steering DODGE NEON 1999 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 107 of 1200

Place gauge (Form A) on edge over end of brake

tubing. Push tubing through jaws until end of tubing

contacts the recessed notch in gauge matching the

tubing size. Squeeze handles of flaring tool and lock

tubing in place. Place 3/16 inch plug of gauge (A)

down in end of tubing. Swing compression disc over

gauge and center tapered flaring screw in recess of

disc. Screw in until plug gauge has seated on jaws of

flaring tool. This action has started to invert the

extended end of the tubing. Remove gauge and con-

tinue to screw down until tool is firmly seated in tub-

ing. Remove tubing from flaring tool and inspect

seat. Refer to tube routing diagrams for proper brake

tube routing and clip locations. Replace any damaged

tube routing clips.

REMOVAL AND INSTALLATION

WHEEL AND TIRE ASSEMBLY

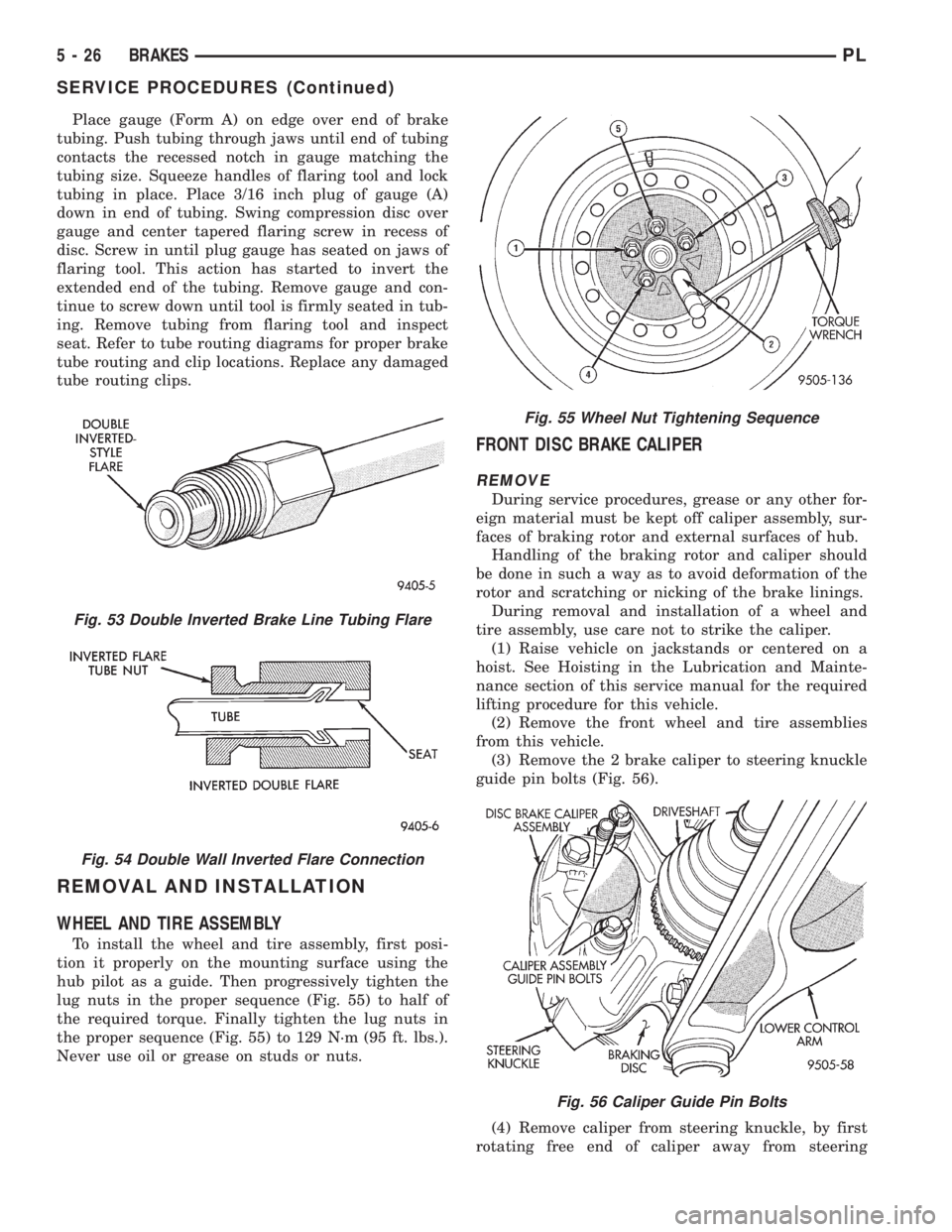

To install the wheel and tire assembly, first posi-

tion it properly on the mounting surface using the

hub pilot as a guide. Then progressively tighten the

lug nuts in the proper sequence (Fig. 55) to half of

the required torque. Finally tighten the lug nuts in

the proper sequence (Fig. 55) to 129 N´m (95 ft. lbs.).

