steering DODGE NEON 1999 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 216 of 1200

Cooling System). Run engine with radiator cap

installed until upper radiator hose is hot. Stop

engine and drain water from system. If water is

dirty, fill, run and drain system again until water

runs clear.

RADIATOR FLUSHING

Drain cooling system and remove radiator hoses

from engine. Install suitable flushing gun in radiator

lower hose. Fill radiator with clean water and turn

on air in short blasts.

CAUTION: Internal radiator pressure must not

exceed 138 kPa (20 psi) as damage to radiator may

result. Continue this procedure until water runs

clear.

ENGINE FLUSHING

Drain radiator (see:Cooling System Draining)

and remove hoses from radiator. Remove engine ther-

mostat and reinstall thermostat housing. A gasket

may be needed to seal the housing to cylinder head

because the seal is part of thermostat. Install suit-

able flushing gun to thermostat housing hose. Turn

on water, and when engine is filled, turn on air, but

no higher than 138 kPa (20 psi) in short blasts. Allowengine to fill between blasts of air. Continue this pro-

cedure until water runs clean. Install thermostat and

fill cooling system. Refer to (Cooling System Refill-

ing) for procedure.

REVERSE FLUSHING

Reverse flushing of the cooling system is the forc-

ing of water through the cooling system, using air

pressure in a direction opposite to that of the normal

flow of water. This is only necessary with dirty sys-

tems and evidence of partial plugging.

CHEMICAL CLEANING

One type of corrosion encountered with aluminum

cylinder heads is aluminum hydroxide deposits. Cor-

rosion products are carried to the radiator and depos-

ited when cooled off. They appear as dark grey when

wet and white when dry. This corrosion can be

removed with a two part cleaner (oxalic acid and

neutralizer) available in auto parts outlets. Follow

manufacturers directions for use.

ADJUSTMENTS

PROPER BELT TENSION

Satisfactory performance of the belt driven accesso-

ries depends on belt condition and proper belt ten-

sion. Refer to Accessory Drive Belt Inspection in this

section. There are two belt tensioning methods given

in order of preference:

²Belt tension gauge method.

²Torque equivalent method.

The belt tension gauge method usually requires the

vehicle to be raised on a hoist and the splash shield

removed.

TORQUE EQUIVALENT METHOD

Adjustable accessory brackets provided with a 13

mm (1/2 in.) square hole for a torque wrench can use

an equivalent torque value for belt adjustment.

Equivalent torque values for adjusting these acces-

sory drive belts are specified in the Belt Tension

Chart.

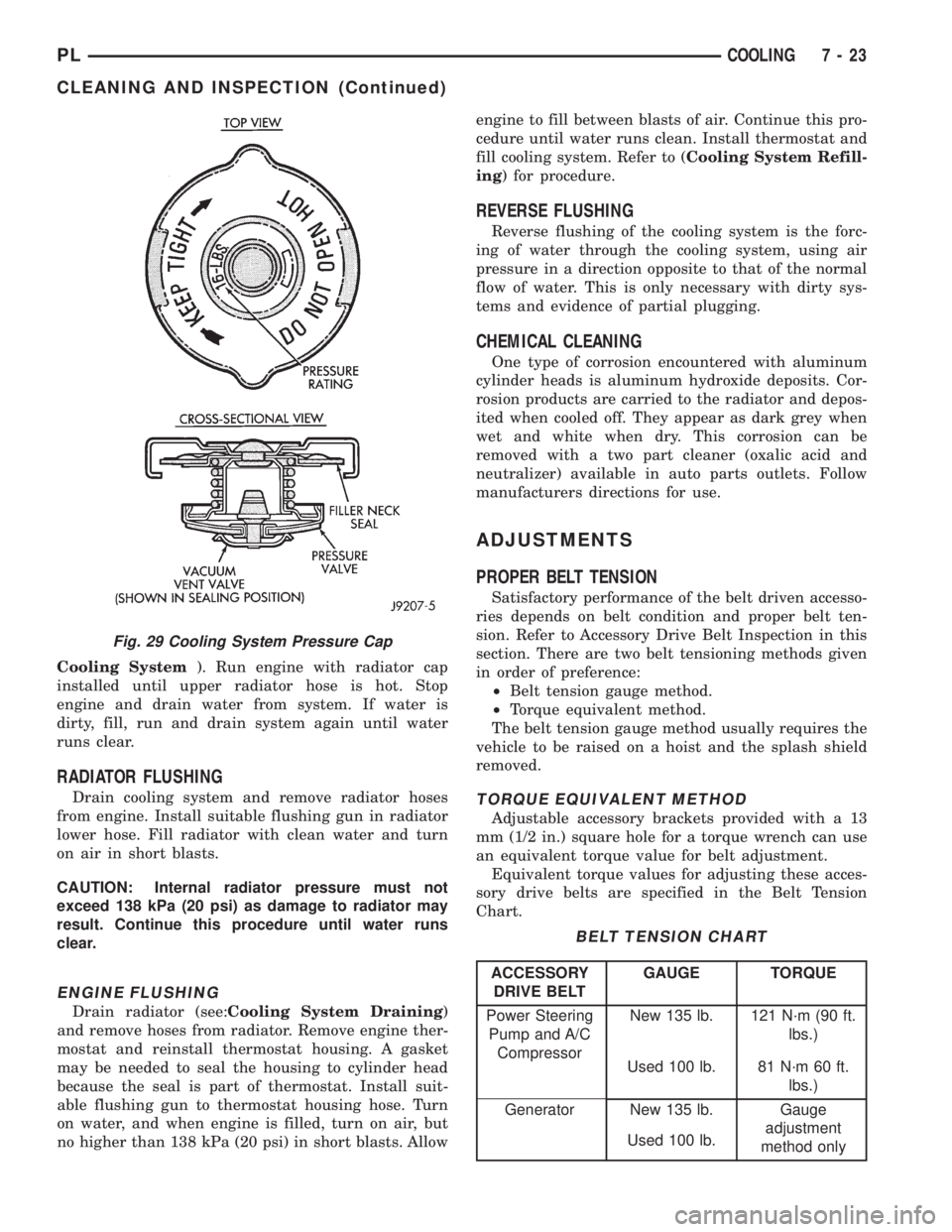

Fig. 29 Cooling System Pressure Cap

BELT TENSION CHART

ACCESSORY

DRIVE BELTGAUGE TORQUE

Power Steering

Pump and A/C

CompressorNew 135 lb. 121 N´m (90 ft.

lbs.)

Used 100 lb. 81 N´m 60 ft.

lbs.)

