lock DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 435 of 537

DESCRIPTION

DOOR

REMOVAL

AND

INSTALLATION

ALIGNMENT

DOOR

TRIM

AND

SEAL

REMOVAL

AND

INSTALLATION

GLASS

RUN

REMOVAL

AND

INSTALLATION

DOOR

VENTILATOR

WINDOW

Optional

REMOVAL

AND

INSTALLATION

j

Body

Frame

DOOR

CONTENTS

BF12

BF

12

BF

12

BF12

BF12

BF12

BF13

BF

13

BF13

BF13

DOOR

GLASS

AND

REGULATOR

REMOVAL

AND

INSTALLATION

ADJUSTMENT

DOOR

LOCK

REMOVAL

AND

INSTALLATION

ADJUSTMENT

DOOR

LOCK

STRIKER

WEATHERSTRIP

DESCRIPTION

REMOVAL

AND

INSTALLATION

BF14

BF14

BF14

BF

14

BF15

BF

15

BF

15

BF

15

8F

15

BF

15

CD

CV

CID

@

@

@

1

Door

sash

2

Window

outside

weatherstrip

3

Wmdow

inside

weatherstrip

4

Door

weatherstrip

5

Rear

glass

run

rubber

6

Door

finish

holder

7

Rear

lower

sash

8

Seal

screen

9

Door

weatherstrip

clip

10

Front

glass

run

rubber

11

Lower

door

hinge

12

Upper

door

hinge

13

Front

lower

sash

14

Door

glass

15

Glazing

rubber

16

Door

glass

bottom

channel

BF030B

Fig

BF

21

Door

without

ventilator

window

BF

11

Page 436 of 537

@

I

r

L

c

@

DESCRIPTION

The

door

consists

of

inner

and

outer

panels

welded

together

to

form

a

rigid

structure

The

curved

glass

provides

greater

shoulder

room

A

door

that

incorporates

a

ventila

tor

window

is

also

available

as

an

option

The

weatherstrip

is

inserted

into

the

groove

on

the

door

sash

side

and

is

attached

by

clips

on

the

door

side

DOOR

REMOVAL

AND

INSTALLATION

I

With

door

in

full

open

position

place

a

garage

jack

or

stand

beneath

door

to

support

its

weight

when

bolts

are

removed

Place

rag

between

door

and

jack

or

stand

to

avoid

damaging

painted

surface

Body

Frame

CD

1

@

@

ID

@

AJ

@

@

@

1

Door

sash

2

Window

outside

weatherstrip

3

Window

inside

weatherstrip

4

Door

atherstrip

5

Rear

glass

run

rubber

6

Door

finish

holder

7

Rear

lower

sash

8

Seal

screen

9

Door

weatherstrip

clip

10

Front

glass

run

rubber

11

Lower

door

hinge

12

Upper

door

hinge

13

Front

lower

sash

14

Door

glass

15

Glazing

rubber

16

Door

glass

bottom

channel

11

Lower

support

18

Upper

support

19

Door

ventilator

assembly

BF031B

Fig

BF

22

Door

with

ntilator

window

Optional

BF023

Fig

BF

23

Supporting

door

2

Separate

lower

door

hinge

hole

cover

from

dash

side

trim

3

While

supporting

door

as

above

back

off

body

to

upper

and

lower

hinge

attaching

bolts

