DATSUN 210 1979 Service Manual

Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 191 of 548

Engine

Electrical

System

IGNITION

COIL

Type

CIT

30

STC

30

Primary

resistance

at

200C

680F

U

0

84

to

1

02

Secondary

resistance

at

200C

680F

KU

8

2

to

12

4

SPARK

PLUG

BP5ES

ll

L46PW

ll

BP5EQ

13

L46PM

13

BPR5ES

BP4E

ll

L47PW

ll

BP4EQ

13

L47PM

13

BPR4ES

Type

BP6ES

I1

L44PW

I1

BP6EQ

13

L45PM

13

BPR6ES

BP7ES

II

L45PW

II

BP7EQ

13

L44PM

13

BPR7ES

Plug

gap

mm

in

1

0

to

1

1

1

1

to

1

3

0

8

to

0

9

0

039

to

0

043

0

043

to

0

051

0

031

to

0

035

TIGHTENING

TORQUE

Magnetic

switch

terminal

SI14

160B

S114

163E

S1l4

253

kg

em

in

Ib

Magnetic

switch

attaching

bolts

Starting

motor

Gear

case

attaching

bolts

Pulley

nut

Alternator

through

bolts

Spark

plug

kg

cm

in

Ib

75

to

100

65

to

87

115

to

160

100

to

139

38

to

51

3

to

44

kg

em

in

lb

kg

m

ft

Ib

kg

cm

in

Ib

kg

m

ft

Ib

64

to

85

56

to

74

4

5

to

6

0

33

to

43

60

to

70

52

to

61

1

5

to

2

5

II

to

18

EE

33

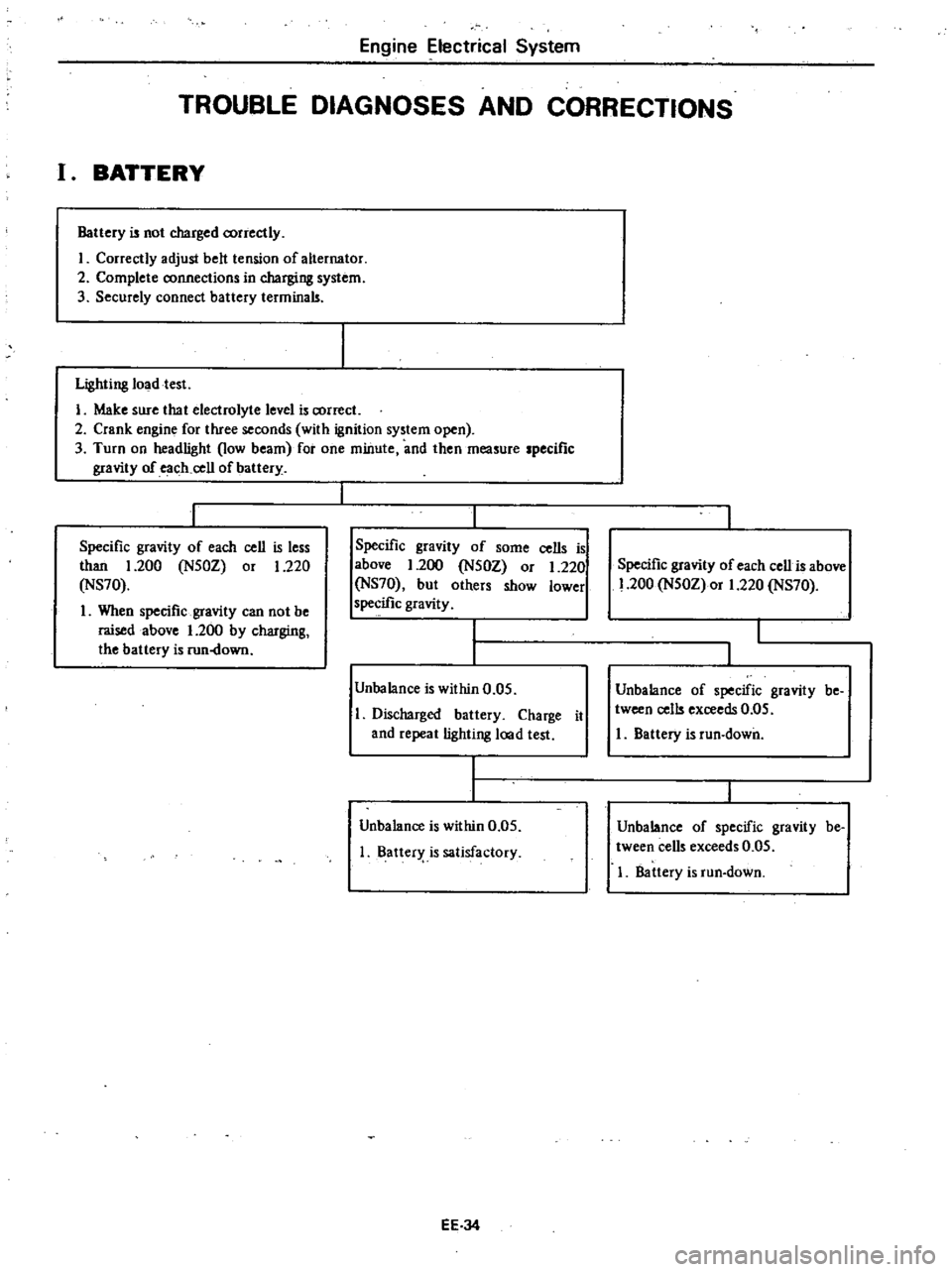

Page 192 of 548

Engine

Electrical

System

TROUBLE

DIAGNOSES

AND

CORRECTIONS

I

BATTERY

Battery

is

not

charged

correctly

I

Correctly

adjust

belt

tension

of

alternator

2

Complete

connections

in

charging

system

3

Securely

connect

battery

terminals

Lighting

Joadtest

I

Make

sure

that

electrolyte

level

is

correct

2

Crank

engine

for

three

seconds

with

ignition

system

open

3

Turn

on

headlight

low

beam

for

one

minute

and

then

measure

specific

gravity

of

each

cell

of

battery

Specific

gravity

of

each

cell

is

less

than

1

200

N50Z

or

1

220

NS70

1

When

specific

gravity

can

not

be

raised

above

1

200

by

charging

the

battery

is

run

down

Specific

gravity

of

some

cells

is

above

1

200

N50Z

or

1

220

NS70

but

others

show

lower

specific

gravity

Unbalance

is

within

0

05

Discharged

battery

Charge

it

and

repeat

lighting

lood

test

Unbalance

is

within

0

05

Batter

is

satisfactory

EE

J4

Specific

gravity

of

each

cell

is

above

1

200

N50Z

or

1

220

NS70

Unbalance

of

specific

gravity

be

tween

cells

exceeds

0

05

I

Battery

is

run

down

Unbalance

of

specific

gravity

be

tween

cells

exceeds

0

05

I

Battery

is

run

down

Page 193 of 548

Engine

Electrical

System

II

STARTING

MOTOR

Condition

Starting

motor

will

not

operate

Noisy

starting

motor

Starting

motor

cranks

lowly

Starting

motor

cranks

slowly

