DATSUN 210 1979 Repair Manual

Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 61 of 548

Engine

Mechanical

Camshaft

journal

and

bearing

specifications

Undemze

uillt

mm

in

Bearing

Camshaft

bearing

Finish

of

camshaft

Camshaft

journal

to

Finish

of

camshaft

Bearing

size

bearing

inner

position

thickness

journal

diameter

bearing

clearance

diame

tee

Standard

1

565

to

1

585

43

783

to

43

796

0

037

to

0

060

43

833

to

43

843

0

0616

to

0

0624

I

7237

to

I

7242

0

0015

to

0

0024

I

7257

to

1

7261

0

25

1

90

to

1

710

43

233

to

43

2

0

037

to

0

060

43

283

to

43

293

0

0098

0

0665

to

0

0673

17021

to

I

7025

0

0015

to

0

0024

1

7041

to

1

7044

No

I

Under

0

50

1

815

to

1

835

43

283

to

43

296

0

037

to

0

060

43

333

to

43

343

size

0

0197

0

0715

to

0

0722

i

7041

to

I

7046

0

0015

to

0

0024

I

7060

to

I

7064

0

75

1

940

to

1

960

43

033

to

43

046

0

037

to

0

060

43

083

to

43

093

0

0295

0764

to

0

0772

1

6942

to

1

69

7

0

0015

to

0

0024

1

6962

to

1

6966

Standard

1

565

to

1

585

43

283

1043

296

0

027

to

0

050

43

323

to

43

333

0

0616

to

0

0624

I

7041

to

I

7046

0

00

II

to

0

0020

I

7056

to

1

7060

0

25

1

690

to

I

710

43

033

to

43

046

0

027

to

0

050

43

073

to

43

083

0

0098

0

0665

to

0

0673

1

6942

to

1

6947

0

00

II

to

0

0020

1

6958

to

1

6962

No

2

Under

0

50

1

815

to

1

835

42

783

to

42

796

0

Oi7

10

0

050

42

823

to

42

833

size

0

0197

0

0715

to

0

0722

1

6844

to

1

6849

0

00

II

to

0

OQ20

1

6859

to

1

6863

0

75

11

940

to

1

960

42

533

1042

546

0

027

to

0

050

42

573

to

42

583

0

0295

0

0764

to

0

0772

1

6745

to

1

6750

0

0011

to

0

0020

1

6761

to

1

6765

Standard

1

565

to

1

585

42

783

to

42

796

0

040

to

0

063

42

836

to

42

846

0

0616

to

0

0624

1

6844

to

1

6849

0

0016

to

0

0025

1

6865

to

1

6868

0

25

1

690

to

1

710

42

533

to

42

546

0

040

to

0

063

42

586

to

42

596

0

0098

0665

to

0

0673

1

6745

to

1

6750

0

0016

to

0

0025

1

6766

to

1

677

No

3

Under

0

50

1

815

to

1

835

42

283

to

42

296

0

040

to

0

063

42

336

to

42

346

size

0

0197

0

0715

to

0

0722

1

6647

to

1

6652

0

0016

to

0

0025

1

6668

to

1

6672

0

75

11

940

to

1

960

42

033

to

42

046

0

040

to

0

063

42

086

to

42

096

0

0295

0

0764

to

0

0772

1

6548

to

1

6554

0

0016

to

0

0025

1

6569

to

1

6573

Standard

1

565

to

1

585

42

283

to

42

296

0

027

to

0

050

42

323

to

42

