DATSUN 210 1979 Service Manual

Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 241 of 548

2

Install

needle

bearing

by

lightly

tapping

around

it

with

a

brass

drift

and

a

hammer

3

Install

reverse

idler

shaft

with

thrust

washer

in

adapter

plate

by

tapping

the

shaft

end

with

a

soft

hammer

TM243A

Fig

MT

I05

Installing

Re

Idler

Shaft

ASSEMBLY

OF

GEAR

ASSEMBLY

Clean

all

parts

in

solvent

and

dry

with

pressed

air

Synchronizer

1

2nd

3rd

41h

5th

speed

synchronizers

I

Place

synchro

hub

into

coupling

sleeve

2

Fit

shifIing

inserts

in

t1lree

grooves

in

synchronozer

hub

3

Install

spread

spring

to

inserts

so

that

insert

is

securely

attached

to

inner

side

of

coupling

sleeve

Install

Ihe

other

spread

spring

on

the

opposite

side

of

synchro

hub

Note

a

Be

careful

not

to

hook

front

and

rear

ends

of

the

spread

spring

to

the

same

insert

b

Be

sure

that

hub

and

sleeve

oper

ates

smoothly

and

correctly

by

hand

TM077

Fig

MT

I06

Enstalling

Spread

Spring

Manual

Transmission

TM131A

Fig

MT

I07

Installing

Spre

d

Spring

2

2

Ist

reverse

synchronizer

I

Position

shifting

insert

springs

and

shifting

inserts

in

three

3

slots

in

synchronizer

hub

2

Put

reverse

gear

on

synchronizer

hub

3

Install

shifting

insert

retainer

to

inserts

so

that

sert

is

securely

attach

ed

to

inner

side

of

reverse

gear

Mainshatt

I

Assemble

3rd

gear

needle

bearing

3rd

gear

baulk

ring

2nd

3rd

speed

synchronizer

assembly

2nd

gear

baulk

ring

2nd

gea

buihirig

needle

bearing

2nd

gea

and

thrust

washer

on

main

shaft

to

2

Press

mainshiift

bearing

onto

mainshaft

uSi

g

Mainshaft

Bearing

Drifl

ST22350000

L

ST22350000

TM711

Fig

MT

I08

Enstalling

Mainshaft

Bearing

Note

Assemble

2nd

3rd

speed

synchronizer

paying

attention

to

its

direction

MT

25

Front

hl

l

h2

2nd

gear

ide

3rd

gear

SIde

hi

h2

Fig

MT

109

Inslalling

2nd

3rd

Speed

Synchronizer

3

Position

5th

gear

needle

bearing

5th

gear

bawk

ring

and

4th

5th

synchronizer

assembly

on

the

front

side

of

mainshaft

4

Fit

a

new

suitable

snap

ring

in

place

so

that

there

exists

a

minimum

clearance

between

end

face

of

hub

and

ring

Note

Make

sure

snap

ring

fits

in

groove

Available

snap

rings

No

Thicknc

ss

mm

tin

2

1

55

to

1

60

0

0610

to

0

0630

1

60

to

1

65

0

0630

to

0

0650

1

65

to

1

70

0

0650

to

0

0669

3

TM798

Fig

MT

IlO

InslallingSnap

Ring

Main

drive

gear

1

Press

main

drive

gear

bearing

onto

shaft

of

main

drive

gear

using

Trans

mission

Drift

ST23800000

Make

sure

that

snap

ring

groove

on

shaft

clears

bearing

Page 242 of 548

H

ST23800000

