CHERY TIGGO 2009 Service Repair Manual

Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 131 of 1903

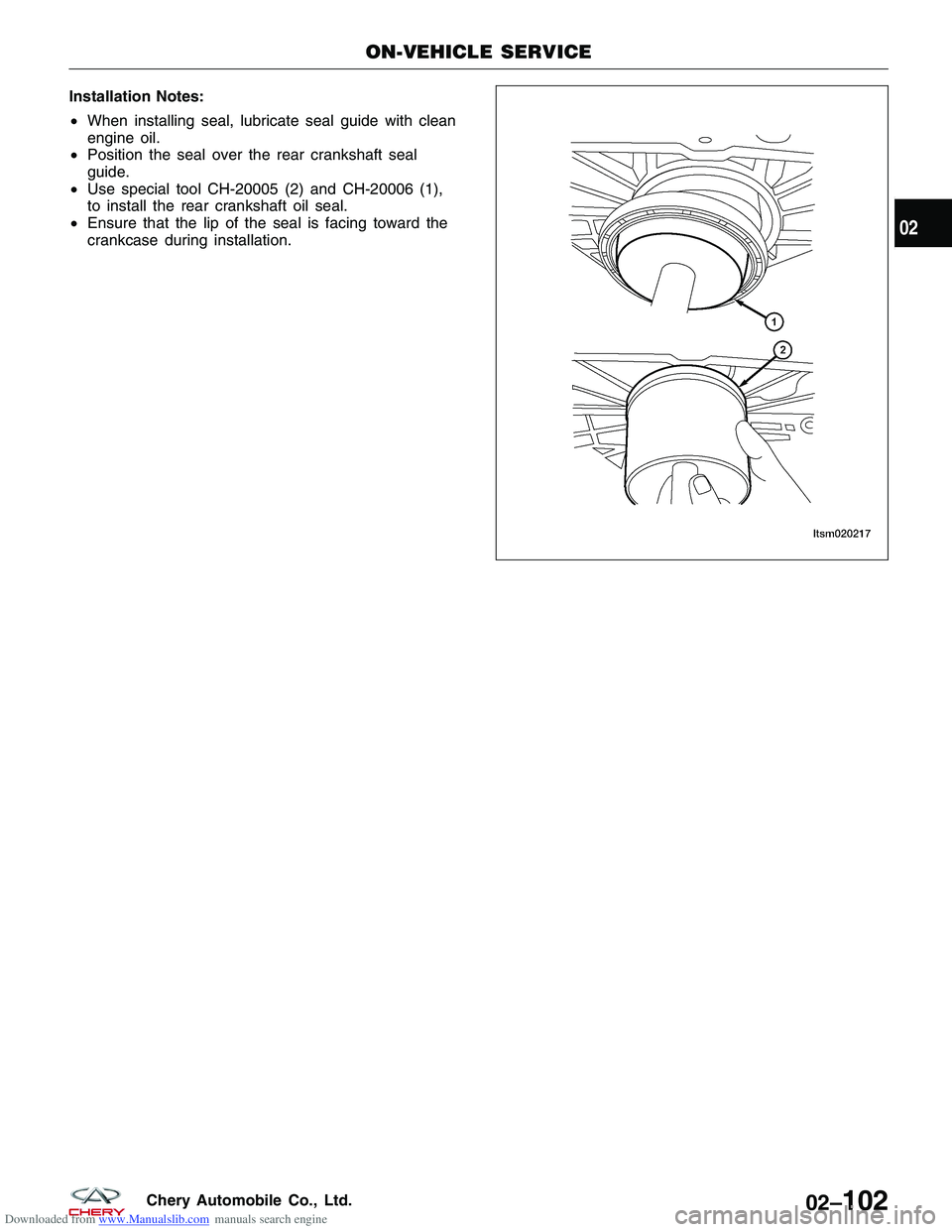

Downloaded from www.Manualslib.com manuals search engine Installation Notes:

•When installing seal, lubricate seal guide with clean

engine oil.

• Position the seal over the rear crankshaft seal

guide.

• Use special tool CH-20005 (2) and CH-20006 (1),

to install the rear crankshaft oil seal.

• Ensure that the lip of the seal is facing toward the

crankcase during installation.

ON-VEHICLE SERVICE

LTSM020217

02

02–102Chery Automobile Co., Ltd.

