ACURA TL 1995 Service Repair Manual

Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 921 of 1771

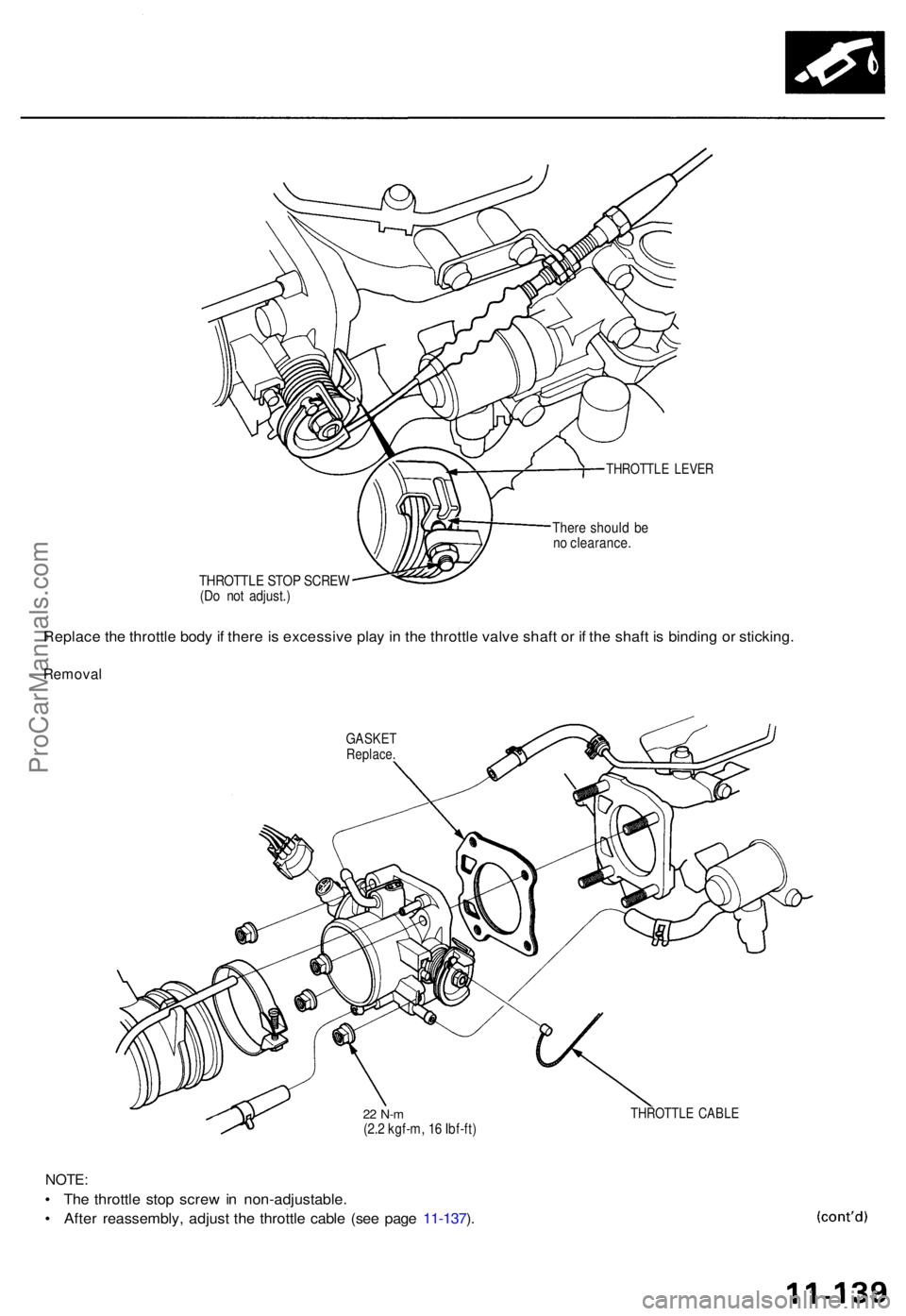

THROTTLE LEVE R

There shoul d b e

n o clearance .

THROTTL E STO P SCRE W

(D o no t adjust. )

Replace th e throttl e bod y if ther e is excessiv e pla y i n th e throttl e valv e shaf t o r i f th e shaf t i s bindin g o r sticking .

Remova l

GASKETReplace .

22 N- m(2.2 kgf-m , 1 6 Ibf-ft )

NOTE :

• Th e throttl e sto p scre w in non-adjustable .

• Afte r reassembly , adjus t th e throttl e cabl e (se e pag e 11-137 ).

