CHEVROLET CAMARO 1967 1.G Chassis Owners Manual

Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 91 of 659

HEATER AND AIR CONDITIONING 1A-68

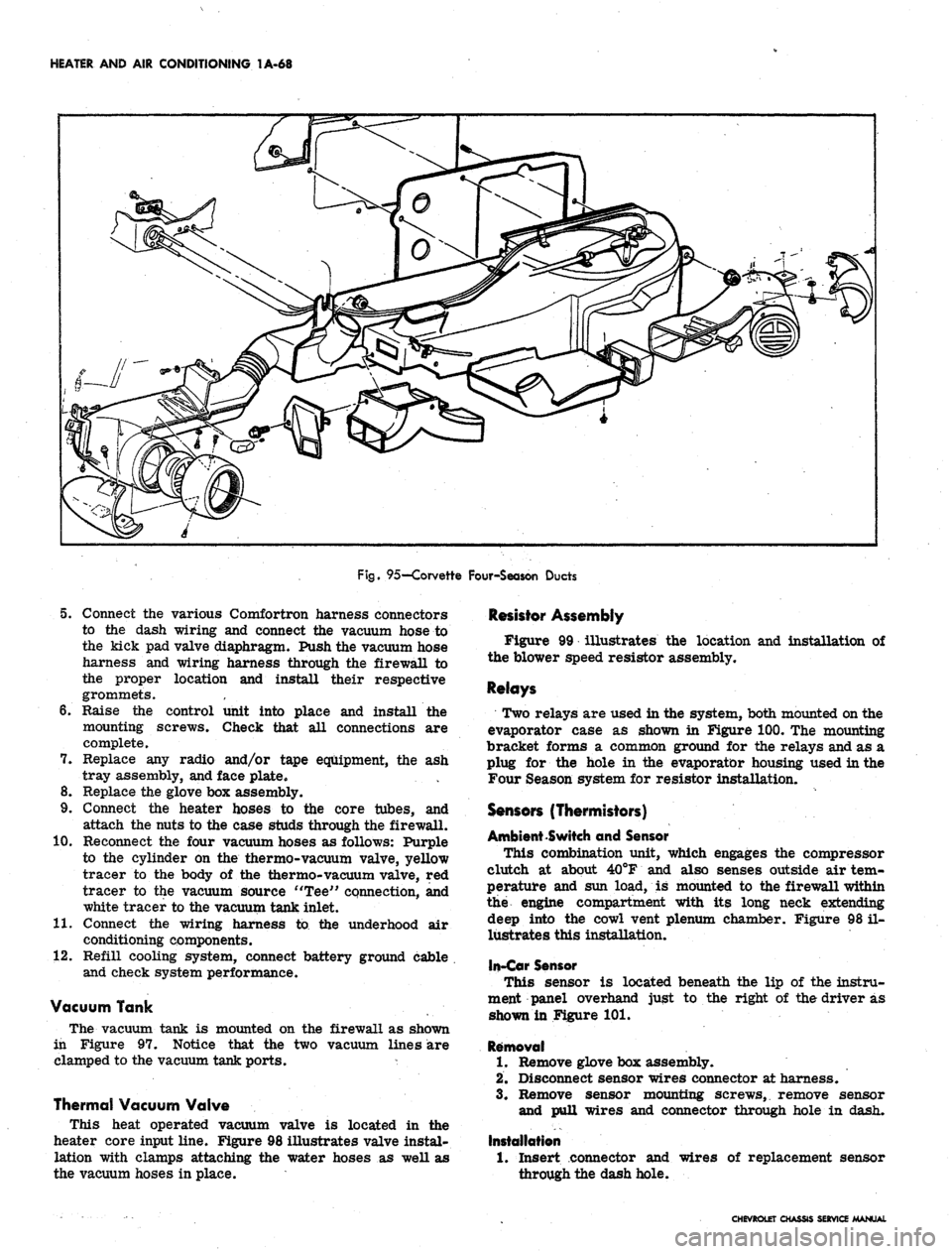

Fig.

95—Corvette Four-Season Ducts

5. Connect the various Comfortron harness connectors

to the dash wiring and connect the vacuum hose to

the kick pad valve diaphragm. Push the vacuum hose

harness and wiring harness through the firewall to

the proper location and install their respective

grommets.

6. Raise the control unit into place and install the

mounting screws. Check that all connections are

complete.

7. Replace any radio and/or tape equipment, the ash

tray assembly, and face plate.

8. Replace the glove box assembly.

9. Connect the heater hoses to the core tubes, and

attach the nuts to the case studs through the firewall.

10.

Reconnect the four vacuum hoses as follows: Purple

to the cylinder on the thermo-vacuum valve, yellow

tracer to the body of the thermo-vacuum valve, red

tracer to the vacuum source "Tee" connection, and

white tracer to the vacuum tank inlet.

11.

Connect the wiring harness to the underhood air

conditioning components.

12.

Refill cooling system, connect battery ground cable

and check system performance.

Vacuum Tank

The vacuum tank is mounted on the firewall as shown

in Figure 97. Notice that the two vacuum lines are

clamped to the vacuum tank ports. *

Thermal Vacuum Valve

This heat operated vacuum valve is located in the

heater core input line. Figure 98 illustrates valve instal-

lation with clamps attaching the water hoses as well as

the vacuum hoses in place.

Resistor Assembly

Figure 99 illustrates the location and installation of

the blower speed resistor assembly.

Relays

Two relays are used in the system, both mounted on the

evaporator case as shown in Figure 100. The mounting

bracket forms a common ground for the relays and as a

plug for the hole in the evaporator housing used in the

Four Season system for resistor installation.

Sensors (Thermistors)

Ambient Switch and Sensor

This combination unit, which engages the compressor

clutch at about 40°F and also senses outside air tem-

perature and sun load, is mounted to the firewall within

the engine compartment with its long neck extending

deep into the cowl vent plenum chamber. Figure 98 il-

lustrates this installation,

In-Car Sensor

This sensor is located beneath the lip of the instru-

ment panel overhand just to the right of the driver as

shown in Figure 101.

Removal

1.

Remove glove box assembly.

2.

Disconnect sensor wires connector at harness.

3.

Remove sensor mounting screws, remove sensor

and pull wires and connector through hole in dash.

Installation

1.

