CHEVROLET CAMARO 1967 1.G Chassis Repair Manual

Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 61 of 659

HEATER AND AIR CONDITIONING 1A-38

HIGH BLOWER

DELAY RELAY

O) MASTER AND

HIGH BLOWER

DELAY RELAY

GROUND

Fig.

49A-Comfortron Wiring Diagram-Underhood

CHEVROLET CHASSIS SERVICE AAANUAL

Page 62 of 659

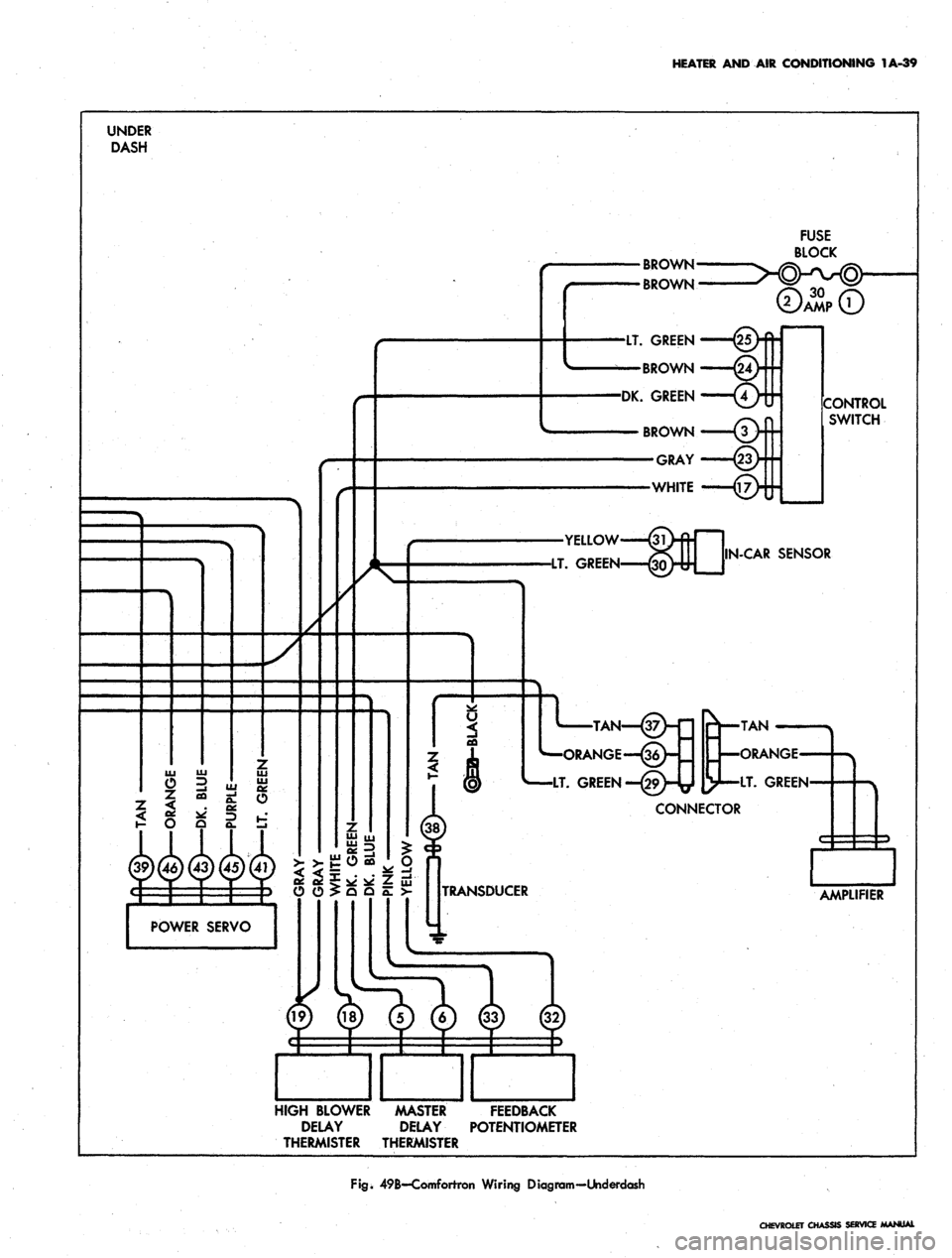

HEATER AND AIR CONDITIONING 1A-39

BROWN

BROWN

LT.

GREEN

BROWN

DK. GREEN

CONTROL

SWITCH

N-CAR

SENSOR

"—ORANGE—(36

[y—LT. GREEN

*)WWWW 55|—jg

TRANSDUCER

POWER SERVO

HIGH BLOWER MASTER FEEDBACK

DELAY DELAY POTENTIOMETER

THERMISTER THERMISTER

Fig.

