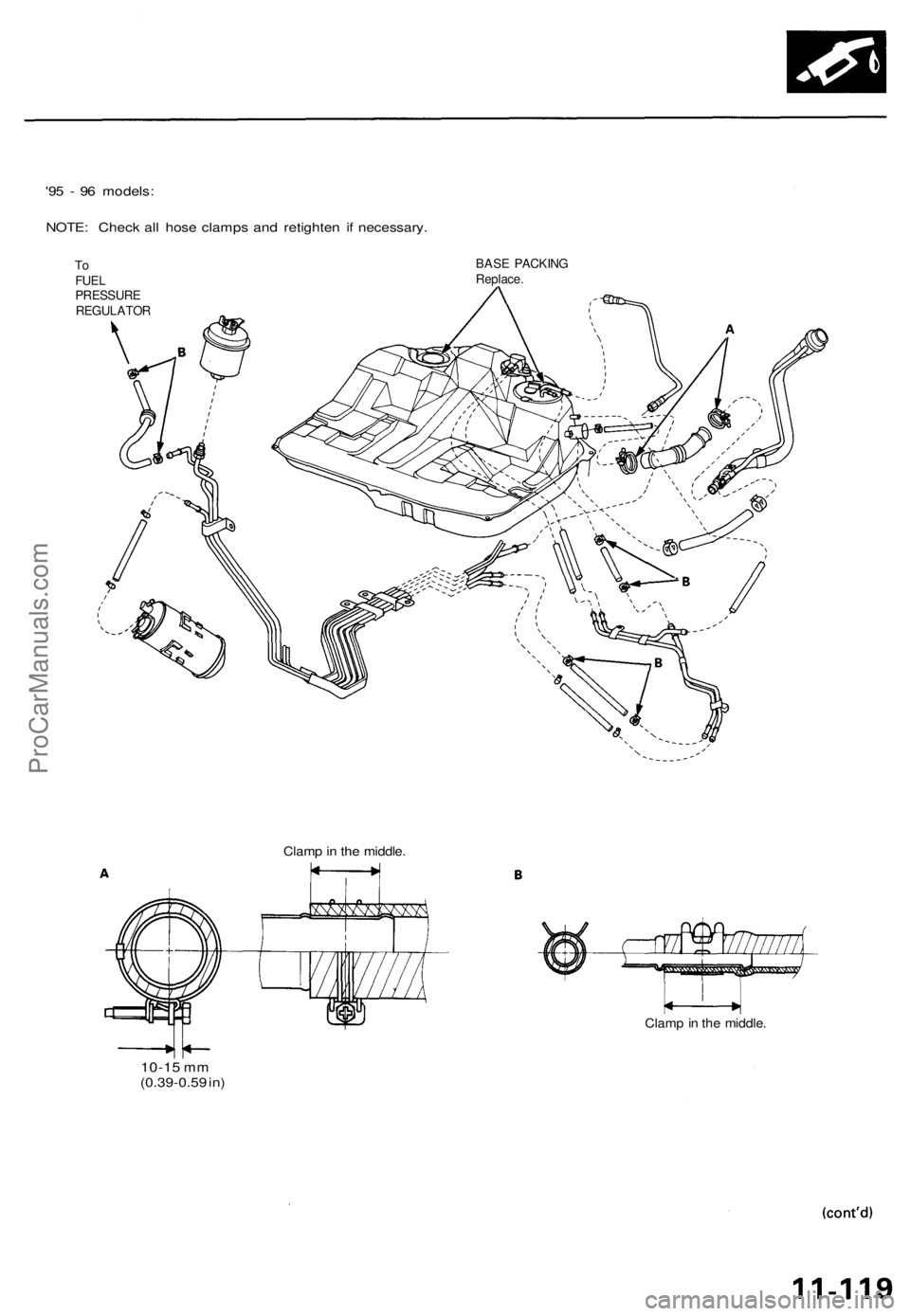

'95 - 96 models:

NOTE: Check all hose clamps and retighten if necessary.

To

FUEL

PRESSURE

REGULATOR

BASE PACKING

Replace.