333

0

0616

to

0

0624

1

6647

to

1

6652

0

00

II

to

0

0020

1

6663

to

1

6667

0

25

1

690

to

I

710

42

033

to

42

046

0

027

to

0

050

42

073

to

42

083

0

0098

0

0665

to

0

0673

1

6548

10

1

6554

0

0011

100

0020

1

6564

to

1

6568

No

4

Under

0

50

1

815

to

1

835

41

783

to

41

796

0

027

to

0

050

41

823

to

41

833

size

0

0197

0

0715

to

0

0722

1

6450

to

1

6455

0

00

II

to

0

0020

1

6466

to

1

6470

1

0

75

11

940

to

1

960

41

533

to

41

546

0

027

to

0

050

41

573

to

41

583

0

0295

0

0764

to

0

0772

1

6352

to

1

6357

0

00

II

to

0

0020

1

6367

to

1

6371

Standard

1

565

to

1

585

41

208

to

41

221

0

037

to

0

060

41

258

to

41

268

0

0616

to

0

0624

1

6224

to

1

6229

0

0015

to

0

0024

1

6243

to

1

6247

0

25

1

690

to

1

710

40

958

to

40

971

0

037

to

0

060

41

008

to

41

018

0

0098

0

0665

to

0

0673

1

6125

to

1

6130

0

0015

to

0

0024

1

6145

to

1

6149

No

5

Unoer

0

50

1

815

to

1

835

40

708

to

40

721

0

037

to

0

060

40

758

to

40

768

size

0

0197

0

0715

to

0

0722

1

6027

to

1

6032

0

0015

to

0

0024

1

6046

to

1

6050

1

0

75

11

940

to

1

960

40

458

to

40

471

0

037

to

0

060

40

508

to

40

518

0

0295

0

0764

to

0

0772

1

5928

to

1

5933

0

0015

to

0

0024

1

5948

to

1

5952

EM

24

Page 62 of 548

Engine

Mechanical

Camshaft

specifications

Valve

timing

Standard

Camshaft

bend

Less

than

oms

0

0006

Intake

36

200

to

36

250

I

4252

to

I

4272

Carn

height

Exhaust

36

930

to

36

980

I

4539

to

I

4559

5

65

0

2224

Intake

Cam

lobe

lift

I

Exhaust

5

92

0

2331

Difference

in

diameter

max

worn

and

min

worn

parts

of

camshaft

journal

0

03

to

0

07

0

0012

to

0

0028

Camshaft

end

play

om

to

0

05

0

0004

to

0

0020

ff

fif

ff

s

D

C

EM120

Unit

degree

a

b

248

d

e

c

14

54

20

256

EM

25

Unit

mm

in

Wear

repair

limit

0

05

0

0020

35

700

I

4055

36

430

1

4342

0

10

0

0039

0

10

0

0039

f

56

Page 63 of 548

CYLINDER

BLocK

t

60

2

36

20

0

79

I

100

CI

94

rJ

L

II

E9

I

Unit

mm

in

EM479

Cylinder

liner

for

service

4

0

0

157

Undersize

4

5

0

177

Undersize

Engine

MechanicliIl

Surface

flatness

Inner

diameter

Cylinder

bore

Out

of

round

X

V

Taper

A

B

Differential

in

inner

diameter

between

cylinders

Piston

to

cylinder

block

clearance

Outside

diameter

80

00

to

80

05

3

1496

to

3

1515

80

50

to

80

55

3

1692

to

3

1712

PISTON

PISTON

RING

AND

PISTON

PIN

Piston

e

e

5

51

co

ED

I

H

EM4S0

Standard

