DATSUN 210 1979 Service Manual

Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 271 of 548

Automatic

Transmission

D

nnse

klckdown

Shift

valvas

In

2nd

sear

position

Vacuum

control

dlophroem

r

r

X

I

i

jI

2

dl

2

l

s

o

@

i

i

JJ

1

1

I

N1

1

JJ

r

OI

r

J

@

I

J

ju

n

II

r

1

o

N

m

II

lln

pru

r

Gov

nor

Iud

pr

ssurel

1

x

x

S

condary

Primor

90V

nor

val

00

rnor

olv

Low

ond

brok

Brak

bond

2

Oil

cooler

I

r

J

80nd

no

C

a

i

0

J

P

N

R

ar

lubrication

aJ

8

ll

Ill

f

I

f

j

l

l

0

1

1

Throttl

drain

voh

i

Xl

U

II

CD

r

lIU

afor

volv

I

l

r

Go

rnor

pr

IU

Torqu

conv

t

r

pr

lur

TIl

rotll

p

lure

AT458

Fig

AT

18

Oil

Pr

mn

Circuit

Diagram

D

rong

kickdown

hift

va

v

s

in

2nd

gear

position

AT

19

X

Throttl

back

up

vain

F

w

I

P

b

I

1

Orific

18

16

ch

ck

X

val

1

r

@2n

3n

lShift

01

l

l

I

Page 272 of 548

Automatic

Transmission

2

RANGE

2ND

GEAR

The

range

2

position

is

used

to

lock

the

car

in

2nd

gear

preventing

upshifts

or

downshifts

under

any

con

ditions

Fluid

flow

opening

the

valVe

and

alloWing

pr

sure

to

p

into

the

line

of

the

throttle

valve

thus

assuring

adequate

throttle

pressure

even

during

decelera

tion

J

he

downshift

solenoid

valve

is

used

as

a

passage

for

line

pre

re

to

lock

the

1

2

and

2

3

shift

valves

Po

r

flow

Power

flow

in

2

raogo

is

the

same

as

in

D2

range

Uoe

pressure

from

the

manual

valve

opens

the

second

lock

valve

against

spring

pressure

As

this

valve

opens

pressure

the

passes

to

apply

the

band

servo

Une

pressure

also

flows

to

the

throttle

back

up

valve

UlllV

I

Governor

Valve

IS

Pressure

Modifier

Valve

2nd

3rd

Timing

Valve

2nd

3rd

Shift

Valve

1st

2nd

Shift

Valve

1st

2nd

Shift

Valve

j

Rear

Clutch

2

1

Band

Servo

Apply

Side

l

Solenoid

Downshift

Vilve

1312nd

3rd

Shift

Valve

1st

2nd

Shift

Valve

Second

Lock

Valve

9

4

Throttle

Back

up

Valve

17

Vacuwn

Throttle

Vilve

16

l

Jre

ModifJerVilve

2nd

3rd

Shift

Valve

2nd

3rd

Timing

Valve

Throttle

Drain

Valve

Pressure

Regulator

Valve

AT

20

Page 273 of 548

2

renge

2nd

Beer

Oil

cool

Reor

lubrication

o

4

Drain

oha

Fron

lubricaf

Drain

vol

x

x

I

Ii

6

II

D

r

ou

alar

01

1

4

Automatic

Transmission

