steering DODGE NEON 1999 Service Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 359 of 1200

CLOCKSPRING

REMOVAL

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE BEFORE

BEGINNING ANY AIRBAG SYSTEM COMPONENT

REMOVAL OR INSTALLATION PROCEDURE. THIS

WILL DISABLE THE AIRBAG SYSTEM. FAILURE TO

DISCONNECT BATTERY COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY. ALLOW SYSTEM CAPACITOR

TO DISCHARGE FOR 2 MINUTES BEFORE REMOV-

ING ANY AIRBAG COMPONENTS.

(1) Place the front road wheels in the straight

ahead position then:

²Rotate the steering wheel half turn (180

degrees) to the right (clockwise)

²Lock column with ignition lock cylinder.

(2) Disconnect and isolate the battery negative

cable.

(3) Wait two minutes for the reserve capacitor to

discharge before removing non-deployed module.

(4) Remove speed control switch mounting screws,

switches and disconnect the wire connectors or

remove covers.

(5) Remove the Driver Airbag Module attaching

bolts from under the speed control switches or covers.

(6) Lift module and disconnect the airbag and horn

wire connectors.

(7) Remove the steering wheel, refer to Steering

Wheel removal procedures.

(8) Remove upper and lower steering column

shrouds to gain access to clockspring wiring.

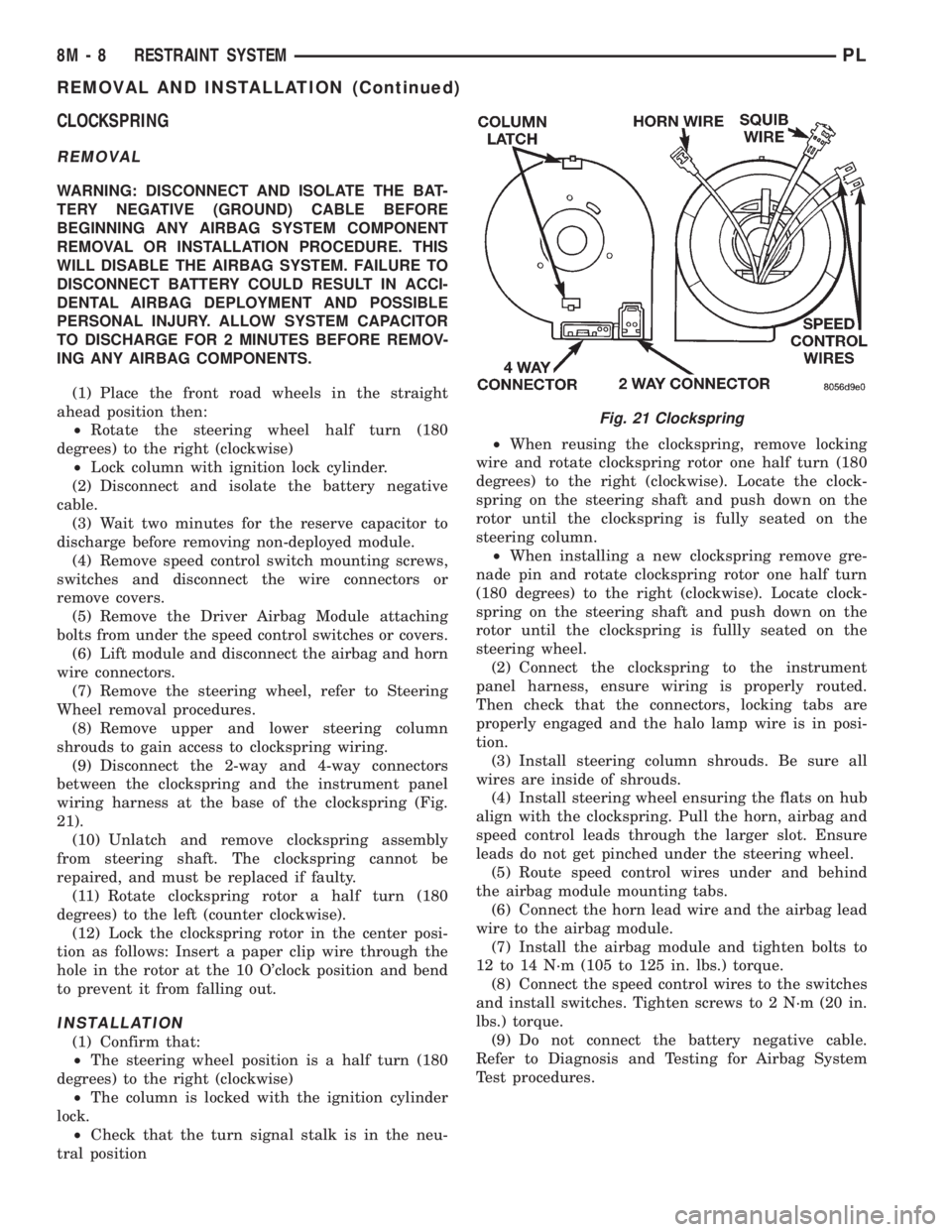

(9) Disconnect the 2-way and 4-way connectors

between the clockspring and the instrument panel

wiring harness at the base of the clockspring (Fig.

21).

(10) Unlatch and remove clockspring assembly

from steering shaft. The clockspring cannot be

repaired, and must be replaced if faulty.

(11) Rotate clockspring rotor a half turn (180

degrees) to the left (counter clockwise).

(12) Lock the clockspring rotor in the center posi-

tion as follows: Insert a paper clip wire through the

hole in the rotor at the 10 O'clock position and bend

to prevent it from falling out.

INSTALLATION

(1) Confirm that:

²The steering wheel position is a half turn (180

degrees) to the right (clockwise)

²The column is locked with the ignition cylinder

lock.

²Check that the turn signal stalk is in the neu-

tral position²When reusing the clockspring, remove locking

wire and rotate clockspring rotor one half turn (180

degrees) to the right (clockwise). Locate the clock-

spring on the steering shaft and push down on the

rotor until the clockspring is fully seated on the

steering column.

²When installing a new clockspring remove gre-

nade pin and rotate clockspring rotor one half turn

(180 degrees) to the right (clockwise). Locate clock-

spring on the steering shaft and push down on the

rotor until the clockspring is fullly seated on the

steering wheel.

(2) Connect the clockspring to the instrument

panel harness, ensure wiring is properly routed.

Then check that the connectors, locking tabs are

properly engaged and the halo lamp wire is in posi-

tion.

(3) Install steering column shrouds. Be sure all

wires are inside of shrouds.

(4) Install steering wheel ensuring the flats on hub

align with the clockspring. Pull the horn, airbag and

speed control leads through the larger slot. Ensure

leads do not get pinched under the steering wheel.

(5) Route speed control wires under and behind

the airbag module mounting tabs.

(6) Connect the horn lead wire and the airbag lead

wire to the airbag module.

(7) Install the airbag module and tighten bolts to

12 to 14 N´m (105 to 125 in. lbs.) torque.

(8) Connect the speed control wires to the switches

and install switches. Tighten screws to 2 N´m (20 in.

lbs.) torque.

(9) Do not connect the battery negative cable.

Refer to Diagnosis and Testing for Airbag System

Test procedures.