49B-Comforrron Wiring Diagram-Underdash

CHEVROLET CHASSIS SERVICE AAANUAL

Page 63 of 659

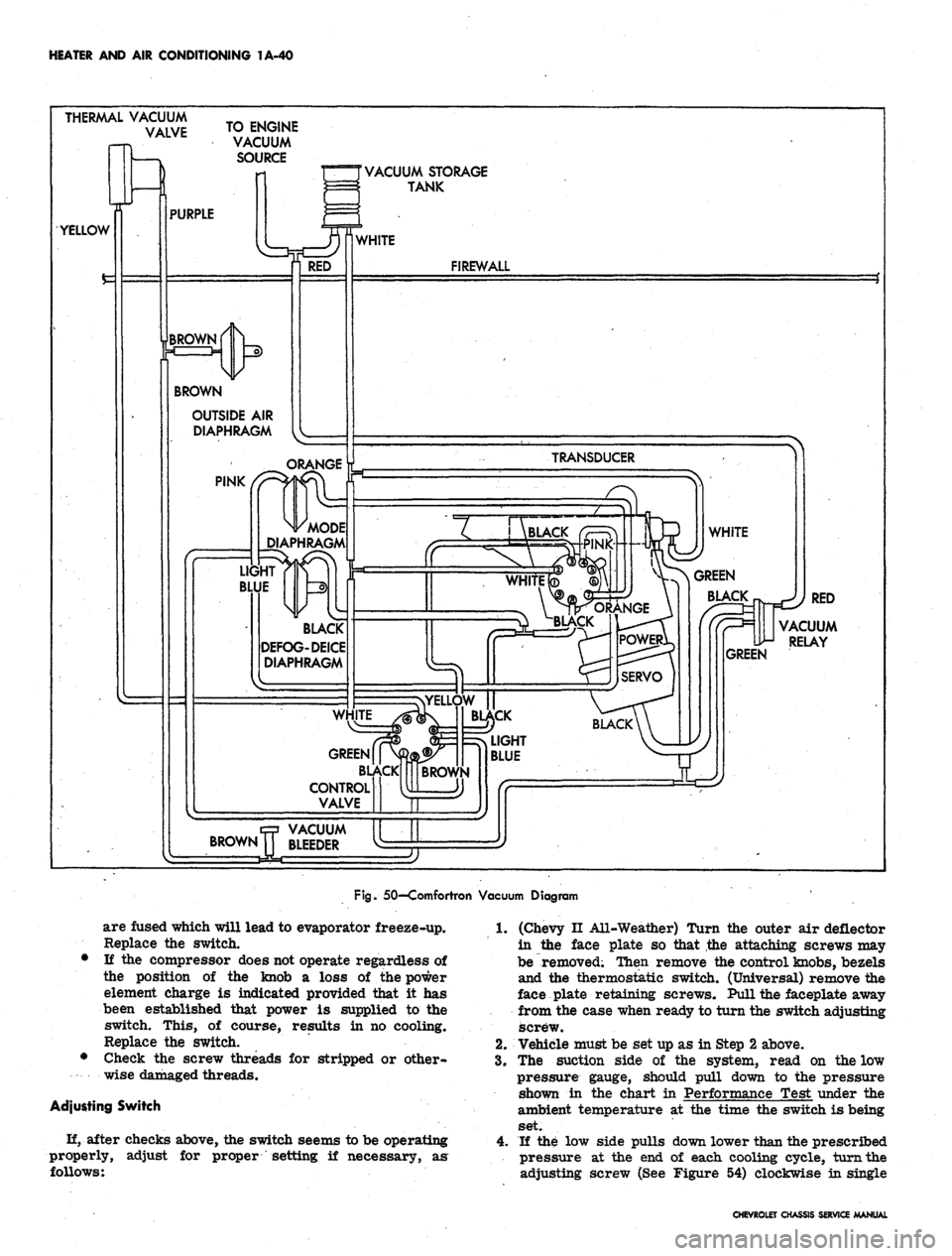

HEATER AND AIR CONDITIONING 1A-40

THERAAAL VACUUM

VALVE

TO ENGINE

VACUUM

SOURCE

VACUUM STORAGE

TANK

OUTSIDE AIR

DIAPHRAGM

MODE

DIAPHRAGM

VACUUM

RELAY

BLACK

DEFOG-DEICE

DIAPHRAGM

GREEN

BLACKj ||

|

BROWN

CONTROL

VALVE

Fig.

50—Comfortron Vacuum Diagram

are fused which will lead to evaporator freeze-up.

Replace the switch.

• If the compressor does not operate regardless of

the position of the knob a loss of the power

element charge is indicated provided that it has

been established that power is supplied to the

switch. This, of course, results in no cooling.

Replace the switch.

• Check the screw threads for stripped or other-

wise damaged threads.

Adjusting Switch

H, after checks above, the switch seems to be operating

properly,

follows:

adjust for proper setting if necessary, as

1.

(Chevy II All-Weather) Turn the outer air deflector

in the face plate so that the attaching screws may

be removed; Then remove the control knobs, bezels

and the thermostatic switch. (Universal) remove the

face plate retaining screws. Pull the faceplate away

from the case when ready to turn the switch adjusting

screw.

2.

Vehicle must be set up as in Step 2 above.

3.

The suction side of the system, read on the low

pressure gauge, should pull down to the pressure

shown in the chart in Performance Test under the

ambient temperature at the time the switch is being

set.

4.

If the low side pulls down lower than the prescribed

pressure at the end of each cooling cycle, turn the

adjusting screw (See Figure 54) clockwise in single

CHEVROLET CHASSIS SERVICE MANUAL

Page 64 of 659

HEATER

AND AIR

CONDITIONING

1A-41

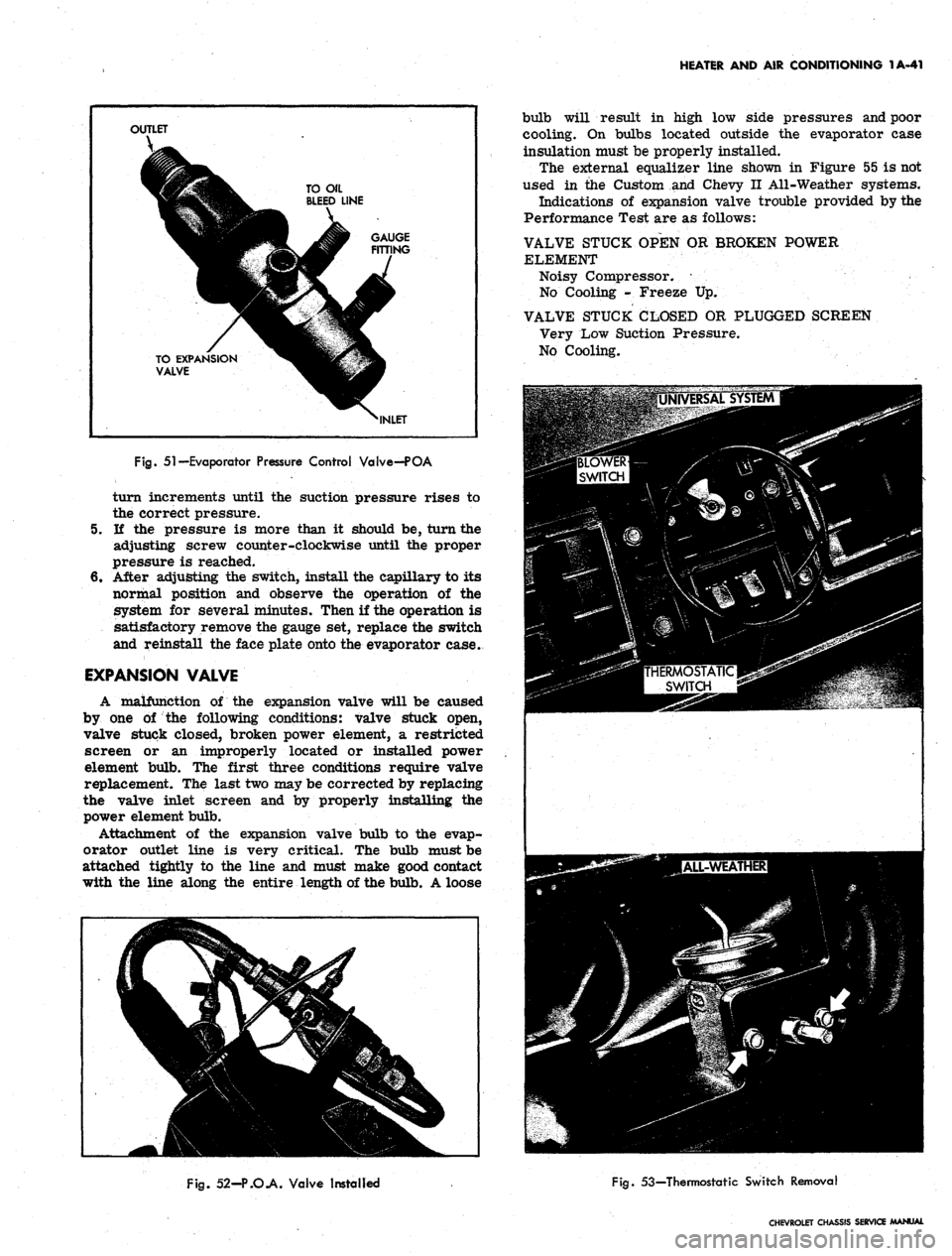

OUTLET

1

TO EXPANSION

^

VALVE

TO

OIL

BLEED LINE

^ INLET

Fig.

51—Evaporator Pressure Control Valve—POA

turn increments until

the

suction pressure rises

to

the correct pressure.

5.

