CHEVROLET CAMARO 1967 1.G Chassis Workshop Manual

Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 111 of 659

CORVETTE BODY 1B-4

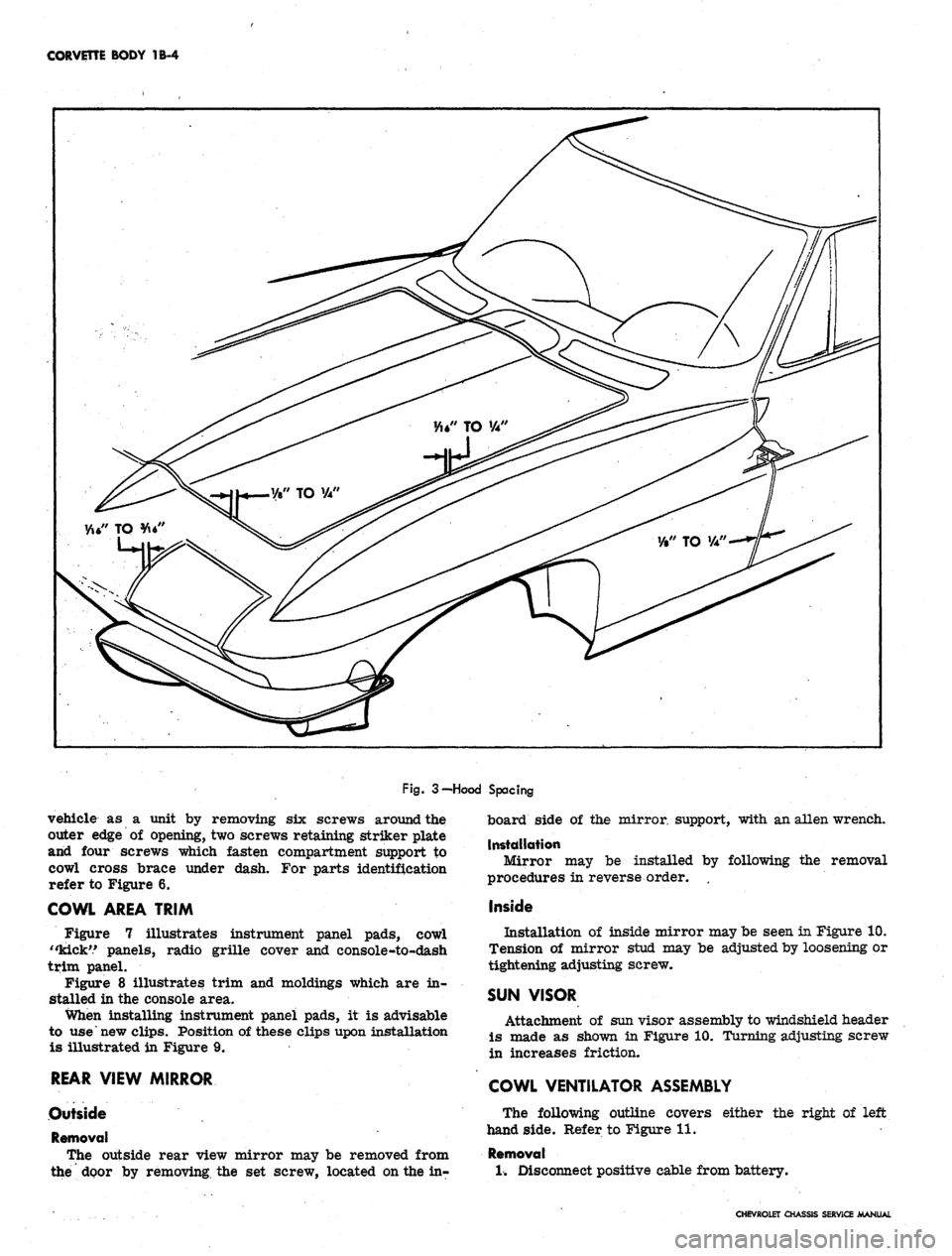

Fig.

3-Hood Spacing

vehicle as a unit by removing six screws around the

outer edge of opening, two screws retaining striker plate

and four screws which fasten compartment support to

cowl cross brace under dash. For parts identification

refer to Figure 6.

COWL AREA TRIM

Figure 7 illustrates instrument panel pads, cowl

"kick'.' panels, radio grille cover and console-to-dash

trim panel.

Figure 8 illustrates trim and moldings which are in-

stalled in the console area.

When installing instrument panel pads, it is advisable

to use new clips. Position of these clips upon installation

is illustrated in Figure 9.

REAR VIEW MIRROR

Outside

Removal

The outside rear view mirror may be removed from

the'

door by removing the set screw, located on the in-

board side of the mirror support, with an alien wrench.

Installation

Mirror may be installed by following the removal

procedures in reverse order. ,

Inside

Installation of inside mirror may be seen in Figure 10.

Tension of mirror stud may be adjusted by loosening or

tightening adjusting screw.

SUN VISOR

Attachment of sun visor assembly to windshield header

is made as shown in Figure 10. Turning adjusting screw

in increases friction.

COWL VENTILATOR ASSEMBLY

The following outline covers either the right of left

hand side. Refer to Figure 11.

Removal

1.

Disconnect positive cable from battery.