Never use oil or grease on studs or nuts.

FRONT DISC BRAKE CALIPER

REMOVE

During service procedures, grease or any other for-

eign material must be kept off caliper assembly, sur-

faces of braking rotor and external surfaces of hub.

Handling of the braking rotor and caliper should

be done in such a way as to avoid deformation of the

rotor and scratching or nicking of the brake linings.

During removal and installation of a wheel and

tire assembly, use care not to strike the caliper.

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication and Mainte-

nance section of this service manual for the required

lifting procedure for this vehicle.

(2) Remove the front wheel and tire assemblies

from this vehicle.

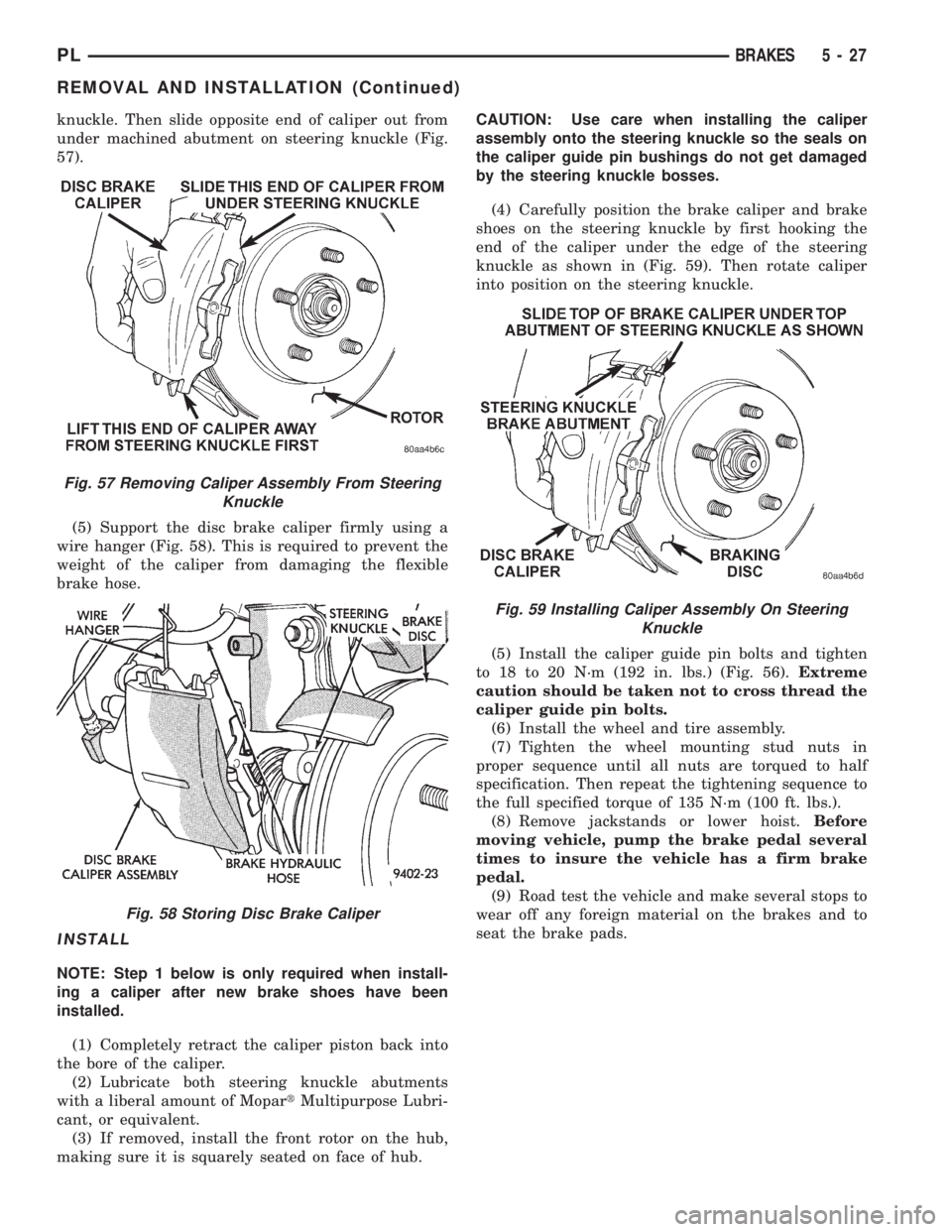

(3) Remove the 2 brake caliper to steering knuckle

guide pin bolts (Fig. 56).

