AUDI A6 2000 C5 / 2.G Changing Clutch 5Speed Manual Gearbox

Manufacturer: AUDI, Model Year: 2000,

Model line: A6,

Model: AUDI A6 2000 C5 / 2.G

Pages: 71, PDF Size: 1.82 MB

AUDI A6 2000 C5 / 2.G Changing Clutch 5Speed Manual Gearbox

A6 2000 C5 / 2.G

AUDI

AUDI

https://www.carmanualsonline.info/img/6/841/w960_841-0.png

AUDI A6 2000 C5 / 2.G Changing Clutch 5Speed Manual Gearbox

Trending: oil level, oil, ECU, clock, relay, wheel bolts, engine

Page 61 of 71

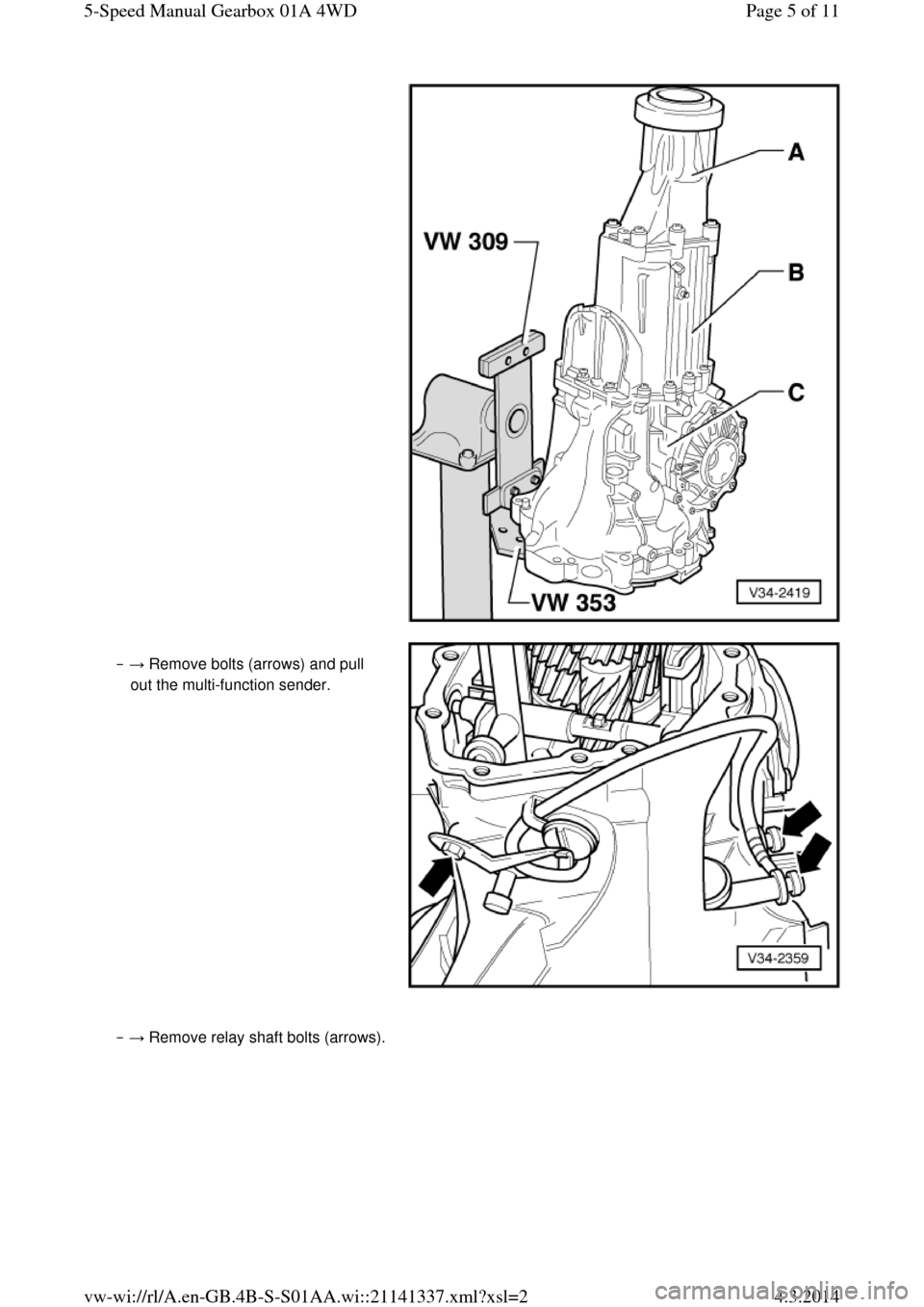

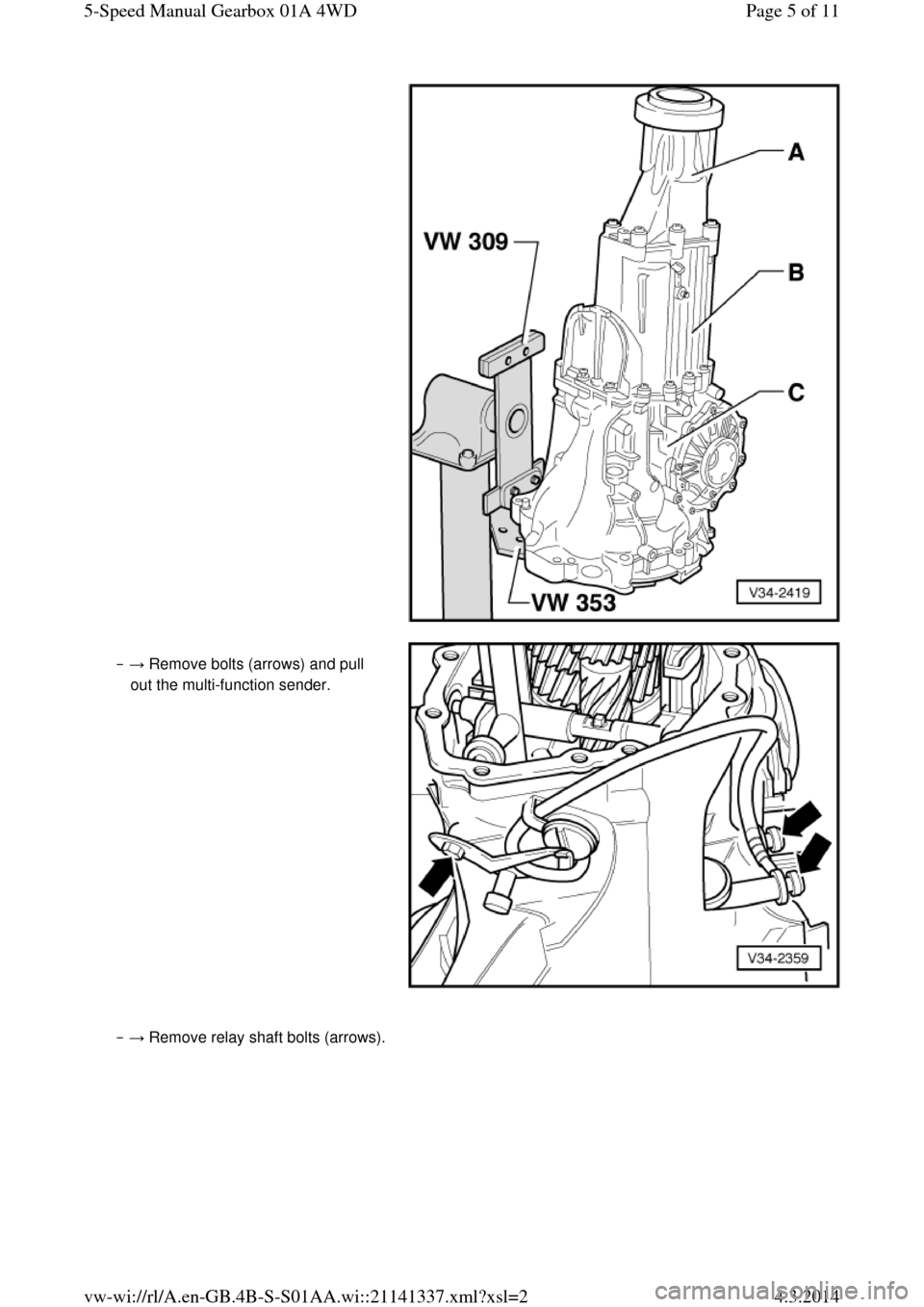

‒ → Remove bolts (arrows) and pull

out the multi-function sender. ‒ → Remove relay shaft bolts (arrows). Page 5 of 115-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141337.xml?xsl=2