If the

pressure

is

more than

it

should

be,

turn the

adjusting screw counter-clockwise until

the

proper

pressure

is

reached.

6. After adjusting

the

switch, install the capillary to

its

normal position

and

observe

the

operation

of the

system

for

several minutes. Then

if

the operation

is

satisfactory remove the gauge

set,

replace the switch

and reinstall the face plate onto the evaporator case.

EXPANSION VALVE

A malfunction

of the

expansion valve will

be

caused

by

one of the

following conditions: valve stuck open,

valve stuck closed, broken power element,

a

restricted

screen

or an

improperly located

or

installed power

element bulb.

The

first three conditions require valve

replacement.

The

last two may be corrected by replacing

the valve inlet screen

and by

properly installing

the

power element bulb.

Attachment

of the

expansion valve bulb

to the

evap-

orator outlet line

is

very critical.

The

bulb must be

attached tightly

to the

line

and

must make good contact

with

the

line along

the

entire length

of

the bulb. A loose

bulb will result

in

high

low

side pressures and poor

cooling.

On

bulbs located outside

the

evaporator case

insulation must be properly installed.

The external equalizer line shown

in

Figure

55 is

not

used

in the

Custom

and

Chevy

II

All-Weather systems.

Indications

of

expansion valve trouble provided by the

Performance Test are

as

follows:

VALVE STUCK OPEN

OR

BROKEN POWER

ELEMENT

Noisy Compressor.

•

No Cooling

-

Freeze

Up.

VALVE STUCK CLOSED

OR

PLUGGED SCREEN

Very Low Suction Pressure.

No Cooling.

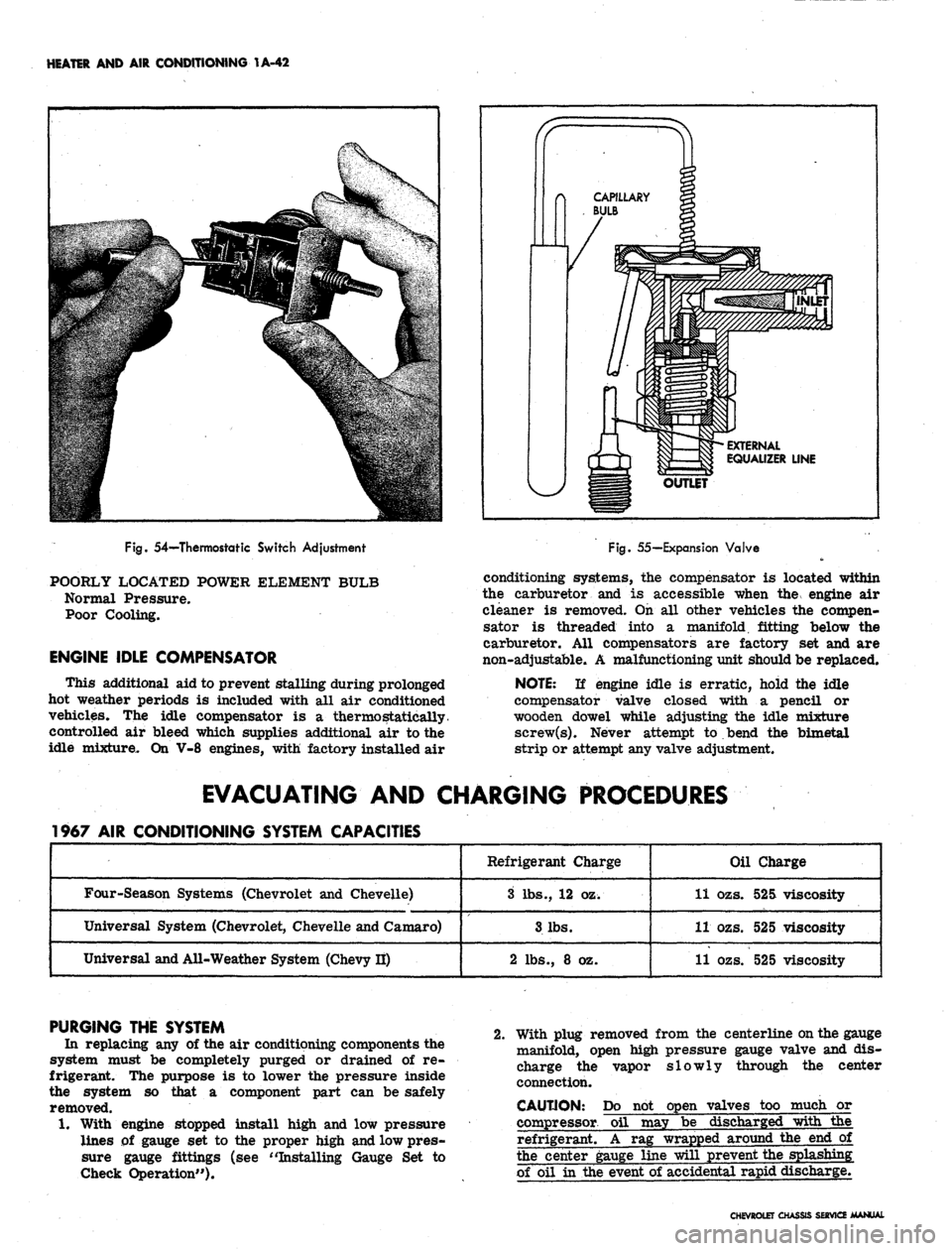

Fig.

52-P.O.A. Valve Installed

Fig.

53—Thermostatic Switch Removal

CHEVROLET CHASSIS SERVICE MANUAL

Page 65 of 659

HEATER AND AIR CONDITIONING 1A-42

EXTERNAL

EQUALIZER LINE

Fig. 54—Thermosratic Switch Adjustment

POORLY LOCATED POWER ELEMENT BULB

Normal Pressure.

Poor Cooling.

ENGINE IDLE COMPENSATOR

This additional aid to prevent stalling during prolonged

hot weather periods is included with all air conditioned

vehicles. The idle compensator is a thermostatically

controlled air bleed which supplies additional air to the

idle mixture. On V-8 engines, with factory installed air

Fig. 55—Expansion Valve

conditioning systems, the compensator is located within

the carburetor and is accessible when the engine air

cleaner is removed. On all other vehicles the compen-

sator is threaded into a manifold, fitting below the

carburetor. All compensators are factory set and are

non-adjustable. A malfunctioning unit should be replaced.

NOTE:

If engine idle is erratic, hold the idle

compensator valve closed with a pencil or

wooden dowel while adjusting the idle mixture

screw(s). Never attempt to bend the bimetal

strip or attempt any valve adjustment.

EVACUATING AND CHARGING PROCEDURES

1967 AIR CONDITIONING SYSTEM CAPACITIES

Four-Season Systems (Chevrolet and Chevelle)

Universal System (Chevrolet, Chevelle and Camaro)

Universal and All-Weather System (Chevy II)

Refrigerant Charge

3 lbs., 12 oz.

3 lbs.

2 lbs., 8 oz.

Oil Charge

11 ozs. 525 viscosity

11 ozs. 525 viscosity

11 ozs. 525 viscosity

PURGING THE SYSTEM

In replacing any of the air conditioning components the

system must be completely purged or drained of re-

frigerant. The purpose is to lower the pressure inside

the system so that a component part can be safely

removed.