CHEVROLET CHASSIS SERVICE MANUAL

Page 112 of 659

CORVETTE BODY 1B-5

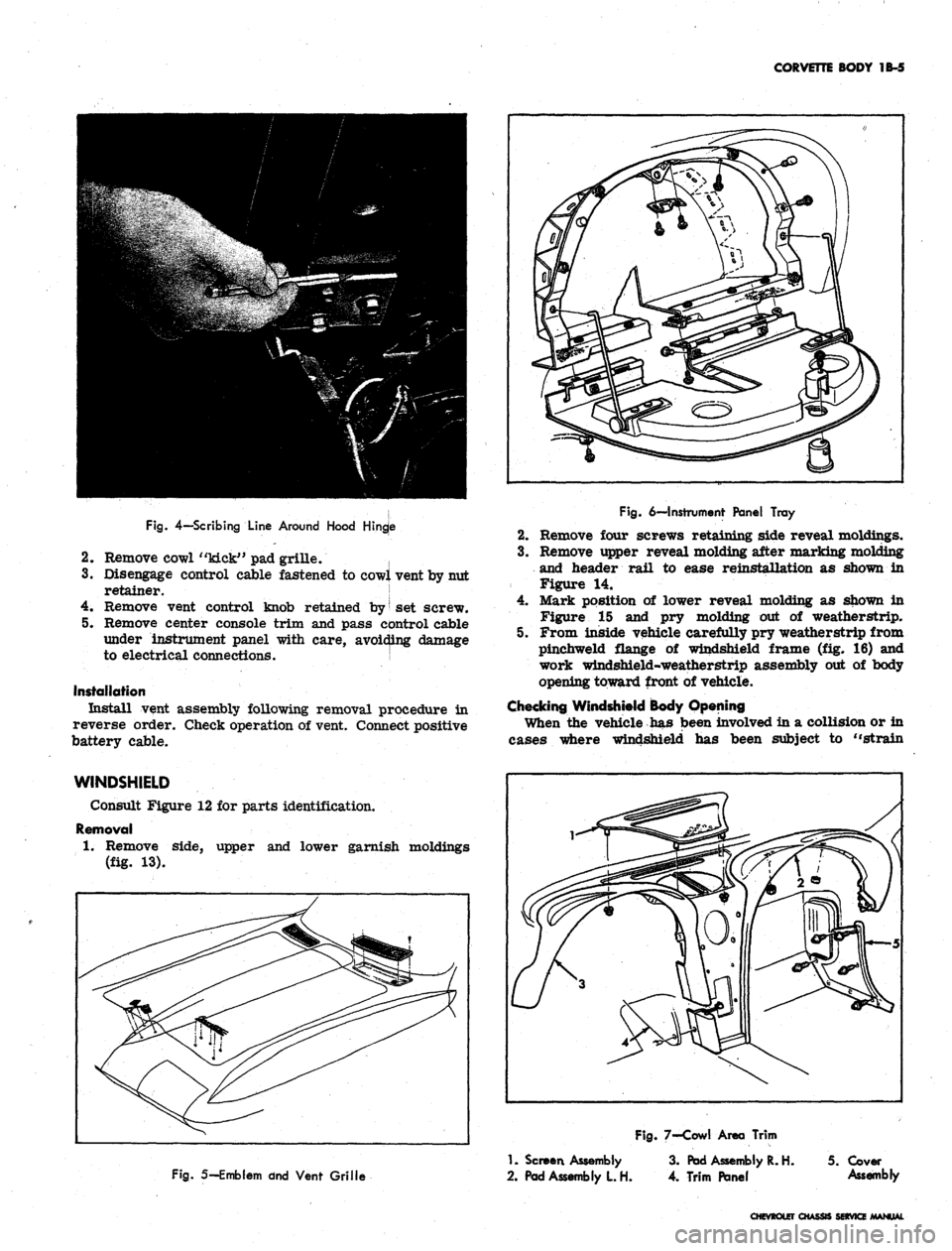

Fig.

4—Scribing

Line

Around

Hood

Hingje

2.

Remove cowl "kick" pad grille. |

3.

Disengage control cable fastened to cowl vent by nut

retainer. !

4.

Remove vent control knob retained by

|

set screw.

5. Remove center console trim and pass control cable

under instrument panel with care, avoiding damage

to electrical connections. j

Installation

Install vent assembly following removal procedure in

reverse order. Check operation of vent. Connect positive

battery cable.

Fig.

6—Instrument

Panel Tray

2.

Remove four screws retaining side reveal moldings.

3.

Remove upper reveal molding after marking molding

and header rail to ease reinstallation as shown in

Figure 14.

4.

Mark position of lower reveal molding as shown in

Figure 15 and pry molding out of weatherstrip.

5. From inside vehicle carefully pry weatherstrip from

pinchweld flange of windshield frame (fig. 16) and

work windshield-weatherstrip assembly out of body

opening toward front of vehicle.

Checking Windshield Body Opening

When the vehicle has been involved in a collision or in

cases where windshield has been subject to "strain

WINDSHIELD

Consult Figure 12 for parts identification.

Removal

1.

Remove side, upper and lower garnish moldings

(fig. 13).

Fig.

5—Emblem dnd

Vent Grille

1.

Screen

Assembly

2.

Pad

Assembly

L H.

