AUDI A6 2000 C5 / 2.G Changing Clutch 5Speed Manual Gearbox

Manufacturer: AUDI, Model Year: 2000, Model line: A6, Model: AUDI A6 2000 C5 / 2.GPages: 71, PDF Size: 1.82 MB

Page 21 of 71

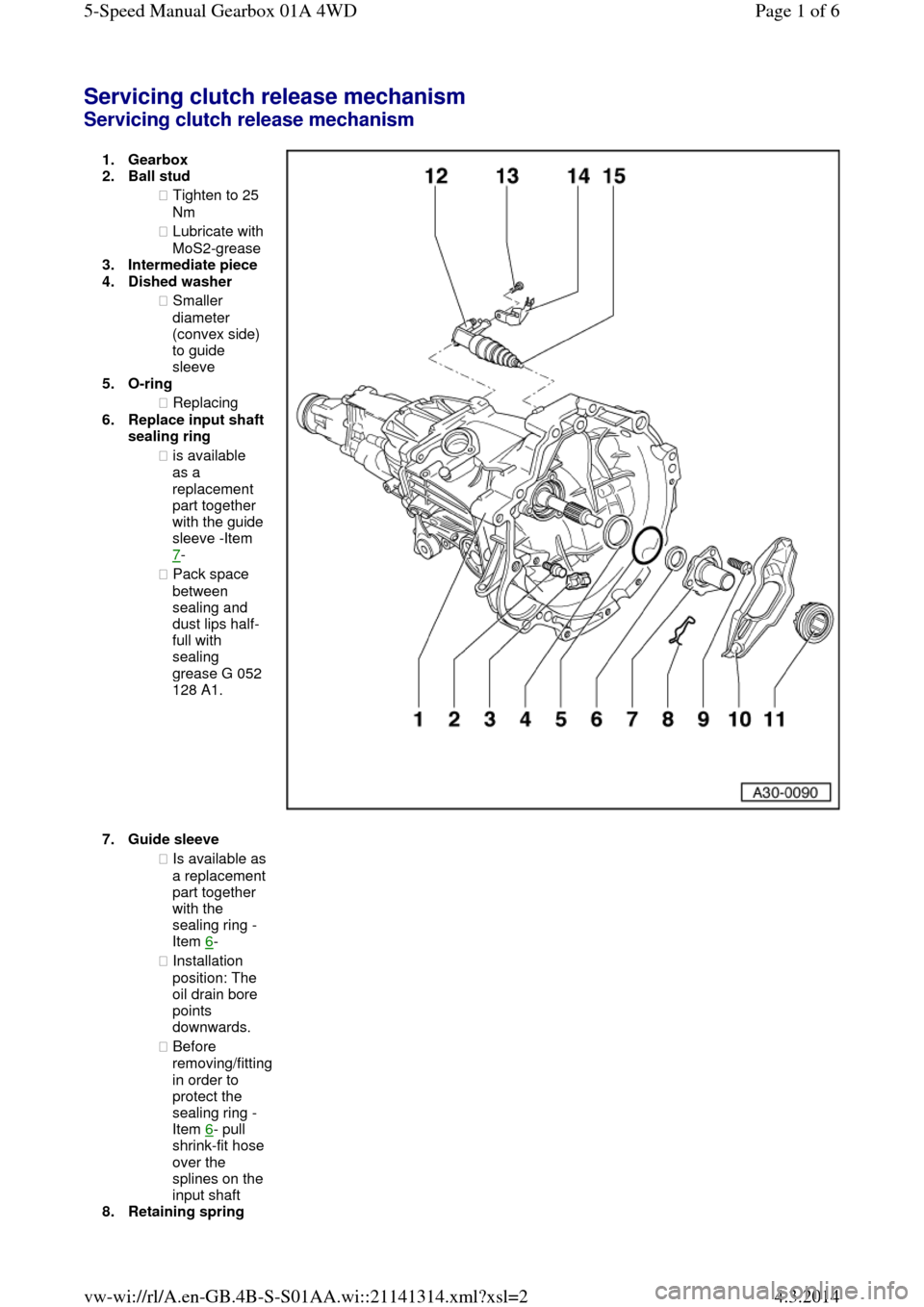

Servicing clutch release mechanism Servicing clutch release mechanism 1.Gearbox 2.Ball stud

◆ Tighten to 25

Nm

◆ Lubricate with MoS2-grease 3.Intermediate piece 4.Dished washer

◆ Smaller

diameter

(convex side)

to guide

sleeve

5.O-ring

◆ Replacing

6.Replace input shaft sealing ring

◆ is available

as a

replacement

part together with the guide sleeve -Item

7-

◆ Pack space

between

sealing and

dust lips half-

full with

sealing grease G 052 128 A1.

7.Guide sleeve ◆ Is available as

a replacement

part together

with the

sealing ring -

Item 6-

◆ Installation

position: The

oil drain bore

points

downwards.

◆ Before removing/fitting in order to

protect the

sealing ring -

Item 6- pull

shrink-fit hose

over the

splines on the

input shaft

8.Retaining spring Page 1 of 65-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141314.xml?xsl=2