10-15

mm

(0.39-0.59 in)

Clamp in the middle.

Clamp in the middle.ProCarManuals.com

Page 898 of 1771

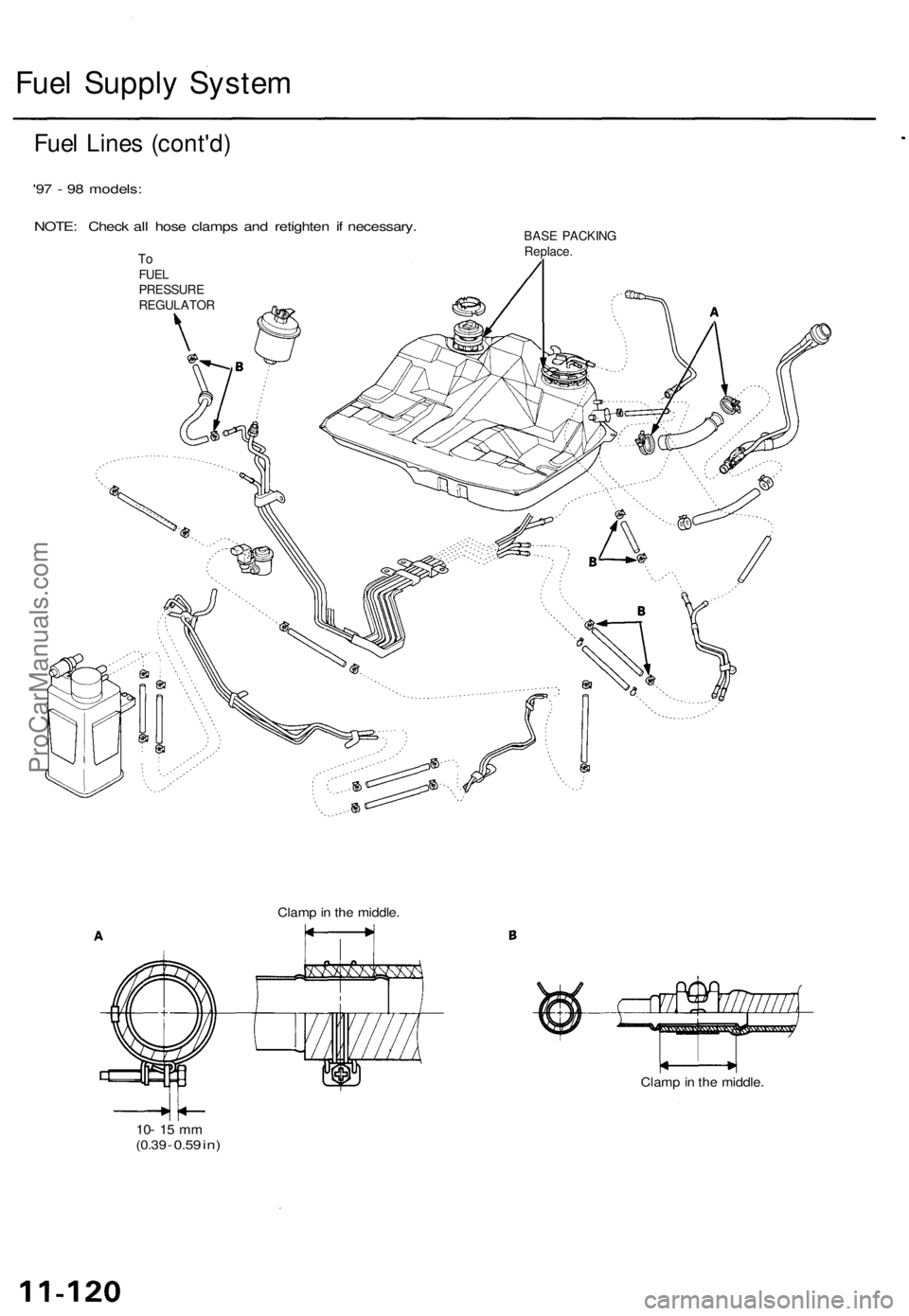

Fuel Supply System

Fuel Lines (cont'd)

'97 - 98 models:

NOTE: Check all hose clamps and retighten if necessary.