Insert connector and

through the dash hole.

wires of replacement sensor

CHEVROLET CHASSIS SERVICE MANUAL

Page 92 of 659

HEATER AND AIR CONDITIONING 1A-69

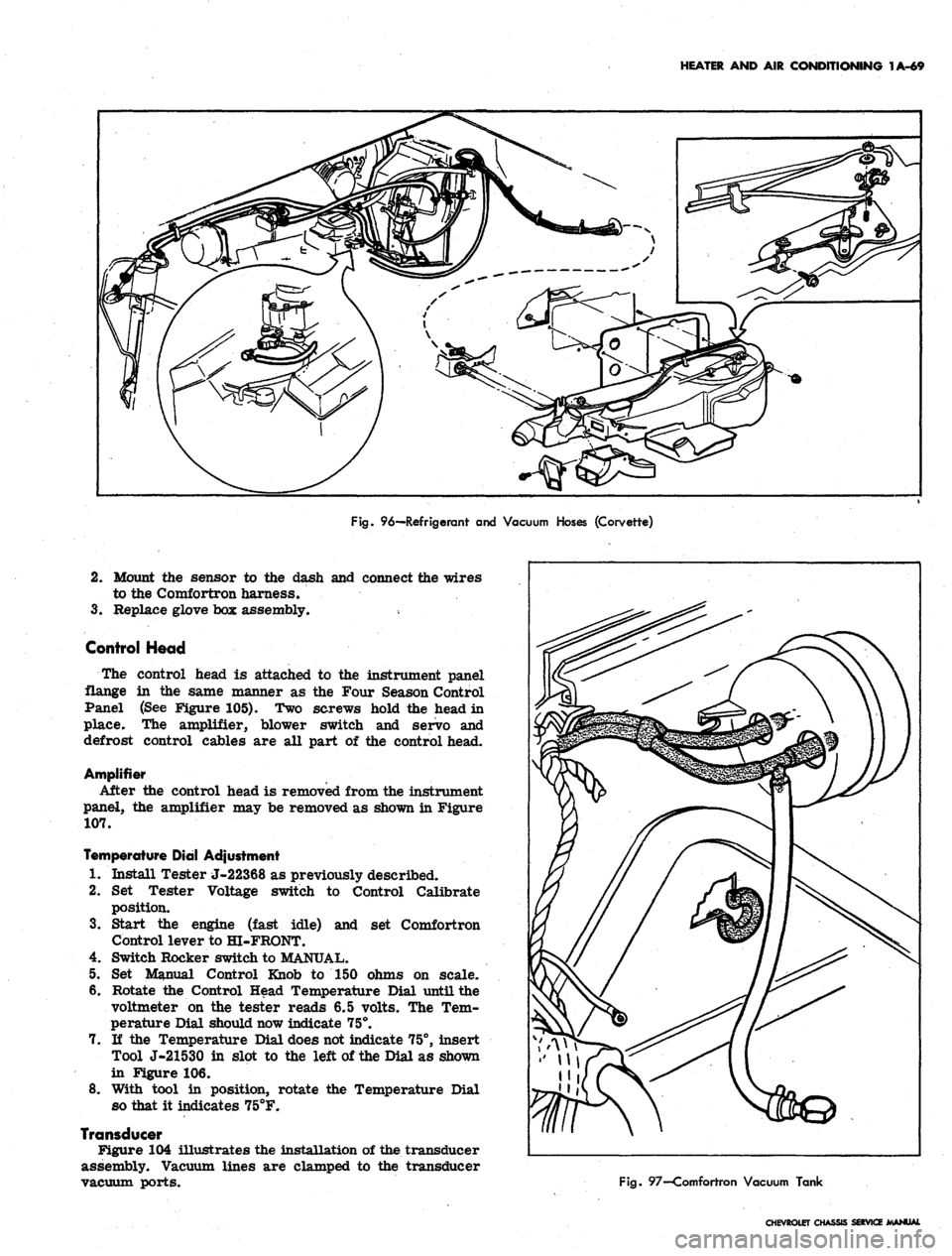

Fig.

96—Refrigerant and Vacuum Hoses (Corvette)

2.

Mount the sensor to the dash and connect the wires

to the Comfortron harness.

3.

Replace glove box assembly.

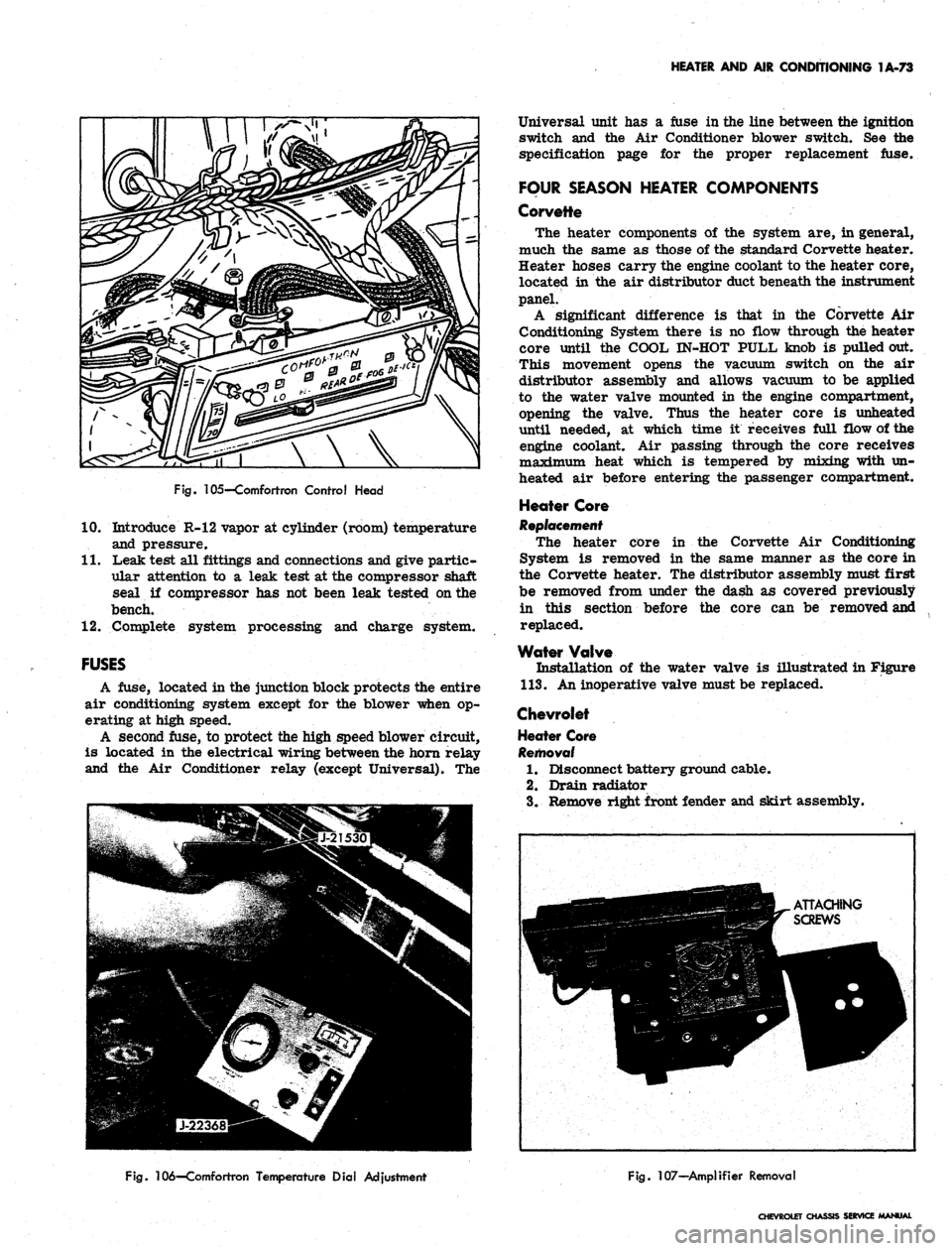

Control Head

The control head is attached to the instrument panel

flange in the same manner as the Four Season Control

Panel (See Figure 105). Two screws hold the head in

place. The amplifier, blower switch and servo and

defrost control cables are all part of the control head.