Page 22 of 71

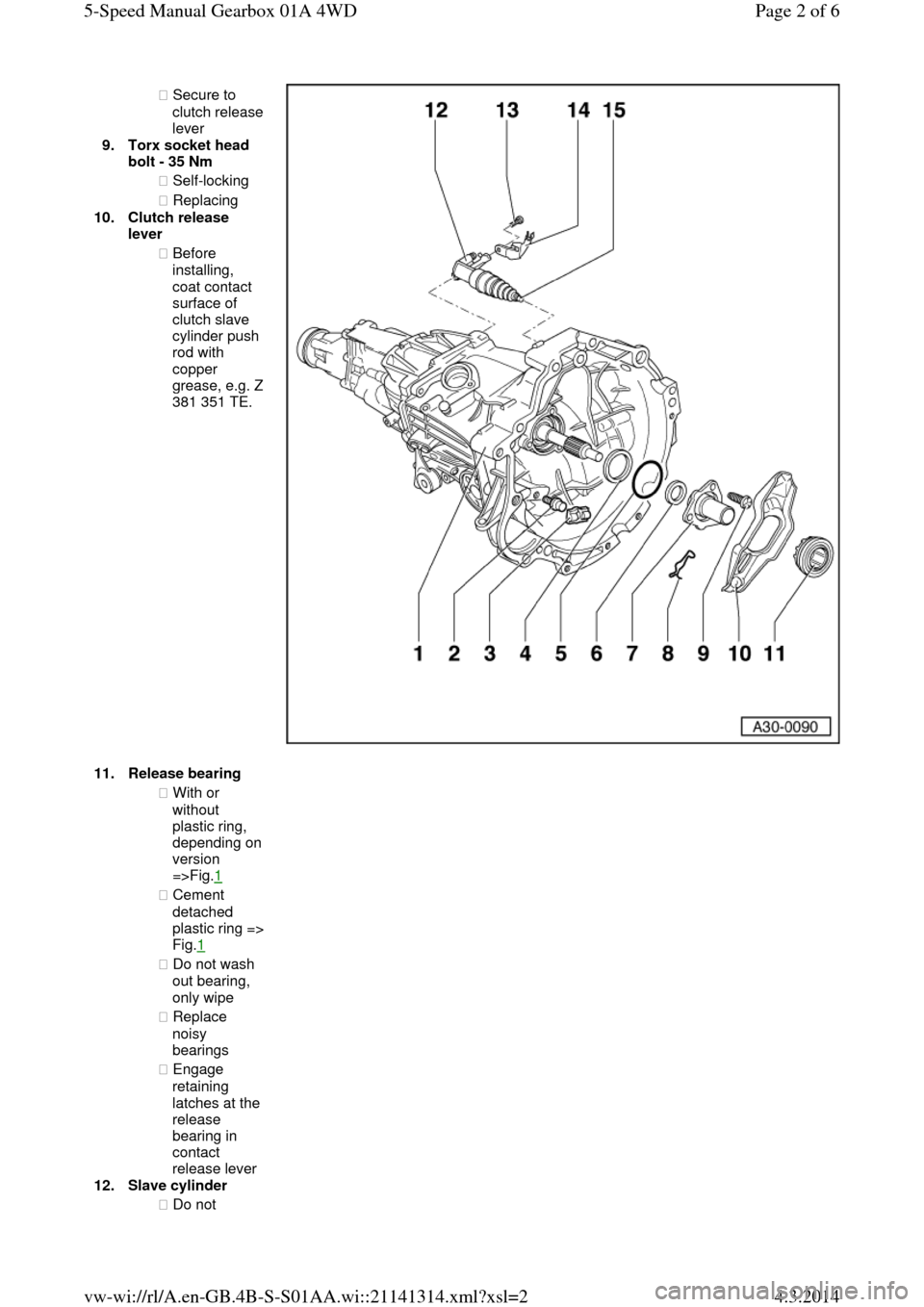

◆ Secure to clutch release lever

9.Torx socket head

bolt - 35 Nm

◆ Self-locking

◆ Replacing

10.Clutch release

lever

◆ Before

installing,

coat contact

surface of

clutch slave

cylinder push

rod with

copper grease, e.g. Z 381 351 TE. 11.Release bearing ◆ With or

without

plastic ring, depending on version

=>Fig.1

◆ Cement

detached plastic ring => Fig.1

◆ Do not wash

out bearing,

only wipe

◆ Replace

noisy

bearings

◆ Engage

retaining

latches at the

release

bearing in

contact

release lever 12.Slave cylinder

◆ Do not Page 2 of 65-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141314.xml?xsl=2