Fig. 21 Clockspring

8M - 8 RESTRAINT SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 360 of 1200

DRIVER AIRBAG MODULE

REMOVAL

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE BEFORE

BEGINNING ANY AIRBAG SYSTEM COMPONENT

REMOVAL OR INSTALLATION PROCEDURE. THIS

WILL DISABLE THE AIRBAG SYSTEM. FAILURE TO

DISCONNECT BATTERY COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY. ALLOW SYSTEM CAPACITOR

TO DISCHARGE FOR 2 MINUTES BEFORE REMOV-

ING ANY AIRBAG COMPONENTS.

When removing a deployed module, rubber gloves,

eye protection and long sleeved shirt should be worn,

as there may be deposits on the surface which could

irritate the skin and eyes.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove speed control switches or covers from

steering wheel armature and disconnect the wires.

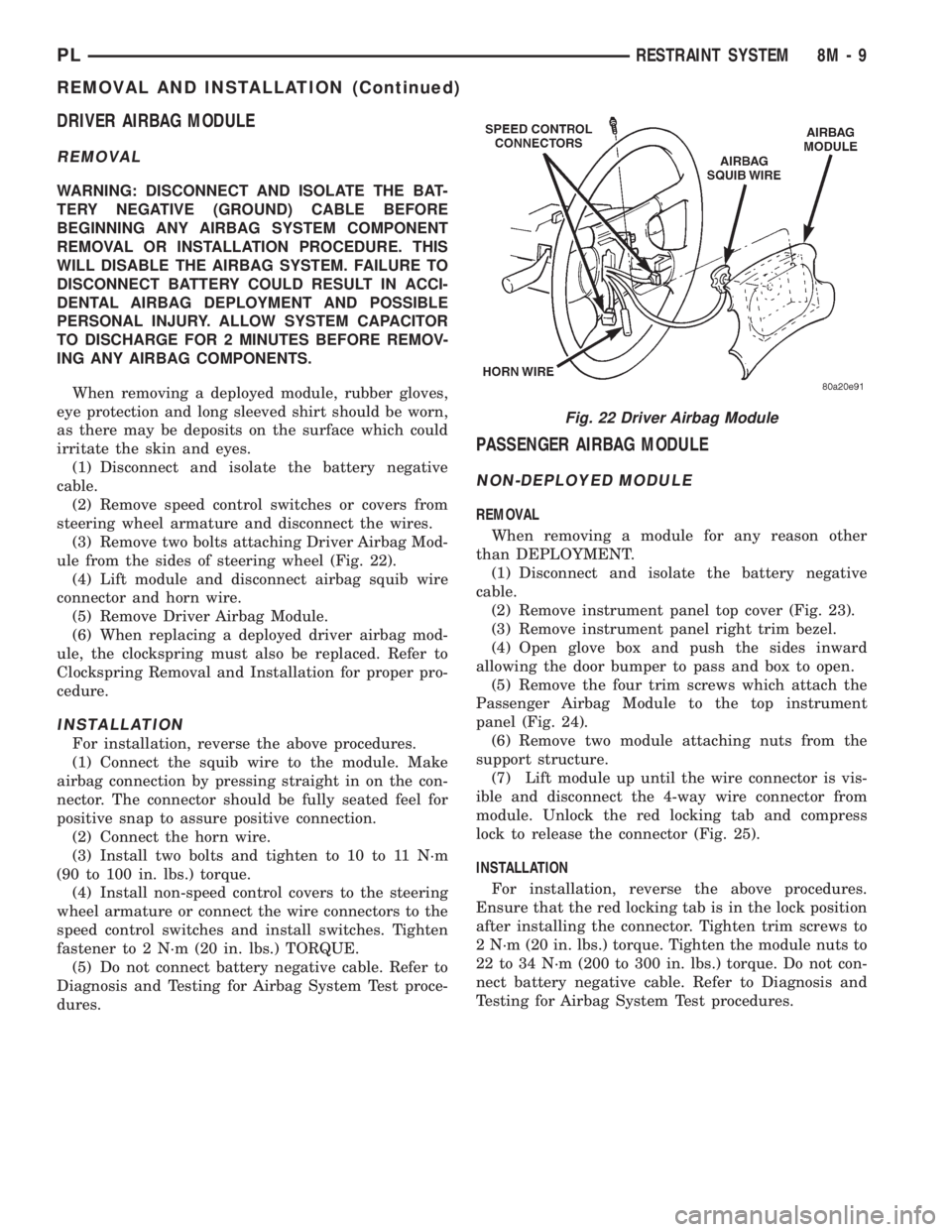

(3) Remove two bolts attaching Driver Airbag Mod-

ule from the sides of steering wheel (Fig. 22).

(4) Lift module and disconnect airbag squib wire

connector and horn wire.

(5) Remove Driver Airbag Module.

(6) When replacing a deployed driver airbag mod-

ule, the clockspring must also be replaced. Refer to

Clockspring Removal and Installation for proper pro-

cedure.

INSTALLATION

For installation, reverse the above procedures.

(1) Connect the squib wire to the module. Make

airbag connection by pressing straight in on the con-

nector. The connector should be fully seated feel for

positive snap to assure positive connection.

(2) Connect the horn wire.

(3) Install two bolts and tighten to 10 to 11 N´m

(90 to 100 in. lbs.) torque.

(4) Install non-speed control covers to the steering

wheel armature or connect the wire connectors to the

speed control switches and install switches. Tighten

fastener to 2 N´m (20 in. lbs.) TORQUE.

(5) Do not connect battery negative cable. Refer to

Diagnosis and Testing for Airbag System Test proce-

dures.

PASSENGER AIRBAG MODULE

NON-DEPLOYED MODULE

REMOVAL

When removing a module for any reason other

than DEPLOYMENT.

(1) Disconnect and isolate the battery negative

cable.