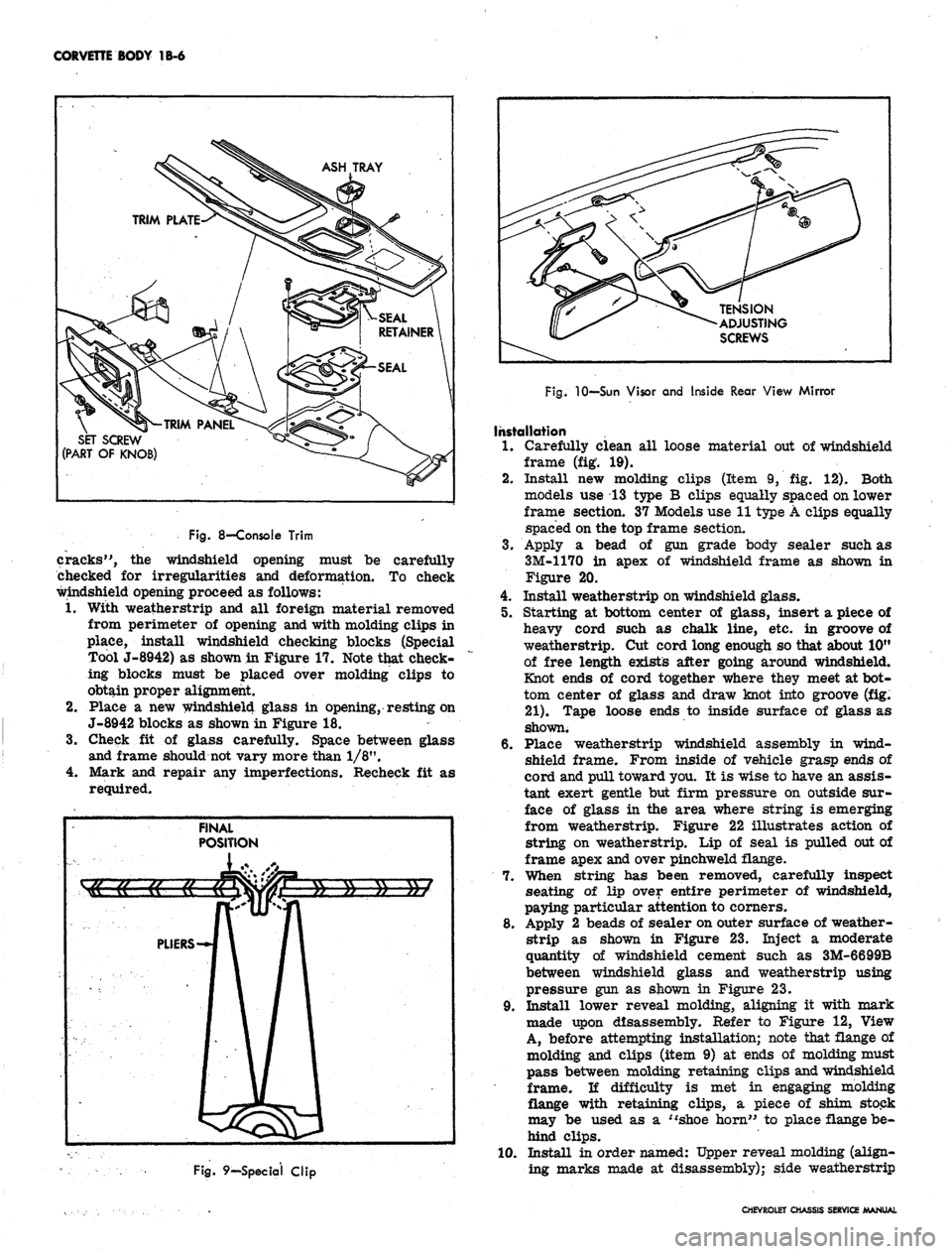

Fig.

7-Cowl

Area Trim

3.

Pad

Assembly

R. H. 5.

Cover

4.

Trim Panel

Assembly

CHEVROLET CHASSIS SERVICE MANUAL

Page 113 of 659

CORVETTE BODY

1B-6

ASH TRAY

SET SCREW

(PART

OF

KNOB)

TENSION

ADJUSTING

SCREWS

Fig.

8—Console Trim

cracks",

the

windshield opening must

be

carefully

checked

for

irregularities

and

deformation.

To

check

windshield opening proceed

as

follows:

1.

With weatherstrip

and all

foreign material removed

from perimeter

of

opening and with molding clips

in

place, install windshield checking blocks (Special

Tool J-8942)

as

shown in Figure 17. Note that check-

ing blocks must

be

placed over molding clips

to

obtain proper alignment.

2.

Place

a new

windshield glass

in

opening, resting on

J-8942 blocks

as

shown in Figure

18.

3.

Check

fit of

glass carefully. Space between glass

and frame should not vary more than 1/8".

4.

Mark

and

repair

any

imperfections. Recheck

fit as

required.

Fig.

9—Special Clip

Fig.

10—Sun Visor and Inside Rear View Mirror

Installation

1.

Carefully clean

all

loose material

out of

windshield

frame

(fig. 19).

2.

Install

new

molding clips (Item

9, fig. 12).

Both

models

use 13

type

B

clips equally spaced on lower

frame section.

37

Models use 11 type A clips equally

spaced on the top frame section.

3.

Apply

a

bead

of gun

grade body sealer such

as

3M-1170

in

apex

of

windshield frame

as

shown

in

Figure

20.

4.

Install weatherstrip on windshield glass.

5. Starting

at

bottom center

of

glass, insert

a

piece

of

heavy cord such

as

chalk line,

etc. in

groove

of

weatherstrip.

Cut

cord long enough so that about 10"

of free length exists after going around windshield.

Knot ends

of

cord together where they meet at bot-

tom center

of

glass

and

draw knot into groove

(fig.

21).

Tape loose ends

to

inside surface

of

glass

as

shown.

6. Place weatherstrip windshield assembly

in

wind-

shield frame. From inside

of

vehicle grasp ends

of

cord and pull toward you.

It is

wise to have an assis-

tant exert gentle

but

firm pressure

on

outside sur-

face

of

glass

in the

area where string

is

emerging

from weatherstrip. Figure

22

illustrates action

of

string

on

weatherstrip.

Lip of

seal

is

pulled out of

frame apex and over pinchweld flange.

7. When string

has

been removed, carefully inspect

seating

of lip

over entire perimeter

of

windshield,

paying particular attention to corners.

8. Apply

2

beads

of

sealer on outer surface

of

weather-

strip

as

shown

in

Figure

23.

Inject

a

moderate

quantity

of

windshield cement such

as

3M-6699B

between windshield glass

and

weatherstrip using

pressure gun

as

shown

in

Figure

23.

9. Install lower reveal molding, aligning

it

with mark

made upon disassembly. Refer

to

Figure

12,

View

A, before attempting installation; note that flange

of

molding

and

clips (item

9) at

ends

of

molding must

pass between molding retaining clips and windshield

frame.

li

difficulty

is met in

engaging molding

flange with retaining clips,

a

piece

of

shim stock

may

be

used

as a

"shoe horn"

to

place flange be-

hind clips.

10.

Install

in

order named: Upper reveal molding (align-

ing marks made

at

disassembly); side weatherstrip

CHEVROLET CHASSIS SERVICE MANUAL

Page 114 of 659

CORVETTE BODY

1B-7

HEAT

CONTROL

€P-

CABLE

VIEW A

HOOD RELEASE

Fig.

11—Cowl Ventilator

and

Controls

and reveal moldings; upper garnish molding; lower

garnish molding; side garnish molding; header latch

plates on 19467 Models and rear view mirror.