Page 23 of 71

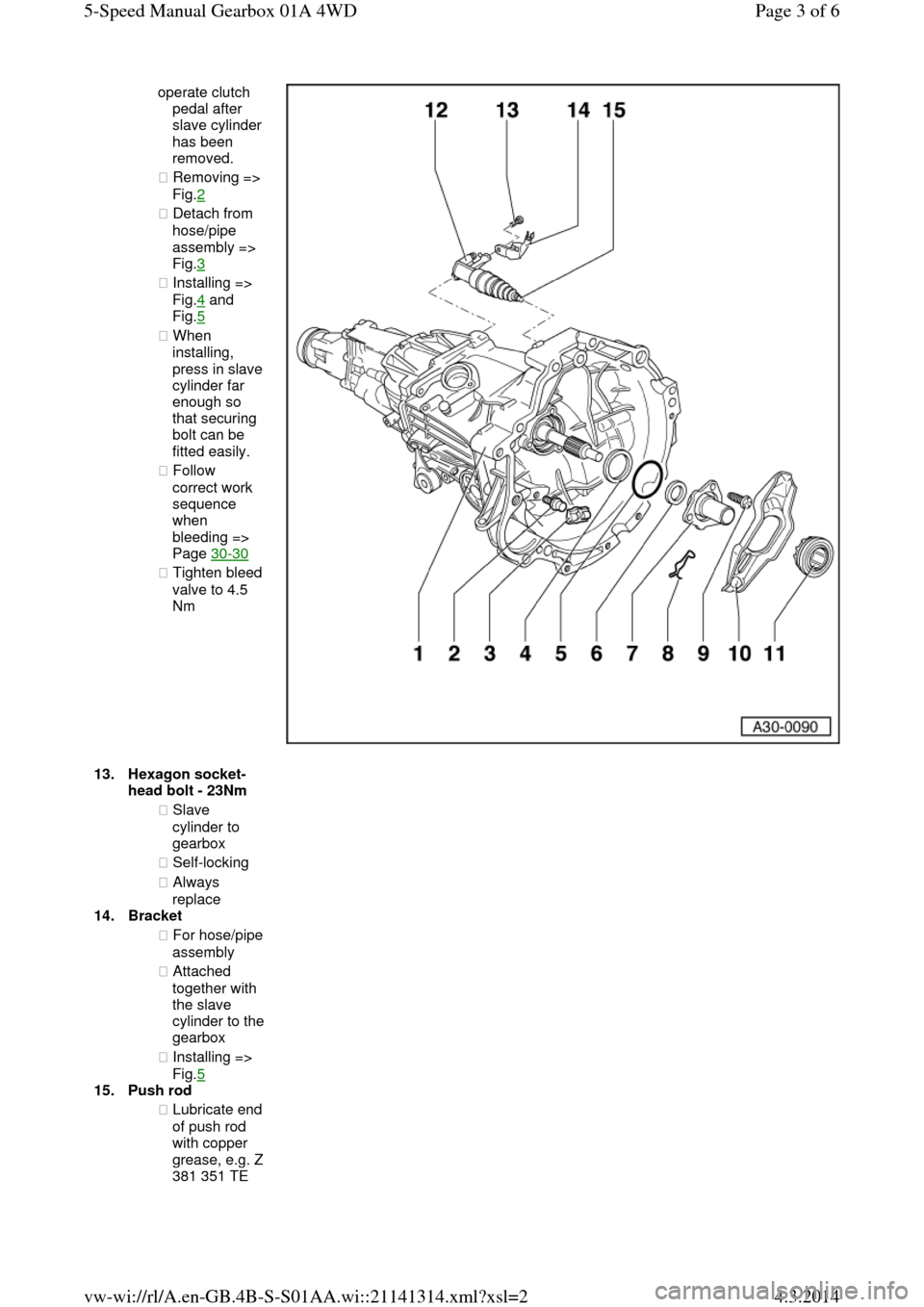

operate clutch

pedal after slave cylinder has been

removed.

◆ Removing => Fig.2

◆ Detach from

hose/pipe

assembly =>

Fig.3

◆ Installing =>

Fig.4 and

Fig.5

◆ When

installing, press in slave cylinder far

enough so

that securing

bolt can be

fitted easily.

◆ Follow

correct work

sequence

when

bleeding =>

Page 30-30

◆ Tighten bleed valve to 4.5

Nm 13.Hexagon socket-head bolt - 23Nm

◆ Slave

cylinder to

gearbox

◆ Self-locking

◆ Always

replace

14.Bracket

◆ For hose/pipe assembly

◆ Attached

together with

the slave cylinder to the gearbox

◆ Installing =>

Fig.5

15.Push rod

◆ Lubricate end of push rod

with copper grease, e.g. Z 381 351 TE Page 3 of 65-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141314.xml?xsl=2

Page 24 of 71

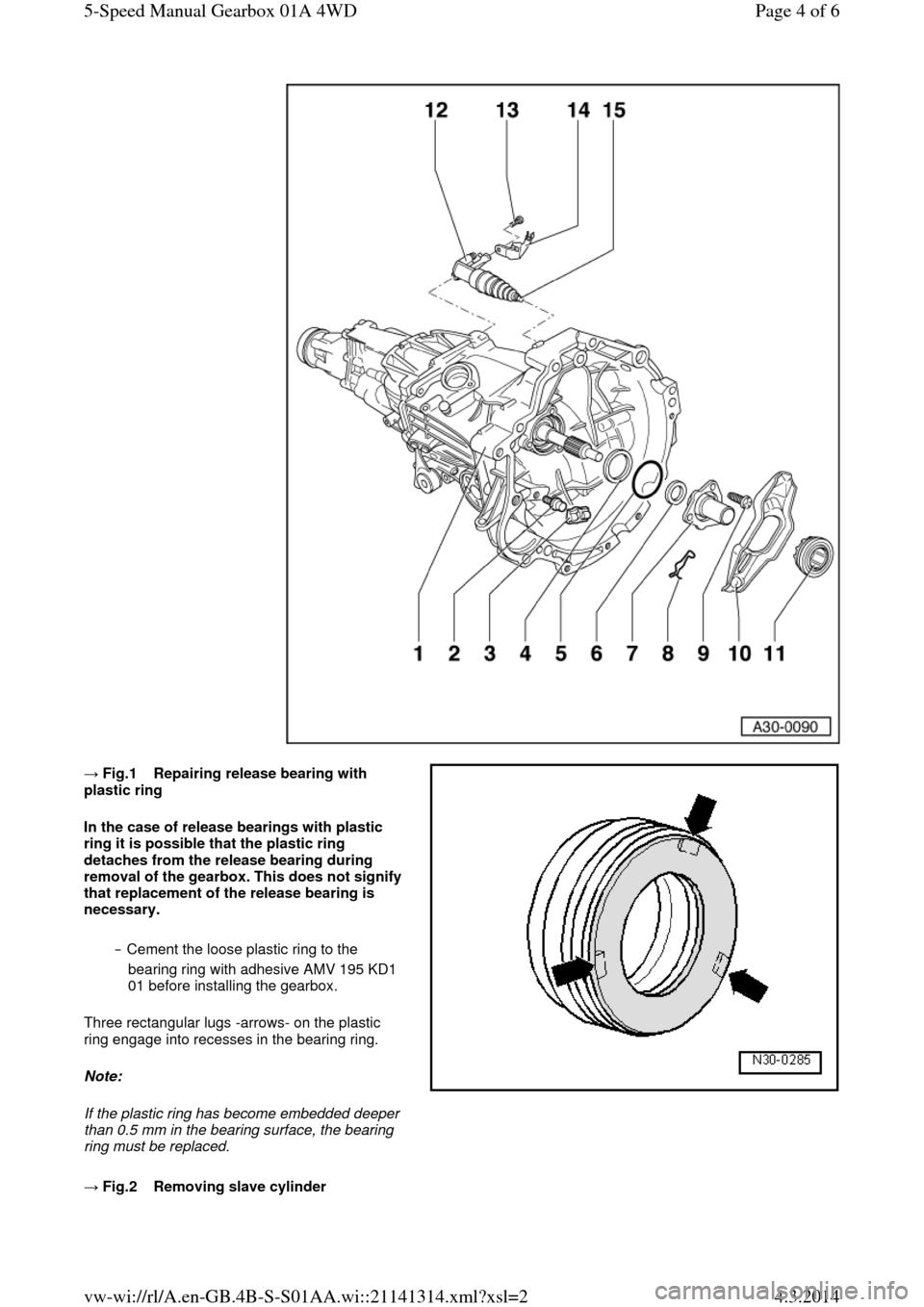

→ Fig.1 Repairing release bearing with plastic ring

In the case of release bearings with plastic

ring it is possible that the plastic ring

detaches from the release bearing during

removal of the gearbox. This does not signify

that replacement of the release bearing is

necessary.