Starting

motor

operate

but

does

not

crank

engine

Starting

motor

will

not

disengage

even

if

ignition

switch

is

turned

off

Probable

cause

Discharged

battery

Damaged

solenoid

witch

Loose

connections

of

terminal

Damaged

field

coil

Damaged

brushes

Damaged

bearing

Damaged

annature

Loose

securing

bolt

Worn

pinion

gear

Poor

lubrication

Worn

commutator

Worn

brushes

Discharged

battery

Loose

connection

of

terminal

Worn

brushes

Locked

brushes

Loose

connections

of

terminal

Damaged

field

coil

Damaged

brushes

Damaged

bearing

Damaged

armature

Dirty

or

worn

commutator

Armature

rubs

field

coil

Damaged

splenoid

switch

Worn

pinion

Locked

pinion

guide

Worn

ring

gear

Damaged

sOlenoid

switch

Damaged

gear

teeth

EE

35

Corrective

action

Charge

or

repiace

battery

Repair

or

replace

solenoid

switch

Clean

and

tighten

terminal

Replace

yoke

Replace

brushes

Replace

bearing

Replace

armature

Tighten

Replace

Add

oil

Replace

Replace

Charge

Clean

and

tighten

Replace

Inspect

brush

pring

tension

or

repair

brush

holder

Clean

and

tighten

terminal

Replace

yoke

Replace

brushe

Replace

bearing

Replace

armature

Clean

and

repair

Repalce

assembly

Repair

or

replace

Replace

Repair

Replace

Repair

or

replace

Replace

damaged

gear

Page 194 of 548

Engine

Electrical

System

III

ALTERNATOR

Including

voltage

regulator

Condition

No

output

Excessive

output

Low

output

Noisy

alternator

Probable

cause

Sticking

brushes

Dirty

brushes

and

slip

rings

Loose

connections

or

broken

leads

Open

stator

winding

Open

rotor

winding

Open

diodes

Shorted

diodes

Shorted

rotor

Shorted

stator

Ground

BAT

terminal

Broken

fan

belt

Voltage

regulator

breakdown

Poor

connection

of

alternator

S

terminal

Open

diode

Loose

or

worn

fan

belt

Slicking

brushes

Low

brush

spring

tension

Voltage

regulator

breakdown

Dirty

slip

ring

Partial

hort

ground

or

open

in

stator

winding

Partially

shorted

or

grounded

rotor

winding

Open

or

damaged

diode

Loose

mounting

Loose

drive

pulley

Broken

ball

bearing

Improperly

seated

brushes

EE

36

Corrective

action

Correct

or

replace

bru

hes

and

brush

springs

Clean

Retigliten

or

older

connection

Replace

leads

if

necessary

Repair

or

replace

stator

Replace

rotor

Replace

Replace

Replace

rotor

Replace

Replace

insulator

Replace

Check

regulator

operation

and

repair

or

replace

a

required

Correct

Replace

Retighten

or

replace

Correct

or

replace

brushes

and

springs

if