Amplifier

After the control head is removed from the instrument

panel, the amplifier may be removed as shown in Figure

107.

Temperature Dial Adjustment

1.

Install Tester J-22368 as previously described.

2.

Set Tester Voltage switch to Control Calibrate

position.

3.

Start the engine (fast idle) and set Comfortron

Control lever to HI-FRONT.

4.

Switch Rocker switch to MANUAL.

5. Set Manual Control Knob to 150 ohms on scale.

6. Rotate the Control Head Temperature Dial until the

voltmeter on the tester reads 6.5 volts. The Tem-

perature Dial should now indicate 75°.

7. If the Temperature Dial does not indicate 75°, insert

Tool J-21530 in slot to the left of the Dial as shown

in Figure 106.

8. With tool in position, rotate the Temperature Dial

so that it indicates 75°F.

Transducer

Figure 104 illustrates the installation of the transducer

assembly. Vacuum lines are clamped to the transducer

vacuum ports.

Fig.

97—Comfortron Vacuum Tank

CHEVROLET CHASSIS SERVICE JWANUAl

Page 93 of 659

HEATER AND AIR CONDITIONING 1A-70

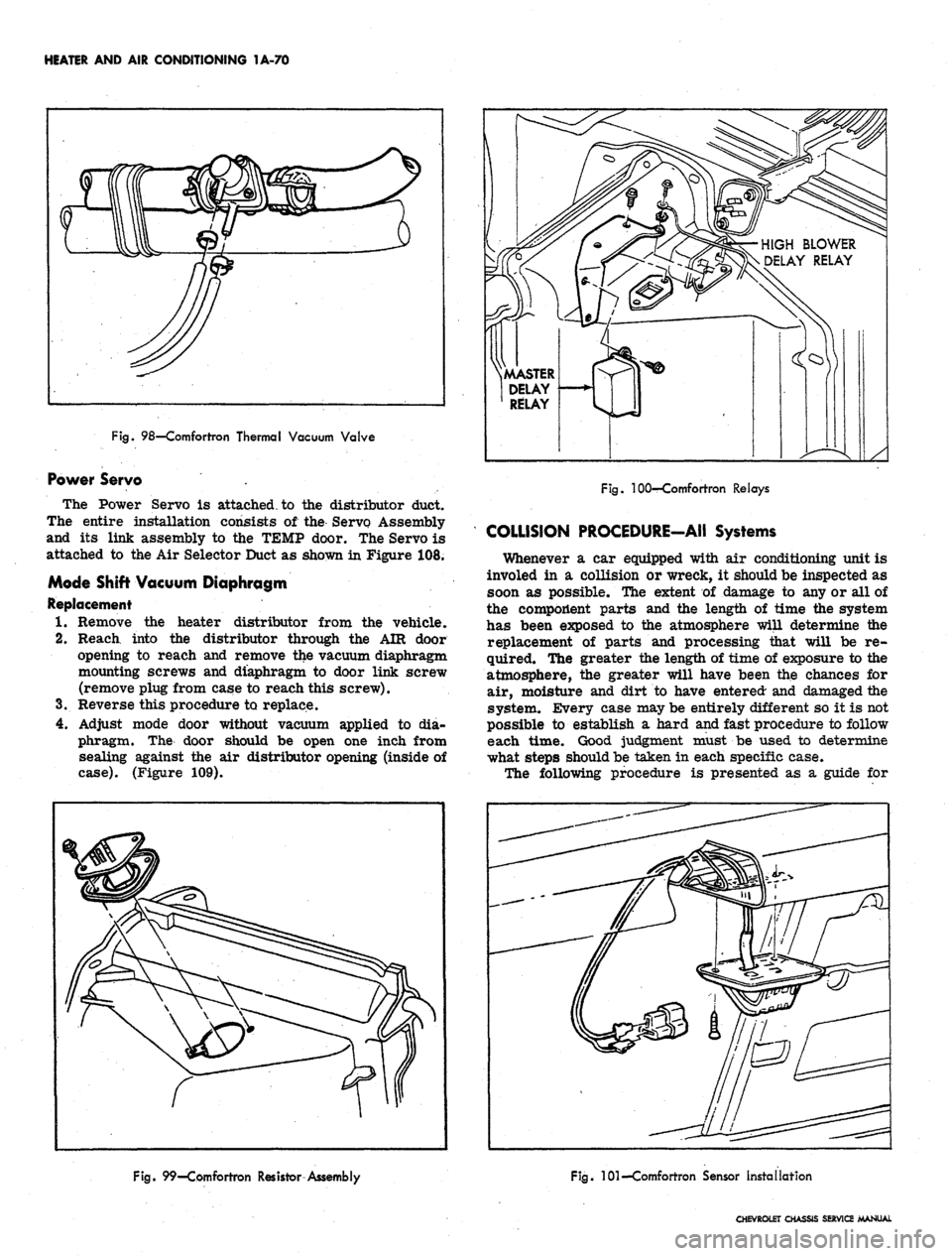

Fig.