Generator New 135 lb. Gauge

adjustment

method only Used 100 lb.

PLCOOLING 7 - 23

CLEANING AND INSPECTION (Continued)

Page 217 of 1200

BELT TENSION GAUGE METHOD

NOTE: Use belt tensioning Special Tool Kit C-4162

for:

²For conventional belts and Poly-V-belts.

Adjust the belt tension for aNeworUsedbelt as

prescribed in the Belt Tension Chart.

SPECIFICATIONS

COOLING SYSTEM CAPACITYTORQUE

DESCRIPTION....................TORQUE

A/C Condenser to Radiator

Screws.....................7.2 N´m (65 in. lbs.)

Fan Module to Radiator

Screws.....................7.2 N´m (65 in. lbs.)

Fan Motor to Shroud (A/C equipped)

Screws.....................3.8 N´m (34 in. lbs.)

Fan Motor to Shroud (Non A/C equipped)

Screws.....................2.3 N´m (20 in. lbs.)

Radiator (Cooling Module) to Body

Screws.....................10N´m(90in.lbs.)

Thermostat Housing/Water Outlet Connector

Screws....................12N´m(105 in. lbs.)

Upper Radiator Crossmember

Bolts......................28N´m(250 in. lbs.)

Water Pump to Engine Block

Bolts......................12N´m(105 in. lbs.)

Water Pump Inlet Tube to Engine Block

Bolts......................12N´m(105 in. lbs.)

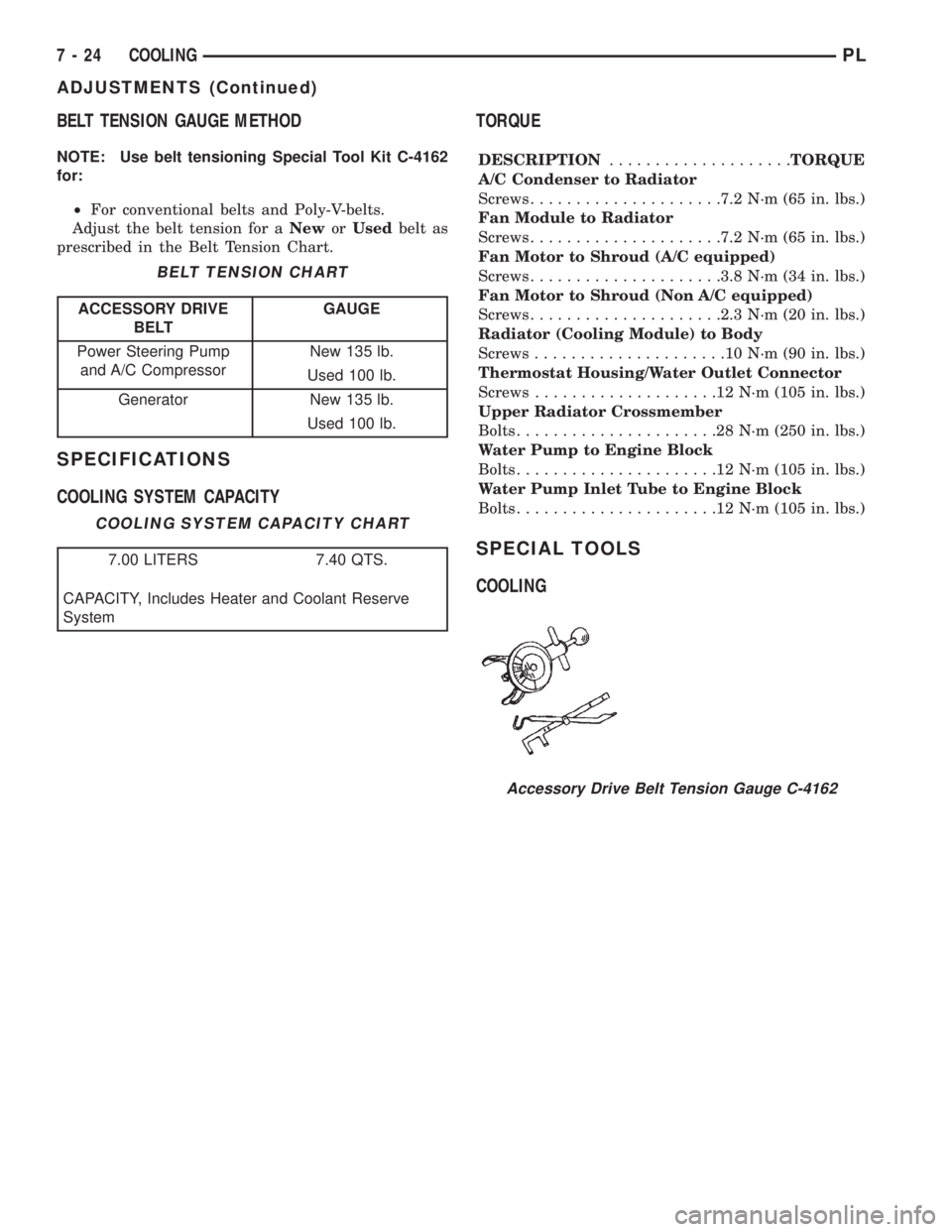

SPECIAL TOOLS

COOLING

BELT TENSION CHART

ACCESSORY DRIVE

BELTGAUGE

Power Steering Pump

and A/C CompressorNew 135 lb.

Used 100 lb.

Generator New 135 lb.

Used 100 lb.

COOLING SYSTEM CAPACITY CHART

7.00 LITERS 7.40 QTS.

CAPACITY, Includes Heater and Coolant Reserve

System

Accessory Drive Belt Tension Gauge C-4162

7 - 24 COOLINGPL

ADJUSTMENTS (Continued)

Page 231 of 1200

charge battery if necessary. Disconnect all testing

equipment and connect ASD relay or the Fuel Sole-

noid. Start the vehicle several times to assure the

problem has been corrected.

STARTING SYSTEM TEST

For circuit descriptions and diagrams, refer to

8W-21, Starting System in Group 8W, Wiring Dia-

grams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

INSPECTION

Before removing any unit from the starting system

for repair or diagnosis, perform the following inspec-

tions:

²Battery- Visually inspect the battery for indi-

cations of physical damage and loose or corroded

cable connections. Determine the state-of-charge and

cranking capacity of the battery. Charge or replace

the battery, if required. Refer to Group 8A, Battery

for more information.²Ignition Switch- Visually inspect the ignition

switch for indications of physical damage and loose

or corroded wire harness connections.

²Clutch Pedal Position Switch- Visually

inspect the clutch pedal position switch for indica-

tions of physical damage and loose or corroded wire

harness connections.

