CITROEN DS3 2018 Handbook (in English)

Manufacturer: CITROEN, Model Year: 2018, Model line: DS3, Model: CITROEN DS3 2018Pages: 248, PDF Size: 8.79 MB

Page 171 of 248

169

If a pressure of 2 bars is not reached after

7 minutes, this indicates that the tyre is

not repairable; contact your dealer or

a

qualified workshop for recovery.

F

O

nce the correct pressure is reached, put

the switch to the " O" position.

F

R

emove the kit then stow it.

Do not drive more than 120

miles (200 km)

with a

temporarily repaired tyre; see your

dealer or a

qualified workshop to change

the tyre.

Should the pressure of one or more tyres

be adjusted, it is necessary to reinitialise

the under-inflation detection system.

For more information on Under-inflation

detection , refer to the corresponding

section.

Spare wheel

Scan the QR code on page 3 to view

e xplanatory videos.

Procedure for changing a

damaged wheel with

the spare wheel using the tools provided with

the vehicle.

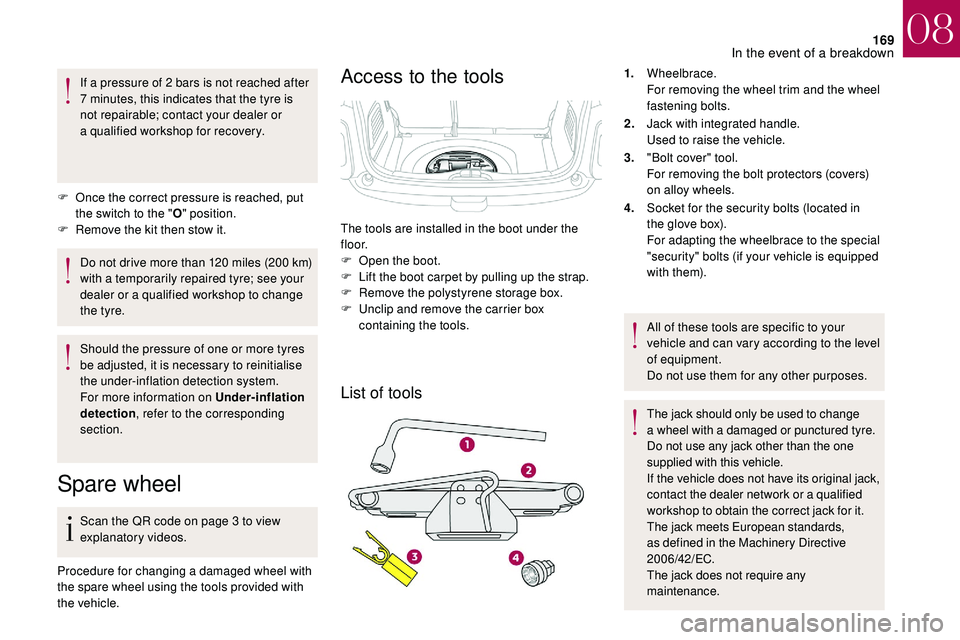

Access to the tools

List of tools

1. Wheelbrace.

For removing the wheel trim and the wheel

fastening bolts.

2. Jack with integrated handle.

Used to raise the vehicle.

3. "Bolt cover" tool.

For removing the bolt protectors (covers)

on alloy wheels.

4. Socket for the security bolts (located in

the glove box).

For adapting the wheelbrace to the special

"security" bolts (if your vehicle is equipped

with them).

All of these tools are specific to your

vehicle and can vary according to the level

of equipment.

Do not use them for any other purposes.

The jack should only be used to change

a

wheel with a damaged or punctured tyre.

Do not use any jack other than the one

supplied with this vehicle.

If the vehicle does not have its original jack,

contact the dealer network or a

qualified

workshop to obtain the correct jack for it.

The jack meets European standards,

as defined in the Machinery Directive

2006/42/EC.

The jack does not require any

maintenance.

The tools are installed in the boot under the

f l o o r.

F

O

pen the boot.

F

L

ift the boot carpet by pulling up the strap.

F

R

emove the polystyrene storage box.

F

U

nclip and remove the carrier box

containing the tools.