98—Comfortron Thermal Vacuum Valve

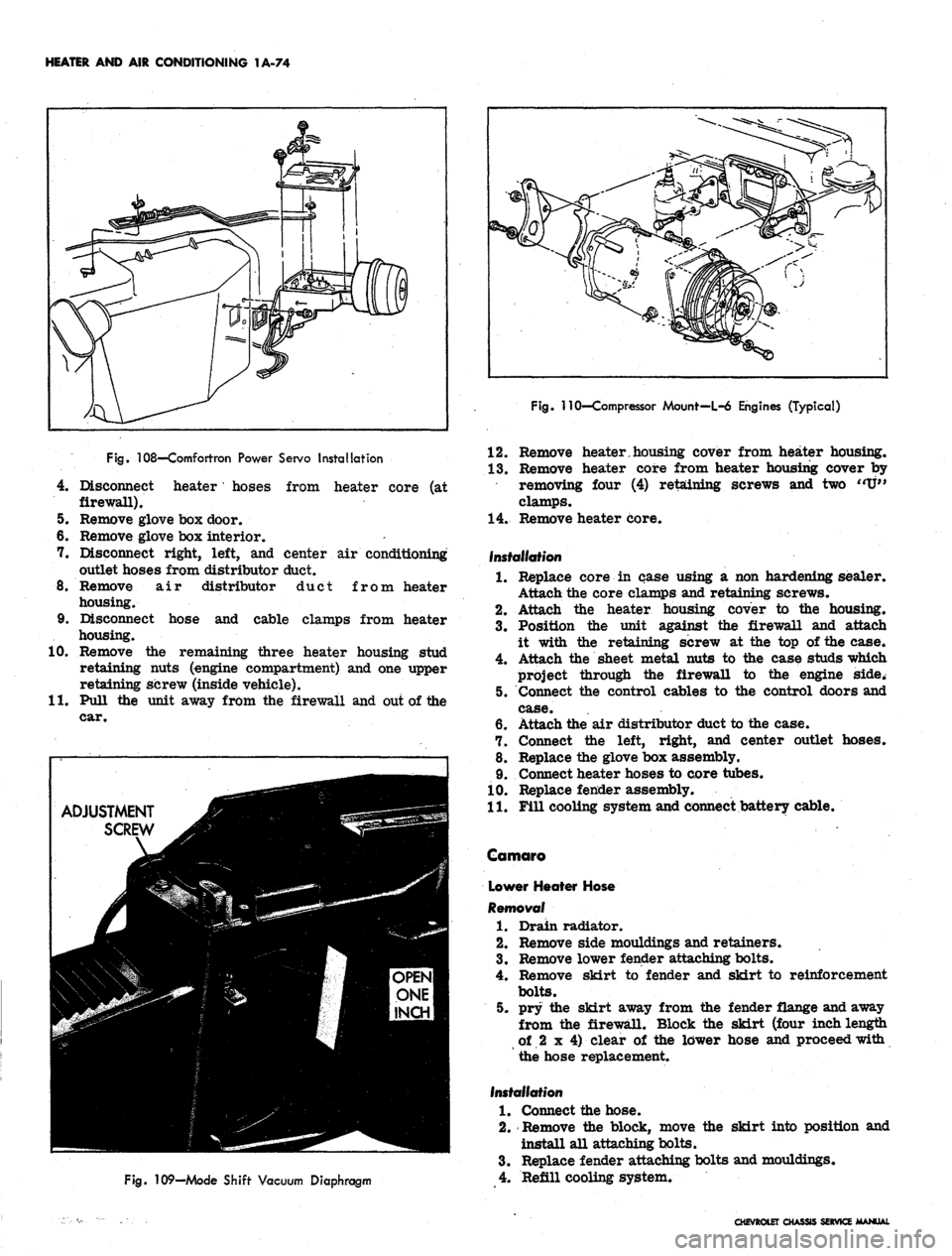

Power Servo .

The Power Servo is attached, to the distributor duct.

The entire installation consists of the Servo Assembly

and its link assembly to the TEMP door. The Servo is

attached to the Air Selector Duct as shown in Figure 108.

Mode Shift Vacuum Diaphragm

Replacement

1.

Remove the heater distributor from the vehicle.

2.

Reach into the distributor through the AIR door

opening to reach and remove the vacuum diaphragm

mounting screws and diaphragm to door link screw

(remove piug from case to reach this screw).

3.

Reverse this procedure to replace.

4.

Adjust mode door without vacuum applied to dia-

phragm. The door should be open one inch from

sealing against the air distributor opening (inside of

case).

(Figure 109).

HIGH BLOWER

DELAY RELAY

.MASTER

DELAY

RELAY

Fig.

100—Comfortron Relays

COLLISION PROCEDURE-AII Systems

Whenever a car equipped with air conditioning unit is

involed in a collision or wreck, it should be inspected as

soon as possible. The extent of damage to any or all of

the component parts and the length of time the system

has been exposed to the atmosphere will determine the

replacement of parts and processing that will be re-

quired. The greater the length of time of exposure to the

atmosphere, the greater will have been the chances for

air, moisture and dirt to have entered and damaged the

system. Every case may be entirely different so it is not

possible to establish a hard and fast procedure to follow

each time. Good judgment must be used to determine

what steps should be taken in each specific case.

The following procedure is presented as a guide for

Fig.

99—Comfortron Resistor Assembly

Fig.