Page 62 of 71

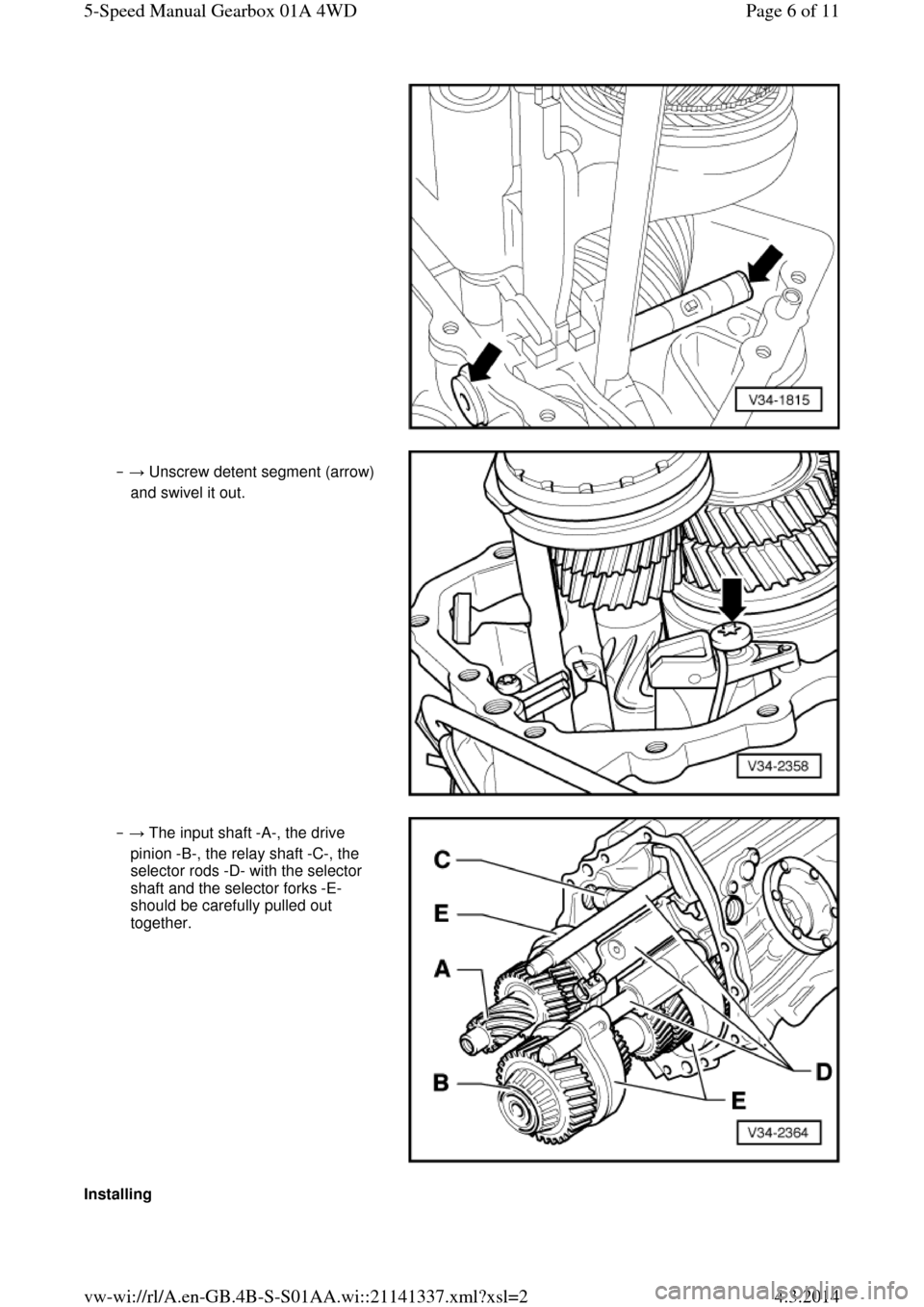

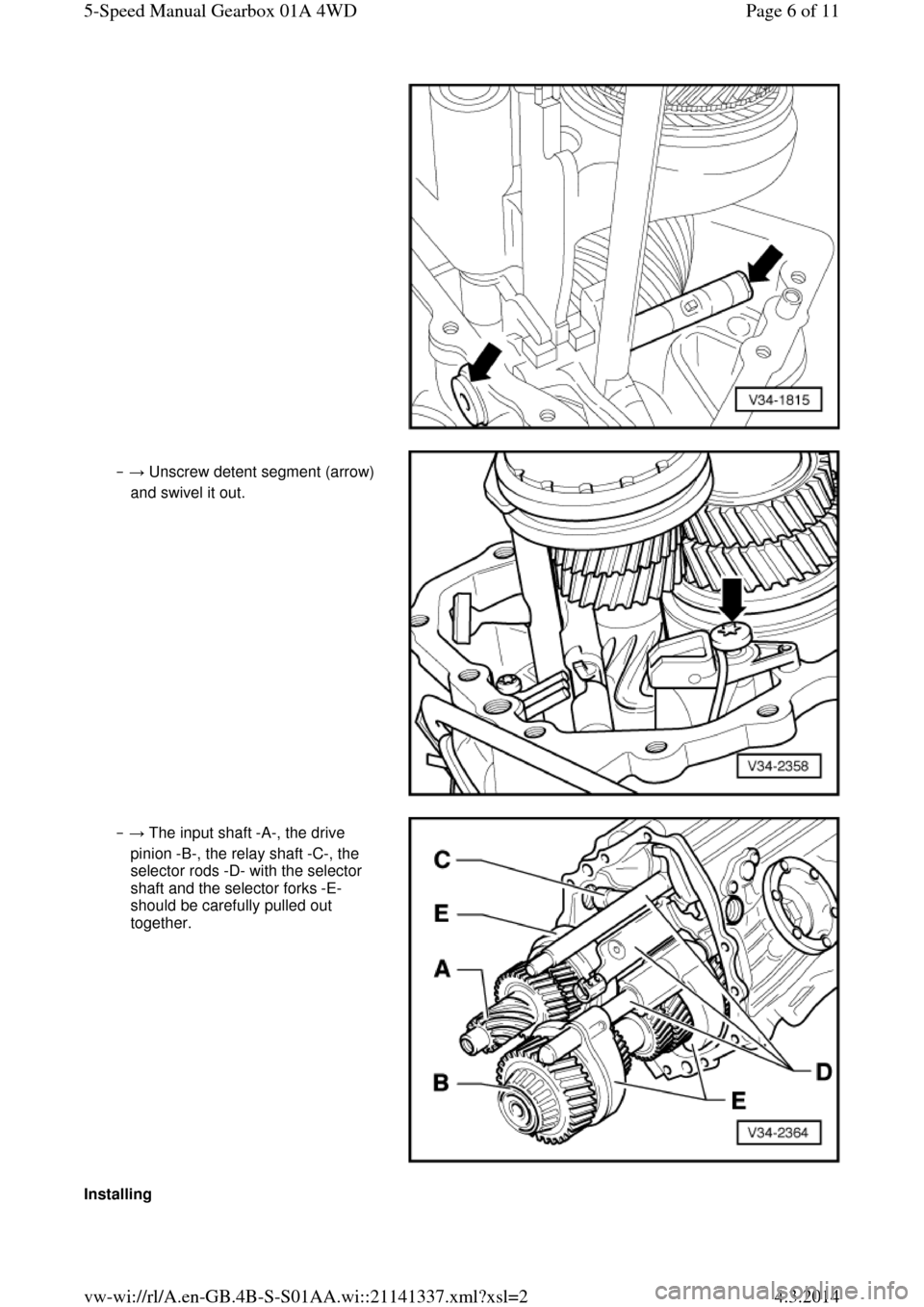

‒ → Unscrew detent segment (arrow)

and swivel it out. ‒ → The input shaft -A-, the drive

pinion -B-, the relay shaft -C-, the

selector rods -D- with the selector

shaft and the selector forks -E-

should be carefully pulled out

together. Installing Page 6 of 115-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141337.xml?xsl=2

Page 63 of 71

Note: If the input shaft ball bearing, the input shaft or the gearbox housing are renewed, it is

necessary to re-determine the thickness of

the circlips for the input shaft =>Page 35-23, adjusting input shaft.

‒ → Swing the gearbox housing into

the position shown.

‒ The components listed below can

then be fitted more easily. ‒ → Put the input shaft -A-, the drive

pinion -B-, the relay shaft -C-, the

selector rods -D- with the selector

shaft and the selector forks -E-

together.

‒ Install these components together

into the gearbox housing.