Page 132 of 1903

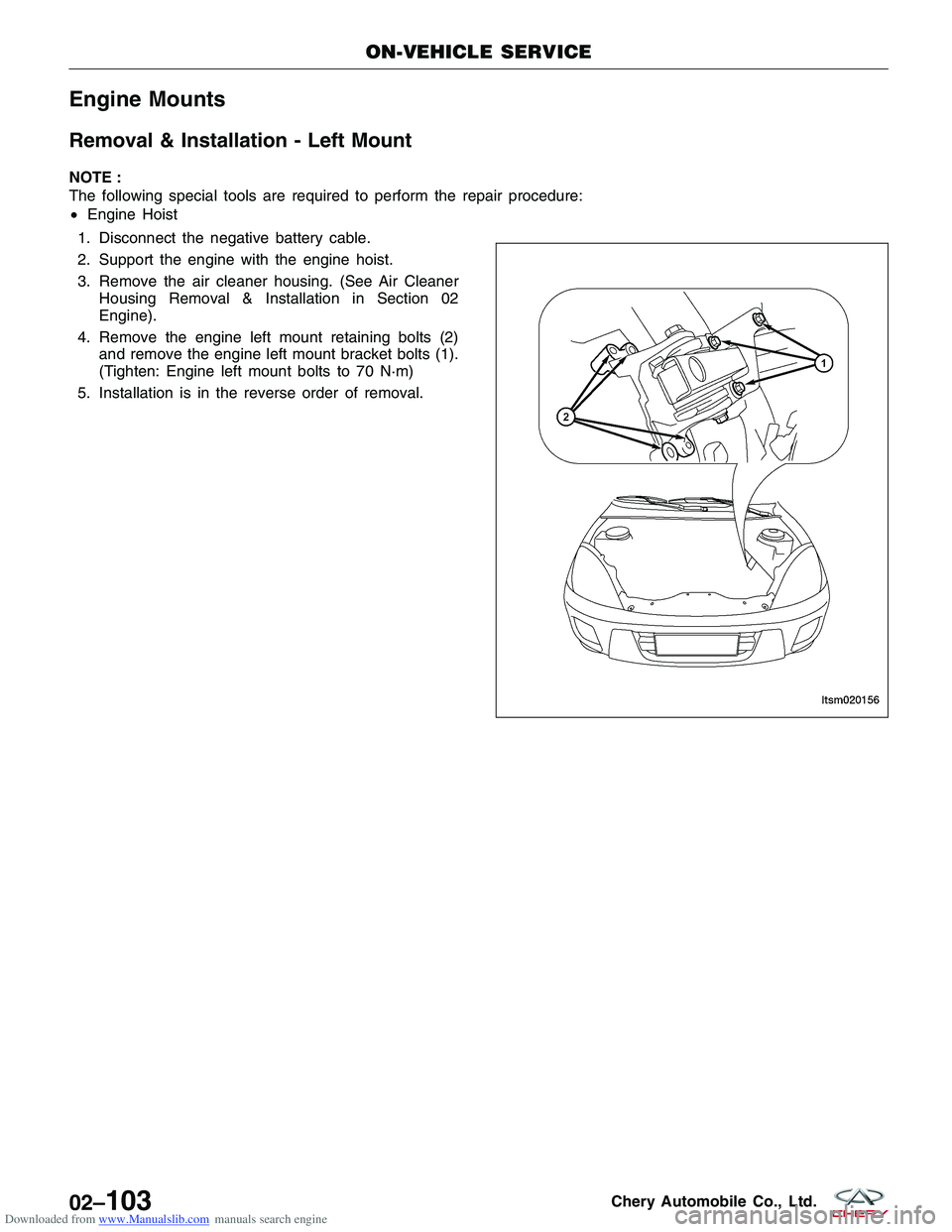

Downloaded from www.Manualslib.com manuals search engine Engine Mounts

Removal & Installation - Left Mount

NOTE :

The following special tools are required to perform the repair procedure:

•Engine Hoist

1. Disconnect the negative battery cable.

2. Support the engine with the engine hoist.

3. Remove the air cleaner housing. (See Air Cleaner Housing Removal & Installation in Section 02

Engine).

4. Remove the engine left mount retaining bolts (2) and remove the engine left mount bracket bolts (1).

(Tighten: Engine left mount bolts to 70 N·m)

5. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM020156

02–103Chery Automobile Co., Ltd.