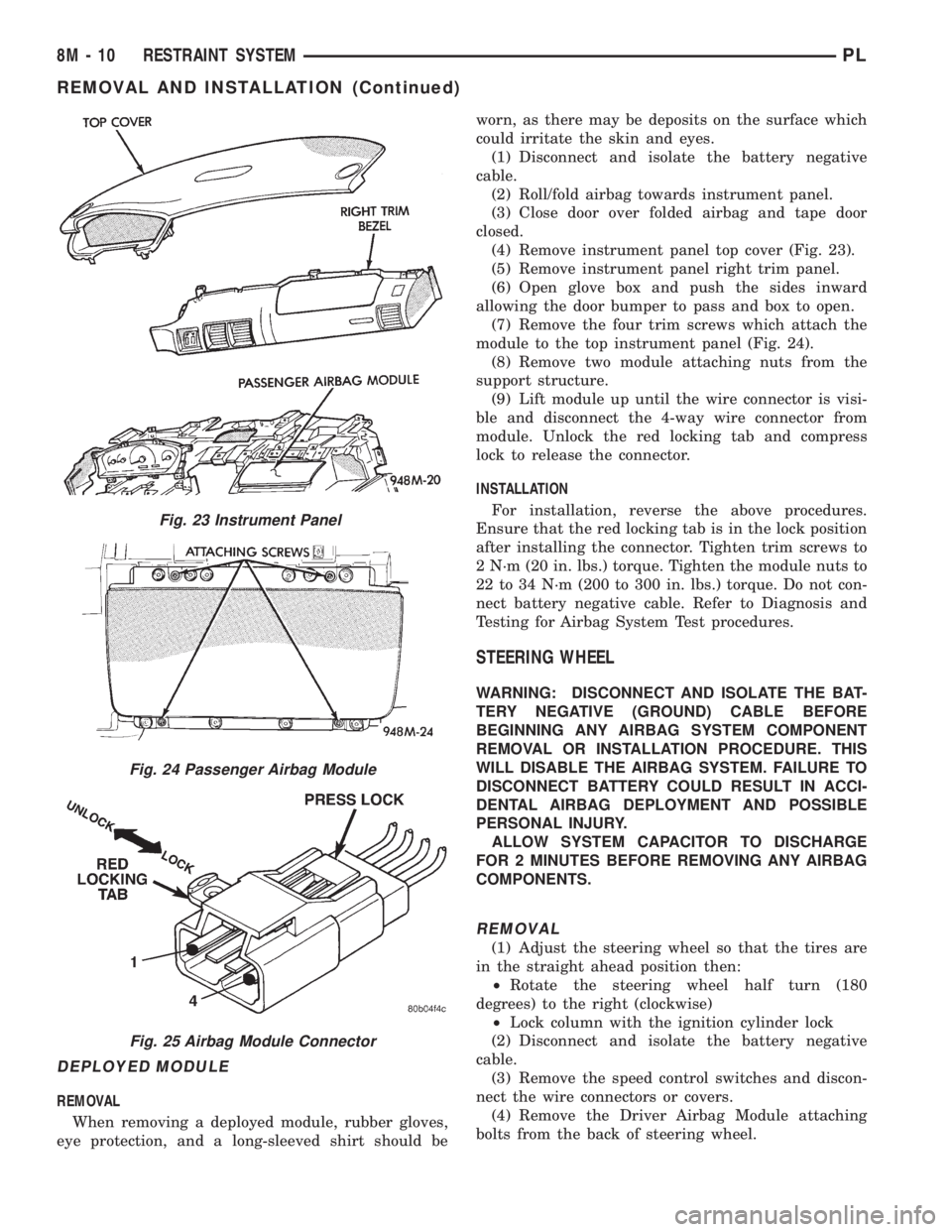

(2) Remove instrument panel top cover (Fig. 23).

(3) Remove instrument panel right trim bezel.

(4) Open glove box and push the sides inward

allowing the door bumper to pass and box to open.

(5) Remove the four trim screws which attach the

Passenger Airbag Module to the top instrument

panel (Fig. 24).

(6) Remove two module attaching nuts from the

support structure.

(7) Lift module up until the wire connector is vis-

ible and disconnect the 4-way wire connector from

module. Unlock the red locking tab and compress

lock to release the connector (Fig. 25).

INSTALLATION

For installation, reverse the above procedures.

Ensure that the red locking tab is in the lock position

after installing the connector. Tighten trim screws to

2 N´m (20 in. lbs.) torque. Tighten the module nuts to

22 to 34 N´m (200 to 300 in. lbs.) torque. Do not con-

nect battery negative cable. Refer to Diagnosis and

Testing for Airbag System Test procedures.

Fig. 22 Driver Airbag Module

PLRESTRAINT SYSTEM 8M - 9

REMOVAL AND INSTALLATION (Continued)

Page 361 of 1200

DEPLOYED MODULE

REMOVAL

When removing a deployed module, rubber gloves,

eye protection, and a long-sleeved shirt should beworn, as there may be deposits on the surface which

could irritate the skin and eyes.

(1) Disconnect and isolate the battery negative

cable.

(2) Roll/fold airbag towards instrument panel.

(3) Close door over folded airbag and tape door

closed.

(4) Remove instrument panel top cover (Fig. 23).

(5) Remove instrument panel right trim panel.

(6) Open glove box and push the sides inward

allowing the door bumper to pass and box to open.

(7) Remove the four trim screws which attach the

module to the top instrument panel (Fig. 24).

(8) Remove two module attaching nuts from the

support structure.

(9) Lift module up until the wire connector is visi-

ble and disconnect the 4-way wire connector from

module. Unlock the red locking tab and compress

lock to release the connector.

INSTALLATION

For installation, reverse the above procedures.

Ensure that the red locking tab is in the lock position

after installing the connector. Tighten trim screws to

2 N´m (20 in. lbs.) torque. Tighten the module nuts to

22 to 34 N´m (200 to 300 in. lbs.) torque. Do not con-

nect battery negative cable. Refer to Diagnosis and

Testing for Airbag System Test procedures.

STEERING WHEEL

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE BEFORE

BEGINNING ANY AIRBAG SYSTEM COMPONENT

REMOVAL OR INSTALLATION PROCEDURE. THIS

WILL DISABLE THE AIRBAG SYSTEM. FAILURE TO

DISCONNECT BATTERY COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

ALLOW SYSTEM CAPACITOR TO DISCHARGE

FOR 2 MINUTES BEFORE REMOVING ANY AIRBAG

COMPONENTS.

REMOVAL

(1) Adjust the steering wheel so that the tires are

in the straight ahead position then:

²Rotate the steering wheel half turn (180

degrees) to the right (clockwise)

²Lock column with the ignition cylinder lock

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the speed control switches and discon-

nect the wire connectors or covers.

(4) Remove the Driver Airbag Module attaching

bolts from the back of steering wheel.

Fig. 23 Instrument Panel

Fig. 24 Passenger Airbag Module

Fig. 25 Airbag Module Connector

8M - 10 RESTRAINT SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 362 of 1200

(5) Lift module and disconnect the airbag and horn

wire connectors.

(6) Remove steering wheel retaining nut.

(7) Remove the steering wheel with a steering

wheel puller. While removing the steering wheel take

care to feed the wires gently through the holes in the

clockspring armature.

INSTALLATION

(1) Confirm that:

²The steering wheel position is a half turn (180

degrees) to the right (clockwise)

²The column is locked with the ignition cylinder

lock.

²Check that the turn signal stalk is in the neu-

tral position

(2) Install the steering wheel ensuring the flats on

hub align with the clockspring. Pull the horn lead,

airbag and speed control leads through the larger

slot. Ensure leads do not get pinched under the steer-

ing wheel.

(3) Install the steering wheel retaining nut, and

tighten it to 61 N´m (45 ft. lbs.) torque.

(4) Install the airbag module. Refer to Driver Air-

bag Module Removal and Installation for proper pro-

cedures.

(5) Do not connect the battery negative cable.

Refer to Diagnosis and Testing for Airbag System

Test procedures.

ADJUSTMENTS

CLOCKSPRING CENTERING PROCEDURE

If the rotating tape within the clockspring is not

positioned properly with the steering wheel and the

front wheels, the clockspring may fail during use.

The following procedure MUST BE USED to center

the clockspring if:²The clockspring is not known to be properly

positioned

²The front wheels were moved

²The steering wheel was moved from the half

turn (180 degrees) to the right (clockwise) position.

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE BEFORE

BEGINNING ANY AIRBAG SYSTEM COMPONENT

REMOVAL OR INSTALLATION PROCEDURE. THIS

WILL DISABLE THE AIRBAG SYSTEM. FAILURE TO

DISCONNECT BATTERY COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

ALLOW SYSTEM CAPACITOR TO DISCHARGE

FOR 2 MINUTES BEFORE REMOVING ANY AIRBAG

COMPONENTS.

(1) Remove clockspring, refer to Clockspring

Removal.

(2) Rotate the clockspring rotor in the CLOCK-

WISE DIRECTION to the end of travel. Do not apply

excessive torque.

(3) From the end of travel, rotate the rotor two full

turns and a half in the counterclockwise direction.

The horn wire and the squib wire should end up at

the bottom. If not, rotate the rotor counter clockwise

until the wires are properly orientated, but not more

than half turn (180 degrees). Engage clockspring

locking mechanism.