Note:

Relay shaft -C- and the selector shaft can

also be retrofitted =>next page, Fig. N34-

0585 and Fig. V34-2120. ‒ → Turn gearbox housing and

engage 3rd gear (direction of arrow). Page 7 of 115-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141337.xml?xsl=2

Page 64 of 71

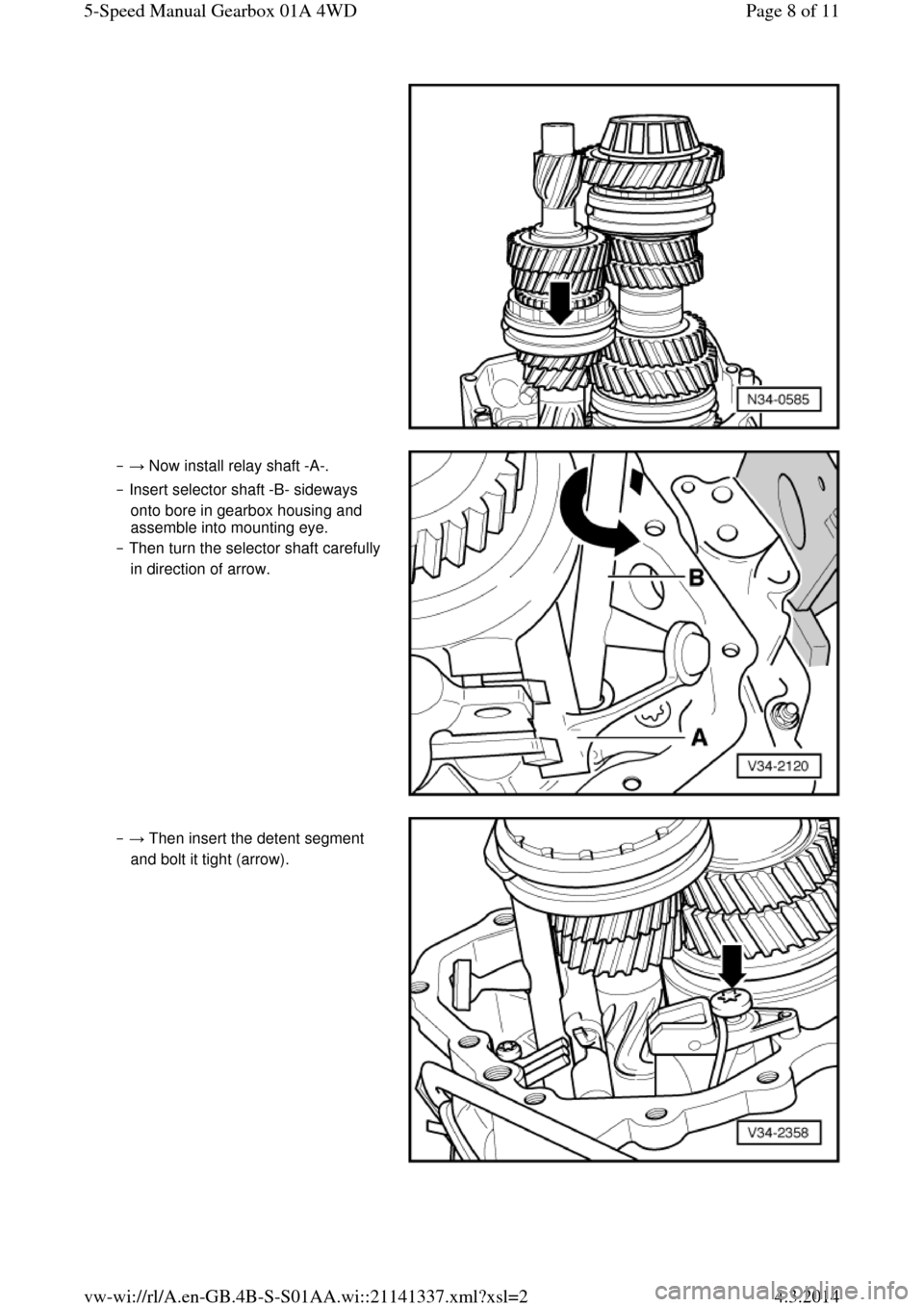

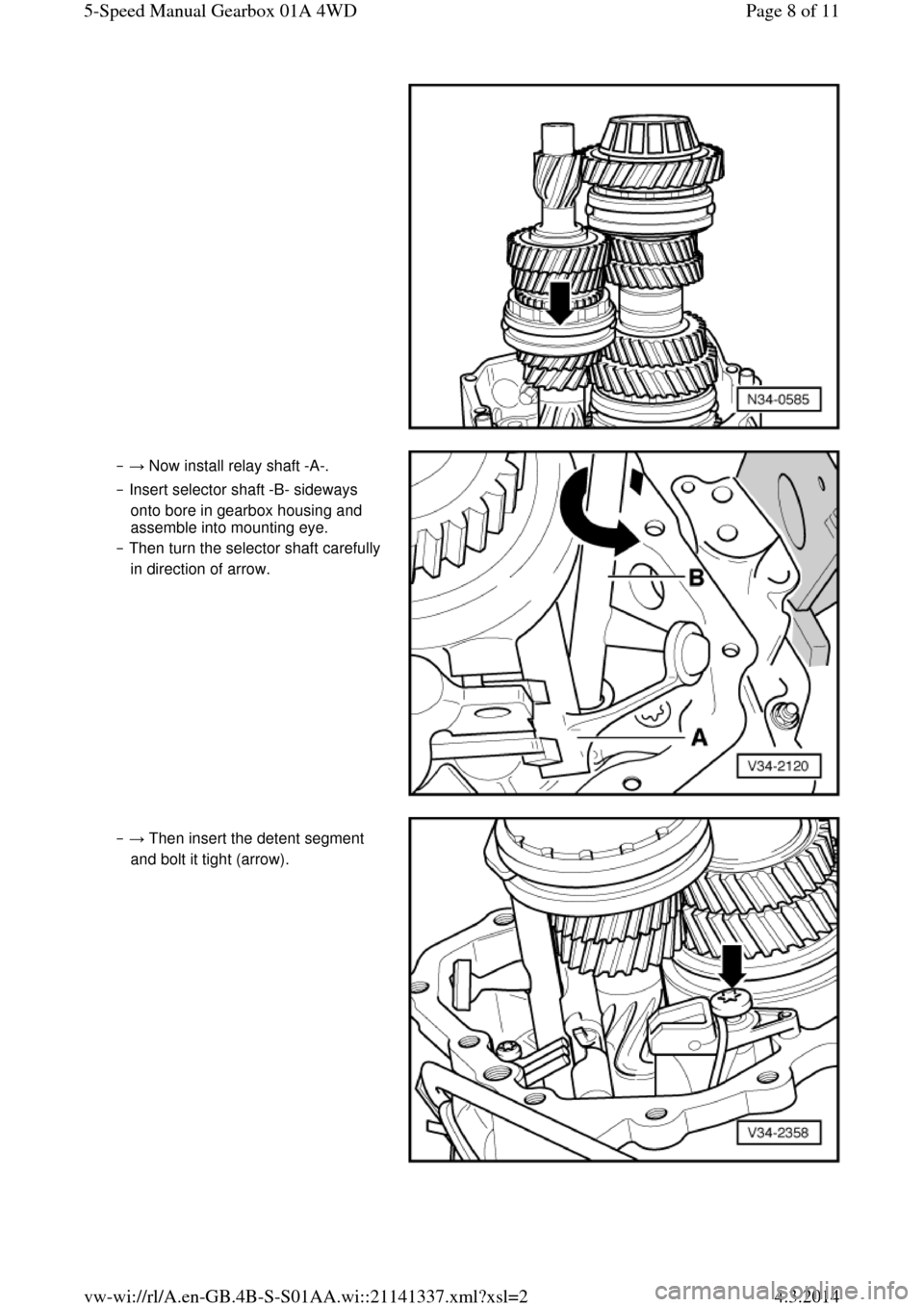

‒ → Now install relay shaft -A-.

‒ Insert selector shaft -B- sideways

onto bore in gearbox housing and

assemble into mounting eye.

‒ Then turn the selector shaft carefully

in direction of arrow. ‒ → Then insert the detent segment

and bolt it tight (arrow). Page 8 of 115-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141337.xml?xsl=2