To

FUEL

PRESSURE

REGULATOR

BASE PACKING

Replace.

10- 15 mm

(0.39

-

0.59

in)

Clamp in the middle.

Clamp in the middle.ProCarManuals.com

Page 899 of 1771

Fuel Tube/Quick-Connec t Fitting s

Precaution s

Do no t smok e whil e workin g o n th e fue l

system . Kee p ope n flame s awa y fro m you r wor k area .

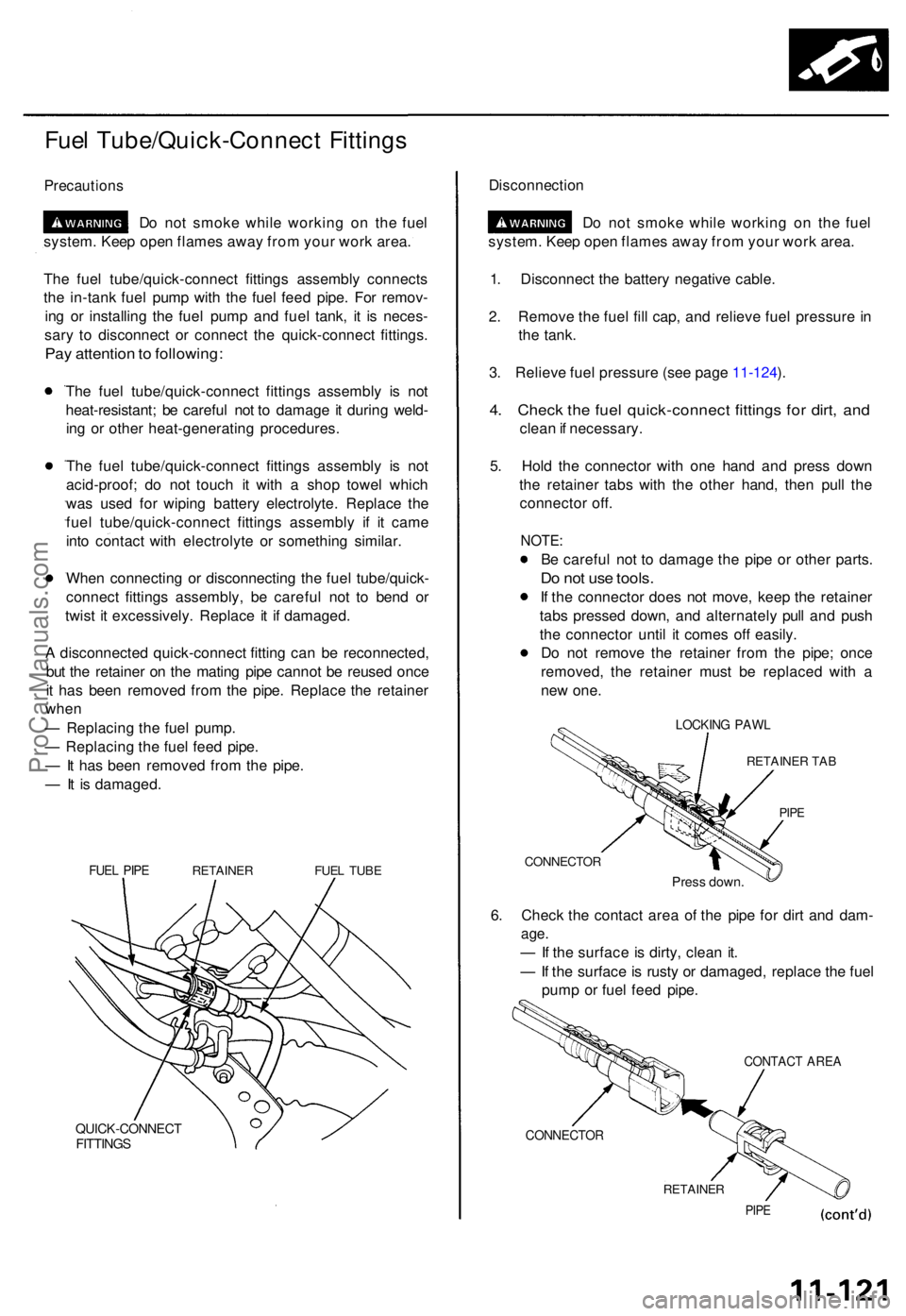

Th e fue l tube/quick-connec t fitting s assembl y connect s

th e in-tan k fue l pum p wit h th e fue l fee d pipe . Fo r remov -

in g o r installin g th e fue l pum p an d fue l tank , i t i s neces -

sar y t o disconnec t o r connec t th e quick-connec t fittings .

