steering DODGE NEON 1999 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 43 of 1200

²Binding strut assembly pivot bearing. If pivot

bearing is replaced it is to be installed with the white

side of bearing facing up (Fig. 74).

²Inspect dust shield for rips and/or deterioration.

²Inspect jounce bumper for cracks and signs of

deterioration.

(11) Replace any components of the strut assembly

found to be worn or defective during the inspection,

before assembling the strut.

ASSEMBLE

(1) Clamp the strut assembly in a vise, with the

strut in a vertical position.When clamping the

strut assembly in the vise, do not clamp strut

using the body of the strut only by strut clevis

bracket (Fig. 67).

(2) Install the compressed coil spring onto the

strut. Coil spring is to be installed with smaller coil

down, so spring correctly seats on strut assembly

(Fig. 73).

(3) Install jounce bumper on the strut shaft (Fig.

72).

(4) Install dust shield, pivot bearing and upper

spring seat as an assembly on the strut (Fig. 71).

(5) Position upper spring seat alignment notch

with clevis bracket on strut assembly.

(6) Install strut mount on strut assembly (Fig. 70)

and the strut mount retaining nut on the shaft of the

strut assembly.

WARNING: THE FOLLOWING 2 STEPS MUST BE

COMPLETELY DONE BEFORE SPRING COMPRES-

SOR, SPECIAL TOOL C-4838 IS RELEASED FROM

THE COIL SPRING.

(7) Install Socket, Strut Nut, Special Tool L-4558A

(or L-4558) on the strut shaft retaining nut (Fig. 69).

Then install a 10 mm socket through the center of

the socket and on the hex of the strut shaft (Fig. 69).

While holding strut shaft from turning, torque strut

shaft retaining nut to 75 N´m (55 ft. lbs.).

(8) Equally loosen both Spring Compressors, Spe-

cial Tool C-4838 until top coil of spring is fully seated

against upper spring seat and strut mount. Then

relieve all tension from spring compressors and

remove spring compressors from strut assembly

spring.

BALL JOINT

DISASSEMBLE

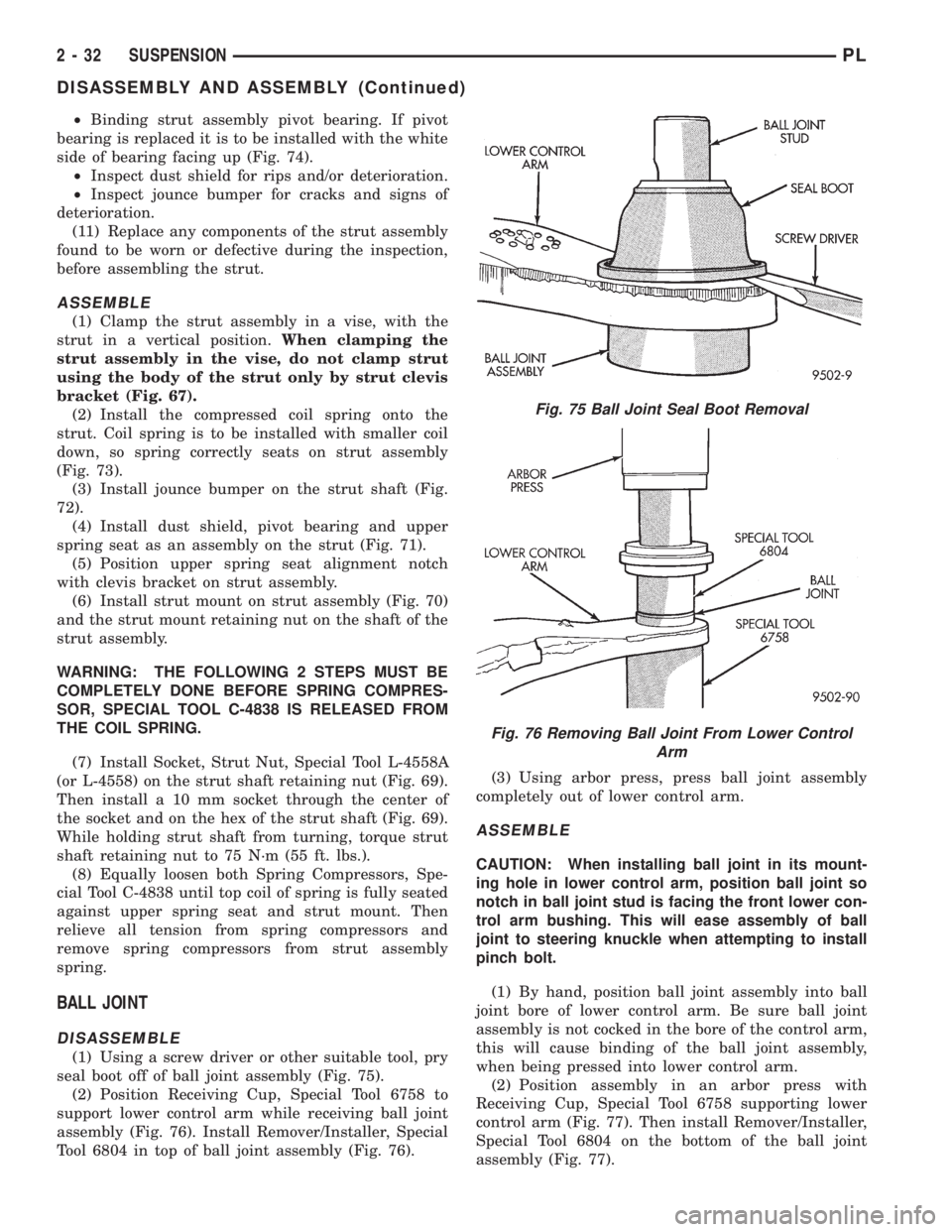

(1) Using a screw driver or other suitable tool, pry

seal boot off of ball joint assembly (Fig. 75).

(2) Position Receiving Cup, Special Tool 6758 to

support lower control arm while receiving ball joint

assembly (Fig. 76). Install Remover/Installer, Special

Tool 6804 in top of ball joint assembly (Fig. 76).(3) Using arbor press, press ball joint assembly

completely out of lower control arm.

ASSEMBLE

CAUTION: When installing ball joint in its mount-

ing hole in lower control arm, position ball joint so

notch in ball joint stud is facing the front lower con-

trol arm bushing. This will ease assembly of ball

joint to steering knuckle when attempting to install

pinch bolt.

(1) By hand, position ball joint assembly into ball

joint bore of lower control arm. Be sure ball joint

assembly is not cocked in the bore of the control arm,

this will cause binding of the ball joint assembly,

when being pressed into lower control arm.

(2) Position assembly in an arbor press with

Receiving Cup, Special Tool 6758 supporting lower

control arm (Fig. 77). Then install Remover/Installer,

Special Tool 6804 on the bottom of the ball joint

assembly (Fig. 77).