accessible

from

inside

cab

three

each

Door

can

now

be

taken

out

from

cab

body

I

t

I

l

f

p1

1

W

JJ

i

Sl

j

Fig

BF

24

Removing

door

hinge

bolt

8F

12

4

To

install

reverse

removal

pro

cedure

ALIGNMENT

Elongated

holes

three

each

in

door

hinge

and

door

lock

striker

pro

vide

for

up

and

down

forward

and

backward

and

or

sideways

adjustment

to

assure

proper

door

fit

to

door

opening

To

adjust

door

alignment

loosen

bolts

and

move

door

to

desired

posi

lion

to

obtain

a

parallel

space

between

door

sides

and

door

opening

Also

check

to

be

certain

that

weatherstrip

contacts

body

opening

evenly

to

pre

vent

entry

of

mud

and

water

DOOR

TRIM

AND

SEAL

REMOVAL

AND

INSTALLATION

1

Remove

screw

securing

inside

door

handle

escutcheon

remove

es

cutcheon

2

Remove

screws

which

hold

pull

handle

and

arm

rest

in

position

Pull

handle

and

arm

rest

can

then

be

taken

out

3

Pull

retaining

spring

off

regulator

handle

Take

out

regulator

handle

and

seat

washer

Page 438 of 537

Body

Frame

DOOR

GLASS

AND

REGULATOR

CD

REMOVAL

AND

INSTALLATION

L

Open

door

lower

glass

all

the

way

2

Remove

iflllide

door

handle

es

cutcheon

3

Remove

pull

handle

4

Remove

arm

rest

5

Remove

regulator

handle

6

Remove

door

finish

7

Peel

off

water

seal

screen

8

Work

off

outer

and

inner

weath

erstrips

from

door

being

sure

not

to

scratch

door

paint

during

operation

Use

a

suitable

plain

screwdriver

or

similar

flat

bladed

tool

io

remove

and

place

a

piece

of

rag

between

screw

driver

and

door

panel

BF643

1

Outet

weatherstrip

2

Screwdriver

3

Piece

of

rag

Fig

BF

31

Removing

outer

weather

trip

9

Remove

three

door

glass

bottom

channel

attaching

bolts

Remove

door

glass

by

lifting

it

straight

up

Fig

BF

30

Door

gl

and

regulator

10

On

door

equipped

with

venti

lator

remove

three

bolts

securing

door

glass

bottom

channel

then

let

glass

go

to

the

bottom

of

door

Remove

ventilator

frame

attaching

bolts

and

lift

frame

straight

up

out

of

door

Remove

door

glass

by

lifting

it

straight

up

11

Back

off

the

five

guide

channel

to

regulator

base

attaching

screws

Take

out

regulator

assembly

through

large

access

hole

in

inside

door

panel

DOOR

LOCK

1

Escutcheon

2

Inside

handle

3

Spring

4

Door

lock

knob

5

Knob

grommet

6

Outside

handle

7

Outside

handle

rod

j

f

ffi

I

Fig

BF

32

BF035

Removing