Page 133 of 1903

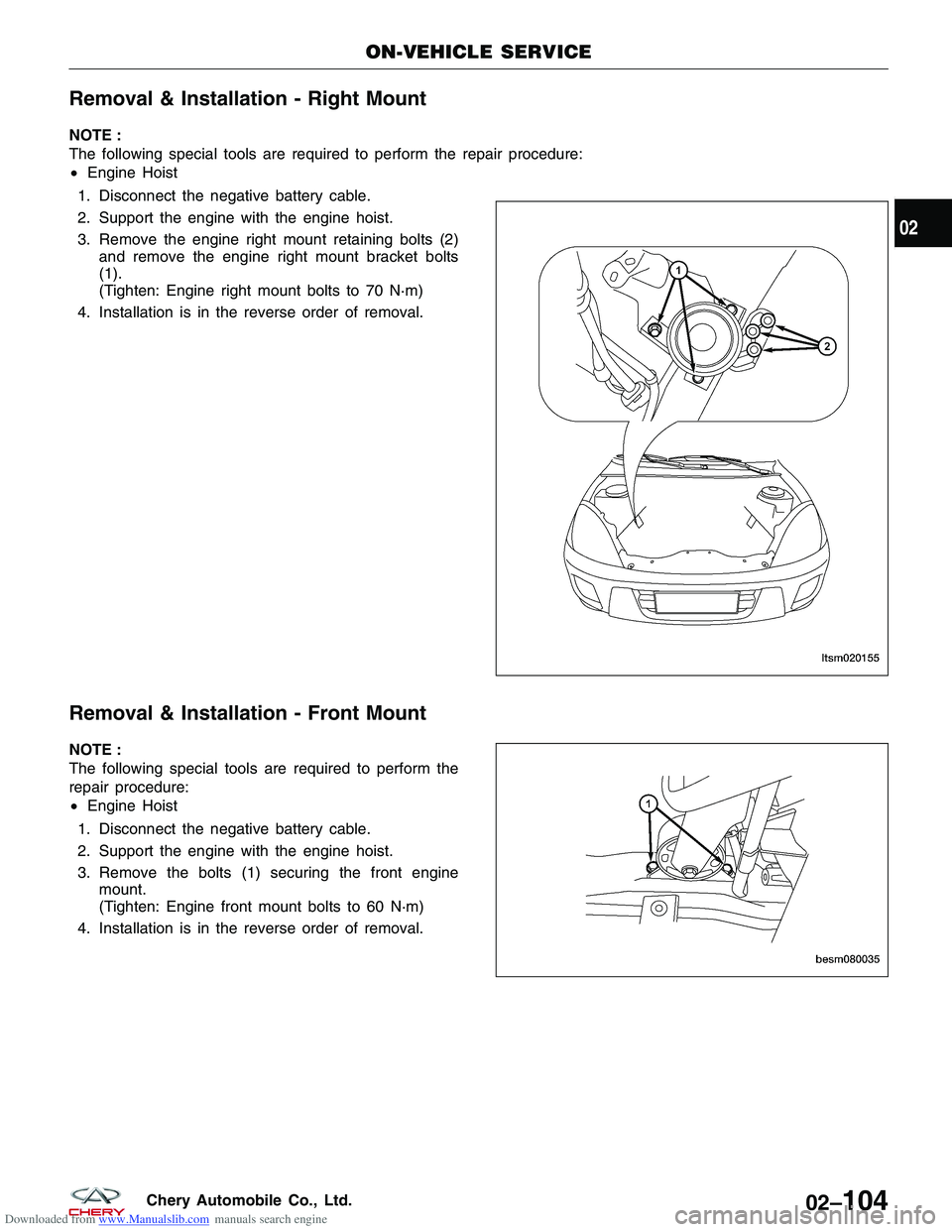

Downloaded from www.Manualslib.com manuals search engine Removal & Installation - Right Mount

NOTE :

The following special tools are required to perform the repair procedure:

•Engine Hoist

1. Disconnect the negative battery cable.

2. Support the engine with the engine hoist.

3. Remove the engine right mount retaining bolts (2) and remove the engine right mount bracket bolts

(1).

(Tighten: Engine right mount bolts to 70 N·m)

4. Installation is in the reverse order of removal.

Removal & Installation - Front Mount

NOTE :

The following special tools are required to perform the

repair procedure:

• Engine Hoist

1. Disconnect the negative battery cable.

2. Support the engine with the engine hoist.

3. Remove the bolts (1) securing the front engine mount.

(Tighten: Engine front mount bolts to 60 N·m)

4. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM020155

BESM080035

02

02–104Chery Automobile Co., Ltd.

Page 134 of 1903

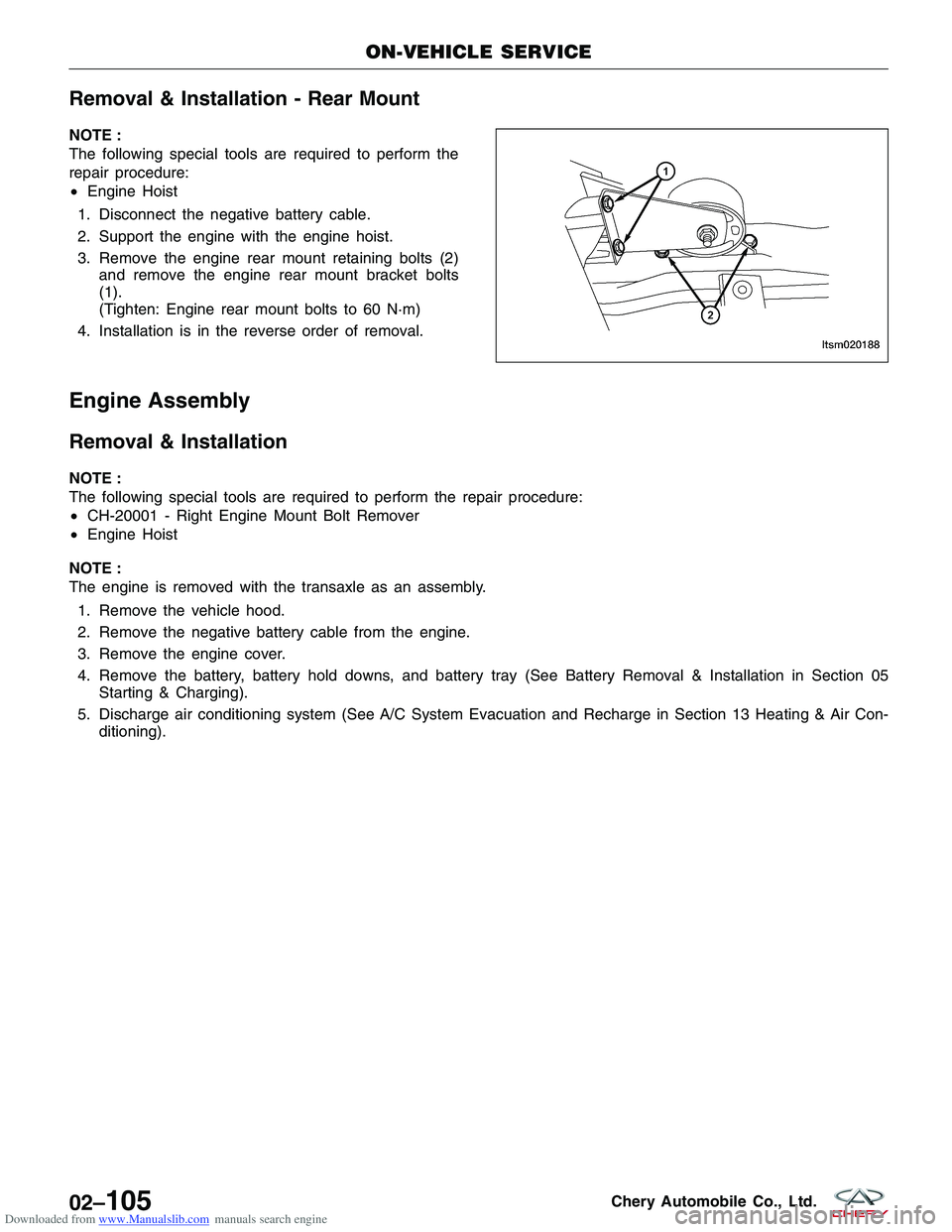

Downloaded from www.Manualslib.com manuals search engine Removal & Installation - Rear Mount

NOTE :

The following special tools are required to perform the

repair procedure:

•Engine Hoist

1. Disconnect the negative battery cable.

2. Support the engine with the engine hoist.

3. Remove the engine rear mount retaining bolts (2) and remove the engine rear mount bracket bolts

(1).