101—Comfortron Sensor Installation

CHEVROLET CHASSIS SERVICE MANUAL

Page 94 of 659

HEATER AND AIR CONDITIONING 1A-71

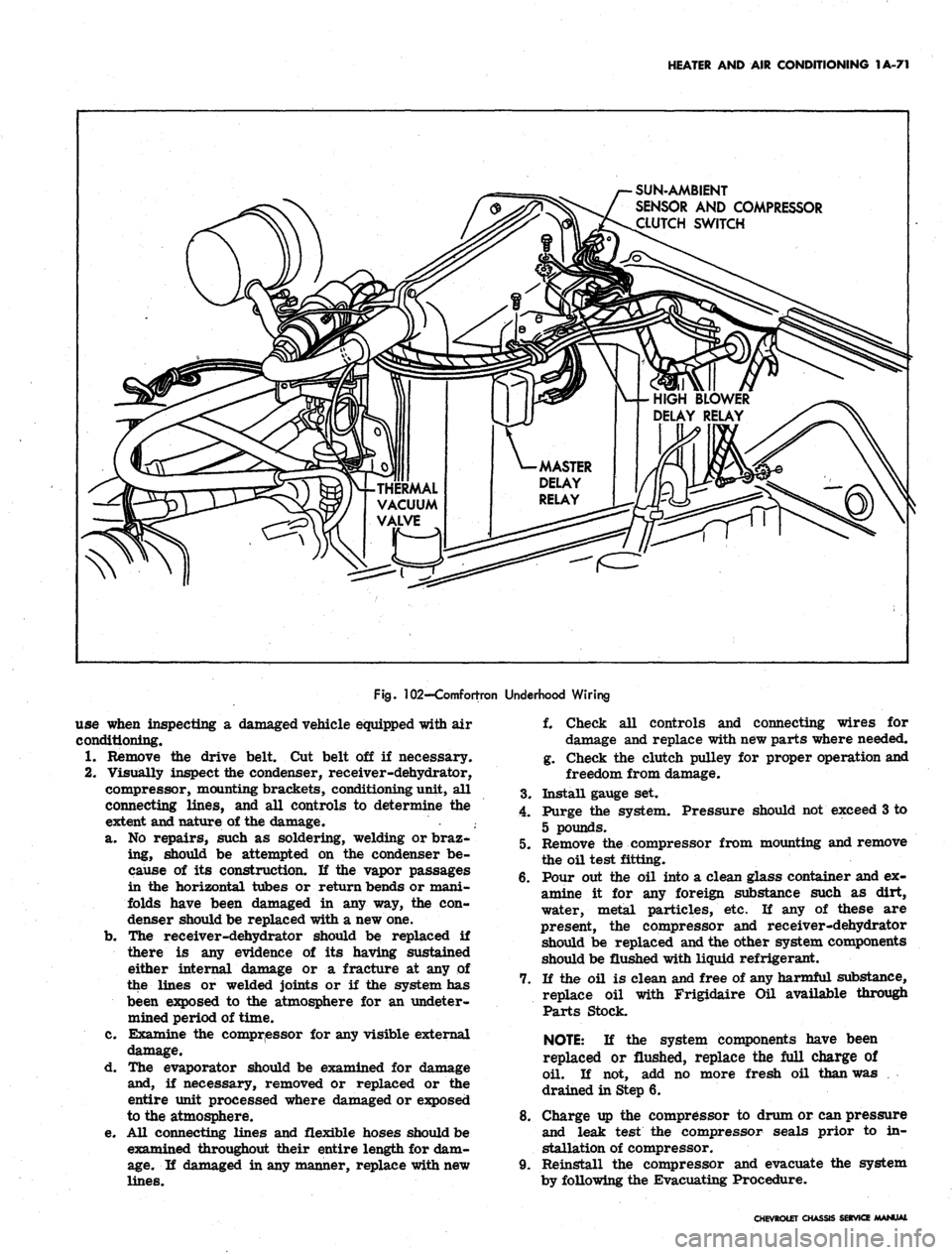

SUN-AMBIENT

SENSOR AND COMPRESSOR

CLUTCH SWITCH

HIGH BLOWER

DELAY RELAY

THERMAL

VACUUM

VALVE

Fig.

102-Comfortron Underhood Wiring

use when inspecting a damaged vehicle equipped with air

conditioning.

1.

Remove the drive belt. Cut belt off if necessary.

2.

Visually inspect the condenser, receiver-dehydrator,

compressor, mounting brackets, conditioning unit, all

connecting lines, and all controls to determine the

extent and nature of the damage.

a. No repairs, such as soldering, welding or braz-

ing, should be attempted on the condenser be-

cause of its construction. If the vapor passages

in the horizontal tubes or return bends or mani-

folds have been damaged in any way, the con-

denser should be replaced with a new one.

b.

The receiver-dehydrator should be replaced if

there is any evidence of its having sustained

either internal damage or a fracture at any of

the lines or welded joints or if the system has

been exposed to the atmosphere for an undeter-

mined period of time.

c. Examine the compressor for any visible external

damage.

d. The evaporator should be examined for damage

and, if necessary, removed or replaced or the

entire unit processed where damaged or exposed

to the atmosphere.

e. All connecting lines and flexible hoses should be

examined throughout their entire length for dam-

age.

If damaged in any manner, replace with new

lines.

f. Check all controls and connecting wires for

damage and replace with new parts where needed.

g. Check the clutch pulley for proper operation and

freedom from damage.

3.

Install gauge set.

4.

Purge the system. Pressure should not exceed 3 to

5 pounds.

5. Remove the compressor from mounting and remove

the oil test fitting.

6. Pour out the oil into a clean glass container and ex-

amine it for any foreign substance such as dirt,

water, metal particles, etc. If any of these are

present, the compressor and receiver-dehydrator

should be replaced and the other system components

should be flushed with liquid refrigerant.

7. If the oil is clean and free of any harmful substance,

replace oil with Frigidaire Oil available through

Parts Stock.

NOTE:

If the system components have been

replaced or flushed, replace the full charge of

oil. If not, add no more fresh oil than was

drained in Step 6.

8. Charge up the compressor to drum or can pressure

and leak test the compressor seals prior to in-

stallation of compressor.

9. Reinstall the compressor and evacuate the system

by following the Evacuating Procedure.