Over

size

0

50

0

0197

1

00

0

0394

EM

26

Standard

Less

than

0

05

0

0020

76

000

to

76

050

2

9921

to

2

994i

Less

than

O

oI5

0

0006

Less

than

O

oI5

0

0006

Less

than

0

05

0

OO20

0

025

to

0

045

0

0010

to

0

0018

Unit

riun

in

Inside

diameter

75

50

to

75

60

2

9724

to

2

9763

Piston

diameter

Unit

mm

in

Wear

limit

0

1

0

0039

0

20

0

0079

0

20

0

0079

Unit

mm

in

75

967

to

76

017

2

9908

to

2

9927

76

467

to

76

517

3

0105

to

3

0124

76

967

to

77

017

3

0301

to

3

0321

Page 64 of 548

Engine

Mechanical

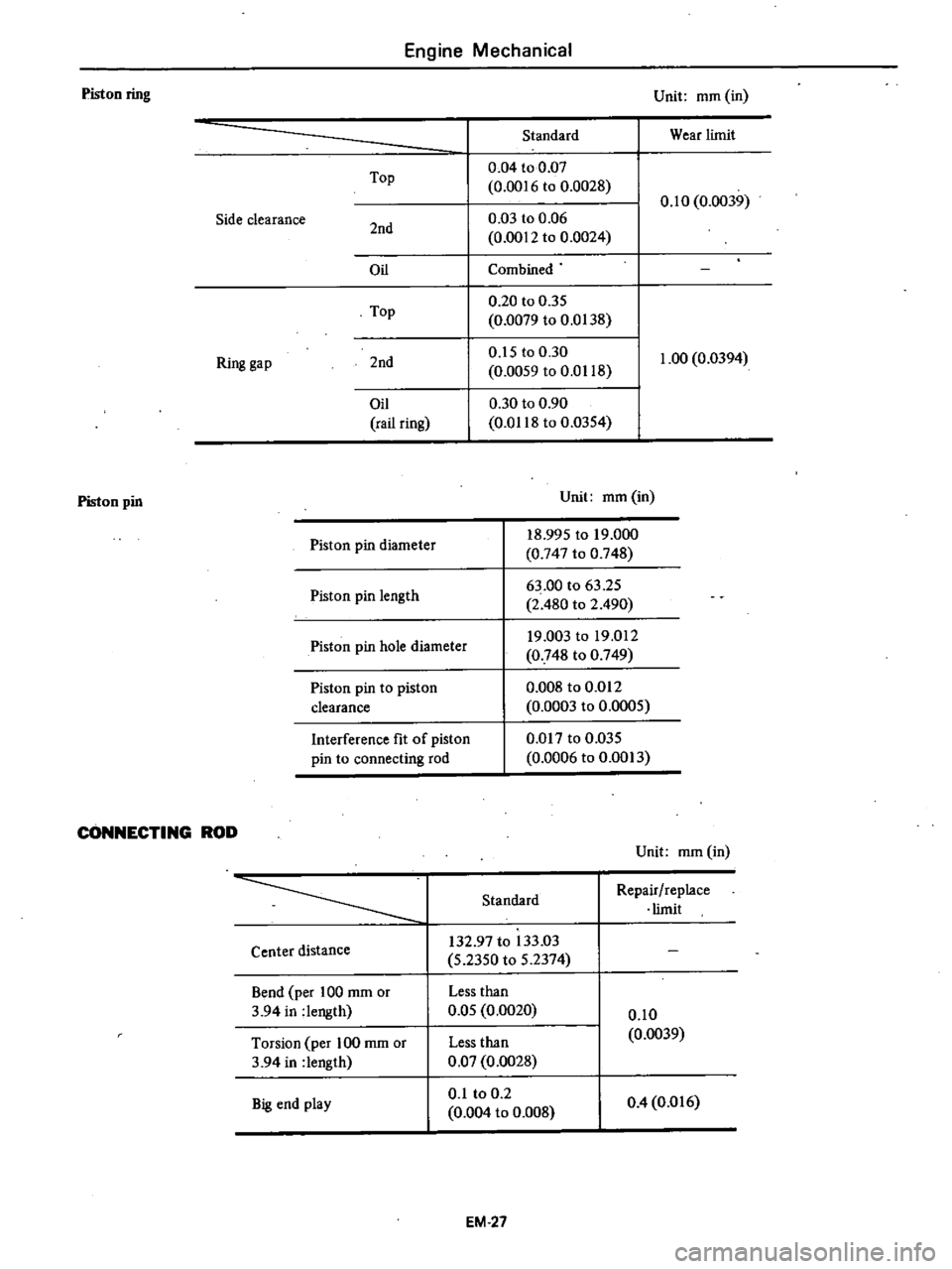

Piston

ring

Unit

mm

in

Standard

Wear

limit

Top

0

04

to

0

07

0

0016

to

0

0028

0

10

0

0039

Side

clearance

2nd

0

03

to

0

06

0

0012

to

0

0024

Oil

Combined

Top

0

20

to

0

35

0

0079

to

0

0138

Ring

gap

2nd

0

15

to

0

30

1

00

0

0394

0

0059

to

0

0118

Oil

0

30

to

0

90

rail

ring

0

0118

to

0

0354

Piston

pin

Unit

mm

in

Interference

fit

of

piston

pin

to

connecting

rod

18

995

to

19

000

0

747

to

0

748

63

00

to

63

25

2

480

to

2

490

19

003

to

19

012

0

748

to

0

749

0

008

to

0

012

0

0003

to

0

0005

0

017

to

0

035

0

0006

to

0

0013

Piston

pin

diameter

Piston

pin

length

Piston

pin

hole

diameter

Piston

pin

to

piston

clearance

CONNECTING

ROD

Unit

mm

in

Standard

Repair

replace

limit

Center

distance

132

97

to

133

03

5

2350

to

5

2374

Bend

per

100

mm

or

3

94

in

length

Less

than

0

05

0

0020

0

10

0

0039

Torsion

per

100

mm

or

3

94

in

length

Big

end

play

Less

than

0

07

0

0028

0

1

to

0

2

0

004

to

0

008

0

4

0

016

EM

27

Page 65 of 548

Engine

Mechanical

CRANKSHAFT

1

Q

I

j

s

l

s

A

B

AI4

AI5

Unit

mm

in

Journal

diameter

A

c

r

49

951

to

49

964

h9666

to

1

967

1

Pin

diameter

8

44

961

to

44

974

I

7701

to

1

7706

EM777

8

38

45

to

38

55

1

5138

to

1

5177

Standard

Out

of

round

X

Y

Taper

A

B

Taper

and

out

of

round

of

Less

than

A

B

journal

and

crank

pin

0

005

0

0002

0

A

B

X

Y

Crankshaft

bend

Less

than

0

025

0

0010

Crankshaft

free

end

play

0

05

to

0

15

EM715

0

0020

to

0

0059

BEARING

Bearing

oil

clearance

Unit

mm

in

Standard

Wear

limit

Main

bearing

clearance

0

026

to

0

090

0

0010

to

0

035

0

10

0

0039

CO

llecting

rod

bearing

clearance

0

030

to

0

079

0

0012

to

0

0031

EM

28

40

95

to

41

05

1

6122

to

1

6161

Unit

mm

in

Wear

limit

0

03

0

0012

0

05

0

0020

0

30

0

0118

Page 66 of 548

Engine

Mechanical

Main

bearing

undersize

Unit