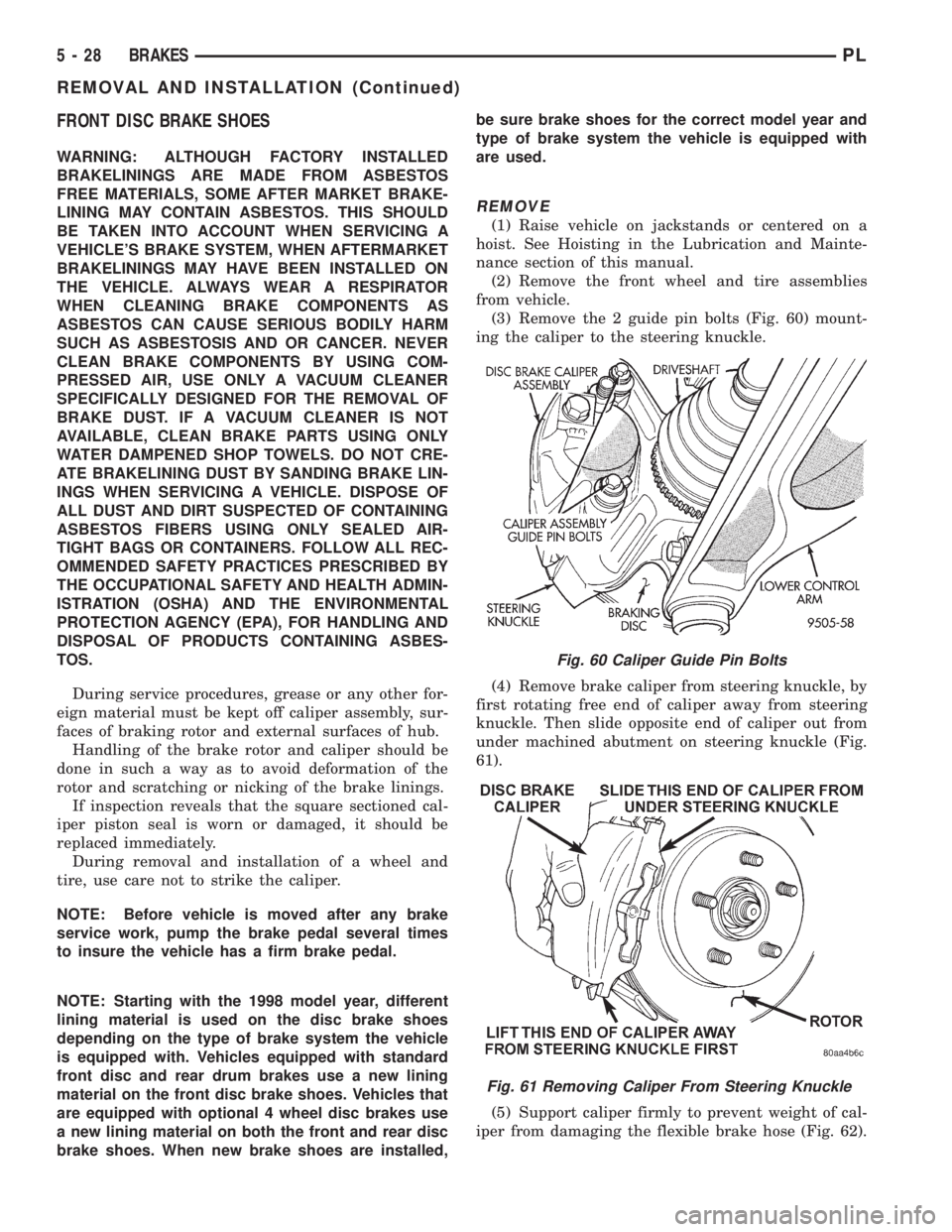

(4) Remove caliper from steering knuckle, by first

rotating free end of caliper away from steering

Fig. 53 Double Inverted Brake Line Tubing Flare

Fig. 54 Double Wall Inverted Flare Connection

Fig. 55 Wheel Nut Tightening Sequence

Fig. 56 Caliper Guide Pin Bolts

5 - 26 BRAKESPL

SERVICE PROCEDURES (Continued)

Page 108 of 1200

knuckle. Then slide opposite end of caliper out from

under machined abutment on steering knuckle (Fig.