Page 65 of 71

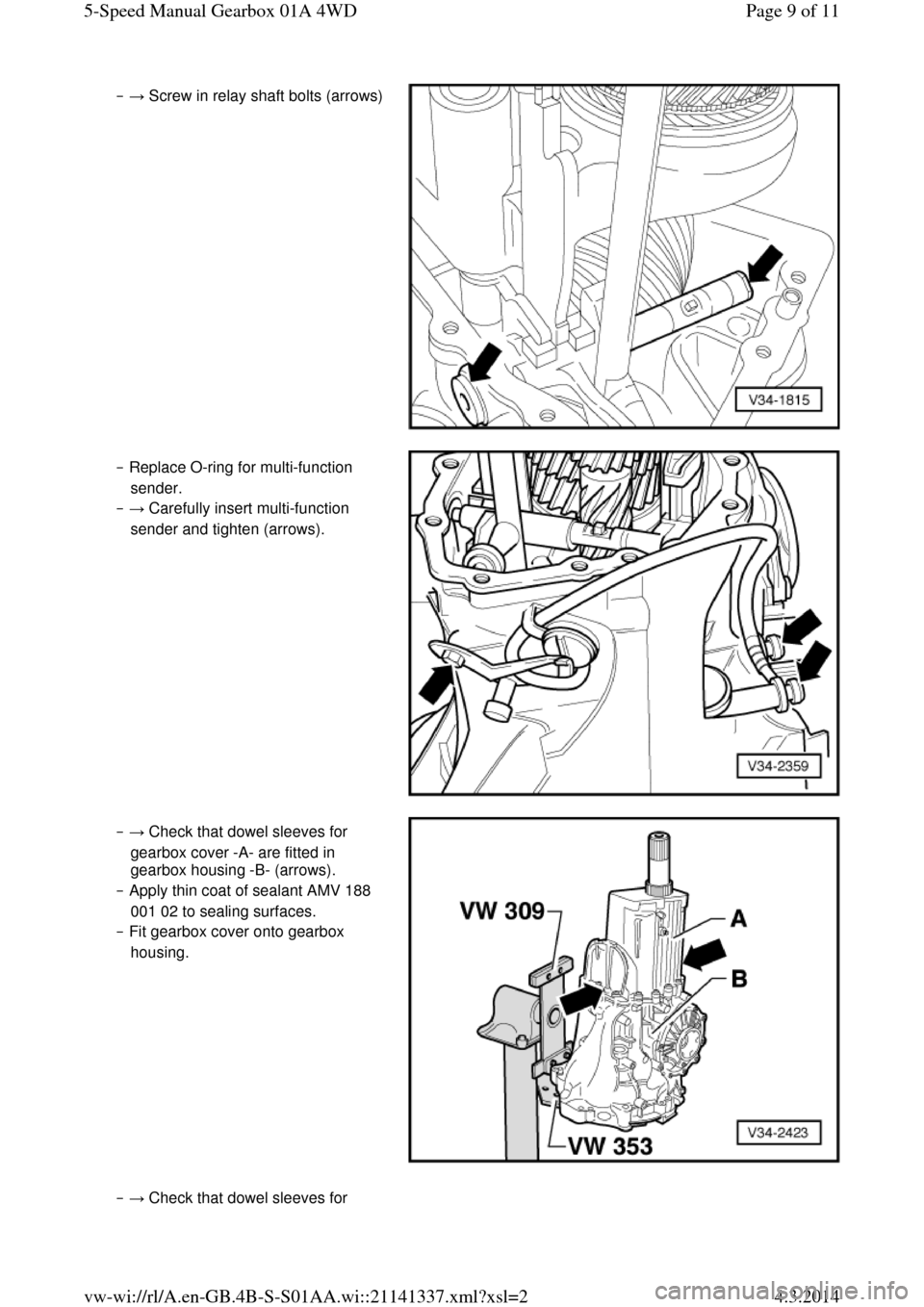

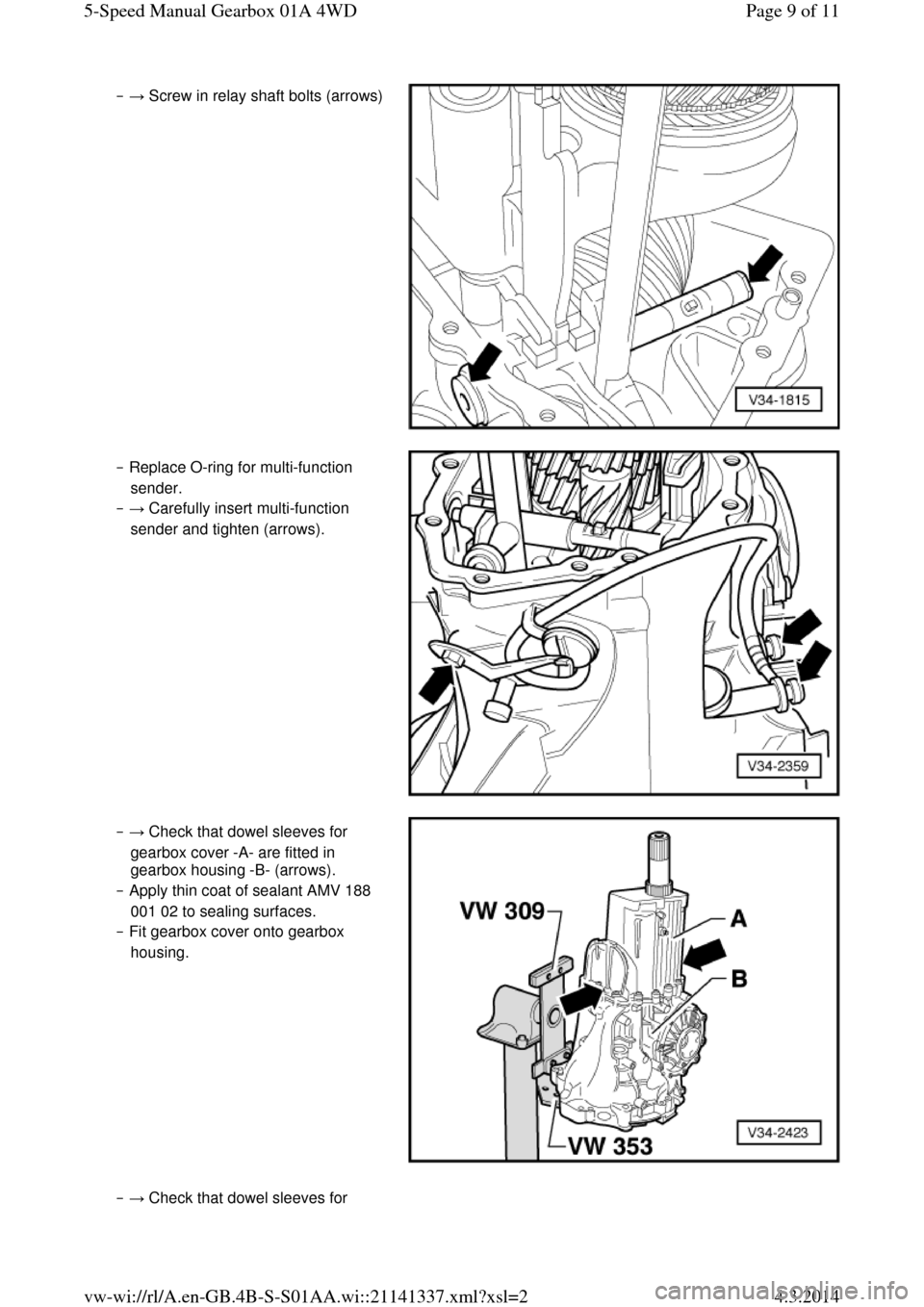

‒ → Screw in relay shaft bolts (arrows) ‒ Replace O-ring for multi-function

sender.

‒ → Carefully insert multi-function

sender and tighten (arrows). ‒ → Check that dowel sleeves for

gearbox cover -A- are fitted in

gearbox housing -B- (arrows).

‒ Apply thin coat of sealant AMV 188

001 02 to sealing surfaces.

‒ Fit gearbox cover onto gearbox

housing. ‒ → Check that dowel sleeves for Page 9 of 115-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141337.xml?xsl=2

Page 66 of 71

cover -A- are fitted in gearbox cover -

B- (arrows).

‒ Fit spring -C-.

‒ Apply thin coat of sealant AMV 188

001 02 to sealing surfaces.

‒ Fit cover with Torsen differential -A-

on gearbox cover -B-. ‒ → Fit rear input shaft ball bearing

circlip (arrow).

‒ Push the ball bearing onto the input

shaft.

‒ Installation position: closed

side of ball cage faces

towards gearbox housing ‒ → Press in ball bearing:

‒ Push thrust pad -A- of pressing-in

tool onto input shaft.

‒ Position pressing-in tool behind

splines for clutch plate.

‒ Screw in the bolts -B- until they make contact.

‒ The bolts bear against the

indentations in thrust pad -A-. ‒ Press in ball bearing onto its seat by

alternately tightening the bolts (1/2

turn at a time). ‒ → Now fit the front circlip -D- for the Page 10 of 115-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141337.xml?xsl=2