(4) For installation, refer to Clockspring Installa-

tion

(5) Do not connect battery negative cable. Refer to

Diagnosis and Testing for Airbag System Test

procedures.

PLRESTRAINT SYSTEM 8M - 11

REMOVAL AND INSTALLATION (Continued)

Page 378 of 1200

SERVICE PROCEDURES

VEHICLE IMMOBILIZER SYSTEM

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: The following tests may not prove conclu-

sive in the diagnosis of this system. The most reli-

able, efficient, and accurate means to diagnose the

Vehicle Immobilizer System involves the use of a

DRB scan tool. Refer to the Vehicle Theft Security

System menu item on the DRB scan tool for the

procedures.

The vehicle immobilizer system and the Chrysler

Collision Detection (CCD) data bus network should

be diagnosed using the DRB scan tool. The DRB will

allow confirmation that the CCD data bus is func-

tional, that the immobilizer receiver is placing the

proper messages on the CCD data bus, and that the

Powertrain Control Module (PCM) is receiving the

CCD data bus messages. Refer to the Vehicle Theft

Security System menu item on the DRB scan tool for

the procedures. Refer to 8W-39 - Vehicle Theft Secu-

rity System in Group 8W - Wiring Diagrams for com-

plete circuit descriptions and diagrams.

(1) With the ignition switch in the Off position,

depress the Lock or Unlock button of the immobilizer

transmitter. Listen for the immobilizer receiver to

issue an audible chirp (Unlock) or chirps (Lock). If

OK, go to Step 2. If not OK, replace the transmitter

batteries with known good units and repeat Step 1. If

still not OK, go to Step 2.

(2) Check the fuse in the Power Distribution Cen-

ter (PDC). If OK, go to Step 3. If not OK, repair the

shorted circuit or component as required and replace

the faulty fuse.

(3) Disconnect and isolate the battery negative

cable. Unplug the wire harness connector at the

immobilizer receiver. Check for continuity between

the ground circuit cavity of the immobilizer receiver

wire harness connector and a good ground. There

should be continuity. If OK, go to Step 4. If not OK,

repair the open circuit to ground as required.

(4) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

immobilizer receiver wire harness connector. If OK,

refer to the Vehicle Theft Security System menu itemon the DRB scan tool for further diagnosis. If not

OK, repair the open circuit to the PDC fuse as

required.REMOVAL AND INSTALLATION

IMMOBILIZER RECEIVER

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

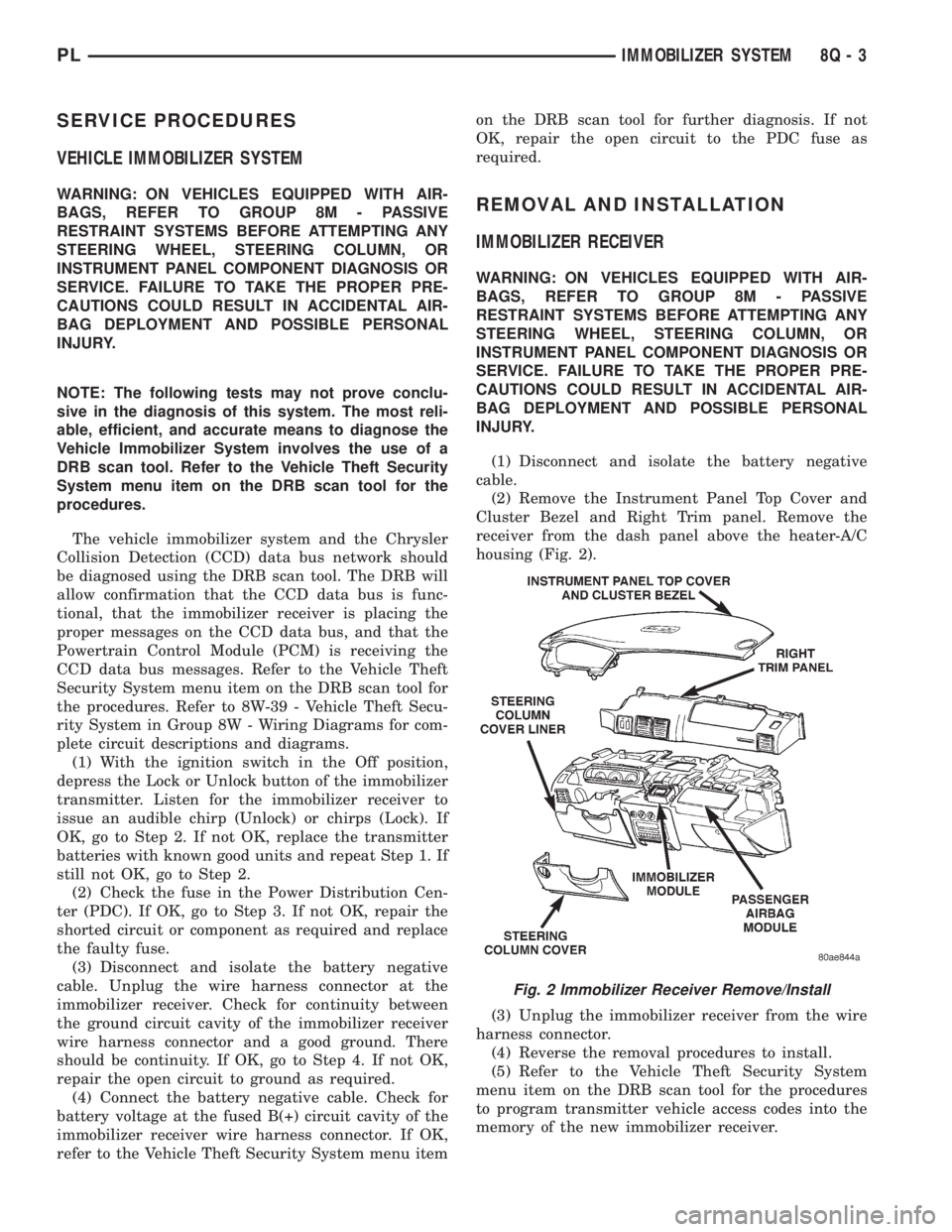

(2) Remove the Instrument Panel Top Cover and

Cluster Bezel and Right Trim panel. Remove the

receiver from the dash panel above the heater-A/C

housing (Fig. 2).

(3) Unplug the immobilizer receiver from the wire

harness connector.

(4) Reverse the removal procedures to install.

(5) Refer to the Vehicle Theft Security System

menu item on the DRB scan tool for the procedures

to program transmitter vehicle access codes into the

memory of the new immobilizer receiver.

Fig. 2 Immobilizer Receiver Remove/Install

PLIMMOBILIZER SYSTEM 8Q - 3

Page 390 of 1200

CHIME WARNING/REMINDER SYSTEM

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DIAGNOSIS AND TESTING

CHIME SYSTEM CONDITIONS.............. 1

FASTEN SEAT BELTS..................... 1

HEADLAMPS LEFT ON.................... 1KEY LEFT IN IGNITION SWITCH............ 1

REMOVAL AND INSTALLATION

CHIME................................. 2

HEADLAMP SWITCH..................... 2

KEY-IN SWITCH......................... 2

SEAT BELT BUCKLE...................... 2

GENERAL INFORMATION

INTRODUCTION

WARNING: ON VEHICLES EQUIPPED WITH AN

AIRBAG, REFER TO THE AIRBAG PORTION OF

THIS SECTION FOR STEERING WHEEL OR SWITCH

REMOVAL AND INSTALLATION PROCEDURES.