08

In the event of a breakdown

Page 172 of 248

170

Access to the spare wheel

Taking out the wheelPutting the wheel back in place

The spare wheel is located in the boot under

t h e f l o o r.

Depending on the country of sale, you will

have a "space-saver" type spare wheel or

a

temporary puncture repair kit.

F

U

nscrew the central nut.

F

R

emove the fastening device (nut and bolt). F

R

aise the spare wheel towards you from the

r e a r.

F

T

ake the wheel out of the boot.

On vehicles with a "space-saver" type

spare wheel, the punctured tyre can

replace the "space-saver" wheel; however,

the boot floor will no longer be even.

F

P

ut the wheel back in its housing.

F

S

lacken the nut on the bolt by a few turns.

F

P

osition the fastening device (nut and bolt)

in the middle of the wheel.

F

T

ighten fully until the central nut clicks, to

retain the wheel correctly. F

P

ut the carrier box back in place in the

centre of the wheel and clip it.

F

P

ut the polystyrene storage box back in

place.

F

R

eposition the carpet at the back of the boot

by folding it gently in two.

08

In the event of a breakdown

Page 173 of 248

171

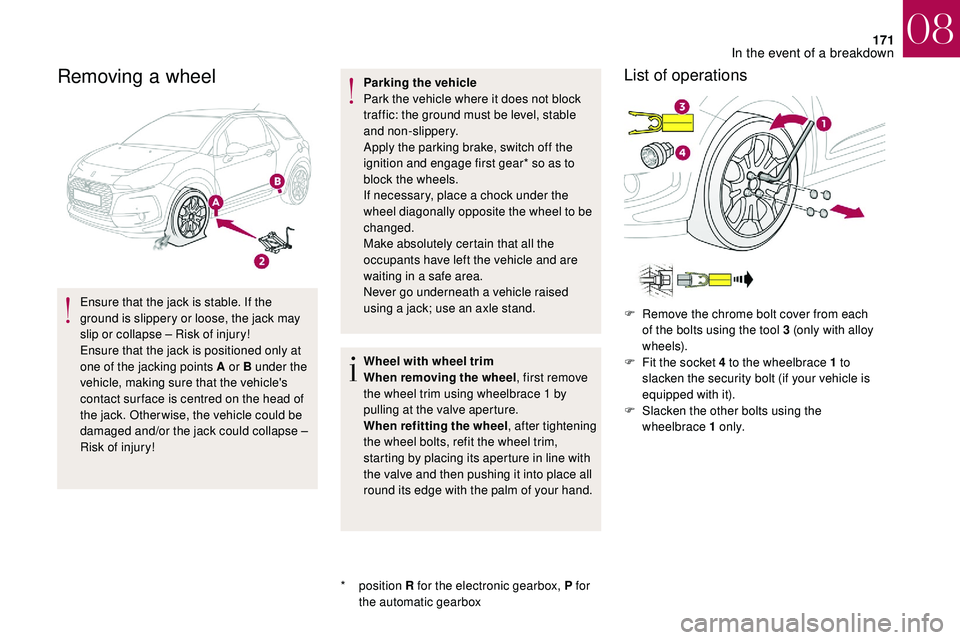

Removing a wheel

Ensure that the jack is stable. If the

ground is slippery or loose, the jack may

slip or collapse – Risk of injury!

Ensure that the jack is positioned only at

one of the jacking points A or B under the

vehicle, making sure that the vehicle's

contact sur face is centred on the head of

the jack. Otherwise, the vehicle could be

damaged and/or the jack could collapse –

Risk of injury!

*

position R for the electronic gearbox, P for

the automatic gearbox Parking the vehicle

Park the vehicle where it does not block

traffic: the ground must be level, stable

and non-slippery.

Apply the parking brake, switch off the

ignition and engage first gear* so as to

block the wheels.

If necessary, place a

chock under the

wheel diagonally opposite the wheel to be

changed.

Make absolutely certain that all the

occupants have left the vehicle and are

waiting in a safe area.

Never go underneath a vehicle raised

using a jack; use an axle stand.

Wheel with wheel trim

When removing the wheel , first remove

the wheel trim using wheelbrace 1

by

pulling at the valve aperture.

When refitting the wheel , after tightening

the wheel bolts, refit the wheel trim,

starting by placing its aperture in line with

the valve and then pushing it into place all

round its edge with the palm of your hand.