Pay attentio n to following :

The fue l tube/quick-connec t fitting s assembl y i s no t

heat-resistant ; b e carefu l no t t o damag e it durin g weld -

in g o r othe r heat-generatin g procedures .

Th e fue l tube/quick-connec t fitting s assembl y i s no t

acid-proof ; d o no t touc h i t wit h a sho p towe l whic h

wa s use d fo r wipin g batter y electrolyte . Replac e th e

fue l tube/quick-connec t fitting s assembl y i f i t cam e

int o contac t wit h electrolyt e o r somethin g similar .

Whe n connectin g o r disconnectin g th e fue l tube/quick -

connec t fitting s assembly , b e carefu l no t t o ben d o r

twis t i t excessively . Replac e i t i f damaged .

A disconnecte d quick-connec t fittin g ca n b e reconnected ,

bu t th e retaine r o n th e matin g pip e canno t b e reuse d onc e

i t ha s bee n remove d fro m th e pipe . Replac e th e retaine r

whe n

— Replacin g th e fue l pump .

— Replacin g th e fue l fee d pipe .

— It ha s bee n remove d fro m th e pipe .

— It i s damaged .

FUEL PIP ERETAINE RFUEL TUB E

QUICK-CONNEC TFITTINGS

Disconnectio n

Do no t smok e whil e workin g o n th e fue l

system . Kee p ope n flame s awa y fro m you r wor k area .

1 . Disconnec t th e batter y negativ e cable .

2 . Remov e th e fue l fil l cap , an d reliev e fue l pressur e in

th e tank .

3 . Reliev e fue l pressur e (se e pag e 11-124 ).

4 . Chec k th e fue l quick-connec t fitting s fo r dirt , an d

clea n if necessary .

5 . Hol d th e connecto r wit h on e han d an d pres s dow n

th e retaine r tab s wit h th e othe r hand , the n pul l th e

connecto r off .

NOTE :

Be carefu l no t t o damag e th e pip e o r othe r parts .

Do no t us e tools .

If th e connecto r doe s no t move , kee p th e retaine r

tab s presse d down , an d alternatel y pul l an d pus h

th e connecto r unti l i t come s of f easily .

D o no t remov e th e retaine r fro m th e pipe ; onc e

removed , th e retaine r mus t b e replace d wit h a

ne w one .

LOCKIN G PAW L

RETAINE R TA B

PIPE

CONNECTO R

Press down .

6. Chec k th e contac t are a o f th e pip e fo r dir t an d dam -

age.

— If th e surfac e is dirty , clea n it .

— If th e surface is rust y o r damaged , replac e th e fue l

pum p o r fue l fee d pipe .

CONTAC T ARE A

CONNECTO R

RETAINER

PIPE

ProCarManuals.com

Page 900 of 1771

Fuel Supply System

Fuel Tube/Quick-Connect Fittings (cont'd)

