AUDI A6 2000 C5 / 2.G Changing Clutch 5Speed Manual Gearbox

Manufacturer: AUDI, Model Year: 2000, Model line: A6, Model: AUDI A6 2000 C5 / 2.GPages: 71, PDF Size: 1.82 MB

Page 31 of 71

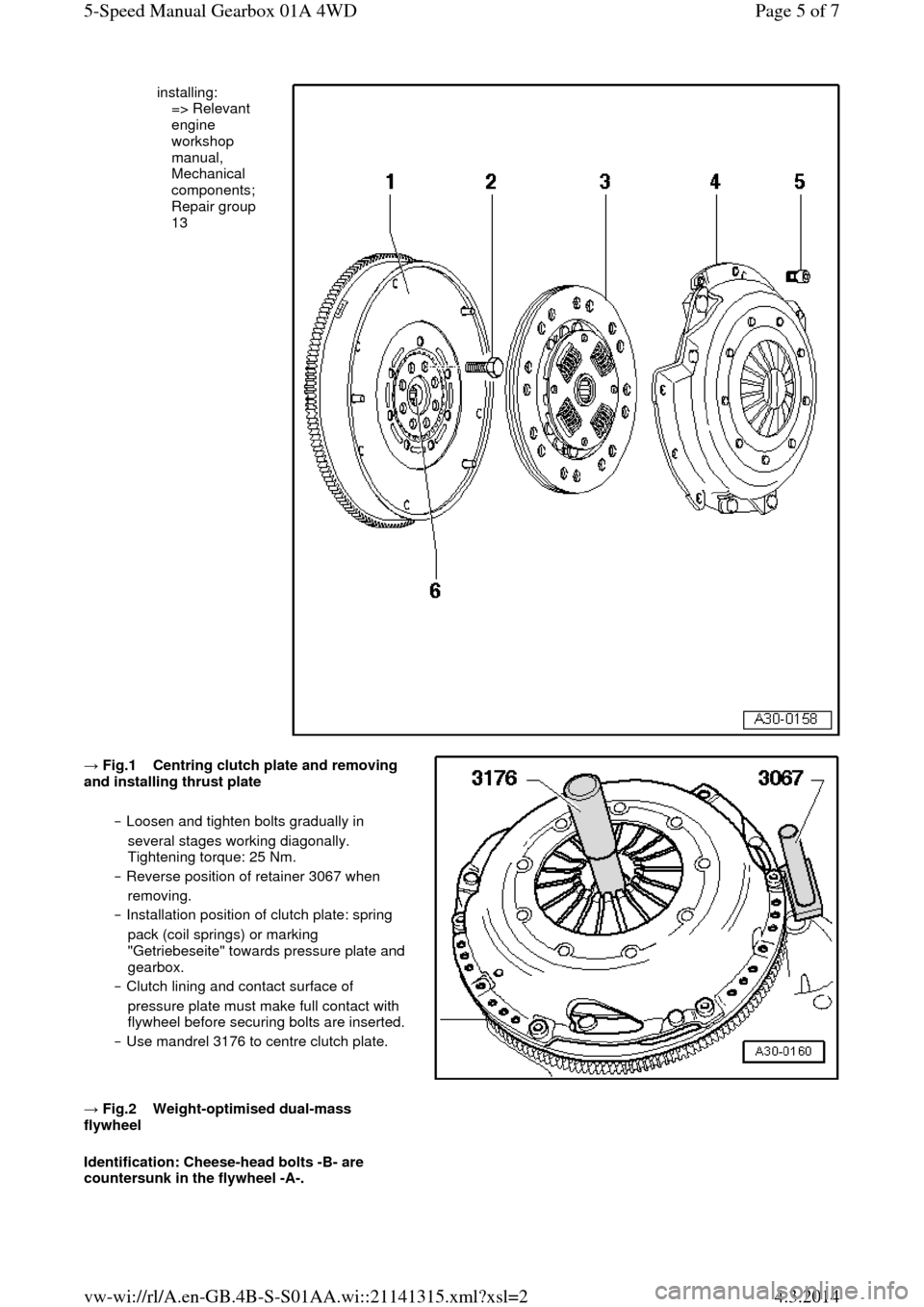

installing:

=> Relevant

engine

workshop

manual,

Mechanical

components;

Repair group

13 → Fig.1 Centring clutch plate and removing and installing thrust plate

‒ Loosen and tighten bolts gradually in

several stages working diagonally.

Tightening torque: 25 Nm.

‒ Reverse position of retainer 3067 when

removing.

‒ Installation position of clutch plate: spring

pack (coil springs) or marking

"Getriebeseite" towards pressure plate and

gearbox.

‒ Clutch lining and contact surface of

pressure plate must make full contact with

flywheel before securing bolts are inserted. ‒ Use mandrel 3176 to centre clutch plate.