11.

Clean

up

excess sealer

and

cement with rag damp-

ened with oleum spirits, prep-sol

or

kerosene;

in-

stall wiper arm assemblies.

DOORS

ADJUSTMENTS

Door Lock Striker

Door lock strikers incorporate

an

inter-lock feature

consisting

of a

notch

in the

striker into which the lock

bolt housing extension engages. With

the

inter-lock

feature

it is

very important that

the

lock extension en-

gages properly

in the

striker notch

and

that, where

necessary,

the

correct striker emergency spacers

are

used to obtain proper engagement.

1.

To

adjust striker

up,

down,

in, or

out loosen striker

plate screws and shift striker and adjusting plates

as

required, then tighten screws.

2.

To determine

if

door lock striker emergency spacers

are required, apply modeling clay

or

body caulking

compound

in the

door lock striker notch where

the

lock extension engages,

and

then close

the

door

to

form

a

measurable impression in the clay

or

caulk-

ing compound,

as

shown

in

Figure

24.

Remove

all

clay

or

compound when adjustment

is

completed.

When dimension

"A"

from inside face

of

striker teeth

to center

of

lock extension

is

less than 3/16", install

emergency spacers

and

proper length striker attaching

screws.

NOTE:

Dimension

"B"

from center

of

lock

extension

to

inside face

of

striker notch should

.

never be less than 1/8".

If check indicates need

for

emergency spacers,

pro-

ceed

as

follows:

1.

With pencil, scribe position

of

striker on body pillar.

2.

Remove three door lock striker attaching screws and

remove striker

and

adjusting plates from pillar.

3.

To

install, place striker, shims and adjusting plates

within scribe marks

on

pillar

and

tighten screws.

IMPORTANT: Whenever

a

door

has

been

re-

moved

and

installed,

or

realigned,

the

door

SHOULD NOT be closed completely until

a

visual

check

is

made to determine

if

the lock extension/

will engage

in the

striker notch. Where

re-

quired, door lock striker emergency spacers

should

be

installed

so

that door

can be

closed

and

an

accurate check made to determine emer-

gency spacer requirements.

Door Window and Vent Adjustment

To move

the top of the

window

in or

out, the bottom

ends

of

both

run

channels

are

adjustable.

The

rear

channel

is

adjusted

by

loosening

the

lower

of

the two

screws

on the

rear face

of

door, "C" Figure 25, and

moving channel

as

necessary.

The

front channel

is ad-

justed

by

removing

the

trim pad and moving the Channel

in

or out by a

stud

and nut

adjustment, "B" Figure 25.

The

top end of the

rear channel

is

not adjustable in

or

out.

On 19467 models

an

adjustment

may be

made

to the

closed-door relationship

of the

vent assembly

to the

windshield frame. This adjustment

is

controlled

by the

stud-nut assembly "B" Figure

25.

The closed position

of the

window

is

controlled

by

bumper assemblies located

at

each end

of

window frame

as shown

in

Figure

26.

^

Access

to

bumper retaining

screw

may be

gained through holes

"D" and

"E"

in

Figure

25.