M

TM714

Fig

MT

111

InstaUing

Main

Drive

Bearing

2

Place

main

drive

bearing

spacer

on

main

drive

bearing

and

secure

main

dtivebearing

with

a

new

tlii

er

snap

ring

that

will

eliminate

end

play

Note

Make

sure

snap

ring

fits

in

groove

1

Main

drive

gear

2

Snap

ring

3

Spacer

4

Main

drive

bearing

TM715

Fig

MT

112

In

talling

Snap

Ring

Available

snap

rings

No

Thickness

mm

in

2

1

34

to

I

40

0

0528

to

0

055

I

l40tol46

0

0551

to

0

0575

I

4610

1

52

0

0575100

0598

1

52101

58

0

0598

10

0

0622

1

58

to

1

64

0

0622

to

0

0646

1

64

to

I

70

0

0646

to

0

0669

I

70

to

I

76

0

0669

10

0

0693

3

4

5

6

7

Counter

cear

I

Install

a

counter

gear

thrust

washer

and

counter

gear

into

transmis

sian

case

and

select

counter

gear

Manual

Transmission

thrust

washer

of

proper

thiclmess

using

straight

edge

Select

washer

from

those

shown

in

the

following

table

so

that

end

play

of

counter

gear

is

specified

value

Standard

end

play

0

10

to

0

20

mm

0

0039

to

0

0079

inl

No

Thickness

mm

in

2

20

to

2

25

0

0866

to

0

0886

2

25

to

2

30

0

0886

to

0

0906

2

30

to

2

35

0

0906

to

0

0925

2

35

to

2

40

0

0925

to

0

0945

2

40

to

2

45

0

0945

to

0

0965

2

45

to

2

50

0

0965

to

0

0984

2

50

to

2

55

0

0984

to

0

1004

2

55

to

2

60

0

1004

to

0

024

2

3

4

5

6

7

8

Note

Be

sure

to

measure

at

two

or

more

positions

on

the

end

surface

of

counter

gear

rr

II

TM244A

Fig

MT

113

Measuring

Counter

Gear

End

Phly

2

Remove

counter

gear

from

the

transmission

case

Assembly

to

adapter

plate

I

Install

baulk

ring

on

main

dtive

gear

and

combine

with

mainshaft

to

complete

the

mainshaft

assembly

Note

l

e

sure

to

iJislall

pilot

bearing

in

place

when

combining

with

mainshaft

MT

26

2

Combine

mainshaft

assembly

with

counter

gear

assembly

and

place

them

into

adapter

plate

simulta

neously

Note

Be

careful

not

to

forget

to

install

thrust

washer

And

when

installing

throst

washer

note

front

1IIllIR

tt

djrections

Front

Thrust

side

Rear

Oil

groove

side

TM285A

Fig

MT

I14

Count

Gear

Thru

t

Washer

3

Pull

mainshaft

assembly

into

adapter

plate

using

Mainshaft

Puller

KV32100400

When

installing

main

shaft

assembly

carefully

hold

gears

by

hand

Install

counter

gear

assembly

together

with

mainshaft

assembly

by

applying

light

blows

with

a

soft

faced

hammer

Make

sure

that

snap

ring

groove

on

mainshaft

rear

bearing

clears

adapter

plate

CAUTION

a

Take

care

not

to

drop

geaB

on

floor

b

Take

care

not

tndamage

bearings

TM245A

Fig

MT

II5

Installing

Main

haft

A