THROTTL E CABL E

ProCarManuals.com

Page 922 of 1771

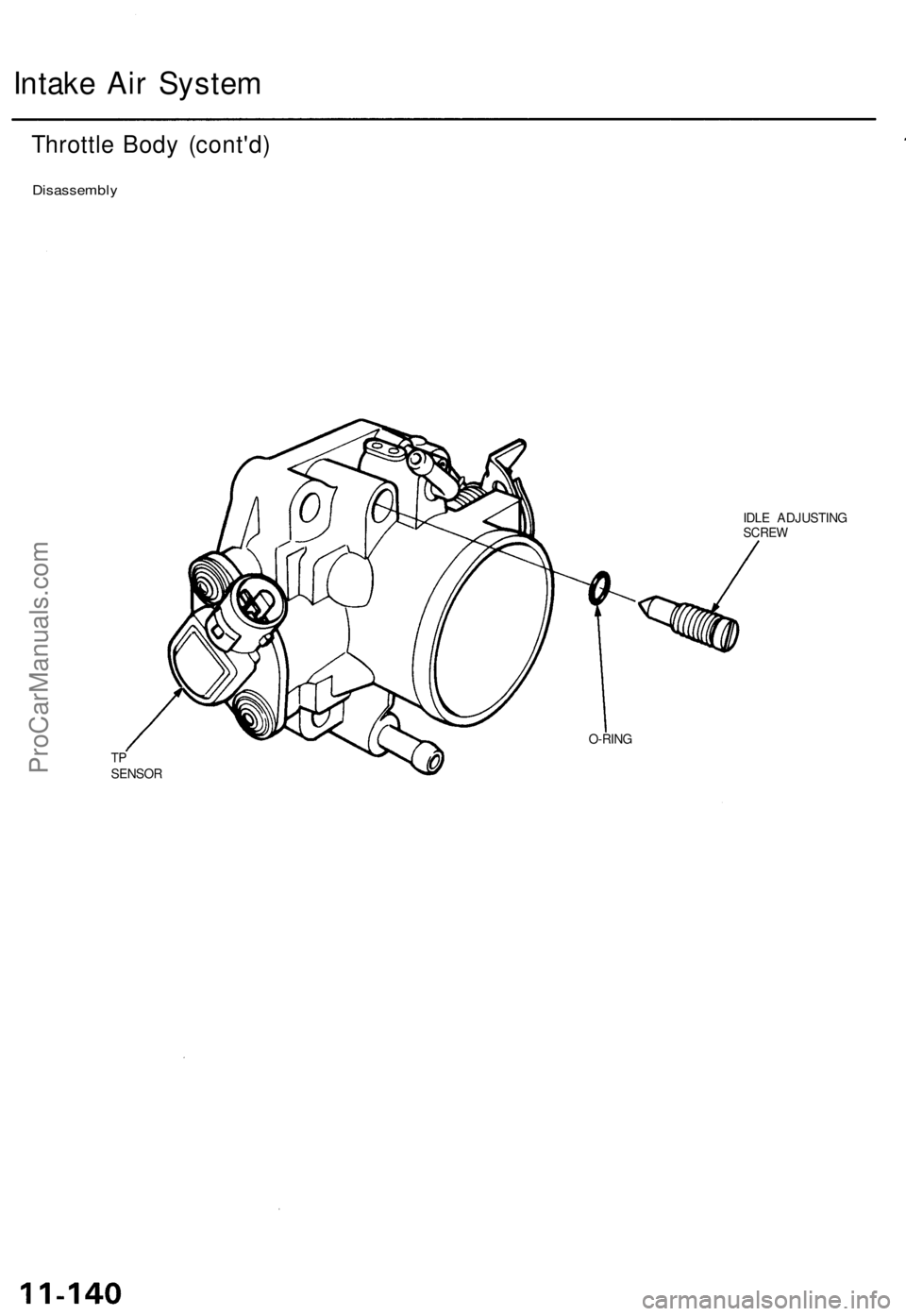

Intake Air System

Throttle Body (cont'd)

Disassembly

IDLE ADJUSTING

SCREW

O-RING

TP

SENSORProCarManuals.com

Page 923 of 1771

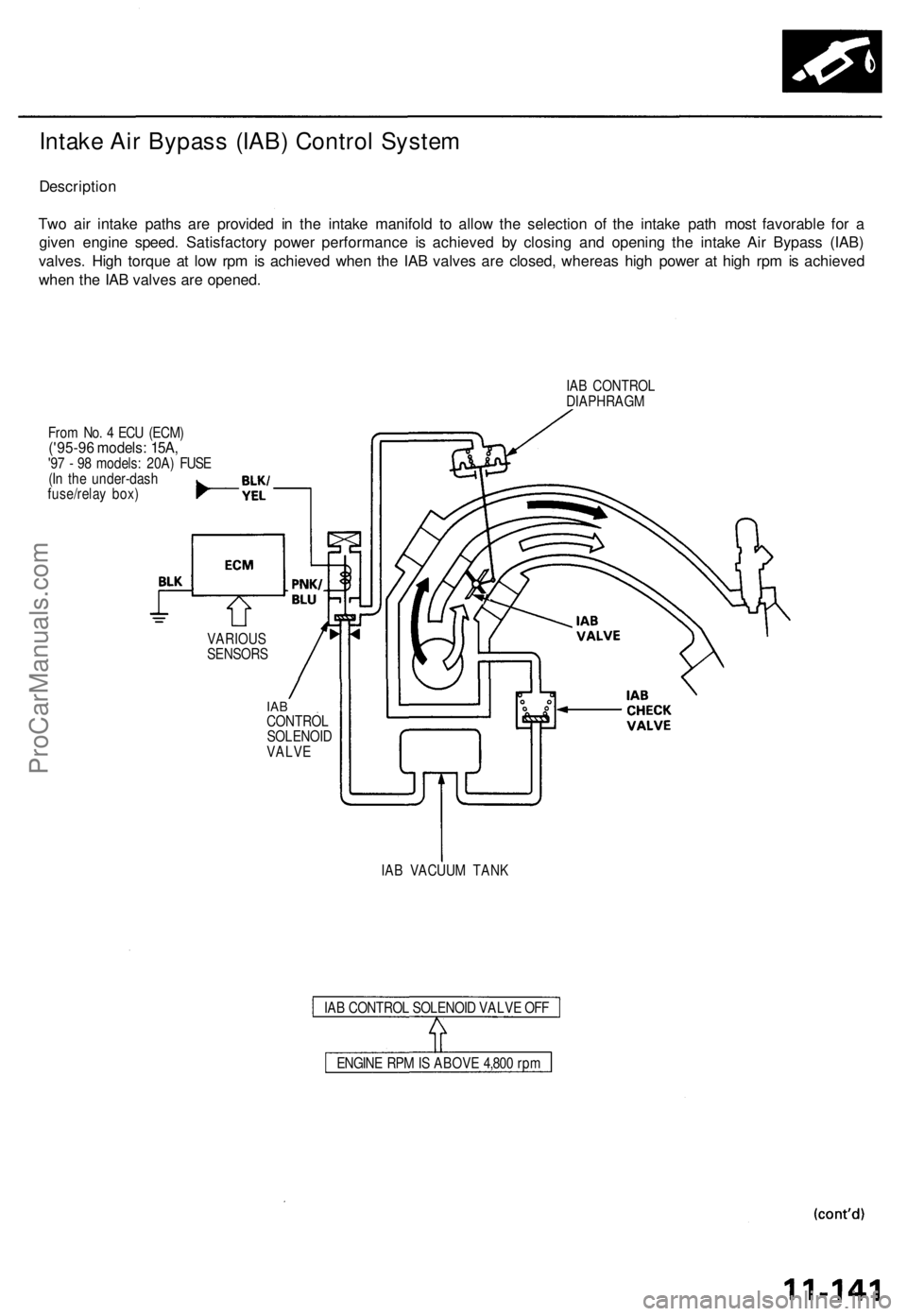

Intake Air Bypass (IAB) Control System

Description

Two air intake paths are provided in the intake manifold to allow the selection of the intake path most favorable for a