57).

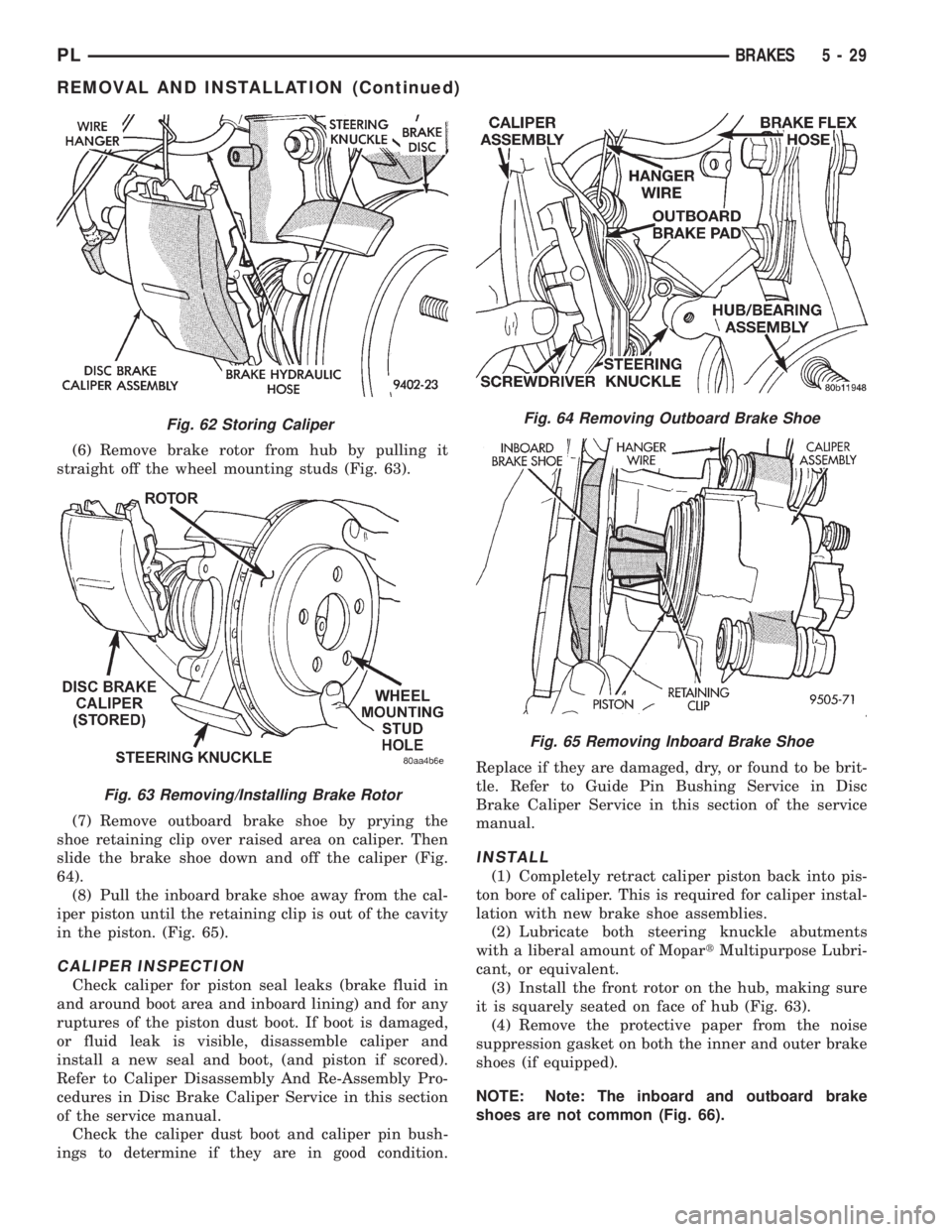

(5) Support the disc brake caliper firmly using a

wire hanger (Fig. 58). This is required to prevent the

weight of the caliper from damaging the flexible

brake hose.