6embly

4

Fit

snap

ring

to

groove

in

main

shaft

rear

bearing

with

snap

ring

pliers

TM23aA

Fig

MT

116

Fitting

Main

haft

Rear

Bearing

Snap

Ring

Page 243 of 548

Note

Make

sure

smp

ring

fits

in

groove

5

Install

bearing

retainer

on

adapter

plate

Torque

screws

and

stake

each

screw

at

two

points

with

a

punch

@

Tightening

tOrque

Mainshaft

bearing

retainer

screw

0

8

to

3

kll

m

15

8

to

9

4

ft

lbl

TM246A

Fig

MT

117

Staking

Bearing

Retainer

Screws

6

Press

Ist

counter

gear

onto

counter

sltaft

using

Drift

ST22360002

TM583

Fig

MT

118

Installing

I

t

Counter

Gear

7

Fit

a

new

suitable

retaining

ring

in

place

so

th

t

there

exists

a

mininum

clearance

between

end

face

of

counter

gear

and

ring

Note

Make

sure

retaining

ring

f

It

in

groove

Available

retaining

rings

No

Thickness

mm

in

2

1

25

to

1

35

0

0492

to

0

0531

1

35

to

I

45

0

0531

to

0

0571

0

d

Converted

tor

q

e

j

Iim

ttine

7

7

7

Manua

Transmission

TM247

A

Fig

MT

119

Installing

Retaining

Ring

8

Install

thrust

washer

to

rear

of

mainshaft

and

idler

shaft

9

Install

synchro

hub

with

reverse

gear

I

st

gear

together

with

needle

bearing

and

bushing

and

idler

gear

together

with

needle

bearing

simulta

neously

OTT

o

1st

gear

side

Ui

Front

Fl

J

I

TM263A

Fig

MT

I20

In

talling

Ist

Reverse

Synchronizer

10

Install

mainshaft

nut

and

tighten

it

temporarily

E

S

f2

80

t1

o

c

v

0

S

v

5

c

o

o

u

10

70

9

60

50

II

With

I

st

and

2nd

gears

doubly

engaged

tighten

mainshaft

nut

to

con

verted

torque

en

See

Fig

MT

123

using

Wrench

ST22520000

Stake

mainshaft

nut

to

groove

of

mainshaft

with

a

punch

ST22520000

TM248A

Fig

MT

I2I

Tightening

Mainshaft

Nut

TM249A

Fig

MT

I22

Staking

Mainshaft

Nut

I

I

Upper

limit

line

40

0

2

0

3

0

4

0

5

0

6

0

7

0

8

m

1

0

1

5

2

0

2

5

ft

L

Effective

length

of

torque

wrench

MT

27

TM258A

Fig

MT

123

Converted

Torque

Page 244 of 548

J

xplanation

of

convet

ted

torque

Mainshaft

nut

should

be

tightened

to

10

to

11

kg

m

72

to

80

ft

Ib

torque

with

the

aid

of

Wrench

ST22520000

When

doing

w

the

amount

of

torque

to

be

read

on

wrench

needle

should

be

modified

according

to

the

following

formula

L

C

kg

m

10

x

L

O

I

to

11

L

x

L

O

I

or

C

ft

Ib

n

x

L

O

33

to

L

80

x

L

0

33

Where

C

Value

read

on

the

torque

wrench

kg

m

ft

Ib

L

Effective

length

of

torque

wrench

m

ft

ST22520000

Torque

wrench

r

Lm

ft

0

1

m

0

3

ft

TM587

Fig

MT

124

Setting

Wrench

Example

When

a

0

4

m

Iong

torque

wrench

is

used

the

C

in

Fig

MT

123

will

be

8

0

to