necessary

Replace

brush

spring

Check

regulator

operation

and

repair

or

replace

as

required

Clean

Replace

tator

Replace

rotor

Replace

diode

Retighten

bolts

Retighten

Replace

Seat

correctly

Page 195 of 548

Engine

Electrical

System

IV

IGNITION

CIRCUIT

When

engine

does

not

start

If

there

is

no

problem

in

fuel

system

ignition

system

should

be

checked

This

can

be

easily

done

by

detaching

a

high

tension

cable

from

distributor

starting

engine

and

ob

serving

oondition

of

spark

that

occurs

between

high

tension

cable

and

engine

block

After

checking

this

repair

as

necessary

tery

and

anti

dieseliilg

wlenoid

valve

connector

to

cuI

off

supply

of

fuel

10

engine

Then

observe

the

condition

of

sparks

while

starter

motor

is

in

operation

Note

Turn

ignilion

switch

off

and

disconnect

ground

cable

from

bat

Condition

Location

Probable

cause

Corrective

action

No

spark

at

all

Distributor

Breakage

of

lead

wire

on

low

tension

side

Repair

Poor

insulation

of

cap

and

rotor

head

Replace

Open

pick

up

coil

Replace

Air

gap

wider

than

specification

Adjust

Ignition

coil

Wire

breakage

or

short

circuit

of

coil

Replace

with

new

one

High

tension

cable

Wire

coming

off

Repair

Faulty

insulation

Replace

IC

ignition

unit

Faulty

IC

ignition

unit

Replace

Breakage

of

circuit

Replace

Detached

connection

Repair

Spark

length

Spark

plugs

Spark

plug

gap

too

wide

Correct

or

replace

More

than

6

mm

Too

much

carbon

Clean

or

replace

0

24

in

Broken

neck

of

insulator

Replace

Expiration

of

plug

life

Replace

Distributor

Air

gap

too

wide

Correct

IC

ignition

unit

Faulty

IC

ignition

unit

Replace

Breakage

of

circuit

Replace

Detached

connection

Repair

EE

37

Page 196 of 548

2

Engine

rotates

but

does

not

run

smoothly

This

may

be

caused

by

the

ignition

Condition

Location

Engine

misses

Distributor

Ignition

coil

High

tension

cable

Spark

plugs

IC

ignition

unit

Engine

causes

knocking

very

often

Distributor

Spark

plugs

Engine

does

not

deliver

enough

power

Distributor

Spark

plugs

Engine

Electrical

System

system

or

other

engine

conditions

not

related

to

ignition

system

Therefore

first

complete

inspection

of

ignition

system

should

be

carried

out

Probable

cause

Foreign

matter

onpicl

up

coil

Improper

air

gap

Leak

of

electricity

at

cap

and

rotor

head

Breakage

of

pick

up

coil

lead

wire

Worn

or

shaky

breaker

plate

Worn

or

shaky

distributor

driVing