door

glass

12

To

install

reverse

removal

pro

cedure

ADJUSTMENT

I

In

and

out

and

fore

and

aft

ad

justment

can

be

made

by

moving

front

or

rear

sash

and

guide

channel

as

required

The

ease

with

which

window

assem

bly

raises

and

lowers

depends

on

ad

justment

of

rear

lower

sash

Rear

lower

sash

should

be

parallel

with

front

lower

sash

2

Fore

and

aft

adjustment

is

deter

mined

by

position

of

guide

channel

and

front

lower

sash

Moving

front

lower

sash

backward

reduces

play

in

window

assembly

j

CID

@

8

Nylon

nut

9

Locking

plate

ring

10

LOcking

plate

11

Door

lock

cylinder

12

Door

lock

13

Stopper

BF

14

BF410A

Fig

BF

33

Door

lock

mechonillm

Page 439 of 537

REMOVAL

AND

INSTALLATION

I

Open

door

2

Remove

inside

door

handle

es

cutcheon

3

Remove

pull

handle

4

Remove

arm

rest

5

Remove

regulator

handle

6

Remove

door

finish

7

Peel

off

water

seal

screen

8

Raise

door

glass

to

full

up

posi

tion

9

Remove

inside

door

lock

knob

10

Remove

rear

lower

sash

attach

iog

bolts

11

Disconnect

remote

control

rod

from

key

cylinder

and

outside

door

handle

12

Remove

three

door

lock

assem

bly

attaching

screws

13

Remove

two

inside

door

handle

attaching

screws

14

Together

with

inside

door

handle

take

out

door

lock

as

an

assembly

through

large

access

hole

in

door

panel

15

Remove

two

outside

door

handle

attaching

nuts

Outside

door

handle

can

then

be

taken

out

16

Remove

lock

plate

from

key

cylinder

and

detach

key

cylinder

17

To

install

door

lock

assembly

outside

and

inside

door

handles

and

key

cylinder

reverse

removal

pro

cedure

18

Lubricate

door

lock

with

grease

which

meets

the

requirements

of

MIL

G

I0924B

or

equivalent

as

listed

below

ALVANIA

GREASE

RA

SHELL

BEACON

325

ESSO

MOBILE

GREASE

22

MOBIL

Body

Frame

ADJUSTMENT

OutsIde

door

handle

Adjustment

of

play

in

outside

door

handle

is

controlled

by

play

adjust

ment

of

nylon

nut

on

threaded

end

of

outside

door

handle

rod

Correct

play

is

1

0

mm

0

039

in

or

below

as

measured

between

nylon

nut

and

locking

plate

Inside

door

handle

Elongated

hole

in

inside

door

handle

provides

for

play

adjustment

of

inside

door

handle

Correct

play

is

1

0

mm

0

039

ill

or

below

as

measured

at

control

rod

A

L

A

I

1

rB

I

B

REMOVAL

AND

INSTAUATION

I

Open

door

2

Free

weatherstrip

from

door

sash

clamp