→ Fig.2 Weight-optimised dual-mass flywheel

Identification: Cheese-head bolts -B- are

countersunk in the flywheel -A-. Page 5 of 75-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141315.xml?xsl=2

Page 32 of 71

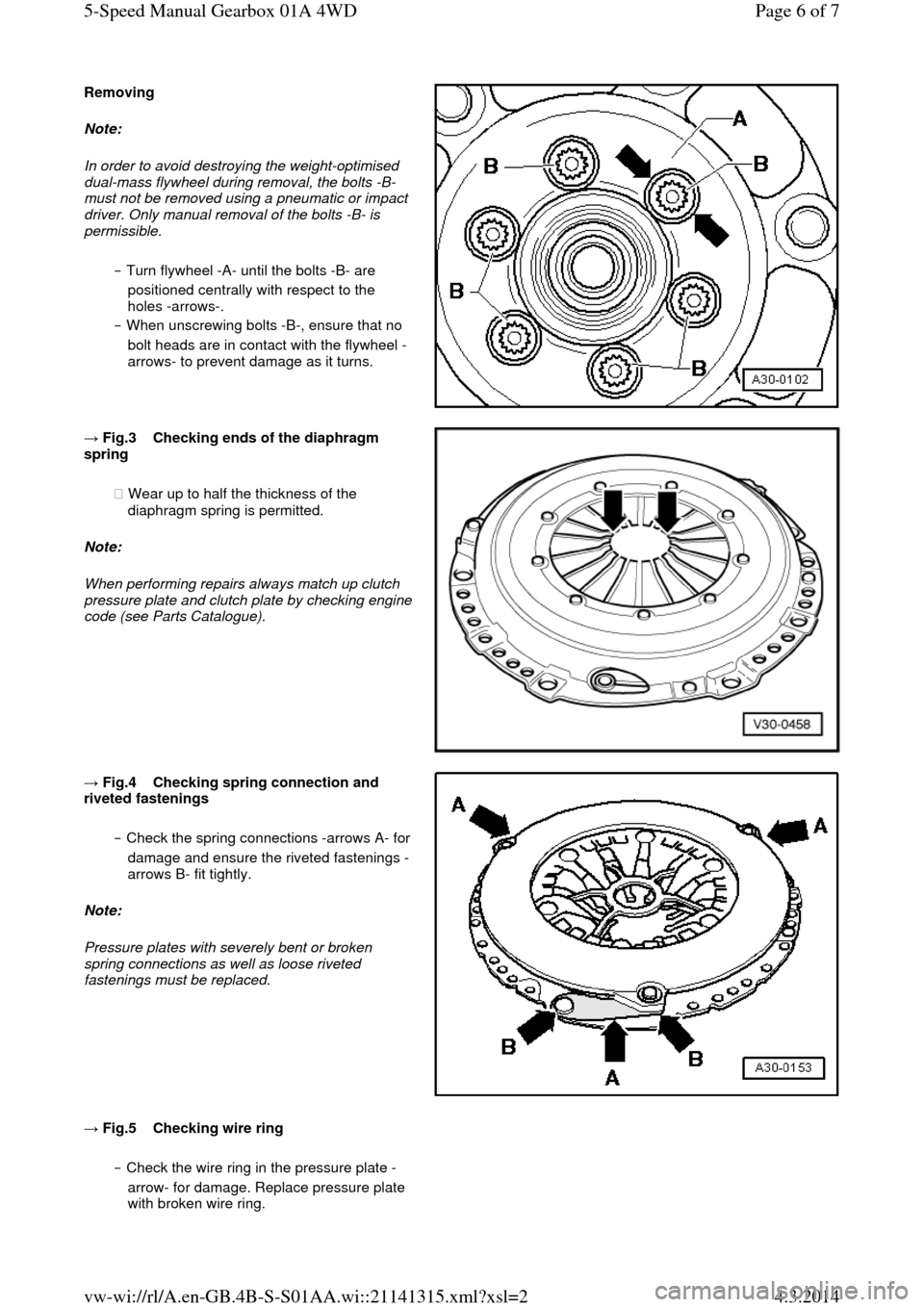

Removing Note:

In order to avoid destroying the weight-optimised

dual-mass flywheel during removal, the bolts -B-

must not be removed using a pneumatic or impact

driver. Only manual removal of the bolts -B- is permissible.

‒ Turn flywheel -A- until the bolts -B- are

positioned centrally with respect to the

holes -arrows-.

‒ When unscrewing bolts -B-, ensure that no

bolt heads are in contact with the flywheel -

arrows- to prevent damage as it turns. → Fig.3 Checking ends of the diaphragm spring

◆ Wear up to half the thickness of the

diaphragm spring is permitted.

Note:

When performing repairs always match up clutch pressure plate and clutch plate by checking engine code (see Parts Catalogue).

→ Fig.4 Checking spring connection and riveted fastenings

‒ Check the spring connections -arrows A- for damage and ensure the riveted fastenings -

arrows B- fit tightly.

Note:

Pressure plates with severely bent or broken

spring connections as well as loose riveted

fastenings must be replaced.