‒ Cement the loose plastic ring to the

bearing ring with adhesive AMV 195 KD1

01 before installing the gearbox.

Three rectangular lugs -arrows- on the plastic

ring engage into recesses in the bearing ring.

Note:

If the plastic ring has become embedded deeper

than 0.5 mm in the bearing surface, the bearing

ring must be replaced. → Fig.2 Removing slave cylinder Page 4 of 65-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141314.xml?xsl=2

Page 25 of 71

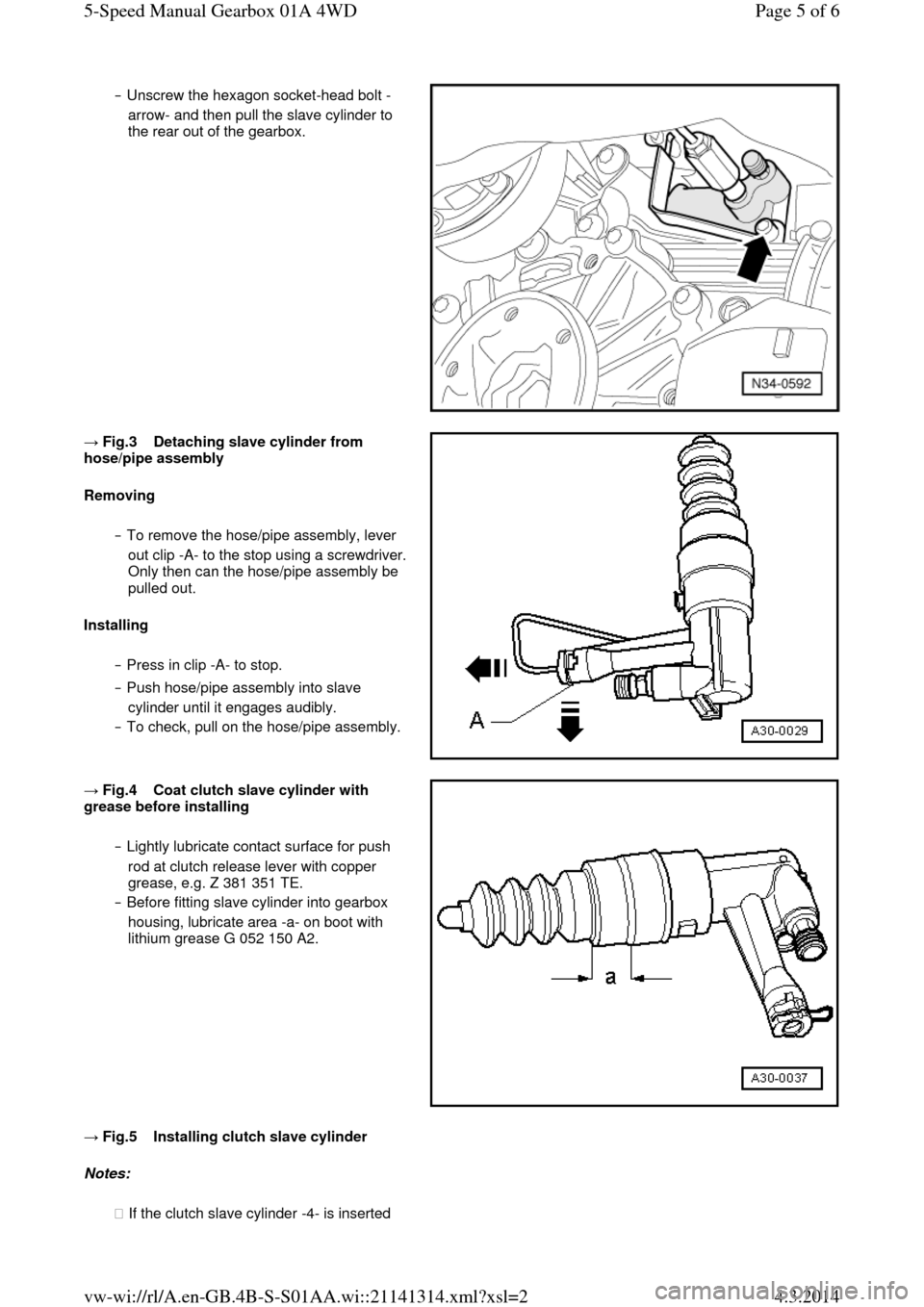

‒ Unscrew the hexagon socket-head bolt -

arrow- and then pull the slave cylinder to

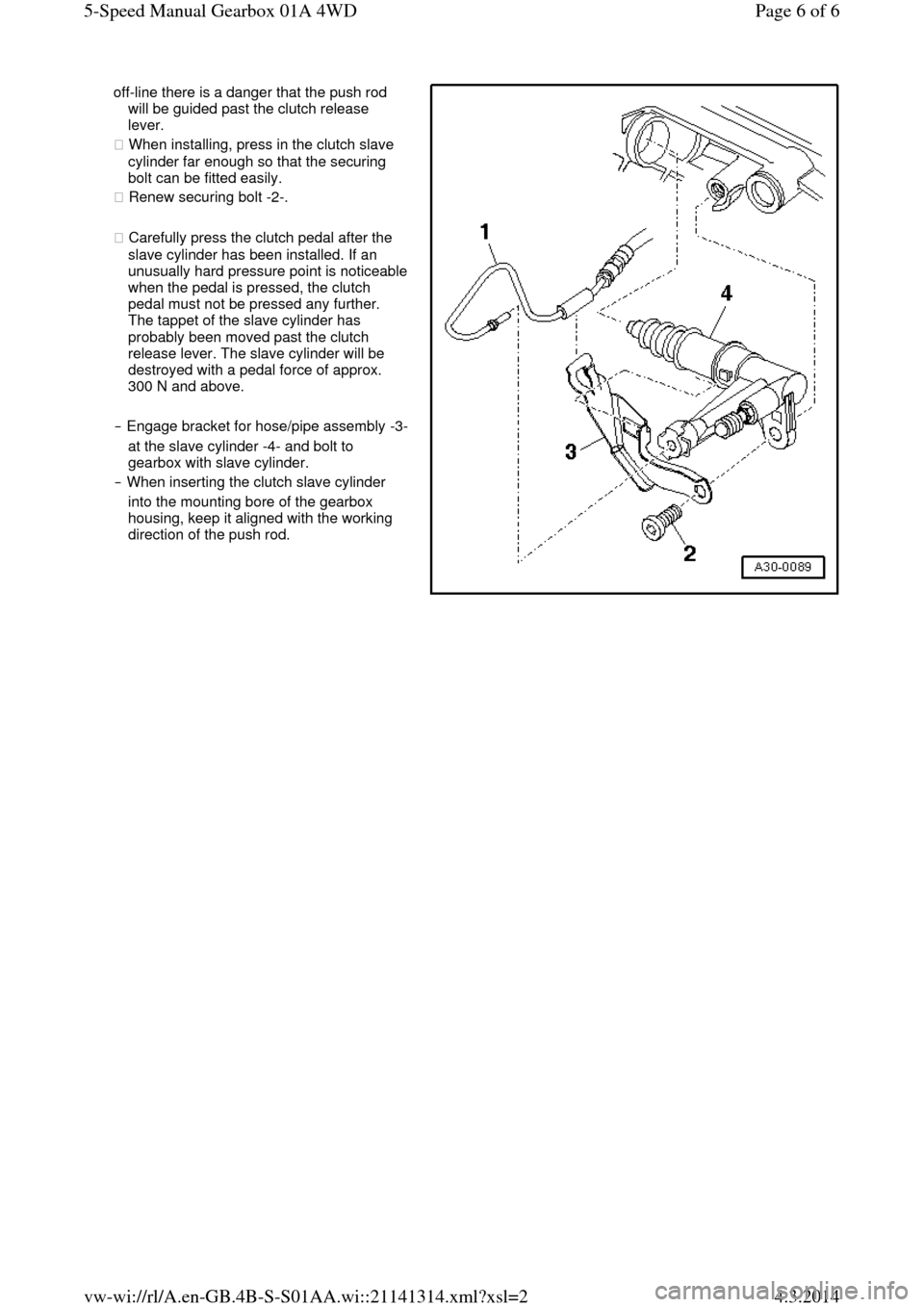

the rear out of the gearbox. → Fig.3 Detaching slave cylinder from hose/pipe assembly

Removing

‒ To remove the hose/pipe assembly, lever

out clip -A- to the stop using a screwdriver. Only then can the hose/pipe assembly be

pulled out.

Installing

‒ Press in clip -A- to stop.

‒ Push hose/pipe assembly into slave

cylinder until it engages audibly.