shaft

Layer

short

circuit

or

inferior

quality

coil

Deterioration

of

insulation

with

cense

quenlleak

of

electricity

Fouled

Leak

of

electricity

at

upper

porcelain

insulator

Spark

plug

gap

too

narrow

Faulty

IC

ignition

unit

Breakage

of

circuit

Detached

connection

Improper

ignition

timing

too

advanced

Coming

off

or

breakage

of

governor

spring

Worn

pin

or

hole

of

governor

Burnt

too

much

Improper

ignition

timing

too

retarded

Improper

functioning

governor

Foreign

particles

stuck

in

air

gap

Fouled

EE

38

Corrective

action

Clean

Correct

Repair

or

replace

Replace

Replace

assembly

Replace

aSsembly

Replace

with

good

one

Replace

Clean

Repair

or

replace

Correct

or

replace

Replace

Replace

Repair

Correct

Correct

or

replace

Replace

Replace

Correct

Replace

assembly

Clean

Clean

Page 197 of 548

DATSUN

210

Model

8310

Series

SECTIONER

ENGINE

REMOVAL

INSTAllATION

CONTENTS

ENGINE

REMOVAL

AND

INSTALLATION

REMOVAL

INSTALLATION

ER

2

ER

3

ER

5

ENGINE

MOUNTING

INSULATOR

SERVICE

DATA

AND

SPECIFICATIONS

TIGHTENING

TORQUE

ER

5

ER

6

ER

6

Page 198 of 548

Engine

Re

lloval

In

tallation

ENGINE

REMOVAL

AND

INSTAllATION

I

Jp

40

1

Front

engine

mounting

ms

ulato

R

H

2

Front

c118ine

mounting

bracket

R

H

3

Front

engine

mounting

bracket

L

K

4

Front

engine

mounting

insulator

L

H

5

Rear

engine

mounting

mem

ber

6

Re4

f

engine

mounting

insulator

Tightening

torque

kg

m

ft

lb

i

J

3

2

to

4

3

23

to

31

@

1

6

to

2

1

12

10

15

@

1

6

to

2

1

12

to

15

@

0

91a

1

2

6

510

8

1

@

0

9101

2

6

5

to

8

1

3

2

to

4

3

23

to

31

E

R479

Fig

ER

1

Engine

Mounting

ER

2

Page 199 of 548

REMOVAL

It

is

much

easier

to

remove

engine

and

transmission

as

a

single

unit

than

to

remove

alone

After

removal

engine

can

be

separated

from

the

transmission

assembly

WARNING

a

Place

wheel

chocks

in

fronl

of

front

wheels

and

in

rear

of

rear

wheels

b

Be

sure

to

hoist

engine

in

a

safe

manner

c

You

should

not

remove

engine

until

exhaust

system

has

com

pletely

cooled

off

Otherwise

you

may

burn

your

self

and

or

fire

may

break

out

in

fuel

line

Note

Fender

coven

should

be

used

to

protect

car

body

1

Disconnect

battery

ground

cable

from

battery

terminal

and

fusible

link

at

wire

connector

2

Remove

hood

as

follows

CAUTION

Have

an

assistant

help

you

so

as

to

prevent

damage

to

body

I

Mark

hood

hinge

locations

on

hood

to

facilitate