→ Fig.5 Checking wire ring ‒ Check the wire ring in the pressure plate -

arrow- for damage. Replace pressure plate

with broken wire ring. Page 6 of 75-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141315.xml?xsl=2

Page 33 of 71

Page 7 of 75-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141315.xml?xsl=2

Page 34 of 71

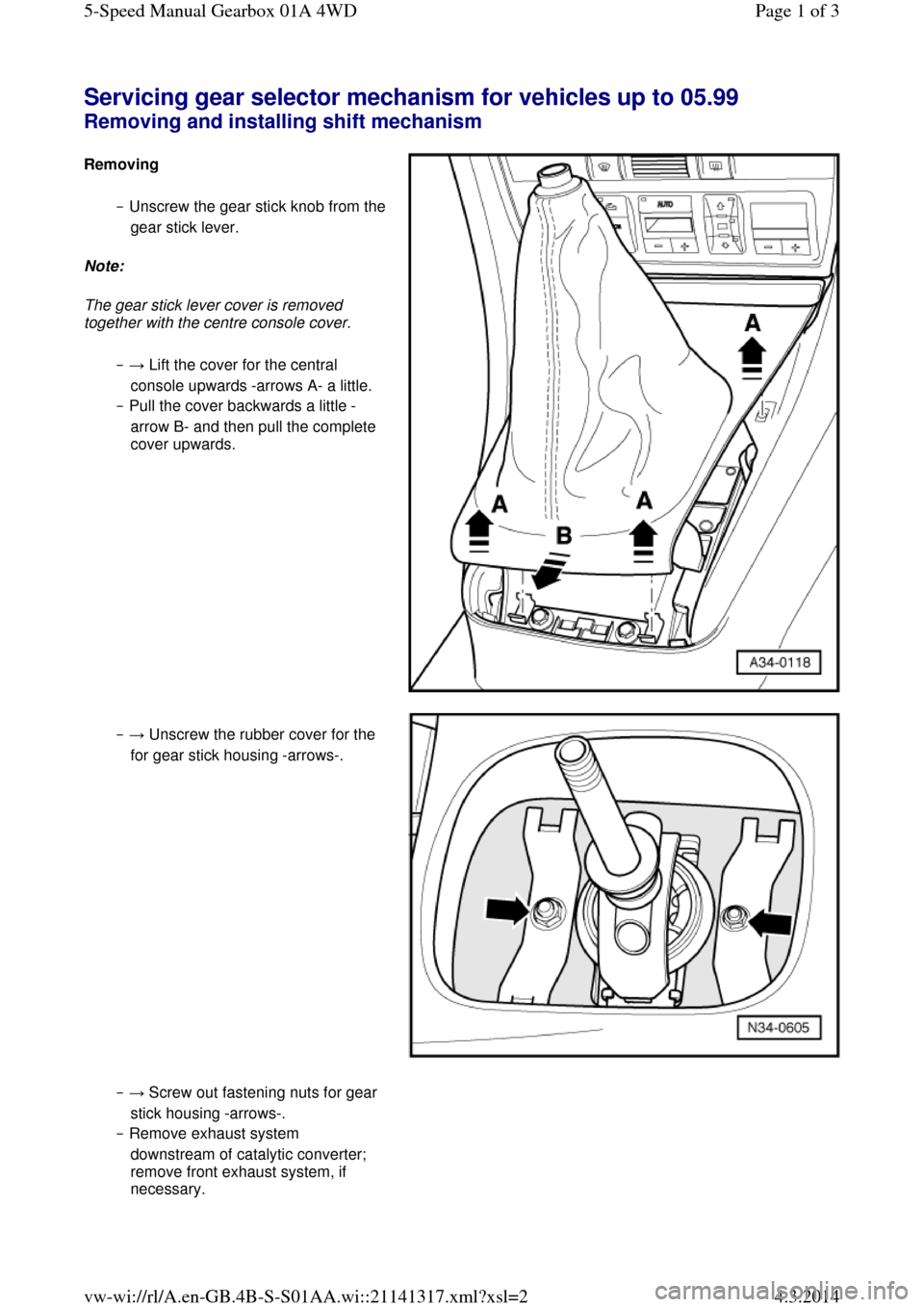

Servicing gear selector mechanism for vehicles up to 05.99 Removing and installing shift mechanism Removing ‒ Unscrew the gear stick knob from the gear stick lever.

Note:

The gear stick lever cover is removed

together with the centre console cover.

‒ → Lift the cover for the central

console upwards -arrows A- a little.