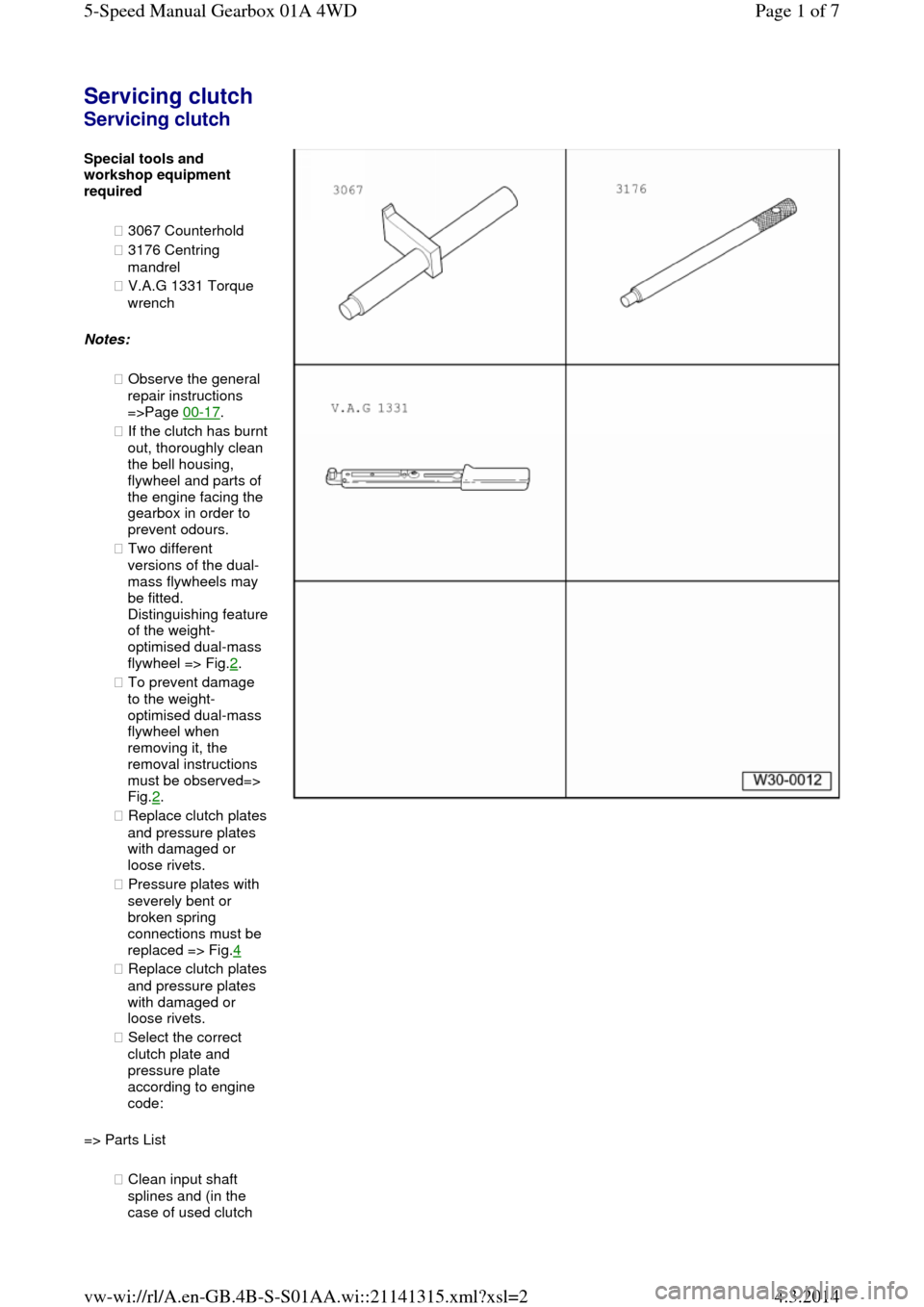

‒ To check, pull on the hose/pipe assembly. → Fig.4 Coat clutch slave cylinder with grease before installing

‒ Lightly lubricate contact surface for push

rod at clutch release lever with copper

grease, e.g. Z 381 351 TE.

‒ Before fitting slave cylinder into gearbox

housing, lubricate area -a- on boot with

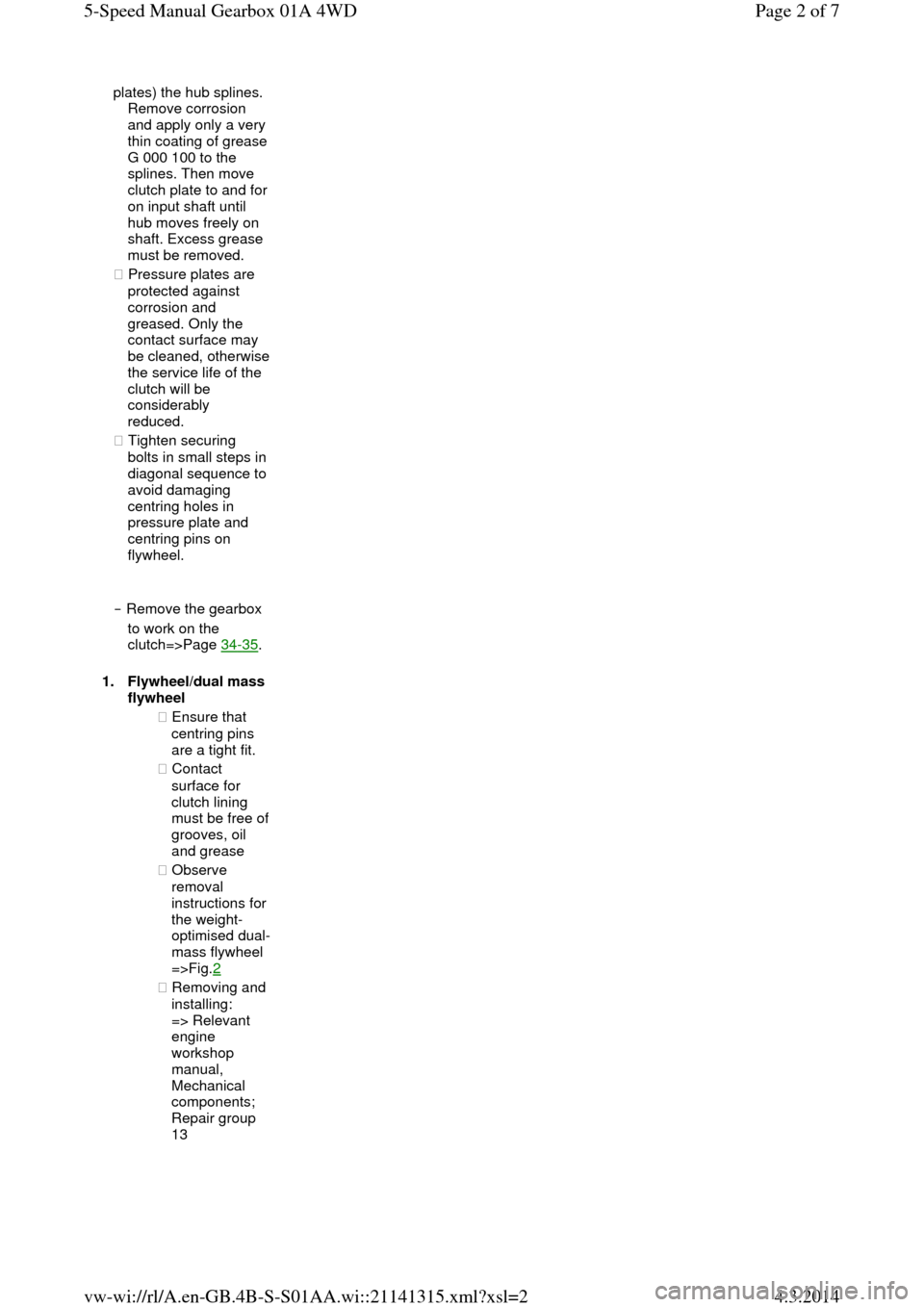

lithium grease G 052 150 A2. → Fig.5 Installing clutch slave cylinder Notes:

◆ If the clutch slave cylinder -4- is inserted Page 5 of 65-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141314.xml?xsl=2

Page 26 of 71

off-line there is a danger that the push rod

will be guided past the clutch release

lever.

◆ When installing, press in the clutch slave

cylinder far enough so that the securing

bolt can be fitted easily.

◆ Renew securing bolt -2-.