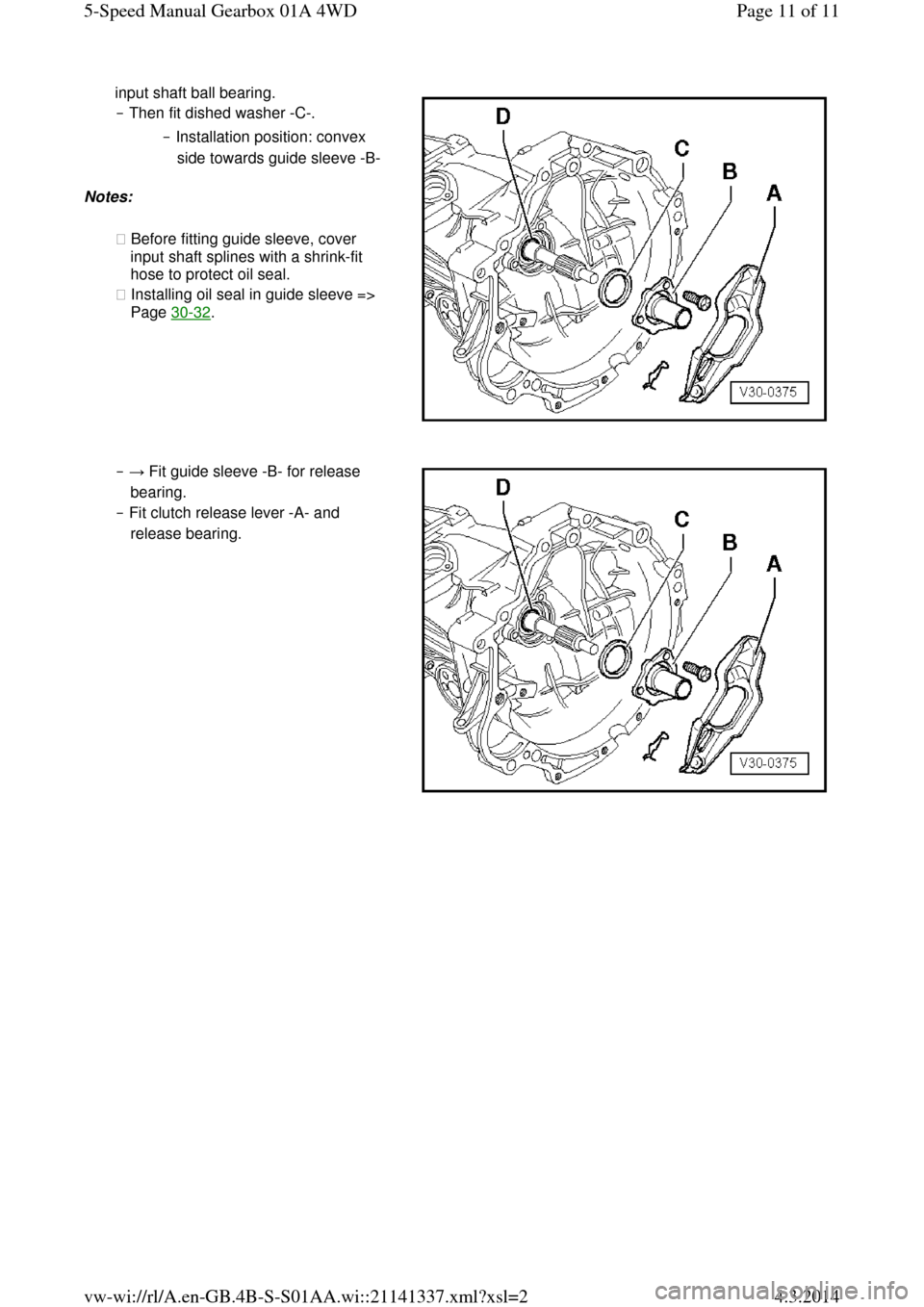

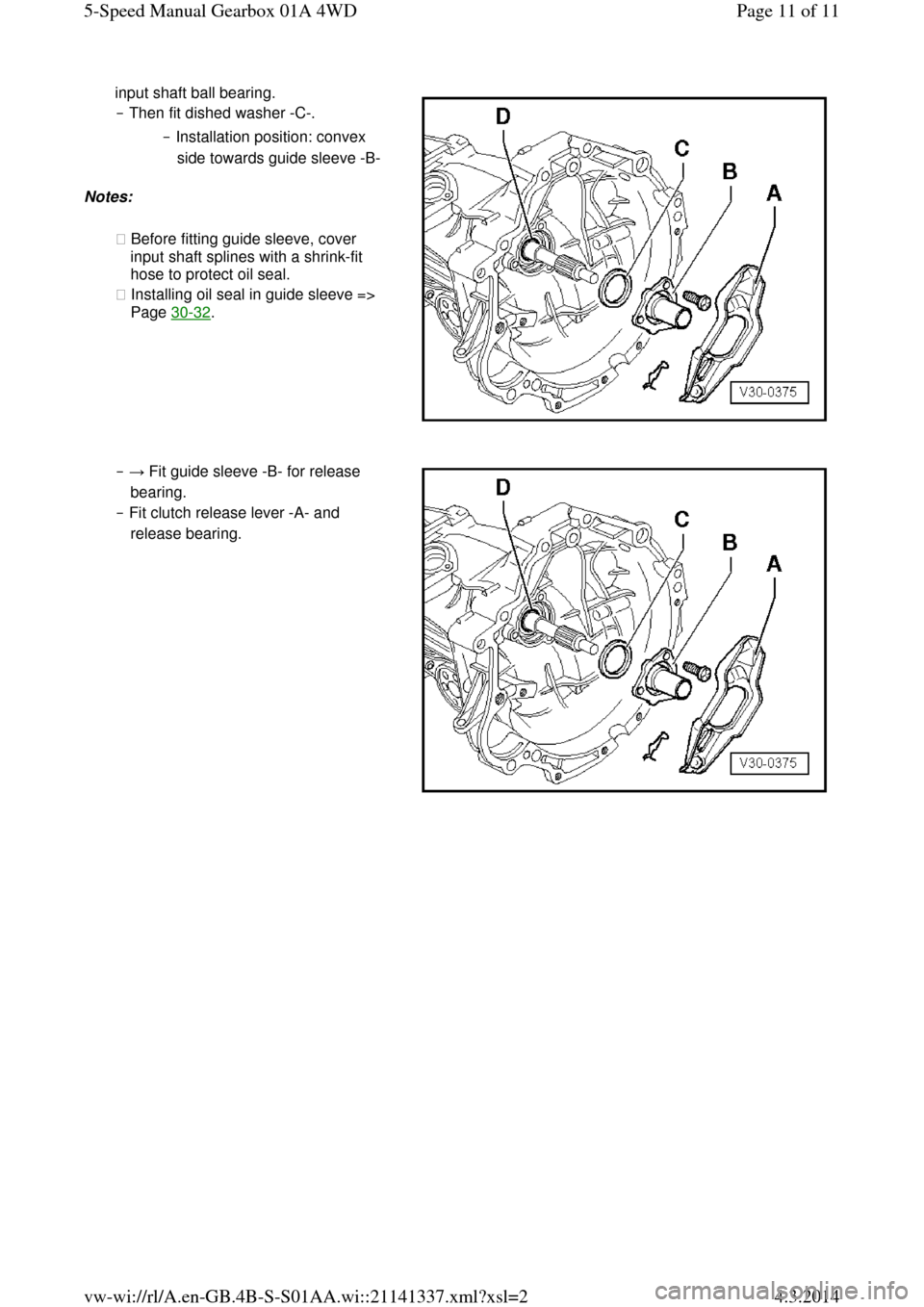

Page 67 of 71

input shaft ball bearing.

‒ Then fit dished washer -C-.

‒ Installation position: convex

side towards guide sleeve -B- Notes:

◆ Before fitting guide sleeve, cover

input shaft splines with a shrink-fit

hose to protect oil seal.

◆ Installing oil seal in guide sleeve =>

Page 30-32. ‒ → Fit guide sleeve -B- for release

bearing.

‒ Fit clutch release lever -A- and

release bearing. Page 11 of 115-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141337.xml?xsl=2