Fig. 75 Ball Joint Seal Boot Removal

Fig. 76 Removing Ball Joint From Lower Control

Arm

2 - 32 SUSPENSIONPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 47 of 1200

ADJUSTMENTS

STRUT ADJUSTMENT COMPETITION PACKAGE

SUSPENSION

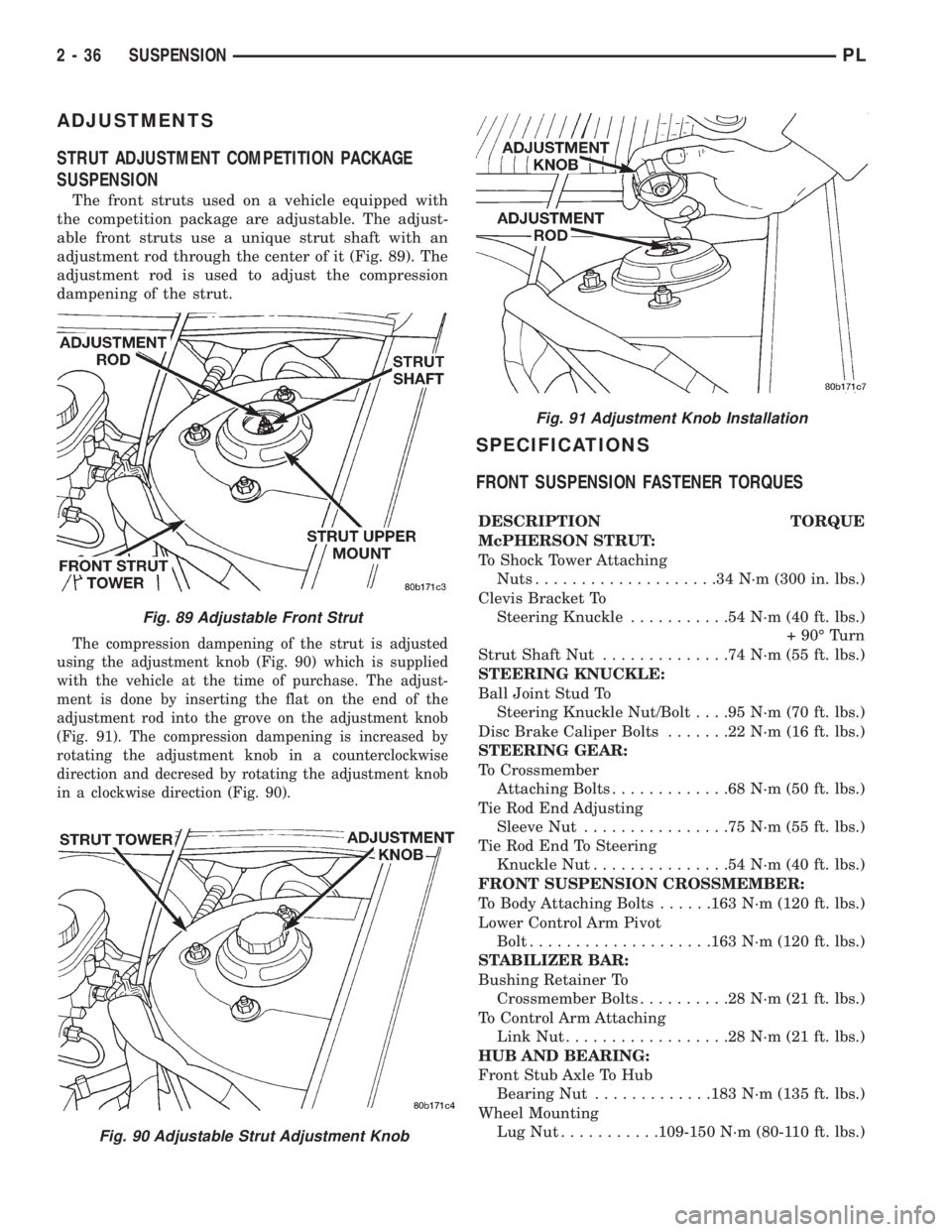

The front struts used on a vehicle equipped with

the competition package are adjustable. The adjust-

able front struts use a unique strut shaft with an

adjustment rod through the center of it (Fig. 89). The

adjustment rod is used to adjust the compression

dampening of the strut.

The compression dampening of the strut is adjusted

using the adjustment knob (Fig. 90) which is supplied

with the vehicle at the time of purchase. The adjust-

ment is done by inserting the flat on the end of the

adjustment rod into the grove on the adjustment knob

(Fig. 91). The compression dampening is increased by

rotating the adjustment knob in a counterclockwise

direction and decresed by rotating the adjustment knob

in a clockwise direction (Fig. 90).

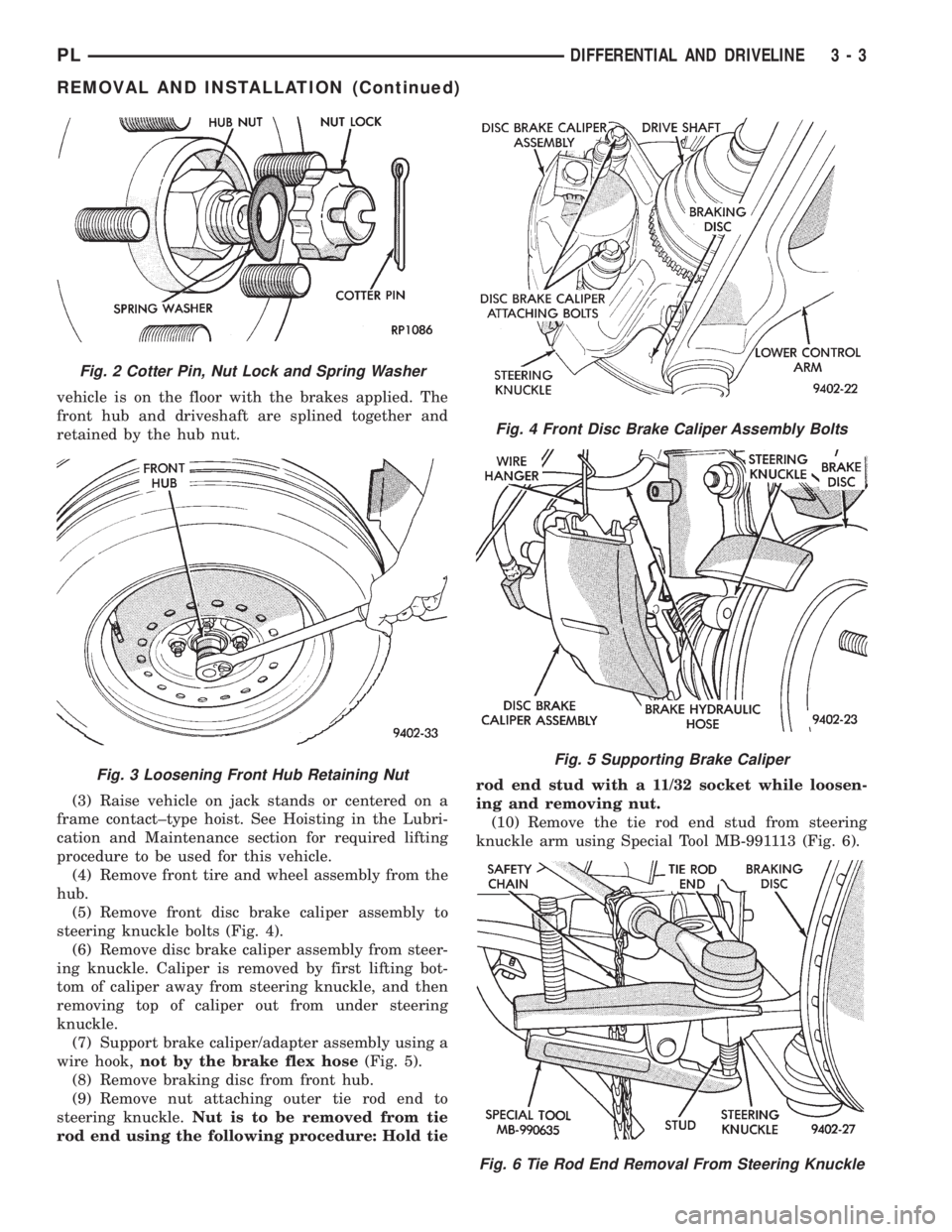

SPECIFICATIONS

FRONT SUSPENSION FASTENER TORQUES

DESCRIPTION TORQUE

McPHERSON STRUT:

To Shock Tower Attaching

Nuts....................34N´m(300 in. lbs.)

Clevis Bracket To

Steering Knuckle...........54N´m(40ft.lbs.)

+ 90É Turn

Strut Shaft Nut..............74N´m(55ft.lbs.)

STEERING KNUCKLE:

Ball Joint Stud To

Steering Knuckle Nut/Bolt. . . .95 N´m (70 ft. lbs.)

Disc Brake Caliper Bolts.......22N´m(16ft.lbs.)

STEERING GEAR:

To Crossmember

Attaching Bolts.............68N´m(50ft.lbs.)

Tie Rod End Adjusting

Sleeve Nut................75N´m(55ft.lbs.)