1.

With engine stopped install high and low pressure

lines of gauge set to the proper high and low pres-

sure gauge fittings (see "Installing Gauge Set to

Check Operation").

2.

With plug removed from the centerline on the gauge

manifold, open high pressure gauge valve and dis-

charge the vapor slowly through the center

connection.

CAUTION: Do

compressor

refrigerant.

not open valves too much or

oil may be discharged with the

A rag wrapped around the end of

the center gauge line will prevent the splashing

of oil in the event of accidental rapid discharge.

CHEVROLET CHASSIS SERVICE MANUAL

Page 66 of 659

HEATER AND AIR CONDITIONING 1A-43

LOW PRESSURE

CONTROL

HIGH PRESSURE

CONTROL

3

VACUUM

CONTROL

4

FREON

CONTROL

Fig,

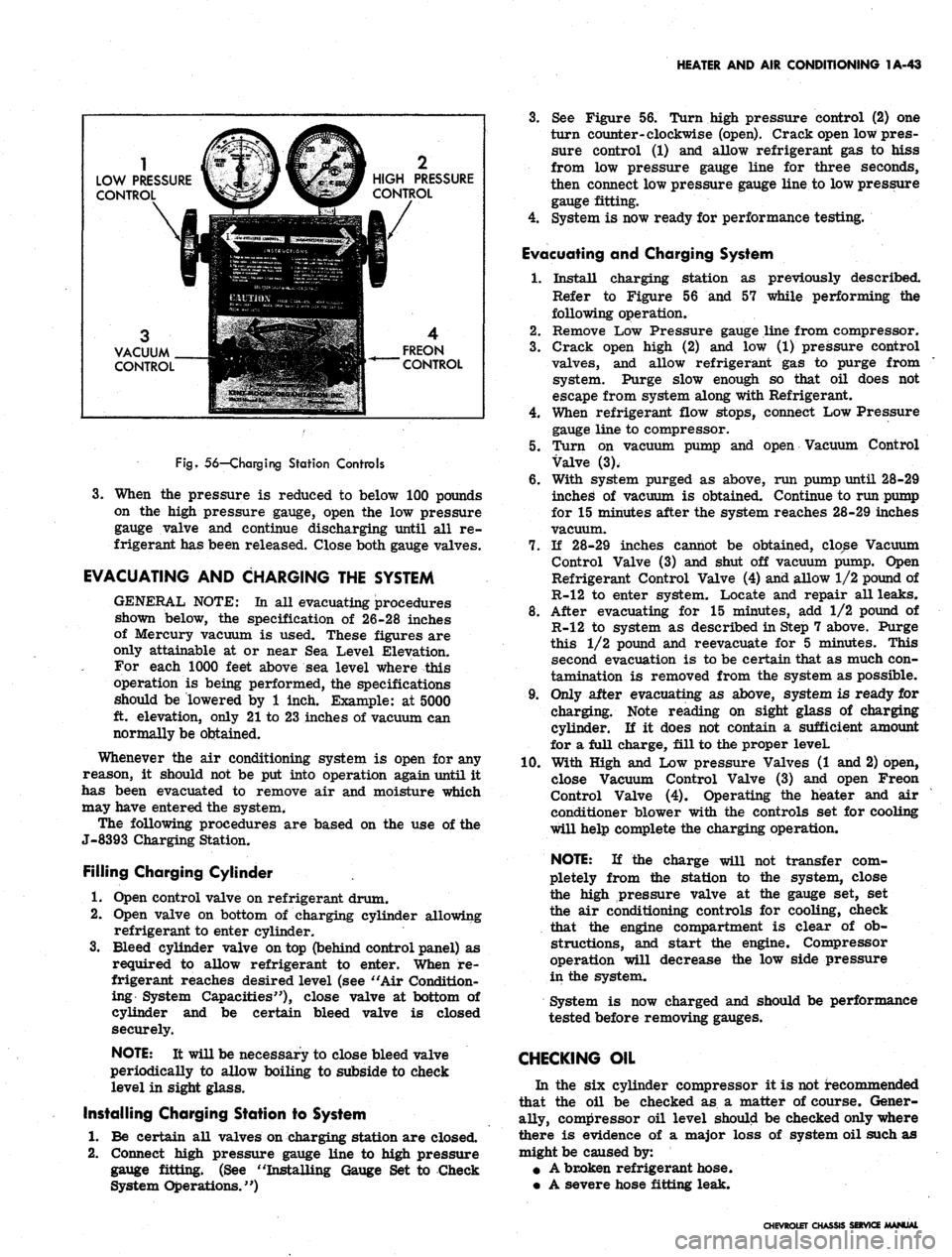

56—Charging Station Controls

3.

When the pressure is reduced to below 100 pounds

on the high pressure gauge, open the low pressure

gauge valve and continue discharging until all re-

frigerant has been released. Close both gauge valves.

EVACUATING AND CHARGING THE SYSTEM

GENERAL NOTE: La all evacuating procedures

shown below, the specification of 26-28 inches

of Mercury vacuum is used. These figures are

only attainable at or near Sea Level Elevation.

For each 1000 feet above sea level where this

operation is being performed, the specifications

should be lowered by 1 inch. Example: at 5000

ft. elevation, only 21 to 23 inches of vacuum can

normally be obtained.

Whenever the air conditioning system is open for any

reason, it should not be put into operation again until it

has been evacuated to remove air and moisture which

may have entered the system.

The following procedures are based on the use of the

J-8393 Charging Station.

Filling Charging Cylinder

1.

Open control valve on refrigerant drum.

2.

Open valve on bottom of charging cylinder allowing

refrigerant to enter cylinder.

3.

Bleed cylinder valve on top (behind control panel) as

required to allow refrigerant to enter. When re-

frigerant reaches desired level (see "Air Condition-

ing System Capacities"), close valve at bottom of

cylinder and be certain bleed valve is closed

securely.

NOTE: It will be necessary to close bleed valve

periodically to allow boiling to subside to check

level in sight glass.

Installing Charging Station to System

1.

Be certain all valves on charging station are closed.

2.

Connect high pressure gauge line to high pressure

gauge fitting. (See "Installing Gauge Set to Check

System Operations.")

3.

See Figure 56. Turn high pressure control (2) one

turn counter-clockwise (open). Crack open low pres-

sure control (1) and allow refrigerant gas to hiss

from low pressure gauge line for three seconds,

then connect low pressure gauge line to low pressure

gauge fitting.

4.

System is now ready for performance testing.

Evacuating and Charging System

1.

Install charging station as previously described.

Refer to Figure 56 and 57 while performing the

following operation.

2.

Remove Low Pressure gauge line from compressor.

3.

Crack open high (2) and low (1) pressure control

valves, and allow refrigerant gas to purge from

system. Purge slow enough so that oil does not

escape from system along with Refrigerant.

4.

When refrigerant flow stops, connect Low Pressure

gauge line to compressor.

5.

Turn on vacuum pump and open Vacuum Control

Valve (3).

6. With system purged as above, run pump until 28-29

inched of vacuum is obtained. Continue to run pump

for 15 minutes after the system reaches 28-29 inches

vacuum.

7.