given engine speed. Satisfactory power performance is achieved by closing and opening the intake Air Bypass (IAB)

valves. High torque at low rpm is achieved when the IAB valves are closed, whereas high power at high rpm is achieved

when the IAB valves are opened.

IAB CONTROL

DIAPHRAGM

From No. 4 ECU (ECM)

('95-96 models: 15A,

'97 - 98 models: 20A) FUSE

(In the under-dash

fuse/relay box)

VARIOUS

SENSORS

IAB

CONTROL

SOLENOID

VALVE

IAB VACUUM TANK

IAB CONTROL SOLENOID VALVE OFF

ENGINE RPM IS ABOVE 4,800 rpmProCarManuals.com

Page 924 of 1771

Intake Ai r Syste m

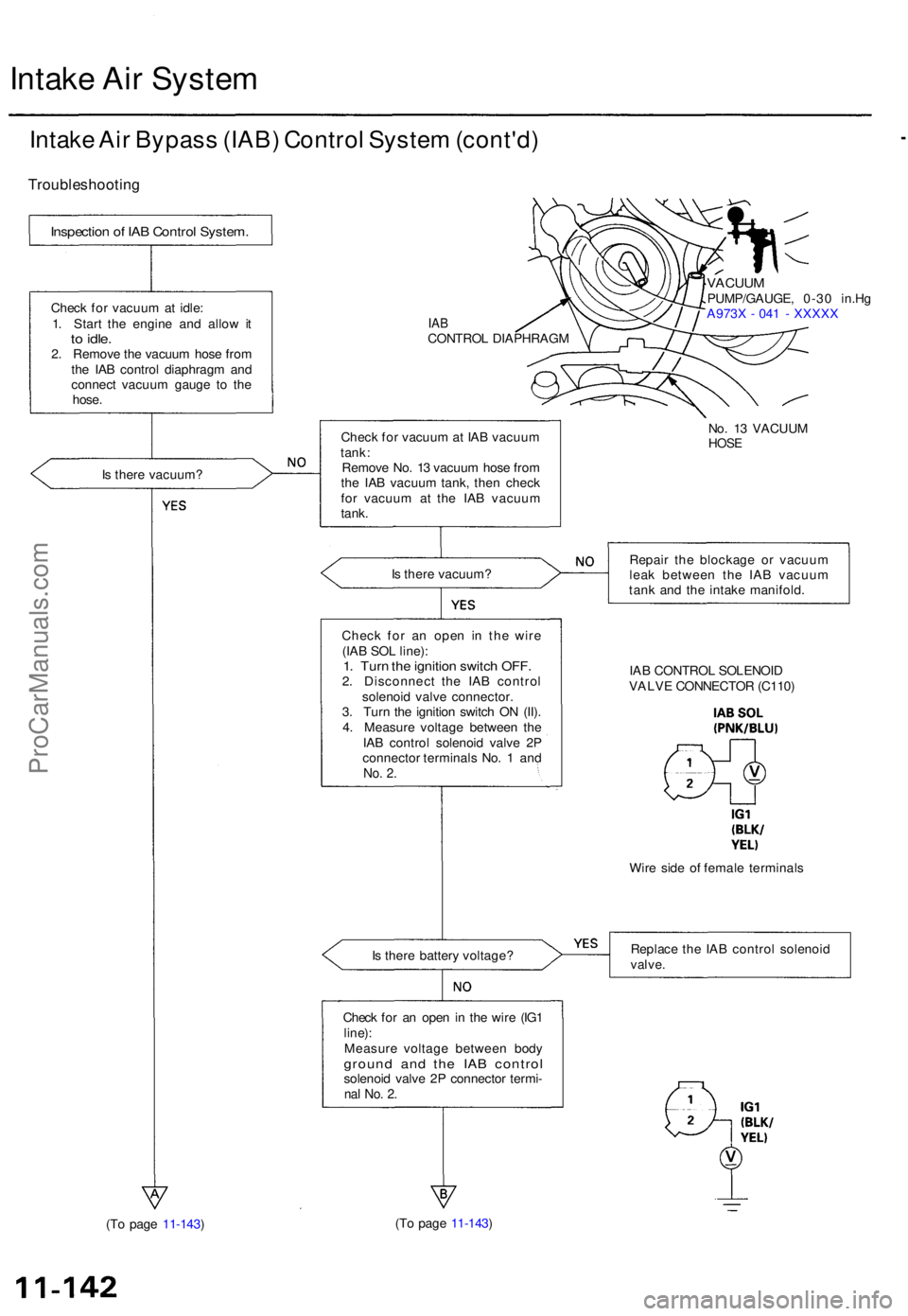

Intake Ai r Bypas s (IAB ) Contro l Syste m (cont'd )

Troubleshootin g

Is ther e vacuum ?

IABCONTRO L DIAPHRAG M

VACUUMPUMP/GAUGE , 0-3 0 in.H g

A973 X - 04 1 - XXXX X

Chec k fo r vacuu m at IA B vacuu m

tank :

Remov e No . 1 3 vacuu m hos e fro m

th e IA B vacuu m tank , the n chec k

fo r vacuu m a t th e IA B vacuu m

tank .

Is ther e vacuum ? Repai

r th e blockag e o r vacuu m

lea k betwee n th e IA B vacuu m

tan k an d th e intak e manifold .