²Park/Neutral Position Switch- Visually

inspect the park/neutral position switch for indica-

tions of physical damage and loose or corroded wire

harness connections.

²Starter Relay- Visually inspect the starter

relay for indications of physical damage and loose or

corroded wire harness connections.

²Starter- Visually inspect the starter for indica-

tions of physical damage and loose or corroded wire

harness connections.

²Starter Solenoid- Visually inspect the starter

solenoid for indications of physical damage and loose

or corroded wire harness connections.

²Wiring- Visually inspect the wire harness for

damage. Repair or replace any faulty wiring, as

required.

8B - 4 STARTINGPL

DIAGNOSIS AND TESTING (Continued)

Page 265 of 1200

MAP/IAT SENSORÐSOHC

Refer to Group 14, Fuel Injection Section for

Removal/Installation.

MAP/IAT SENSORÐDOHC

Refer to Group 14, Fuel Injection Section for

Removal/Installation..

THROTTLE POSITION SENSOR

Refer to Group 14, Fuel Injection Section, for

Removal/Installation.

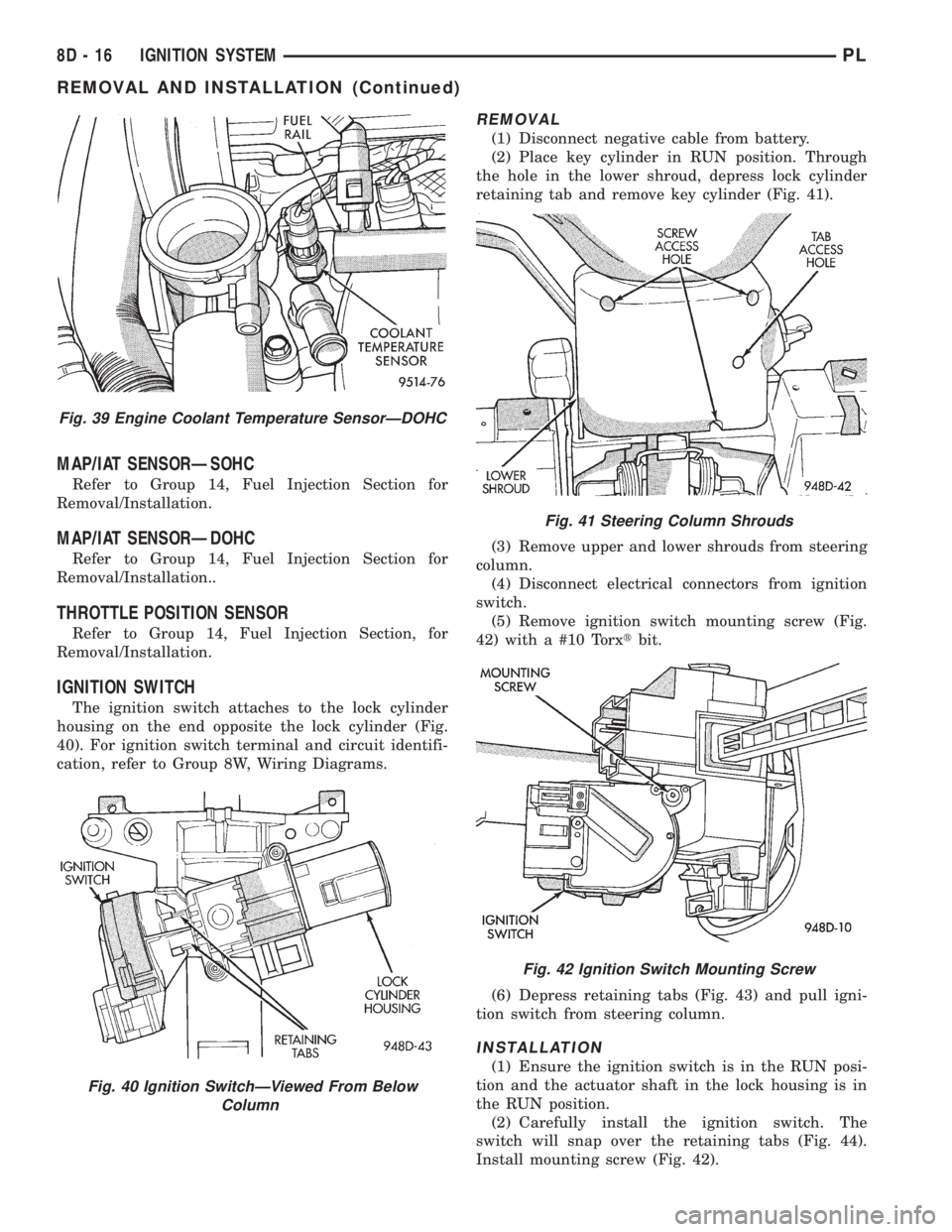

IGNITION SWITCH

The ignition switch attaches to the lock cylinder

housing on the end opposite the lock cylinder (Fig.

40). For ignition switch terminal and circuit identifi-

cation, refer to Group 8W, Wiring Diagrams.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Place key cylinder in RUN position. Through

the hole in the lower shroud, depress lock cylinder

retaining tab and remove key cylinder (Fig. 41).

(3) Remove upper and lower shrouds from steering

column.

(4) Disconnect electrical connectors from ignition

switch.

(5) Remove ignition switch mounting screw (Fig.

42) with a #10 Torxtbit.

(6) Depress retaining tabs (Fig. 43) and pull igni-

tion switch from steering column.

INSTALLATION

(1) Ensure the ignition switch is in the RUN posi-

tion and the actuator shaft in the lock housing is in

the RUN position.

(2) Carefully install the ignition switch. The

switch will snap over the retaining tabs (Fig. 44).

Install mounting screw (Fig. 42).

Fig. 39 Engine Coolant Temperature SensorÐDOHC

Fig. 40 Ignition SwitchÐViewed From Below

Column

Fig. 41 Steering Column Shrouds

Fig. 42 Ignition Switch Mounting Screw

8D - 16 IGNITION SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 267 of 1200

IGNITION INTERLOCK

Refer to Group 21, Transaxle for Shifter/Ignition

Interlock Service.

LOCK CYLINDER HOUSING

Refer to Steering Column in Group 19, Steering,

for Lock Cylinder Housing Service.

SPECIFICATIONS

VECI LABEL

If anything differs between the specifications found

on the Vehicle Emission Control Information (VECI)

label and the following specifications, use specifica-

tions on VECI label. The VECI label is located in the

engine compartment.