(Tighten: Engine rear mount bolts to 60 N·m)

4. Installation is in the reverse order of removal.

Engine Assembly

Removal & Installation

NOTE :

The following special tools are required to perform the repair procedure:

• CH-20001 - Right Engine Mount Bolt Remover

• Engine Hoist

NOTE :

The engine is removed with the transaxle as an assembly. 1. Remove the vehicle hood.

2. Remove the negative battery cable from the engine.

3. Remove the engine cover.

4. Remove the battery, battery hold downs, and battery tray (See Battery Removal & Installation in Section 05 Starting & Charging).

5. Discharge air conditioning system (See A/C System Evacuation and Recharge in Section 13 Heating & Air Con- ditioning).

ON-VEHICLE SERVICE

LTSM020188

02–105Chery Automobile Co., Ltd.

Page 135 of 1903

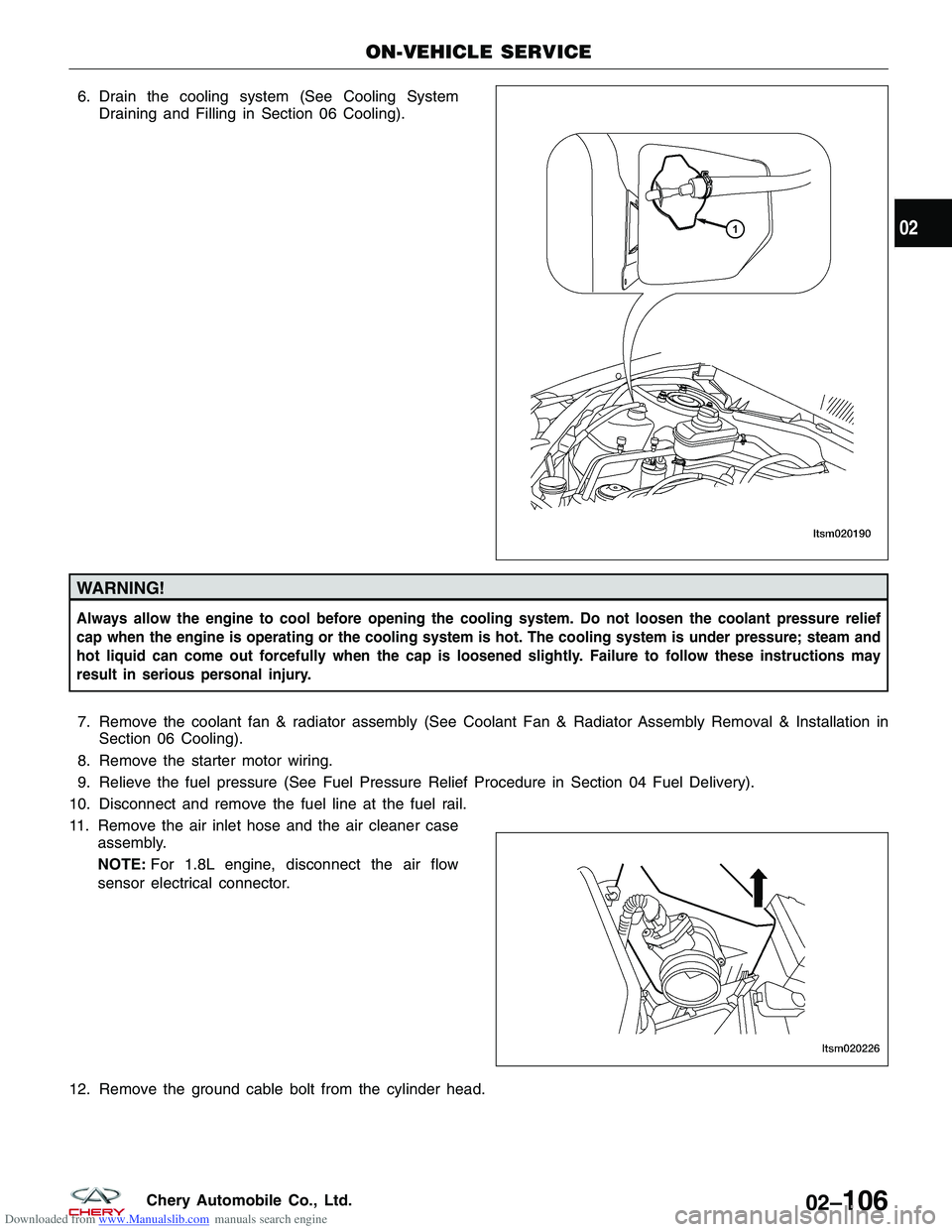

Downloaded from www.Manualslib.com manuals search engine 6. Drain the cooling system (See Cooling SystemDraining and Filling in Section 06 Cooling).

WARNING!

Always allow the engine to cool before opening the cooling system. Do not loosen the coolant pressure relief

cap when the engine is operating or the cooling system is hot. The cooling system is under pressure; steam and

hot liquid can come out forcefully when the cap is loosened slightly. Failure to follow these instructions may

result in serious personal injury.

7. Remove the coolant fan & radiator assembly (See Coolant Fan & Radiator Assembly Removal & Installation inSection 06 Cooling).

