steering DODGE NEON 1999 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 296 of 1200

the correct fuse. If the horn fail to sound and the

new fuse blows when depressing the horn switch, a

short circuit in the horn or the horn wiring between

the fuse terminal and the horn is responsible, or a

defective horn switch allowed the horn to burn out is

responsible.

If the fuse is OK, test horn relay refer to Horn

Relay Test.

If the relay is OK, test horn refer to Horn Test.CAUTION: Continuous sounding of horn may

cause horn relay to fail.

Should the horn sound continuously:

²Unplug the horn relay from Power Distribution

Center.

²Refer to Horn Relay Test.

Refer to Group 8W, wiring Disgrams for circuit and

wiring information.

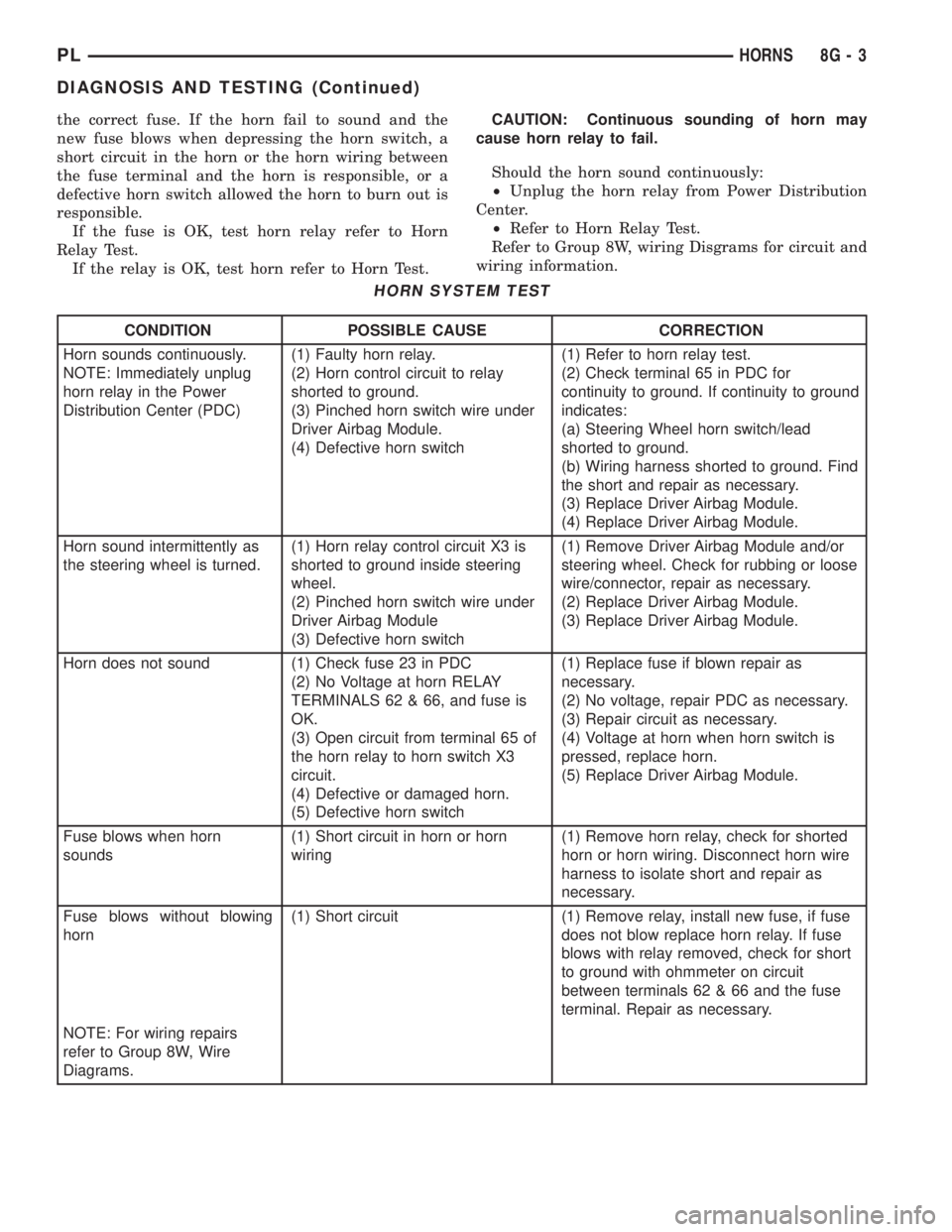

HORN SYSTEM TEST

CONDITION POSSIBLE CAUSE CORRECTION

Horn sounds continuously.

NOTE: Immediately unplug

horn relay in the Power

Distribution Center (PDC)(1) Faulty horn relay.

(2) Horn control circuit to relay

shorted to ground.

(3) Pinched horn switch wire under

Driver Airbag Module.

(4) Defective horn switch(1) Refer to horn relay test.

(2) Check terminal 65 in PDC for

continuity to ground. If continuity to ground

indicates:

(a) Steering Wheel horn switch/lead

shorted to ground.

(b) Wiring harness shorted to ground. Find

the short and repair as necessary.

(3) Replace Driver Airbag Module.

(4) Replace Driver Airbag Module.

Horn sound intermittently as

the steering wheel is turned.(1) Horn relay control circuit X3 is

shorted to ground inside steering

wheel.

(2) Pinched horn switch wire under

Driver Airbag Module

(3) Defective horn switch(1) Remove Driver Airbag Module and/or

steering wheel. Check for rubbing or loose

wire/connector, repair as necessary.

(2) Replace Driver Airbag Module.

(3) Replace Driver Airbag Module.

Horn does not sound (1) Check fuse 23 in PDC

(2) No Voltage at horn RELAY

TERMINALS 62 & 66, and fuse is

OK.

(3) Open circuit from terminal 65 of

the horn relay to horn switch X3

circuit.

(4) Defective or damaged horn.

(5) Defective horn switch(1) Replace fuse if blown repair as

necessary.

(2) No voltage, repair PDC as necessary.

(3) Repair circuit as necessary.

(4) Voltage at horn when horn switch is

pressed, replace horn.

(5) Replace Driver Airbag Module.

Fuse blows when horn

sounds(1) Short circuit in horn or horn

wiring(1) Remove horn relay, check for shorted

horn or horn wiring. Disconnect horn wire

harness to isolate short and repair as

necessary.

Fuse blows without blowing

horn(1) Short circuit (1) Remove relay, install new fuse, if fuse

does not blow replace horn relay. If fuse

blows with relay removed, check for short

to ground with ohmmeter on circuit

between terminals 62 & 66 and the fuse

terminal. Repair as necessary.

NOTE: For wiring repairs

refer to Group 8W, Wire

Diagrams.

PLHORNS 8G - 3

DIAGNOSIS AND TESTING (Continued)