List of operations

F Remove the chrome bolt cover from each of the bolts using the tool 3 (only with alloy

w h e e l s).

F

F

it the socket 4 to the wheelbrace 1 to

slacken the security bolt (if your vehicle is

equipped with it).

F

S

lacken the other bolts using the

wheelbrace 1

o n l y.

08

In the event of a breakdown

Page 174 of 248

172

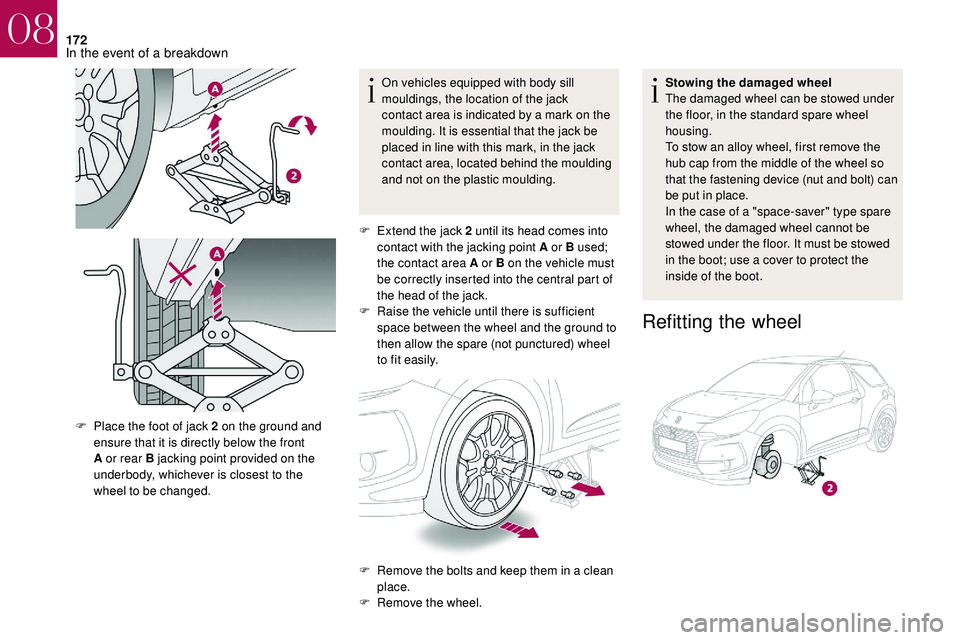

On vehicles equipped with body sill

mouldings, the location of the jack

contact area is indicated by a mark on the

moulding. It is essential that the jack be

placed in line with this mark, in the jack

contact area, located behind the moulding

and not on the plastic moulding.

F

E

xtend the jack 2 until its head comes into

contact with the jacking point A or B used;

the contact area A or B on the vehicle must

be correctly inserted into the central part of

the head of the jack.

F

Ra

ise the vehicle until there is sufficient

space between the wheel and the ground to

then allow the spare (not punctured) wheel

to fit easily. Stowing the damaged wheel

The damaged wheel can be stowed under

the floor, in the standard spare wheel

housing.

To stow an alloy wheel, first remove the

hub cap from the middle of the wheel so

that the fastening device (nut and bolt) can

be put in place.

In the case of a "space-saver" type spare

wheel, the damaged wheel cannot be

stowed under the floor. It must be stowed

in the boot; use a

cover to protect the

inside of the boot.

Refitting the wheel

F Place the foot of jack 2 on the ground and

ensure that it is directly below the front

A or rear B jacking point provided on the

underbody, whichever is closest to the

wheel to be changed.

F

R

emove the bolts and keep them in a clean

place.

F

R

emove the wheel.

08

In the event of a breakdown

Page 175 of 248

173

Fitting the "space-saver " spare wheel

If your vehicle is fitted with alloy wheels,

when tightening the bolts on fitting, it is

normal to notice that the washers do not

come into contact with the "space-saver"

spare wheel. The wheel is secured by the

conical contact of each bolt.

After changing a

wheel

Do not exceed 50

mph (80 km/h) when

driving with the "space-saver" type spare

wheel fitted.