If 28-29 inches cannot be obtained, close Vacuum

Control Valve (3) and shut off vacuum pump. Open

Refrigerant Control Valve (4) and allow 1/2 pound of

R-12 to enter system. Locate and repair all leaks.

8. After evacuating for 15 minutes, add 1/2 pound of

R-12 to system as described in Step 7 above. Purge

this 1/2 pound and reevacuate for 5 minutes. This

second evacuation is to be certain that as much con-

tamination is removed from the system as possible.

9. Only after evacuating as above, system is ready for

charging. Note reading on sight glass of charging

cylinder. If it does not contain a sufficient amount

for a full charge, fill to the proper leveL

10.

With High and Low pressure Valves (1 and 2) open,

close Vacuum Control Valve (3) and open Freon

Control Valve (4). Operating the heater and air

conditioner blower with the controls set for cooling

will help complete the charging operation.

NOTE: If the charge will not transfer com-

pletely from the station to the system, close

the high pressure valve at the gauge set, set

the air conditioning controls for cooling, check

that the engine compartment is clear of ob-

structions, and start the engine. Compressor

operation will decrease the low side pressure

in the system.

System is now charged and should be performance

tested before removing gauges.

CHECKING OIL

In the six cylinder compressor it is not recommended

that the oil be checked as a matter of course. Gener-

ally, compressor oil level should be checked only where

there is evidence of a major loss of system oil such as

might be caused by:

• A broken refrigerant hose.

• A severe hose fitting leak.

CHEVROLET CHASSIS SERVICE MANUAL

Page 67 of 659

HEATER AND AIR CONDITIONING 1A-44

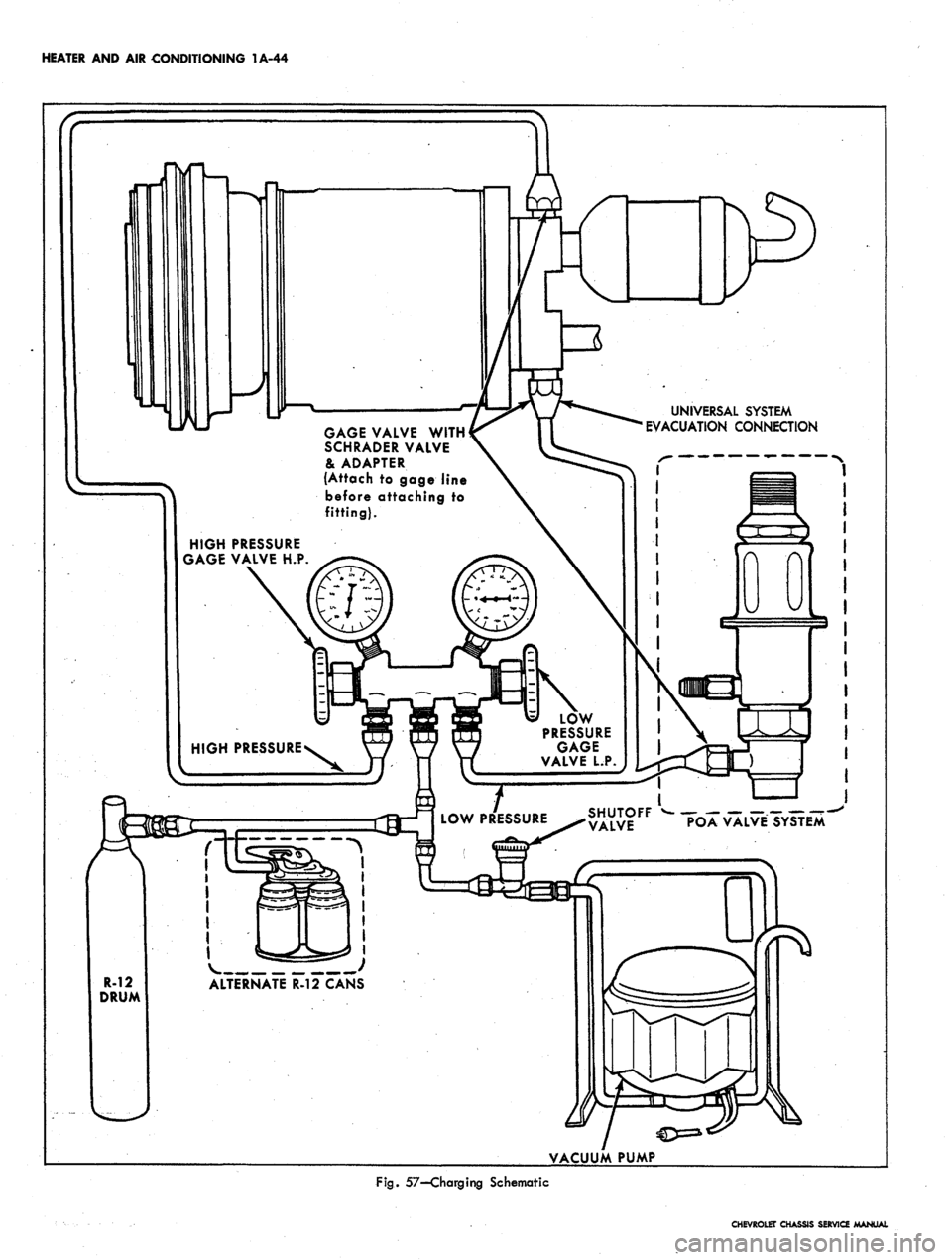

UNIVERSAL SYSTEM

EVACUATION CONNECTION

GAGE VALVE WITH

SCHRADER VALVE

& ADAPTER

(Attach

to

gage line

before attaching to

fitting).

HIGH PRESSURE

GAGE VALVE H.P.

LOW

PRESSURE

GAGE

VALVE L.P.

LOW PRESSURE

VALVE

POA

VALVE SYSTEM

ALTERNATE R-12 CANS

VACUUM PUMP

Fig.

57—Charging Schematic

CHEVROLET CHASSIS SERVICE MANUAL

Page 68 of 659

HEATER AND AIR CONDITIONING 1A-45

• A very badly leaking compressor seal.

• Collision damage to the system components.

As a quick check on compressor oil charge, with the

engine off, carefully crack open the oil drain plug on the

bottom of the compressor. If oil comes out, the com-

pressor has the required amount of oil To further check

the compressor oil charge, should the above test show

insufficient oil, it is necessary to remove the compressor

from the vehicle, drain and measure the oil.

Checking Compressor Oil Charge

1.

Run the system for 10 minutes at 500-600 engine

rpm with controls set for maximum cooling and

high blower speed.

2.

Turn off engine, discharge the system, remove

compressor from vehicle, place it in a horizontal

position with the drain plug downward. Remove the

drain plug and, tipping the compressor back and

forth and rotating the compressor shaft, drain the

oil into a clean container, measure and discard the

oiL

3.

a. If the quantity drained was 4 fluid oz. or more,

add the same amount of new refrigerant oil to

the replacement compressor.

b.

If the quantity drained was less than 4 fluid oz.,

add 6 fluid oz. of new refrigeration oil to the

replacement compressor.

c. If a new service compressor is being installed,

drain all oil from it and replace only the amount

specified in Steps 3a and 3b above.

d. If a field repaired compressor is being installed,

add an additional 1 fluid oz. to the compressor.

4.