Page 298 of 1200

VEHICLE SPEED CONTROL SYSTEM

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

POWERTRAIN CONTROL MODULE.......... 3

SERVO CABLE.......................... 3

SPEED CONTROL SERVO.................. 1

SPEED CONTROL SWITCHES.............. 2

STOP LAMP SWITCH..................... 3

VACUUM RESERVOIR.................... 3

VEHICLE SPEED AND DISTANCE............ 3

DIAGNOSIS AND TESTING

CHECKING FOR DIAGNOSTIC CODES........ 4

ELECTRICAL TESTS AT POWERTRAIN

CONTROL MODULE..................... 7

OVERSHOOT/UNDERSHOOT FOLLOWING

SPEED CONTROL SET................... 6ROAD TEST............................ 3

SERVO VACUUM TEST.................... 6

SPEED CONTROL ELECTRICAL TEST........ 4

SPEED CONTROL SWITCH TEST............ 6

STOP LAMP SWITCH TEST................ 6

VACUUM SUPPLY TEST................... 8

VEHICLE SPEED SENSOR................. 8

REMOVAL AND INSTALLATION

POWERTRAIN CONTROL MODULE......... 10

SPEED CONTROL SERVO CABLE............ 9

SPEED CONTROL SERVO.................. 8

SPEED CONTROL SWITCH................. 8

STOP LAMP SWITCH.................... 8

VACUUM RESERVOIR................... 10

VEHICLE SPEED SENSOR................ 10

GENERAL INFORMATION

INTRODUCTION

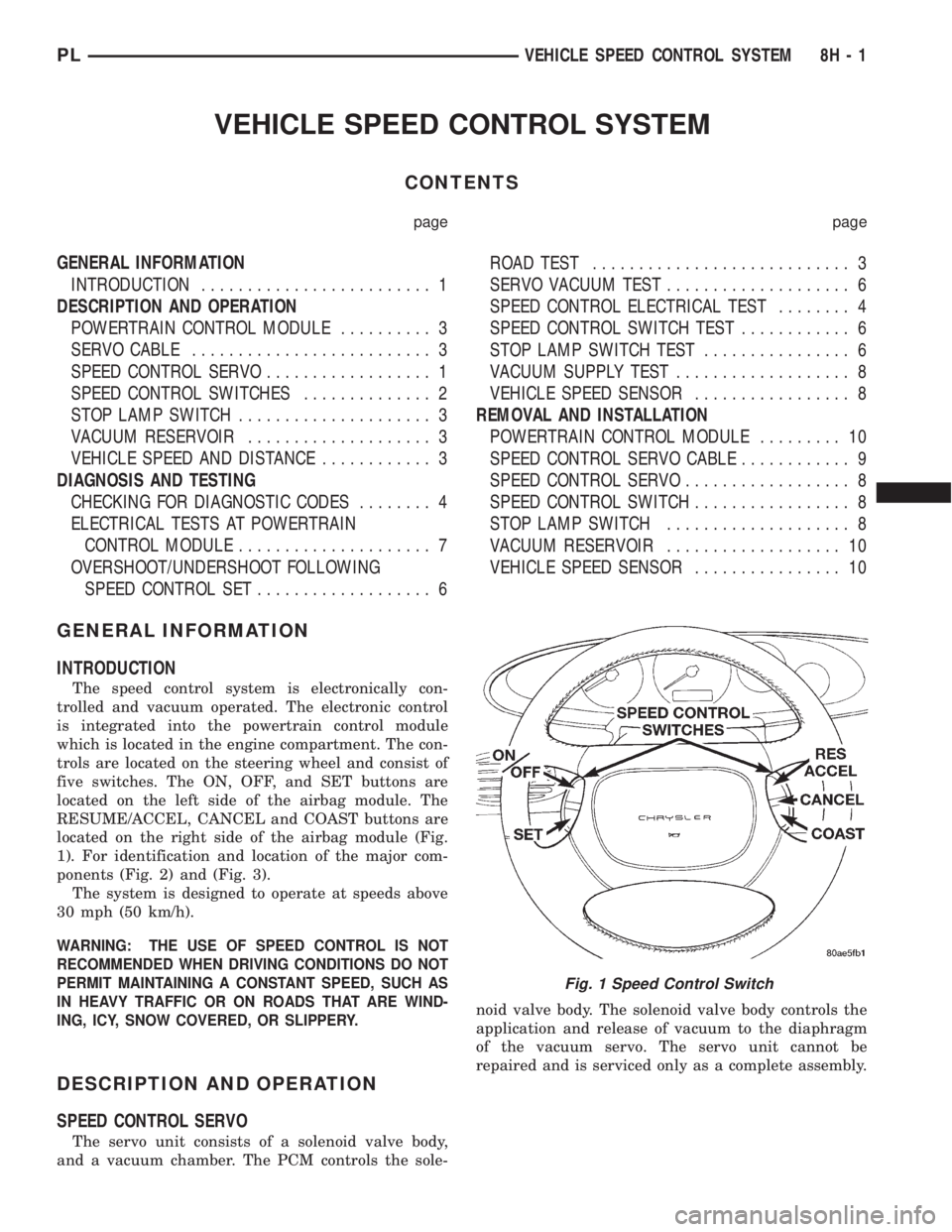

The speed control system is electronically con-

trolled and vacuum operated. The electronic control

is integrated into the powertrain control module

which is located in the engine compartment. The con-

trols are located on the steering wheel and consist of

five switches. The ON, OFF, and SET buttons are

located on the left side of the airbag module. The

RESUME/ACCEL, CANCEL and COAST buttons are

located on the right side of the airbag module (Fig.

1). For identification and location of the major com-

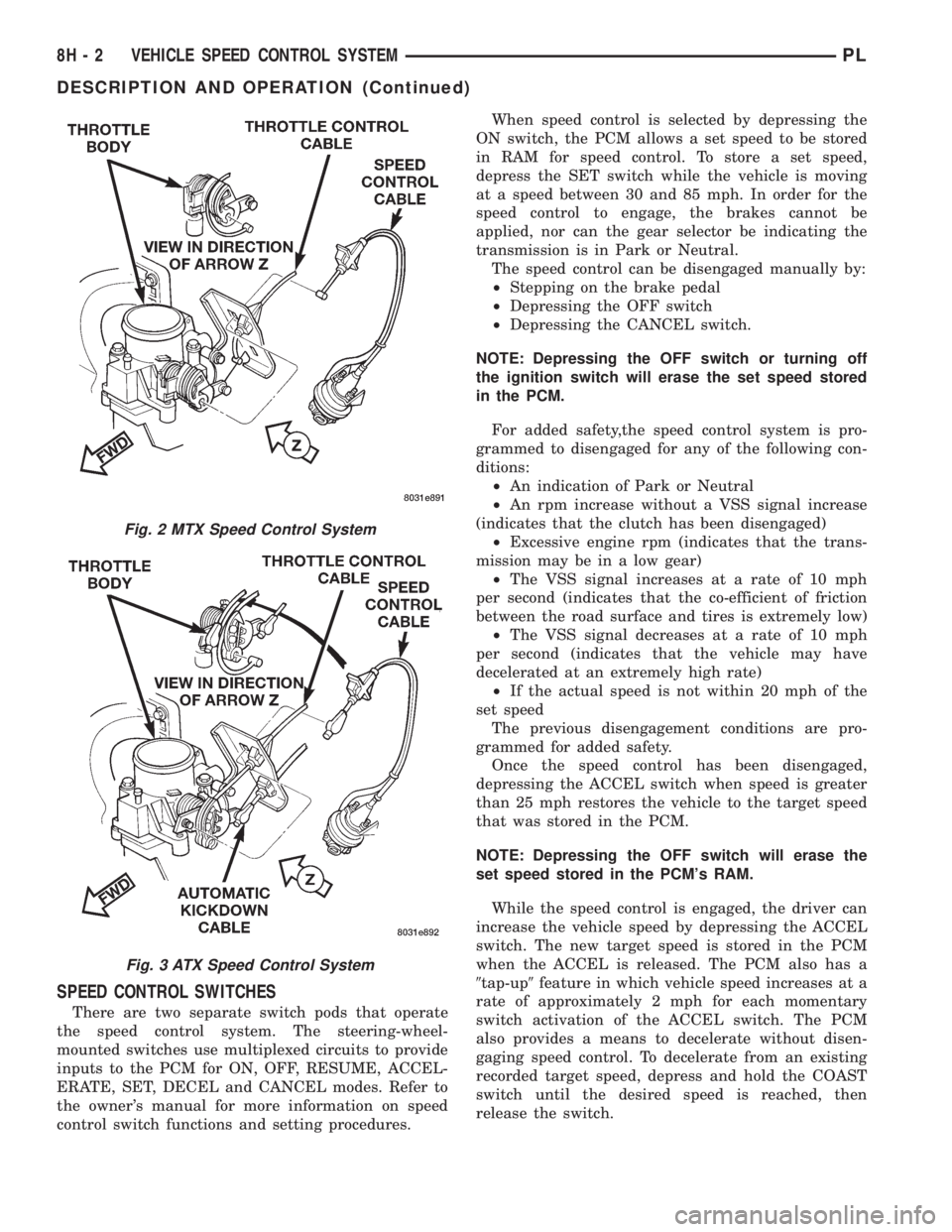

ponents (Fig. 2) and (Fig. 3).

The system is designed to operate at speeds above

30 mph (50 km/h).

WARNING: THE USE OF SPEED CONTROL IS NOT

RECOMMENDED WHEN DRIVING CONDITIONS DO NOT

PERMIT MAINTAINING A CONSTANT SPEED, SUCH AS

IN HEAVY TRAFFIC OR ON ROADS THAT ARE WIND-

ING, ICY, SNOW COVERED, OR SLIPPERY.