INSTALL

NOTE: Step 1 below is only required when install-

ing a caliper after new brake shoes have been

installed.

(1) Completely retract the caliper piston back into

the bore of the caliper.

(2) Lubricate both steering knuckle abutments

with a liberal amount of MopartMultipurpose Lubri-

cant, or equivalent.

(3) If removed, install the front rotor on the hub,

making sure it is squarely seated on face of hub.CAUTION: Use care when installing the caliper

assembly onto the steering knuckle so the seals on

the caliper guide pin bushings do not get damaged

by the steering knuckle bosses.

(4) Carefully position the brake caliper and brake

shoes on the steering knuckle by first hooking the

end of the caliper under the edge of the steering

knuckle as shown in (Fig. 59). Then rotate caliper

into position on the steering knuckle.

(5) Install the caliper guide pin bolts and tighten

to 18 to 20 N´m (192 in. lbs.) (Fig. 56).Extreme

caution should be taken not to cross thread the

caliper guide pin bolts.

(6) Install the wheel and tire assembly.

(7) Tighten the wheel mounting stud nuts in

proper sequence until all nuts are torqued to half

specification. Then repeat the tightening sequence to

the full specified torque of 135 N´m (100 ft. lbs.).

(8) Remove jackstands or lower hoist.Before

moving vehicle, pump the brake pedal several

times to insure the vehicle has a firm brake

pedal.

(9) Road test the vehicle and make several stops to

wear off any foreign material on the brakes and to

seat the brake pads.

Fig. 57 Removing Caliper Assembly From Steering

Knuckle

Fig. 58 Storing Disc Brake Caliper

Fig. 59 Installing Caliper Assembly On Steering

Knuckle

PLBRAKES 5 - 27

REMOVAL AND INSTALLATION (Continued)

Page 109 of 1200

FRONT DISC BRAKE SHOES

WARNING: ALTHOUGH FACTORY INSTALLED

BRAKELININGS ARE MADE FROM ASBESTOS

FREE MATERIALS, SOME AFTER MARKET BRAKE-

LINING MAY CONTAIN ASBESTOS. THIS SHOULD

BE TAKEN INTO ACCOUNT WHEN SERVICING A

VEHICLE'S BRAKE SYSTEM, WHEN AFTERMARKET

BRAKELININGS MAY HAVE BEEN INSTALLED ON

THE VEHICLE. ALWAYS WEAR A RESPIRATOR

WHEN CLEANING BRAKE COMPONENTS AS

ASBESTOS CAN CAUSE SERIOUS BODILY HARM

SUCH AS ASBESTOSIS AND OR CANCER. NEVER

CLEAN BRAKE COMPONENTS BY USING COM-

PRESSED AIR, USE ONLY A VACUUM CLEANER

SPECIFICALLY DESIGNED FOR THE REMOVAL OF

BRAKE DUST. IF A VACUUM CLEANER IS NOT

AVAILABLE, CLEAN BRAKE PARTS USING ONLY

WATER DAMPENED SHOP TOWELS. DO NOT CRE-

ATE BRAKELINING DUST BY SANDING BRAKE LIN-

INGS WHEN SERVICING A VEHICLE. DISPOSE OF

ALL DUST AND DIRT SUSPECTED OF CONTAINING

ASBESTOS FIBERS USING ONLY SEALED AIR-

TIGHT BAGS OR CONTAINERS. FOLLOW ALL REC-

OMMENDED SAFETY PRACTICES PRESCRIBED BY

THE OCCUPATIONAL SAFETY AND HEALTH ADMIN-

ISTRATION (OSHA) AND THE ENVIRONMENTAL

PROTECTION AGENCY (EPA), FOR HANDLING AND

DISPOSAL OF PRODUCTS CONTAINING ASBES-

TOS.

During service procedures, grease or any other for-

eign material must be kept off caliper assembly, sur-

faces of braking rotor and external surfaces of hub.

Handling of the brake rotor and caliper should be

done in such a way as to avoid deformation of the

rotor and scratching or nicking of the brake linings.

If inspection reveals that the square sectioned cal-

iper piston seal is worn or damaged, it should be

replaced immediately.

During removal and installation of a wheel and

tire, use care not to strike the caliper.

NOTE: Before vehicle is moved after any brake

service work, pump the brake pedal several times

to insure the vehicle has a firm brake pedal.