8. Remove the starter motor wiring.

9. Relieve the fuel pressure (See Fuel Pressure Relief Procedure in Section 04 Fuel Delivery).

10. Disconnect and remove the fuel line at the fuel rail.

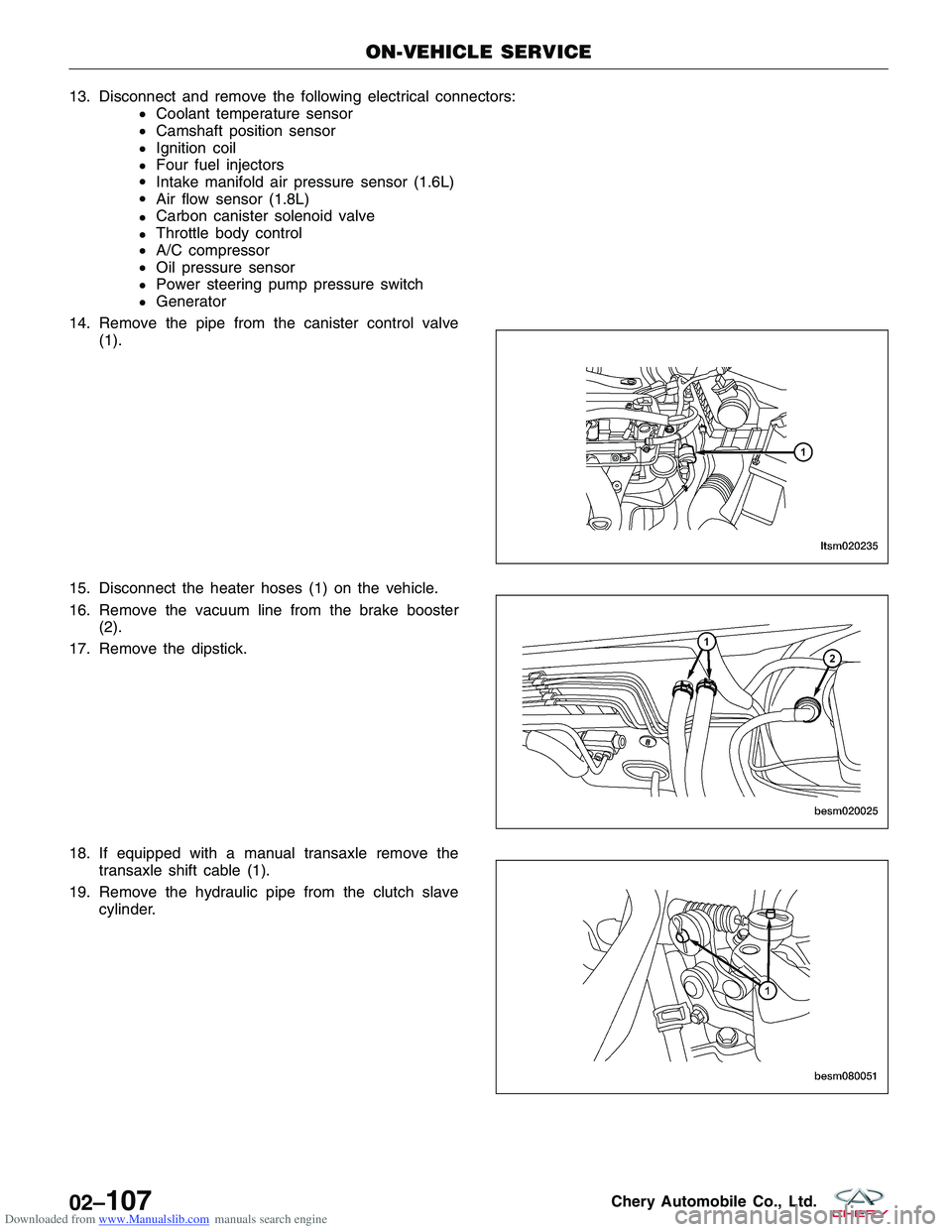

11. Remove the air inlet hose and the air cleaner case assembly.

NOTE: For 1.8L engine, disconnect the air flow

sensor electrical connector.

12. Remove the ground cable bolt from the cylinder head.

ON-VEHICLE SERVICE

LTSM020190

LTSM020226

02

02–106Chery Automobile Co., Ltd.

Page 136 of 1903

Downloaded from www.Manualslib.com manuals search engine 13.Disconnectandremovethefollowingelectricalconnectors:

€Coolanttemperaturesensor

€Camshaftpositionsensor

€Ignitioncoil

€Fourfuelinjectors

€Intakemanifoldairpressuresensor(1.6L)

€Airflowsensor(1.8L)

€Carboncanistersolenoidvalve

€Throttlebodycontrol

€A/Ccompressor

€Oilpressuresensor

€Powersteeringpumppressureswitch

€Generator

14.Removethepipefromthecanistercontrolvalve

(1).

15.Disconnecttheheaterhoses(1)onthevehicle.

16.Removethevacuumlinefromthebrakebooster

(2).

17.Removethedipstick.

18.Ifequippedwithamanualtransaxleremovethe

transaxleshiftcable(1).

19.Removethehydraulicpipefromtheclutchslave

cylinder.

ON-VEHICLESERVICE

LTSM020235

BESM020025

BESM080051

02–107CheryAutomobileCo.,Ltd.