DESCRIPTION AND OPERATION

SPEED CONTROL SERVO

The servo unit consists of a solenoid valve body,

and a vacuum chamber. The PCM controls the sole-noid valve body. The solenoid valve body controls the

application and release of vacuum to the diaphragm

of the vacuum servo. The servo unit cannot be

repaired and is serviced only as a complete assembly.

Fig. 1 Speed Control Switch

PLVEHICLE SPEED CONTROL SYSTEM 8H - 1

Page 299 of 1200

SPEED CONTROL SWITCHES

There are two separate switch pods that operate

the speed control system. The steering-wheel-

mounted switches use multiplexed circuits to provide

inputs to the PCM for ON, OFF, RESUME, ACCEL-

ERATE, SET, DECEL and CANCEL modes. Refer to

the owner's manual for more information on speed

control switch functions and setting procedures.When speed control is selected by depressing the

ON switch, the PCM allows a set speed to be stored

in RAM for speed control. To store a set speed,

depress the SET switch while the vehicle is moving

at a speed between 30 and 85 mph. In order for the

speed control to engage, the brakes cannot be

applied, nor can the gear selector be indicating the

transmission is in Park or Neutral.

The speed control can be disengaged manually by:

²Stepping on the brake pedal

²Depressing the OFF switch

²Depressing the CANCEL switch.

NOTE: Depressing the OFF switch or turning off

the ignition switch will erase the set speed stored

in the PCM.

For added safety,the speed control system is pro-

grammed to disengaged for any of the following con-

ditions:

²An indication of Park or Neutral

²An rpm increase without a VSS signal increase

(indicates that the clutch has been disengaged)

²Excessive engine rpm (indicates that the trans-

mission may be in a low gear)

²The VSS signal increases at a rate of 10 mph

per second (indicates that the co-efficient of friction

between the road surface and tires is extremely low)

²The VSS signal decreases at a rate of 10 mph

per second (indicates that the vehicle may have

decelerated at an extremely high rate)

²If the actual speed is not within 20 mph of the

set speed

The previous disengagement conditions are pro-

grammed for added safety.

Once the speed control has been disengaged,

depressing the ACCEL switch when speed is greater

than 25 mph restores the vehicle to the target speed

that was stored in the PCM.

NOTE: Depressing the OFF switch will erase the

set speed stored in the PCM's RAM.

While the speed control is engaged, the driver can

increase the vehicle speed by depressing the ACCEL

switch. The new target speed is stored in the PCM

when the ACCEL is released. The PCM also has a

9tap-up9feature in which vehicle speed increases at a

rate of approximately 2 mph for each momentary

switch activation of the ACCEL switch. The PCM

also provides a means to decelerate without disen-

gaging speed control. To decelerate from an existing

recorded target speed, depress and hold the COAST

switch until the desired speed is reached, then

release the switch.

Fig. 2 MTX Speed Control System

Fig. 3 ATX Speed Control System

8H - 2 VEHICLE SPEED CONTROL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 301 of 1200

CHECKING FOR DIAGNOSTIC CODES

When trying to verify a speed control system elec-

tronic malfunction: Connect a DRB scan tool if avail-

able to the data link connector. The connector is

located at left side of the steering column, and at

lower edge of the panel.

(1) A speed control malfunction may occur without

a diagnostic code being indicated.

Refer to Group 25, for further information and use-

age of the DRB scan tool and a more complete list of

Diagnostic Trouble Code.

SPEED CONTROL SLOWS DOWN BY ITSELF

Test vehicle speed sensor, refer to group 8E. If sen-

sor fails replace sensor, if it passes perform the fol-

lowing test:

(1) Perform the speed control switch test on the

DECEL switch, if it fails replace switch.

(2) If the switch passes, conduct the vacuum sup-

ply test.

(3) If it passes, conduct the servo vacuum test. If it

fails replace servo.

(4) If continuity, replace the PCM.

SPEED CONTROL ELECTRICAL TEST

Electronic speed control systems may be tested

using two different methods. One involves use of aDRB. If this test method is desired, refer to the Pow-

ertrain Diagnostic Test Procedures for charging and

speed control system manual.

The other test method uses a volt/ohm meter. The

volt/ohm meter method is described in the following

tests.

If any information is needed concerning wiring,

refer to Group 8W, Wiring Diagrams (Fig. 4).

CAUTION: When test probing for voltage or conti-

nuity at electrical connectors, care must be taken

not to damage connector, terminals, or seals. If

these components are damaged, intermittent or

complete system failure may occur.

When electrical connections are removed, corrosion

should be removed from electrical terminals and a

light coating of Mopar Multi-Purpose Grease, or

equivalent, applied. Inspect connectors for damage

terminals.

A poor connection can cause a complete or inter-

mittent malfunction and is also the only connection

in the circuit, that can not be tested. For this reason,

a loose connection may be misdiagnosed as a compo-

nent malfunction.

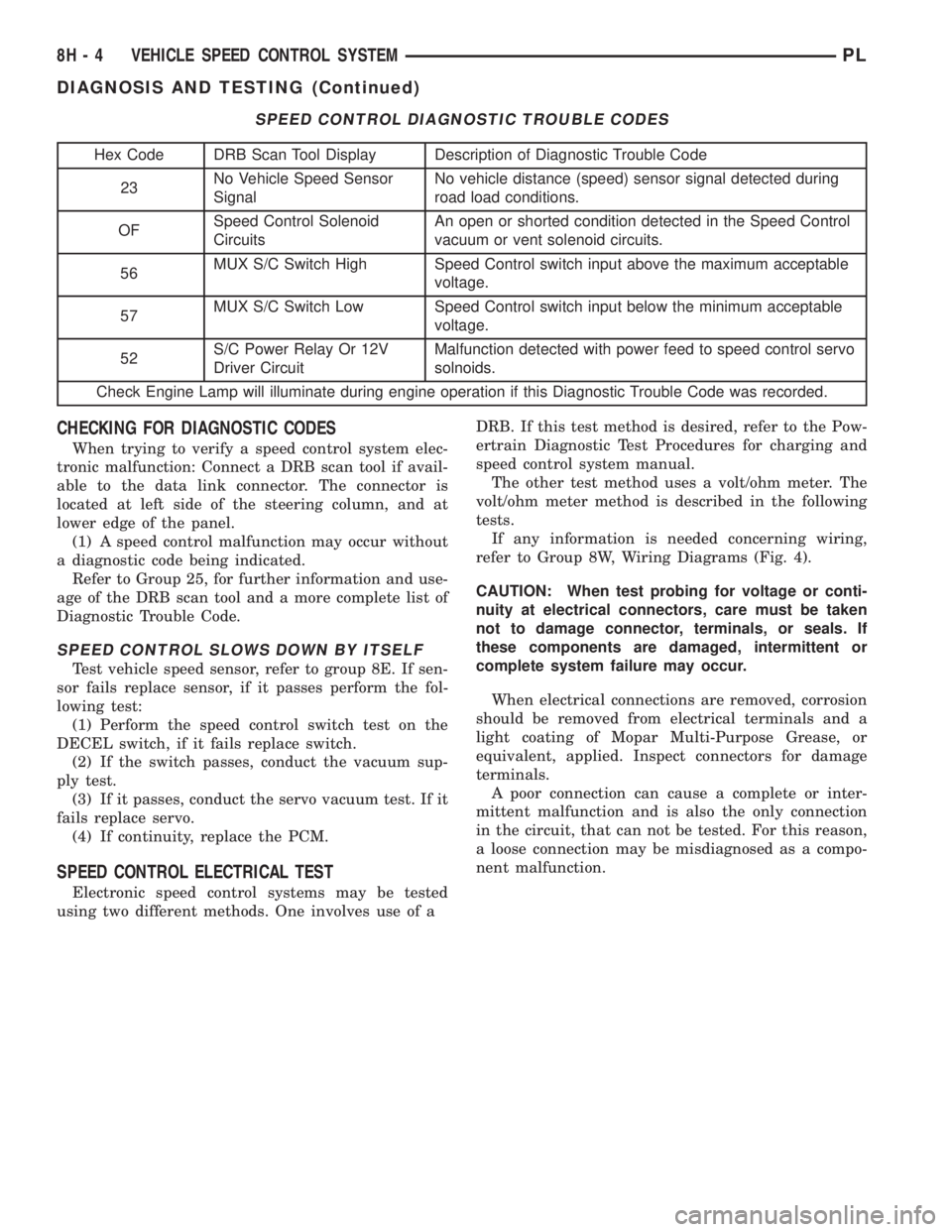

SPEED CONTROL DIAGNOSTIC TROUBLE CODES

Hex Code DRB Scan Tool Display Description of Diagnostic Trouble Code

23No Vehicle Speed Sensor

SignalNo vehicle distance (speed) sensor signal detected during

road load conditions.