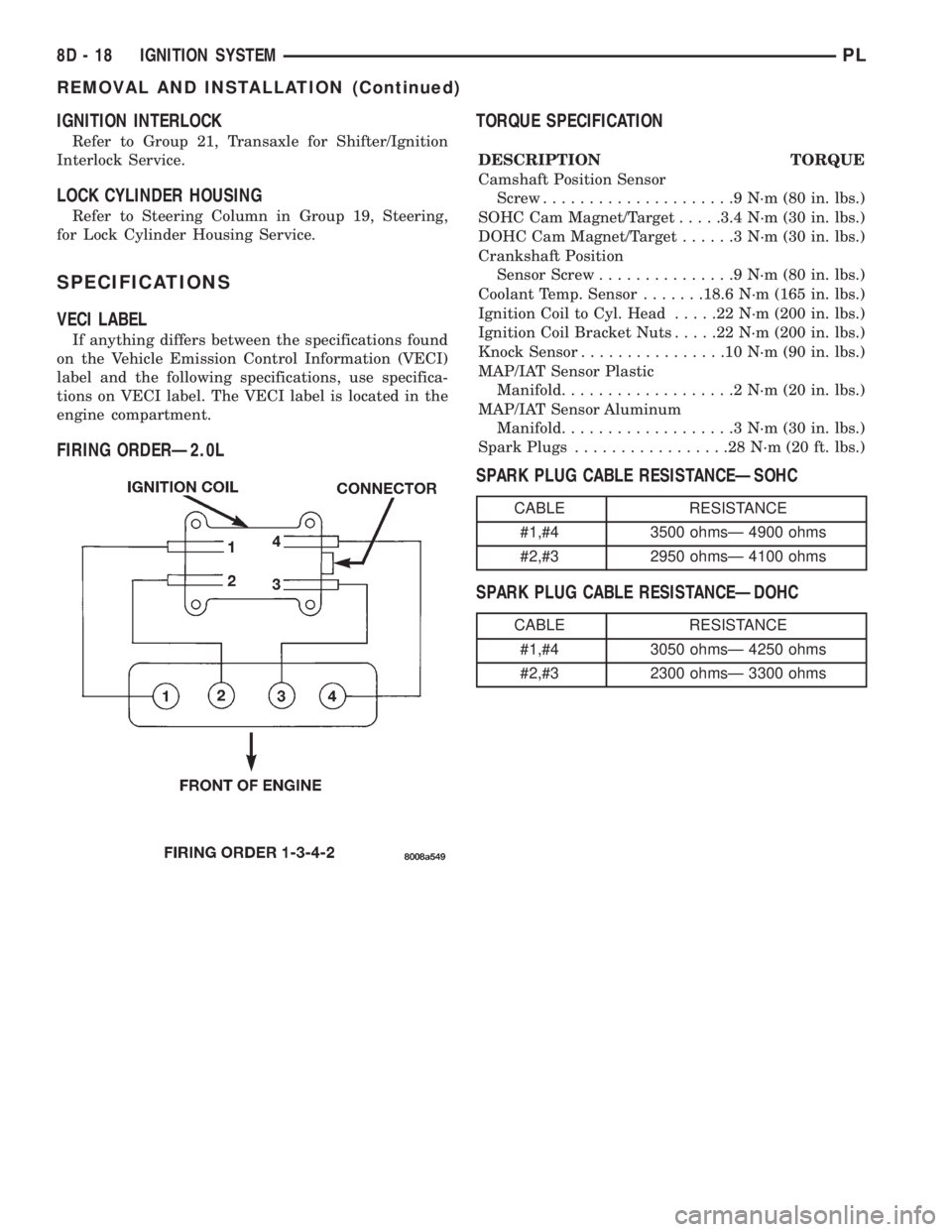

FIRING ORDERÐ2.0LTORQUE SPECIFICATION

DESCRIPTION TORQUE

Camshaft Position Sensor

Screw.....................9N´m(80in.lbs.)

SOHC Cam Magnet/Target.....3.4 N´m (30 in. lbs.)

DOHC Cam Magnet/Target......3N´m(30in.lbs.)

Crankshaft Position

Sensor Screw...............9N´m(80in.lbs.)

Coolant Temp. Sensor.......18.6 N´m (165 in. lbs.)

Ignition Coil to Cyl. Head.....22N´m(200 in. lbs.)

Ignition Coil Bracket Nuts.....22N´m(200 in. lbs.)

Knock Sensor................10N´m(90in.lbs.)

MAP/IAT Sensor Plastic

Manifold...................2N´m(20in.lbs.)

MAP/IAT Sensor Aluminum

Manifold...................3N´m(30in.lbs.)

Spark Plugs.................28N´m(20ft.lbs.)

SPARK PLUG CABLE RESISTANCEÐSOHC

SPARK PLUG CABLE RESISTANCEÐDOHC

CABLE RESISTANCE

#1,#4 3500 ohmsÐ 4900 ohms

#2,#3 2950 ohmsÐ 4100 ohms

CABLE RESISTANCE

#1,#4 3050 ohmsÐ 4250 ohms

#2,#3 2300 ohmsÐ 3300 ohms

8D - 18 IGNITION SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 270 of 1200