CHEVROLET CHASSIS SERVICE MANUAL

Page 95 of 659

HEATER AND AIR CONDITIONING 1A-72

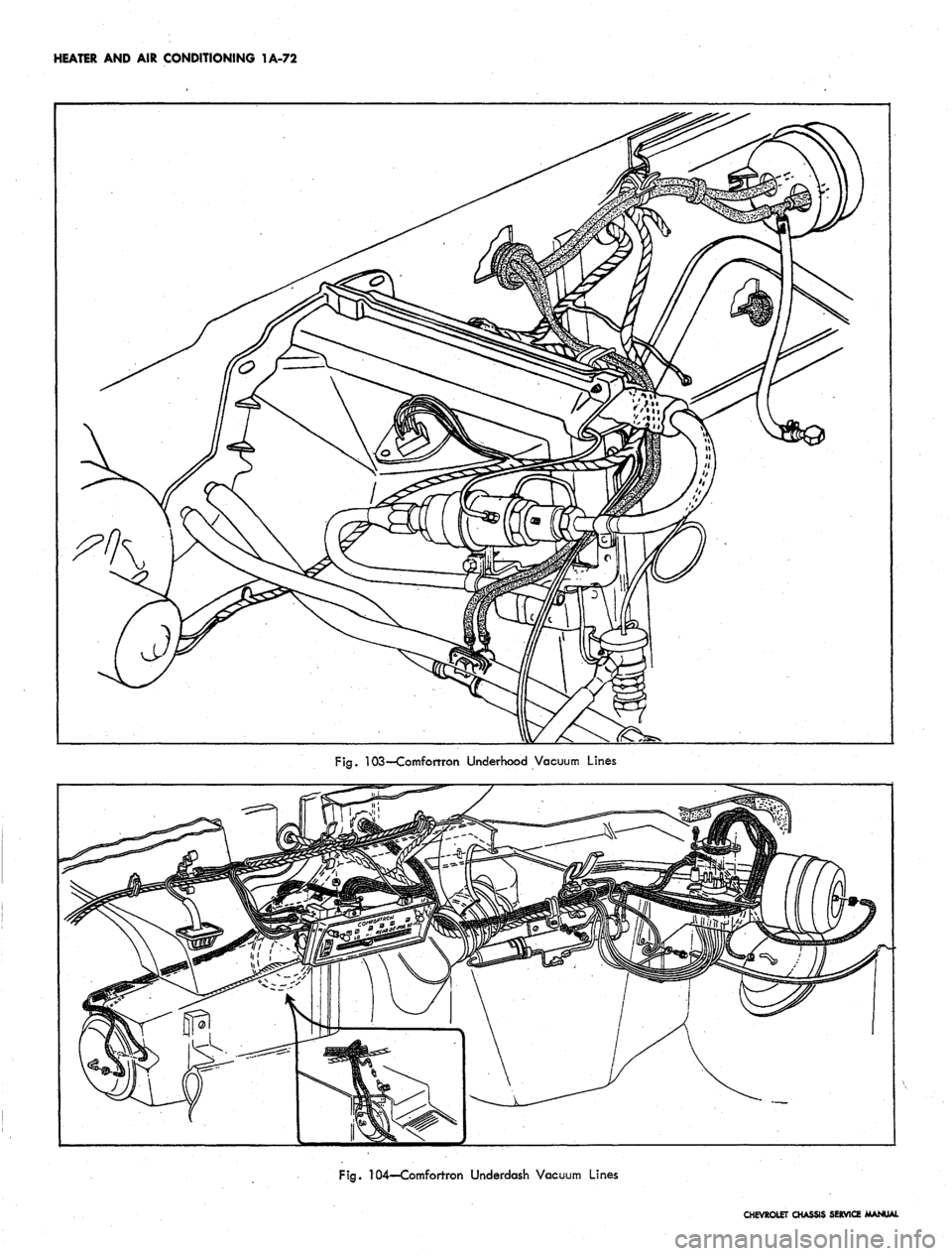

Fig.

103—Comforrron Underhood Vacuum Lines

Fig.

104—Comfortron Underdash Vacuum Lines

CHEVROLET CHASSIS SERVICE MANUAL

Page 96 of 659

HEATER AND AIR CONDITIONING 1A-73

Fig.

105—Comfortron Control Head

10.

Introduce R-12 vapor at cylinder (room) temperature

and pressure.

11.

Leak test all fittings and connections and give partic-

ular attention to a leak test at the compressor shaft

seal if compressor has not been leak tested on the

bench.

12.

Complete system processing and charge system.

FUSES

A fuse, located in the junction block protects the entire

air conditioning system except for the blower when op-

erating at high speed.

A second fuse, to protect the high speed blower circuit,

is located in the electrical wiring between the horn relay

and the Air Conditioner relay (except Universal). The

Universal unit has a fuse in the line between the ignition

switch and the Air Conditioner blower switch. See the

specification page for the proper replacement fuse.

FOUR SEASON HEATER COMPONENTS

Corvette

The heater components of the system are, in general,

much the same as those of the standard Corvette heater.

Heater hoses carry the engine coolant to the heater core,

located in the air distributor duct beneath the instrument

panel.

A significant difference is that in the Corvette Air

Conditioning System there is no flow through the heater

core until the COOL IN-HOT PULL knob is pulled out.

This movement opens the vacuum switch on the air

distributor assembly and allows vacuum to be applied

to the water valve mounted in the engine compartment,

opening the valve. Thus the heater core is unheated

until needed, at which time it receives full flow of the

engine coolant. Air passing through the core receives

maximum heat which is tempered by mixing with un-

heated air before entering the passenger compartment.

Heater Core

Replacement

The heater core in the Corvette Air Conditioning

System is removed in the same manner as the core in

the Corvette heater. The distributor assembly must first

be removed from under the dash as covered previously

in this section before the core can be removed and

replaced.

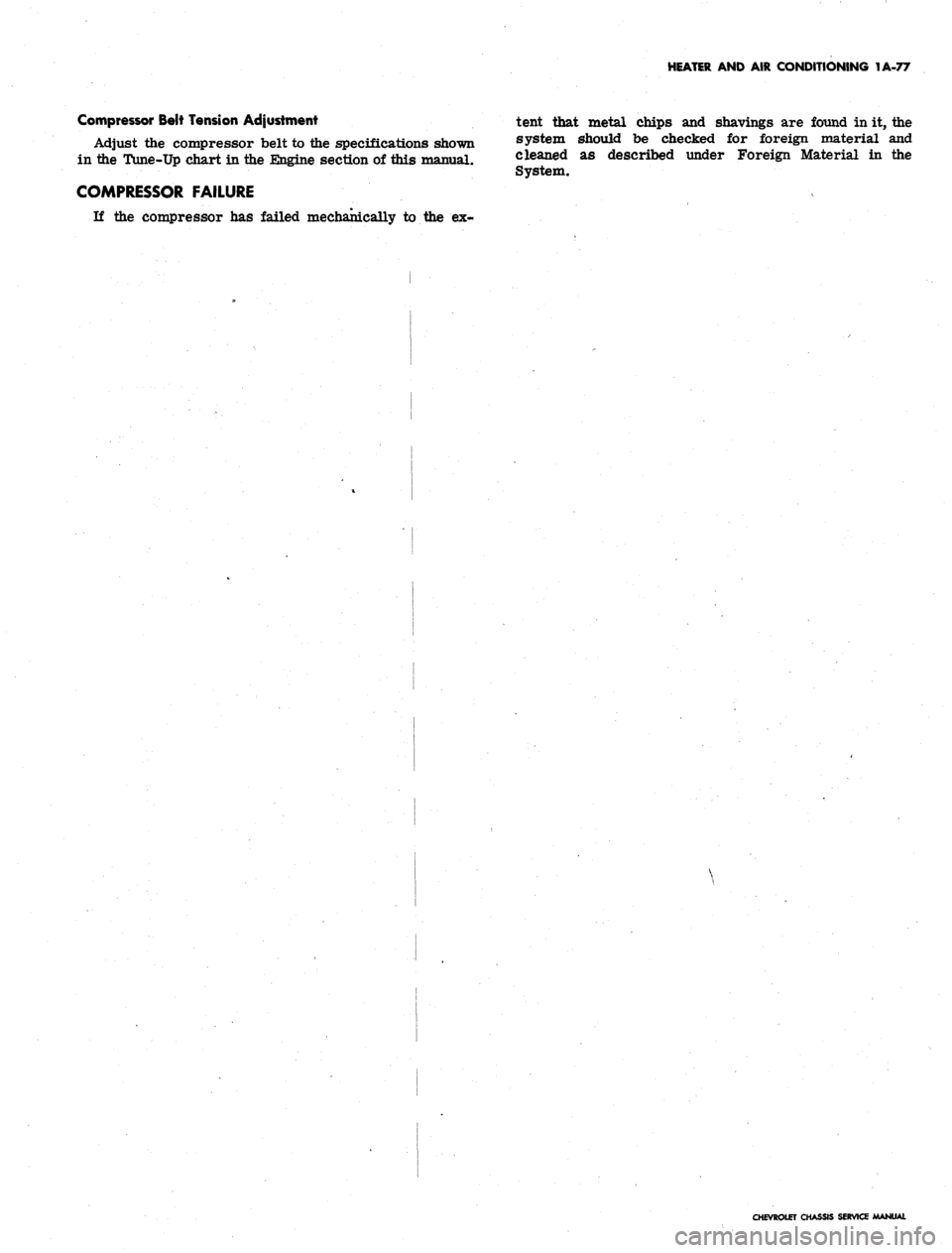

Water Valve

Installation of the water valve is illustrated in Figure

113.