BF

15

DOOR

LOCK

STRIKER

Adjustment

of

door

lock

striker

should

be

made

after

door

hinge

has

been

adjusted

correctly

Elongated

holes

three

provide

for

up

and

down

or

fore

and

aft

adjust

ment

to

establish

proper

engagement

between

door

lock

striker

and

door

lock

latch

WEATHERSTRIP

DESCRIPTION

The

weatherstrip

is

retained

by

clamp

to

the

door

sash

and

by

19

clips

to

the

door

panel

No

adhesive

is

used

to

retain

the

weatherstrip

to

door

Section

A

A

j

Section

B

B

BF645

Fig

BF

34

Door

weatheratrip

3

Pry

off

clips

from

door

panel

remove

weatherstrip

4

To

instaH

reverse

removal

pro

cedure

Page 443 of 537

2

1

Back

trim

2

Back

inside

imisher

3

Clip

1

CENTER

CONSOLE

REMOVAL

AND

INSTALLATION

Except

for

air

conditioner

equipped

models

I

Remove

two

bolts

from

rear

of

center

console

2

Remove

center

console

by

pulling

it

back

3

To

properly

install

center

con

sole

insert

its

front

portion

into

bracket

on

the

floor

and

install

and

tighten

rear

attaching

bolts

SEAT

DESCRIPTION

There

are

two

types

of

seats

a

semi

separate

bench

seat

for

the

standard

wheelbase

and

long

wheelbase

models

and

a

separate

seat

for

the

Deluxe

Cab

models

CAUTION

In

conforming

with

M

Y

S

s

No

302

be

sure

to

remove

the

thin

polyethylene

covers

from

seat

cushions

seat

backs

and

head

restraints

at

the

time

of

a

Pre

delivery

service

b

Parts

replacement

Body

Frame

BF0328

Fig

BF

45

Back

trim

and

back

inside

finisher

BE033B

Fig

BF

46

Removing

center

console

SEAT

BENCH

SEAT

8F

19

Air

conditioner

equipped

models

I

Remove

two

bolts

from

front

of

center

console

2

Remove

two

bolts

from

the

rear

and

remove

center

console

CONSOLE

WITH

ARMREST

DELUXE

CAB

REMOVAL

AND

INSTALLATION

I

Remove

two

bolts

from

front

of

console

armrest

unit

2

Remove

one

bolt

in

the

console

box

and

remove

center

console

3

Installation

is

the

reverse

order

of

removal

BF034B

Fig

BF

47

Console

with

annrest

JJ

t

qJ

1

Seat

assembly

2

Seat

slide

3

Seat

slide

lock

handle

4

Seat

slide

lock

wire

BF474A

Fig

BF

48

Bench

seal

Page 444 of 537

Body

Frame

Removal

and

installation

assembly

2

To

install

seat

reverse

above

re

moval

procedure

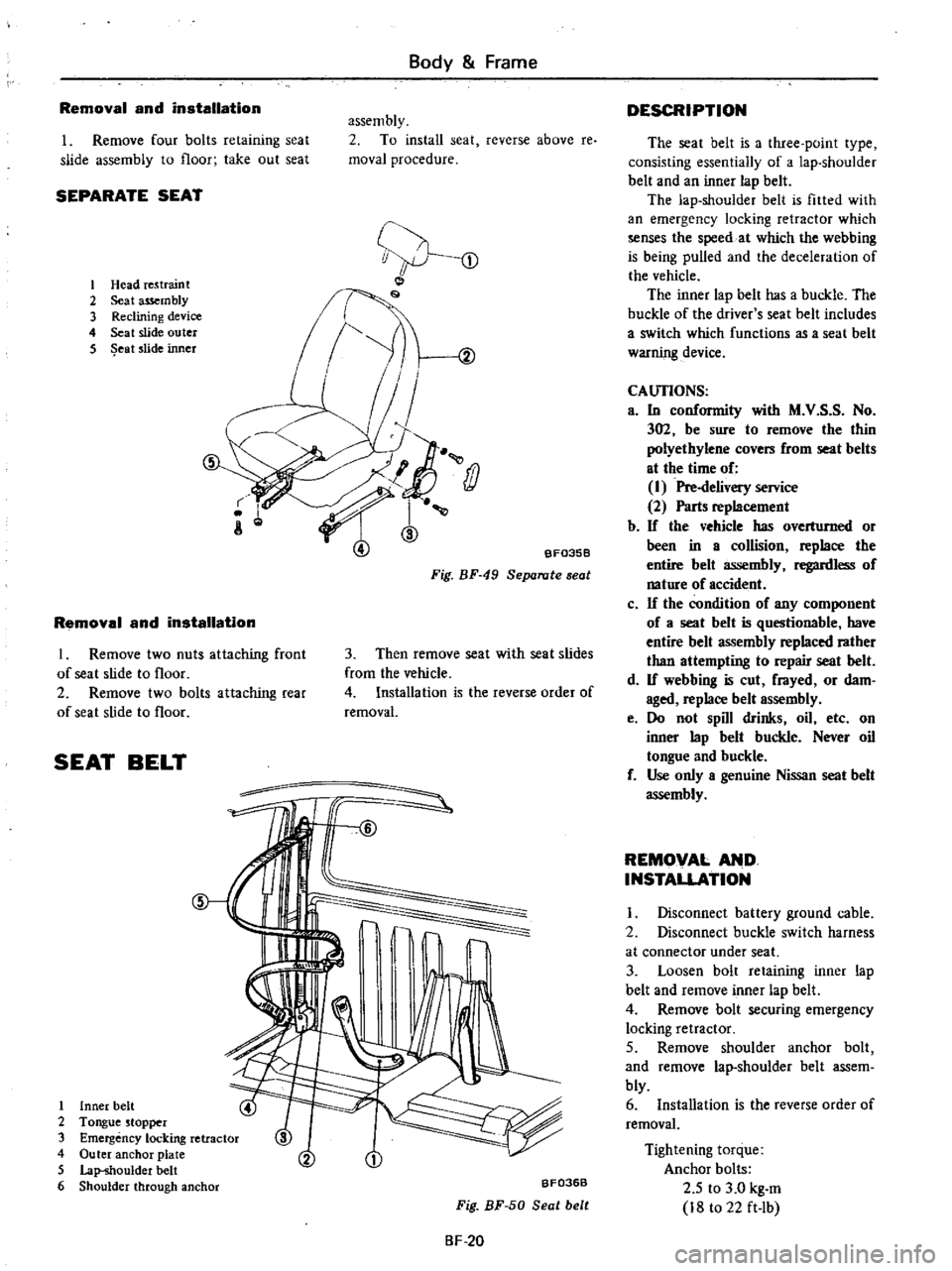

1

Remove

four

bolts

retaining

seat

slide

assembly

to

floor

take

out

seat

SEPARATE

SEAT

1

Head

re5traint

2

Seat

assembly