◆ Carefully press the clutch pedal after the

slave cylinder has been installed. If an unusually hard pressure point is noticeable when the pedal is pressed, the clutch

pedal must not be pressed any further.

The tappet of the slave cylinder has

probably been moved past the clutch

release lever. The slave cylinder will be

destroyed with a pedal force of approx.

300 N and above.

‒ Engage bracket for hose/pipe assembly -3- at the slave cylinder -4- and bolt to

gearbox with slave cylinder.

‒ When inserting the clutch slave cylinder

into the mounting bore of the gearbox

housing, keep it aligned with the working

direction of the push rod. Page 6 of 65-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141314.xml?xsl=2

Page 27 of 71

Servicing clutch Servicing clutch Special tools and workshop equipment

required

◆ 3067 Counterhold

◆ 3176 Centring

mandrel

◆ V.A.G 1331 Torque

wrench

Notes:

◆ Observe the general

repair instructions

=>Page 00-17.

◆ If the clutch has burnt out, thoroughly clean

the bell housing,

flywheel and parts of

the engine facing the

gearbox in order to

prevent odours.

◆ Two different

versions of the dual-

mass flywheels may

be fitted. Distinguishing feature of the weight-

optimised dual-mass

flywheel => Fig.2.

◆ To prevent damage

to the weight-

optimised dual-mass

flywheel when

removing it, the

removal instructions

must be observed=>

Fig.2.

◆ Replace clutch plates and pressure plates

with damaged or

loose rivets.

◆ Pressure plates with

severely bent or

broken spring

connections must be

replaced => Fig.4

◆ Replace clutch plates and pressure plates

with damaged or

loose rivets.

◆ Select the correct

clutch plate and

pressure plate

according to engine

code:

=> Parts List

◆ Clean input shaft

splines and (in the

case of used clutch Page 1 of 75-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141315.xml?xsl=2

Page 28 of 71

plates) the hub splines.

Remove corrosion

and apply only a very thin coating of grease G 000 100 to the

splines. Then move clutch plate to and for on input shaft until

hub moves freely on

shaft. Excess grease

must be removed.

◆ Pressure plates are

protected against

corrosion and

greased. Only the

contact surface may be cleaned, otherwise the service life of the

clutch will be

considerably

reduced.

◆ Tighten securing

bolts in small steps in

diagonal sequence to

avoid damaging

centring holes in

pressure plate and

centring pins on

flywheel.

‒ Remove the gearbox

to work on the

clutch=>Page 34-35.