In the event that it is not possible to idle the com-

pressor as outlined in Step 1 to effect oil return to

it, proceed as follows:

a. Remove the compressor, drain, measure and

discard the oil.

b.

If the amount drained is more than 1-1/2 fluid

oz.

and the system shows no signs of a major

leak, add the same amount to the replacement

compressor.

c. If the amount drained is less than 1-1/2 fluid oz.

and the system appears to have lost an excessive

amount of oil add 6 fluid oz. of clean refrigeration

oil to replacement compressor, 7 fluid oz. to a

repaired compressor.

If the oil contains chips or other foreign ma-

terial, replace the receiver-dehydrator and flush

or replace all component parts as necessary. Add

the full specified volume of new refrigeration oil

to the system.

5.

Add additional oil in the following amounts for any

system components being replaced.

Evaporator 3 fluid oz.

Condenser . . . . ... . . . . . . 1 fluid oz.

Receiver-Dehydrator ....... 1 fluid oz.

NOTE: When adding oil to the compressor, it

will be necessary to tilt the rear end of the

compressor up so that the oil will not run out

of the suction and discharge ports. Do not set

the compressor on the shaft end.

Adding Oil to the System

The system should be completely assembled and un-

charged before adding oil. Use only uncontaminated

refrigerant oil (525 viscosity) and add as follows:

1.

Connect the low pressure line from the gauge set

to the low pressure gauge fitting on the P.O.A.

valve (Four-Season) or low pressure fitting on the

compressor connector Mock (Universal System).

2.

Connect the high pressure line from the charging

station gauge set to the compressor muffler or high

pressure side of the connector block.

3.

Disconnect the high pressure line from the gauge set,

make certain that the line is clean, and place the

end in a graduated container.

4.

Pour enough refrigerant oil into the container so

that the required volume may be drawn into the

system by the high pressure hose.

5.

Close the high pressure valve at the gauge set,

and open the low pressure valve.

6. Operate the vacuum pump to drop the pressure within

the system and cause atmospheric pressure to force

oil through the high pressure line into the system.

When the oil level has dropped the required volume,

pull the line out of the oil container and continue

vacuum pump operation to force the oil contained

in the line into the system.

7.

Shut off the vacuum pump and connect ttye high

pressure line to the gauge set. Open the high

pressure valve and evacuate the system through

the high and low pressure sides of the system.

Complete the charging operation as outlined in Step

10 under "Evacuating and Charging System".

COMPONENT REPLACEMENT AND MINOR REPAIRS

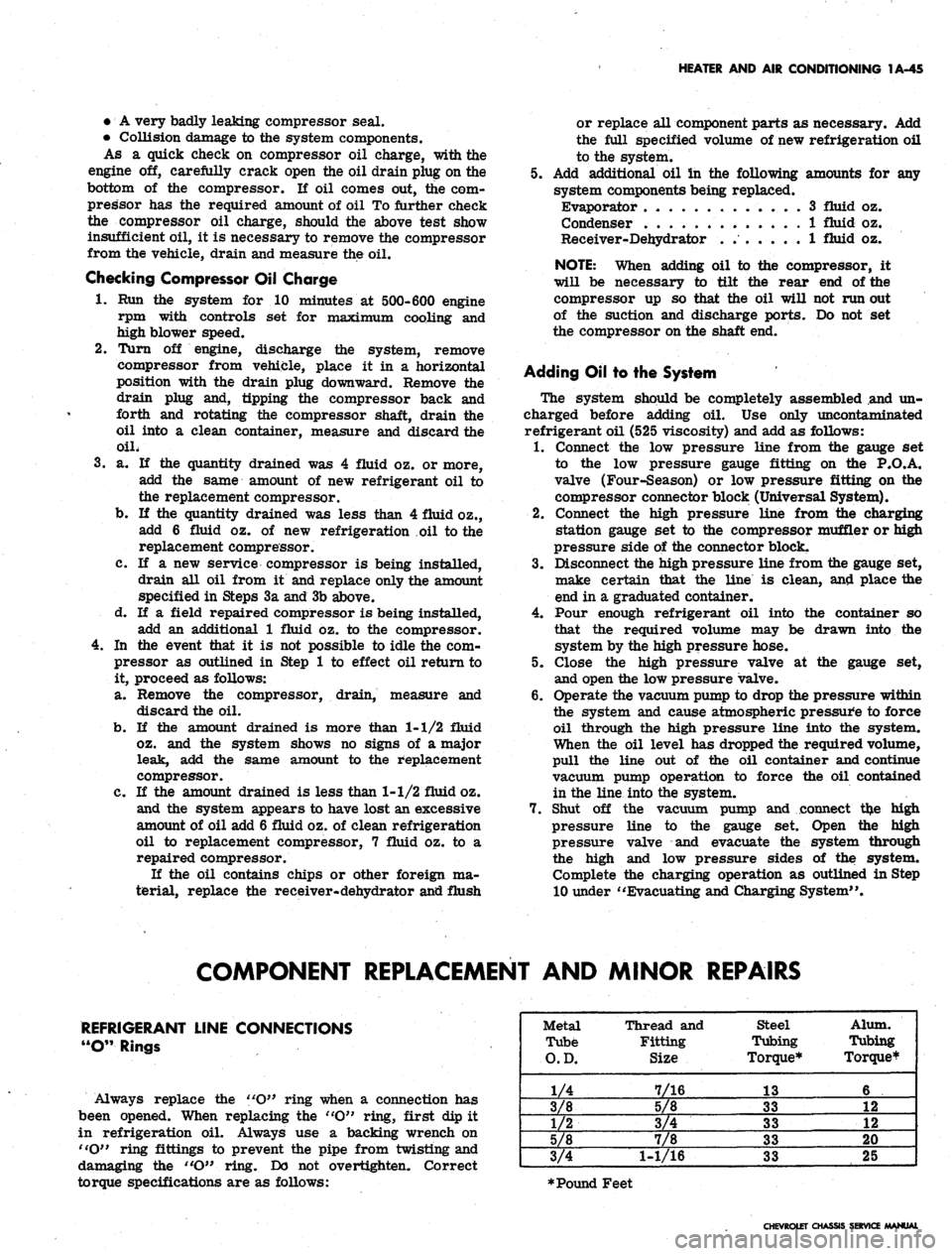

REFRIGERANT LINE CONNECTIONS

"O"

Rings

Always replace the "O" ring when a connection has

been opened. When replacing the "O" ring, first dip it

in refrigeration oil. Always use a backing wrench on

"O"

ring fittings to prevent the pipe from twisting and

damaging the "O" ring. Do not overtighten. Correct

torque specifications are as follows:

Metal

Tube

O.D.

1/4

3/8

1/2

5/8

3/4

Thread and

Fitting

Size

7/16

5/8

3/4

7/8

1-1/16

Steel

Tubing

Torque*

13

33

33

33

33

Alum.