Chec k fo r a n ope n i n th e wir e

(IA B SO L line) :

1. Tur n th e ignitio n switc h OFF .2. Disconnec t th e IA B contro l

solenoi d valv e connector .

3 . Tur n th e ignitio n switc h O N (II) .

4 . Measur e voltag e betwee n th e

IA B contro l solenoi d valv e 2 P

connecto r terminal s No . 1 an d

No. 2 .

IA B CONTRO L SOLENOI D

VALV E CONNECTO R (C110 )

Wir e sid e o f femal e terminal s

I s ther e batter y voltage ? Replac

e th e IA B contro l solenoi d

valve.

Check fo r a n ope n in th e wir e (IG 1line) :Measur e voltag e betwee n bod ygroun d an d th e IA B contro lsolenoid valv e 2 P connecto r termi -nal No . 2 .

(T o pag e 11-143 ) (T

o pag e 11-143 )

Inspectio n o f IA B Contro l System .

Check fo r vacuu m at idle :

1 . Star t th e engin e an d allo w i t

to idle .2. Remov e th e vacuu m hos e fro m

th e IA B contro l diaphrag m an d

connec t vacuu m gaug e t o th e

hose .

No. 1 3 VACUU M

HOSE

ProCarManuals.com

Page 925 of 1771

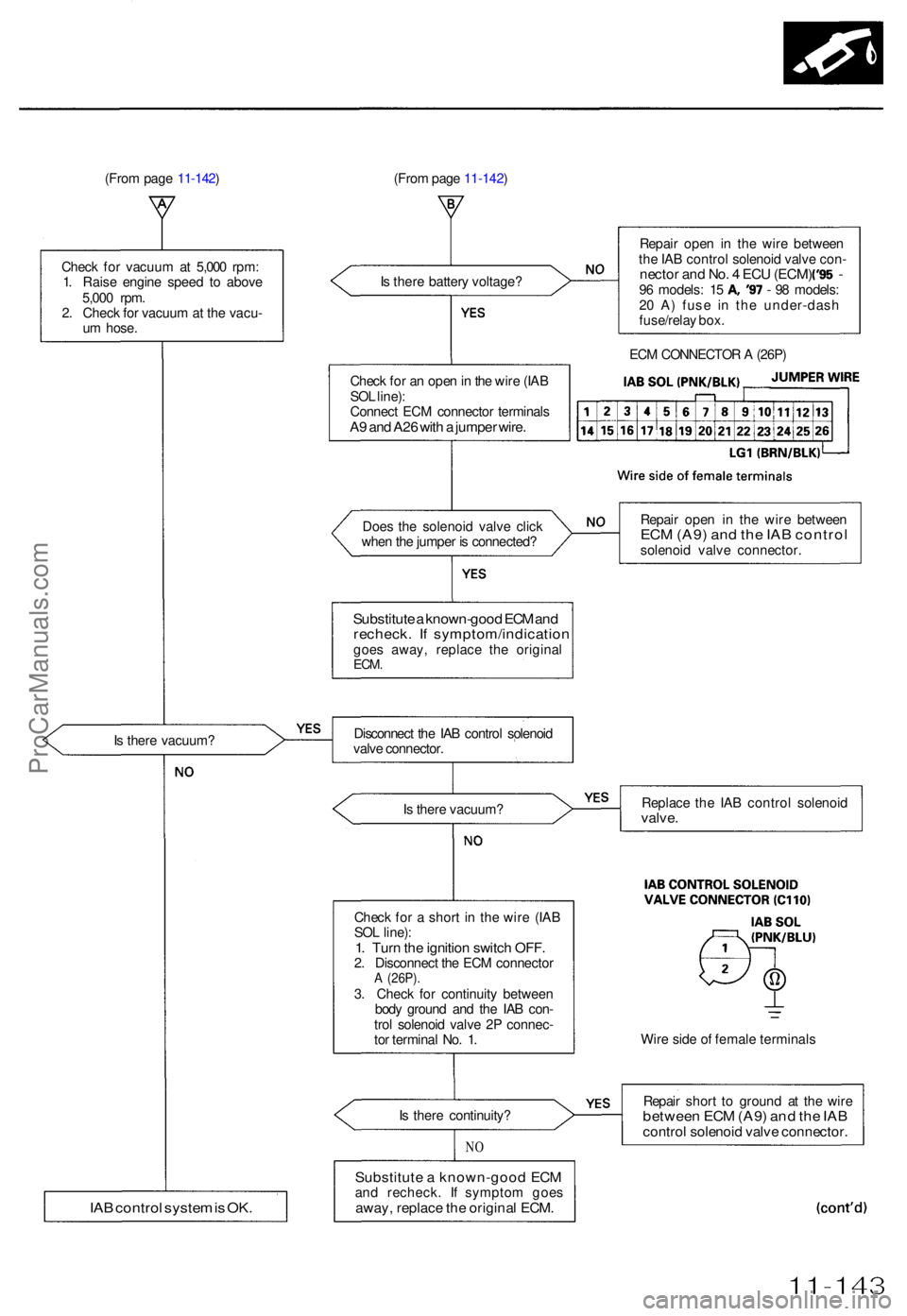

(From pag e 11-142 ) (From pag e 11-142 )

I s ther e batter y voltage ? Repai

r ope n i n th e wir e betwee n

th e IA B contro l solenoi d valv e con -

necto r an d No . 4 EC U (ECM ) ('95 -96 models : 1 5 A , '9 7 - 9 8 models :

2 0 A ) fus e i n th e under-das h

fuse/rela y box .

Chec k fo r a n ope n in th e wir e (IA B

SO L line) :

Connec t EC M connecto r terminal s

A9 an d A2 6 wit h a jumpe r wire .

Doe s th e solenoi d valv e clic k

whe n th e jumpe r i s connected ?

Substitute a known-goo d EC M an drecheck . I f symptom/indicatio ngoes away , replac e th e origina lECM.

Is ther e vacuum ?