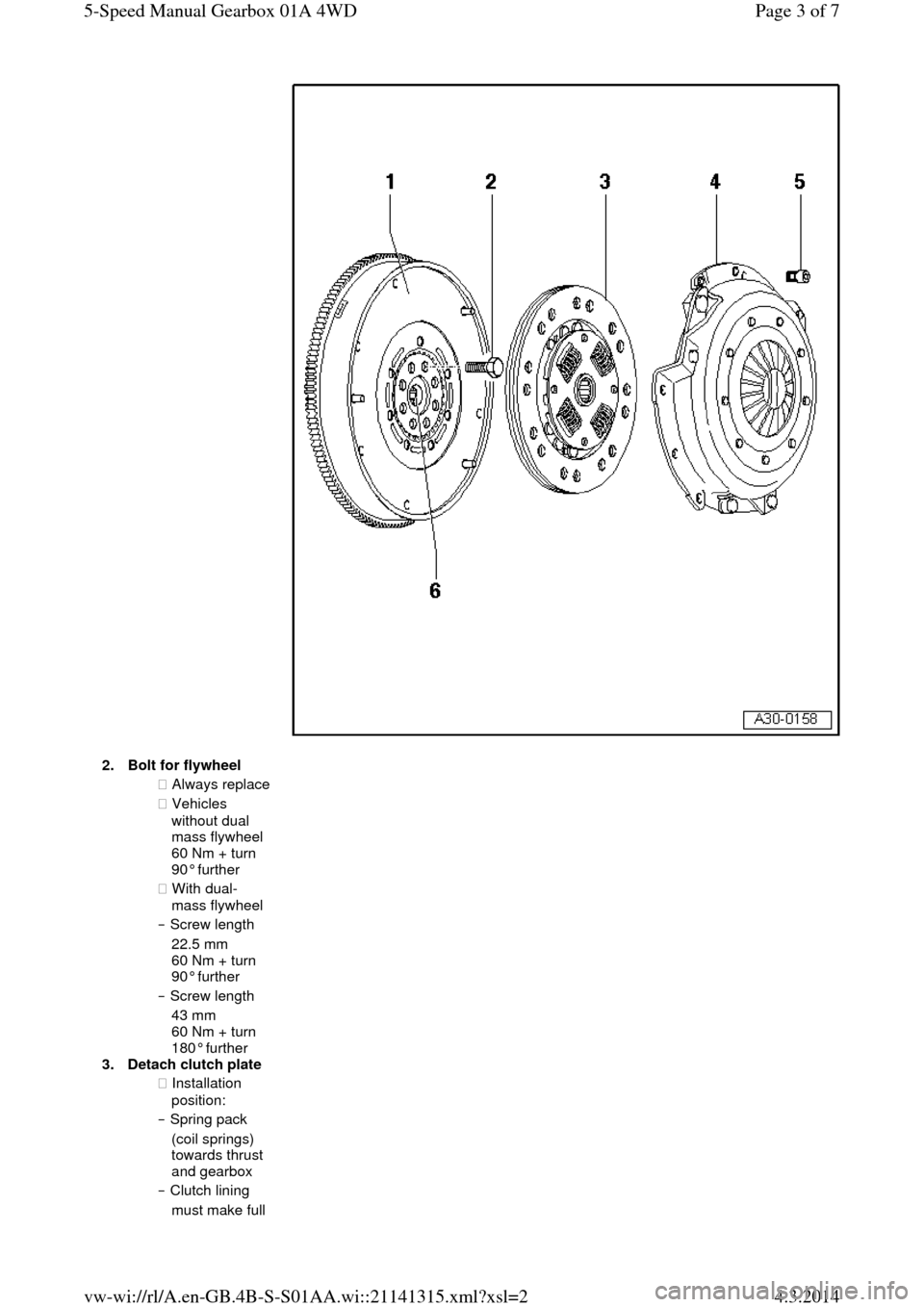

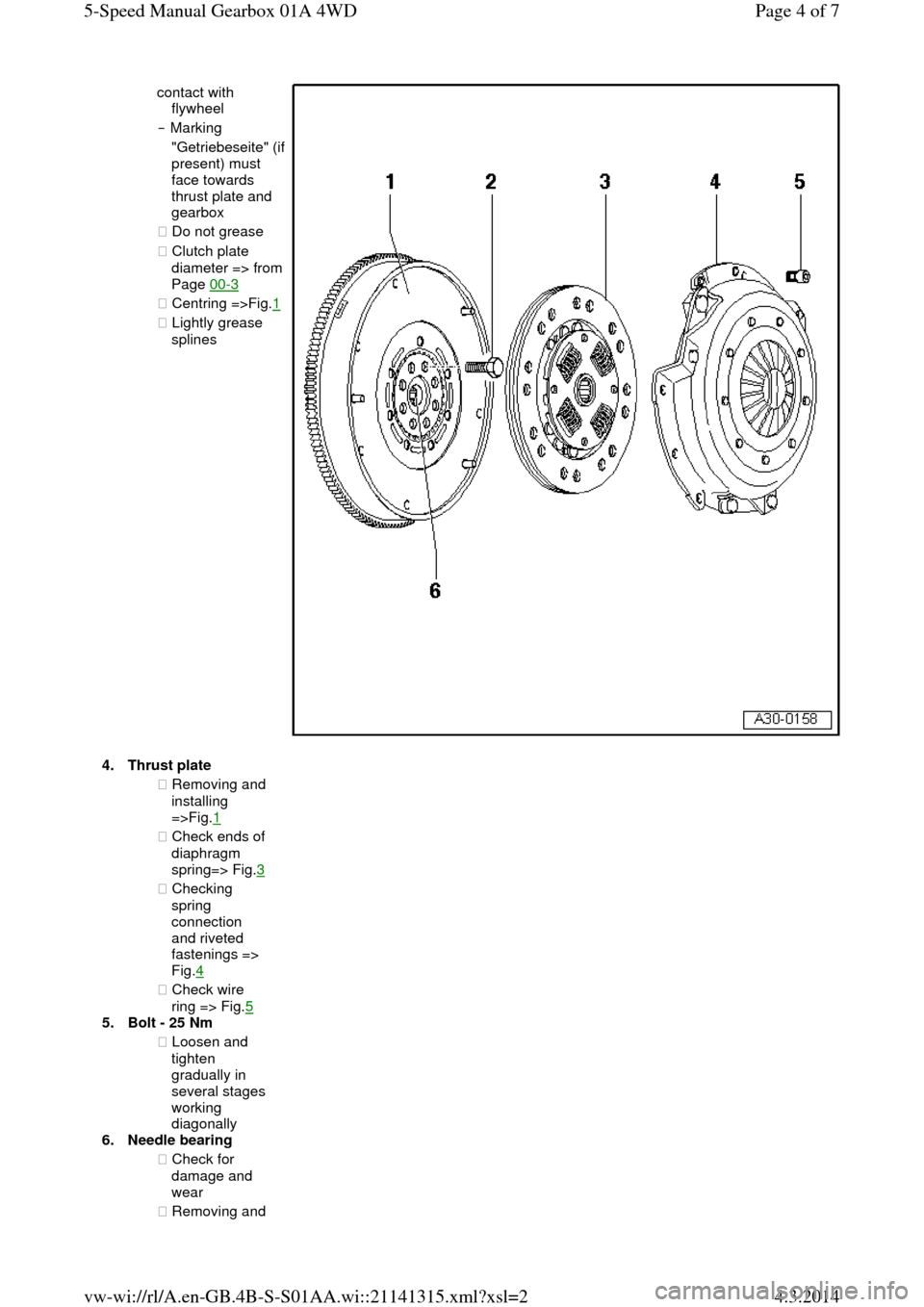

1.Flywheel/dual mass

flywheel

◆ Ensure that

centring pins

are a tight fit.

◆ Contact

surface for

clutch lining must be free of grooves, oil

and grease

◆ Observe

removal

instructions for

the weight-

optimised dual-

mass flywheel

=>Fig.2

◆ Removing and

installing:

=> Relevant

engine

workshop

manual,

Mechanical

components;

Repair group

13 Page 2 of 75-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141315.xml?xsl=2

Page 29 of 71

2.Bolt for flywheel ◆ Always replace ◆ Vehicles

without dual

mass flywheel

60 Nm + turn

90° further

◆ With dual-

mass flywheel ‒ Screw length

22.5 mm

60 Nm + turn

90° further

‒ Screw length

43 mm

60 Nm + turn

180° further

3.Detach clutch plate

◆ Installation

position:

‒ Spring pack

(coil springs)

towards thrust

and gearbox

‒ Clutch lining

must make full Page 3 of 75-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141315.xml?xsl=2

Page 30 of 71

contact with

flywheel

‒ Marking "Getriebeseite" (if present) must

face towards

thrust plate and

gearbox

◆ Do not grease

◆ Clutch plate diameter => from Page 00-3

◆ Centring =>Fig.1 ◆ Lightly grease

splines 4.Thrust plate ◆ Removing and

installing

=>Fig.1

◆ Check ends of

diaphragm

spring=> Fig.3 ◆ Checking

spring

connection

and riveted

fastenings =>

Fig.4

◆ Check wire

ring => Fig.5

5.Bolt - 25 Nm

◆ Loosen and

tighten

gradually in

several stages

working

diagonally

6.Needle bearing

◆ Check for

damage and

wear

◆ Removing and Page 4 of 75-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141315.xml?xsl=2