An inoperative valve must be replaced.

Chevrolet

Heater Core

Removal

1.

Disconnect battery ground cable.

2.

Drain radiator

3.

Remove right front fender and skirt assembly.

Fig.

106—Comfortron Temperature Dial Adjustment

Fig.

107—Amplifier Removal

CHEVROLET CHASSIS SERVICE MANUAL

Page 97 of 659

HEATER AND AIR CONDITIONING 1A-74

Fig.

108—Comfortron Power Servo Installation

4.

Disconnect heater' hoses from heater core (at

firewall).

5. Remove glove box door.

6. Remove glove box interior.

7. Disconnect right, left, and center air conditioning

outlet hoses from distributor duct.

8. Remove air distributor duct from heater

housing.

9. Disconnect hose and cable clamps from heater

housing.

10.

Remove the remaining three heater housing stud

retaining nuts (engine compartment) and one upper

retaining screw (inside vehicle).

11.

Pull the unit away from the firewall and out of the

car.

ADJUSTMENT

SCREW

Fig.

109—Mode Shift Vacuum Diaphragm

Fig. 110'—Compressor Mount—L-6 Engines (Typical)

12.

Remove heater.housing cover from heater housing.

13.

Remove heater core from heater housing cover by

removing four (4) retaining screws and two "U"

clamps.

14.

Remove heater core.

Installation

1.

Replace core in case using a non hardening sealer.

Attach the core clamps and retaining screws.

2.

Attach the heater housing cover to the housing.

3.

Position the unit against the firewall and attach

it with the retaining screw at the top of the case.

4.

Attach the sheet metal nuts to the case studs which

project through the firewall to the engine side.

5. Connect the control cables to the control doors and

case.

6. Attach the air distributor duct to the case.

7. Connect the left, right, and center outlet hoses.

8. Replace the glove box assembly.

9. Connect heater hoses to core tubes.

10.

Replace fender assembly.

11.

Fill cooling system and connect battery cable.

Camaro

Lower Heater Hose

Removal

1.

Drain radiator.

2.

Remove side mouldings and retainers.

3.

Remove lower fender attaching bolts.

4.

Remove skirt to fender and skirt to reinforcement

bolts.

5. pry the skirt away from the fender flange and away

from the firewall. Block the skirt (four inchlengtti

of 2 x 4) clear of the lower hose and proceed with

the hose replacement.

Installation

1.

Connect the hose.

2.

Remove the block, move the skirt into position and

install all attaching bolts.

3.

Replace fender attaching bolts and mouldings.

4.

Refill cooling system.

CHEVROLET CHASSIS SERVICE MANUAL

Page 98 of 659

HEATER AND AIR CONDITIONING 1A-75

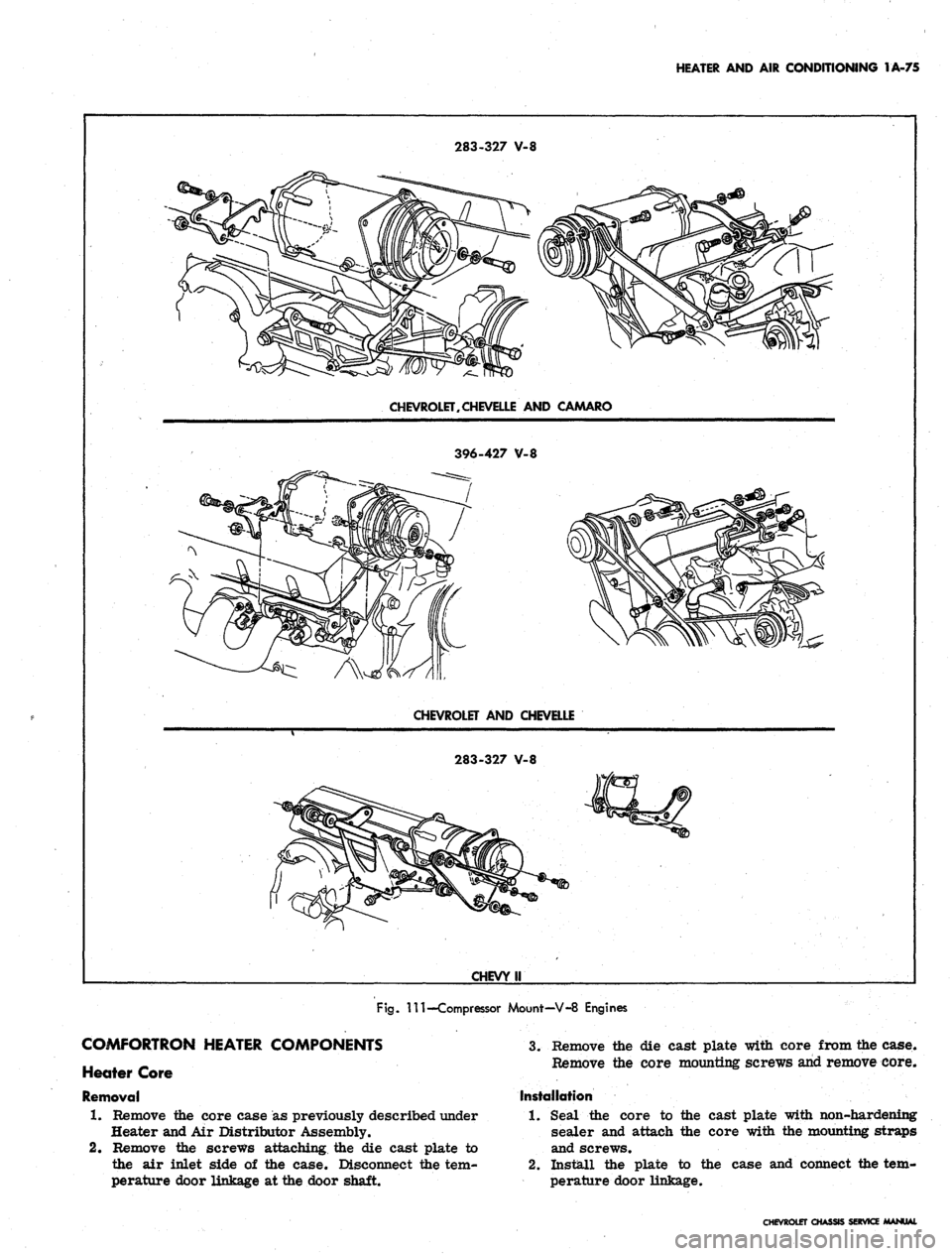

283-327 V-8

CHEVROLET, CHEVELLE AND CAMARO

396-427 V-8

CHEVROLET AND CHEVELLE

283-327 V-8

CHEVY II

Fig.