NOTE: Starting with the 1998 model year, different

lining material is used on the disc brake shoes

depending on the type of brake system the vehicle

is equipped with. Vehicles equipped with standard

front disc and rear drum brakes use a new lining

material on the front disc brake shoes. Vehicles that

are equipped with optional 4 wheel disc brakes use

a new lining material on both the front and rear disc

brake shoes. When new brake shoes are installed,be sure brake shoes for the correct model year and

type of brake system the vehicle is equipped with

are used.

REMOVE

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication and Mainte-

nance section of this manual.

(2) Remove the front wheel and tire assemblies

from vehicle.

(3) Remove the 2 guide pin bolts (Fig. 60) mount-

ing the caliper to the steering knuckle.

(4) Remove brake caliper from steering knuckle, by

first rotating free end of caliper away from steering

knuckle. Then slide opposite end of caliper out from

under machined abutment on steering knuckle (Fig.

61).

(5) Support caliper firmly to prevent weight of cal-

iper from damaging the flexible brake hose (Fig. 62).

Fig. 60 Caliper Guide Pin Bolts

Fig. 61 Removing Caliper From Steering Knuckle

5 - 28 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 110 of 1200

(6) Remove brake rotor from hub by pulling it

straight off the wheel mounting studs (Fig. 63).

(7) Remove outboard brake shoe by prying the

shoe retaining clip over raised area on caliper. Then

slide the brake shoe down and off the caliper (Fig.

64).

(8) Pull the inboard brake shoe away from the cal-

iper piston until the retaining clip is out of the cavity

in the piston. (Fig. 65).

CALIPER INSPECTION

Check caliper for piston seal leaks (brake fluid in

and around boot area and inboard lining) and for any

ruptures of the piston dust boot. If boot is damaged,

or fluid leak is visible, disassemble caliper and

install a new seal and boot, (and piston if scored).

Refer to Caliper Disassembly And Re-Assembly Pro-

cedures in Disc Brake Caliper Service in this section

of the service manual.

Check the caliper dust boot and caliper pin bush-

ings to determine if they are in good condition.Replace if they are damaged, dry, or found to be brit-

tle. Refer to Guide Pin Bushing Service in Disc

Brake Caliper Service in this section of the service

manual.

INSTALL

(1) Completely retract caliper piston back into pis-

ton bore of caliper. This is required for caliper instal-

lation with new brake shoe assemblies.

(2) Lubricate both steering knuckle abutments

with a liberal amount of MopartMultipurpose Lubri-

cant, or equivalent.

(3) Install the front rotor on the hub, making sure

it is squarely seated on face of hub (Fig. 63).

(4) Remove the protective paper from the noise

suppression gasket on both the inner and outer brake

shoes (if equipped).