‒ Pull the cover backwards a little -

arrow B- and then pull the complete

cover upwards. ‒ → Unscrew the rubber cover for the

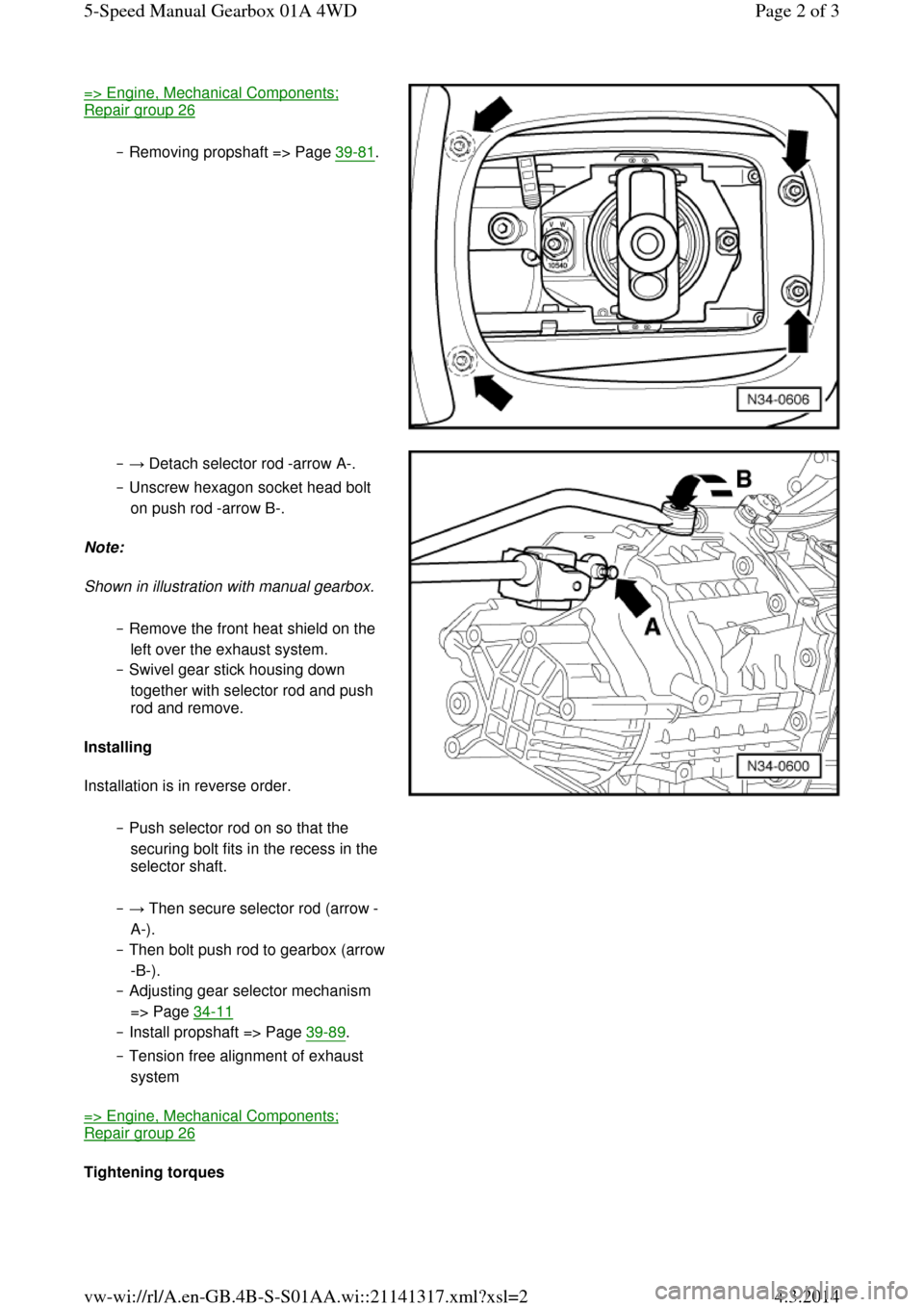

for gear stick housing -arrows-. ‒ → Screw out fastening nuts for gear

stick housing -arrows-.

‒ Remove exhaust system

downstream of catalytic converter;

remove front exhaust system, if

necessary. Page 1 of 35-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141317.xml?xsl=2