Chec k fo r a shor t i n th e wir e (IA B

SO L line) :

1. Tur n th e ignitio n switc h OFF .2. Disconnec t th e EC M connecto rA (26P) .3. Chec k fo r continuit y betwee n

bod y groun d an d th e IA B con -

tro l solenoi d valv e 2 P connec -

to r termina l No . 1 .

I s ther e continuity ?

NO

Substitut e a known-goo d EC Mand recheck . I f sympto m goe saway, replac e th e origina l ECM .

Repai r ope n i n th e wir e betwee nECM (A9 ) an d th e IA B contro lsolenoid valv e connector .

Replac e th e IA B contro l solenoi d

valve.

Wire sid e o f femal e terminal s

Repai r shor t t o groun d a t th e wir e

betwee n EC M (A9 ) an d th e IA Bcontro l solenoi d valv e connector .

11-143

Check fo r vacuu m a t 5,00 0 rpm :

1 . Rais e engin e spee d t o abov e

5,00 0 rpm .

2 . Chec k fo r vacuu m a t th e vacu -

u m hose .

I s ther e vacuum ? Disconnec

t th e IA B contro l solenoi d

valv e connector .

IAB contro l syste m is OK .

ECM CONNECTO R A (26P )

ProCarManuals.com

Page 926 of 1771

Intake Ai r Syste m Emissio

n Contro l Syste m

Intake Ai r Bypas s (IAB ) Contro l

Syste m (cont'd )

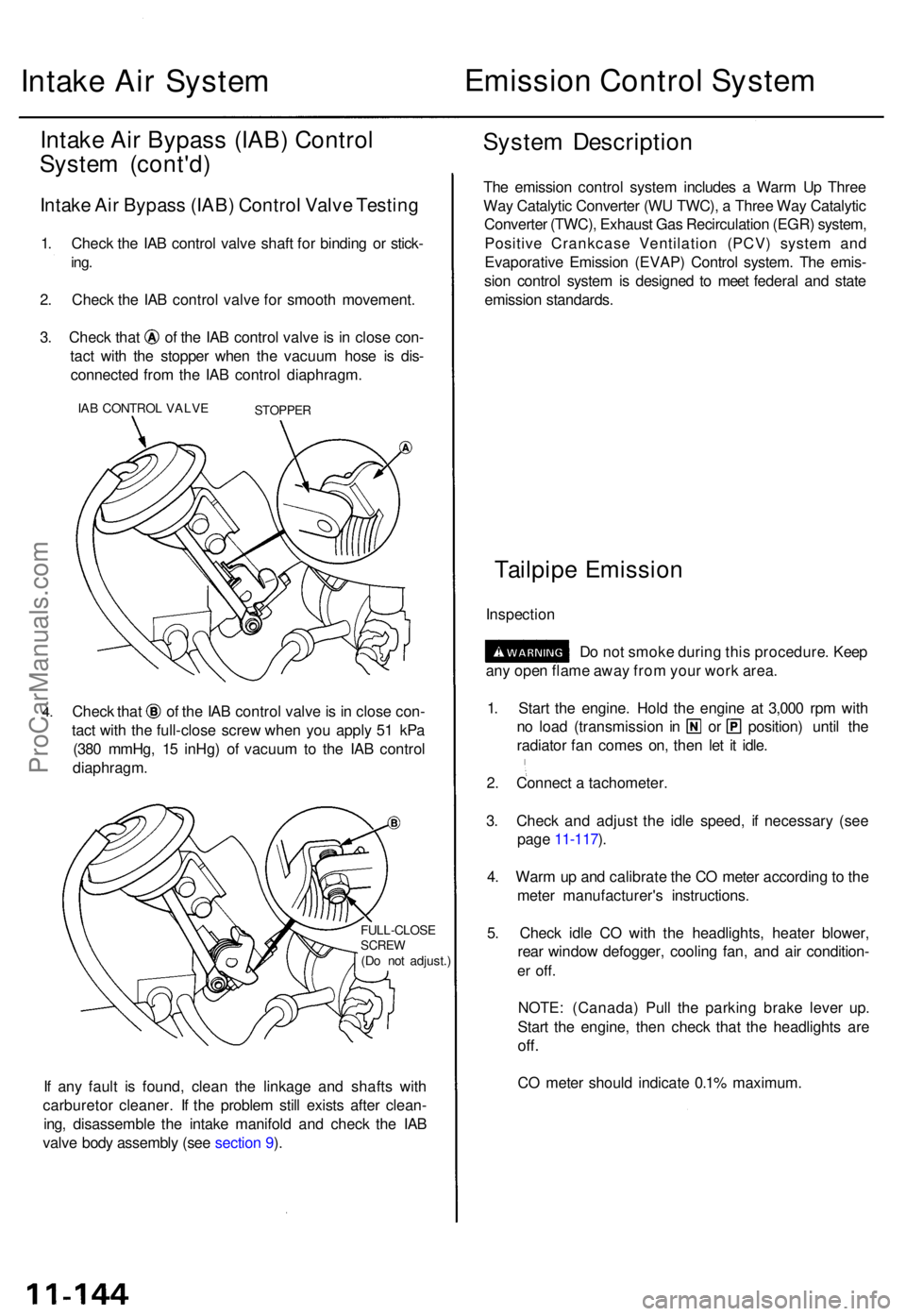

Intake Ai r Bypas s (IAB ) Contro l Valv e Testin g

1. Chec k th e IA B contro l valv e shaf t fo r bindin g o r stick -

ing.

2. Chec k th e IA B contro l valv e fo r smoot h movement .

3. Chec k tha t o f th e IA B contro l valv e is i n clos e con -

tac t wit h th e stoppe r whe n th e vacuu m hos e i s dis -

connecte d fro m th e IA B contro l diaphragm .

IAB CONTRO L VALV ESTOPPE R

4.Chec k tha t o f th e IA B contro l valv e is in clos e con -

tac t wit h th e full-clos e scre w whe n yo u appl y 5 1 kP a

(38 0 mmHg , 1 5 inHg ) o f vacuu m to th e IA B contro l

diaphragm .