J

R

or

j

j

I

r

r

Bond

0

0

41

9

10

Throttl

I

r

lc

uP

a

II

J

I

i

ll

fr

t

rr

1

1

I

i

Throttle

I

drain

ahe

j

01

1816

x

@Zn6

3rd

Shift

101

1

J

is

t1

1x

J

I

I

n

s

t

Z

l

n

S

II

I

1

1

1

II

IS

N

U

g

2nd

3rd

timing

X

vol

I

I

2

S

j

000j

Ul

I1

I

w

X

fo4anuol

P

R

lIo

Not

Morked

X

art

drain

Slcondory

govunor

ViII

Primor

go

nor

vol

line

pr

ur

Go

nor

lid

pr

ure

G

o

rnOI

pr

Torqul

con

r

p

JUri

Th

rotU

p

AT459

Fig

AT

19

Oil

ProIlU

Circuit

Diagram

2

range

2nd

tar

AT

21

Page 274 of 548

Automatic

Transmission

l

RANGE

LOW

AND

2ND

GEAR

second

12

afwvernor

preSsure

pre

vents

the

I

2

shift

valve

from

closing

The

range

1

position

is

used

to

lock

the

car

in

1st

gear

preventing

any

upshifts

If

the

selector

lever

is

moved

to

the

I

position

while

the

car

is

moving

at

high

speeds

the

transmis

sion

w

ill

not

shift

into

first

gear

until

car

speed

slows

to

approxiniately

55

km

h

35

mph

Instead

it

will

shift

to

Po

r

flow

The

power

flow

in

11

differs

slight

ly

from

01

in

that

the

low

and

reverse

band

is

applied

to

hold

the

rear

gear

set

planet

carrier

providing

engine

hraking

Power

flow

in

12

is

the

same

a

io02

Manual

Valve

Governor

Valve

15

Pressure

Modifier

Valve

I

Fluid

flow

Lolft

ar

Manual

pressure

passing

through

the

1

2

shift

valve

is

used

to

close

the

1

2

shift

valve

preventing

a

1

2

up

shift

Manual

pressure

pusing

through

the

downshift

valve

lock

the

2

3

siuit

valve

closed

along

with

applying

addi

tional

closing

pressure

to

the

I

2

shift

valve

2nd

3rd

Timing

Valve

2nd

3rd

Shift

Valve

lst

2ndSti

ft

Valve

1st

2nd

Shift

Valve

iRea

Clutcb

I

4

Solenoid

Downshift

Valve

13

I2nd

3rd

Shift

Valve

ht

2nd

Shift

Valve

Throttle

Back

up

Valve

5

C

1st

2nd

Shift

Valve

12

I

Throttle

Back

up

Valve

y

Low

Reverse

Bra1ce

I

Fluid

flow

2nd

ar

Manual

Valve

Governor

Valve

15

Preuurc

Modjfier

Valve

2nd

3rd

Timing

Valve

2nd

3rd

Shift

Valve

1st

2nd

Shift

Valve

8

1st

2nd

Shift

Valve

Second

Lock

Valve

9

I

Band

Servo

I

Apply

Side

4

t

Rear

Clutch

I

Solenoid

Downshift

Valve

13

I

2nd

3rd

Shift

Valve

ht

2nd

Shift

Valve

Throttle

Back

up

Valve

17