8

8

kg

m

58

to

64

ft

Ib

12

Measure

gear

end

play

Make

sure

that

they

are

held

within

the

specified

values

For

details

refer

to

Page

MT

23

for

Inspection

13

Fit

1

0

IDm

0

039

in

thick

snap

ring

10

the

front

side

of

main

shaft

end

bearing

14

Install

mainshaft

end

bearing

using

Bearing

Drift

ST22350000

Fit

thick

snap

ring

to

the

rear

side

of

bearing

to

eliminate

end

play

Manual

Transmission

Available

Sllap

ring

No

Thickness

IDm

in

1

1

0

0

039

2

1

2

0

047

on

LST22350000

TM250A

Fig

MT

125

In

talling

Main

haft

End

Bearing

Shift

forks

and

fork

rods

1

Insert

1st

reverse

fork

rod

into

its

shift

fork

and

adapter

plate

2

With

1st

reverse

fork

rod

set

at

Neutral

insert

interlock

plunger

into

adapter

plate

3

Insert

2nd

3rd

fork

rod

into

adapter

plate

2nd

3rd

and

4th

5th

shift

forks

4

With

2nd

3rd

fork

rod

set

at

Neutral

insert

interlock

plunger

into

adapter

plate

5

Insert

4th

5th

fork

rod

into

adapter

plate

and

its

s

Uft

fork

6

Secureshift

forks

and

fork

rOd

s

with

new

retaining

pins

Note

a

Be

sure

to

install

interlock

plunger

when

installing

any

adjacent

fork

rods

to

adapter

plate

Properly

align

the

groove

in

assem

bleMork

rod

with

inle

rlQck

plung

er

See

Fig

MT

SO

b

Be

su

to

align

4th

5th

shift

fork

with

the

groove

in

their

coupling

sleeve

befo

instalting

c

Also

align

2nd

3rd

shift

fork

with

their

coupling

sleeve

properly

be

fore

instalting

7

Install

check

balls

and

check

ball

springs

Applying

locking

sealer

to

check

ball

plug

and

install

in

place

Align

center

notch

in

each

fork

rod

with

check

ball

Note

a

Check

ball

plug

for

1st

reverse

fork

rod

is

longer

than

those

for

2nd

3rd

fork

rod

and

4th

5th

fork

rod

b

To

insure

that

interlock

plunger

i

installed

properly

slide

2nd

3rd

fork

rnd

andoperate

the

other

fork

rod

Make

sure

thaI

gear

except

20d

or

3rd

gear

doe

not

mesh

8

Apply

gear

oil

to

all

sliding

sur

faces

and

check

to

see

that

shift

rods

operate

correctly

and

gears

engage

smoothly

L

1

u

Revene

TM251A

Fig

MT

126

In

talling

Shift

Forks

and

Fork

Roth

MT

28

Page 245 of 548

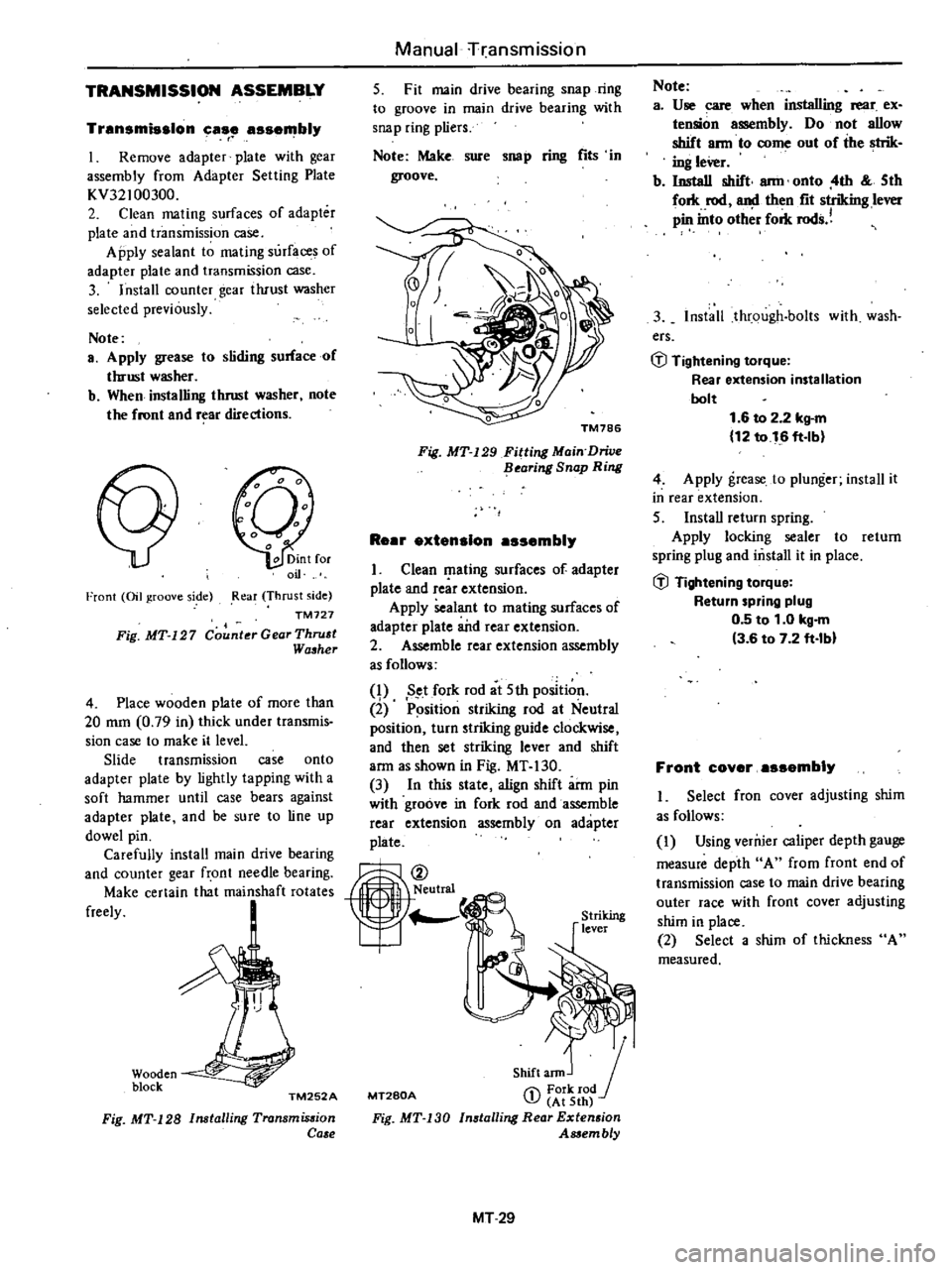

TRANSMISSION

ASSEMBLY

Transmission

case

assembly

r

I

Remove

adapter

plate

with

gear

assembly

from

Adapter

Setting

Plate

KV32100300

2

Clean

mating

surfaces

of

adapter

plate

and

transmission

case

Apply

sealant

to

mating

surfaces

of

adapter

plate

and

transmission

case

3

Install

counter

gear

tluust

washer

selected

previously

Note

a

Apply

grease

to

sliding

surface

of

thrust

washer

b

When