3

Reclining

device

4

Seat

slide

outer

5

eat

slide

inner

s

J

j

BF0358

Fig

BF

49

Separate

seat

Removal

and

installation

I

Remove

two

nuts

attaching

front

of

seat

slide

to

floor

2

Remove

two

bolts

attaching

rear

of

seat

slide

to

floor

3

Then

remove

seat

with

seat

slides

from

the

vehicle

4

Installation

is

the

reverse

order

of

removal

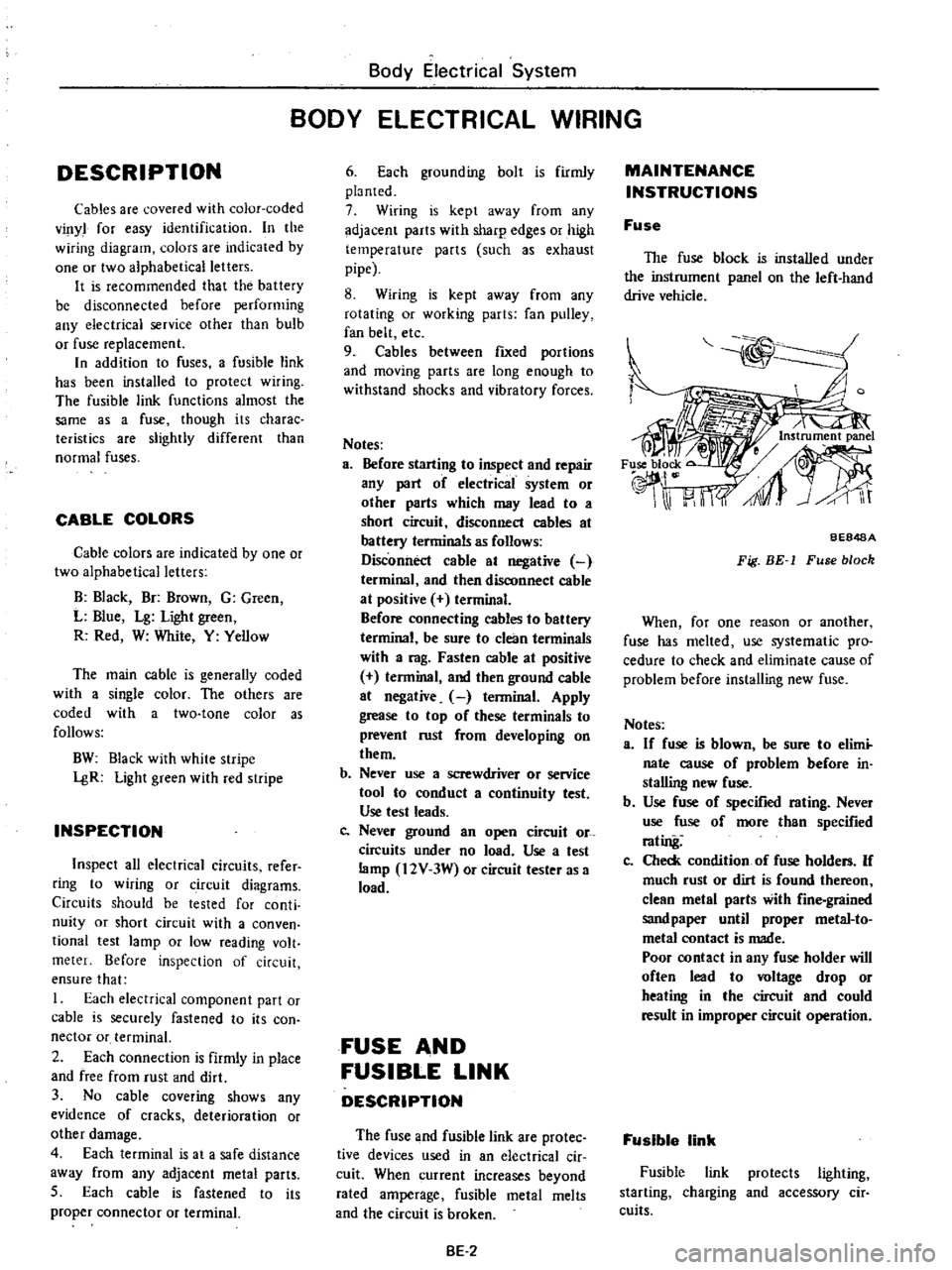

SEAT

BELT

1

Inner

belt

2

Tongue

stopper

3

Emergency

locking

retractor

4

Outer

anchor

plate

5

Lap

shoulder

belt

6

Shoulder

through

anchor

BF036B

Fig

BF

50

Seat

belt

BF

20

DESCRIPTION

The

seat

belt

is

a

three

point

type

consisting

essentiaily

of

a

lap

shoulder

belt

and

an

inner

lap

belt

The

lap

shoulder

belt

is

fitted

with

an

emergency

locking

retractor

which

senses

the

speed

at

which

the

webbing

is

being

pulled

and

the

deceleration

of

the

vehicle

The

inner

lap

belt

has

a

buckle

The

buckle

of

the

driver

s

seat

belt

includes

a

switch

which

functions

as

a

seat

belt

warning

device

CAlJI10NS

a

In

conformity

with

M

V

S

S

No

302

be

sure

to

remove

the

thin

polyethylene

covers

from

seat

belts

at

the

time

of

I

Pre

delivery

service

2

Parts

replacement

b

If

the

vehicle

has

overturned

or

been

in

a

collision

replace

the

entire

belt

assembly

regardless

of

nature

of

accident

c

If

the

condition

of

any

component

of

a

seat

belt

is

questionable

have

entire

belt

assembly

replaced

rather

than

attempting

to

repair

seat

belt

d

If

webbing

is

cut

frayed

or

dam

aged

replace

belt

assembly

e

Do

not

spill

drinks

oil

etc

on

inner

lap

belt

buckle

Never

oil

tongue

and

buckle

f

Use

only

a

genuine

Nissan

seat

belt

assembly

REMOVAL

AND

INSTAUATION

I

Disconnect

battery

ground

cable

2

Disconnect

buckle

switch

harness

at

connector

under

seat

3

Loosen

bolt

retaining

inner

lap

belt

and

remove

inner

lap

belt

4

Remove

bolt

securing

emergency

locking

retractor

5

Remove

shoulder

anchor

bolt

and

remove

lap

shoulder

belt

assem

bly

6

Installation

is

the

reverse

order

of

removal

Tightening

torque

Anchor

bolts

2

5

to

3

0

kg

m

18

to

22

ft

lb

Page 445 of 537

Body

Frame

Note

When

installing

emergency

locking

retractor

make

sure

that

it

is

set

vertically

@

I

g@

BF650A

Fig

BF

51

Seat

belt

anchorages

8F

21

INSPECTION

OF

BUCKLE

SWITCH

The

contacts

of

the

buckle

switch

are