Visit the dealer network or a

qualified

workshop as soon as possible to have the

tightness of the bolts and the pressure of

the spare wheel checked.

Have the punctured wheel checked. After

inspection, the technician will let you know

if the tyre can be repaired or if it must be

replaced.List of operations

F Put the wheel in place on the hub.

F S crew in the bolts by hand to the stop.

F

P

re-tighten the security bolt (if your vehicle

is so equipped) using the wheelbrace

1

fitted with the security socket 4 .

F

P

re-tighten the other bolts using the

wheelbrace 1

o n l y.

F

N

ow lower the vehicle fully.

F

F

old the jack 2 and detach it. F

T

ighten fully the security bolt (if your vehicle

is so equipped) using the wheelbrace

1 fitted with the security socket 4

.

F T ighten the other bolts using the

wheelbrace 1 o n l y.

F

P

ut the chrome bolt covers back on each of

the bolts (only with alloy wheels).

F

S

tore the tools in the box.

08

In the event of a breakdown

Page 176 of 248

174

Changing a bulb

The headlamps have polycarbonate

lenses with a

protective coating:

F

d

o not clean them using a dr y or

abrasive cloth, nor with a

detergent

or solvent product,

F

u

se a sponge and soapy water or a pH

neutral product,

F

w

hen using a high pressure washer

on persistent marks, do not keep the

lance directed towards the lamps or

their edges for too long, so as not to

damage their protective coating and

seals.

Changing a

bulb must only be done with

the ignition off and after the headlamp has

been switched off for several minutes –

Risk of serious burns!

F

D

o not touch the bulb directly with your

fingers, use a

lint-free cloth.

It is essential only to use anti-ultraviolet

(UV) type bulbs, so as not to damage the

headlamp.

Always replace a

failed bulb with a new

bulb with the same type and specification.

Front lamps

Halogen headlamps

1. Direction indicators (PY21W amber).

2. Sidelamps (W5W).

3. Main beam headlamps (H1-55W).

4. Dipped beam headlamps (H7-55W).

5. LED foglamps.

6. LED daytime running lamps.

Direction indicators

Rapid flashing of the direction indicator

lamp (left or right) indicates that one of

the bulbs on the corresponding side has

failed.

F

T

urn the bulb holder a quarter turn and

remove it.

F

P

ull the bulb out and change it.

To refit, carry out these operations in reverse

o r d e r.

Amber colour bulbs, such as the direction

indicators, must be replaced by bulbs with

identical colour and specifications.

To refit, close the protective cover very

carefully to guarantee the leak-tightness

of the lamp.

08

In the event of a breakdown

Page 177 of 248

175

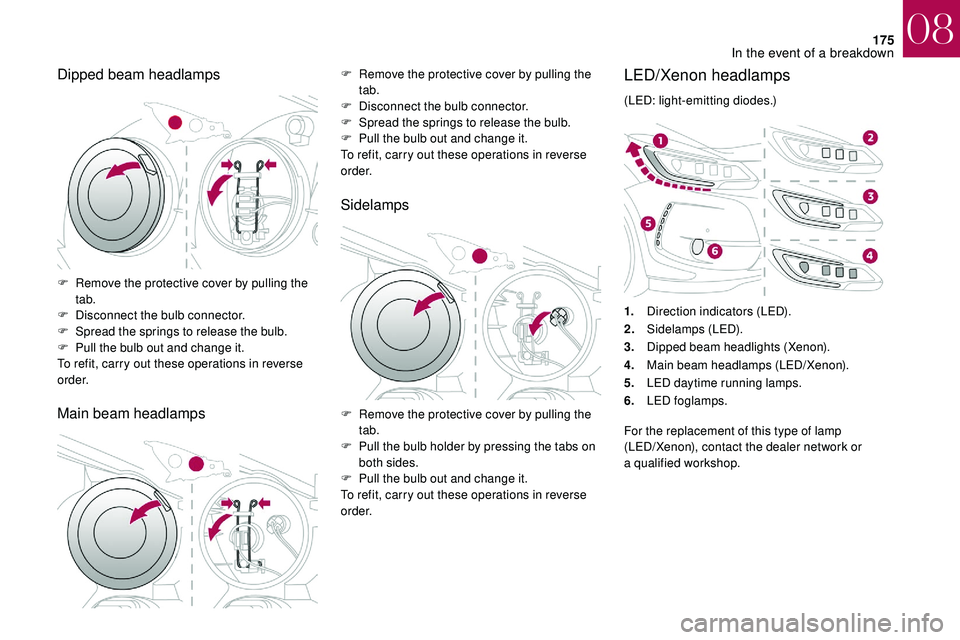

Dipped beam headlamps

Main beam headlampsF Remove the protective cover by pulling the tab.