Door Hinges

The position

of the

door assembly in the body opening

is adjusted

by the

striker plate position covered

pre-

viously

and the

position

of the

door

on

the hinge rear

CHEVROLET

a

SERVICE

Page 115 of 659

CORVETTE

BODY 1B-8

2A

13

A

TYPICAL

OF 19437

AND

/3'B

LOWER

REVEAL

MOULDING

19467

13B

2B

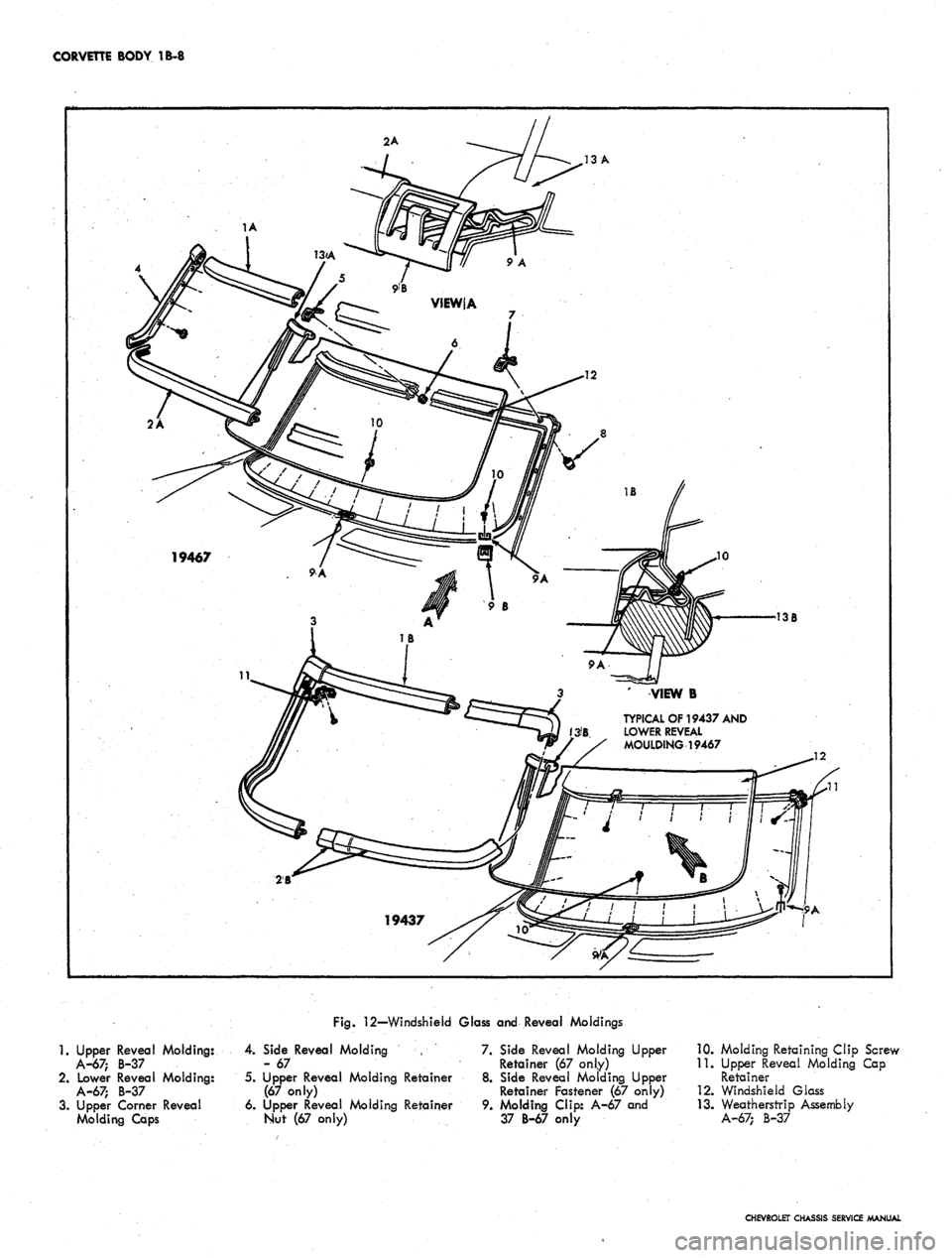

Fig.

12—Windshield Glass and Reveal Moldings

1.

Upper Reveal Molding:

A-67;

B-37

2.

Lower Reveal Molding:

A-67;

B-37

3.

Upper Corner Reveal

Molding

Caps

4.

Side Reveal Molding

- 67

5.

Upper Reveal Molding Retainer

(67 only)

6. Upper Reveal Molding Retainer

Nut (67 only)

7.

Side Reveal Molding Upper

Retainer (67 only)

8. Side Reveal Molding Upper

Retainer Fastener (67 only)

9. Molding Clip: A-67 and

37 B-67 only

10.

Molding Retaining Clip Screw

11.

Upper Reveal Molding Cap

Retainer

12.

Windshield Glass

13.

Weatherstrip Assembly

A-67;

B-37

CHEVROLET CHASSIS SERVICE MANUAL

Page 116 of 659

CORVETTE BODY 1B-9

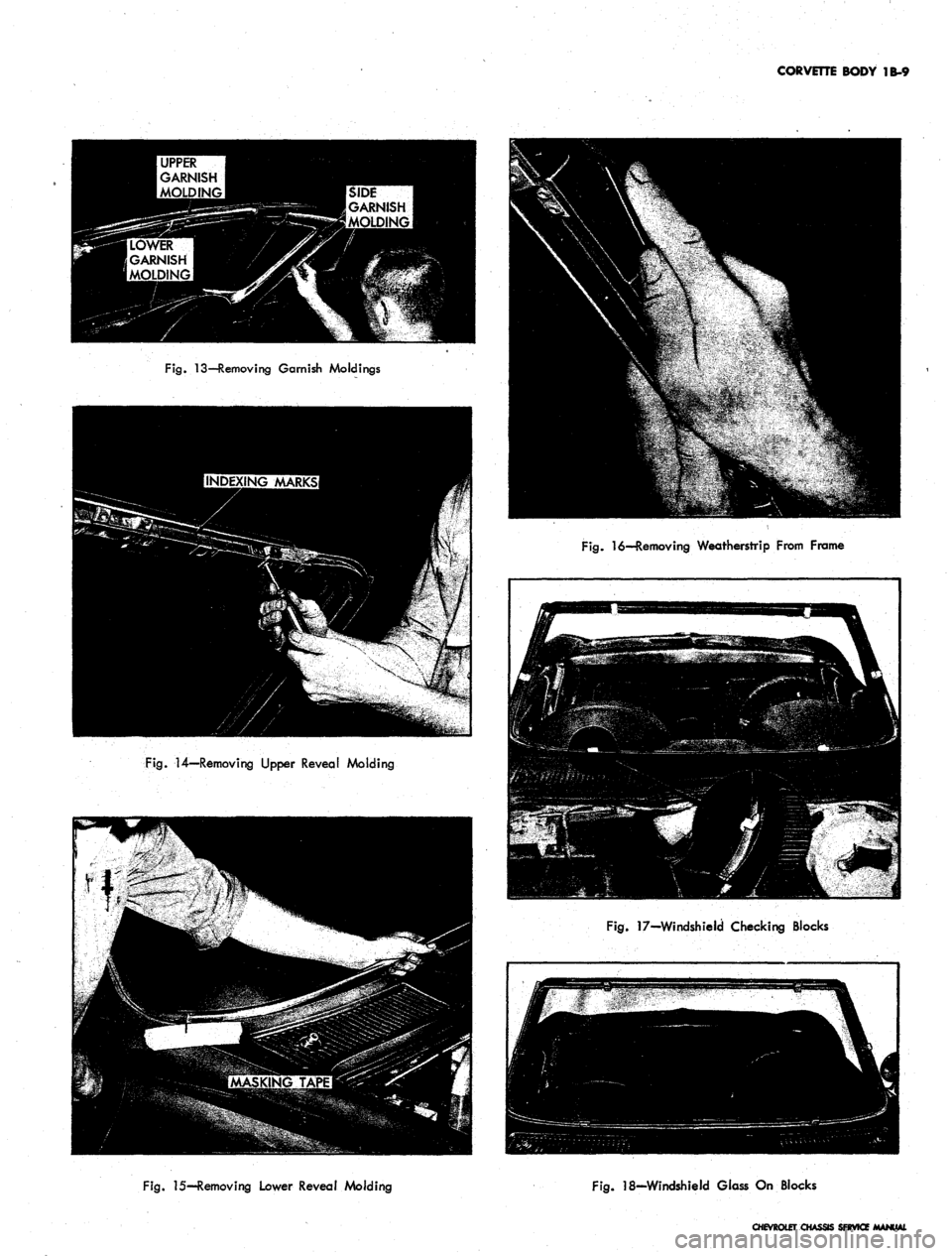

Fig.

13—Removing Garnish Moldings

Fig.

14—Removing Upper Reveal Molding

Fig.