FULL-CLOS ESCREW(Do no t adjust. )

If an y faul t i s found , clea n th e linkag e an d shaft s wit h

carbureto r cleaner . I f th e proble m stil l exist s afte r clean -

ing , disassembl e th e intak e manifol d an d chec k th e IA B

valv e bod y assembl y (se e sectio n 9 ).

Syste m Descriptio n

The emissio n contro l syste m include s a War m U p Thre e

Wa y Catalyti c Converte r (W U TWC) , a Thre e Wa y Catalyti c

Converte r (TWC) , Exhaus t Ga s Recirculatio n (EGR ) system ,

Positiv e Crankcas e Ventilatio n (PCV ) syste m an d

Evaporativ e Emissio n (EVAP ) Contro l system . Th e emis -

sio n contro l syste m is designe d t o mee t federa l an d stat e

emissio n standards .

Tailpipe Emissio n

Inspectio n

Do no t smok e durin g thi s procedure . Kee p

an y ope n flam e awa y fro m you r wor k area .

1 . Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h

no loa d (transmissio n i n o r position ) unti l th e

radiato r fa n come s on , the n le t i t idle .

2 . Connec t a tachometer .

3 . Chec k an d adjus t th e idl e speed , i f necessar y (se e

pag e 11-117 ).

4 . War m u p an d calibrat e th e C O mete r accordin g to th e

mete r manufacturer' s instructions .

5 . Chec k idl e C O wit h th e headlights , heate r blower ,

rea r windo w defogger , coolin g fan , an d ai r condition -

er off .

NOTE : (Canada ) Pul l th e parkin g brak e leve r up .

Star t th e engine , the n chec k tha t th e headlight s ar e

off.

CO mete r shoul d indicat e 0.1 % maximum .

ProCarManuals.com

Page 927 of 1771

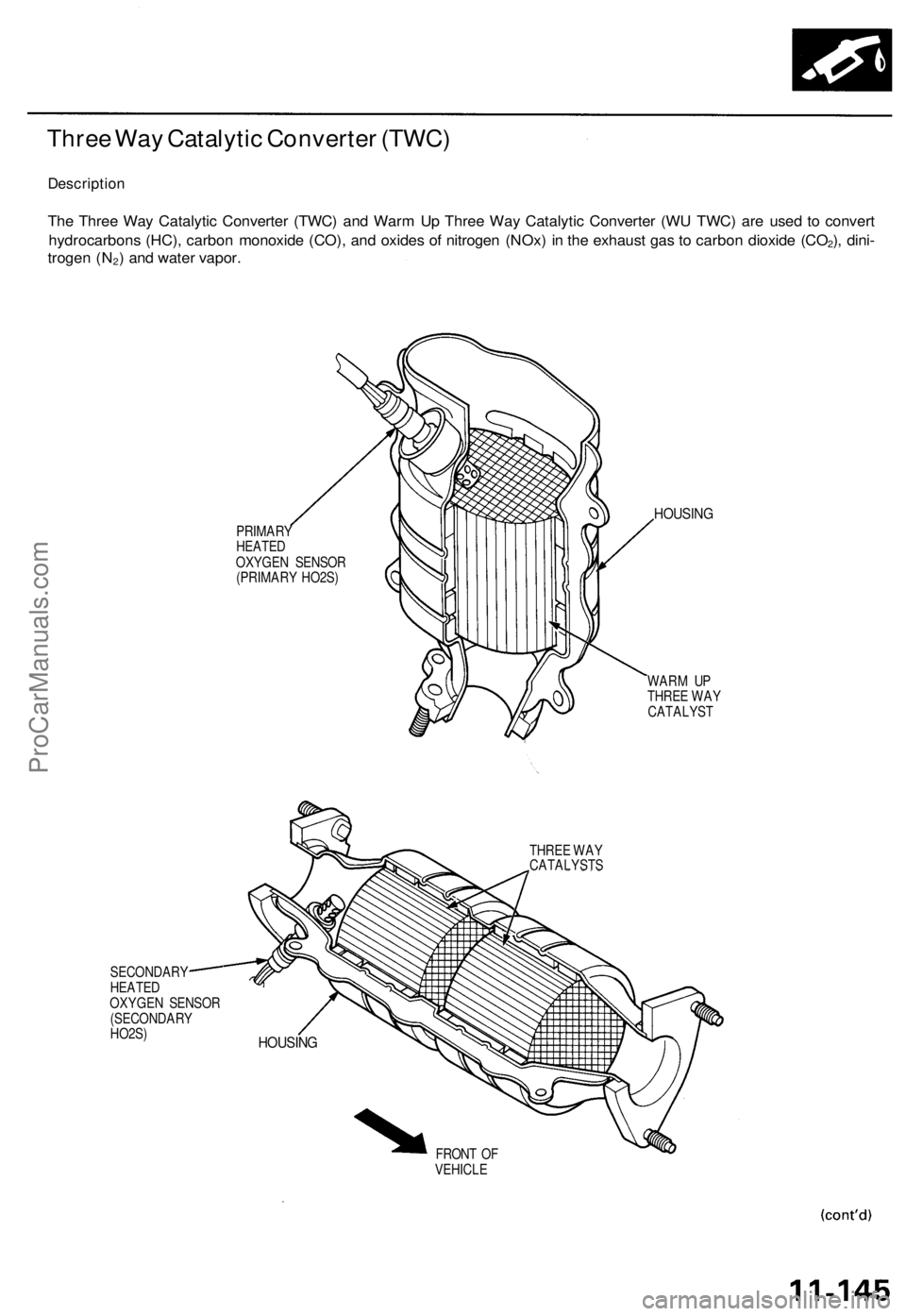

Three Way Catalytic Converter (TWC)

Description

The Three Way Catalytic Converter (TWC) and Warm Up Three Way Catalytic Converter (WU TWC) are used to convert

hydrocarbons (HC), carbon monoxide (CO), and oxides of nitrogen (NOx) in the exhaust gas to carbon dioxide (CO2), dini-

trogen (N2) and water vapor.