reinstallation

2

Support

hood

by

ltand

and

re

move

bolts

securing

it

to

hood

hinge

being

careful

not

to

let

hood

slip

when

bolts

are

removed

See

Fig

ER

2

3

Remove

hood

from

hood

hinge

f

Il

I

BF133A

Fig

ER

2

Removing

Hood

Remove

under

cover

Drain

radiator

coolant

and

engine

3

4

oil

5

Disconnect

upper

and

lower

hoses

from

radiator

and

disconnect

oil

cooler

hoses

automatic

transmission

only

6

Remove

four

bolts

securing

radia

Engine

Removal

Installation

tor

to

body

and

detach

radiator

after

removing

radiator

shroud

7

Remove

air

cleaner

assembly

from

carburetor

as

follows

1

Remove

fresh

air

duct

from

air

cleaner

2

Remove

hot

air

duct

from

air

cleaner

3

Loosen

air

cleaner

band

bolt

4

Disconnect

air

cleaner

to

air

pump

hose

at

air

cleaner

5

Disconnect

air

cleaner

ta

rocker

cover

hose

at

rocker

cover

6

Disconnect

air

cleaner

to

A

B

valve

hose

at

air

cleaner

7

Disconnect

air

cleaner

to

related

vacuum

hoses

at

air

cleaner

8

Disconnect

accelerator

control

wire

from

carburetor

9

Disconnect

the

following

cables

wires

and

hoses

Wire

to

auto

choke

heater

Wire

to

throttle

opener

cut

solenoid

or

throttle

switch

Wire

to

fuel

cut

solenoid

Wire

to

vacuum

switching

valve

High

tension

cable

between

igni

tion

coil

and

distributor

Battery

cable

to

starter

motor

Wire

to

distributor

Wire

to

thermal

transmitter

Wire

to

alternator

Engine

ground

cable

oil

pressure

switch

and

engine

harness

No

2

See

Fig

ER

3

o

1

Ground

cable

2

Engine

harness

No

2

3

Oil

pressure

switch

Fig

ER

3

EA368

Disconnecting

Cable

and

Wire

Fuel

hose

at

fuel

pump

and

fuel

return

hose

at

connection

Air

pump

air

cleaner

hose

Carbon

canister

hoses

Heater

inlet

and

outlet

hoses

if

so

equipped

ER

3

Vacuum

hose

of

brake

booster

at

intake

manifold

Air

conditioner

equipped

model

10

Remove

compressor

belt

To

remove

loosen

idler

pulley

nut

and

adjusting

bolt

1

Remove

air

pump

2

Remove

compressor

retaining

bolts

and

move

compressor

toward

fender

to

facilitate

removal

of

engine

Nole

Never

discharge

gas

from

com

pressor

while

work

is

being

per

formed

II

Compressor

EA478

Fig

ER

4

Location

of

Air

Compressor

3

Disconnect

vacuum

hose

of

air

conditioner

from

connector

of

intake

manifold

4

Remove

F

i

C

D

actuator

from

bracket

II

Remove

clutch

operating

cylin

der

from

clutch

housing

manual

trans

mission

only