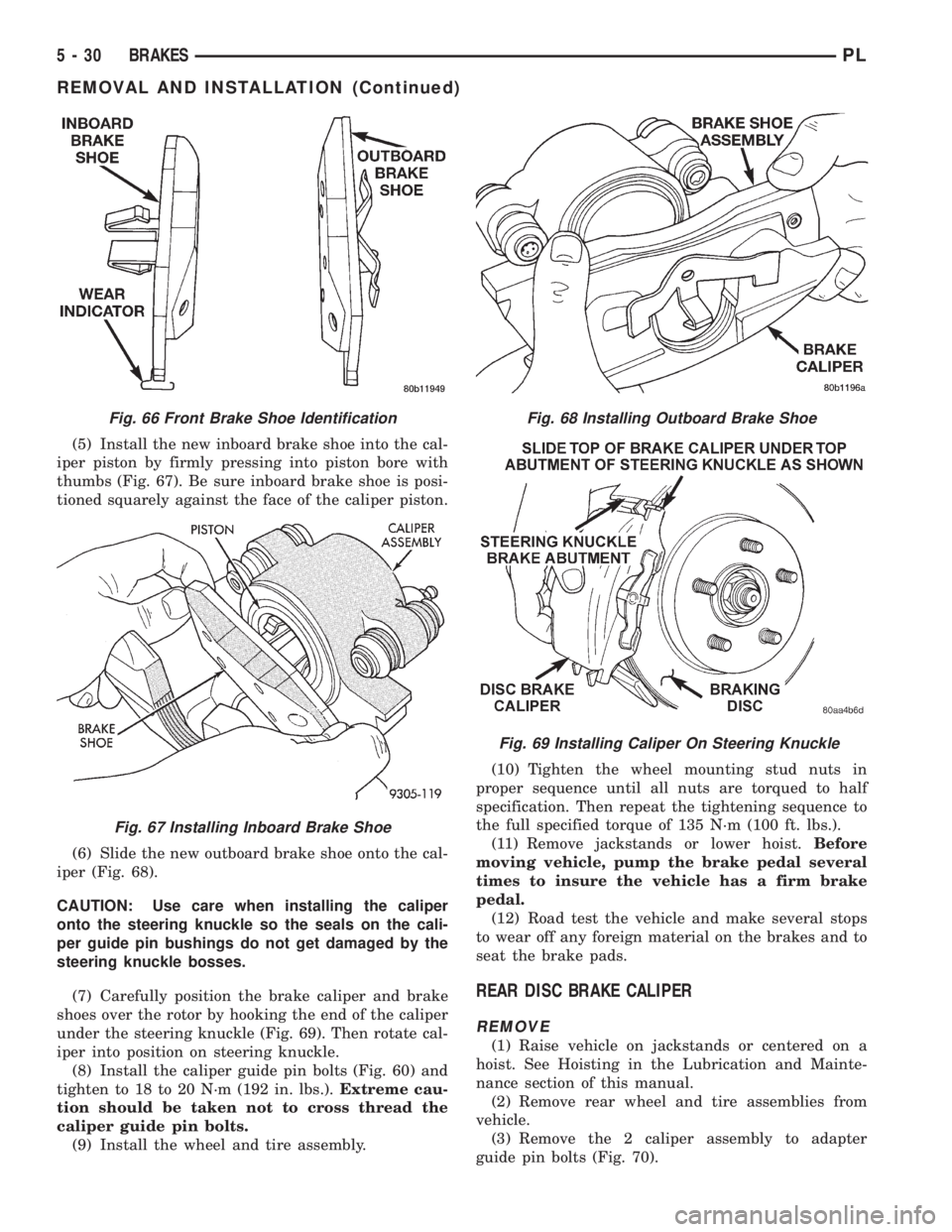

NOTE: Note: The inboard and outboard brake

shoes are not common (Fig. 66).

Fig. 62 Storing Caliper

Fig. 63 Removing/Installing Brake Rotor

Fig. 64 Removing Outboard Brake Shoe

Fig. 65 Removing Inboard Brake Shoe

PLBRAKES 5 - 29

REMOVAL AND INSTALLATION (Continued)

Page 111 of 1200

(5) Install the new inboard brake shoe into the cal-

iper piston by firmly pressing into piston bore with

thumbs (Fig. 67). Be sure inboard brake shoe is posi-

tioned squarely against the face of the caliper piston.

(6) Slide the new outboard brake shoe onto the cal-

iper (Fig. 68).

CAUTION: Use care when installing the caliper

onto the steering knuckle so the seals on the cali-

per guide pin bushings do not get damaged by the

steering knuckle bosses.

(7) Carefully position the brake caliper and brake

shoes over the rotor by hooking the end of the caliper

under the steering knuckle (Fig. 69). Then rotate cal-

iper into position on steering knuckle.

(8) Install the caliper guide pin bolts (Fig. 60) and

tighten to 18 to 20 N´m (192 in. lbs.).Extreme cau-

tion should be taken not to cross thread the

caliper guide pin bolts.

(9) Install the wheel and tire assembly.(10) Tighten the wheel mounting stud nuts in

proper sequence until all nuts are torqued to half

specification. Then repeat the tightening sequence to

the full specified torque of 135 N´m (100 ft. lbs.).

(11) Remove jackstands or lower hoist.Before

moving vehicle, pump the brake pedal several

times to insure the vehicle has a firm brake

pedal.

(12) Road test the vehicle and make several stops

to wear off any foreign material on the brakes and to

seat the brake pads.

REAR DISC BRAKE CALIPER

REMOVE

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication and Mainte-

nance section of this manual.

(2) Remove rear wheel and tire assemblies from

vehicle.

(3) Remove the 2 caliper assembly to adapter

guide pin bolts (Fig. 70).