Tie Rod End To Steering

Knuckle Nut...............54N´m(40ft.lbs.)

FRONT SUSPENSION CROSSMEMBER:

To Body Attaching Bolts......163 N´m (120 ft. lbs.)

Lower Control Arm Pivot

Bolt....................163 N´m (120 ft. lbs.)

STABILIZER BAR:

Bushing Retainer To

Crossmember Bolts..........28N´m(21ft.lbs.)

To Control Arm Attaching

Link Nut..................28N´m(21ft.lbs.)

HUB AND BEARING:

Front Stub Axle To Hub

Bearing Nut.............183 N´m (135 ft. lbs.)

Wheel Mounting

LugNut...........109-150 N´m (80-110 ft. lbs.)

Fig. 89 Adjustable Front Strut

Fig. 90 Adjustable Strut Adjustment Knob

Fig. 91 Adjustment Knob Installation

2 - 36 SUSPENSIONPL

Page 67 of 1200

the jounce and rebound travel of the front suspen-

sion.

On vehicles equipped with ABS brakes, the outer

C/V joint is equipped with a tone wheel used to

determine vehicle speed for ABS brake operation.

The inner tripod joint of both driveshafts is splined

into the transaxle side gears. The inner tripod joints

are retained in the side gears of the transaxle using

a snap ring located in the stub shaft of the tripod

joint. The outer C/V joint has a stub shaft that is

splined into the wheel hub and retained by a hub nut

using a nut lock and cotter pin.

NOTE: This vehicle does not use a rubber±lip bear-

ing seal as on previous front±wheel±drive cars to

prevent contamination of the front wheel bearing.

On these vehicles, the face of the outer C/V joint

fits deeply into the steering knuckle, using a close

outer C/V joint±to±steering knuckle fit. This design

deters direct water splash on bearing seal while

allowing any water that gets in, to run out the bot-

tom of the steering knuckle bearing bore. It is

important to thoroughly clean the outer C/V joint

and the wheel bearing area in the steering knuckle

before it is assembled after servicing.

DIAGNOSIS AND TESTING

DRIVESHAFT DIAGNOSIS

VEHICLE INSPECTION

(1) Check for grease in the vicinity of the inboard

tripod joint and outboard C/V joint; this is a sign of

inner or outer joint seal boot or seal boot clamp dam-

age.

(2) A light film of grease may appear on the right

inner tripod joint seal boot; this is considered normal

and should not require replacement of the seal boot.

The right inner tripod joint seal boot is made of sili-

cone rubber; which will allow the weeping (sweating)

of the joint lubricant to pass through it while in oper-

ation.

NOISE AND/OR VIBRATION IN TURNS

A clicking noise and/or a vibration in turns could

be caused by one of the following conditions.

(1) Damaged outer C/V or inner tripod joint seal

boot or seal boot clamps. This will result in the loss

and/or contamination of the joint grease, resulting in

inadequate lubrication of the joint.

(2) Noise may also be caused by another compo-

nent of the vehicle coming in contact with the drive-

shafts.

CLUNKING NOISE DURING ACCELERATION

This noise may be a result of one of the following

conditions:

(1) A torn seal boot on the inner or outer joint of

the driveshaft assembly.

(2) A loose or missing clamp on the inner or outer

joint of the driveshaft assembly.

(3) A damaged or worn driveshaft C/V joint.

SHUDDER OR VIBRATION DURING

ACCELERATION

(1) A worn or damaged driveshaft inner tripod

joint.

(2) A sticking tripod joint spider assembly (inner

tripod joint only).

(3) Improper wheel alignment. See Wheel Align-

ment in this group for alignment checking and set-

ting procedures and specifications.

VIBRATION AT HIGHWAY SPEEDS

(1) Foreign material (mud, etc.) packed on the

backside of the wheel(s).

(2) Out of balance front tires or wheels. See Group

22, Wheels And Tires for the required balancing pro-

cedure.

(3) Improper tire and/or wheel runout. See Group

22, Wheels And Tires for the required runout check-

ing procedure.

REMOVAL AND INSTALLATION

FRONT DRIVESHAFTS

CAUTION: Boot sealing is vital to retain special

lubricants and to prevent foreign contaminants

from entering the C/V joint. Mishandling, such as

allowing the assemblies to dangle unsupported, or

pulling or pushing the ends can cut boots or dam-

age C/V joints. During removal and installation pro-

cedures, always support both ends of the driveshaft

to prevent damage.

REMOVAL

CAUTION: The driveshaft, when installed, acts as a

bolt and secures the front hub/bearing assembly. If

vehicle is to be supported or moved on its wheels

with a driveshaft removed, install a PROPER±SIZED

BOLT AND NUT through front hub. Tighten bolt and

nut to 203 N´m (150 ft. lbs.). This will ensure that

the hub bearing cannot loosen.

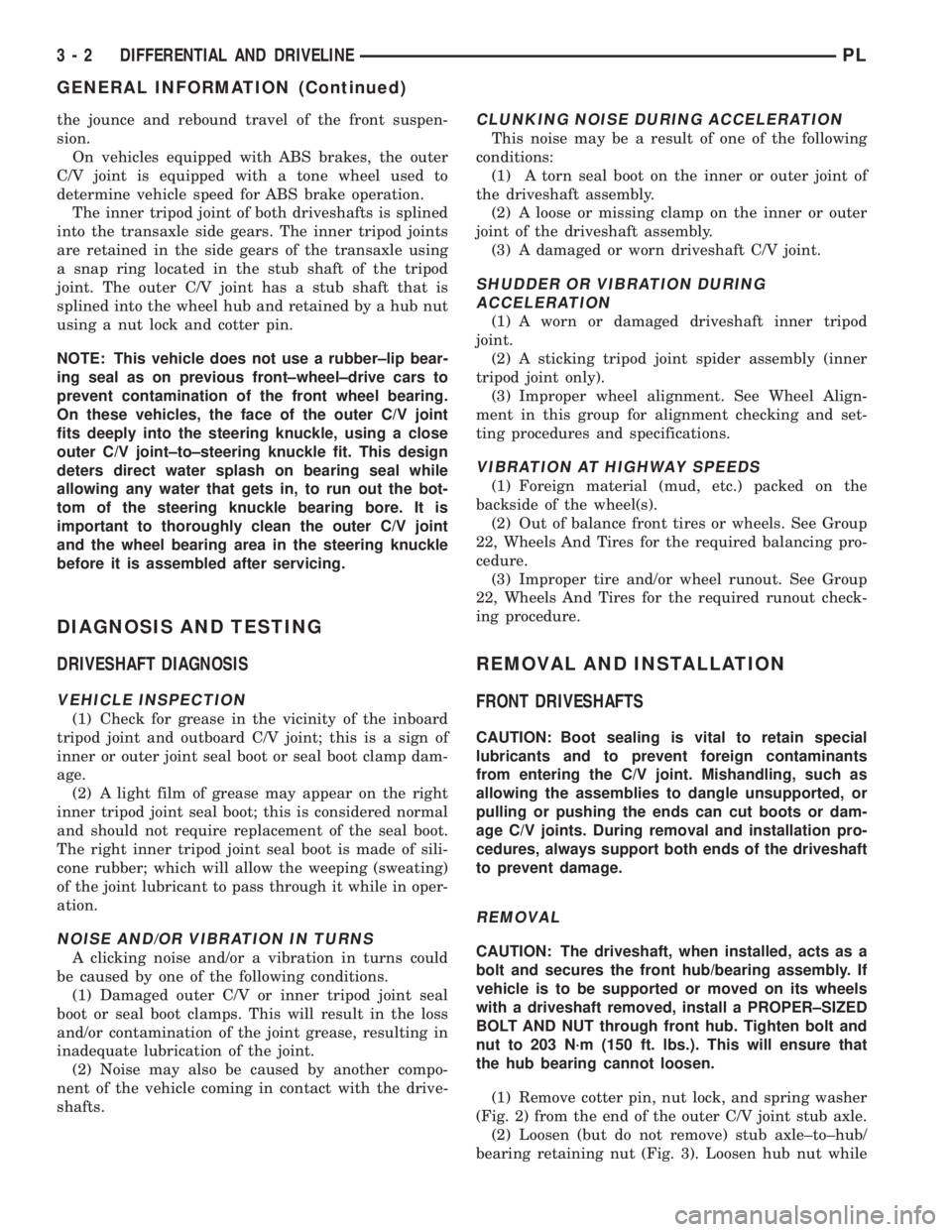

(1) Remove cotter pin, nut lock, and spring washer

(Fig. 2) from the end of the outer C/V joint stub axle.