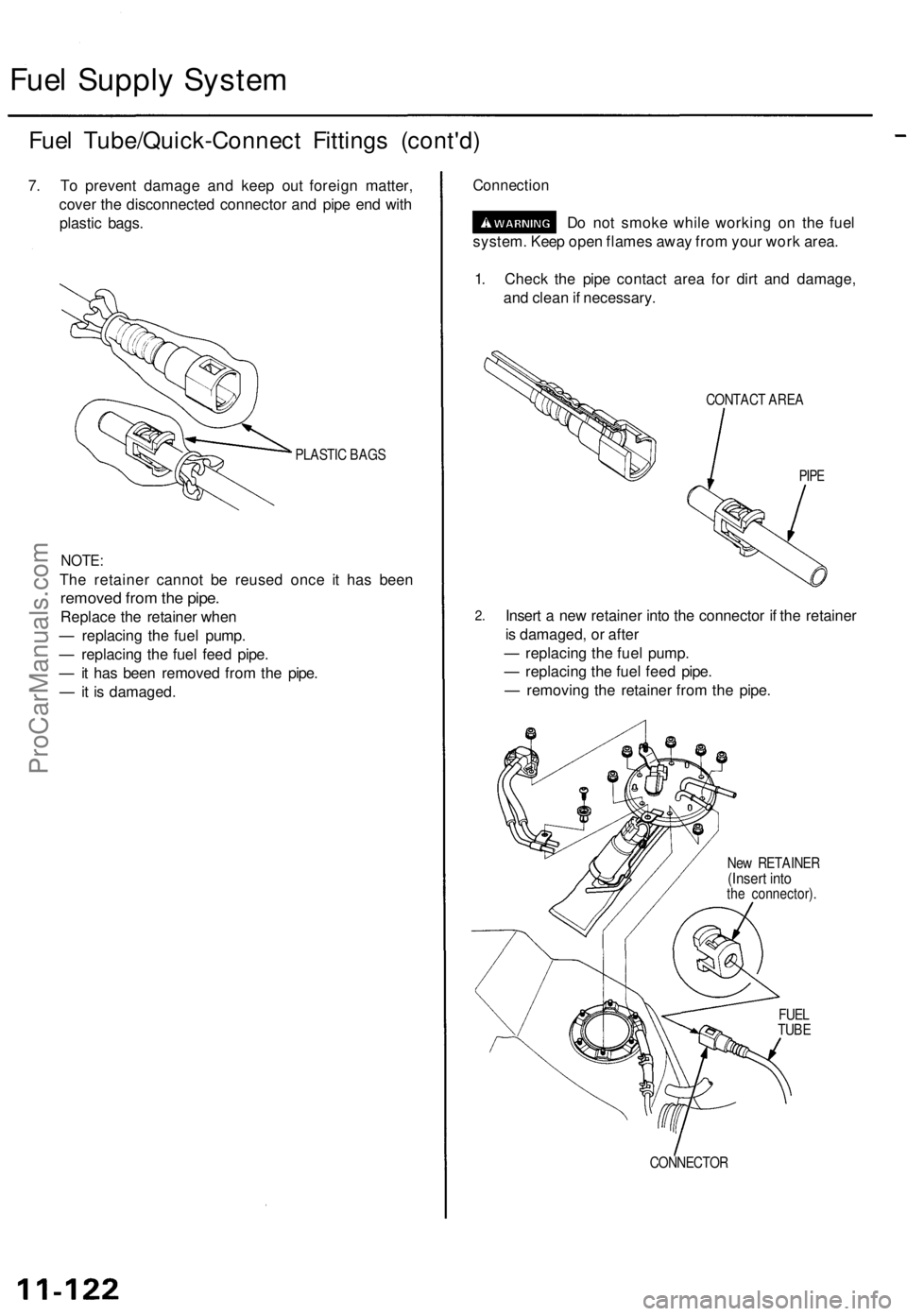

7. To prevent damage and keep out foreign matter,

cover the disconnected connector and pipe end with

plastic bags.

PLASTIC BAGS

NOTE:

The retainer cannot be reused once it has been

removed from the pipe.

Replace the retainer when

— replacing the fuel pump.

— replacing the fuel feed pipe.

— it has been removed from the pipe.

— it is damaged.

Connection

Do not smoke while working on the fuel

system. Keep open flames away from your work area.

1. Check the pipe contact area for dirt and damage,

and clean if necessary.

CONTACT AREA

PIPE

2.

Insert a new retainer into the connector if the retainer

is damaged, or after

— replacing the fuel pump.

— replacing the fuel feed pipe.

— removing the retainer from the pipe.

New RETAINER

(Insert into

the connector).

CONNECTOR

FUEL

TUBEProCarManuals.com