Tubing

Torque*

6

12

12

20

25

* Pound Feet

CHEVROLET CHASSIS SERVICE

Page 69 of 659

HEATER AND AIR CONDITIONING 1A-46

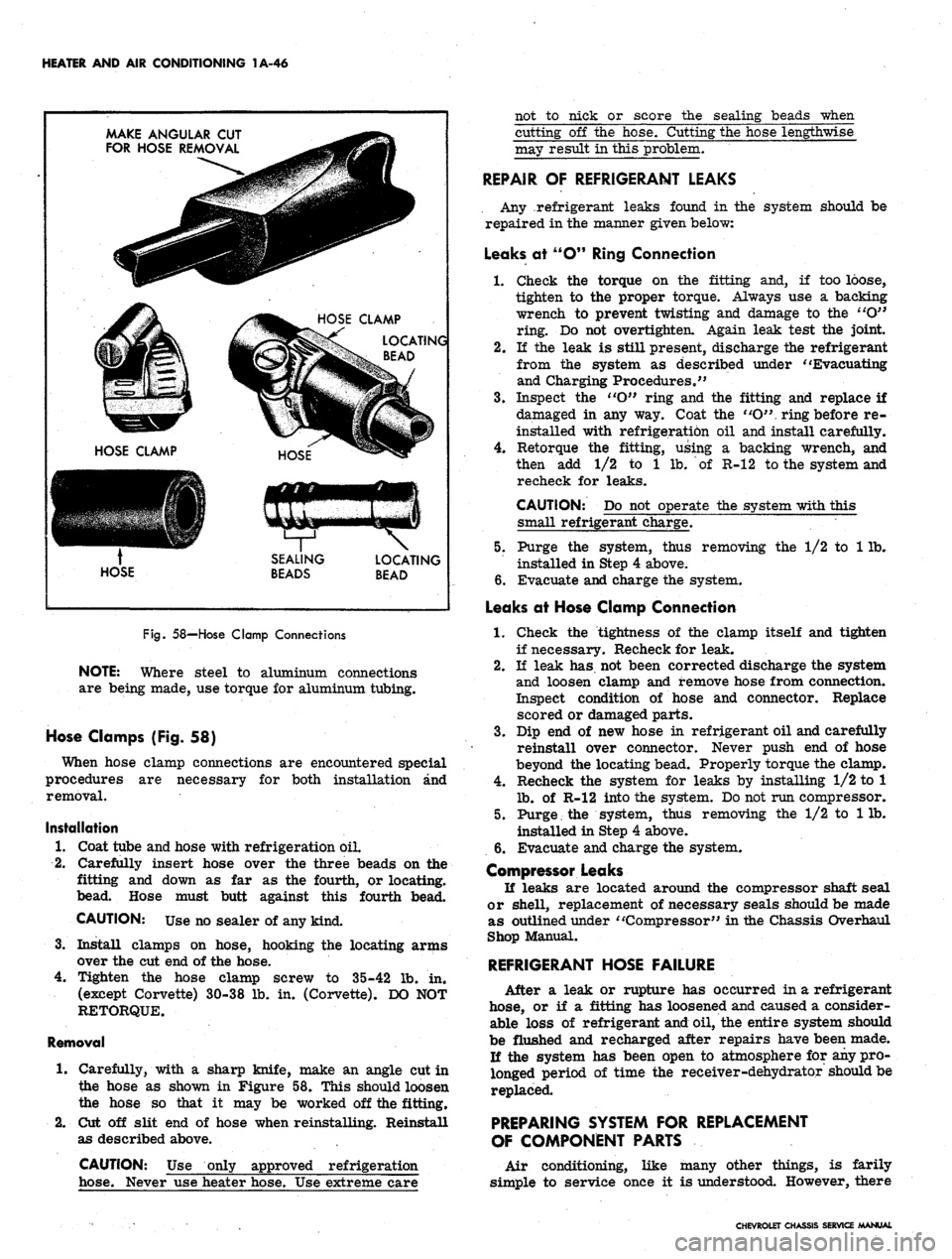

MAKE ANGULAR CUT

FOR HOSE REMOVAL

LOCATING

BEAD

SEALING

BEADS

LOCATING

BEAD

not to nick or score the sealing beads when

cutting off the hose. Cutting the hose lengthwise

may result in this problem.

Fig.

58—Hose Clamp Connections

NOTE:

Where steel to aluminum connections

are being made, use torque for aluminum tubing.

Hose Clamps (Fig. 58)

When hose clamp connections are encountered special

procedures are necessary for both installation and

removal.

Installation

1.

Coat tube and hose with refrigeration oil.

2.

Carefully insert hose over the three beads on the

fitting and down as far as the fourth, or locating,

bead. Hose must butt against this fourth bead.

CAUTION: Use no sealer of any kind.

3.

Install clamps on hose, hooking the locating arms

over the cut end of the hose.

4.

Tighten the hose clamp screw to 35-42 lb. in.

(except Corvette) 30-38 lb. in. (Corvette). DO NOT

RETORQUE.

Removal

1.

Carefully, with a sharp knife, make an angle cut in

the hose as shown in Figure 58. This should loosen

the hose so that it may be worked off the fitting.

2.

Cut off slit end of hose when reinstalling. Reinstall

as described above.

CAUTION: Use only approved refrigeration

hose. Never use heater hose. Use extreme care

REPAIR OF REFRIGERANT LEAKS

Any refrigerant leaks found in the system should be

repaired in the manner given below:

Leaks at "O" Ring Connection

1.

Check the torque on the fitting and, if too loose,

tighten to the proper torque. Always use a backing

wrench to prevent twisting and damage to the "O"

ring. Do not overtighten. Again leak test the joint.

2.

If the leak is still present, discharge the refrigerant

from the system as described under "Evacuating

and Charging Procedures."

3.

Inspect the ''O" ring and the fitting and replace if

damaged in any way. Coat the "O". ring before re-

installed with refrigerati6n oil and install carefully.

4.

Retorque the fitting, using a backing wrench, and

then add 1/2 to 1 lb. of R-12 to the system and

recheck for leaks.

CAUTION: Do not operate the system with this

small refrigerant charge.

5. Purge the system, thus removing the 1/2 to 1 lb.

installed in Step 4 above.

6. Evacuate and charge the system.

Leaks at Hose Clamp Connection

1.

Check the tightness of the clamp itself and tighten

if necessary. Recheck for leak.

2.

If leak has not been corrected discharge the system

and loosen clamp and remove hose from connection.

Inspect condition of hose and connector. Replace

scored or damaged parts.

3.

Dip end of new hose in refrigerant oil and carefully

reinstall over connector. Never push end of hose

beyond the locating bead. Properly torque the clamp.

4.

Recheck the system for leaks by installing 1/2 to 1

lb.

of R-12 into the system. Do not run compressor.

5. Purge. the system, thus removing the 1/2 to 1 lb.

installed in Step 4 above.

6. Evacuate and charge the system.

Compressor Leaks

If leaks are located around the compressor shaft seal

or shell, replacement of necessary seals should be made

as outlined under "Compressor" in the Chassis Overhaul

Shop Manual.

REFRIGERANT HOSE FAILURE

After a leak or rupture has occurred in a refrigerant

hose, or if a fitting has loosened and caused a consider-

able loss of refrigerant and oil, the entire system should

be flushed and recharged after repairs have been made.

Ji the system has been open to atmosphere for any pro-

longed period of time the receiver-dehydrator should be

replaced.