Page 35 of 71

=> Engine, Mechanical Components; Repair group 26

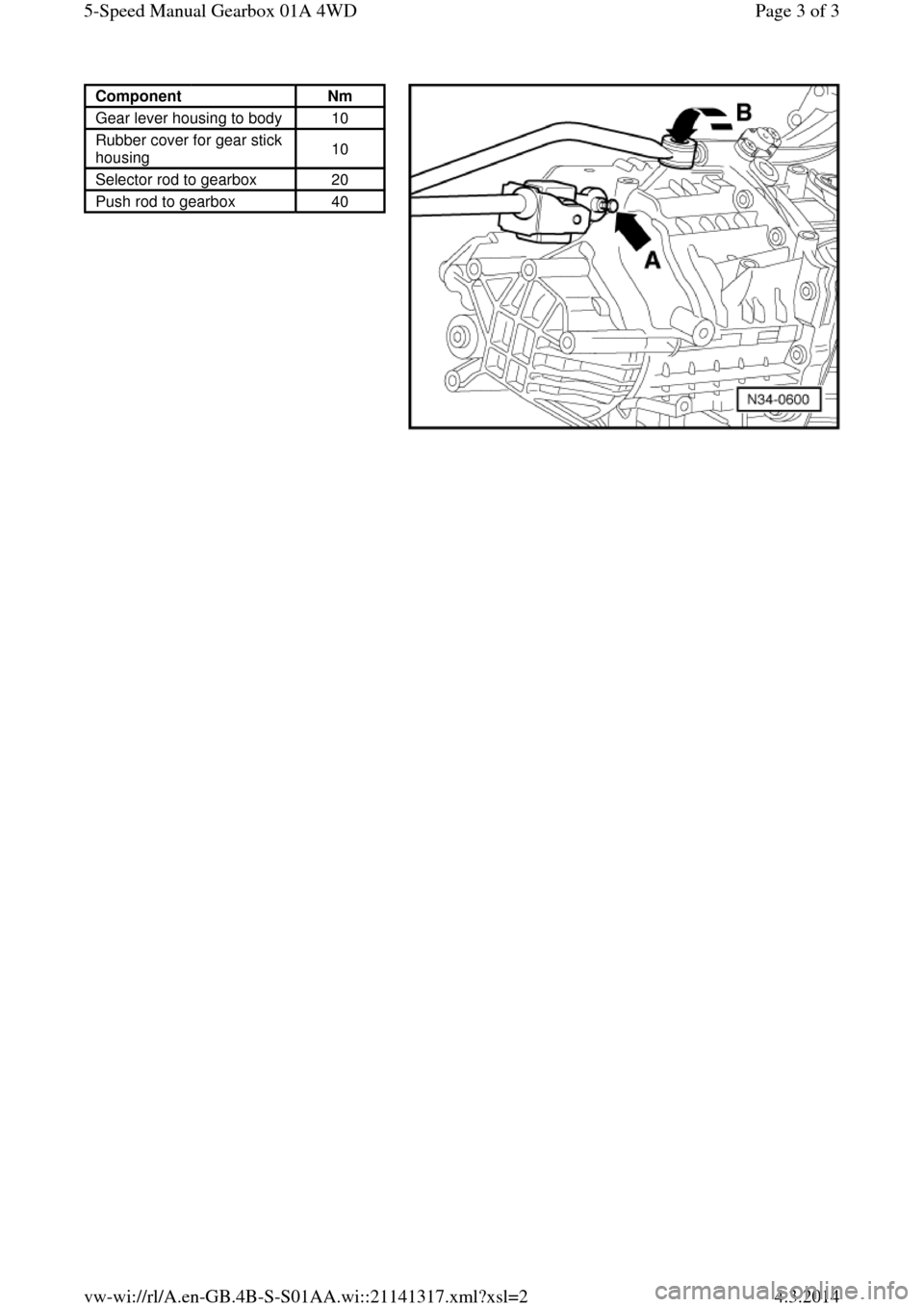

‒ Removing propshaft => Page 39-81. ‒ → Detach selector rod -arrow A-.

‒ Unscrew hexagon socket head bolt

on push rod -arrow B-.

Note:

Shown in illustration with manual gearbox.

‒ Remove the front heat shield on the

left over the exhaust system.

‒ Swivel gear stick housing down

together with selector rod and push

rod and remove.

Installing

Installation is in reverse order.

‒ Push selector rod on so that the

securing bolt fits in the recess in the

selector shaft. ‒ → Then secure selector rod (arrow -

A-).

‒ Then bolt push rod to gearbox (arrow -B-).

‒ Adjusting gear selector mechanism

=> Page 34-11

‒ Install propshaft => Page 39-89.

‒ Tension free alignment of exhaust

system

=> Engine, Mechanical Components; Repair group 26

Tightening torques Page 2 of 35-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141317.xml?xsl=2

Page 36 of 71

Component Nm

Gear lever housing to body 10

Rubber cover for gear stick

housing 10

Selector rod to gearbox 20

Push rod to gearbox 40 Page 3 of 35-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141317.xml?xsl=2

Page 37 of 71

Servicing gear selector mechanism for vehicles up to 05.99 Adjusting gear selector mechanism

Preconditions:

◆ Perfect gear linkage operating and transfer elements.

◆ Gear selector mechanism moves smoothly.

◆ Gearbox, clutch and clutch mechanism must be in proper condition.

◆ Gearbox in neutral.

‒ Unscrew the gear stick knob from the gear stick lever. Note:

The gear stick lever cover is removed

together with the centre console cover.