The seat belt reminder system uses both visual

and audible signals. A combined seat belt and key

reminder chime with a red light on the instrument

panel.

The system will always illuminate the seat belt

reminder lamp for four to eight seconds when the

ignition switch is turned to the ON position. The

CHIME will sound during the same time interval if

the driver's seat belt is not fastened. Passenger belts

are not connected to the system. The chime will acti-

vate if the drivers door is opened and:

²The key is in the ignition switch, with the igni-

tion switch in either the OFF or accessory (ACC)

position

²The head lamps are ON.

The chime is part of the instrument cluster.

NOTE: This group covers both Left-Hand Drive

(LHD) and Right-Hand Drive (RHD) versions of this

model. Whenever required and feasible, the RHD

versions of affected vehicle components have been

constructed as mirror-image of the LHD versions.

While most of the illustrations used in this group

represent only the LHD version, the diagnostic and

service procedures outlined can generally be

applied to either version. Exceptions to this rule

have been clearly identified as LHD, RHD, or Export

if a special illustration or procedure is required.

DIAGNOSIS AND TESTING

FASTEN SEAT BELTS

To test the fasten seat belts function, turn the igni-

tion switch to the ON position with the driver's seat

belt unbuckled and fully retracted. The seat belt

warning lamp should light for four to eight seconds

and the tone should sound three to five times.

HEADLAMPS LEFT ON

To test the headlamps left on function:

²Turn headlamps

²Driver's door open

²Key removed from the ignition switch

Chime should sound until headlamps are turned

off or driver's door is closed.

KEY LEFT IN IGNITION SWITCH

To test the key left in ignition function, insert key

into the ignition and open driver's door. Chime

should sound until key is removed from ignition or

driver's door is closed.

CHIME SYSTEM CONDITIONS

The cluster harness connector, J1 is car right and

the J2 is car left.

NO TONE WHEN IGNITION SWITCH IS

TURNED ON AND DRIVERS SEAT BELT IS

UNBUCKLED

(1) Using an ohmmeter, with the seat belt fully

retracted, check for continuity to ground at Pin 4 of

the J1 wire harness connector (Fig. 1). If OK, go to

step 2. If not OK, repair as necessary .

(2) Check for continuity to ground at Pin 8 of the

J1 wire harness connector. If OK, go to Step 3. If not

OK, repair as necessary.

(3) Using voltmeter, check for battery feed at Pin 6

of the J1 wire harness connector. Check for ignition

feed at Pin 5 of the J1 wire harness connector. If not

OK, repair as necessary.

PLCHIME WARNING/REMINDER SYSTEM 8U - 1

Page 397 of 1200

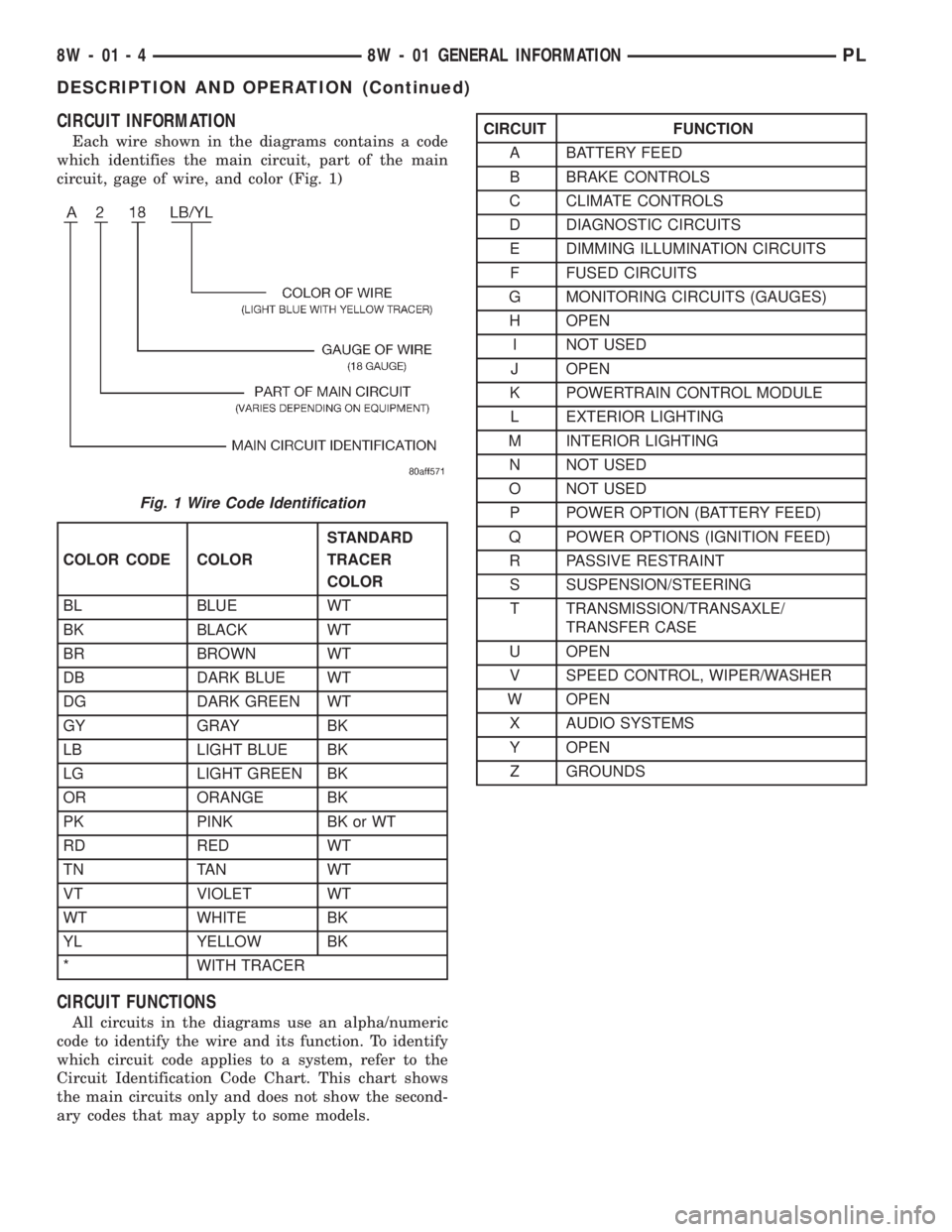

CIRCUIT INFORMATION

Each wire shown in the diagrams contains a code

which identifies the main circuit, part of the main

circuit, gage of wire, and color (Fig. 1)

CIRCUIT FUNCTIONS

All circuits in the diagrams use an alpha/numeric

code to identify the wire and its function. To identify

which circuit code applies to a system, refer to the

Circuit Identification Code Chart. This chart shows

the main circuits only and does not show the second-

ary codes that may apply to some models.