mm

in

Main

bearing

undersi

ze

Crank

journal

diameter

Standard

size

49

943

to

49

964

1

9663

to

1

9671

0

25

0

0098

49701

to

49

714

1

9567

to

1

9572

Undersize

0

50

0

0197

49451

to

49

464

1

9469

to

1

9474

0

75

0

0295

49

201

to

49

214

1

9370

to

1

9376

Connecting

rod

bearing

undersize

Unit

mm

in

Connecting

rod

bearing

undersize

Crank

pin

diameter

Standard

size

44

954

to

44

974

1

7698

to

I

7706

0

08

0

0031

44

881

to

44

894

1

7670

to

1

7675

0

25

0

0098

44

711

to

44

724

1

7603

to

1

7608

Undersize

0

50

0

0197

44

461

to

44

474

1

7504

to

1

7509

0

75

0

0295

44

211

to

44

224

1

7406

to

I

7411

MISCELLANEOUS

COMPONENTS

Unit

mm

in

Max

tolerance

Runout

of

camshaft

0

1

0

004

0

15

0

0059

Runout

of

flywheel

EM

29

Page 67 of 548

t

IGHTENING

TORQUE

Cylinder

head

bolt

Rocker

shaft

bracket

bolt

ain

bearing

cap

bolt

Flywheel

fixing

bolt

Drive

plate

fixing

bolt

Al4

AlS

Connecting

rod

cap

nut

Camshaft

sprocket

bolt

Locating

plate

bolt

Valve

rocker

adjusting

nut

Oil

strainer

bolt

Oil

pan

bolt

Oil

pan

drain

plug

Timing

chain

cover

bolt

Crank

pulley

bolt

Water

pump

bolt

Fuel

pump

bolt

Spark

plug

Engine

mounting

securing

bolt

Engine

Mechanical

Unit

kg

iii

ft

lb

7

0

to

7

5

51

to

54

2

0t02

5

14to

18

5

0

to

6

0

36

to

43

8

0

to

9

0

58

to

65

8

0

to

9

0

58

to

65

8

5

to

9

5

61

to

69

3

2

to

3

8

23

to

27

4

0

to

4

8

29

to

35

0

5

to

0

8

3

6

to

5

8

1

6

to

2

2

12to

16

0

9

to

I

4

6

5

to

10

1

0

4

to

0

6

2

9

to

4

3

2

0

to

3

0

14

to

22

0

5

to

0

7

3

6

to

5

1

15to

20

l08

to

145

0

9

to

I

4

6

5

to

1O

l

0

9

to

I

4

6

5

to

10

1

1

5

to

2

0

11

to

14

1

9

to

2

5

14to

18

EM

30

Page 68 of 548

Engine

Mechanical

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

I

Noill

f

onglno

Knocking

of

crank

shaft

and

bearing

Piston

and

connecting

rod

knocking

Camshaft

knocking

Timilli

chain

noise

Camshaft

and

valve

mechanism

knock

ing

Probable

cause

Loose

main

bearing

Seized

bearing

Ben

crankshaft

Excessive

crankshaft

end

play

Loose

bearing

Seized

bearing

Loose

piston

pin

Loose

piston

in

cylinder

Broken

piston

ring

Improper

connecting

rod

alignment

Loose

bearing

Exc

essive

axial

play

Rough

ge

r

teeth

8roken

cam

gear

Improper

chain

tension

Worn

and

or

damaged

chain

I

Wom

sprocket

Worn

and

or

broken

tension

adjusting

mecha

nism

Excessive

camshaft

and

bearing

clearance

Improper

valve

clearance

Worn