normally

closed

When

tongue

latches

the

buckle

tip

end

of

the

tongue

pushes

the

push

rod

to

open

the

switch

contacts

I

Disconnect

battery

ground

cable

2

Disconnect

buckle

switch

wire

harness

3

Using

a

test

light

check

buckle

switch

for

proper

operation

The

light

should

go

out

when

tongue

of

outer

lap

belt

latches

buckle

and

go

on

when

it

unlatches

buckle

Replace

belt

assembly

if

necessary

Note

When

checking

buckle

switch

operation

make

sure

that

power

is

held

below

16

volts

and

13

mA

Page 447 of 537

DESCRIPTION

Cables

are

covered

with

color

coded

vinyl

for

easy

identification

In

the

wiring

diagram

colors

are

indicated

by

one

or

two

alphabetical

letters

It

is

recommended

that

the

battery

be

disconnected

before

performing

any

electrical

service

other

than

bulb

or

fuse

replacement

In

addition

to

fuses

a

fusible

link

has

been

installed

to

protect

wiring

The

fusible

link

functions

almost

the

same

as

a

fuse

though

its

eharac

teristics

are

slightly

different

than

normal

fuses

CABLE

COLORS

Cable

colors

are

indicated

by

one

or

two

alphabetical

letters

B

Black

Be

Brown

G

Green

L

Blue

Lg

Light

green

R

Red

W

White

Y

Yellow

The

main

cable

is

generally

coded

with

a

single

color

The

others

are

coded

with

a

two

tone

color

as

follows

BW

Black

with

white

stripe

gR

Light

green

with

red

stripe

INSPECTION

Inspect

all

electrical

circuits

refer

ring

to

wiring

or

circuit

diagrams

Circuits

should

be

tested

for

conti

nuity

or

short

circuit

with

a

conven

tional

test

lamp

or

low

reading

volt

meter

Before

inspection

of

circuit

ensure

that

I

Each

electrical

component

part

or

cable

is

securely

fastened

to

its

con

nector

or

terminal

2

Each

connection

is

firmly

in

place

and

free

from

rust

and

dirt

3

No

cable

covering

shows

any

evidence

of

cracks

deterioration

or

other

damage

4

Each

terminal

is

at

a

safe

distance

away

from

any

adjacent

metal

parts

5

Each

cable

is

fastened

to

its

proper

connector

or

terminal

Body

Electrical

System

BODY

ELECTRICAL

WIRING

6

Each

grounding

bolt

is

firmly

pbnted

7

Wiring

is

kept

away

from

any

adjacent

parts

with

sharp

edges

or

high

temperature

parts

such

as

exhaust

pipe

8

Wiring

is

kept

away

from

any

rotating

or

working

parts

fan

pulley

fan

belt

etc

9

Cables

between

ftxed

portions

and

moving

parts

are