installing

thrust

washer

note

the

front

and

r

ar

directions

Front

Oil

groove

side

Rear

Thrust

side

TM727

Fig

MT

127

Counter

Gear

Thru

t

Wa

her

4

Place

wooden

plate

of

more

than

20

mm

0

79

in

thick

under

transmis

sion

case

to

make

it

level

Slide

transmission

case

onto

adapter

plate

by

lightly

tapping

with

a

soft

hammer

until

case

bears

against

adapter

plate

and

be

sure

to

line

up

dowel

pin

Carefully

install

main

drive

bearing

and

counter

gear

front

needle

bearing

Make

certain

that

mainshaft

rotates

freely

Wooden

block

TM252A

Fig

MT

128

Installing

Transmis

ion

Ca

e

Manual

rransmission

5

Fit

main

drive

bearing

snap

ring

to

groove

in

main

drive

bearing

with

snap

ring

pliers

Note

Make

sure

sno

p

ring

fits

in

groove

Fig

MT

129

Fitting

Main

Drive

flearing

Snap

Ring

ReBr

extension

assembly

I

Clean

I

lating

surfaces

of

adapter

plate

and

rcar

extension

Apply

sealant

to

mating

surfaces

of

adapter

plate

a

itd

rear

extension

2

Assemble

rear

extension

assembly

as

follows

q

Set

fork

rod

at

5th

position

2

P

sition

striking

rod

at

Neutral

position

turn

striking

guide

clockwise

and

then

set

striking

lever

and

shift

arm

as

shown

in

Fig

MT

130

3

In

this

state

align

shift

arm

pin

with

groove

in

fork

rod

and

assemble

rear

extension

assembly

on

adapter

plate

MT280A

Shift

ann

J

1

Fork

rod

J

At

5th

Installing

Rear

Extension

Assembly

Fig

MT

130

MT29

Note

a

Use

care

when

installing

rear

ex

tension

assembly

Do

not

allow

shift

ann

to

come

out

of

the

strik

ing

leVer

b

Install

shift

ann

onto

4th

5th

fork

rod

and

then

fit

striking

lever

pin

into

oth

r

fork

rods

3

Install

through

bolts

with

wash

ers

GJ

Tightening

torque

Rear

extension

installation

bolt

1

6

to

2

2

kg

m

12

to

16

ft

lb

4

Apply

grease

to

plunger

install

it

in

rear

extension

5

InstaU

return

spring

Apply

locking

sealer

to

return

spring

plug

and

mstall

it

in

place

GJ

Tightening

torque

Return

spring

plug

0

5

to

1

0

kg

m

3

6

to

7

2

ft

lbl

Front

coyer

assembly

I

Select

fron

cover

adjusting

shim

as

follows

I

Using

verruer

caliper

depth

gauge

measure

depth

A

from

front

end

of

transmission

case

to

main

drive

bearing

outer

race

with

front

cover

adjusting

shim

in

place

2

Select

a

shim

of

thickness

A

measured

Page 246 of 548

No

A

mm

in

Manual

Ttansniissio

n

Adjusting

shim

mm

in

0

50

0

0197

0

55

0

0217

0

60

0

0236

0

6

0

9756

0

70

0

0276

0

75

0

0295

0

80

0

0315

I

2

3

4

5

6

7

6

05

to

6

09

0

2382

to

0

2398

6

10to

6

14

0

2402

to

0

2417

6