Page 68 of 71

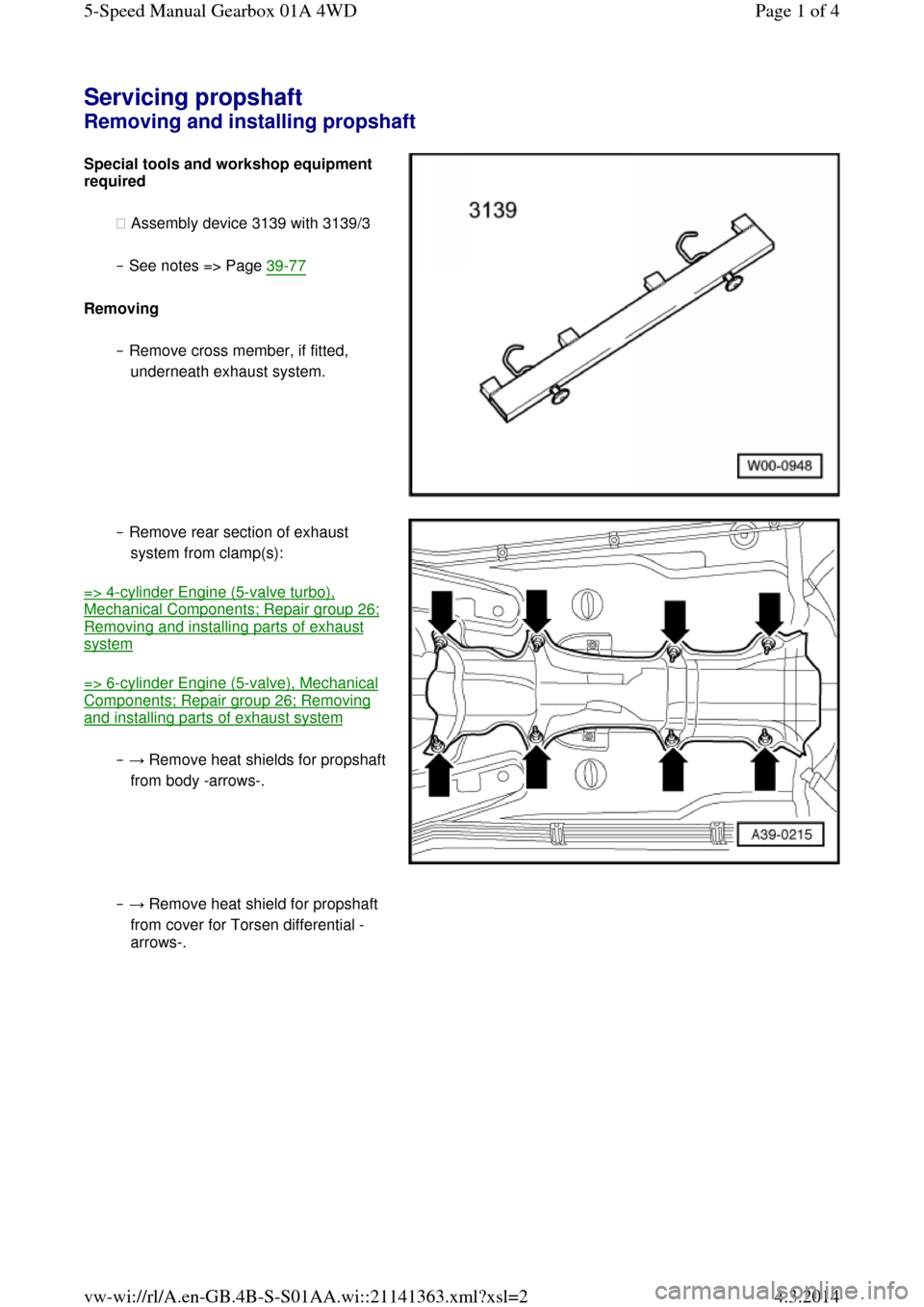

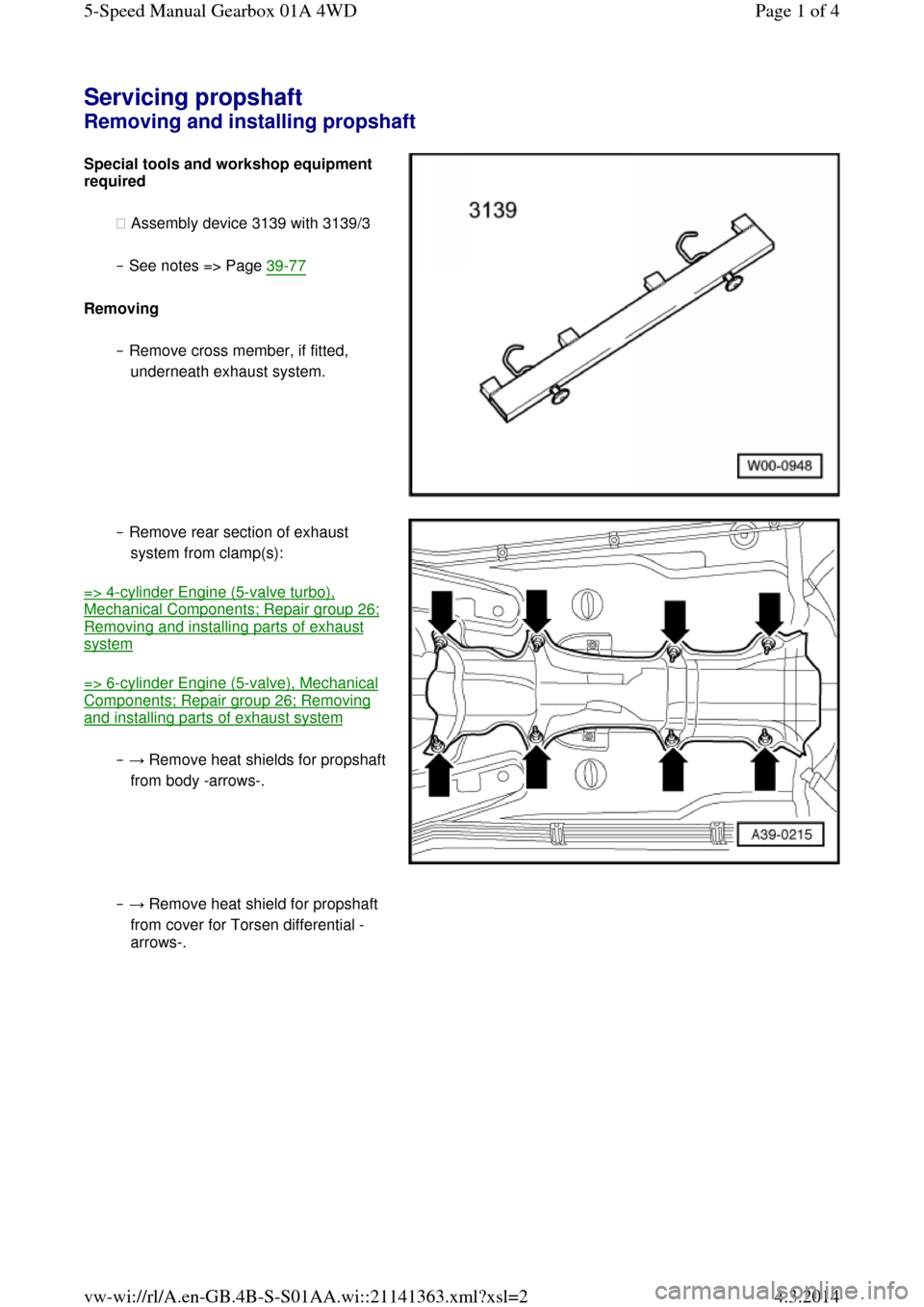

Servicing propshaft Removing and installing propshaft Special tools and workshop equipment required

◆ Assembly device 3139 with 3139/3

‒ See notes => Page 39-77

Removing

‒ Remove cross member, if fitted,

underneath exhaust system. ‒ Remove rear section of exhaust

system from clamp(s):

=> 4-cylinder Engine (5-valve turbo), Mechanical Components; Repair group 26; Removing and installing parts of exhaust system

=> 6-cylinder Engine (5-valve), Mechanical Components; Repair group 26; Removing and installing parts of exhaust system

‒ → Remove heat shields for propshaft from body -arrows-. ‒ → Remove heat shield for propshaft

from cover for Torsen differential -

arrows-. Page 1 of 45-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141363.xml?xsl=2