PreSlure

Modifier

Valve

2nd

3rd

Shift

Valve

2nd

3rd

Timing

Valve

Throttle

Drain

Valve

s

ht

2nd

Shift

Valve

Pressure

Regulator

Valve

AT

22

Page 275 of 548

Il

j

rJl

12

I

ff1

Bond

i

Vacuum

r

o

CI

tlltOfflt

9

10

volY

11

I

11

J

I

H

H

1

r

II

J

1

6

Otific

ch

ck

101

I

24

ol

TO

6

3

X

r

6

3

tA

g

@2n

r3

1

ift

j

I

In

s

U

g

2nd

3rd

Ii

mln

II

III

1

1

S

dI

c

I

1

ir

lJX

l

Il

I

n

l

3

if

p

2

1

f1

1

5

15

1

11

6

1

X

X

PnmOfJ

r

01

1

0

1

10

Secon

or

101

1

QO

l

rnor

X

all

droin

Not

Mork

r

ud

pr

uu

Go

llrno

L

in

P

USUf

Irtr

ov

rnat

pt

u

1

1

G

r

ur

Torqu

convut

r

p

TII

totUt

pr

ur

I

Low

geer

renge

Torqut

conv

rt

Iii

cool

Ip

r

uur

TIC

tlno

101

I

RIot

lubri

c

oJion

i

4

Fron

lubricat

0

1

Xl

6

6

II

CD

r

r

0

Transmission

Automatic

R

ar

lCh

I

l

I

II

21

12

IL

t

2

j

Sh

1

olQ1

Circuit

Diagram

Oil

Pn

sure

Fig

AT

20

AT460

Low

g

ar

11

rang

AT

23

Page 276 of 548

X

F

1

2

dll

U

Sflift

lllvI

21

I

S

nd

lock

6

Ir

II

P

UX

6

I

Mo

ol

f

L

t

u

uu

u

u

I

f5

LI

P

OI

I

Go

o

fo

d

P

I

ren

e

2nd

eer

Torqul

con

rter

Oil

pump

Oil

tool

RIAr

Ivbri

cor

ion

D

Orain

fa

hi

Front

lubrici

lti

0

0

0

1

I

tU

x

j

Pr

l

UQU

010r

Yol

u

1

Automatic

Transmission

Front

lulch

Riot

x

l

N

r

N

N

I

I

i

l

I

18

16

ahl

J

@

Vacuum

Huottl

Vol

if

J

II

Throttl

drain

yol

l

II

@2ft

3rd

Shiff

101

1

iii

1J

g

2nd

3rd

timino

101

11

8

Goy

rnor

prlUUAI

Torque

Cony

tar

pr

r

Th

toni

pt

ure

Slcondor

governor

vol

1

Primo

00

vlrnor

va

AT461

Fig

AT

21

Oil

Pr

Circuit

Dwgrom

12

ro

2nd

ear

AT

24

Page 277 of 548

Automatic

Transmission

REMOVAL

AND

INSTALLATION

TRANSMISSION

ASSEMBLY

When

dismounting

the

automatic

transmission

from

a

car

pay

attention

to

the

following

points

I

Before

dismounting

the

trans

mission

rigidly

inspect

it

by

aid

of

the

Trouble

shooting

Chart

and

dis

mount

it

only

when

coll5idered

to

be

necessary

2

Dismount

the

transmission

with

utmost

care

and

when

mounting

observe

the

tightening

torque

indi

cated

on

another

table

not

to

exert

excessive

force

REMOVAL

In

dismounting

automatic

transmis

sion

from

car

proceed

as

follows

I

Disconnect

battery