OFSpeed Control Solenoid

CircuitsAn open or shorted condition detected in the Speed Control

vacuum or vent solenoid circuits.

56MUX S/C Switch High Speed Control switch input above the maximum acceptable

voltage.

57MUX S/C Switch Low Speed Control switch input below the minimum acceptable

voltage.

52S/C Power Relay Or 12V

Driver CircuitMalfunction detected with power feed to speed control servo

solnoids.

Check Engine Lamp will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

8H - 4 VEHICLE SPEED CONTROL SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 304 of 1200

(5) Stop lamp switch adjustment is detailed in

Group 5, Brakes.

ELECTRICAL TESTS AT POWERTRAIN CONTROL

MODULE

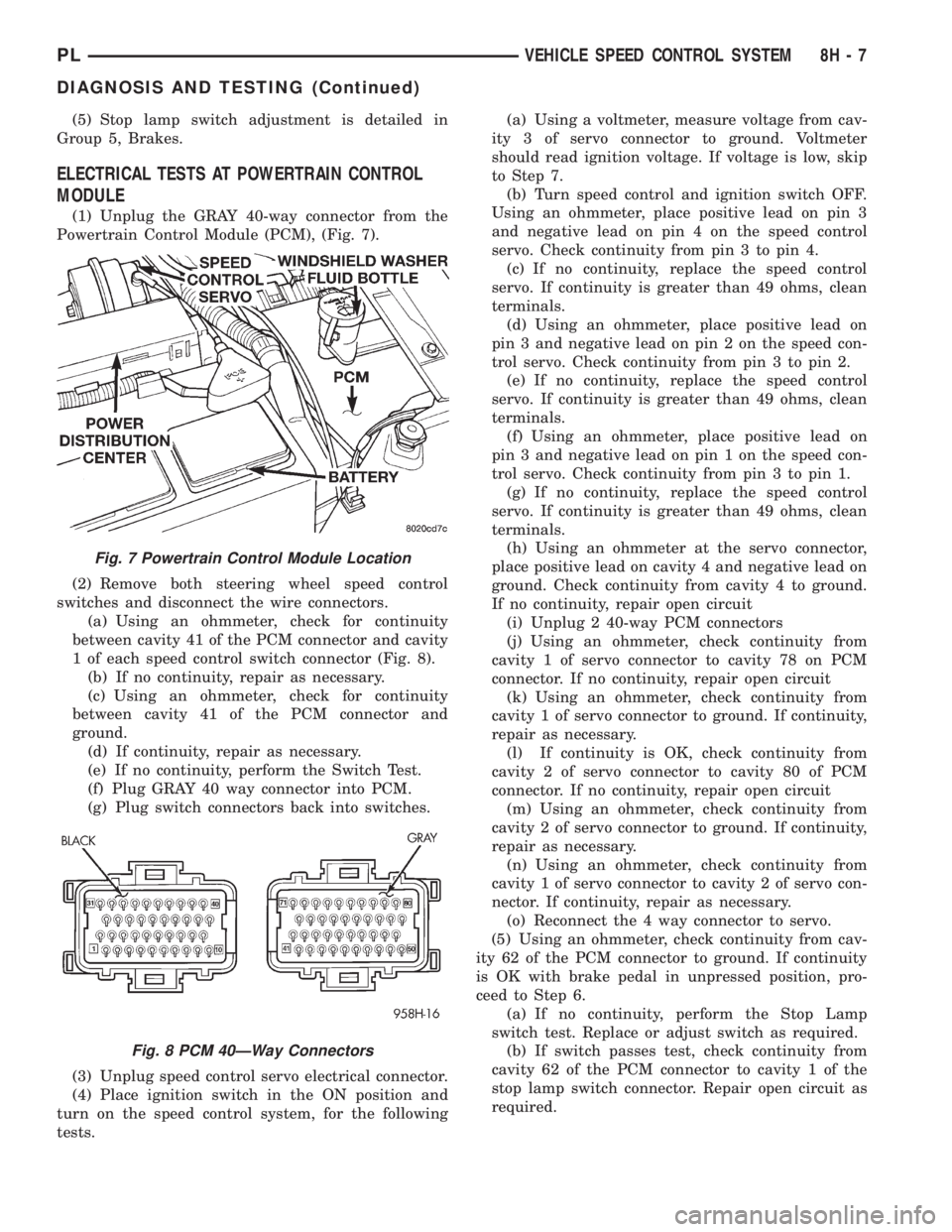

(1) Unplug the GRAY 40-way connector from the

Powertrain Control Module (PCM), (Fig. 7).

(2) Remove both steering wheel speed control

switches and disconnect the wire connectors.

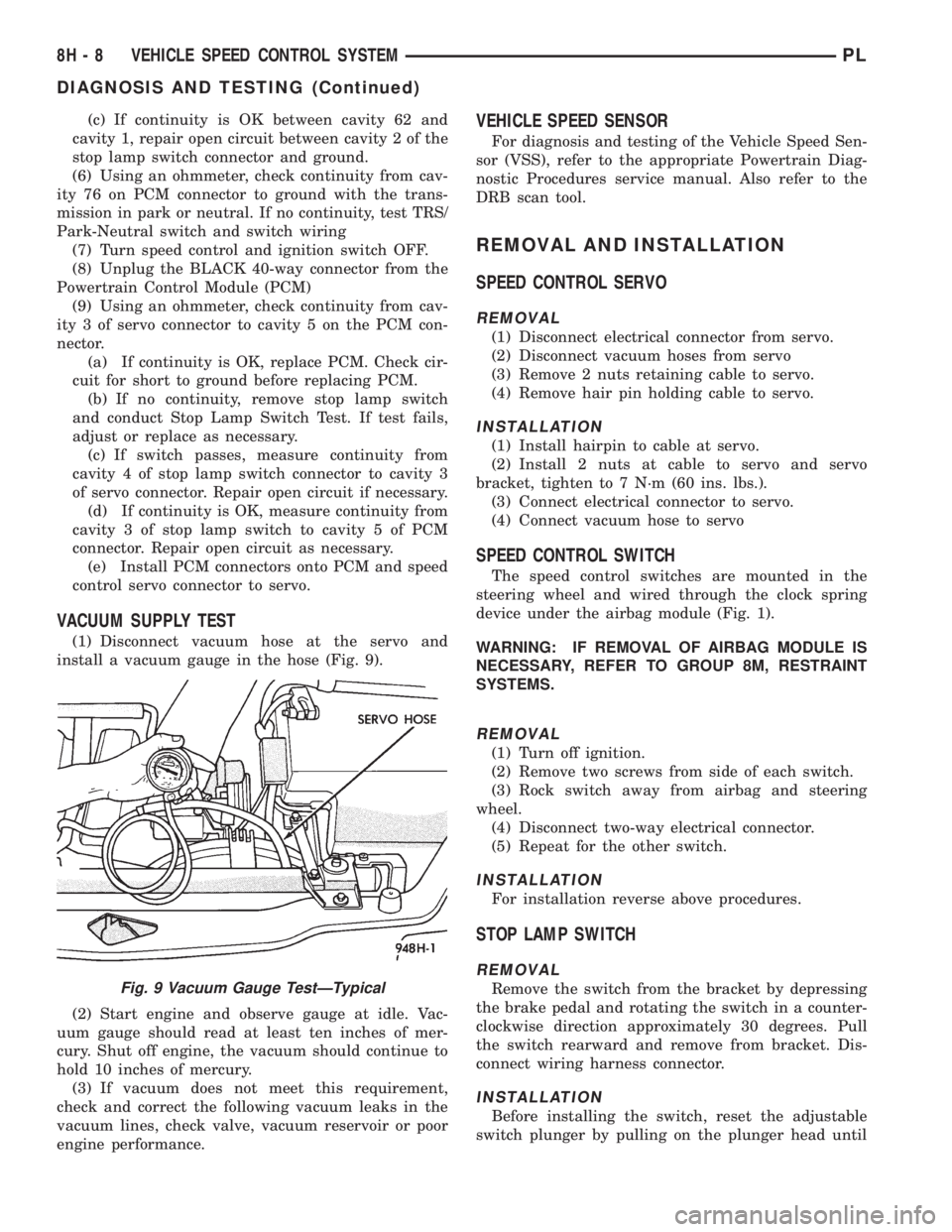

(a) Using an ohmmeter, check for continuity

between cavity 41 of the PCM connector and cavity

1 of each speed control switch connector (Fig. 8).