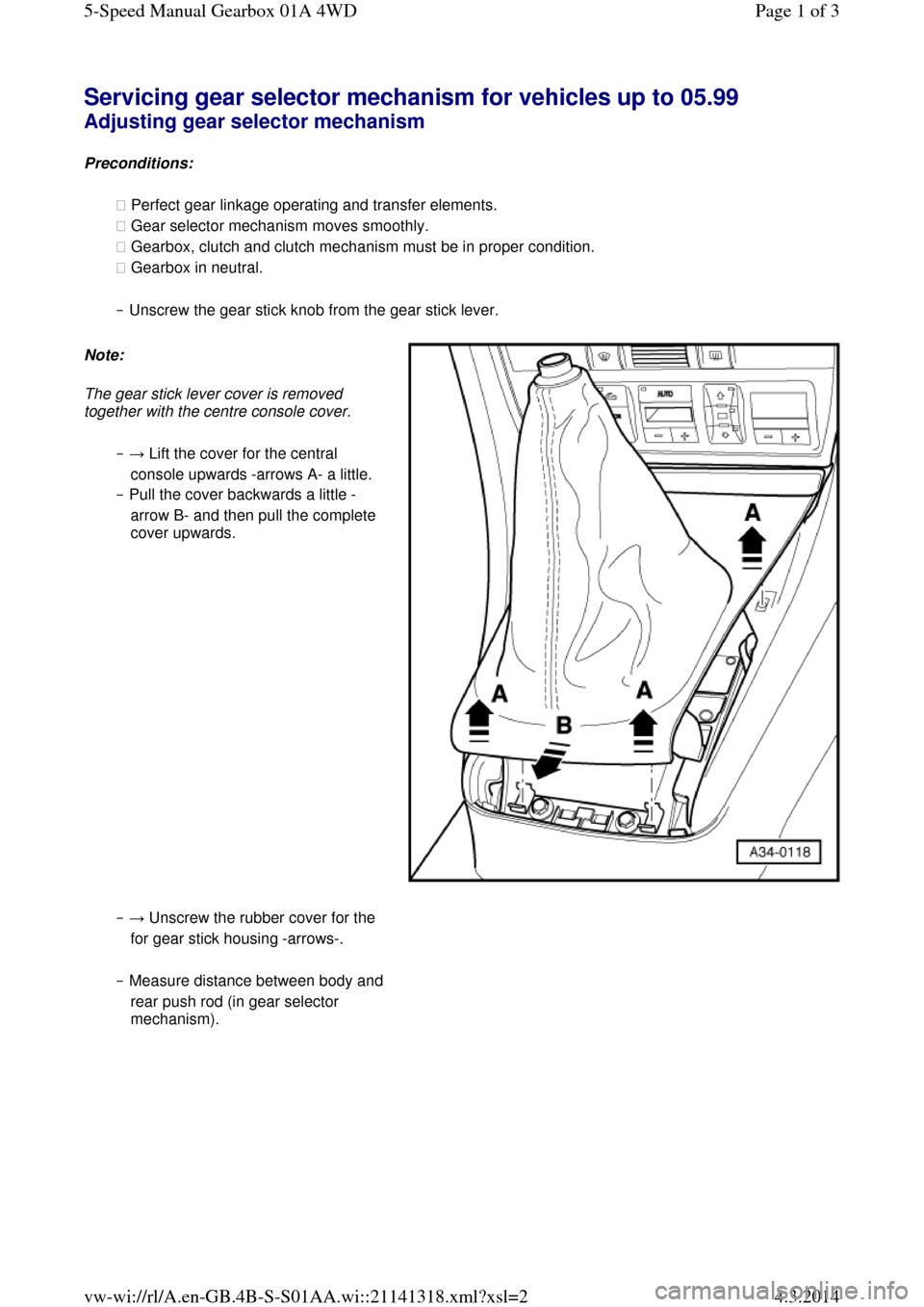

‒ → Lift the cover for the central

console upwards -arrows A- a little.

‒ Pull the cover backwards a little -

arrow B- and then pull the complete

cover upwards.

‒ → Unscrew the rubber cover for the

for gear stick housing -arrows-.

‒ Measure distance between body and rear push rod (in gear selector

mechanism). Page 1 of 35-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141318.xml?xsl=2