Fig. 1 Wire Code Identification

COLOR CODE COLORSTANDARD

TRACER

COLOR

BL BLUE WT

BK BLACK WT

BR BROWN WT

DB DARK BLUE WT

DG DARK GREEN WT

GY GRAY BK

LB LIGHT BLUE BK

LG LIGHT GREEN BK

OR ORANGE BK

PK PINK BK or WT

RD RED WT

TN TAN WT

VT VIOLET WT

WT WHITE BK

YL YELLOW BK

* WITH TRACER

CIRCUIT FUNCTION

A BATTERY FEED

B BRAKE CONTROLS

C CLIMATE CONTROLS

D DIAGNOSTIC CIRCUITS

E DIMMING ILLUMINATION CIRCUITS

F FUSED CIRCUITS

G MONITORING CIRCUITS (GAUGES)

H OPEN

I NOT USED

J OPEN

K POWERTRAIN CONTROL MODULE

L EXTERIOR LIGHTING

M INTERIOR LIGHTING

N NOT USED

O NOT USED

P POWER OPTION (BATTERY FEED)

Q POWER OPTIONS (IGNITION FEED)

R PASSIVE RESTRAINT

S SUSPENSION/STEERING

T TRANSMISSION/TRANSAXLE/

TRANSFER CASE

U OPEN

V SPEED CONTROL, WIPER/WASHER

W OPEN

X AUDIO SYSTEMS

Y OPEN

Z GROUNDS

8W - 01 - 4 8W - 01 GENERAL INFORMATIONPL

DESCRIPTION AND OPERATION (Continued)