INSTRUMENT PANEL AND SYSTEMS

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

DOME LAMP............................ 1

ELECTRONIC DIGITAL CLOCK.............. 1

INSTRUMENT CLUSTER................... 2

WARNING AND INDICATOR LAMPS......... 2

DIAGNOSIS AND TESTING

AIRBAG WARNING SYSTEM............... 2

BRAKE SYSTEM WARNING LAMP TEST...... 2

FOG LAMP SWITCH TEST................. 2

FUEL TANK SENDING UNIT TEST........... 3

HEADLAMP SWITCH TEST................. 3

HEATER A/C BLOWER SWITCH TEST........ 3

HEATER BLOWER SWITCH TEST............ 3

INDIVIDUAL GAUGE INOPERATIVE.......... 4

INSTRUMENT PANEL AND COMPONENTS.... 4

LOW OIL PRESSURE WARNING LAMP TEST . . 4

MULTIPLE GAUGE INOPERATIVE TEST....... 4

SEAT BELT REMINDER SYSTEM TEST....... 6

SENDING UNIT......................... 6

SERVICE ENGINE SOON INDICATOR......... 6

VEHICLE SPEED SENSOR TEST............. 6

REMOVAL AND INSTALLATION

ASH RECEIVER RETAINER AND LAMP....... 6

CENTER BEZEL.......................... 6

CIGAR LIGHTER RECEPTACLE.............. 6

CLUSTER LAMP......................... 7

CLUSTER PRINTED CIRCUIT BOARD........ 7CLUSTER.............................. 7

DOME LENS/LAMP....................... 8

FLOOR CONSOLE........................ 8

GAUGE................................ 8

GLOVE BOX DOOR/BIN................... 8

GLOVE BOX SWITCH/LAMP................ 9

HEADLAMP SWITCH..................... 9

HEATER A/C CONTROL BLOWER SWITCH . . . 10

HEATER A/C CONTROL LAMP............ 10

HEATER A/C CONTROL................... 9

HEATER CONTROL BLOWER SWITCH....... 10

IGNITION KEY LAMP.................... 10

INSTRUMENT PANEL.................... 10

LEFT TRIM PANEL...................... 10

ODOMETER............................ 10

RADIO................................ 12

REAR WINDOW DEFOGGER AND/OR FOG

LAMP SWITCH....................... 12

RIGHT TRIM PANEL..................... 12

SHIFTER KNOB......................... 13

STEERING COLUMN COVER LINER......... 13

STEERING COLUMN COVER.............. 13

STEERING COLUMN SHROUDS............ 13

TOP COVER AND CLUSTER BEZEL

REMOVAL........................... 14

TRANSMISSION RANGE INDICATOR LAMP . . 14

TRUNK LAMP/LENS..................... 14

VEHICLE SPEED SENSOR................ 14

GENERAL INFORMATION

INTRODUCTION

The purpose of the dash gauges and indicator

lamps is to keep the driver informed about the oper-

ating condition of the vehicle. If an abnormal condi-

tion occurs, the driver is informed by indicator lamp.

The driver can seek service before damage occurs.

Indicator lamps use ON/OFF switch functions for

operation, while gauges use a sending unit or sensor.

DESCRIPTION AND OPERATION

DOME LAMP

The Dome Lamp operates when a door is open or

when the headlamp switch is placed in courtesy posi-

tion.

ELECTRONIC DIGITAL CLOCK

The electronic digital clock is in the radio. The

clock and radio each use the display panel built into

the radio. A digital readout indicates the time in

hours and minutes whenever the ignition switch is in

the ON or ACC position.

PLINSTRUMENT PANEL AND SYSTEMS 8E - 1

Page 278 of 1200

GLOVE BOX SWITCH/LAMP

REMOVAL

(1) Disconnect battery negative cable and isolate it

or remove fuse 12 prior to removing the switch, or

wires may short to ground.

(2) Open the glove box and push the glove box

sides inward allowing the door bumpers to clear and

the box to tip rearward.

(3) Reach inside the opening and squeeze the

lamp/switch retainers until they are disengage.

(4) Pull the switch/lamp rearward and remove it.

Replace the lamp. To replace the switch disconnect

wire and replace the switch.

INSTALLATION

For installation, reverse the above procedures.

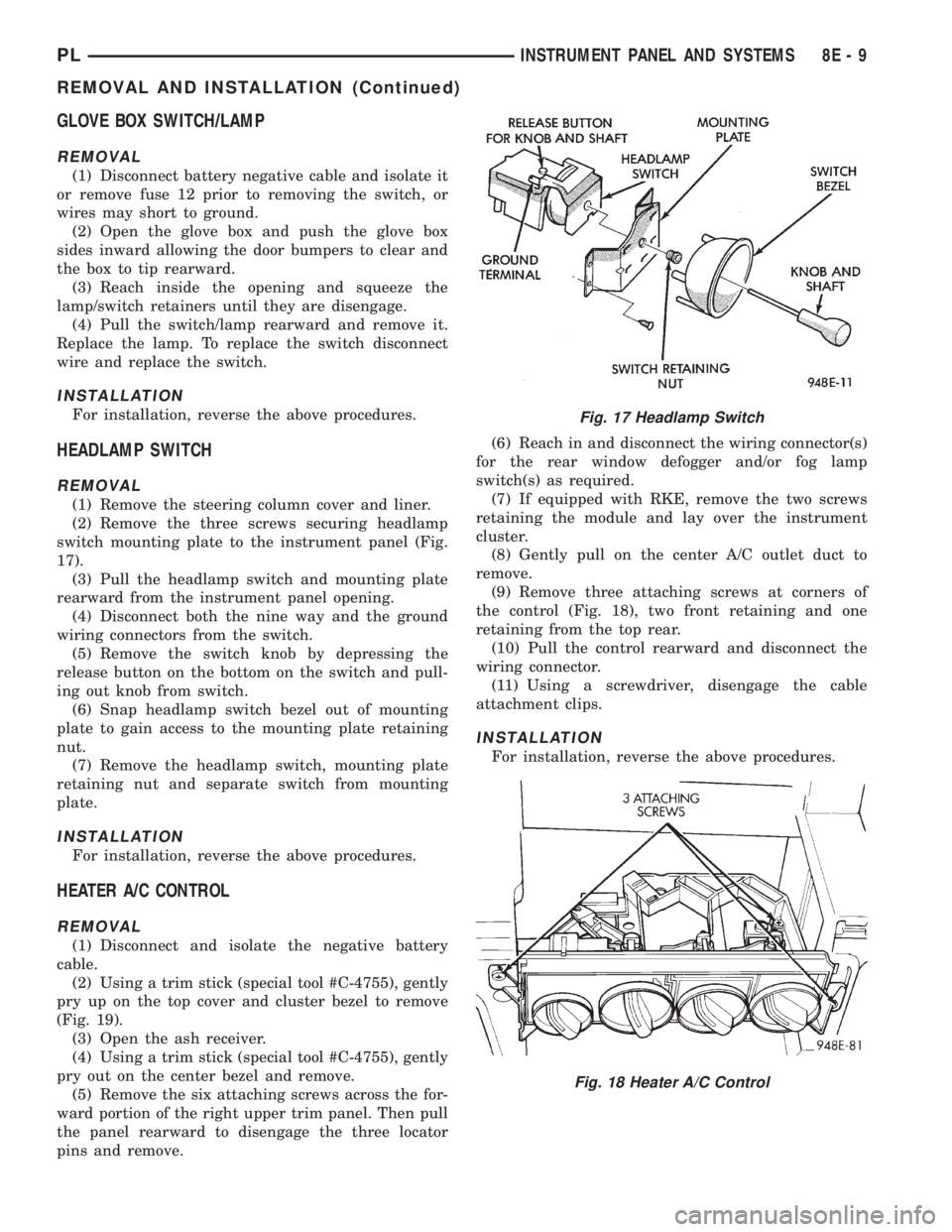

HEADLAMP SWITCH

REMOVAL

(1) Remove the steering column cover and liner.