(2) Loosen (but do not remove) stub axle±to±hub/

bearing retaining nut (Fig. 3). Loosen hub nut while

3 - 2 DIFFERENTIAL AND DRIVELINEPL

GENERAL INFORMATION (Continued)

Page 68 of 1200

vehicle is on the floor with the brakes applied. The

front hub and driveshaft are splined together and

retained by the hub nut.

(3) Raise vehicle on jack stands or centered on a

frame contact±type hoist. See Hoisting in the Lubri-

cation and Maintenance section for required lifting

procedure to be used for this vehicle.

(4) Remove front tire and wheel assembly from the

hub.

(5) Remove front disc brake caliper assembly to

steering knuckle bolts (Fig. 4).

(6) Remove disc brake caliper assembly from steer-

ing knuckle. Caliper is removed by first lifting bot-

tom of caliper away from steering knuckle, and then

removing top of caliper out from under steering

knuckle.

(7) Support brake caliper/adapter assembly using a

wire hook,not by the brake flex hose(Fig. 5).

(8) Remove braking disc from front hub.

(9) Remove nut attaching outer tie rod end to

steering knuckle.Nut is to be removed from tie

rod end using the following procedure: Hold tierod end stud with a 11/32 socket while loosen-

ing and removing nut.

(10) Remove the tie rod end stud from steering

knuckle arm using Special Tool MB-991113 (Fig. 6).

Fig. 2 Cotter Pin, Nut Lock and Spring Washer

Fig. 3 Loosening Front Hub Retaining Nut

Fig. 4 Front Disc Brake Caliper Assembly Bolts

Fig. 5 Supporting Brake Caliper

Fig. 6 Tie Rod End Removal From Steering Knuckle

PLDIFFERENTIAL AND DRIVELINE 3 - 3

REMOVAL AND INSTALLATION (Continued)

Page 69 of 1200

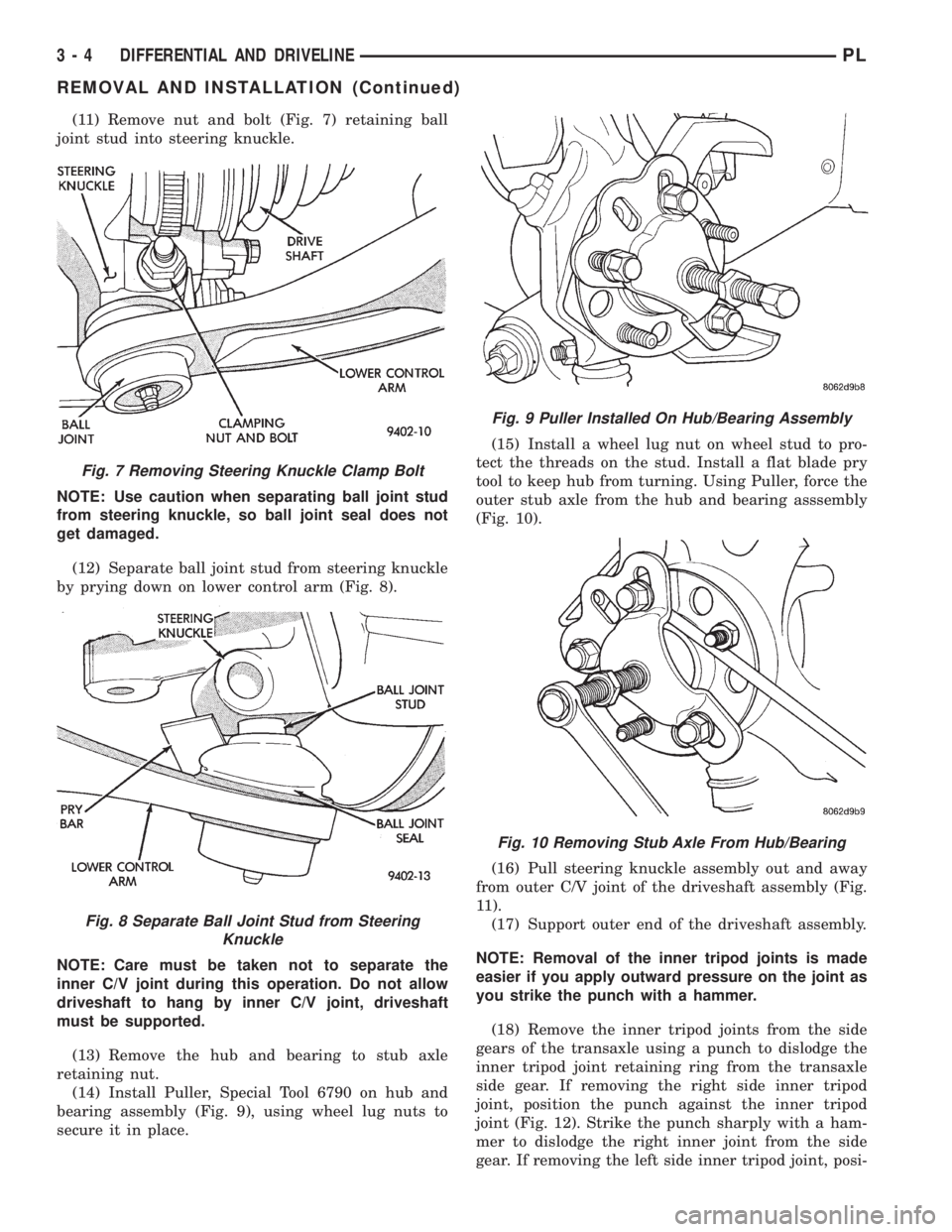

(11) Remove nut and bolt (Fig. 7) retaining ball

joint stud into steering knuckle.

NOTE: Use caution when separating ball joint stud

from steering knuckle, so ball joint seal does not

get damaged.