ground

cable

from

terminal

2

Disengage

torsion

shaft

from

ac

eelerator

linkage

3

Jack

up

vehicle

and

support

its

weight

on

safety

stands

Recommend

a

hydraulic

hoist

or

open

pit

be

utilized

if

available

Make

sure

that

safety

is

insured

4

Remove

propeller

shaft

Note

Pl

ll

up

the

openina

in

the

rear

extension

to

prevent

oil

from

flow

ing

out

S

Disconnect

front

exhaust

tube

6

Disconnect

selector

ra

8e

lever

from

manual

shaft

7

Disconnect

wire

connections

at

inhibitor

switch

8

Disconnect

vacuum

lube

from

vacuum

diaphragm

and

wire

connee

tions

at

downshift

solenoid

9

Disconnect

speedometer

cable

from

rear

exlension

10

Disconnect

oil

charging

pipe

II

Disconnect

oil

cooler

inlet

and

outlet

tubes

al

transmission

case

12

Support

engine

by

locating

a

jack

under

oil

pan

with

a

wooden

block

used

between

oil

pan

and

jack

Support

transmission

by

means

of

a

transmission

jack

CAUTION

Do

not

plecs

the

jack

under

the

oil

pin

dnin

plug

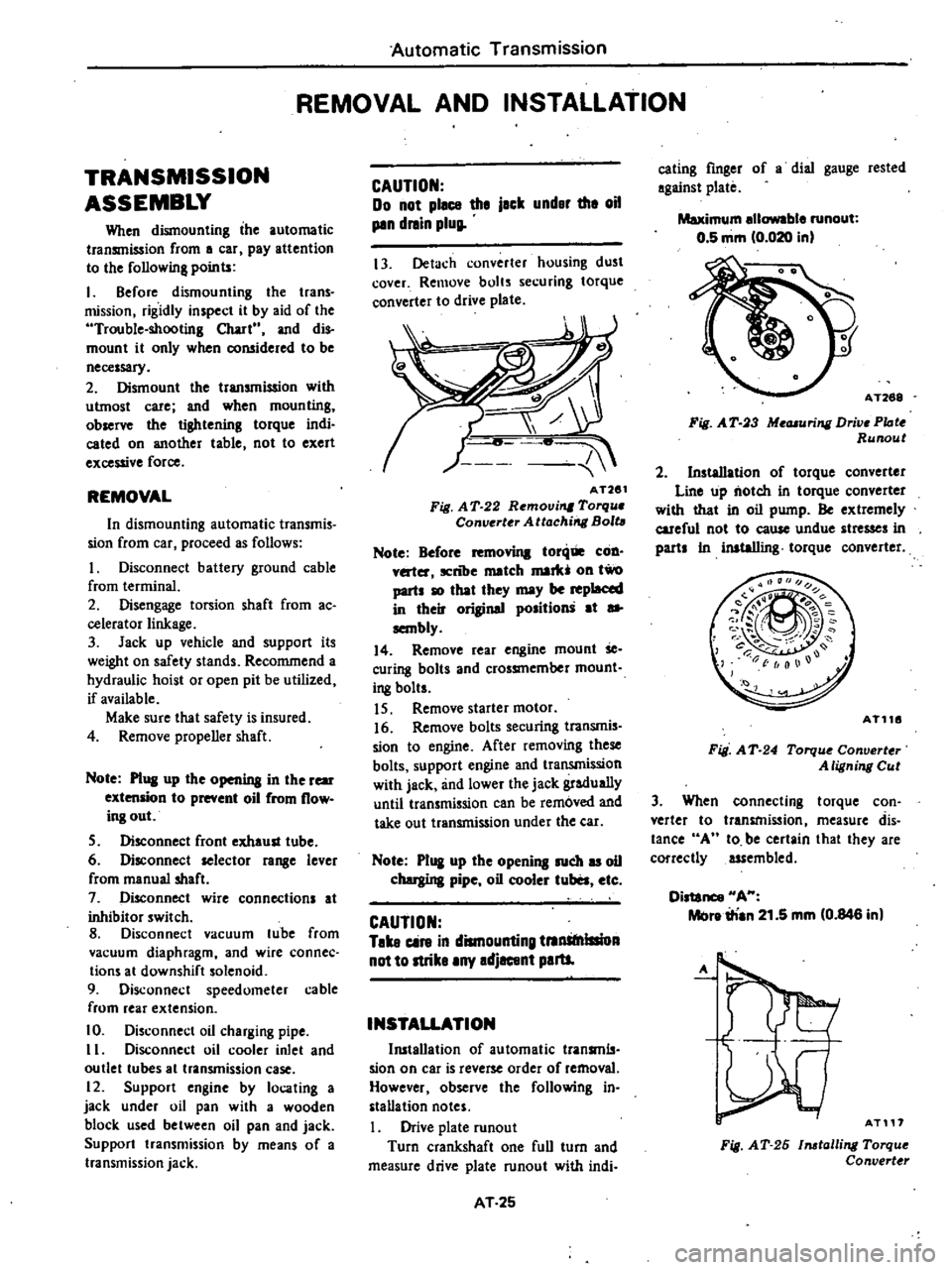

13

Detach

converter

housing

dust

cover

Remove

bolts

securing

torque

converter

to

drive

plate

AT261

Fig

A

T

22

Removi

Torqu

Converter

Attachirrg

Bolt

Note

Before

toni

COD

v

ter

ICnlJe

match

mark

011

two

parts

10

that

they

may

be

replaced

in

their

original

position

at

sa

sembly

14

Remove

rear

engine

mount

Se

curing

bolts

and

crossmember

mount

i

8

bolts

IS

Remove

starter

motor

16

Remove

bolts

securing

transmis

sion

to

engine

After

removing

these

bolts

support

engine

and

transmission

with

jack

and

lower

the

jack

gradually

until

transmission

can

be

removed

and

take

out

transmission

under

the

ear

Note

P1

I

up

the

opening

such

u

oil

chergina

pipe

oil

cooler

tuba

etc

CAUTION

Take

cin

in

dismounting

tnnStnlllioA

not

to

strike

any

adjacent

paru

INSTALLATION

Ill5tallation

of

automatic

transmls

sian

on

car

is

reverse

order

of

removal

However

observe

the

following

in

stallation

notes

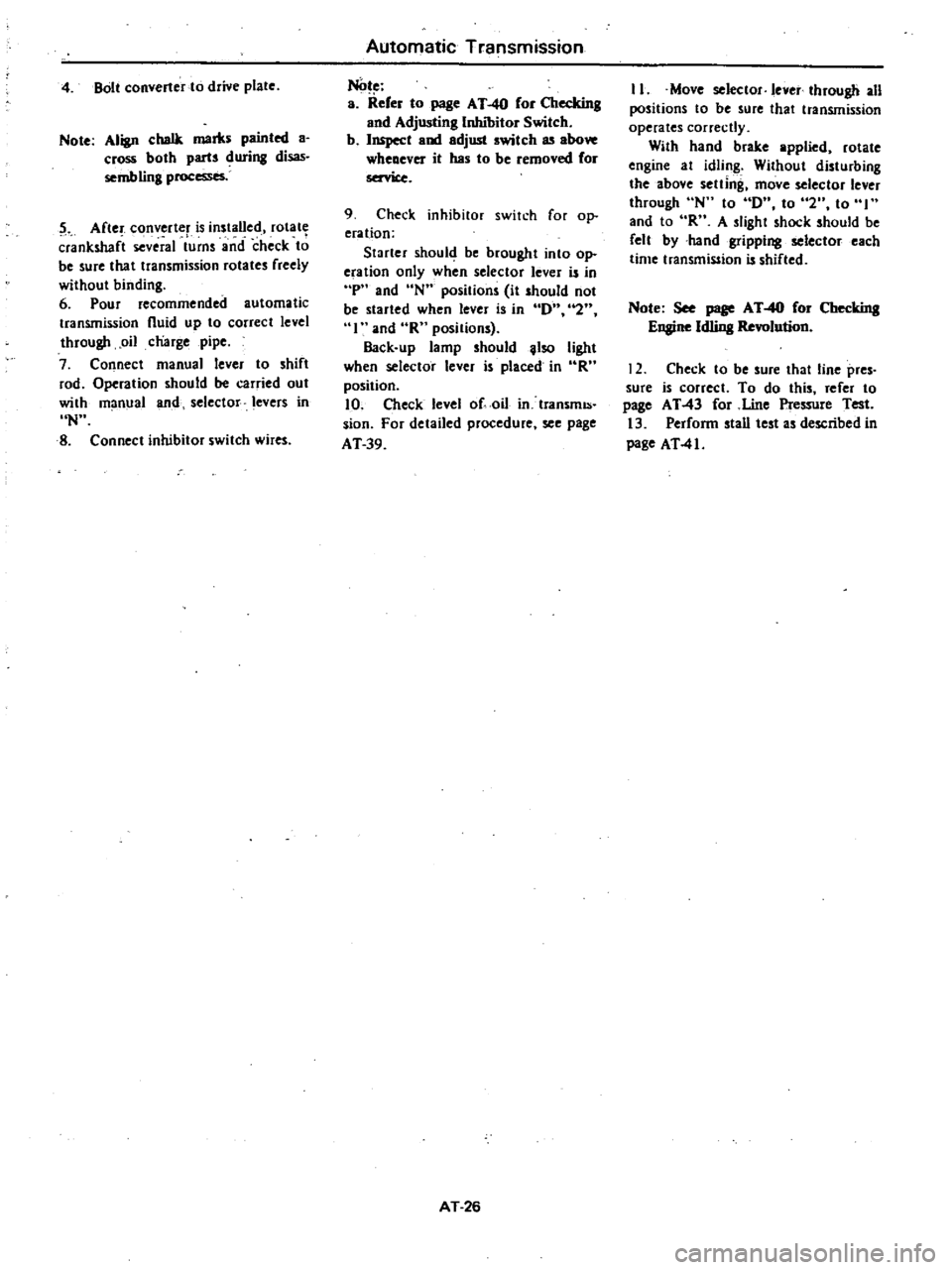

Drive

plate

runout

Turn

crankshaft

one

full

turn

and

measure

drive

plate

runout

with

indi

AT

25

eating

finger

of

a

dial

gauge

rested

against

plate

Maximum

ellowable

runout

0

5

mm

0

020

in

AT268

Fig

A

T

3

Me

uring