adjusting

screw

Worn

rocker

face

Loose

valve

stem

in

guide

Weakened

valve

pring

Seized

valve

EM

31

Corrective

action

Replace

Replac

Repair

or

replace

Peplace

center

thrust

bearing

l

Replace

Replace

Replace

pin

or

bushing

Recondition

cylinder

Replace

Realign

Replace

Replace

bearing

thrust

plate

Repair

Replace

Adjust

Replace

Replace

Replace

Replace

AdjUst

Replace

Replace

Replace

guide

Replace

Repair

or

replace

Page 69 of 548

Condition

Waterpurnp

knocking

II

Othw

mllChani

troubl

Stuck

valve

Seized

valve

seat

Excessively

wom

cylinder

and

piston

Engine

Mechanical

Probab

Ie

cause

Improper

shaft

end

play

Broken

impeller

Improper

valve

clearance

Insufficient

clearance

between

valve

stem

and

guide

Weakened

or

broken

valve

pring

Biting

or

damage

of

valve

stem

Poor

fuel

quality

Il1

prop

r

valve

clearance

Weakened

valve

pring

Thin

valve

head

edge

Narrow

valve

seat

Overheating

Over

speeding

Sticked

valve

guide

Shortage

ofengine

oil

Dirty

engine

oil

Poor

oil

quality

Overheat

Wrong

assembly

of

piston

with

connecting

rod

Improper

piston

ring

clearance

Dirty

air

cleaner

Too

rich

mixture

Engine

over

run

Stuck

choke

valve

Over

choking

EM

32

Corrective

action

Replace

Replace

Adjust

Clean

stem

or

ream

the

guide

Replace

Repil

ce

or

clean

Use

good

fuel

Adjust

Replace

Replace

valve

Reface

Repair

or

replace

Drive

at

proper

speed

Repair

Add

or

replace

oil

Check

oil

level

on

daily

basis

Clean

crankcase

replace

oil

and

re

place

oil

ftIter

element

Use

proper

oil

Repair

or

replace

Repair

or

replace

Adjust

Clean

periodically

Adju

t

Drive

correctly

Clean

and

adjust

Start

in

correct

way

Page 70 of 548

Condition

Faulty

connecting

rod

Faulty

crankshaft

bearing

Engine

Mechanical

Probable

cause

Shortage

of

engine

oil

Low

oil

pressure

Poor

engine

oil

quality

Rough

crankshaft

surface

Clogged

oil

passage

Bearing

worn

or

eccentric

Bearing

improperly

assembled

Loose

bearing

Incorrect

connecting

rod

alignment

Shortage

of

engine

oil

Low

oil

pressure

Poor

quality

engine

oil

Worn

or

out

of

round

crankshaft

journal

Clogged

oil

passage

in

crankshaft

Bearing

worn

or

eccentric

Bearing

inproperly

assembled

Non

co

centric

crankshaft

or

bearing

EM

33

Corrective

action

Add

or

replace

oil

Check

oil

level

on

daily

basis

Correct

Use

proper

oil

Grind

and

replace

bearing

Clean

Replace

Repair

Replace

Repair

or

replace

Add

or

replace

Check

oil

level

on

daily

basis

Adjust

Use

proper

oil

Repair

Clean

Replace

Repair

Replace