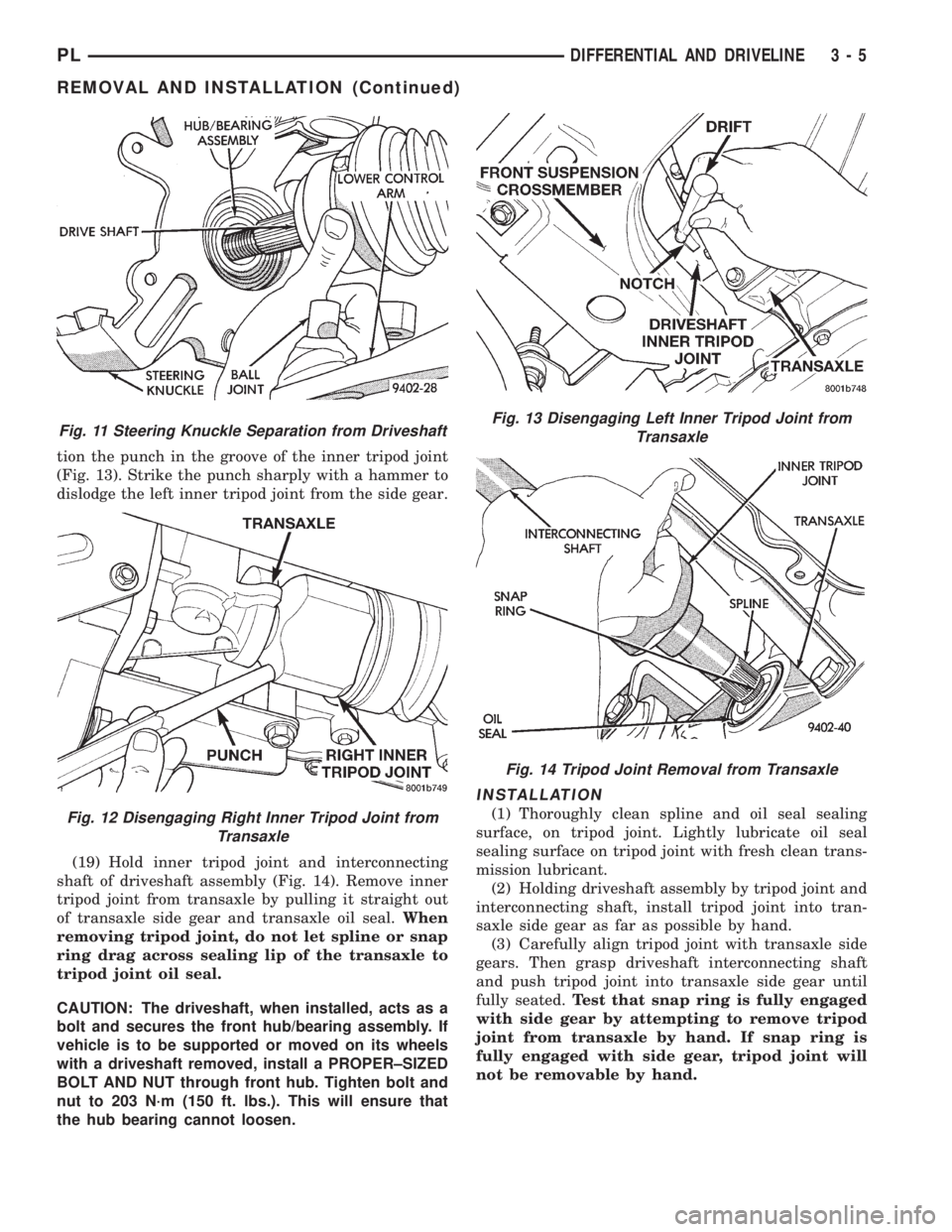

(12) Separate ball joint stud from steering knuckle

by prying down on lower control arm (Fig. 8).

NOTE: Care must be taken not to separate the

inner C/V joint during this operation. Do not allow

driveshaft to hang by inner C/V joint, driveshaft

must be supported.

(13) Remove the hub and bearing to stub axle

retaining nut.

(14) Install Puller, Special Tool 6790 on hub and

bearing assembly (Fig. 9), using wheel lug nuts to

secure it in place.(15) Install a wheel lug nut on wheel stud to pro-

tect the threads on the stud. Install a flat blade pry

tool to keep hub from turning. Using Puller, force the

outer stub axle from the hub and bearing asssembly

(Fig. 10).

(16) Pull steering knuckle assembly out and away

from outer C/V joint of the driveshaft assembly (Fig.

11).

(17) Support outer end of the driveshaft assembly.

NOTE: Removal of the inner tripod joints is made

easier if you apply outward pressure on the joint as

you strike the punch with a hammer.

(18) Remove the inner tripod joints from the side

gears of the transaxle using a punch to dislodge the

inner tripod joint retaining ring from the transaxle

side gear. If removing the right side inner tripod

joint, position the punch against the inner tripod

joint (Fig. 12). Strike the punch sharply with a ham-

mer to dislodge the right inner joint from the side

gear. If removing the left side inner tripod joint, posi-

Fig. 7 Removing Steering Knuckle Clamp Bolt

Fig. 8 Separate Ball Joint Stud from Steering

Knuckle

Fig. 9 Puller Installed On Hub/Bearing Assembly

Fig. 10 Removing Stub Axle From Hub/Bearing

3 - 4 DIFFERENTIAL AND DRIVELINEPL

REMOVAL AND INSTALLATION (Continued)

Page 70 of 1200

tion the punch in the groove of the inner tripod joint

(Fig. 13). Strike the punch sharply with a hammer to

dislodge the left inner tripod joint from the side gear.

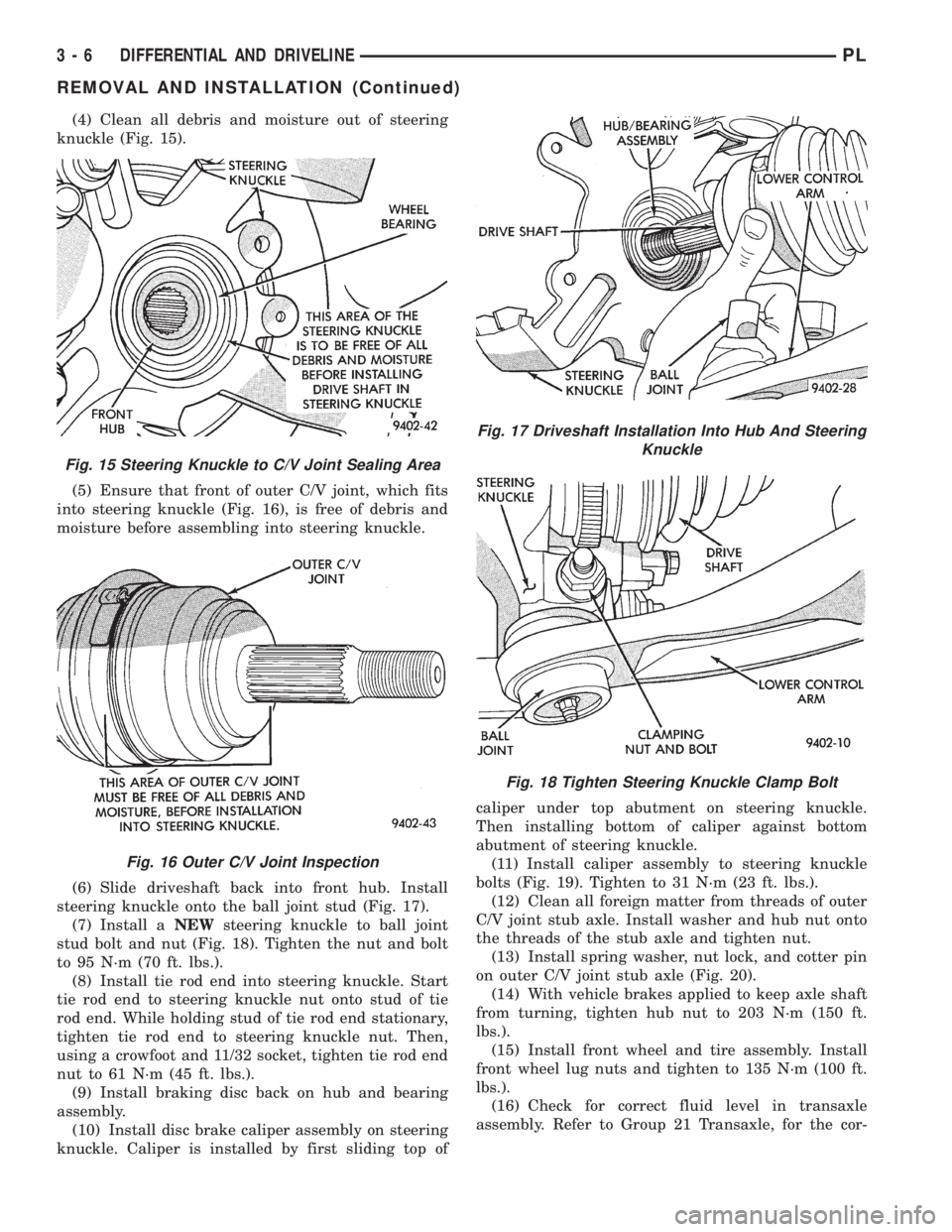

(19) Hold inner tripod joint and interconnecting

shaft of driveshaft assembly (Fig. 14). Remove inner

tripod joint from transaxle by pulling it straight out

of transaxle side gear and transaxle oil seal.When

removing tripod joint, do not let spline or snap

ring drag across sealing lip of the transaxle to

tripod joint oil seal.