(2) Remove the three screws securing headlamp

switch mounting plate to the instrument panel (Fig.

17).

(3) Pull the headlamp switch and mounting plate

rearward from the instrument panel opening.

(4) Disconnect both the nine way and the ground

wiring connectors from the switch.

(5) Remove the switch knob by depressing the

release button on the bottom on the switch and pull-

ing out knob from switch.

(6) Snap headlamp switch bezel out of mounting

plate to gain access to the mounting plate retaining

nut.

(7) Remove the headlamp switch, mounting plate

retaining nut and separate switch from mounting

plate.

INSTALLATION

For installation, reverse the above procedures.

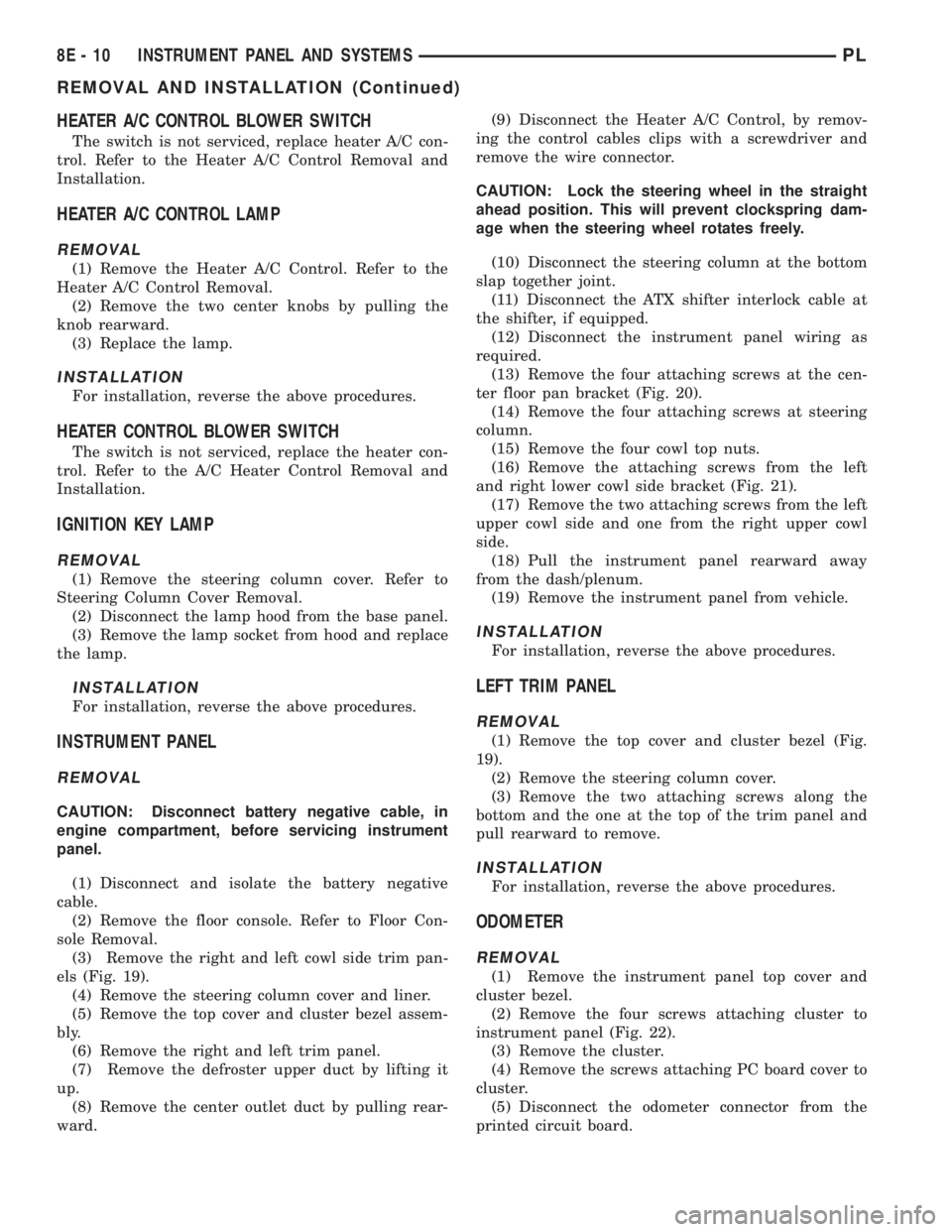

HEATER A/C CONTROL

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Using a trim stick (special tool #C-4755), gently

pry up on the top cover and cluster bezel to remove

(Fig. 19).

(3) Open the ash receiver.

(4) Using a trim stick (special tool #C-4755), gently

pry out on the center bezel and remove.

(5) Remove the six attaching screws across the for-

ward portion of the right upper trim panel. Then pull

the panel rearward to disengage the three locator

pins and remove.(6) Reach in and disconnect the wiring connector(s)

for the rear window defogger and/or fog lamp

switch(s) as required.

(7) If equipped with RKE, remove the two screws

retaining the module and lay over the instrument

cluster.

(8) Gently pull on the center A/C outlet duct to

remove.

(9) Remove three attaching screws at corners of

the control (Fig. 18), two front retaining and one

retaining from the top rear.

(10) Pull the control rearward and disconnect the

wiring connector.

(11) Using a screwdriver, disengage the cable

attachment clips.

INSTALLATION

For installation, reverse the above procedures.

Fig. 17 Headlamp Switch

Fig. 18 Heater A/C Control

PLINSTRUMENT PANEL AND SYSTEMS 8E - 9

REMOVAL AND INSTALLATION (Continued)

Page 279 of 1200

HEATER A/C CONTROL BLOWER SWITCH

The switch is not serviced, replace heater A/C con-

trol. Refer to the Heater A/C Control Removal and

Installation.

HEATER A/C CONTROL LAMP

REMOVAL

(1) Remove the Heater A/C Control. Refer to the

Heater A/C Control Removal.

(2) Remove the two center knobs by pulling the

knob rearward.

(3) Replace the lamp.

INSTALLATION

For installation, reverse the above procedures.

HEATER CONTROL BLOWER SWITCH

The switch is not serviced, replace the heater con-

trol. Refer to the A/C Heater Control Removal and

Installation.

IGNITION KEY LAMP

REMOVAL

(1) Remove the steering column cover. Refer to

Steering Column Cover Removal.

(2) Disconnect the lamp hood from the base panel.

(3) Remove the lamp socket from hood and replace

the lamp.

INSTALLATION

For installation, reverse the above procedures.

INSTRUMENT PANEL

REMOVAL

CAUTION: Disconnect battery negative cable, in

engine compartment, before servicing instrument

panel.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the floor console. Refer to Floor Con-

sole Removal.