Page 410 of 1200

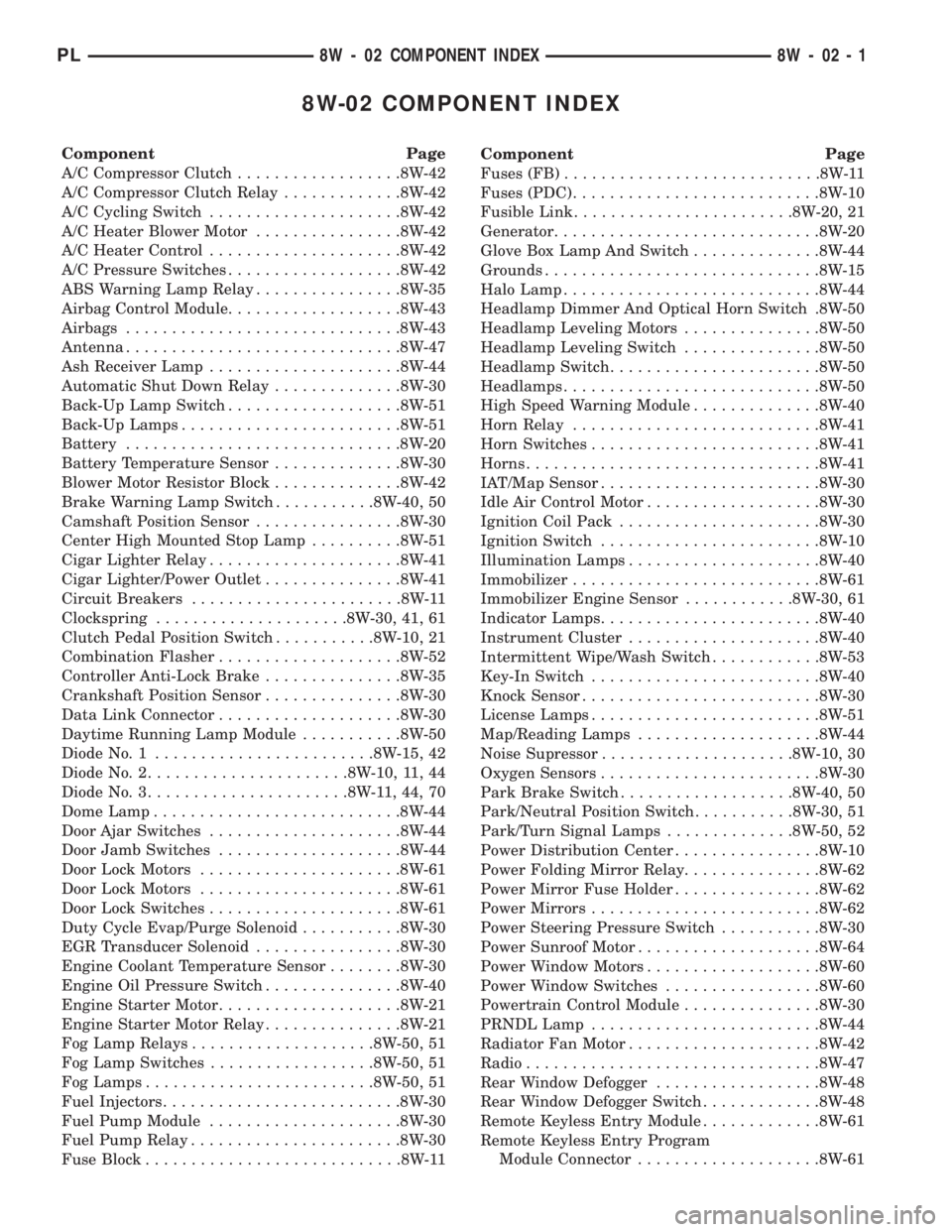

8W-02 COMPONENT INDEX

Component Page

A/C Compressor Clutch..................8W-42

A/C Compressor Clutch Relay.............8W-42

A/C Cycling Switch.....................8W-42

A/C Heater Blower Motor................8W-42

A/C Heater Control.....................8W-42

A/C Pressure Switches...................8W-42

ABS Warning Lamp Relay................8W-35

Airbag Control Module...................8W-43

Airbags..............................8W-43

Antenna..............................8W-47

Ash Receiver Lamp.....................8W-44

Automatic Shut Down Relay..............8W-30

Back-Up Lamp Switch...................8W-51

Back-Up Lamps........................8W-51

Battery..............................8W-20

Battery Temperature Sensor..............8W-30

Blower Motor Resistor Block..............8W-42

Brake Warning Lamp Switch...........8W-40, 50

Camshaft Position Sensor................8W-30

Center High Mounted Stop Lamp..........8W-51

Cigar Lighter Relay.....................8W-41

Cigar Lighter/Power Outlet...............8W-41

Circuit Breakers.......................8W-11

Clockspring.....................8W-30, 41, 61

Clutch Pedal Position Switch...........8W-10, 21

Combination Flasher....................8W-52

Controller Anti-Lock Brake...............8W-35

Crankshaft Position Sensor...............8W-30

Data Link Connector....................8W-30

Daytime Running Lamp Module...........8W-50

Diode No. 1........................8W-15, 42

Diode No. 2......................8W-10, 11, 44

Diode No. 3......................8W-11,44,70

Dome Lamp...........................8W-44

Door Ajar Switches.....................8W-44

Door Jamb Switches....................8W-44

Door Lock Motors......................8W-61

Door Lock Motors......................8W-61

Door Lock Switches.....................8W-61

Duty Cycle Evap/Purge Solenoid...........8W-30

EGR Transducer Solenoid................8W-30

Engine Coolant Temperature Sensor........8W-30

Engine Oil Pressure Switch...............8W-40

Engine Starter Motor....................8W-21

Engine Starter Motor Relay...............8W-21

Fog Lamp Relays....................8W-50, 51

Fog Lamp Switches..................8W-50, 51

Fog Lamps.........................8W-50, 51

Fuel Injectors..........................8W-30

Fuel Pump Module.....................8W-30

Fuel Pump Relay.......................8W-30

Fuse Block............................8W-11Component Page

Fuses (FB)............................8W-11

Fuses (PDC)...........................8W-10

Fusible Link........................8W-20, 21

Generator.............................8W-20

Glove Box Lamp And Switch..............8W-44

Grounds..............................8W-15

Halo Lamp............................8W-44

Headlamp Dimmer And Optical Horn Switch .8W-50

Headlamp Leveling Motors...............8W-50

Headlamp Leveling Switch...............8W-50

Headlamp Switch.......................8W-50

Headlamps............................8W-50

High Speed Warning Module..............8W-40

Horn Relay...........................8W-41

Horn Switches.........................8W-41

Horns................................8W-41

IAT/Map Sensor........................8W-30

Idle Air Control Motor...................8W-30

Ignition Coil Pack......................8W-30

Ignition Switch........................8W-10

Illumination Lamps.....................8W-40

Immobilizer...........................8W-61

Immobilizer Engine Sensor............8W-30, 61

Indicator Lamps........................8W-40

Instrument Cluster.....................8W-40

Intermittent Wipe/Wash Switch............8W-53

Key-In Switch.........................8W-40

Knock Sensor..........................8W-30

License Lamps.........................8W-51

Map/Reading Lamps....................8W-44

Noise Supressor.....................8W-10, 30

Oxygen Sensors........................8W-30

Park Brake Switch...................8W-40, 50

Park/Neutral Position Switch...........8W-30, 51

Park/Turn Signal Lamps..............8W-50, 52

Power Distribution Center................8W-10

Power Folding Mirror Relay...............8W-62

Power Mirror Fuse Holder................8W-62

Power Mirrors.........................8W-62

Power Steering Pressure Switch...........8W-30

Power Sunroof Motor....................8W-64

Power Window Motors...................8W-60

Power Window Switches.................8W-60

Powertrain Control Module...............8W-30

PRNDL Lamp.........................8W-44

Radiator Fan Motor.....................8W-42

Radio................................8W-47

Rear Window Defogger..................8W-48

Rear Window Defogger Switch.............8W-48

Remote Keyless Entry Module.............8W-61

Remote Keyless Entry Program

Module Connector....................8W-61

PL8W - 02 COMPONENT INDEX 8W - 02 - 1

Page 454 of 1200

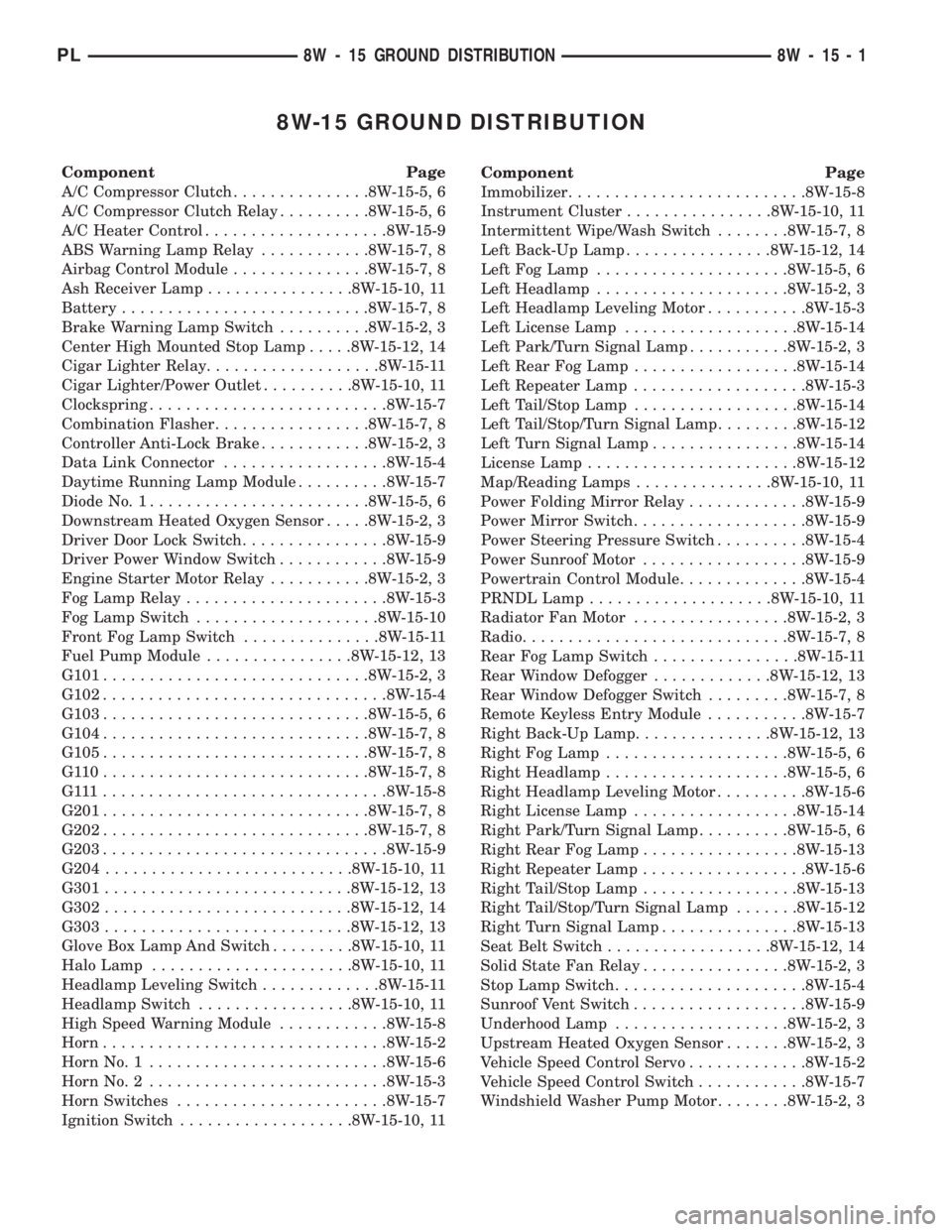

8W-15 GROUND DISTRIBUTION

Component Page