16—Removing Weatherstrip From Frame

Fig.

17-Windshield Checking Blocks

Fig.

15—Removing Lower Reveal Molding

Fig.

18-Windshield Glass On Blocks

CHEVROLET CHASSIS SERVICE

Page 117 of 659

CORVETTE BODY IB-10

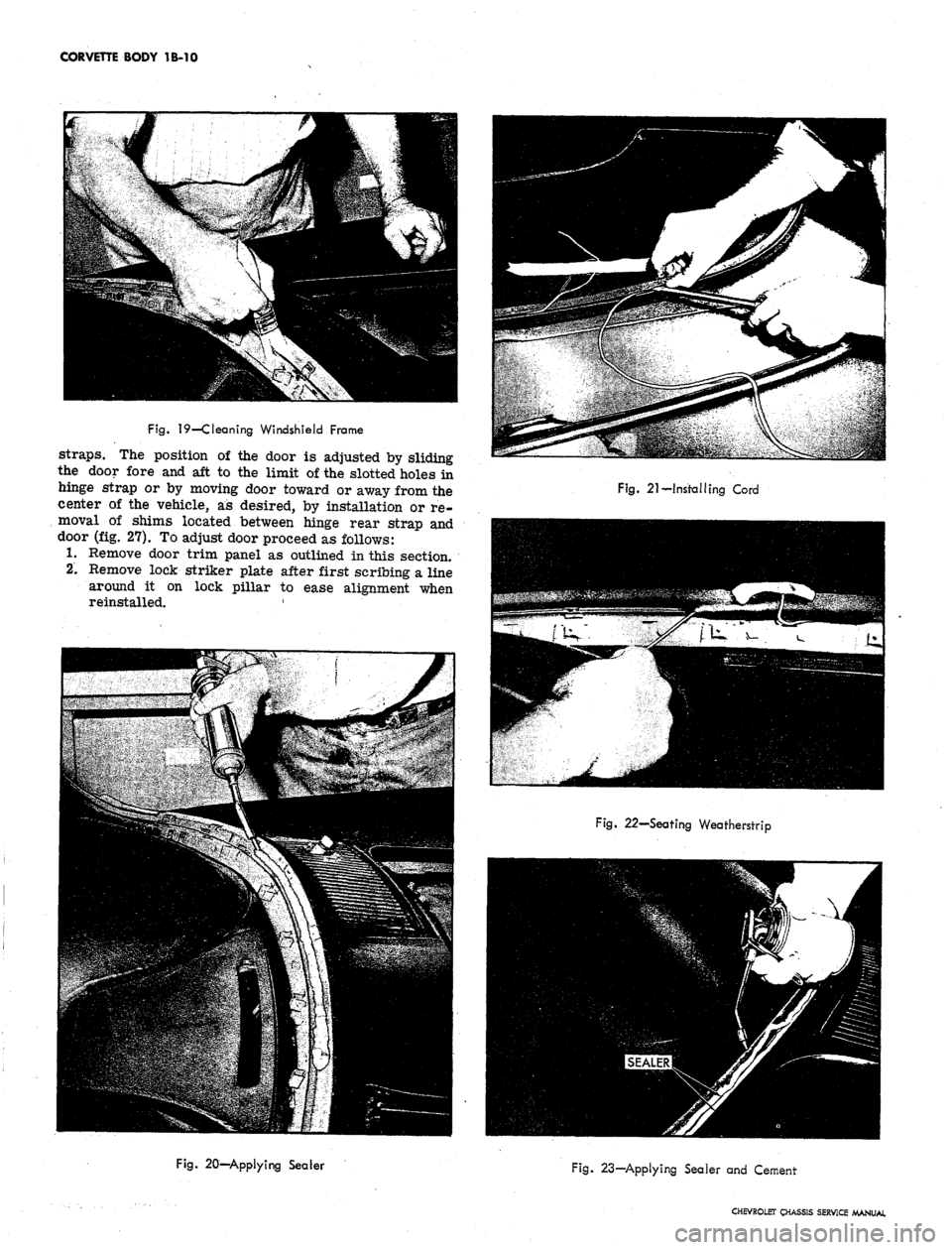

Fig.

19—Cleaning Windshield Frame

straps.

The position of the door is adjusted by sliding

the door fore and aft to the limit of the slotted holes in

hinge strap or by moving door toward or away from the

center of the vehicle, as desired, by installation or re-

moval of shims located between hinge rear strap and

door (fig. 27). To adjust door proceed as follows:

1.

Remove door trim panel as outlined in this section.

2.

Remove lock striker plate after first scribing a line

around it on lock pillar to ease alignment when

reinstalled. '

Fig. 21-Installing Cord

Fig. 22—Seating Weatherstrip

Fig. 20—Applying Sealer

Fig. 23—Applying Sealer and Cement

CHEVROLET CHASSIS SERVICE MANUAL

Page 118 of 659

CORVETTE BODY 1B-11

CLAYOfc

CAULKING

COMPOUND

Fig. 26-Window Rear Stop - Typical

Fig. 24—Checking Adjustment of Striker

3.

Adjust door as required. Location of hinge retaining

bolts may be seen in Figure 25 at "A". Do not allow

doors to hang on one hinge without support.

4.

Install trim pad and lubricate door "hold opens" and

hinges with Lubriplate or its equivalent.

NOTE:

After performing any door adjustment,

the window and door post should be checked for

alignment and adjusted as necessary. In addi-

tion,

never slam the door after adjustment with-

out first checking the door lock and striker plate

engagement. An adjustment may be necessary.

TRIM PANEL, AND INSIDE HANDLES

Figure 29 is an exploded view of integral arm rest,

inside handles, and trim panel fastenings.

Removal of trim panel may be accomplished as

follows:

1.

Remove two screws under arm rest.

2.

Using Tool J-7797, remove clips retaining window

crank and lock remote control as shown in Figure 28.

3.

Remove knob from door lock control by turning

counter-clockwise.

4.

Remove 2 screws retaining inside pull handle.

5. Remove sheet metal screws and special washers

retaining trim panel to door assembly.