Page 38 of 71

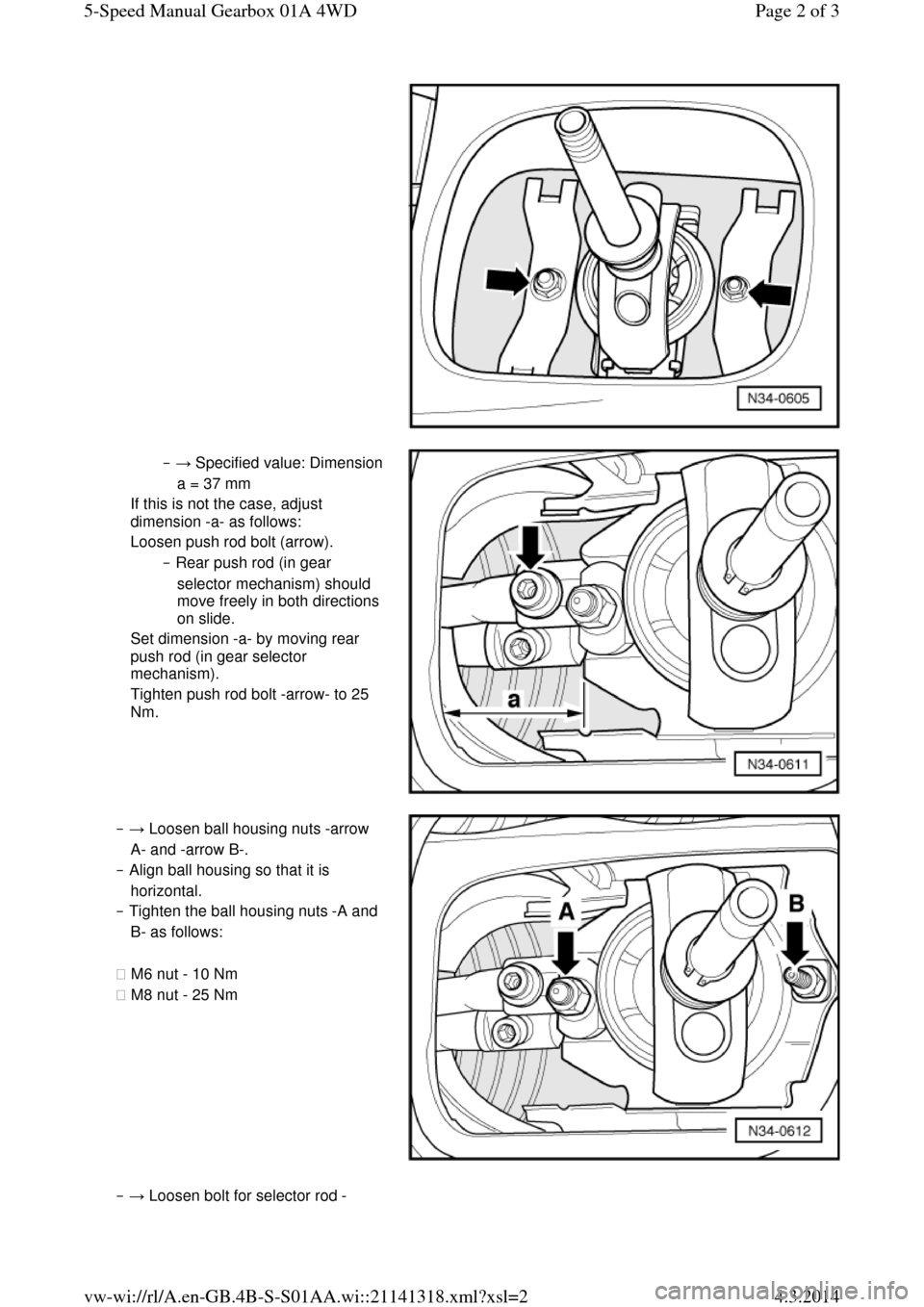

‒ → Specified value: Dimension a = 37 mm

If this is not the case, adjust

dimension -a- as follows:

Loosen push rod bolt (arrow).

‒ Rear push rod (in gear

selector mechanism) should

move freely in both directions

on slide.

Set dimension -a- by moving rear

push rod (in gear selector

mechanism).

Tighten push rod bolt -arrow- to 25

Nm. ‒ → Loosen ball housing nuts -arrow

A- and -arrow B-.

‒ Align ball housing so that it is

horizontal.

‒ Tighten the ball housing nuts -A and

B- as follows:

◆ M6 nut - 10 Nm

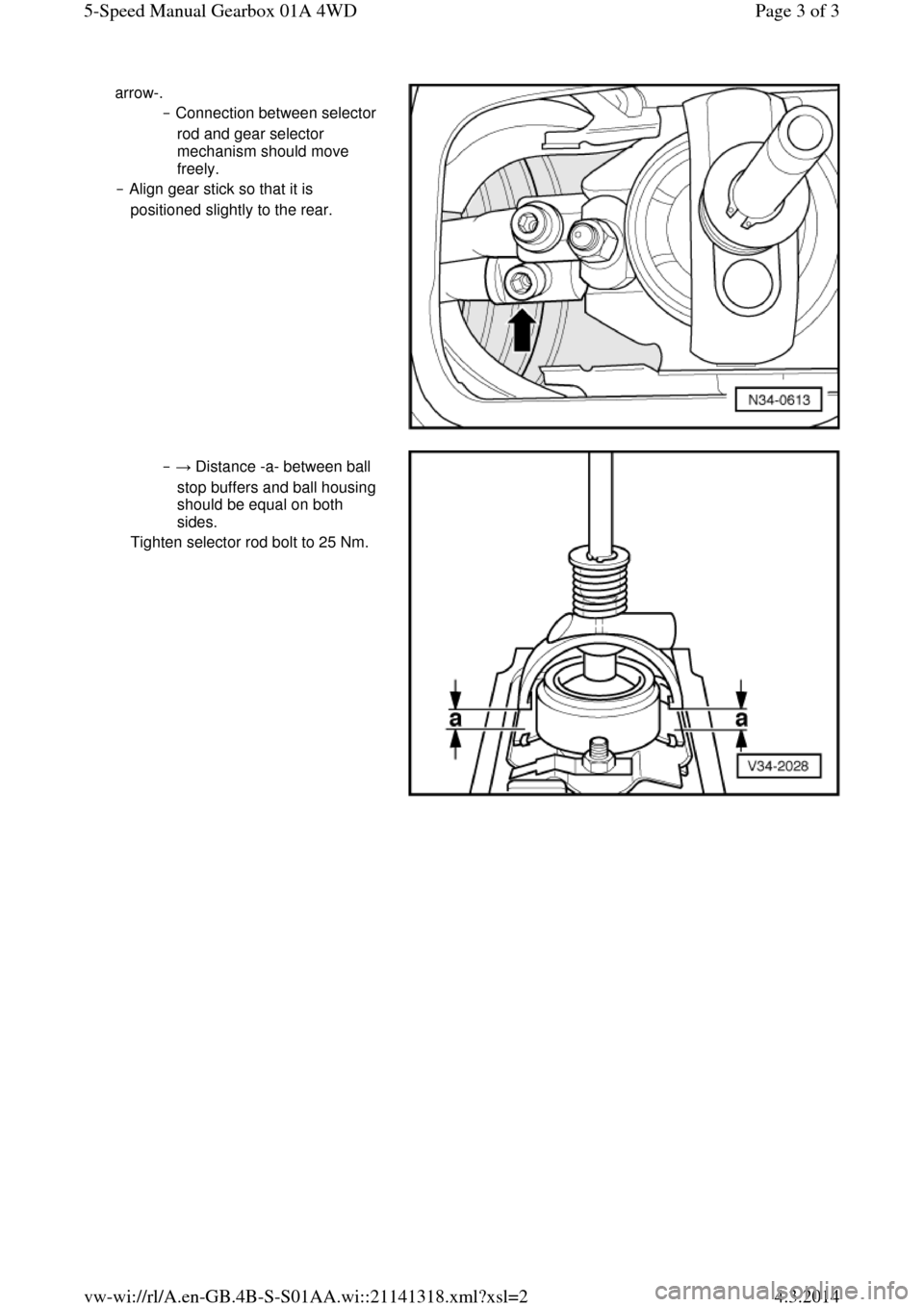

◆ M8 nut - 25 Nm ‒ → Loosen bolt for selector rod -Page 2 of 35-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141318.xml?xsl=2

Page 39 of 71

arrow-.