A/C Compressor Clutch...............8W-15-5, 6

A/C Compressor Clutch Relay..........8W-15-5, 6

A/C Heater Control....................8W-15-9

ABS Warning Lamp Relay............8W-15-7, 8

Airbag Control Module...............8W-15-7, 8

Ash Receiver Lamp................8W-15-10, 11

Battery...........................8W-15-7, 8

Brake Warning Lamp Switch..........8W-15-2, 3

Center High Mounted Stop Lamp.....8W-15-12, 14

Cigar Lighter Relay...................8W-15-11

Cigar Lighter/Power Outlet..........8W-15-10, 11

Clockspring..........................8W-15-7

Combination Flasher.................8W-15-7, 8

Controller Anti-Lock Brake............8W-15-2, 3

Data Link Connector..................8W-15-4

Daytime Running Lamp Module..........8W-15-7

Diode No. 1........................8W-15-5, 6

Downstream Heated Oxygen Sensor.....8W-15-2, 3

Driver Door Lock Switch................8W-15-9

Driver Power Window Switch............8W-15-9

Engine Starter Motor Relay...........8W-15-2, 3

Fog Lamp Relay......................8W-15-3

Fog Lamp Switch....................8W-15-10

Front Fog Lamp Switch...............8W-15-11

Fuel Pump Module................8W-15-12, 13

G101.............................8W-15-2, 3

G102...............................8W-15-4

G103.............................8W-15-5, 6

G104.............................8W-15-7, 8

G105.............................8W-15-7, 8

G110.............................8W-15-7, 8

G111...............................8W-15-8

G201.............................8W-15-7, 8

G202.............................8W-15-7, 8

G203...............................8W-15-9

G204...........................8W-15-10, 11

G301...........................8W-15-12, 13

G302...........................8W-15-12, 14

G303...........................8W-15-12, 13

Glove Box Lamp And Switch.........8W-15-10, 11

Halo Lamp......................8W-15-10, 11

Headlamp Leveling Switch.............8W-15-11

Headlamp Switch.................8W-15-10, 11

High Speed Warning Module............8W-15-8

Horn...............................8W-15-2

Horn No. 1..........................8W-15-6

Horn No. 2..........................8W-15-3

Horn Switches.......................8W-15-7

Ignition Switch...................8W-15-10, 11Component Page

Immobilizer..........................8W-15-8

Instrument Cluster................8W-15-10, 11

Intermittent Wipe/Wash Switch........8W-15-7, 8

Left Back-Up Lamp................8W-15-12, 14

Left Fog Lamp.....................8W-15-5, 6

Left Headlamp.....................8W-15-2, 3

Left Headlamp Leveling Motor...........8W-15-3

Left License Lamp...................8W-15-14

Left Park/Turn Signal Lamp...........8W-15-2, 3

Left Rear Fog Lamp..................8W-15-14

Left Repeater Lamp...................8W-15-3

Left Tail/Stop Lamp..................8W-15-14

Left Tail/Stop/Turn Signal Lamp.........8W-15-12

Left Turn Signal Lamp................8W-15-14

License Lamp.......................8W-15-12

Map/Reading Lamps...............8W-15-10, 11

Power Folding Mirror Relay.............8W-15-9

Power Mirror Switch...................8W-15-9

Power Steering Pressure Switch..........8W-15-4

Power Sunroof Motor..................8W-15-9

Powertrain Control Module..............8W-15-4

PRNDL Lamp....................8W-15-10, 11

Radiator Fan Motor.................8W-15-2, 3

Radio.............................8W-15-7, 8

Rear Fog Lamp Switch................8W-15-11

Rear Window Defogger.............8W-15-12, 13

Rear Window Defogger Switch.........8W-15-7, 8

Remote Keyless Entry Module...........8W-15-7

Right Back-Up Lamp...............8W-15-12, 13

Right Fog Lamp....................8W-15-5, 6

Right Headlamp....................8W-15-5, 6

Right Headlamp Leveling Motor..........8W-15-6

Right License Lamp..................8W-15-14

Right Park/Turn Signal Lamp..........8W-15-5, 6

Right Rear Fog Lamp.................8W-15-13

Right Repeater Lamp..................8W-15-6

Right Tail/Stop Lamp.................8W-15-13

Right Tail/Stop/Turn Signal Lamp.......8W-15-12

Right Turn Signal Lamp...............8W-15-13

Seat Belt Switch..................8W-15-12, 14

Solid State Fan Relay................8W-15-2, 3

Stop Lamp Switch.....................8W-15-4

Sunroof Vent Switch...................8W-15-9

Underhood Lamp...................8W-15-2, 3

Upstream Heated Oxygen Sensor.......8W-15-2, 3

Vehicle Speed Control Servo.............8W-15-2

Vehicle Speed Control Switch............8W-15-7

Windshield Washer Pump Motor........8W-15-2, 3

PL8W - 15 GROUND DISTRIBUTION 8W - 15 - 1

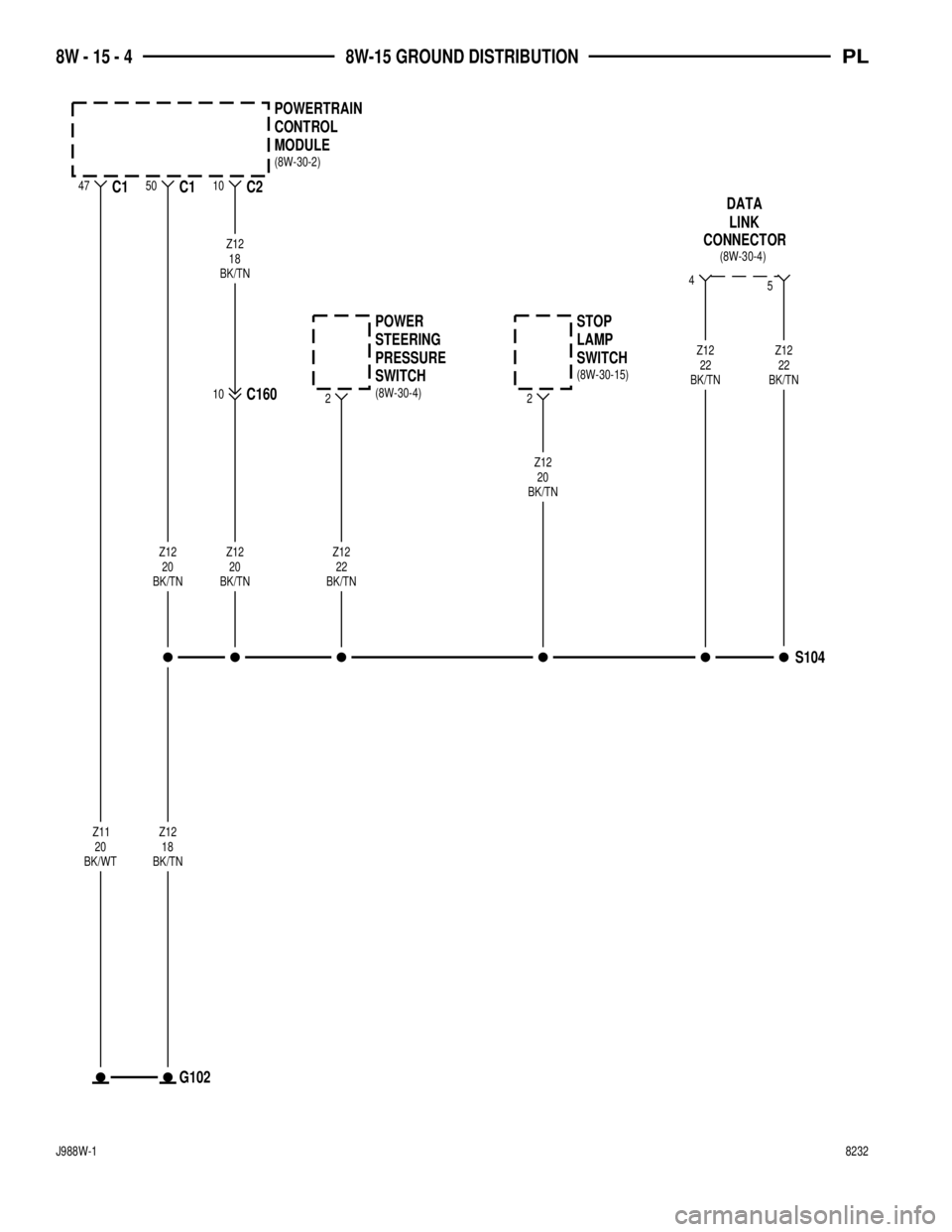

Page 457 of 1200

C14750C1C210

POWERTRAIN

CONTROL

MODULE

Z12

18

BK/TN

10C160

BK/TN20 Z12

Z12

20

BK/TN

Z11

20

BK/WT

2

SWITCH PRESSURE

STEERING

POWER

Z12

22

BK/TN

2

Z12

20

BK/TN

SWITCH LAMP

STOPZ12

22

BK/TNZ12

22

BK/TN

Z12

18

BK/TN

G102S104

4

5

LINK DATA

CONNECTOR

(8W-30-2)

(8W-30-4)(8W-30-15)(8W-30-4)

8W - 15 - 4 8W-15 GROUND DISTRIBUTIONPL

J988W-18232