15

to

6

19

0

2421

to

0

2437

6

20

to

6

2

4

9

1

41

t

19

2457

6

25

to

6

29

0

2461

to

0

2476

6

30

to

6

34

0

2480

to

0

2496

6

35

to

6

39

0

2500

to

0

2516

TM816

Fig

MT

131

MetuUring

Front

CoV

r

Adju

ting

Shim

1

Transmission

case

2

Main

drive

gear

3

Adjusting

shim

4

Bearing

TM817

Fig

MT

132

Selecting

Front

CoV

r

Adju

ti1l8

shim

2

Clean

maling

surfaces

of

front

cover

and

transmission

case

3

Install

front

cover

to

transmission

case

with

the

adjUsting

shim

and

0

ring

in

place

@

Tight

ning

torque

Front

co

erinstallation

bolt

1

0

to

1

6

kg

m

7

to

12

ft

Ib

Outer

parts

assembly

I

Install

speedometer

pinion

assem

bly

and

install

securing

bolt

and

tighten

@

Tightening

torque

Speedometer

sl

locking

plate

bolt

0

3

to

0

5

kg

m

2

2

to

3

6

ft

lb

2

Install

reverse

lamp

switch

and

tighten

At

the

same

time

install

top

detecting

switch

if

so

equipped

Be

sure

to

apply

locking

sealer

before

installation

MT30

@

Ti

ltening

torque

Rewene

lamp

switch

and

top

detecting

switch

2

0

to

3

5

kg

m

14

to

25

fHb

3

Apply

a

light

coat

of

multi

purpose

grease

to

withdrawal

lever

release

bearing

ahd

bearing

sleeve

in

stall

them

on

transmission

case

After

connecting

them

with

holder

spring

install

dust

cover

to

transmis

sion

case

4

Install

control

lever

temporarily

and

move

shift

coritrol

lever

through

all

gears

to

make

sure

that

gears

op

rate

smoothly

5

InstaU

draiiI

plug

coated

with

sealant

in

place

@

Tightening

torque

Drain

plug

2

5

to

4

0

kg

m

18

to

29

fHb

6

Make

sure

that

main

drive

shaft

rotates

smoothly

in

Neutral

v

Jin

drive

gear

routing

torque

less

than

1

8

leg

em

1

6

in

Ib

Page 247 of 548

Manual

Transmission

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

Transmission

model

F4W60L

FS5W60L

Item

No

of

speeds

4

5

Synchromesh

type

Warner

Shift

type

t

3

I

I

R

2

4

2

4

R

r

I

I

1

3

5

1st

3

513

3

513

2nd

2

170

2

170

3rd

1

378

1

378

Gear

ratio

4th

1

000

1

000

5th

0

846

Rev

3

764

3

464

Final

gear

ratio

3

700

3

700

155

13

6

15

13

4PR

16

5

Speedometer

Tire

155SRI3

16

5

gear

ratio

175

70SR13

16

5

Oil

capacity

liter

US

pt

Imp

pt

1

3

2

U

2

Y

I

1

2

2

i

i

i

MT31

Page 248 of 548

Manual

Transmission

INSPECTION

AND

ADJUSTMENT

Transmission

model

Item

Ist

gear

2nd

gear

Gear

end

play

mm

in

3rd

gear

5th

gear

Counter

gear

Reverse

idler

gear

Clearance

between

baulk

ring

and

gear

rom

in

Main

drive

coupter

drive

gear

1st

gear

2nd

gear

Gear

backlash

mm

in

3rd

gear

5th

gear

Reverse

counter

to