Page 137 of 1903

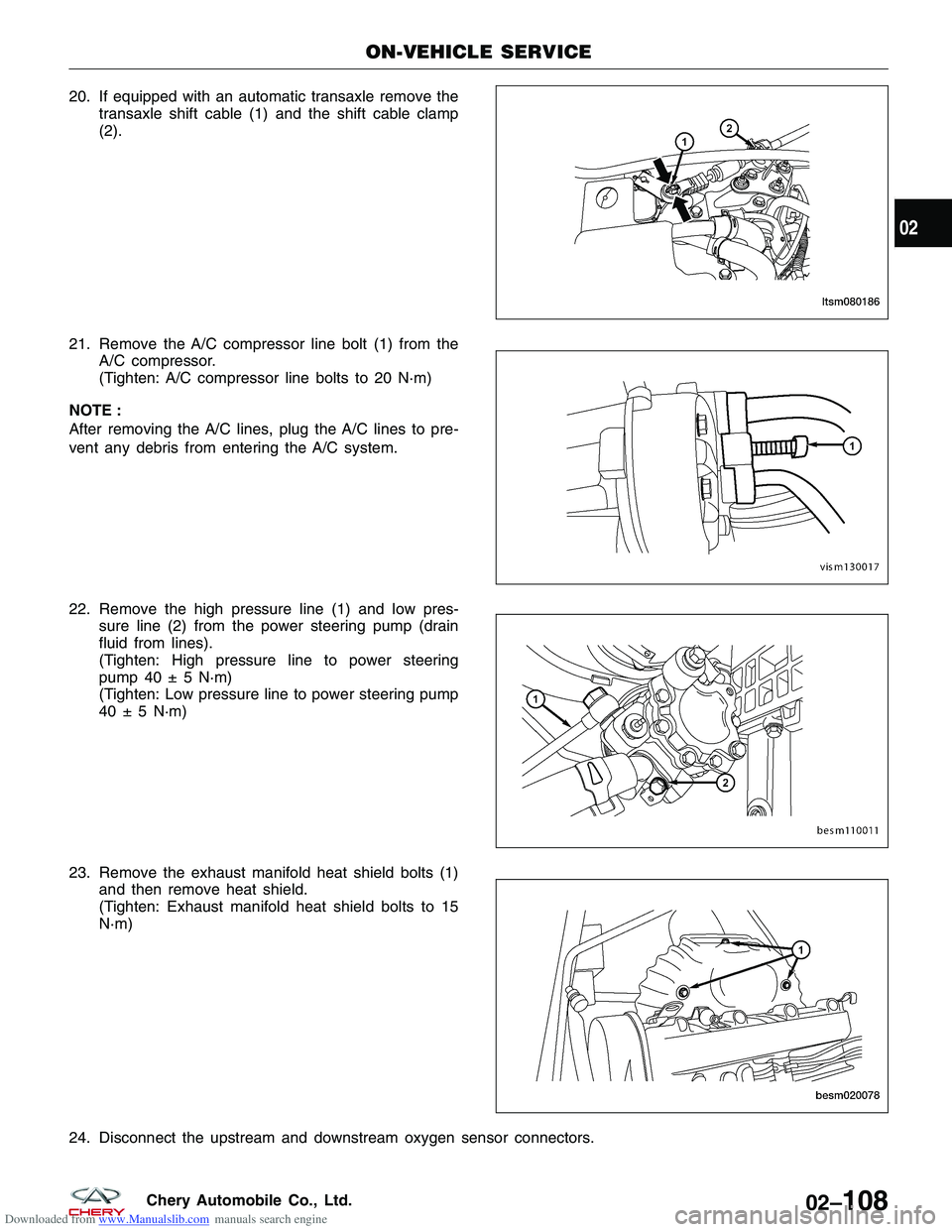

Downloaded from www.Manualslib.com manuals search engine 20. If equipped with an automatic transaxle remove thetransaxle shift cable (1) and the shift cable clamp

(2).

21. Remove the A/C compressor line bolt (1) from the A/C compressor.

(Tighten: A/C compressor line bolts to 20 N·m)

NOTE :

After removing the A/C lines, plug the A/C lines to pre-

vent any debris from entering the A/C system.

22. Remove the high pressure line (1) and low pres- sure line (2) from the power steering pump (drain

fluid from lines).

(Tighten: High pressure line to power steering

pump 40 ± 5 N·m)

(Tighten: Low pressure line to power steering pump

40 ± 5 N·m)

23. Remove the exhaust manifold heat shield bolts (1) and then remove heat shield.

(Tighten: Exhaust manifold heat shield bolts to 15

N·m)

24. Disconnect the upstream and downstream oxygen sensor connectors.

ON-VEHICLE SERVICE

LTSM080186

VISM130017

BESM110011

BESM020078

02

02–108Chery Automobile Co., Ltd.