dJ

Tightening

torque

Clutch

operating

cylinder

E

A3

to

clutch

housing

3

1

to

4

1

kg

22

to

30

ft

lbl

Fig

ER

5

Removing

Clutch

Operating

Cylinder

Page 200 of 548

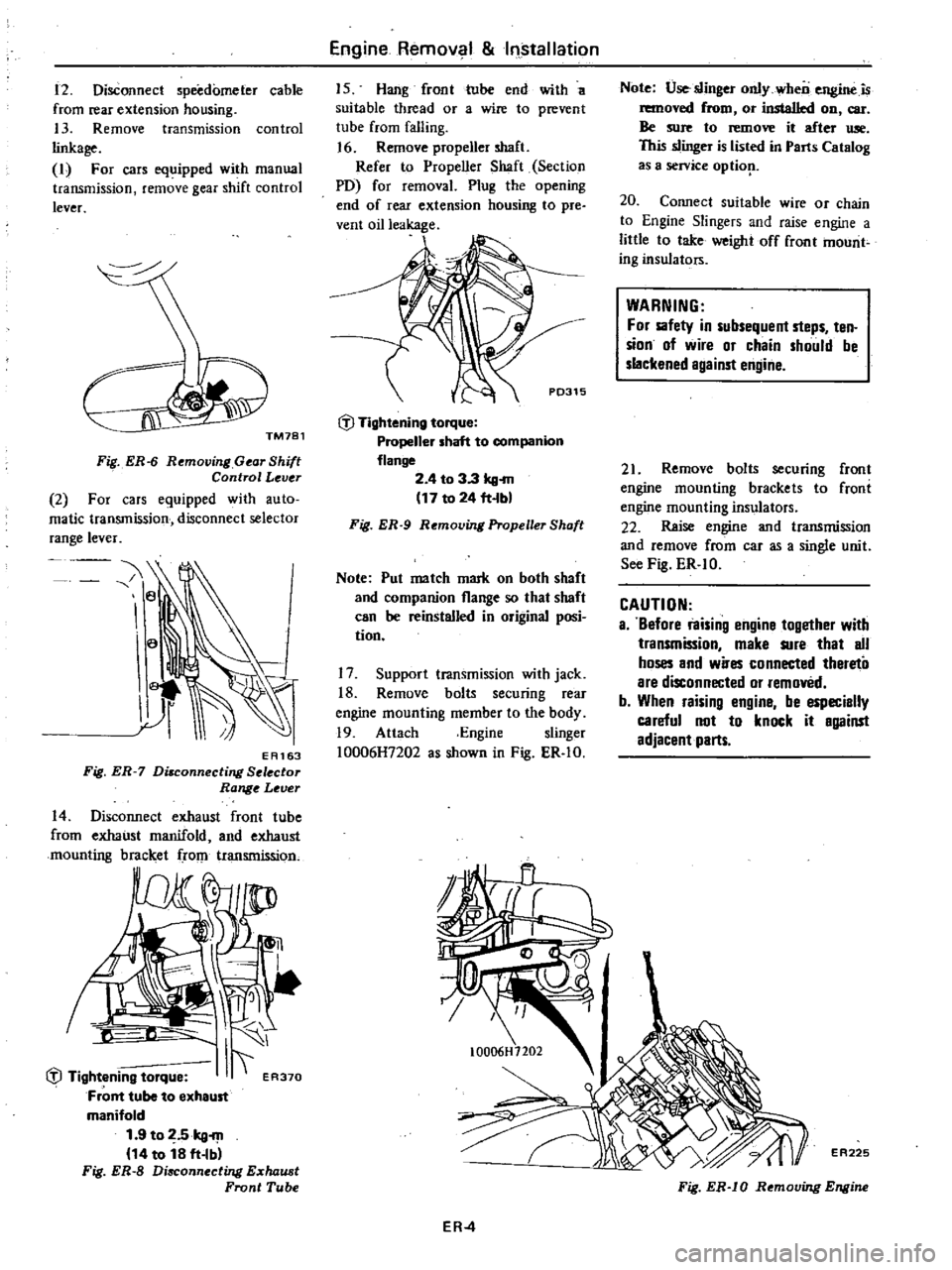

12

Disconnect

speedometer

cable

from

rear

extension

housing

13

Remove

transmission

control

linkage

I

For

cars

equipped

with

manual

transmission

remove

gear

shift

control

lever

Fig

ER

6

Removing

Gear

Shift

Control

Lever

2

For

cars

equipped

with

auto

matic

transmission

disconnect

selector

range

lever

e

a

EA163

Fig

ER

7

Di8connecting

Selector

Range

Lever

14

Disconnect

exhaust

front

tube

from

exhaust

manifold

and

exhaust

mounting

bracket

rom

transmission

I

liJ

Tightening

torque

I

ER370

Front

tube

to

exheust

manifold

1

9

to

2

5kg

m

14

to

18

ft

Ibl

Fig

ER

S

Disconnecting

E

chaust

Front

Tube

Engine

Remov

1

Installation

15

Hang

front

tube

end

with

a

suitable

thread

or

a

wire

to

prevent

tube

from

falling

J

6

Remove

propeller

shaft

Refer

to

Propeller

Shaft

Section

PO

for

removal

Plug

the

opening

end

of

rear

extension

housing

to

pre

vent

oil

leakage

P0315

liJ

Tightening

torque

Propeller

shaft

to

companion

flange

2

4

to

3

3

kg

m

17

to

24

ft

bl

Fig

ER

9

Removing

Propeller

Shaft

Note

Pul

me

tch

mark

on

both

shaft

and

companion

flange

so

that

shoft

can

be

reinstalled

in

original

posi

tion

17

Support

transmission

with

jack

18

Remove

bolts

securing

rear

engine

mounting

member

to

the

body

19

Attach

Engine

slinger

10006H7202

as

shown

in

Fig

ER

IO

Note

Use

slinger

only

wheo

engine

is

removed

from

or

installed

on

car

Be

sure

to

remove

it

efter

Ulle

This

slinger

is

listed

in

Parts

Cet

log

as

a

service

optiop

20

Connect

suitable

wire

or

chain

to

Engine

Slingers

and

raise

engine

a

little

to

take

weight

off

front

mount

ing

insulators

WARNING

For

sofety

in

subsequent

steps

ten

sion

of

wire

or

chain

should

be

slackened

against

engine

21

Remove

bolts

securing

front

engine

mounting

brackets

to

froni

engine

mounting

insulators

22

Reise

engine

and

transmission

and

remove

from

car

as

a

single

unit

See

Fig

ER

IO

CAUTION

a

Before

raising

engine

10gether

with

transmission

make

sure

that

all

hoses

and

wires

connected

thereto

are

disconnected

or

removed

b

When

raising

engine

be

especially

careful

not

to

knock

it

against

adjacent

parts

ER

4

EA225

Fig

ER

IO

Removing

Engine