F

D

isconnect the bulb connector.

F

S

pread the springs to release the bulb.

F

P

ull the bulb out and change it.

To refit, carry out these operations in reverse

o r d e r.

Sidelamps

F Remove the protective cover by pulling the tab.

F

D

isconnect the bulb connector.

F

S

pread the springs to release the bulb.

F

P

ull the bulb out and change it.

To refit, carry out these operations in reverse

o r d e r.

F

R

emove the protective cover by pulling the

tab.

F

P

ull the bulb holder by pressing the tabs on

both sides.

F

P

ull the bulb out and change it.

To refit, carry out these operations in reverse

o r d e r.

LED/Xenon headlamps

(LED: light-emitting diodes.)

1. Direction indicators (LED).

2. Sidelamps (LED).

3. Dipped beam headlights (Xenon).

4. Main beam headlamps (LED/Xenon).

5. LED daytime running lamps.

6. LED foglamps.

For the replacement of this type of lamp

(LED/Xenon), contact the dealer network or

a

qualified workshop.

08

In the event of a breakdown

Page 178 of 248

176

Integrated direction indicator side

repeaters

Contact the dealer network or a qualified

w orkshop to obtain the module.

LED foglamps

LED daytime running lampsRear lamps

Model with conventional bulb lamps

1. Brake/sidelamps (P21/5W).

2. Sidelamps (P5W).

3. Direction indicators (PY21W amber).

4. Foglamp (PR21W red) or reversing lamp

(P21W ).

Model with rear 3D lamps

F Insert a screwdriver towards the centre of

the repeater between the repeater and the

base of the mirror.

F

L

ever with the screwdriver to extract the

repeater and pull it out.

F

D

isconnect the connector from the repeater.

F

R

eplace the module.

To refit, carry out these operations in reverse

o r d e r. For the replacement of this type of diode

lamp, contact the dealer network or a

qualified

workshop.

For the replacement of this type of diode

lamp, contact the dealer network or a

qualified

workshop. 1.

3D LED sidelamps.

2. LED brake/sidelamps.

08

In the event of a breakdown

Page 179 of 248

177

3.LED side marker lamps.

4. Direction indicators (PY21W amber).

5. Foglamp (H21W red) or reversing lamp

(H21W ).

Amber or red colour bulbs, such as the

direction indicators or foglamps, must be

replaced by bulbs with identical colour and

specifications.

Access to bulbs

Removing the access cover

F Open the boot.

Ty p e 1 Ty p e 2Removing the lamp

To reassemble, proceed in reverse order.

Make sure to engage the lamp unit in its guides

while keeping it in line with the vehicle.

Refitting the access cover

Ty p e 1

F

R

emove the access cover by pulling it

downwards.

F

U

nscrew the lamp fixing wing nut.

F

U

nclip the lamp unit connector.

F

E

xtract the lamp unit carefully pulling it

straight towards the outside. F

P

osition the 3 hooks A of the cover in the

lower part.

08

In the event of a breakdown

Page 180 of 248

178

Ty p e 2

Changing bulbs

Model with conventional bulb lampsModel with rear 3D lamps

Direction indicators (4) and foglamp or

reversing lamp (5)

Replacing LED sidelamps and brake

lamps (diodes)

For the replacement of this type of diode

lamp, contact the dealer network or a

qualified

workshop.

F

T

ip the cover upwards and position the

hooks B under the boot trim.

F

Ra

ise the cover.

F

S

lide the cover so as to put it properly back

in place. F

P

osition the cover in the lower part.

F

T

ip the cover upwards.

F

T

urn the bulb a quarter of a turn and change

it.

F

S

pread the four tabs and remove the bulb

h o l d e r.

F

T

urn the bulb a

quarter turn and change it.

08

In the event of a breakdown