Page 69 of 71

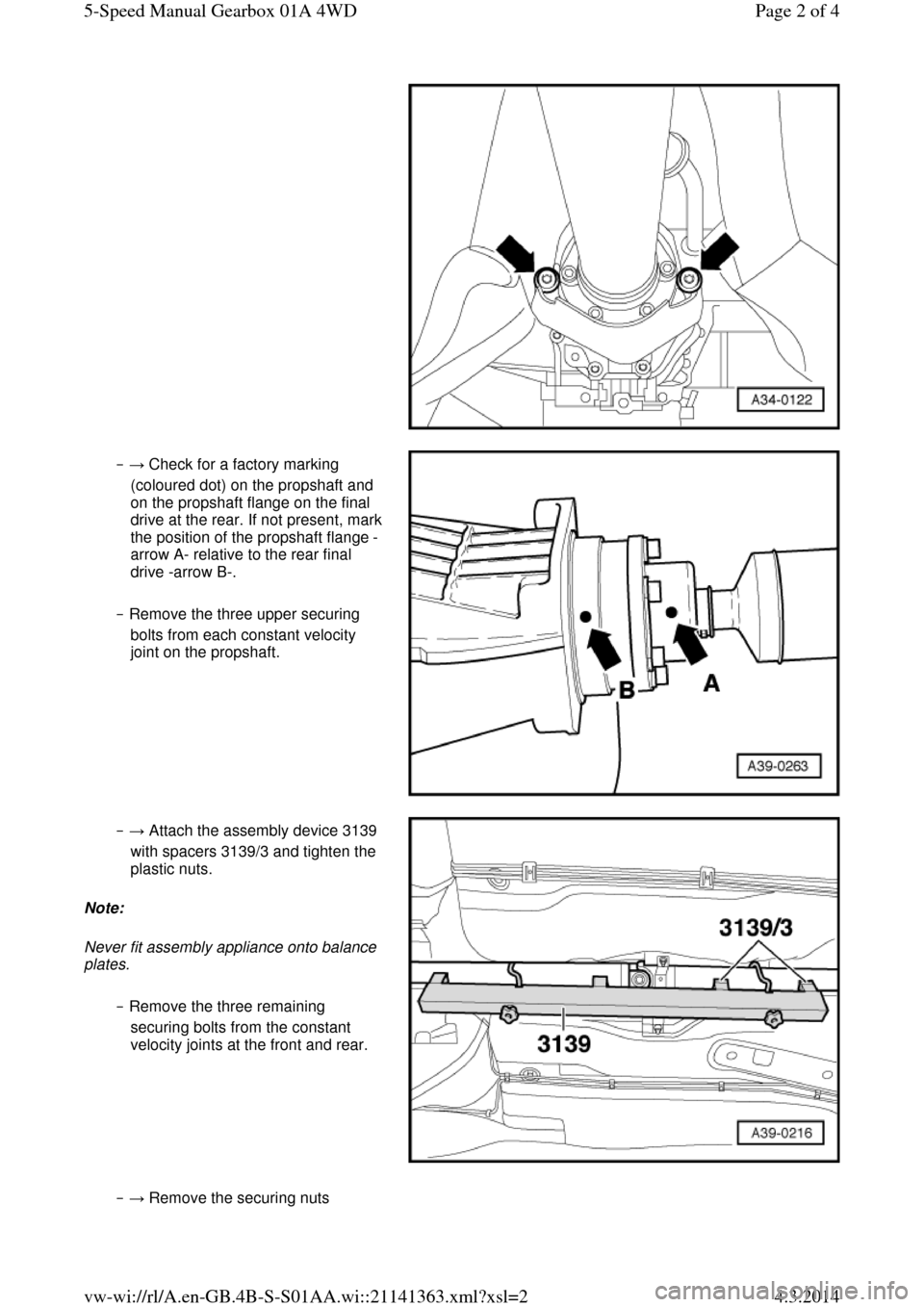

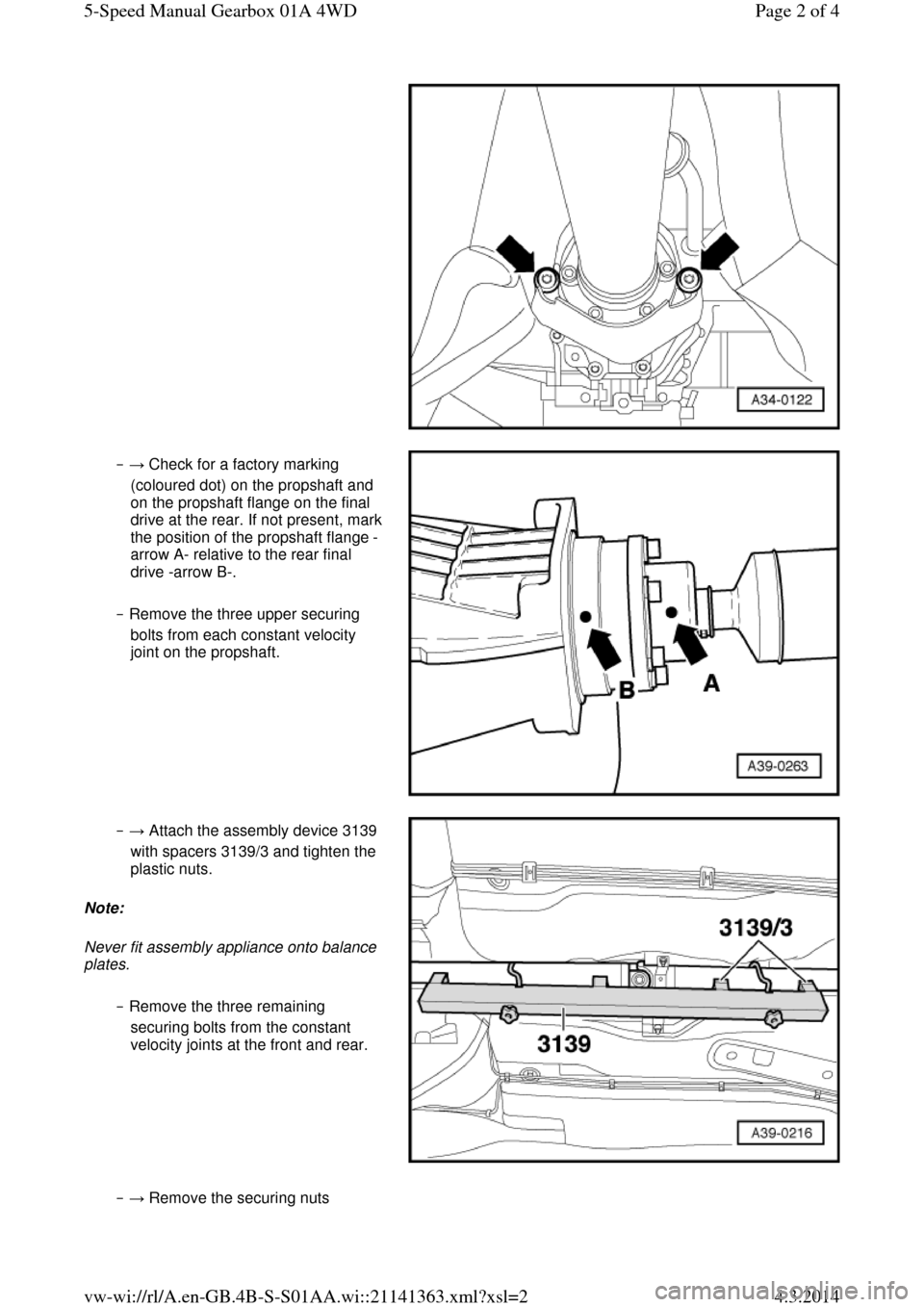

‒ → Check for a factory marking

(coloured dot) on the propshaft and

on the propshaft flange on the final drive at the rear. If not present, mark the position of the propshaft flange -

arrow A- relative to the rear final

drive -arrow B-.

‒ Remove the three upper securing

bolts from each constant velocity

joint on the propshaft. ‒ → Attach the assembly device 3139

with spacers 3139/3 and tighten the

plastic nuts.

Note:

Never fit assembly appliance onto balance plates.

‒ Remove the three remaining

securing bolts from the constant

velocity joints at the front and rear. ‒ → Remove the securing nuts Page 2 of 45-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141363.xml?xsl=2