long

enough

to

withstand

shocks

and

vibratory

forces

Notes

a

Before

starting

to

inspect

and

repair

any

part

of

electrical

system

or

other

parts

which

may

lead

to

a

short

circuit

disconnect

cables

at

battery

terminals

as

follows

Disconnect

cable

at

negative

terminal

and

then

disconnect

cable

at

positive

terminal

Before

connecting

cables

to

battery

terminal

be

sure

to

clean

terminals

with

a

rag

Fasten

cable

at

positive

terminal

and

then

ground

cable

at

negative

terminal

Apply

grease

to

top

of

these

terminals

to

prevent

rust

from

developing

on

them

b

Never

use

a

screwdriver

or

senrice

tool

to

conduct

a

continuity

test

Use

test

leads

c

Never

ground

an

open

circuit

or

circuits

under

no

load

Use

a

test

lamp

12V

3W

or

circuit

tester

as

a

load

FUSE

AND

FUSIBLE

LINK

DESCRIPTION

The

fuse

and

fusible

link

are

protec

tive

devices

used

in

an

electrical

cir

cuit

When

current

increases

beyond

rated

amperage

fusible

metal

melts

and

the

circuit

is

broken

BE

2

MAINTENANCE

INSTRUCTIONS

Fuse

The

fuse

block

is

installed

under

the

instrument

panel

on

the

left

hand

drive

vehicle

BE848A

Fig

BE

1

Fuse

block

When

for

one

reason

or

another

fuse

has

melted

use

systematic

pro

cedure

to

check

and

eliminate

cause

of

problem

before

installing

new

fuse

Notes

a

If

fuse

is

blown

be

sure

to

elimi

nate

cause

of

problem

before

in

stalling

new

fuse

b

Use

fuse

of

specified

rating

Never

use

fuse

of

more

than

specified

rating

Co

Check

condition

of

fuse

holders

If

much

rust

or

dirt

is

found

thereon

clean

metal

parts

with

fine

grained

sandpaper

until

proper

metal

to

metal

contact

is

made

Poor

contact

in

any

fuse

holder

will

often

lead

to

voltage

drop

or

heating

in

the

circuit

and

could

result

in

improper

circuit

operation

Fusible

link

Fusible

link

protects

lighting

starting

charging

and

accessory

cir

cuits

Page 449 of 537

Body

Electrical

System

DESCRIPTION

LIGHTING

SYSTEM

CI

RCUIT

DIAGRAM

Headlamp

tail

lamp

and

license

lamp

system

G

o

@

LI

U

CIl

HEADl

AMP

L

H

e

FRONT

SlOE

lIIIARI

ER

LAMP

IR

H

USl

LE

LINK

CJ

lOA

CJ

154

CJ

CJ

FUSE

BLOCK

I

2

IR

n

fMP

IL

H

l

REAR

SIDE

MARKER

LAMP

R

1

1

LIGHTING

SWITCH

l

J

ll

f

1121

I

r

1

x

DIMMER

SWITCH

101

1

I

ON

t

0

I

EA

i

METE

LAMP

ILLUMINATION

LAMP

jSTOPBrURH

STOP

8

TURN

TAIL

TAIL

BSAOC

UP