(3) Remove the right and left cowl side trim pan-

els (Fig. 19).

(4) Remove the steering column cover and liner.

(5) Remove the top cover and cluster bezel assem-

bly.

(6) Remove the right and left trim panel.

(7) Remove the defroster upper duct by lifting it

up.

(8) Remove the center outlet duct by pulling rear-

ward.(9) Disconnect the Heater A/C Control, by remov-

ing the control cables clips with a screwdriver and

remove the wire connector.

CAUTION: Lock the steering wheel in the straight

ahead position. This will prevent clockspring dam-

age when the steering wheel rotates freely.

(10) Disconnect the steering column at the bottom

slap together joint.

(11) Disconnect the ATX shifter interlock cable at

the shifter, if equipped.

(12) Disconnect the instrument panel wiring as

required.

(13) Remove the four attaching screws at the cen-

ter floor pan bracket (Fig. 20).

(14) Remove the four attaching screws at steering

column.

(15) Remove the four cowl top nuts.

(16) Remove the attaching screws from the left

and right lower cowl side bracket (Fig. 21).

(17) Remove the two attaching screws from the left

upper cowl side and one from the right upper cowl

side.

(18) Pull the instrument panel rearward away

from the dash/plenum.

(19) Remove the instrument panel from vehicle.

INSTALLATION

For installation, reverse the above procedures.

LEFT TRIM PANEL

REMOVAL

(1) Remove the top cover and cluster bezel (Fig.

19).

(2) Remove the steering column cover.

(3) Remove the two attaching screws along the

bottom and the one at the top of the trim panel and

pull rearward to remove.

INSTALLATION

For installation, reverse the above procedures.

ODOMETER

REMOVAL

(1) Remove the instrument panel top cover and

cluster bezel.

(2) Remove the four screws attaching cluster to

instrument panel (Fig. 22).

(3) Remove the cluster.

(4) Remove the screws attaching PC board cover to

cluster.

(5) Disconnect the odometer connector from the

printed circuit board.

8E - 10 INSTRUMENT PANEL AND SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)

Page 282 of 1200

the panel rearward to disengage the three locator

pins and remove.

(6) Reach in and disconnect the wiring connector(s)

for the rear window defogger and/or fog lamp

switch(s) as required.

INSTALLATION

For installation, reverse the above procedures.

SHIFTER KNOB

AUTOMATIC TRANSMISSION SHIFTER

REMOVAL

(1) Loosen the set screw at the left side under the

button area.

(2) Pull up until the knob slides off the shifter

shaft.

INSTALLATION

For installation, reverse the above procedures.

MANUAL TRANSMISSION SHIFTER

REMOVAL

(1) Pull the top part of the boot down until the two

tabs at the bottom of the knob are exposed.

(2) Release the locking tabs from the pins on the

shifter shaft.

(3) Pull up until the knob slides off the shifter

shaft.INSTALLATION

For installation, reverse the above procedures.

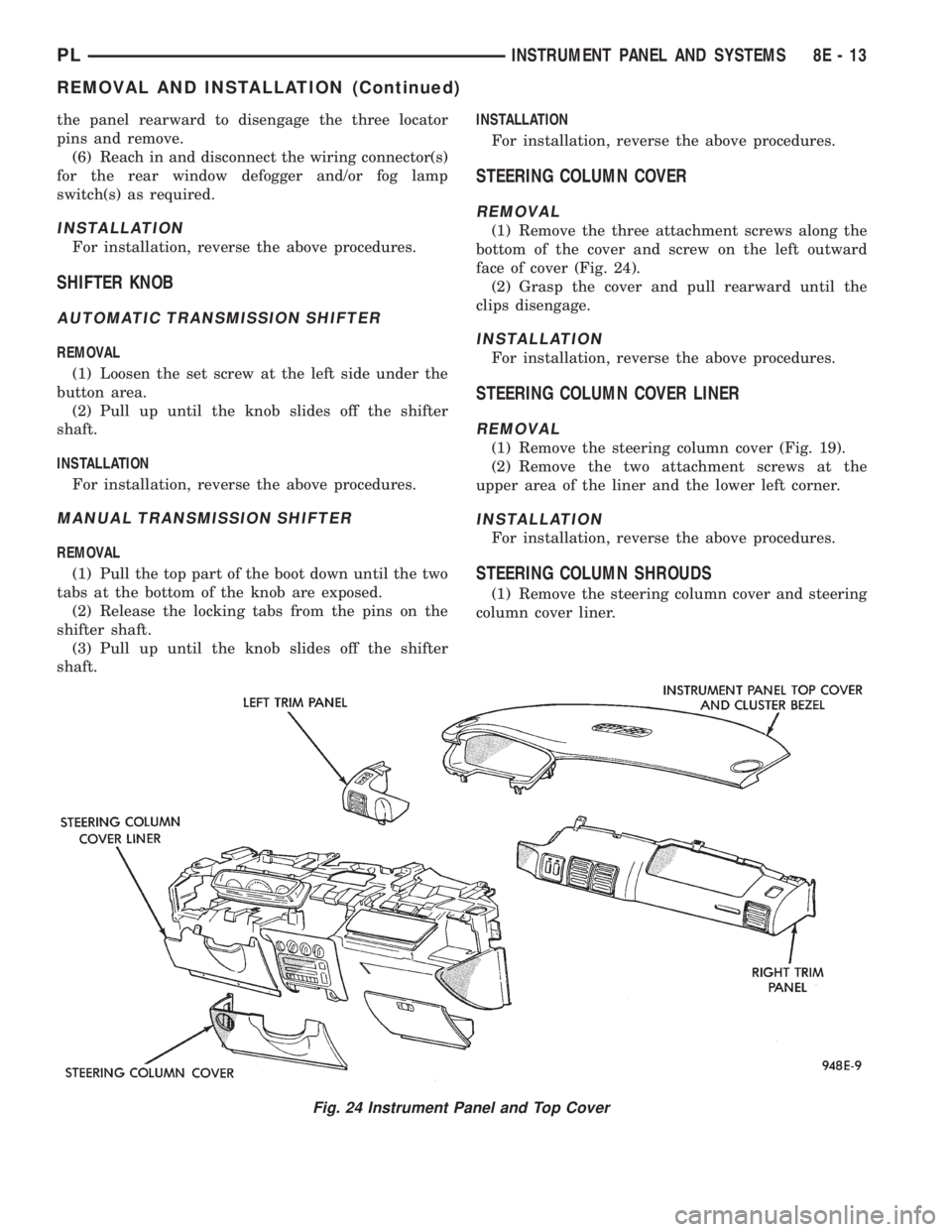

STEERING COLUMN COVER

REMOVAL

(1) Remove the three attachment screws along the

bottom of the cover and screw on the left outward

face of cover (Fig. 24).