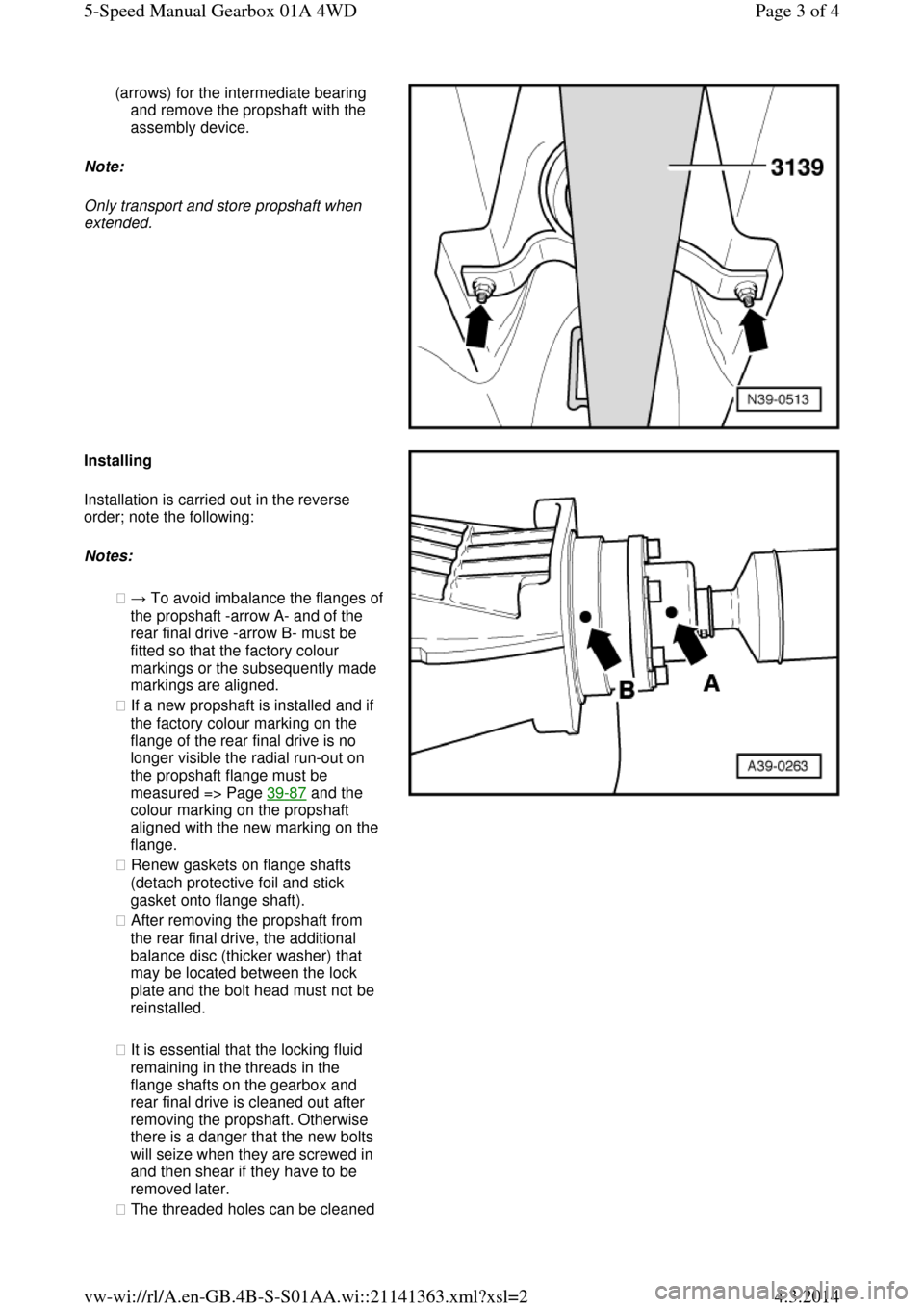

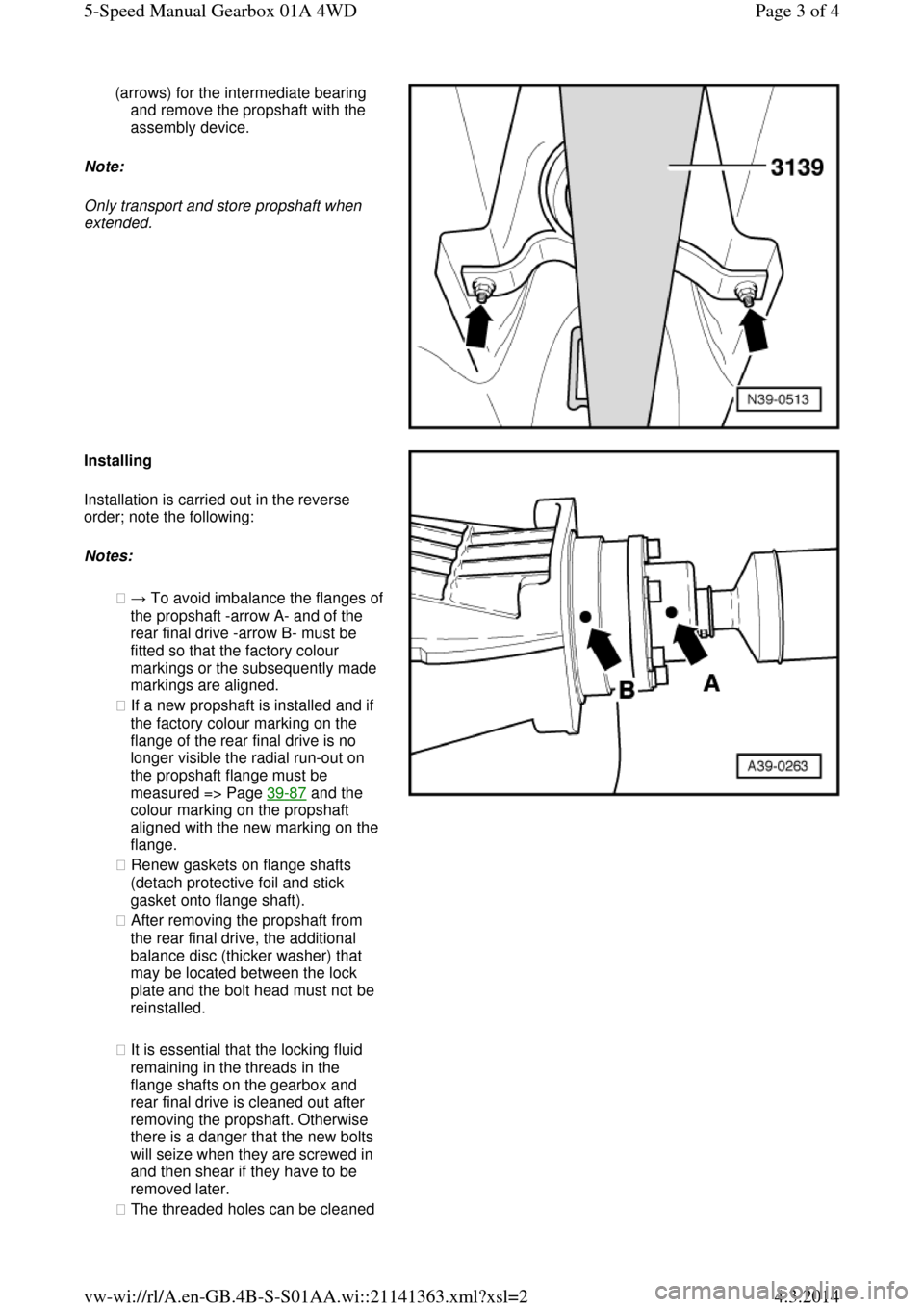

Page 70 of 71

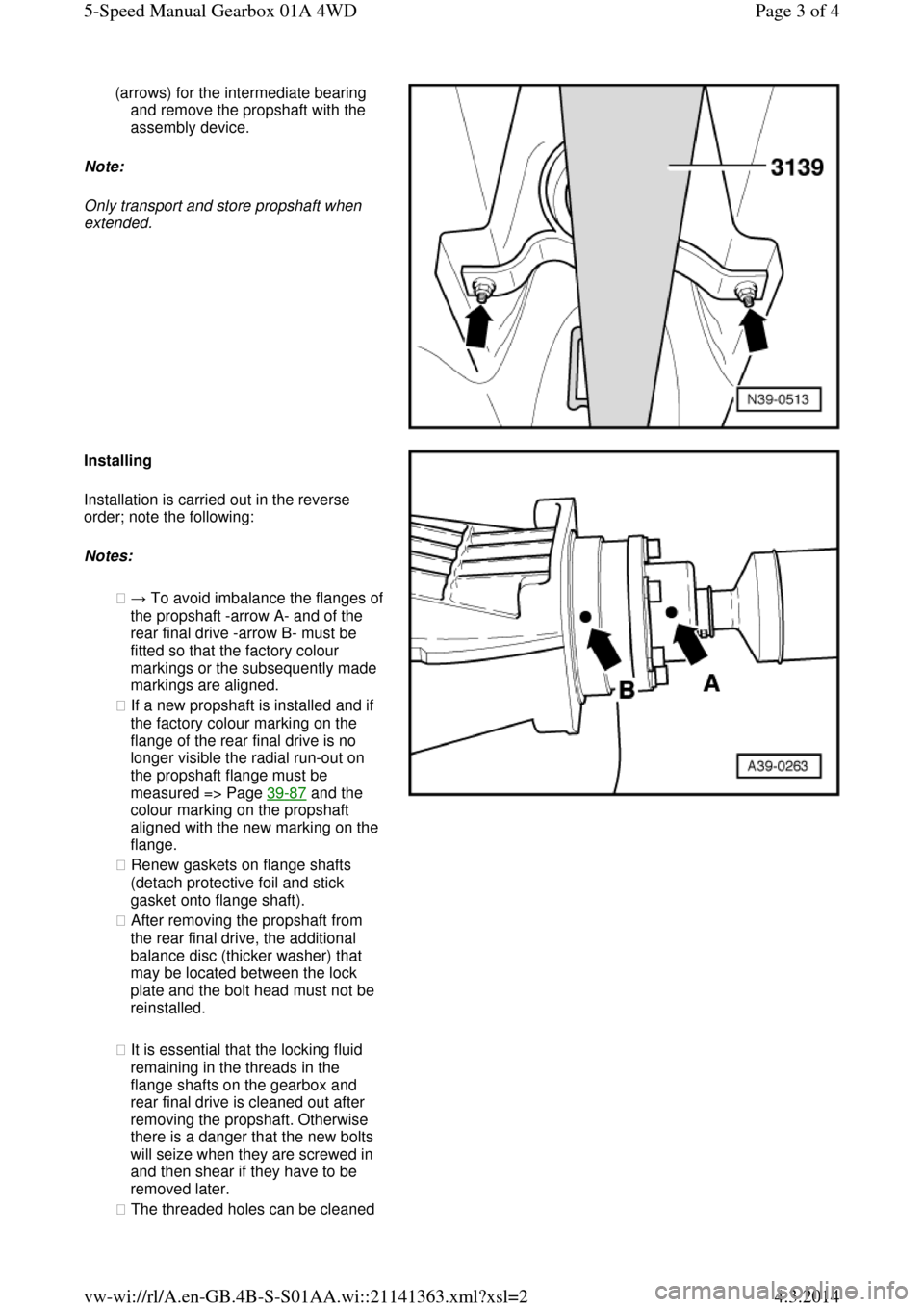

(arrows) for the intermediate bearing

and remove the propshaft with the

assembly device.

Note:

Only transport and store propshaft when

extended. Installing Installation is carried out in the reverse

order; note the following:

Notes:

◆ → To avoid imbalance the flanges of the propshaft -arrow A- and of the

rear final drive -arrow B- must be

fitted so that the factory colour

markings or the subsequently made

markings are aligned.

◆ If a new propshaft is installed and if

the factory colour marking on the

flange of the rear final drive is no

longer visible the radial run-out on

the propshaft flange must be

measured => Page 39-87 and the

colour marking on the propshaft

aligned with the new marking on the

flange.

◆ Renew gaskets on flange shafts

(detach protective foil and stick

gasket onto flange shaft).

◆ After removing the propshaft from

the rear final drive, the additional

balance disc (thicker washer) that

may be located between the lock

plate and the bolt head must not be

reinstalled.

◆ It is essential that the locking fluid

remaining in the threads in the

flange shafts on the gearbox and

rear final drive is cleaned out after

removing the propshaft. Otherwise

there is a danger that the new bolts

will seize when they are screwed in

and then shear if they have to be

removed later.

◆ The threaded holes can be cleaned Page 3 of 45-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141363.xml?xsl=2

Trending: brake light, navigation, lock, fuel, check engine light, light, length