Page 138 of 1903

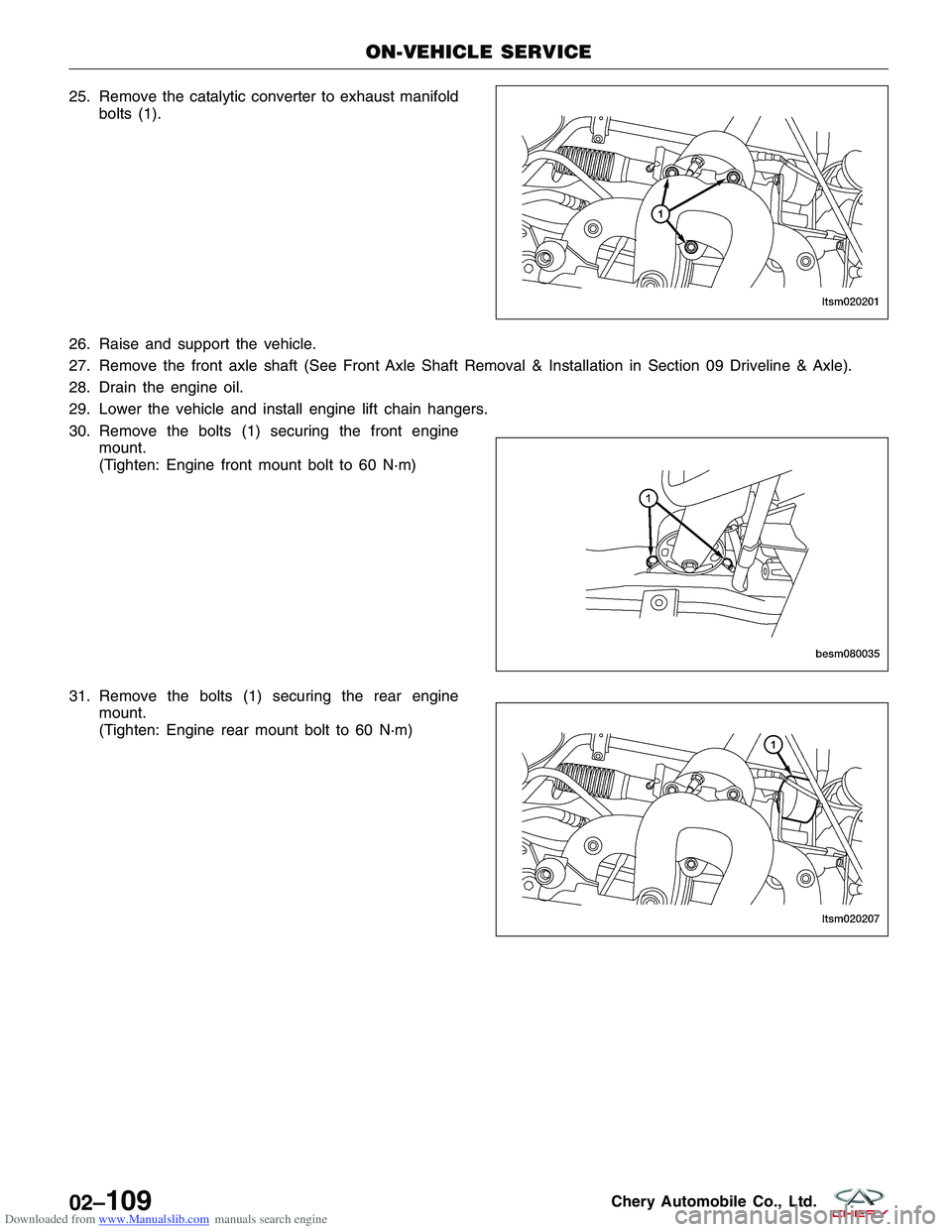

Downloaded from www.Manualslib.com manuals search engine 25. Remove the catalytic converter to exhaust manifoldbolts (1).

26. Raise and support the vehicle.

27. Remove the front axle shaft (See Front Axle Shaft Removal & Installation in Section 09 Driveline & Axle).

28. Drain the engine oil.

29. Lower the vehicle and install engine lift chain hangers.

30. Remove the bolts (1) securing the front engine mount.

(Tighten: Engine front mount bolt to 60 N·m)

31. Remove the bolts (1) securing the rear engine mount.

(Tighten: Engine rear mount bolt to 60 N·m)

ON-VEHICLE SERVICE

LTSM020201

BESM080035 LTSM020207

02–109Chery Automobile Co., Ltd.

Page 139 of 1903

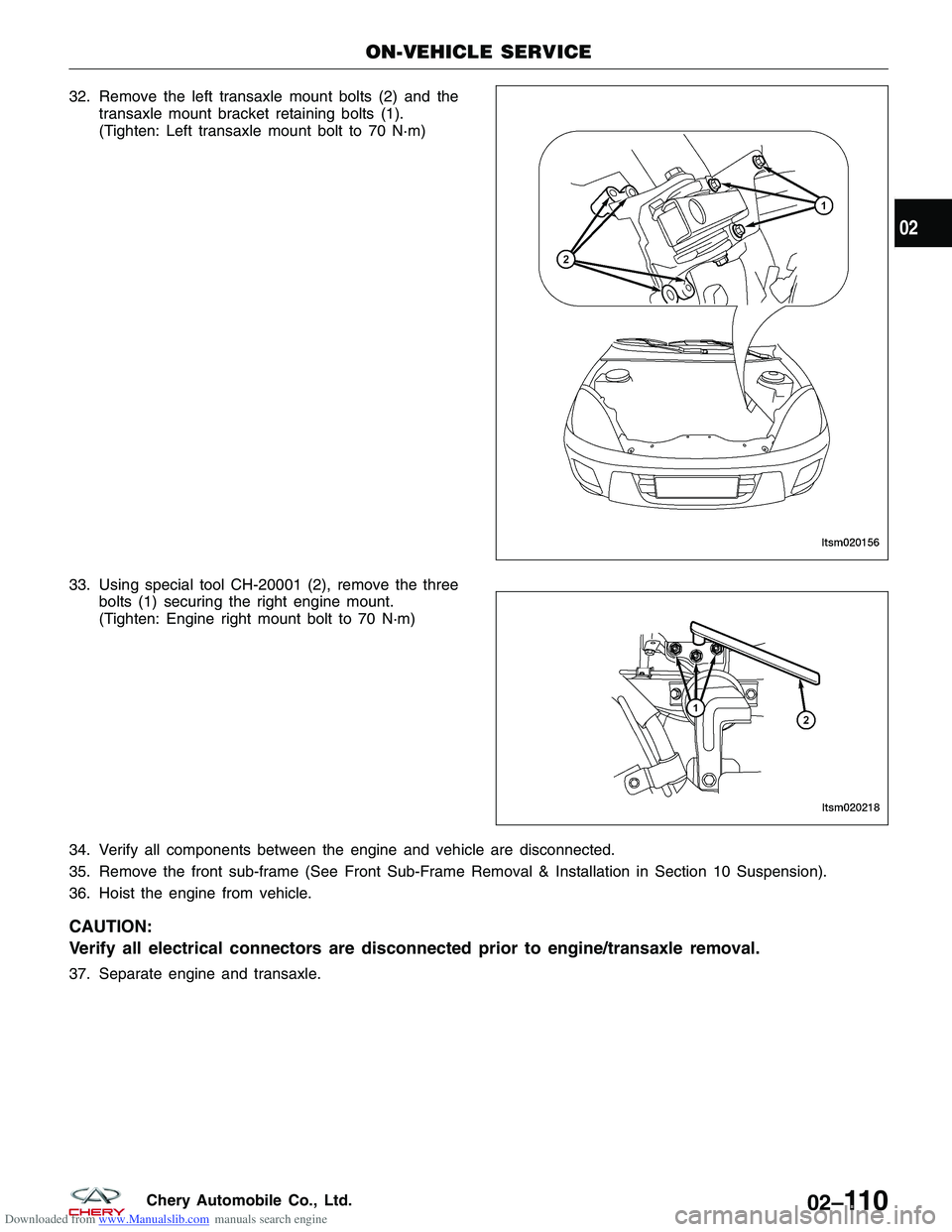

Downloaded from www.Manualslib.com manuals search engine 32. Remove the left transaxle mount bolts (2) and thetransaxle mount bracket retaining bolts (1).