(b) If no continuity, repair as necessary.

(c) Using an ohmmeter, check for continuity

between cavity 41 of the PCM connector and

ground.

(d) If continuity, repair as necessary.

(e) If no continuity, perform the Switch Test.

(f) Plug GRAY 40 way connector into PCM.

(g) Plug switch connectors back into switches.

(3) Unplug speed control servo electrical connector.

(4) Place ignition switch in the ON position and

turn on the speed control system, for the following

tests.(a) Using a voltmeter, measure voltage from cav-

ity 3 of servo connector to ground. Voltmeter

should read ignition voltage. If voltage is low, skip

to Step 7.

(b) Turn speed control and ignition switch OFF.

Using an ohmmeter, place positive lead on pin 3

and negative lead on pin 4 on the speed control

servo. Check continuity from pin 3 to pin 4.

(c) If no continuity, replace the speed control

servo. If continuity is greater than 49 ohms, clean

terminals.

(d) Using an ohmmeter, place positive lead on

pin 3 and negative lead on pin 2 on the speed con-

trol servo. Check continuity from pin 3 to pin 2.

(e) If no continuity, replace the speed control

servo. If continuity is greater than 49 ohms, clean

terminals.

(f) Using an ohmmeter, place positive lead on

pin 3 and negative lead on pin 1 on the speed con-

trol servo. Check continuity from pin 3 to pin 1.

(g) If no continuity, replace the speed control

servo. If continuity is greater than 49 ohms, clean

terminals.

(h) Using an ohmmeter at the servo connector,

place positive lead on cavity 4 and negative lead on

ground. Check continuity from cavity 4 to ground.

If no continuity, repair open circuit

(i) Unplug 2 40-way PCM connectors

(j) Using an ohmmeter, check continuity from

cavity 1 of servo connector to cavity 78 on PCM

connector. If no continuity, repair open circuit

(k) Using an ohmmeter, check continuity from

cavity 1 of servo connector to ground. If continuity,

repair as necessary.

(l) If continuity is OK, check continuity from

cavity 2 of servo connector to cavity 80 of PCM

connector. If no continuity, repair open circuit

(m) Using an ohmmeter, check continuity from

cavity 2 of servo connector to ground. If continuity,

repair as necessary.

(n) Using an ohmmeter, check continuity from

cavity 1 of servo connector to cavity 2 of servo con-

nector. If continuity, repair as necessary.

(o) Reconnect the 4 way connector to servo.

(5) Using an ohmmeter, check continuity from cav-

ity 62 of the PCM connector to ground. If continuity

is OK with brake pedal in unpressed position, pro-

ceed to Step 6.

(a) If no continuity, perform the Stop Lamp

switch test. Replace or adjust switch as required.

(b) If switch passes test, check continuity from

cavity 62 of the PCM connector to cavity 1 of the

stop lamp switch connector. Repair open circuit as

required.

Fig. 7 Powertrain Control Module Location

Fig. 8 PCM 40ÐWay Connectors

PLVEHICLE SPEED CONTROL SYSTEM 8H - 7

DIAGNOSIS AND TESTING (Continued)

Page 305 of 1200

(c) If continuity is OK between cavity 62 and

cavity 1, repair open circuit between cavity 2 of the

stop lamp switch connector and ground.

(6) Using an ohmmeter, check continuity from cav-

ity 76 on PCM connector to ground with the trans-

mission in park or neutral. If no continuity, test TRS/

Park-Neutral switch and switch wiring

(7) Turn speed control and ignition switch OFF.

(8) Unplug the BLACK 40-way connector from the

Powertrain Control Module (PCM)

(9) Using an ohmmeter, check continuity from cav-

ity 3 of servo connector to cavity 5 on the PCM con-

nector.

(a) If continuity is OK, replace PCM. Check cir-

cuit for short to ground before replacing PCM.

(b) If no continuity, remove stop lamp switch

and conduct Stop Lamp Switch Test. If test fails,

adjust or replace as necessary.

(c) If switch passes, measure continuity from

cavity 4 of stop lamp switch connector to cavity 3

of servo connector. Repair open circuit if necessary.

(d) If continuity is OK, measure continuity from

cavity 3 of stop lamp switch to cavity 5 of PCM

connector. Repair open circuit as necessary.

(e) Install PCM connectors onto PCM and speed

control servo connector to servo.

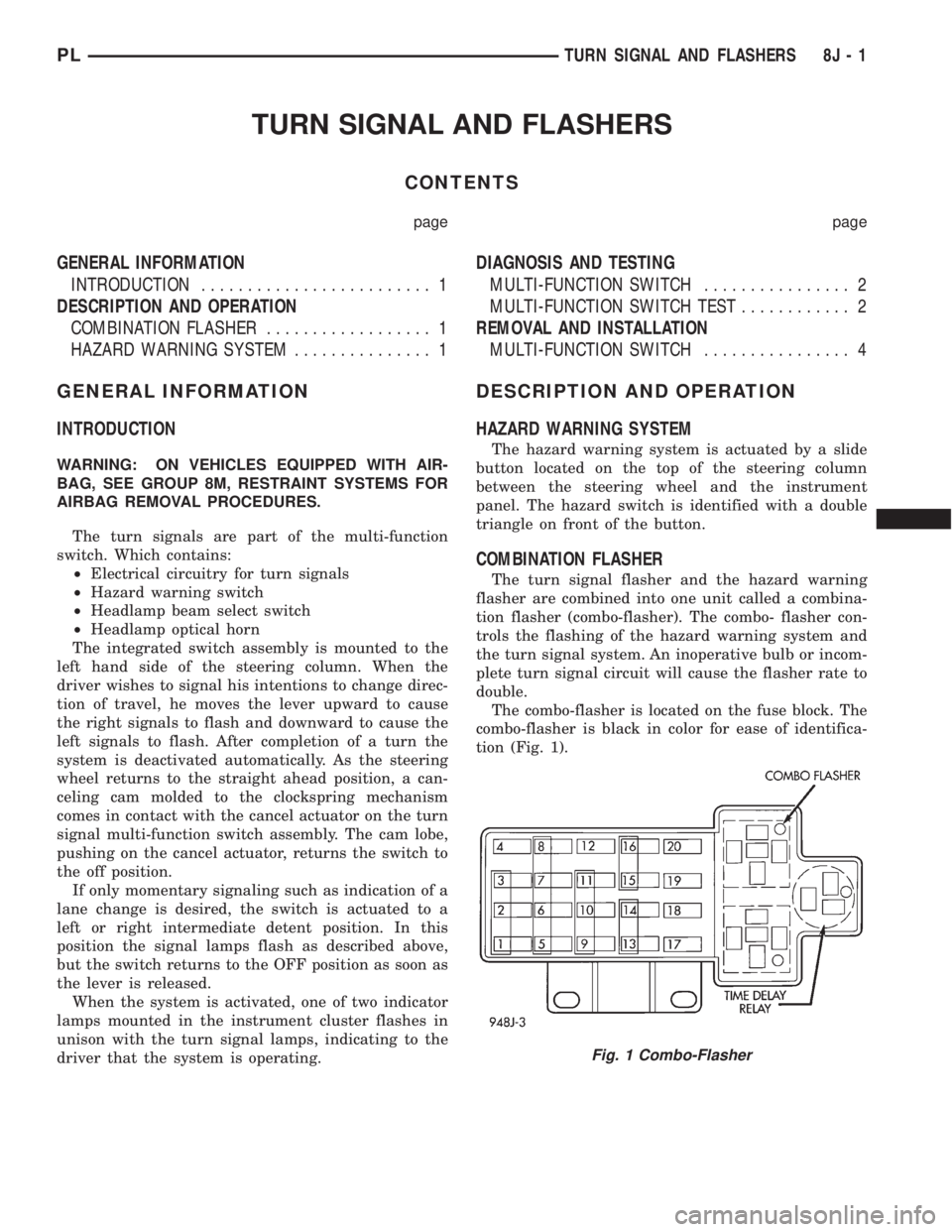

VACUUM SUPPLY TEST

(1) Disconnect vacuum hose at the servo and

install a vacuum gauge in the hose (Fig. 9).