CAUTION: The driveshaft, when installed, acts as a

bolt and secures the front hub/bearing assembly. If

vehicle is to be supported or moved on its wheels

with a driveshaft removed, install a PROPER±SIZED

BOLT AND NUT through front hub. Tighten bolt and

nut to 203 N´m (150 ft. lbs.). This will ensure that

the hub bearing cannot loosen.

INSTALLATION

(1) Thoroughly clean spline and oil seal sealing

surface, on tripod joint. Lightly lubricate oil seal

sealing surface on tripod joint with fresh clean trans-

mission lubricant.

(2) Holding driveshaft assembly by tripod joint and

interconnecting shaft, install tripod joint into tran-

saxle side gear as far as possible by hand.

(3) Carefully align tripod joint with transaxle side

gears. Then grasp driveshaft interconnecting shaft

and push tripod joint into transaxle side gear until

fully seated.Test that snap ring is fully engaged

with side gear by attempting to remove tripod

joint from transaxle by hand. If snap ring is

fully engaged with side gear, tripod joint will

not be removable by hand.

Fig. 11 Steering Knuckle Separation from Driveshaft

Fig. 12 Disengaging Right Inner Tripod Joint from

Transaxle

Fig. 13 Disengaging Left Inner Tripod Joint from

Transaxle

Fig. 14 Tripod Joint Removal from Transaxle

PLDIFFERENTIAL AND DRIVELINE 3 - 5

REMOVAL AND INSTALLATION (Continued)

Page 71 of 1200

(4) Clean all debris and moisture out of steering

knuckle (Fig. 15).

(5) Ensure that front of outer C/V joint, which fits

into steering knuckle (Fig. 16), is free of debris and

moisture before assembling into steering knuckle.

(6) Slide driveshaft back into front hub. Install

steering knuckle onto the ball joint stud (Fig. 17).

(7) Install aNEWsteering knuckle to ball joint

stud bolt and nut (Fig. 18). Tighten the nut and bolt

to 95 N´m (70 ft. lbs.).

(8) Install tie rod end into steering knuckle. Start

tie rod end to steering knuckle nut onto stud of tie

rod end. While holding stud of tie rod end stationary,

tighten tie rod end to steering knuckle nut. Then,

using a crowfoot and 11/32 socket, tighten tie rod end

nut to 61 N´m (45 ft. lbs.).

(9) Install braking disc back on hub and bearing

assembly.

(10) Install disc brake caliper assembly on steering

knuckle. Caliper is installed by first sliding top ofcaliper under top abutment on steering knuckle.

Then installing bottom of caliper against bottom

abutment of steering knuckle.

(11) Install caliper assembly to steering knuckle

bolts (Fig. 19). Tighten to 31 N´m (23 ft. lbs.).

(12) Clean all foreign matter from threads of outer

C/V joint stub axle. Install washer and hub nut onto

the threads of the stub axle and tighten nut.

(13) Install spring washer, nut lock, and cotter pin

on outer C/V joint stub axle (Fig. 20).

(14) With vehicle brakes applied to keep axle shaft

from turning, tighten hub nut to 203 N´m (150 ft.

lbs.).

(15) Install front wheel and tire assembly. Install

front wheel lug nuts and tighten to 135 N´m (100 ft.

lbs.).

(16) Check for correct fluid level in transaxle

assembly. Refer to Group 21 Transaxle, for the cor-

Fig. 15 Steering Knuckle to C/V Joint Sealing Area

Fig. 16 Outer C/V Joint Inspection

Fig. 17 Driveshaft Installation Into Hub And Steering

Knuckle

Fig. 18 Tighten Steering Knuckle Clamp Bolt

3 - 6 DIFFERENTIAL AND DRIVELINEPL

REMOVAL AND INSTALLATION (Continued)