(2) Grasp the cover and pull rearward until the

clips disengage.

INSTALLATION

For installation, reverse the above procedures.

STEERING COLUMN COVER LINER

REMOVAL

(1) Remove the steering column cover (Fig. 19).

(2) Remove the two attachment screws at the

upper area of the liner and the lower left corner.

INSTALLATION

For installation, reverse the above procedures.

STEERING COLUMN SHROUDS

(1) Remove the steering column cover and steering

column cover liner.

Fig. 24 Instrument Panel and Top Cover

PLINSTRUMENT PANEL AND SYSTEMS 8E - 13

REMOVAL AND INSTALLATION (Continued)

Page 294 of 1200

HORNS

CONTENTS

page page

DESCRIPTION AND OPERATION

INTRODUCTION......................... 1

DIAGNOSIS AND TESTING

HORN RELAY........................... 2

HORN SWITCH.......................... 2

HORN................................. 1SYSTEM TEST.......................... 2

REMOVAL AND INSTALLATION

HORN RELAY........................... 4

HORN SWITCHES........................ 4

HORN................................. 4

DESCRIPTION AND OPERATION

INTRODUCTION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

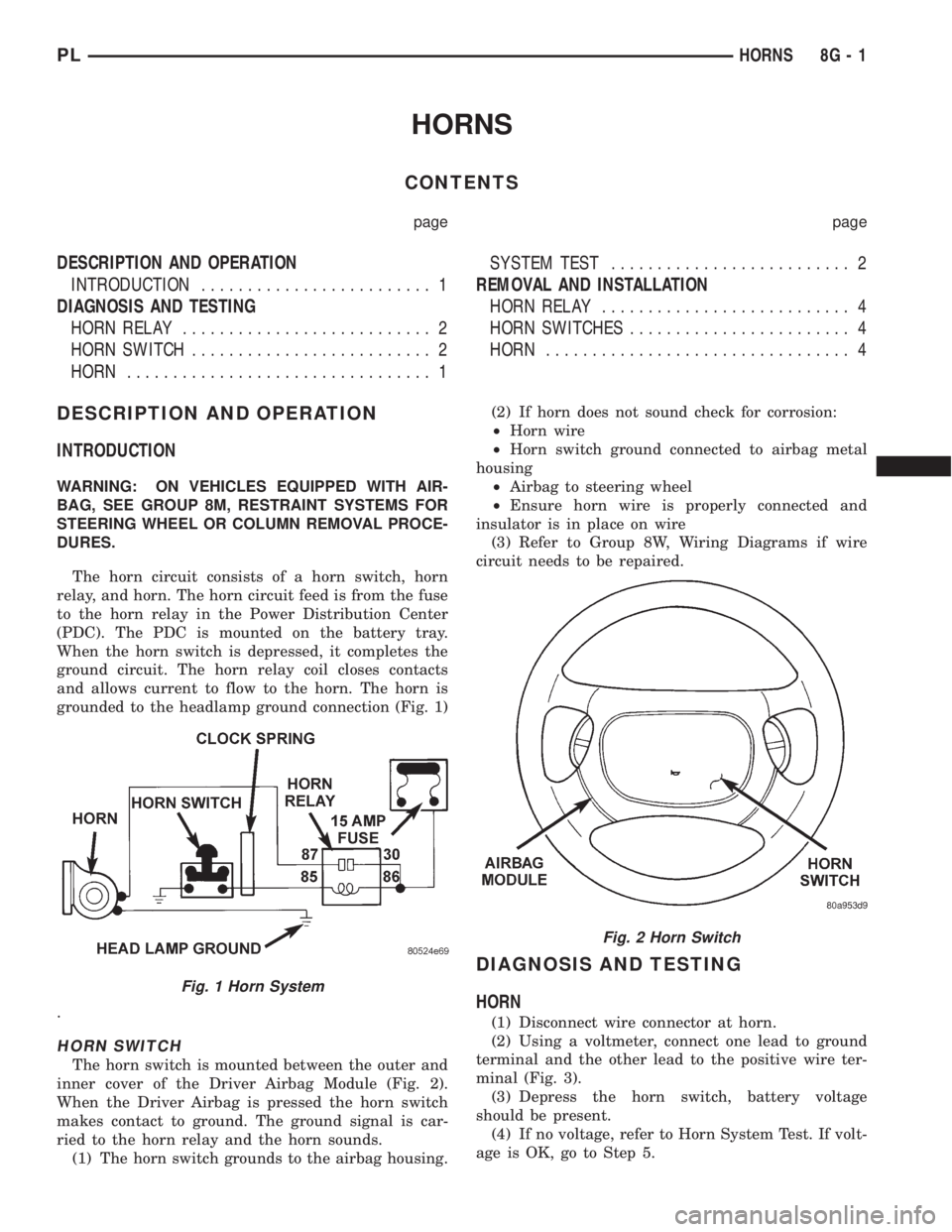

The horn circuit consists of a horn switch, horn

relay, and horn. The horn circuit feed is from the fuse

to the horn relay in the Power Distribution Center

(PDC). The PDC is mounted on the battery tray.

When the horn switch is depressed, it completes the

ground circuit. The horn relay coil closes contacts

and allows current to flow to the horn. The horn is

grounded to the headlamp ground connection (Fig. 1)

.

HORN SWITCH

The horn switch is mounted between the outer and

inner cover of the Driver Airbag Module (Fig. 2).

When the Driver Airbag is pressed the horn switch

makes contact to ground. The ground signal is car-

ried to the horn relay and the horn sounds.

(1) The horn switch grounds to the airbag housing.(2) If horn does not sound check for corrosion:

²Horn wire

²Horn switch ground connected to airbag metal

housing

²Airbag to steering wheel

²Ensure horn wire is properly connected and

insulator is in place on wire

(3) Refer to Group 8W, Wiring Diagrams if wire

circuit needs to be repaired.

DIAGNOSIS AND TESTING

HORN

(1) Disconnect wire connector at horn.

(2) Using a voltmeter, connect one lead to ground

terminal and the other lead to the positive wire ter-

minal (Fig. 3).

(3) Depress the horn switch, battery voltage

should be present.

(4) If no voltage, refer to Horn System Test. If volt-

age is OK, go to Step 5.

Fig. 1 Horn System

Fig. 2 Horn Switch

PLHORNS 8G - 1