(2) Start engine and observe gauge at idle. Vac-

uum gauge should read at least ten inches of mer-

cury. Shut off engine, the vacuum should continue to

hold 10 inches of mercury.

(3) If vacuum does not meet this requirement,

check and correct the following vacuum leaks in the

vacuum lines, check valve, vacuum reservoir or poor

engine performance.

VEHICLE SPEED SENSOR

For diagnosis and testing of the Vehicle Speed Sen-

sor (VSS), refer to the appropriate Powertrain Diag-

nostic Procedures service manual. Also refer to the

DRB scan tool.

REMOVAL AND INSTALLATION

SPEED CONTROL SERVO

REMOVAL

(1) Disconnect electrical connector from servo.

(2) Disconnect vacuum hoses from servo

(3) Remove 2 nuts retaining cable to servo.

(4) Remove hair pin holding cable to servo.

INSTALLATION

(1) Install hairpin to cable at servo.

(2) Install 2 nuts at cable to servo and servo

bracket, tighten to 7 N´m (60 ins. lbs.).

(3) Connect electrical connector to servo.

(4) Connect vacuum hose to servo

SPEED CONTROL SWITCH

The speed control switches are mounted in the

steering wheel and wired through the clock spring

device under the airbag module (Fig. 1).

WARNING: IF REMOVAL OF AIRBAG MODULE IS

NECESSARY, REFER TO GROUP 8M, RESTRAINT

SYSTEMS.

REMOVAL

(1) Turn off ignition.

(2) Remove two screws from side of each switch.

(3) Rock switch away from airbag and steering

wheel.

(4) Disconnect two-way electrical connector.

(5) Repeat for the other switch.

INSTALLATION

For installation reverse above procedures.

STOP LAMP SWITCH

REMOVAL

Remove the switch from the bracket by depressing

the brake pedal and rotating the switch in a counter-

clockwise direction approximately 30 degrees. Pull

the switch rearward and remove from bracket. Dis-

connect wiring harness connector.

INSTALLATION

Before installing the switch, reset the adjustable

switch plunger by pulling on the plunger head until

Fig. 9 Vacuum Gauge TestÐTypical

8H - 8 VEHICLE SPEED CONTROL SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 310 of 1200

TURN SIGNAL AND FLASHERS

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

COMBINATION FLASHER.................. 1

HAZARD WARNING SYSTEM............... 1DIAGNOSIS AND TESTING

MULTI-FUNCTION SWITCH................ 2

MULTI-FUNCTION SWITCH TEST............ 2

REMOVAL AND INSTALLATION

MULTI-FUNCTION SWITCH................ 4

GENERAL INFORMATION

INTRODUCTION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

AIRBAG REMOVAL PROCEDURES.

The turn signals are part of the multi-function

switch. Which contains:

²Electrical circuitry for turn signals

²Hazard warning switch

²Headlamp beam select switch

²Headlamp optical horn

The integrated switch assembly is mounted to the

left hand side of the steering column. When the

driver wishes to signal his intentions to change direc-

tion of travel, he moves the lever upward to cause

the right signals to flash and downward to cause the

left signals to flash. After completion of a turn the

system is deactivated automatically. As the steering

wheel returns to the straight ahead position, a can-

celing cam molded to the clockspring mechanism

comes in contact with the cancel actuator on the turn

signal multi-function switch assembly. The cam lobe,

pushing on the cancel actuator, returns the switch to

the off position.

If only momentary signaling such as indication of a

lane change is desired, the switch is actuated to a

left or right intermediate detent position. In this

position the signal lamps flash as described above,

but the switch returns to the OFF position as soon as

the lever is released.

When the system is activated, one of two indicator

lamps mounted in the instrument cluster flashes in

unison with the turn signal lamps, indicating to the

driver that the system is operating.

DESCRIPTION AND OPERATION

HAZARD WARNING SYSTEM

The hazard warning system is actuated by a slide

button located on the top of the steering column

between the steering wheel and the instrument

panel. The hazard switch is identified with a double

triangle on front of the button.

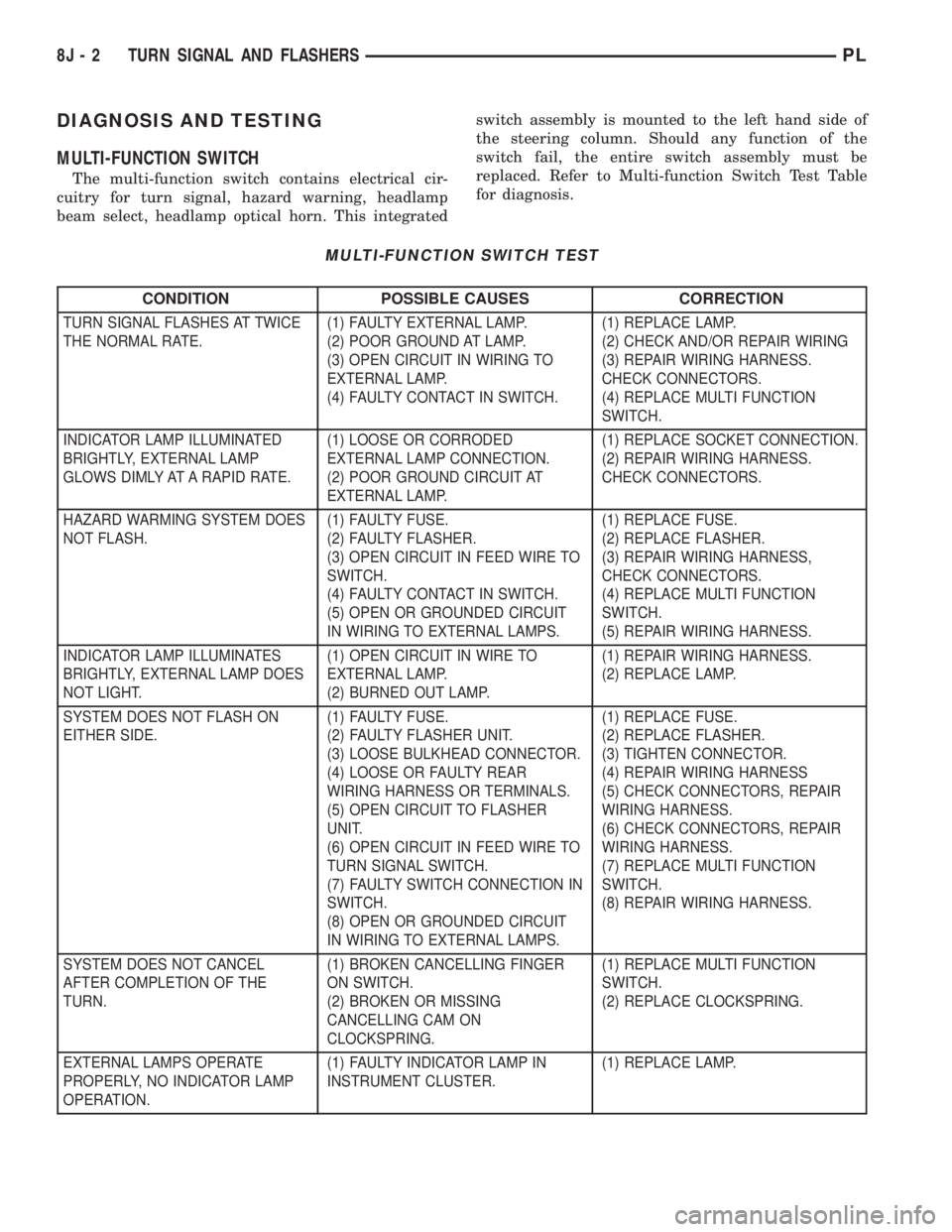

COMBINATION FLASHER

The turn signal flasher and the hazard warning

flasher are combined into one unit called a combina-

tion flasher (combo-flasher). The combo- flasher con-

trols the flashing of the hazard warning system and

the turn signal system. An inoperative bulb or incom-

plete turn signal circuit will cause the flasher rate to

double.