Page 83 of 1200

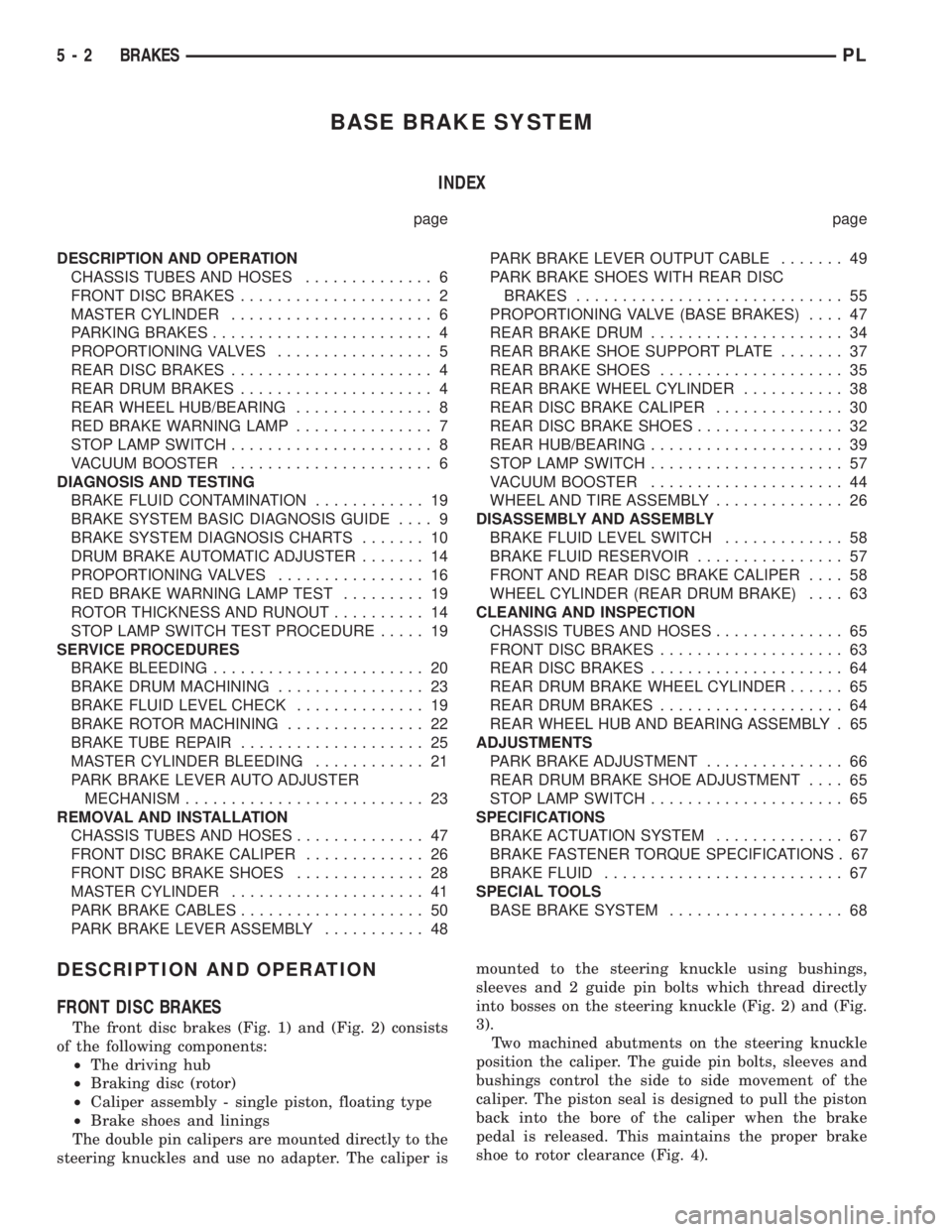

BASE BRAKE SYSTEM

INDEX

page page

DESCRIPTION AND OPERATION

CHASSIS TUBES AND HOSES.............. 6

FRONT DISC BRAKES..................... 2

MASTER CYLINDER...................... 6

PARKING BRAKES........................ 4

PROPORTIONING VALVES................. 5

REAR DISC BRAKES...................... 4

REAR DRUM BRAKES..................... 4

REAR WHEEL HUB/BEARING............... 8

RED BRAKE WARNING LAMP............... 7

STOP LAMP SWITCH...................... 8

VACUUM BOOSTER...................... 6

DIAGNOSIS AND TESTING

BRAKE FLUID CONTAMINATION............ 19

BRAKE SYSTEM BASIC DIAGNOSIS GUIDE.... 9

BRAKE SYSTEM DIAGNOSIS CHARTS....... 10

DRUM BRAKE AUTOMATIC ADJUSTER....... 14

PROPORTIONING VALVES................ 16

RED BRAKE WARNING LAMP TEST......... 19

ROTOR THICKNESS AND RUNOUT.......... 14

STOP LAMP SWITCH TEST PROCEDURE..... 19

SERVICE PROCEDURES

BRAKE BLEEDING....................... 20

BRAKE DRUM MACHINING................ 23

BRAKE FLUID LEVEL CHECK.............. 19

BRAKE ROTOR MACHINING............... 22

BRAKE TUBE REPAIR.................... 25

MASTER CYLINDER BLEEDING............ 21

PARK BRAKE LEVER AUTO ADJUSTER

MECHANISM.......................... 23

REMOVAL AND INSTALLATION

CHASSIS TUBES AND HOSES.............. 47

FRONT DISC BRAKE CALIPER............. 26

FRONT DISC BRAKE SHOES.............. 28

MASTER CYLINDER..................... 41

PARK BRAKE CABLES.................... 50

PARK BRAKE LEVER ASSEMBLY........... 48PARK BRAKE LEVER OUTPUT CABLE....... 49

PARK BRAKE SHOES WITH REAR DISC

BRAKES............................. 55

PROPORTIONING VALVE (BASE BRAKES).... 47

REAR BRAKE DRUM..................... 34

REAR BRAKE SHOE SUPPORT PLATE....... 37

REAR BRAKE SHOES.................... 35

REAR BRAKE WHEEL CYLINDER........... 38

REAR DISC BRAKE CALIPER.............. 30

REAR DISC BRAKE SHOES................ 32

REAR HUB/BEARING..................... 39

STOP LAMP SWITCH..................... 57

VACUUM BOOSTER..................... 44

WHEEL AND TIRE ASSEMBLY.............. 26

DISASSEMBLY AND ASSEMBLY

BRAKE FLUID LEVEL SWITCH............. 58

BRAKE FLUID RESERVOIR................ 57

FRONT AND REAR DISC BRAKE CALIPER.... 58

WHEEL CYLINDER (REAR DRUM BRAKE).... 63

CLEANING AND INSPECTION

CHASSIS TUBES AND HOSES.............. 65

FRONT DISC BRAKES.................... 63

REAR DISC BRAKES..................... 64

REAR DRUM BRAKE WHEEL CYLINDER...... 65

REAR DRUM BRAKES.................... 64

REAR WHEEL HUB AND BEARING ASSEMBLY . 65

ADJUSTMENTS

PARK BRAKE ADJUSTMENT............... 66

REAR DRUM BRAKE SHOE ADJUSTMENT.... 65

STOP LAMP SWITCH..................... 65

SPECIFICATIONS

BRAKE ACTUATION SYSTEM.............. 67

BRAKE FASTENER TORQUE SPECIFICATIONS . 67

BRAKE FLUID.......................... 67

SPECIAL TOOLS

BASE BRAKE SYSTEM................... 68

DESCRIPTION AND OPERATION

FRONT DISC BRAKES

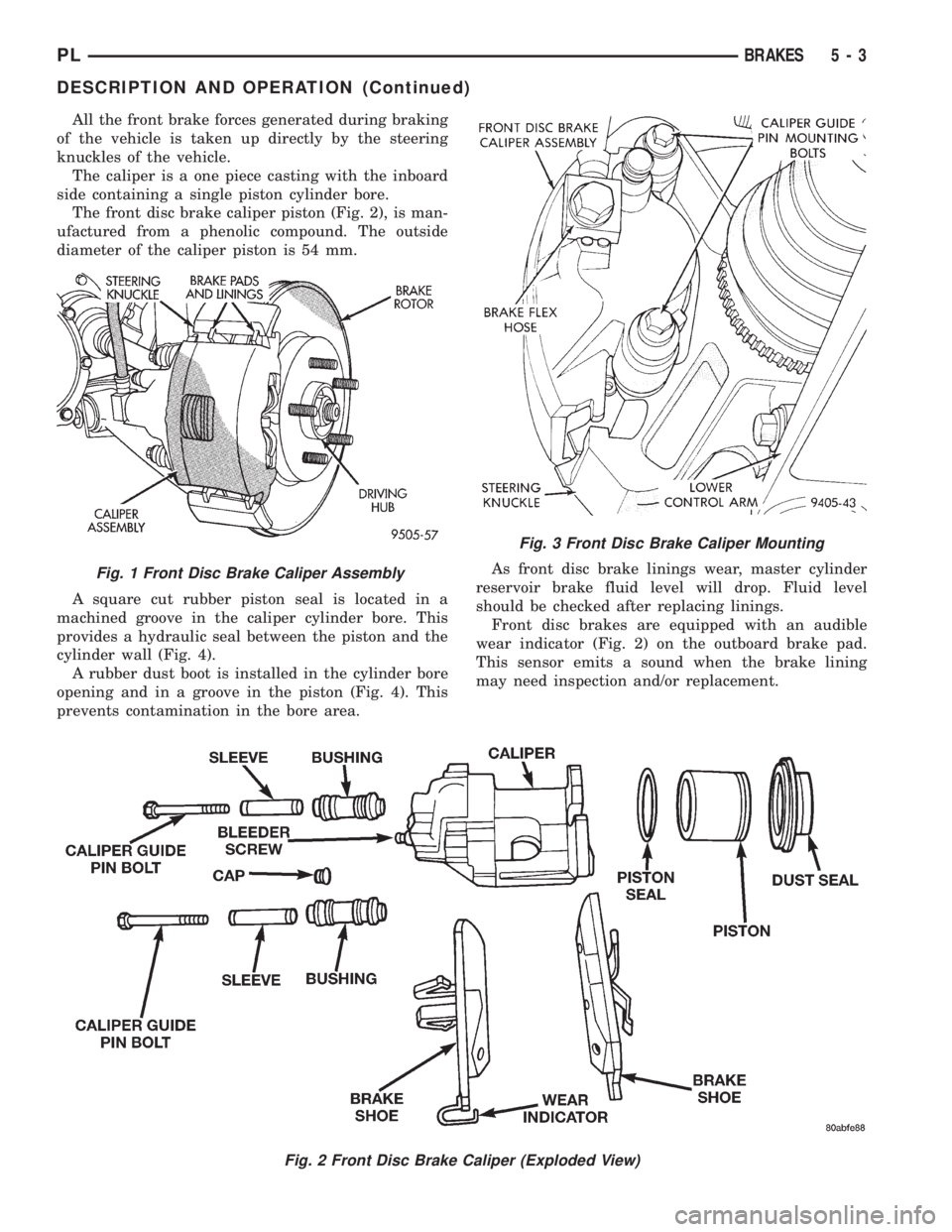

The front disc brakes (Fig. 1) and (Fig. 2) consists

of the following components:

²The driving hub

²Braking disc (rotor)

²Caliper assembly - single piston, floating type

²Brake shoes and linings

The double pin calipers are mounted directly to the

steering knuckles and use no adapter. The caliper ismounted to the steering knuckle using bushings,

sleeves and 2 guide pin bolts which thread directly

into bosses on the steering knuckle (Fig. 2) and (Fig.

3).

Two machined abutments on the steering knuckle

position the caliper. The guide pin bolts, sleeves and

bushings control the side to side movement of the

caliper. The piston seal is designed to pull the piston

back into the bore of the caliper when the brake

pedal is released. This maintains the proper brake

shoe to rotor clearance (Fig. 4).

5 - 2 BRAKESPL

Page 84 of 1200

All the front brake forces generated during braking

of the vehicle is taken up directly by the steering

knuckles of the vehicle.

The caliper is a one piece casting with the inboard

side containing a single piston cylinder bore.