6. Pull trim panel out. at bottom, tap bottom edge of

trim panel with hand to disengage from top of door.

Remove trim panel from vehicle.

WEATHERSTRIP

Figure

30

illustrates both 19437 and 19467 model door

COWL

Fig.

25-Door Adjustment Points

Fig.

27-Door Hinge

CHEVROLET CHASSIS SERVICE MANUAL

Page 119 of 659

CORVETTE BODY 1B-12

RETAINING SPRING

(DISENGAGED)

INSIDE HANDLE

PUSH TOOL IN

DIRECTION OF

ARROW.

TOOL ±7797

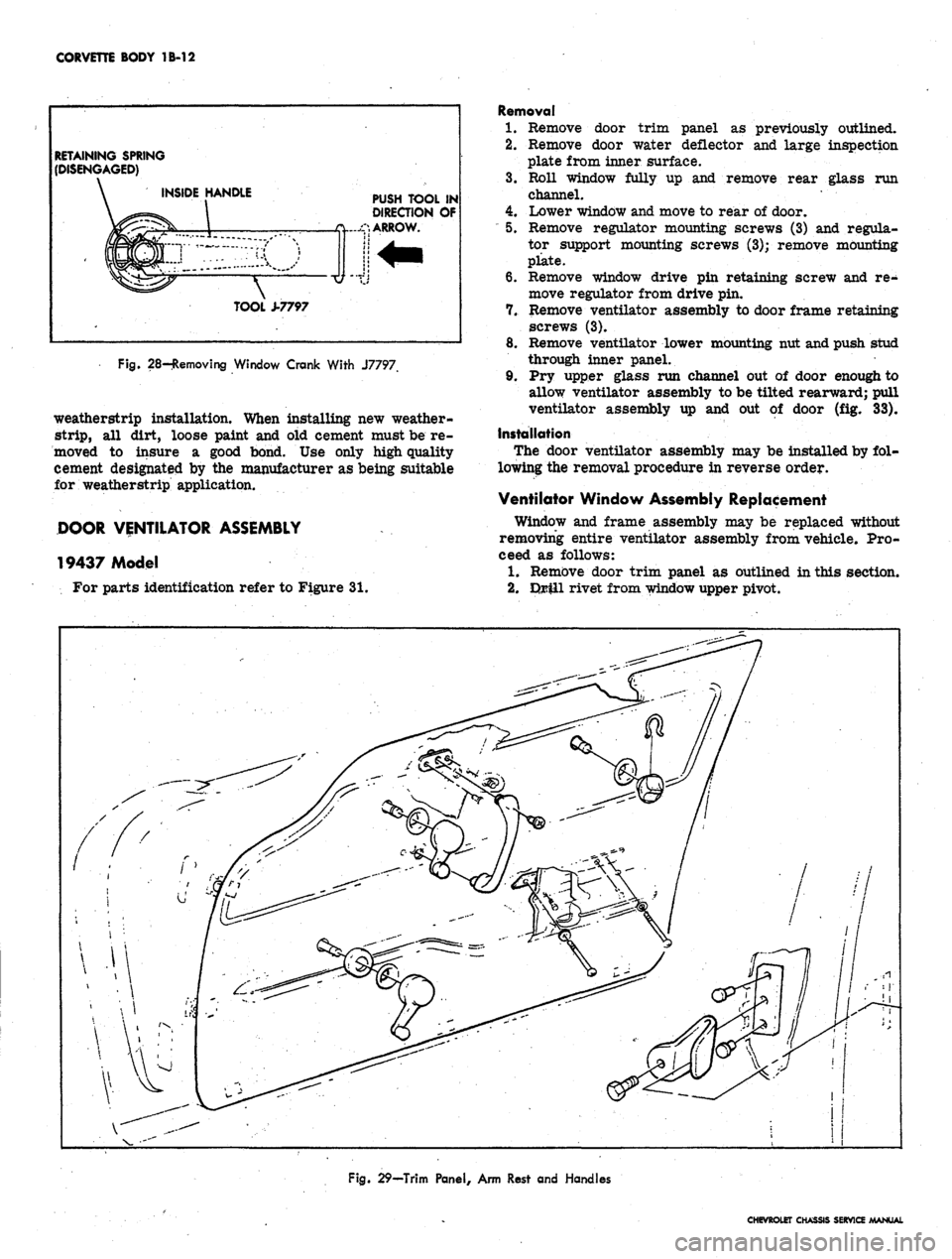

Fig. 28-Removing Window Crank With J7797

weatherstrip installation. When installing new weather-

strip,

all dirt, loose paint and old cement must be re-

moved to insure a good bond. Use only high quality

cement designated by the manufacturer as being suitable

for weatherstrip application.

DOOR VENTILATOR ASSEMBLY

19437 Model

For parts identification refer to Figure 31.

Removal

1.

Remove door trim panel as previously outlined.

2.

Remove door water deflector and large inspection

plate from inner surface.

3.

Roll window fully up and remove rear glass run

channel. •

4.

Lower window and move to rear of door.

"

5. Remove regulator mounting screws (3) and regula-

tor support mounting screws (3); remove mounting

plate.

6. Remove window drive pin retaining screw and re-

move regulator from drive pin.

7. Remove ventilator assembly to door frame retaining

screws (3).

8. Remove ventilator lower mounting nut and push stud

through inner panel.

9. Pry upper glass run channel out of door enough to

allow ventilator assembly to be tilted rearward; pull

ventilator assembly up and out of door (fig. 33).

Installation

The door ventilator assembly may be installed by fol-

lowing the removal procedure in reverse order.

Ventilator Window Assembly Replacement

Window and frame assembly may be replaced without

removing entire ventilator assembly from vehicle. Pro-

ceed as follows:

1.

Remove door trim panel as outlined in this section.

2.

Drill rivet from window upper pivot.