The combo-flasher is located on the fuse block. The

combo-flasher is black in color for ease of identifica-

tion (Fig. 1).

Fig. 1 Combo-Flasher

PLTURN SIGNAL AND FLASHERS 8J - 1

Page 311 of 1200

DIAGNOSIS AND TESTING

MULTI-FUNCTION SWITCH

The multi-function switch contains electrical cir-

cuitry for turn signal, hazard warning, headlamp

beam select, headlamp optical horn. This integratedswitch assembly is mounted to the left hand side of

the steering column. Should any function of the

switch fail, the entire switch assembly must be

replaced. Refer to Multi-function Switch Test Table

for diagnosis.

MULTI-FUNCTION SWITCH TEST

CONDITION POSSIBLE CAUSES CORRECTION

TURN SIGNAL FLASHES AT TWICE

THE NORMAL RATE.(1) FAULTY EXTERNAL LAMP.

(2) POOR GROUND AT LAMP.

(3) OPEN CIRCUIT IN WIRING TO

EXTERNAL LAMP.

(4) FAULTY CONTACT IN SWITCH.(1) REPLACE LAMP.

(2) CHECK AND/OR REPAIR WIRING

(3) REPAIR WIRING HARNESS.

CHECK CONNECTORS.

(4) REPLACE MULTI FUNCTION

SWITCH.

INDICATOR LAMP ILLUMINATED

BRIGHTLY, EXTERNAL LAMP

GLOWS DIMLY AT A RAPID RATE.(1) LOOSE OR CORRODED

EXTERNAL LAMP CONNECTION.

(2) POOR GROUND CIRCUIT AT

EXTERNAL LAMP.(1) REPLACE SOCKET CONNECTION.

(2) REPAIR WIRING HARNESS.

CHECK CONNECTORS.

HAZARD WARMING SYSTEM DOES

NOT FLASH.(1) FAULTY FUSE.

(2) FAULTY FLASHER.

(3) OPEN CIRCUIT IN FEED WIRE TO

SWITCH.

(4) FAULTY CONTACT IN SWITCH.

(5) OPEN OR GROUNDED CIRCUIT

IN WIRING TO EXTERNAL LAMPS.(1) REPLACE FUSE.

(2) REPLACE FLASHER.

(3) REPAIR WIRING HARNESS,

CHECK CONNECTORS.

(4) REPLACE MULTI FUNCTION

SWITCH.

(5) REPAIR WIRING HARNESS.

INDICATOR LAMP ILLUMINATES

BRIGHTLY, EXTERNAL LAMP DOES

NOT LIGHT.(1) OPEN CIRCUIT IN WIRE TO

EXTERNAL LAMP.

(2) BURNED OUT LAMP.(1) REPAIR WIRING HARNESS.

(2) REPLACE LAMP.

SYSTEM DOES NOT FLASH ON

EITHER SIDE.(1) FAULTY FUSE.

(2) FAULTY FLASHER UNIT.

(3) LOOSE BULKHEAD CONNECTOR.

(4) LOOSE OR FAULTY REAR

WIRING HARNESS OR TERMINALS.

(5) OPEN CIRCUIT TO FLASHER

UNIT.

(6) OPEN CIRCUIT IN FEED WIRE TO

TURN SIGNAL SWITCH.

(7) FAULTY SWITCH CONNECTION IN

SWITCH.

(8) OPEN OR GROUNDED CIRCUIT

IN WIRING TO EXTERNAL LAMPS.(1) REPLACE FUSE.

(2) REPLACE FLASHER.

(3) TIGHTEN CONNECTOR.

(4) REPAIR WIRING HARNESS

(5) CHECK CONNECTORS, REPAIR

WIRING HARNESS.

(6) CHECK CONNECTORS, REPAIR

WIRING HARNESS.

(7) REPLACE MULTI FUNCTION

SWITCH.

(8) REPAIR WIRING HARNESS.

SYSTEM DOES NOT CANCEL

AFTER COMPLETION OF THE

TURN.(1) BROKEN CANCELLING FINGER

ON SWITCH.

(2) BROKEN OR MISSING

CANCELLING CAM ON

CLOCKSPRING.(1) REPLACE MULTI FUNCTION

SWITCH.

(2) REPLACE CLOCKSPRING.

EXTERNAL LAMPS OPERATE

PROPERLY, NO INDICATOR LAMP

OPERATION.(1) FAULTY INDICATOR LAMP IN

INSTRUMENT CLUSTER.(1) REPLACE LAMP.

8J - 2 TURN SIGNAL AND FLASHERSPL

Page 313 of 1200

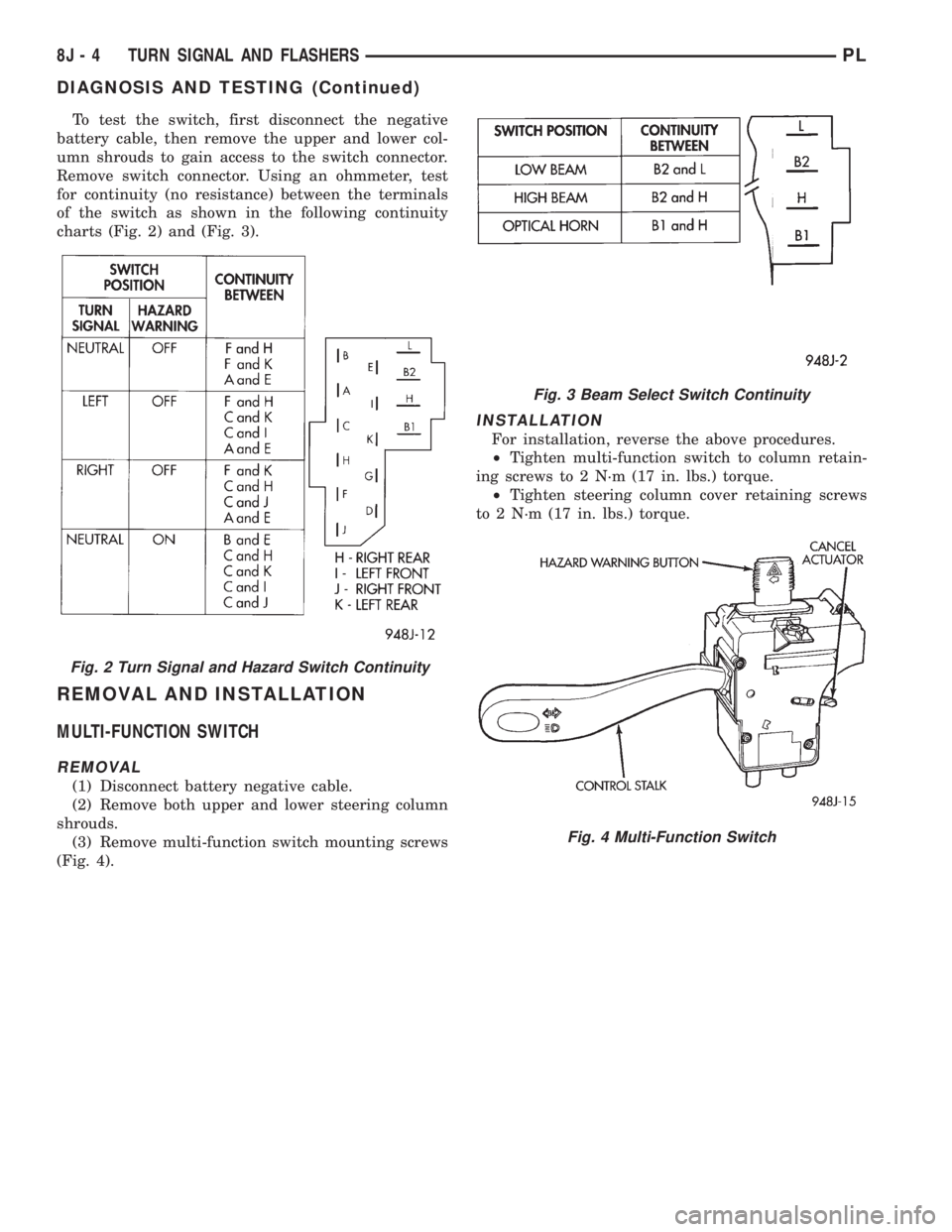

To test the switch, first disconnect the negative

battery cable, then remove the upper and lower col-

umn shrouds to gain access to the switch connector.