‒ Connection between selector

rod and gear selector

mechanism should move

freely.

‒ Align gear stick so that it is

positioned slightly to the rear. ‒ → Distance -a- between ball

stop buffers and ball housing

should be equal on both

sides.

Tighten selector rod bolt to 25 Nm. Page 3 of 35-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141318.xml?xsl=2

Page 40 of 71

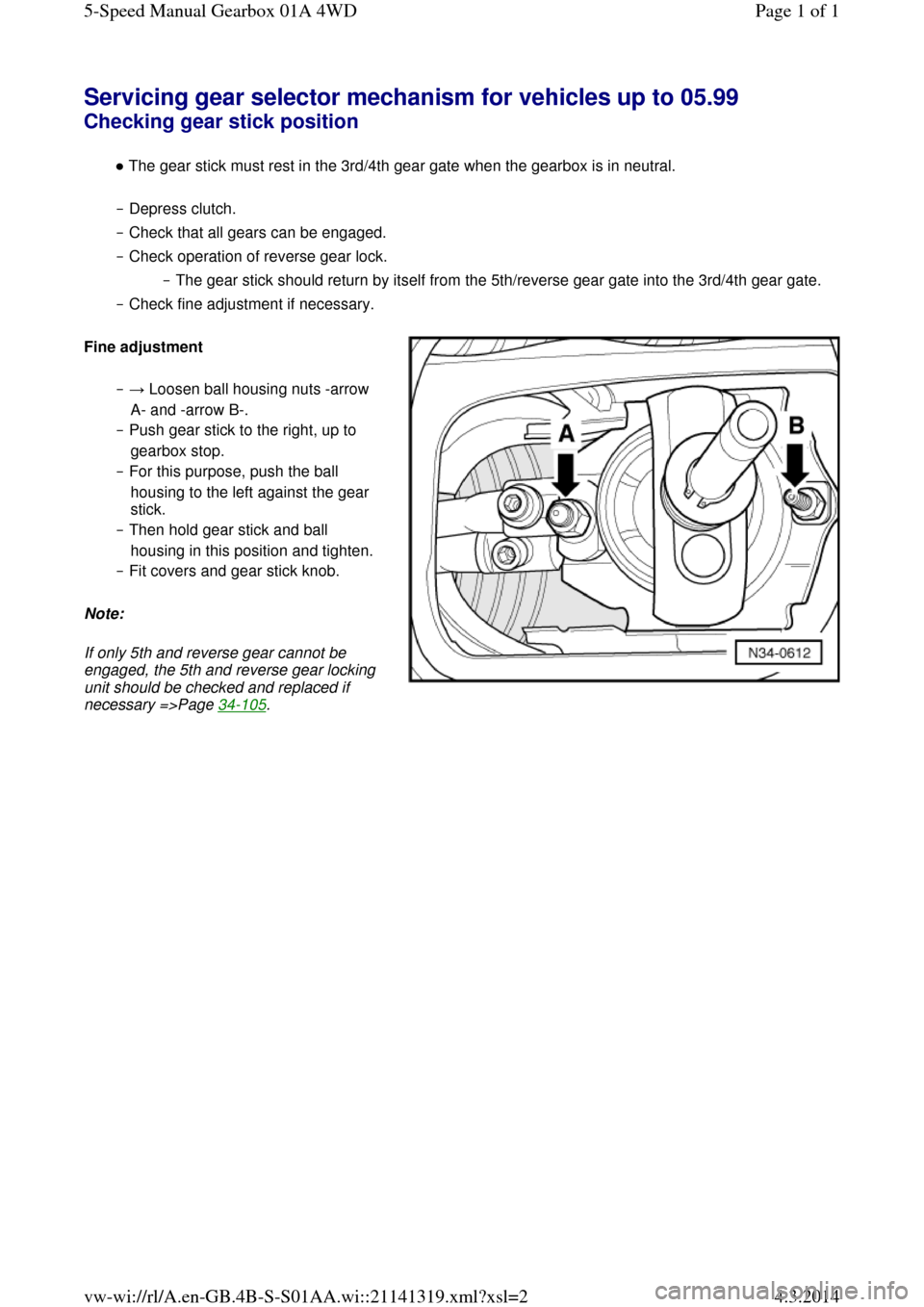

Servicing gear selector mechanism for vehicles up to 05.99 Checking gear stick position

● The gear stick must rest in the 3rd/4th gear gate when the gearbox is in neutral.

‒ Depress clutch.

‒ Check that all gears can be engaged.

‒ Check operation of reverse gear lock.

‒ The gear stick should return by itself from the 5th/reverse gear gate into the 3rd/4th gear gate.

‒ Check fine adjustment if necessary. Fine adjustment ‒ → Loosen ball housing nuts -arrow

A- and -arrow B-.

‒ Push gear stick to the right, up to

gearbox stop.

‒ For this purpose, push the ball

housing to the left against the gear

stick.

‒ Then hold gear stick and ball

housing in this position and tighten.

‒ Fit covers and gear stick knob.

Note:

If only 5th and reverse gear cannot be

engaged, the 5th and reverse gear locking

unit should be checked and replaced if necessary =>Page 34-105. Page 1 of 15-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141319.xml?xsl=2