Drive

PIote

Runout

2

Installation

of

torque

converter

Line

up

notch

in

torque

converter

with

that

in

oil

pump

Be

extremely

careful

not

to

eause

undue

stresses

in

parts

In

inataIIing

torque

converter

AT116

Fig

A

T

24

Torqu

Converter

A

ligning

Cut

3

When

connecting

torque

con

verter

to

transmission

measure

dis

tance

A

10

be

certain

that

they

are

correctly

assembled

Distance

HA

Melre

irian

21

5

mm

0

846

in

A

AT117

Fig

AT

26

1116talling

Torque

Convert

r

Page 278 of 548

4

Bolt

converter

to

drive

plate

Note

Align

chalk

mark

painted

a

cro5S

both

parts

during

disas

sembling

p

S

After

converter

is

installed

rotat

r

nkshait

veral

turns

and

check

to

be

sure

that

transmission

rotates

freely

without

binding

6

Pour

recommended

automatic

transmission

fluid

up

to

correct

level

through

oil

charge

pipe

7

Connect

manual

lever

to

shift

rod

Operation

should

be

carried

out

with

m

mual

and

selector

levers

in

N

8

Connect

inhibitor

switch

wires

Automatic

Transmission

NOte

a

Refer

to

page

AT40

for

Checking

and

Adjusting

Inhibitor

Switch

b

Inspect

end

edjust

switch

as

abo

whe

ever

it

has

to

be

removed

for

servi

e

9

Check

inhibitor

switch

for

op

eration

Starter

should

be

brought

into

op

eration

only

when

selector

lever

is

in

P

and

N

positions

it

should

not

be

started

when

lever

is

in

D

n

and

Ru

positions

Back

up

lamp

should

Iso

light

when

selector

lever

is

placed

in

R

position

10

Check

level

of

oil

in

transm

sion

For

detailed

procedure

see

page

AT39

AT

26

II

Move

selector

leve

through

all

positions

to

be

sure

that

transmission

operates

correctly

With

hand

brake

applied

rotate

engine

at

idling

Without

disturbing

the

above

seUlng

move

selector

lever

through

N

to

D

to

2

to

I

and

to

R

A

slight

shock

should

be

reU

by

handgripping

selector

each

time

transmission

is

shifted

Note

See

page

AT40

for

Checking

Engine

Idling

Revolution

12

Check

to

be

sure

that

line

pres

sure

is

correct

To

do

this

refer

to

page

AT

43

for

Line

Pressure

Test

13

Perform

stan

test

as

described

in

page

AT41

Page 279 of 548

Automatic

Transmission

MAJOR

REPAIR

OPERATION

SERVICE

NOTICE

FOR

DISASSEMBLY

AND

ASSEMBLY

I

It

is