Remove switch connector. Using an ohmmeter, test

for continuity (no resistance) between the terminals

of the switch as shown in the following continuity

charts (Fig. 2) and (Fig. 3).

REMOVAL AND INSTALLATION

MULTI-FUNCTION SWITCH

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove both upper and lower steering column

shrouds.

(3) Remove multi-function switch mounting screws

(Fig. 4).

INSTALLATION

For installation, reverse the above procedures.

²Tighten multi-function switch to column retain-

ing screws to 2 N´m (17 in. lbs.) torque.

²Tighten steering column cover retaining screws

to 2 N´m (17 in. lbs.) torque.

Fig. 2 Turn Signal and Hazard Switch Continuity

Fig. 3 Beam Select Switch Continuity

Fig. 4 Multi-Function Switch

8J - 4 TURN SIGNAL AND FLASHERSPL

DIAGNOSIS AND TESTING (Continued)

Page 314 of 1200

WINDSHIELD WIPERS AND WASHERS

CONTENTS

page page

WINDSHIELD WASHER SYSTEM............. 8WINDSHIELD WIPERS..................... 1

WINDSHIELD WIPERS

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

WIPER BLADES.......................... 1

DIAGNOSIS AND TESTING

WINDSHIELD WIPER CONDITION............ 2

WIPER MOTOR.......................... 3

WIPER SWITCH.......................... 5

REMOVAL AND INSTALLATION

WIPER ARM............................. 5WIPER BLADE ELEMENT.................. 5

WIPER BLADE........................... 5

WIPER LINKAGE......................... 6

WIPER MODULE......................... 6

WIPER MOTOR.......................... 6

WIPER SWITCH.......................... 6

CLEANING AND INSPECTION

WIPER BLADES.......................... 6

ADJUSTMENTS

WIPER ARM ADJUSTMENT................. 7

GENERAL INFORMATION

INTRODUCTION

WARNING: VEHICLES ARE EQUIPPED WITH AN

AIRBAG, REFER TO GROUP 8M, RESTRAINT SYS-

TEMS FOR STEERING WHEEL OR COLUMN SER-

VICE PROCEDURES.

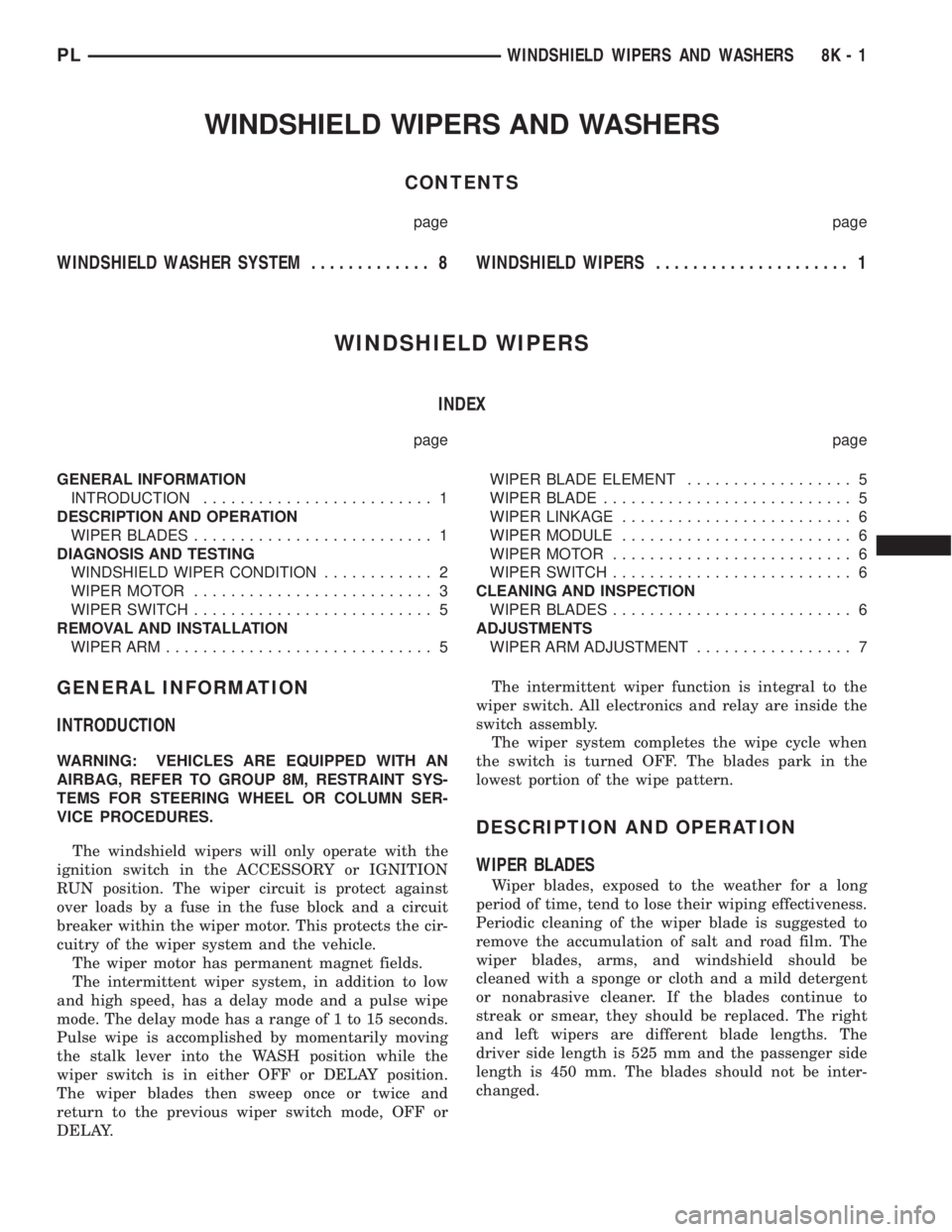

The windshield wipers will only operate with the

ignition switch in the ACCESSORY or IGNITION

RUN position. The wiper circuit is protect against

over loads by a fuse in the fuse block and a circuit

breaker within the wiper motor. This protects the cir-

cuitry of the wiper system and the vehicle.

The wiper motor has permanent magnet fields.

The intermittent wiper system, in addition to low

and high speed, has a delay mode and a pulse wipe

mode. The delay mode has a range of 1 to 15 seconds.

Pulse wipe is accomplished by momentarily moving

the stalk lever into the WASH position while the

wiper switch is in either OFF or DELAY position.

The wiper blades then sweep once or twice and

return to the previous wiper switch mode, OFF or

DELAY.The intermittent wiper function is integral to the

wiper switch. All electronics and relay are inside the

switch assembly.

The wiper system completes the wipe cycle when

the switch is turned OFF. The blades park in the

lowest portion of the wipe pattern.

DESCRIPTION AND OPERATION

WIPER BLADES

Wiper blades, exposed to the weather for a long

period of time, tend to lose their wiping effectiveness.

Periodic cleaning of the wiper blade is suggested to

remove the accumulation of salt and road film. The

wiper blades, arms, and windshield should be

cleaned with a sponge or cloth and a mild detergent

or nonabrasive cleaner. If the blades continue to

streak or smear, they should be replaced. The right

and left wipers are different blade lengths. The

driver side length is 525 mm and the passenger side

length is 450 mm. The blades should not be inter-

changed.

PLWINDSHIELD WIPERS AND WASHERS 8K - 1