reverse

idler

Reverse

idler

to

reverse

main

Main

drive

gear

rotating

torque

kg

cm

in

lb

F4W60L

0

15

to

0

25

0

0059

to

0

0098

0

30

to

0

40

0

0118

to

0

0157

0

15

to

0

30

0

0059

to

0

0118

0

10

to

0

20

0

0039

to

0

0079

0

1

0

to

0

27

0

0039

to

0

0106

0

80

to

1

65

0

0315

to

0

0650

0

05

to

0

15

0

0020

to

0

0059

0

05

to

0

15

0

0020

to

0

0059

0

05

to

0

15

0

0020

10

0

0059

0

05

to

0

15

0

0020

to

0

0059

0

05

to

0

18

0

0020

to

0

0071

0

05

to

0

18

0

0020

to

0

0071

Ie

thaI

1

8

1

6

MT32

FS5W60L

0

15

to

0

25

0

0059

to

0

0098

0

15

to

0

25

0

0059

to

0

0098

0

30

to

0

40

0

0118

to

0

0157

O

lSto

0

30

0

0059

to

0

Q118

0

1

0

to

0

20

0

0039

to

0

0079

0

15

to

0

40

0

0059

to

0

Q157

0

80

to

1

65

0

0315

1

0

0650

0

05

to

0

15

0

0020

to

0

0059

O

OSto

0

15

0

0020

to

0

0059

0

05

to

0

15

0

0020

to

0

0059

0

05

to

0

15

0

0020

to

0

0059

0

05

to

0

15

0

0020

to

0

0059

0

05

to

0

18

0

0020

to

0

071

0

05

to

0

18

0

0020

to

0

0071

less

than

1

8

I

6

Page 249 of 548

TIGHTENING

TORQUE

Ball

pin

Striking

lever

lock

nut

S

llft

arm

bracket

Mainshaft

bearing

retainer

screw

Mainshaft

lock

nut

Rear

extension

installation

bolt

Stopper

pin

bolt

Front

cover

installation

bolt

Speedometer

sleeve

lock

ing

plate

bolt

Top

detecting

switch

Reverse

lamp

switch

Neutral

switch

Return

spring

plug

Gear

oil

filler

plug

Gear

oil

drain

plug

Transmission

to

engine

installation

bolt

Tr

msmissiori

to

engihe

rear

plate

installation

bolt

Transmission

to

gusset

installation

bolt

Starting

motor

to

trans

inissi

n

installation

bolt

Rear

mounting

insulator

to

transmission

installation

bolt

Crossmember

mounting

bolt

Rear

engine

mount

installation

bolt

Clutch

operating

cylinder

installation

bolt

Propeller

shaft

to

differential

carrier

Control

lever

pin

installation

nut

Exhaust

mounting

bracket

to

exhaust

front

tube

FU

model

only

Manual

Transmission

F4W60L

2

0

to

3

0

14

to

22

0

9

to

1

2

6

5

to

8

7

0

7

to

1

0

5

1

to

7

2

1

6

to

2

2

12

to

16

0

5

to

0

8

3

6

to

5

8

1

0

to

1

6

7

to

12

0

3

to

0

5

2

2

to

3

6

2

0

to

3

5

14

to

25

2

0

to

3

5

14

to

25

0

5

to

1

0

3

6

to

7

2

2

5

to

4

0

18

to

29

2

5

to

4

0

18

to

29

1

6

to

2

2

12Jo

16

1

6

to

2

2

12

t

16

4

6

to

6

1

33

to

44

3

0

to

4

0

22

to

29

0

9

to

1

2

6

5

to

8

7

3

2

to

4

3

23

to

31

0

9

to

1

2

6

5

to

8

7

3

1

to

4

1

22

to

30

2

4

to

3

3

17

to

24

1

3

to

1

7

9

to

12

3

2

to