PRIMARY

HEATED

OXYGEN SENSOR

(PRIMARY HO2S)

HOUSING

WARM UP

THREE WAY

CATALYST

THREE WAY

CATALYSTS

SECONDARY

HEATED

OXYGEN SENSOR

(SECONDARY

HO2S)

FRONT OF

VEHICLE

HOUSINGProCarManuals.com

Page 928 of 1771

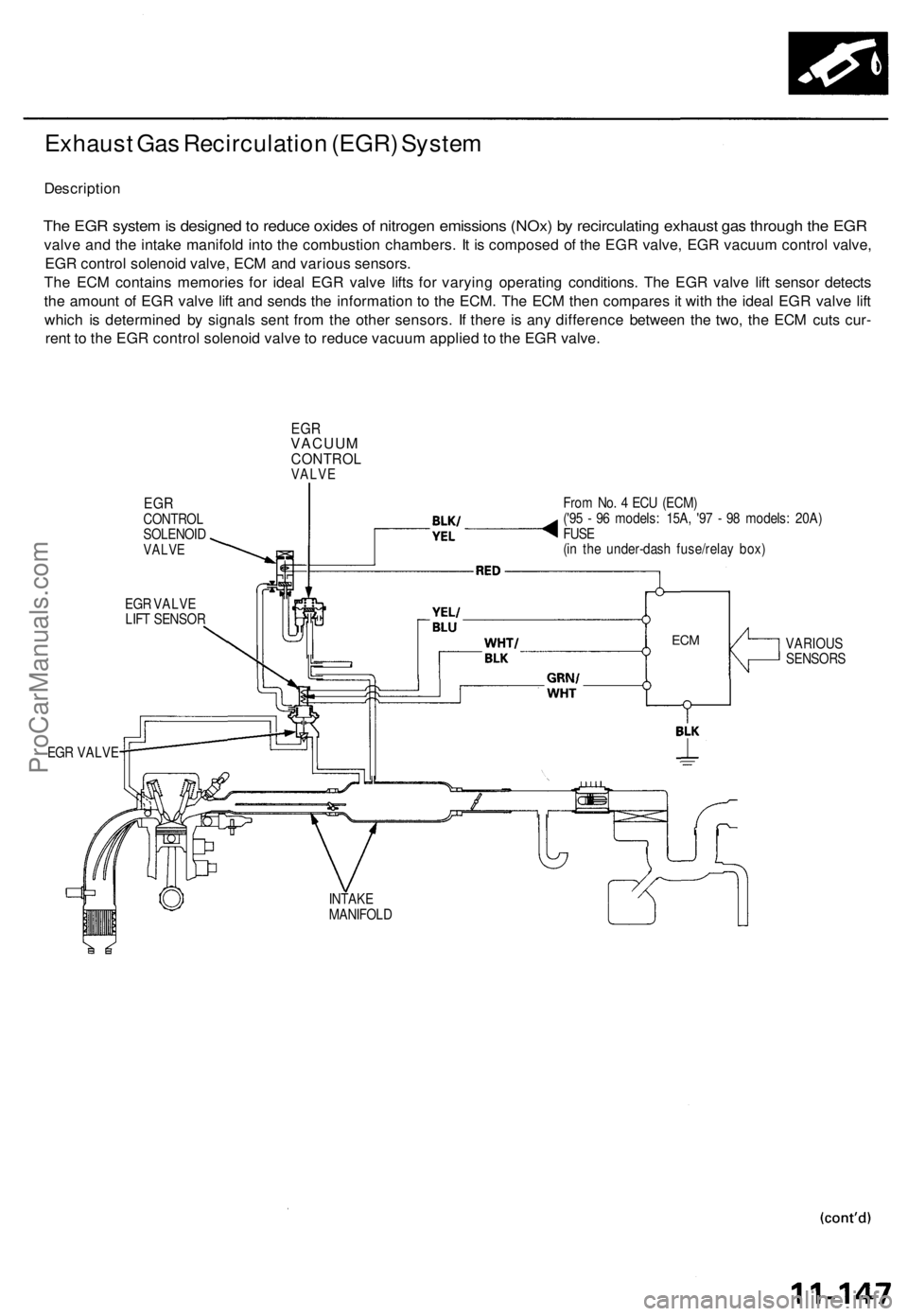

Exhaust Ga s Recirculatio n (EGR ) Syste m

Descriptio n

The EG R syste m is designe d to reduc e oxide s o f nitroge n emission s (NOx ) b y recirculatin g exhaus t ga s throug h th e EG R

valv e an d th e intak e manifol d int o th e combustio n chambers . I t i s compose d o f th e EG R valve , EG R vacuu m contro l valve ,

EG R contro l solenoi d valve , EC M an d variou s sensors .

Th e EC M contain s memorie s fo r idea l EG R valv e lift s fo r varyin g operatin g conditions . Th e EG R valv e lif t senso r detect s

th e amoun t o f EG R valv e lif t an d send s th e informatio n t o th e ECM . Th e EC M the n compare s it wit h th e idea l EG R valv e lif t

whic h i s determine d b y signal s sen t fro m th e othe r sensors . I f ther e i s an y differenc e betwee n th e two , th e EC M cut s cur -

ren t t o th e EG R contro l solenoi d valv e to reduc e vacuu m applie d to th e EG R valve .