advisable

that

repair

opera

tions

be

carried

out

in

a

dust

proof

room

2

Due

to

the

differences

of

the

engine

capacities

the

specifications

of

component

parts

for

each

model

s

transmission

may

be

different

They

do

however

have

common

adjust

ment

and

repair

procedures

as

well

as

cleaning

and

inspection

procedures

outlined

hereinafter

3

During

repair

operations

refer

to

Service

Data

and

Specific3ti

H1s

see

tion

for

the

correct

parts

for

each

model

4

Before

removing

any

of

subas

semblies

thoroughly

clean

the

outside

of

the

transmission

to

prevent

dirt

from

entering

the

mechanical

parts

5

Do

not

use

a

waste

rag

Use

a

nylon

or

paper

cloth

6

After

disassembling

wash

all

dis

assembled

parts

and

examine

them

to

see

if

there

3re

any

worn

damaged

or

defective

parts

and

how

they

are

affected

Refer

to

Service

Data

for

the

extent

of

damage

that

justifies

replacement

7

As

a

rule

packings

seals

and

similar

parts

once

disassembled

should

be

replaced

with

new

ones

TORQUE

CONVERTER

The

torque

converter

is

a

welded

construction

and

can

not

be

disas

sembled

INSPECTION

I

Check

torque

convert

for

any

sign

of

damage

bending

oil

leak

or

deformation

If

necessary

replace

2

Remove

rust

from

pilots

and

bosses

completely

If

torque

converter

oil

is

fouled

or

contaminated

due

to

burnt

clutch

flush

the

torque

converter

as

follows

I

Drain

oil

in

torque

converter

2

Pour

non

lead

gasoline

or

kero

sene

into

torque

converter

approxi

mately

0

5

liter

I

J

V

S

pt

U

Imp

pt

3

Blow

air

into

torque

converter

and

flush

and

drain

out

gasoline

4

Fill

torque

converter

with

torque

converter

oil

approximately

0

5

liter

I

J

V

S

pt

U

Imp

pt

5

Again

blow

air

into

torque

con

verter

and

drain

torque

converter

oil

TRANSMISSION

DISASSEM

LY

I

Drain

oil

from

the

end

of

rear

extension

Mount

transmission

on

Transmission

Case

Stand

ST07g70000

or

ST07860000

Remove

oil

pan

AT118

Fig

A

T

26

R

movin

g

Oil

Pan

2

Remove

bolts

securing

converter

housing

to

transmission

case

Remove

torque

converter

housing

3

Remove

speedometer

pinion

sleeve

bolt

Withdraw

pinion

4

Remove

downshift

solenoid

and

vacuum

diaphragm

Do

not

leave

dia