The front disc brake caliper piston (Fig. 2), is man-

ufactured from a phenolic compound. The outside

diameter of the caliper piston is 54 mm.

A square cut rubber piston seal is located in a

machined groove in the caliper cylinder bore. This

provides a hydraulic seal between the piston and the

cylinder wall (Fig. 4).

A rubber dust boot is installed in the cylinder bore

opening and in a groove in the piston (Fig. 4). This

prevents contamination in the bore area.As front disc brake linings wear, master cylinder

reservoir brake fluid level will drop. Fluid level

should be checked after replacing linings.

Front disc brakes are equipped with an audible

wear indicator (Fig. 2) on the outboard brake pad.

This sensor emits a sound when the brake lining

may need inspection and/or replacement.

Fig. 1 Front Disc Brake Caliper Assembly

Fig. 2 Front Disc Brake Caliper (Exploded View)

Fig. 3 Front Disc Brake Caliper Mounting

PLBRAKES 5 - 3

DESCRIPTION AND OPERATION (Continued)

Page 95 of 1200

DRUM BRAKE AUTOMATIC ADJUSTER

Place the vehicle on a hoist with a helper in the

driver's seat to apply the brakes. Remove the access

plug from the rear adjustment slot in each brake

support plate to provide access to the adjuster star

wheel. Then, to eliminate the possibility of maximum

adjustment, back the star wheel off approximately 10

notches. It will be necessary to hold the adjuster

lever away from the star wheel to permit this adjust-

ment.

Apply the brake pedal. This application of force

will cause the brake shoes to leave the anchor. Upon

application of the brake pedal, the lever should move

downward, turning the star wheel. Thus, a definite

rotation of the adjuster star wheel can be observed if

the automatic adjuster is working properly. If one or

more adjusters do not function properly, the respec-

tive drum must be removed for adjuster servicing.

ROTOR THICKNESS AND RUNOUT

Any servicing of the rotor requires extreme care to

maintain the rotor within service tolerances to

ensure proper brake action.

Before refinishing or refacing a rotor, the disc

should be checked and inspected for the following

conditions:

Braking surface scoring, rust, impregnation of lin-

ing material and worn ridges.

Excessive lateral runout or wobble.

Thickness variation (Parallelism).

Dishing or distortion (Flatness).

If a vehicle has not been driven for a period of

time, the rotor surface will rust in the area not cov-

ered by the brake lining and cause noise and chatter

when the brakes are applied.

Excessive wear and scoring of the rotor can cause

temporary improper lining contact if ridges are not

removed before installation of new brake pad assem-

blies.

Some discoloration or wear of the rotor surface is

normal and does not require resurfacing when lin-

ings are replaced.

Excessive runout or wobble in a rotor can increase

pedal travel due to piston knock back. This will

increase guide pin sleeve wear due to tendency of cal-

iper to follow rotor wobble.

Thickness variation in a rotor can also result in

pedal pulsation, chatter and surge due to variation in

brake output. This can also be caused by excessive

runout in rotor or hub.

Dishing or distortion can be caused by extreme

heat and abuse of the brakes.

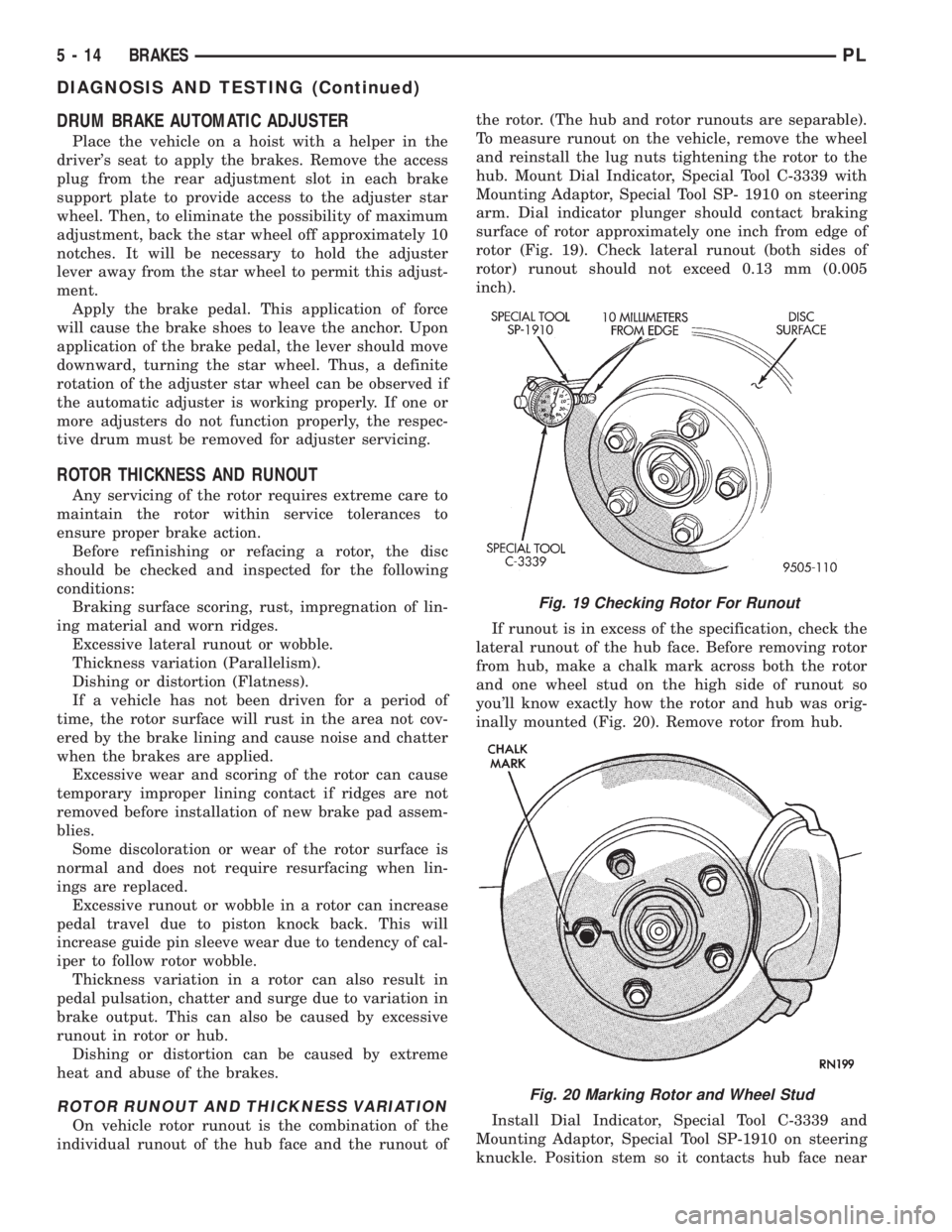

ROTOR RUNOUT AND THICKNESS VARIATION

On vehicle rotor runout is the combination of the

individual runout of the hub face and the runout ofthe rotor. (The hub and rotor runouts are separable).

To measure runout on the vehicle, remove the wheel

and reinstall the lug nuts tightening the rotor to the

hub. Mount Dial Indicator, Special Tool C-3339 with

Mounting Adaptor, Special Tool SP- 1910 on steering

arm. Dial indicator plunger should contact braking

surface of rotor approximately one inch from edge of

rotor (Fig. 19). Check lateral runout (both sides of

rotor) runout should not exceed 0.13 mm (0.005

inch).

If runout is in excess of the specification, check the

lateral runout of the hub face. Before removing rotor

from hub, make a chalk mark across both the rotor

and one wheel stud on the high side of runout so

you'll know exactly how the rotor and hub was orig-

inally mounted (Fig. 20). Remove rotor from hub.

Install Dial Indicator, Special Tool C-3339 and

Mounting Adaptor, Special Tool SP-1910 on steering

knuckle. Position stem so it contacts hub face near

Fig. 19 Checking Rotor For Runout

Fig. 20 Marking Rotor and Wheel Stud

5 - 14 BRAKESPL

DIAGNOSIS AND TESTING (Continued)