Ill—Compressor Mount—V-8 Engines

COMFORTRON HEATER COMPONENTS

Heater Core

Removal

1.

Remove the core case as previously described under

Heater and Air Distributor Assembly.

2.

Remove the screws attaching the die cast plate to

the air inlet side of the case. Disconnect the tem-

perature door linkage at the door shaft.

3.

Remove the die cast plate with core from the case.

Remove the core mounting screws and remove core.

Installation

1.

Seal the core to the cast plate with non-hardening

sealer and attach the core with the mounting straps

and screws.

2.

Install the plate to the case and connect the tem-

perature door linkage.

CHEVROLET CHASSIS SERVICE MANUAL

Page 99 of 659

HEATER AND AIR CONDITIONING 1A-76

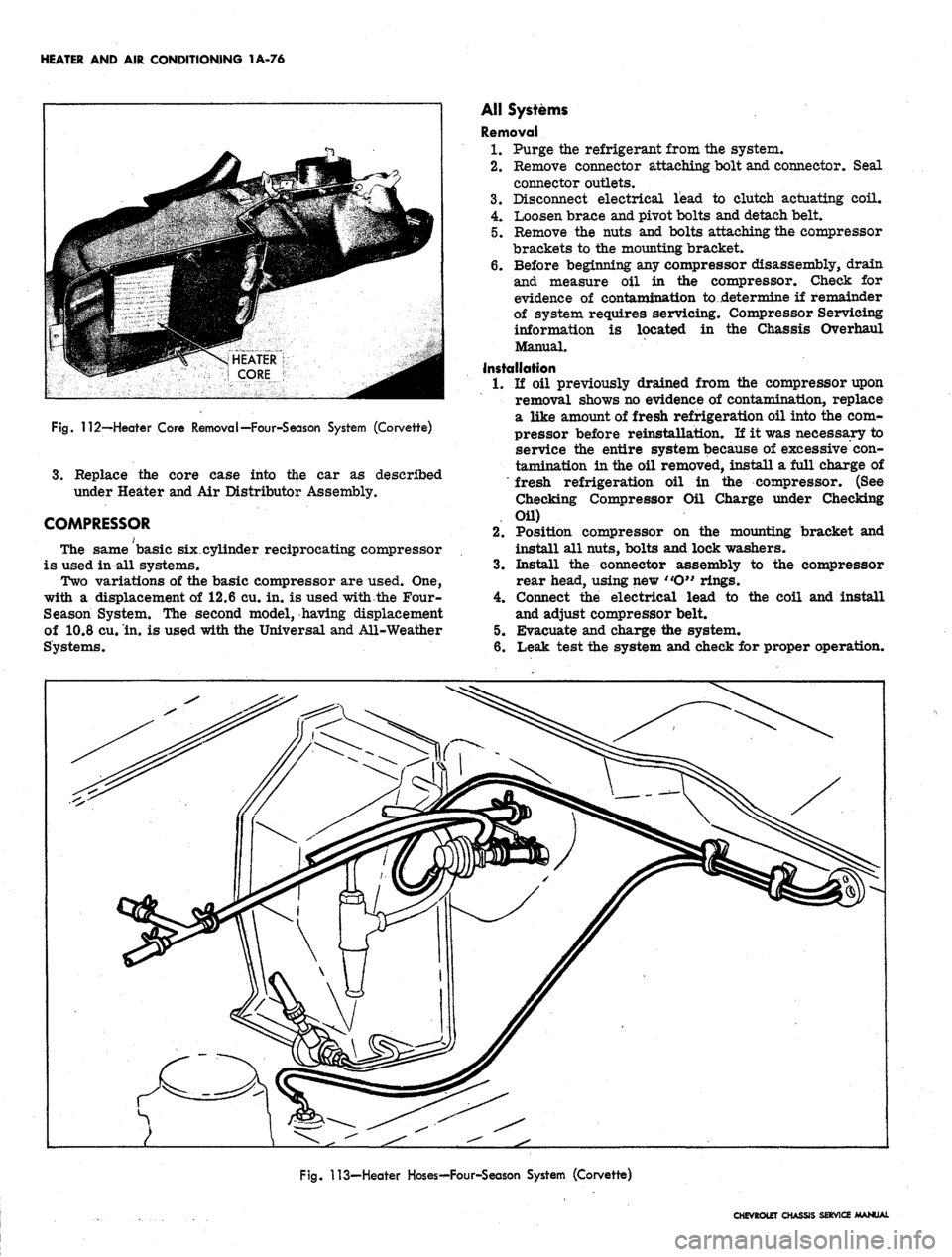

Fig.

112—-Heater Core Removal—Four-Season System (Corvette)

3.

Replace the core case into the car as described

under Heater and Air Distributor Assembly.

COMPRESSOR

The same basic six.cylinder reciprocating compressor

is used in all systems.

Two variations of the basic compressor are used. One,

with a displacement of 12.6 cu. in. is used with the Four-

Season System. The second model, having displacement

of 10.8 cu. in. is used with the Universal and All-Weather

Systems.

AH Systems

Removal

1.

Purge the refrigerant from the system.

2.

Remove connector attaching bolt and connector. Seal

connector outlets.

3.

Disconnect electrical lead to clutch actuating coil.

4.

Loosen brace and pivot bolts and detach belt.

5. Remove the nuts and bolts attaching the compressor

brackets to the mounting bracket.

6. Before beginning any compressor disassembly, drain

and measure oil in the compressor. Check for

evidence of contamination to ..determine if remainder

of system requires servicing. Compressor Servicing

information is located in the Chassis Overhaul

Manual.

Installation

1.

li oil previously drained from the compressor upon

removal shows no evidence of contamination, replace

a like amount of fresh refrigeration oil into the com-

pressor before reinstallatLon. If it was necessary to

service the entire system because of excessive con-

tamination in the oil removed, install a full charge of

"fresh refrigeration oil in the compressor. (See

Checking Compressor Oil Charge under Checking

Oil)

2.

Position compressor on the mounting bracket and

install all nuts, bolts and lock washers.

3.

Install the connector assembly to the compressor

rear head, using new "O" rings.

4.

Connect the electrical lead to the coil and install

and adjust compressor belt.

5. Evacuate and charge the system.

6. Leak test the system and check for proper operation.

Fig.

113—Heater Hoses^-Four-Season System (Corvette)

CHEVROLET CHASSIS SERVICE MANUAL

Page 100 of 659

HEATER AND AIR CONDITIONING 1A-77

Compressor Belt Tension Adjustment

Adjust the compressor belt to the specifications shown

in the Tune-Up chart in the Engine section of this manual.

COMPRESSOR FAILURE

If the compressor has failed mechanically to the ex-

tent that metal chips and shavings are found in it, the

system should be checked for foreign material and

cleaned as described under Foreign Material in the

System.

CHEVROLET CHASSIS SERVICE MANUAL