phragm

rod

at

this

stage

of

dis

assembly

Rod

is

assembled

in

top

of

vacuum

diaphragm

Fig

A

T

27

Dowmhift

Solenoid

and

Vacuum

Diaphragm

AT

27

5

Remove

bolts

which

hold

valve

body

to

transmission

case

Fig

AT

28

Removing

Valve

Body

6

Loosen

lock

nut

CV

on

piston

stem

CD

Then

tighten

piston

stem

in

order

to

prevent

front

clutch

drum

from

falling

when

oil

pump

is

withdrawn

AT121

Fig

AT

29

Loosening

Band

Se11

Jo

7

Pull

out

input

shaft

8

Withdraw

oil

pump

using

Sliding

Hammer

ST25850000

Do

not

allow

front

clutch

to

come

out

of

position

and

drop

onto

floor

AT122

Fig

AT

30

Removing

Oil

Pump

Page 280 of 548

Fig

A

T

31

Removing

Bond

St

t

10

Remove

brake

band

front

clutch

and

rear

clutch

as

an

assembled

unit

II

Remove

connecting

shell

rear

clutch

hub

and

front

planetary

carrier

asa

unit

I

AT12

Fig

AT

32

Removing

Connecting

Shell

12

With

the

aid

of

Snap

Ring

Re

mover

HT69860000

pry

snap

ring

off

output

shaft

fig

A

T

33

Removing

Snap

Ring

13

Remove

connecting

drum

and

inner

gear

of

rear

planetary

carrier

as

an

assembly

Automatic

Transmission

AT126

Fig

A

T

34

Removing

Connecting

D

m

14

Remove

snap

rings

and

then

remove

rear

planetary

carrier

internal

gear

connecting

drum

one

way

clutch

outer

race

nd

one

way

clutch

in

that

order

I

S

Remove

rear

extension

by

loosening

securing

bolts

Fig

A

T

35

Removing

Rear

Extemion

16

Pull

out

output

shaft

remove

oil

distributor

@

together

with

governor

Ive

D

Fig

AT

36

Remov

ngGovernorand

Oil

Di

tributor

17

Pry

off

snap

ring

using

a

pair

of

pliers

Remove

retaining

plate

drive

plate

driven

plate

and

dish

plate

in

that

order

AT

28

Fig

AT

37

Removing

Drive

and

Driven

PltJte

18

Reaching

through

back

side

of

transnlission

case

remove

hex

head

slotted

bolts

To

do

this

use

Hex

head

E

xt

ens

ion

S

T

2

55

7

000

I

ST25570000

One

way

clutch

inner

race

thrust

washer

piston

return

spring

and

thrust

spring

ring

can

now

be

removed

snSS70001

Fig

A

T

38

Removi

Hex

head

Slolted

Boll

19

Blowout

low

and

reverse

brake

piston

by

directing

a

jet

of

air

into

hole

in

cylinder

Fig

A

T

39

Rem

wing

Piolon

20

Remove

band

servo

loosening

allaching

bolts