Fig. 29—Trim Panel, Arm Rest and Handles

CHEVROLET CHASSIS SERVICE MANUAL

Page 120 of 659

CORVETTE BODY 1B-13

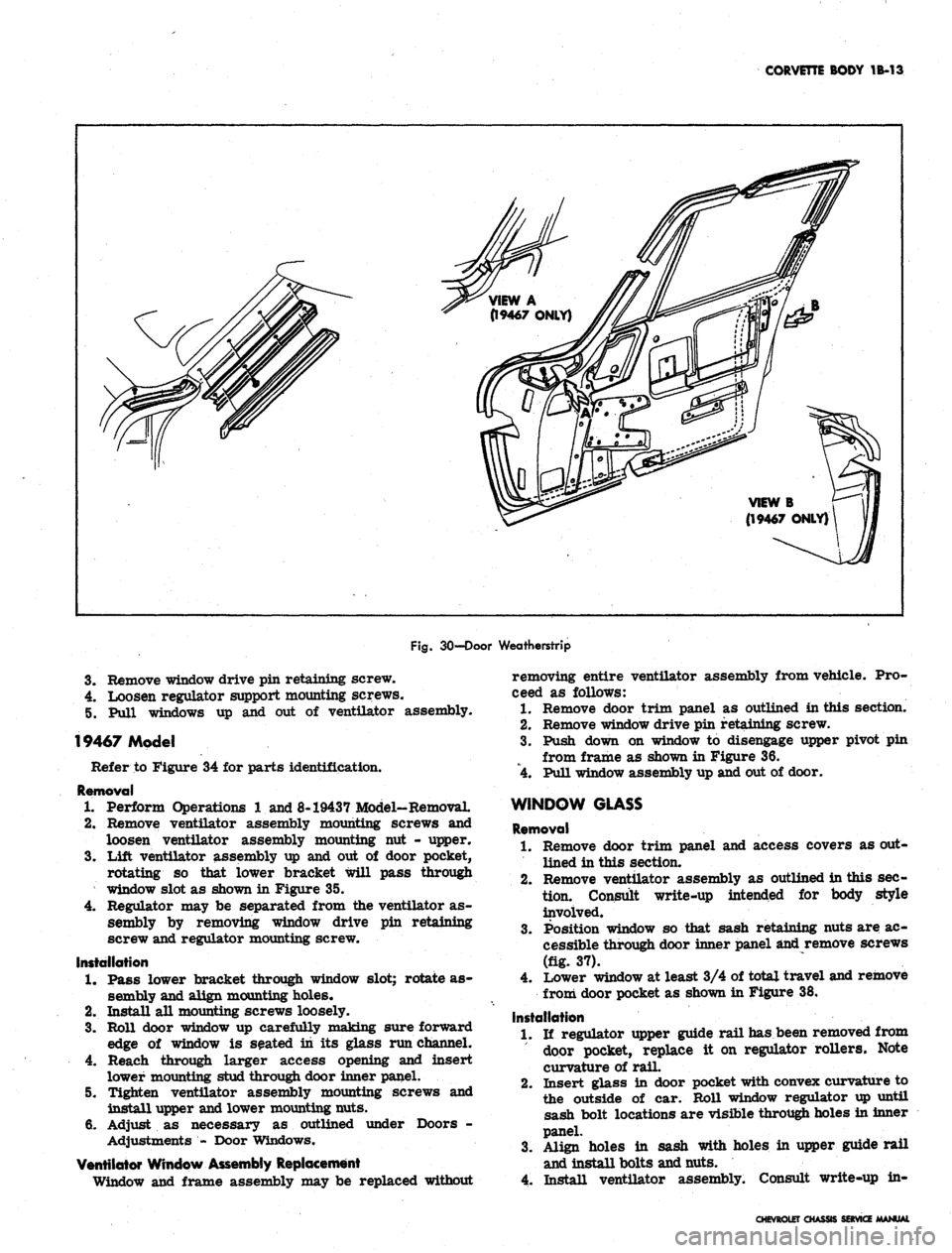

Fig.

30-Door Weatherstrip

3.

Remove window drive pin retaining screw.

4.

Loosen regulator support mounting screws.

5. Pull windows up and out of ventilator assembly.

19467 Model

Refer to Figure 34 for parts identification.

Removal

1.

Perform Operations 1 and 8-19437 Model-Removal.

2.

Remove ventilator assembly mounting screws and

loosen ventilator assembly mounting nut - upper.

3.

Lift ventilator assembly up and out of door pocket,

rotating so that lower bracket will pass through

window slot as shown in Figure 35.

4.

Regulator may be separated from the ventilator as-

sembly by removing window drive pin retaining

screw and regulator mounting screw.

Installation

1.

Pass lower bracket through window slot; rotate as-

sembly and align mounting holes*

2.

Install all mounting screws loosely.

3.

Roll door window up carefully making sure forward

edge of window is seated in its glass run channel.

4.

Reach through larger access opening and insert

lower mounting stud through door inner panel.

5. Tighten ventilator assembly mounting screws and

install upper and lower mounting nuts.

6. Adjust as necessary as outlined under Doors -

Adjustments - Door Windows.

Ventilator Window Assembly Replacement

Window and frame assembly may be replaced without

removing entire ventilator assembly from vehicle. Pro-

ceed as follows:

1.

Remove door trim panel as outlined in this section.

2.

Remove window drive pin retaining screw.

3.

Push down on window to disengage upper pivot pin

from frame as shown in Figure 36.

4.

Pull window assembly up and out of door.

WINDOW GLASS

Removal

1.

Remove door trim panel and access covers as out-

lined in this section.

2.

Remove ventilator assembly as outlined in this sec+

tion.

Consult write-up intended for body style

involved.

Position window so that sash retaining nuts are ac-

cessible through door inner panel and remove screws

(fig. 37).

Lower window at least 3/4 of total travel and remove

3.

4.

from door pocket as shown in Figure 38.

Installation

1.

If regulator upper guide rail has been removed from

door pocket, replace it on regulator rollers. Note

curvature of rail.

2.

Insert glass in door pocket with convex curvature to

the outside of car. Roll window regulator up until

sash bolt locations are visible through holes in inner

panel.

3.

Align holes in sash with holes in upper guide rail

and install bolts and nuts.

4.

Install ventilator assembly. Consult write-up in-

CHEVROLETCH>

SERVICE