RE

AR

COMBINATION

LAMP

R

H

I

J

LICE

NSf

r

LAMP

I3

BACIC

UP

TA

L

ST

OP8TURN

TAIL

STOP8TURN

REAR

COMBINATION

LAMP

ILH

I

Q

REAR

SIDE

NAR

tAMP

BEBSOA

Fig

BE

3

Headlamp

tail

lamp

and

liceme

lamp

ay6t

m

Turn

signal

hazard

warning

lamp

stop

lamp

and

back

up

lamp

system

I

HEAOLAMP

R

H

l

CR

H

Ll

lHTINIi

j

nn

A

iNAnON

8A

LAMP

BATTERY

@

4j

Jl

FRONT

COM8IfUl

1ON

LAMP

H

FUSIBLE

LINK

I

a

FUSE

BLOCK

FUSE

FROM

IGNITION

SWITCH

@

h

FRONT

COMBINATION

LAMP

L

H

REAR

COMBINATION

LAMP

R

H

BACK

UP

LAMP

T

A

I

L

SWITCH

n

8ACK

UP

E

W

P

HAZARO

FLASHER

UNIT

HAIARD

2

ON

WA

NING

SWITCH

3

r

TU

N

SIGNAL

FLASHER

UNIT

CJ

U

t

N

iH

ij

I

STOP

t

H

J

EL

L

H

I

TURN

SIGNAL

INDICATOR

LAMP

TURN

SIGNAL

SWITCH

G

BACK

UP

JTA

STOP8TURN

TAIL

STOP

8

TURN

REAR

COMelNATlON

LAMP

IL

H

I

BE851A

Fig

BE

4

Turn

signal

Juuard

warning

lamp

stop

lamp

and

back

up

lamp

system

BE

4

Page 450 of 537

Body

Electrical

System

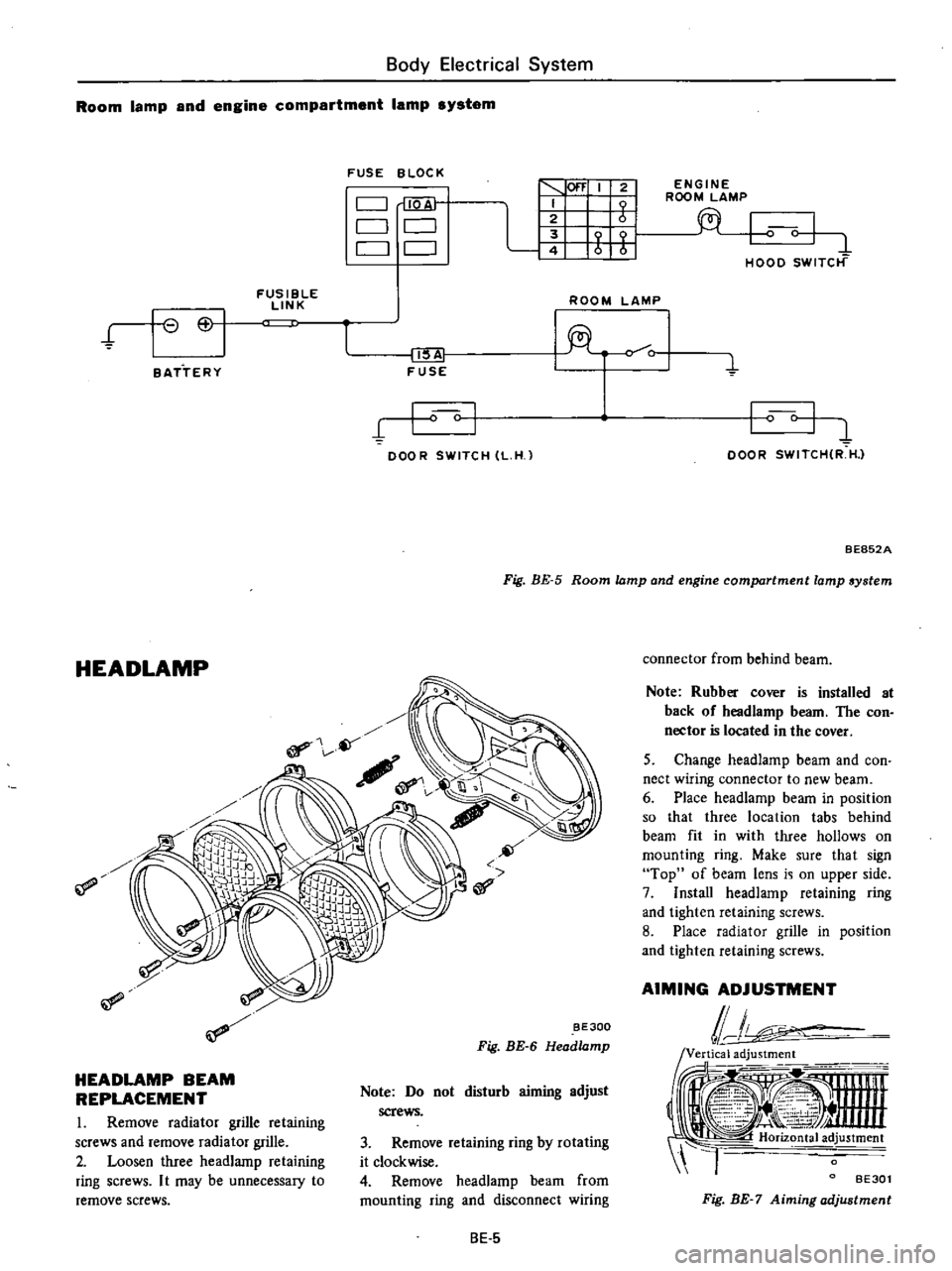

Room

lamp

and

engine

compartment

lamp

system

FUSE

BLOC

K

C

J

QA

C

J

CJ

CJ

CJ

1

100

I

2

I

I

t1

Wf

t

fi

FUSIBLE

LINK

ROOM

LAMP

t

I

6

I

II

lA

FUSE

o

C

1

BATTERY

I

I

DOOR

SWITCH

L

H

l

ENGINE

ROOM

LAMP

I

0

I

1

HOOD

SWITCt

f

I

c

I

DOOR

SWITCHIR

H

l

Fig

BE

5

Room

lamp

and

engine

compartment

lamp

system

BE852A

HEADLAMP

if

BE300

Fig

BE

6

Head

amp

HEADLAMP

BEAM

REPLACEMENT

I

Remove

radiator

grille

retaining

screws

and

remove

radiator

grille

2

Loosen

three

headlamp

retaining

ring

screws

I

t

may

be

unnecessary

to

remove

screws

Note

Do

not

disturb

aiming

adjust

screws

3

Remove

retaining

ring

by

rotating

it

clockwise

4

Remove

headlamp

beam

from

mounting

ring

and

disconnect

wiring

8E

5

connector

from

behind

beam

Note

Rubber

cover

is

installed

at

back

of

headlamp

beam

The

con

nector

is

located

in

the

cover

5

Change

headlamp

beam

and

con

nect

wiring

connector

to

new

beam

6

Place

headlamp

beam

in

position

so

that

three

location

tabs

behind

beam

fit

in

with

three

hollows

on

mounting

ring

Make

sure

that

sign

Top

of

beam

lens

i

i

on

upper

side

7

Install

headlamp

retaining

ring

and

tighten

retaining

screws

8

Place

radIator

grille

in

position

and

tighten

retaining

screws

AIMING

ADJUSTMENT

lJ

ii

i

tooi

1

Ji

Y

4

nnn

4

I

Horiz

tal

ad

justment

l

BE30l

Fig

BE

7

Aiming

adjustment