4

3

23

to

31

MT33

Unit

kg

m

ft

lb

FS5W60L

2

0

to

3

0

14

to

22

0

9

to

1

2

6

5

to

8

7

8

2

to

10

0

59

to

72

0

8

to

1

3

5

8

to

9

4

10

0

to

11

0

72

to

80

1

6

to

2

2

12

to

16

1

0

to

1

6

7

to

12

0

3

to

0

5

2

2

to

3

6

2

0

to

3

5

14

to

25

2

0

to

3

5

14

to

25

2

0

to

3

5

14

to

25

0

5

to

1

0

3

6

to

7

2

2

5

to

4

0

18

to

29

i

5

to

4

0

18

to

29

1

6

to

2

2

12

to

16

1

6

to

2

2

12

to

16

4

6

to

6

1

33

to

44

3

0

to

4

0

22

to

29

0

9

to

1

2

6

5

to

8

7

3

2

to

4

3

23

to

31

0

9

to

1

2

6

5

to

8

7

3

1

to

4

1

22

to

30

2

4

to

3

3

17

to

24

1

3

to

1

7

9

to

12

3

2

to

4

3

23

to

31

Page 250 of 548

Manual

Transmission

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Difficult

to

intermesh

gears

Causes

for

difficult

gear

shifting

are

classi

fie

t

o

ro

lb

c

QncerlJing

coJltr

1

syste

and

transmission

When

gear

shift

lever

is

heavy

and

it

is

difficult

to

shift

gears

clutch

disengagement

may

also

be

unsmooth

First

make

sure

that

clutch

operates

correctly

and

inspect

transmjssion

Gear

slips

out

of

mesh

In

most

cases

this

troubk

occurs

when

check

baD

and

or

spring

is

waIn

or

weaken

ed

or

when

control

system

is

faulty

In

this

case

the

troubk

cannot

be

correct

by

replacing

gears

and

therefore

trouble

shoot

ing

must

be

carried

out

carefuDy

It

should

also

be

noted

that

gear

slips

out

of

mesh

due

to

vibration

generated

by

weakened

front

and

rear

enigne

mounts

Noise

When

noise

occurs

with

engine

idling

and

ceases

when

clutch

is

disengaged

or

when

noise

occurs

while

shifting

gears

it

is

an

indication

that

the

noise

is

from

trans

mission

Transmission

may

rallk

during

engine

idling

Check

air

fuel

mixture

and

ignition

timing

After

above

procedure

readjust

engine

idling

Probable

cause

Worn

gears

shaft

and

or

bearing

Insufficient

operating

stroke

due

to

worn

or

loose

sliding

part

Worn

or

damaged

syncluonizer

Worn

check

baD

and

or

weakened

or

broken

spring

Worn

fork

rod

baU

groove

Worn

or

damaged

bearing

Worn

or

damaged

gear

Insufficient

or

improper

lubricant

Oil

leaking

due

to

damaged

oil

seal

or

sealant

clogged

breather

etc

Worn

bearing

High

humming

occurs

at

a

high

speed

Damaged

bearing

Cyclic

knocking

sound

occurs

also

at

a

low

speed

Worn

spline

Worn

bushing

MT34

Corrective

action

Replace

Repair

ClI

replace

Replace

Replace

Replace

Replace

Replace

Add

oil

or

replace

with

designated

oil

Clean

or

replace

Replace

Replace

Replace

Replace

as

a

rear

ex

tension

assembly