EGRVACUU MCONTRO LVALVE

EGRCONTRO L

SOLENOI D

VALVE

EGR VALV E

LIF T SENSO R Fro

m No . 4 EC U (ECM )

('9 5 - 9 6 models : 15A , '9 7 - 9 8 models : 20A )

FUS E

(i n th e under-das h fuse/rela y box )

VARIOU S

SENSOR S

EG R VALV E

INTAKE

MANIFOL D

ECM

ProCarManuals.com

Page 929 of 1771

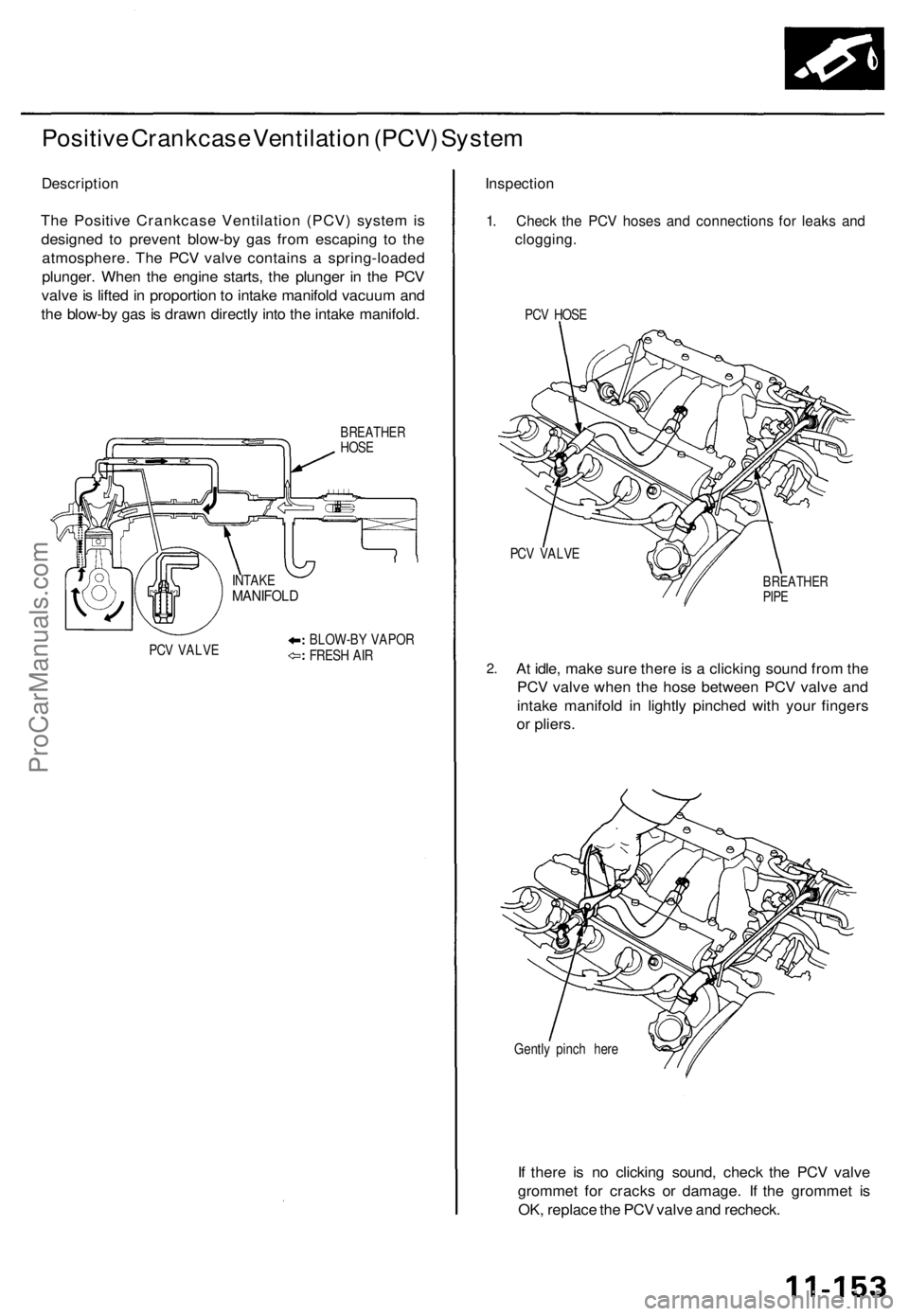

Positive Crankcase Ventilation (PCV) System

Description

The Positive Crankcase Ventilation (PCV) system is

designed to prevent blow-by gas from escaping to the

atmosphere. The PCV valve contains a spring-loaded

plunger. When the engine starts, the plunger in the PCV

valve is lifted in proportion to intake manifold vacuum and

the blow-by gas is drawn directly into the intake manifold.

BREATHER

HOSE

PCV VALVE

BLOW-BY VAPOR

FRESH AIR

Inspection

1. Check the PCV hoses and connections for leaks and

clogging.

PCV HOSE

PCV VALVE

2.

BREATHER

PIPE

At idle, make sure there is a clicking sound from the

PCV valve when the hose between PCV valve and

intake manifold in lightly pinched with your fingers

or pliers.

Gently pinch here

If there is no clicking sound, check the PCV valve

grommet for cracks or damage. If the grommet is

OK, replace the PCV valve and recheck.

INTAKE

MANIFOLDProCarManuals.com

Page 930 of 1771

Emission Control System

Evaporative Emission (EVAP) Controls

Description

The evaporative emission controls are designed to minimize the amount of fuel vapor escaping to the atmosphere. The

system consists of the following components:

A. Evaporative Emission (EVAP) Control Canister

An EVAP control canister is used for the temporary storage of fuel vapor until the fuel vapor can be purged from the

EVAP control canister into the engine and burned.

B. Vapor Purge Control System

EVAP control canister purging is accomplished by drawing fresh air through the EVAP control canister and into a port

on the throttle body. The purging vacuum is controlled by the EVAP purge control solenoid valve.

'95 - 96 models:

EVAP PURGE CONTROL SOLENOID VALVE OFF AFTER

STARTING ENGINE

'97 - 98 models:

EVAP PURGE CONTROL SOLENOID VALVE DUTY CON-

TROLLED AFTER STARTING ENGINE

C. Fuel Tank Vapor Control System

When fuel vapor pressure in the fuel tank is higher than the set value of the EVAP two way valve, the valve opens and

regulates the flow of fuel vapor to the EVAP control canister.

ENGINE COOLANT TEMPERATURE ABOVE 167°F (75°C)

ENGINE COOLANT TEMPERATURE ABOVE 158°F (70°C)ProCarManuals.com