(Tighten: Left transaxle mount bolt to 70 N·m)

33. Using special tool CH-20001 (2), remove the three bolts (1) securing the right engine mount.

(Tighten: Engine right mount bolt to 70 N·m)

34. Verify all components between the engine and vehicle are disconnected.

35. Remove the front sub-frame (See Front Sub-Frame Removal & Installation in Section 10 Suspension).

36. Hoist the engine from vehicle.

CAUTION:

Verify all electrical connectors are disconnected prior to engine/transaxle removal.

37. Separate engine and transaxle.

ON-VEHICLE SERVICE

LTSM020156

LTSM020218

02

02–11 0Chery Automobile Co., Ltd.

Page 140 of 1903

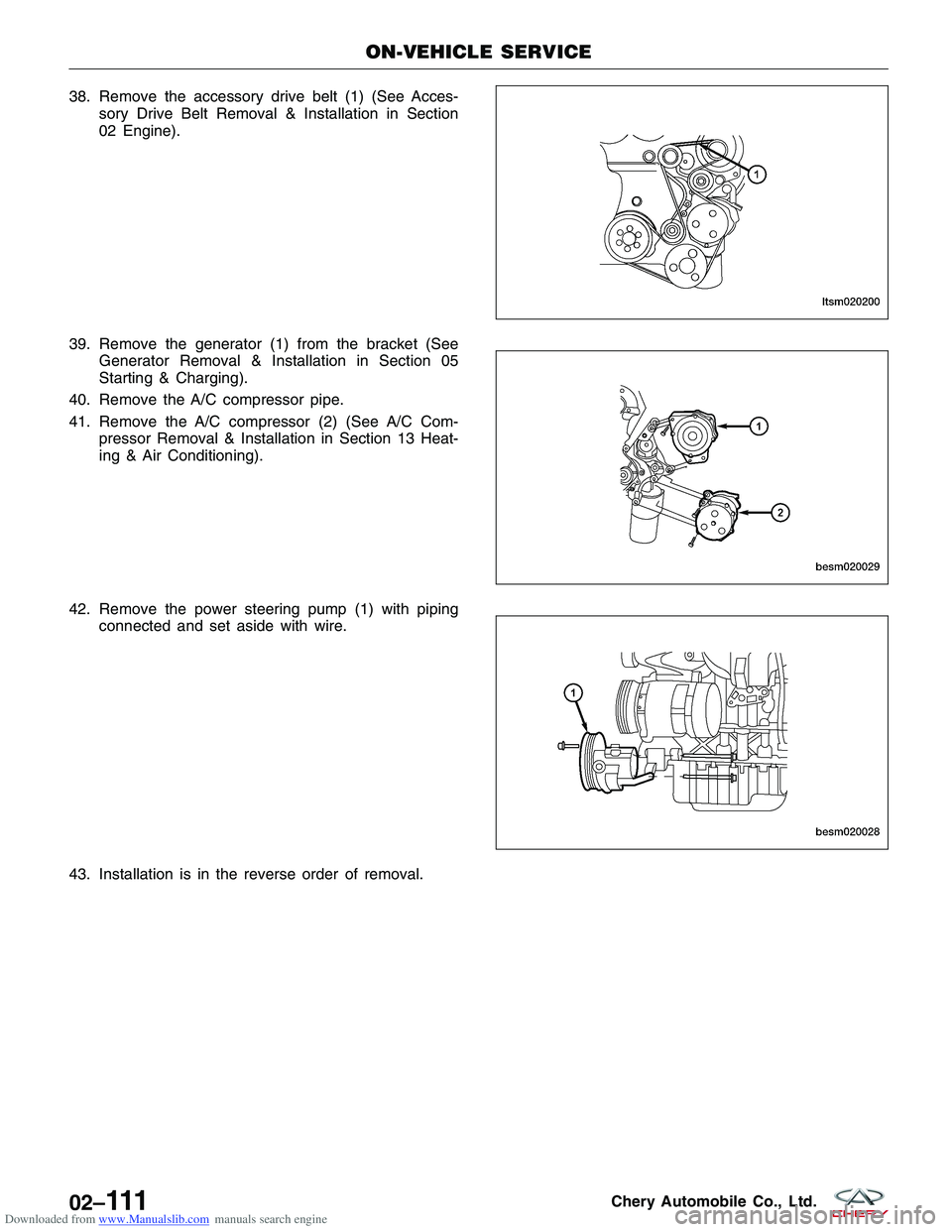

Downloaded from www.Manualslib.com manuals search engine 38. Remove the accessory drive belt (1) (See Acces-sory Drive Belt Removal & Installation in Section

02 Engine).

39. Remove the generator (1) from the bracket (See Generator Removal & Installation in Section 05

Starting & Charging).

40. Remove the A/C compressor pipe.

41. Remove the A/C compressor (2) (See A/C Com- pressor Removal & Installation in Section 13 Heat-

ing & Air Conditioning).

42. Remove the power steering pump (1) with piping connected and set aside with wire.

43. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM020200

BESM020029

BESM020028

02–111Chery Automobile Co., Ltd.