PREPARING SYSTEM FOR REPLACEMENT

OF COMPONENT PARTS

Air conditioning, like many other things, is farily

simple to service once it is understood. However, there

CHEVROLET CHASSIS SERVICE MANUAL

Page 70 of 659

HEATER AND AIR CONDITIONING 1A-47

are certain procedures, practices and precautions that

should be followed to prevent costly repairs, personal

injury or damage to equipment. For this reason it is

strongly recommended that the preceding information in

this section be studied thoroughly before attempting to

service the sytem.

Great emphasis must be placed upon keeping the sys-

tem clean. Use plugs or caps to close system components

and hoses when they are opened to the atmosphere. Keep

your work area clean.

In removing and replacing any part which requires

unsealing the refrigerant circuit the following operations,

which are described in this section, must be performed

in the sequence shown.

1.

Purge the system by releasing the refrigerant to the

atmosphere.

2.

Remove and replace the defective part.

3.

Evacuate and charge the system with R-12.

CAUTION: Always wear protective goggles

when working on refrigeration systems. Goggles

J-5453 are included in the set of air conditioning

special tools. Also, beware of the danger of

carbon monoxide fumes by avoiding running the

engine in closed or improperly ventilated

garages.

FOREIGN MATERIAL IN THE SYSTEM

Whenever foreign material is found in the system,

it must be removed before restoring the system to

operation.

In the case of compressor mechanical failure, perform

the following operations:

1.

Remove the compressor.

2.

Remove the receiver-dehydrator and discard me

unit.

3.

Flush the condenser to remove foreign material

which has been pumped into it.

4.

Disconnect the line from the receiver-dehydrator

at the inlet connection of the expansion valve. Inspect

the inlet screen for the presence of metal chips

or other foreign material. If the screen is plugged,

replace it. Reconnect the line to the expansion

valve.

5. Install a new receiver dehydrator.

6. Install the replacement compressor.

7. Add the necessary quantity of oil to the system (one

fluid ounce because of receiver-dehydrator replace-

ment plus the quantity needed for the replacement

compressor—see Checking Compressor Oil Charge

under Checking Oil.

8. Evacuate and charge the system.

9. Check system performance.

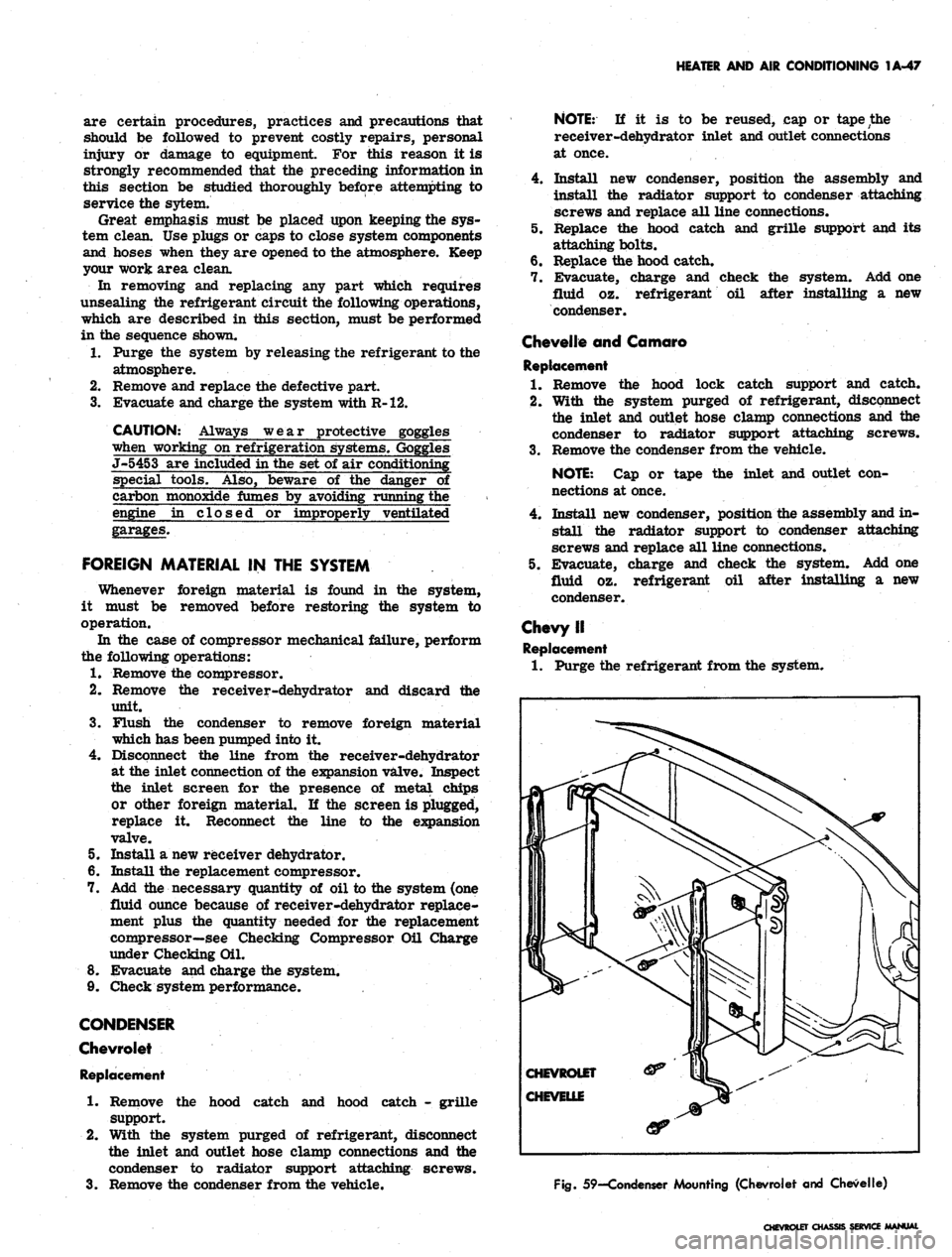

CONDENSER

Chevrolet

Replacement

1.

Remove the hood catch and hood catch - grille

support.

2.

With the system purged of refrigerant, disconnect

the inlet and outlet hose clamp connections and the

condenser to radiator support attaching screws.

3.

Remove the condenser from the vehicle.

NOTE:

If it is to be reused, cap or tape the

receiver-dehydrator inlet and outlet connections

at once.

4.

Install new condenser, position the assembly and

install the radiator support to condenser attaching

screws and replace all line connections.

5. Replace the hood catch and grille support and its

attaching bolts.

6. Replace the hood catch.

7. Evacuate, charge and check the system. Add one

fluid oz. refrigerant oil after installing a new

condenser.

Chevelle and Camaro

Replacement

1.

Remove the hood lock catch support and catch.

2.

With the system purged of refrigerant, disconnect

the inlet and outlet hose clamp connections and the

condenser to radiator support attaching screws.

3.

Remove the condenser from the vehicle.

NOTE:

Cap or tape the inlet and outlet con-

nections at once.

4.

Install new condenser, position the assembly and in-

stall the radiator support to condenser attaching

screws and replace all line connections.

5. Evacuate, charge and check the system. Add one

fluid oz. refrigerant oil after installing a new

condenser.

Chevy II

Replacement

1.

Purge the refrigerant from the system.

Fig.

59—Condenser Mounting (Chevrolet and Chevelle)

CHEVROLET CHASSIS SERVICE MANUAL