Fig. 66 Front Brake Shoe Identification

Fig. 67 Installing Inboard Brake Shoe

Fig. 68 Installing Outboard Brake Shoe

Fig. 69 Installing Caliper On Steering Knuckle

5 - 30 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 126 of 1200

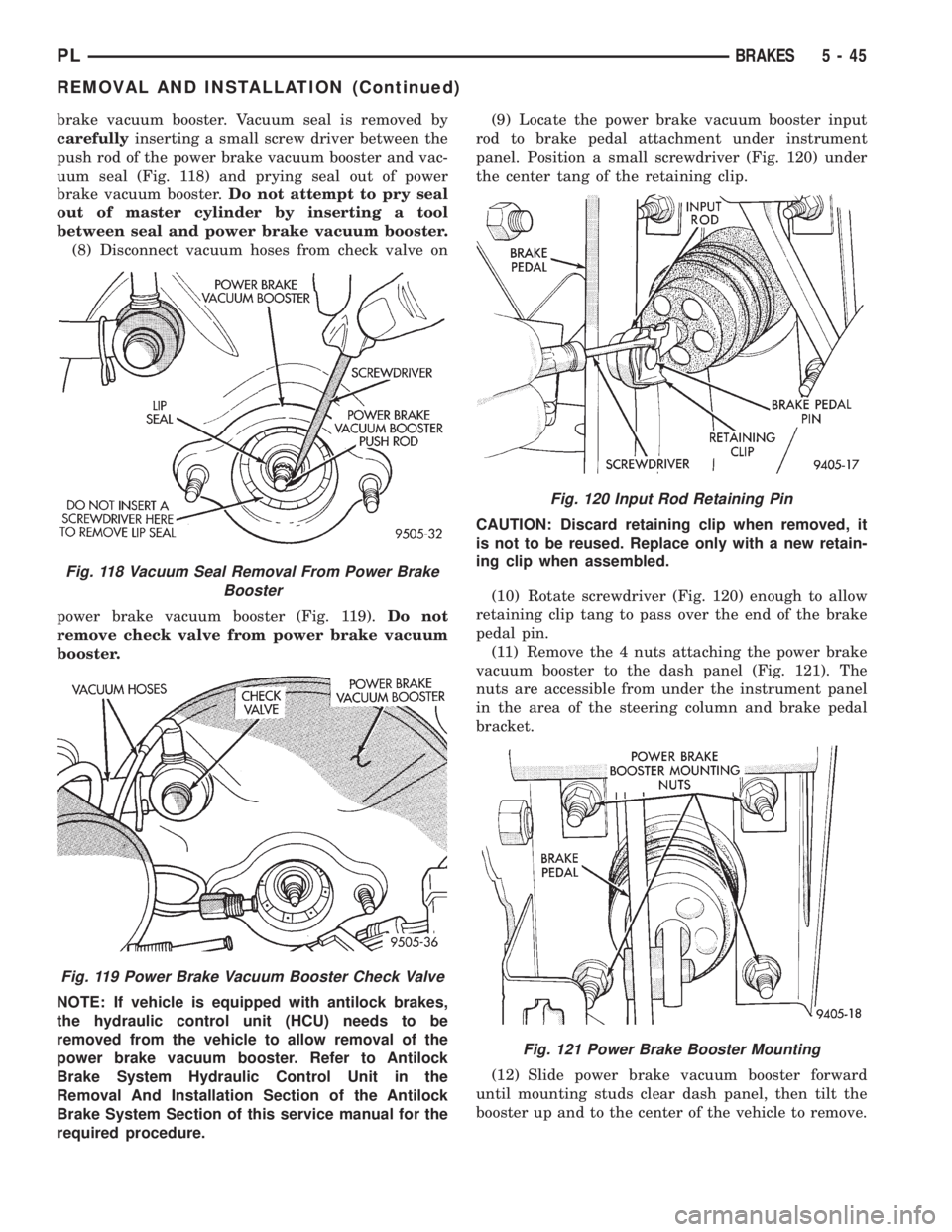

brake vacuum booster. Vacuum seal is removed by

carefullyinserting a small screw driver between the

push rod of the power brake vacuum booster and vac-

uum seal (Fig. 118) and prying seal out of power

brake vacuum booster.Do not attempt to pry seal

out of master cylinder by inserting a tool

between seal and power brake vacuum booster.

(8) Disconnect vacuum hoses from check valve on

power brake vacuum booster (Fig. 119).Do not

remove check valve from power brake vacuum

booster.

NOTE: If vehicle is equipped with antilock brakes,

the hydraulic control unit (HCU) needs to be

removed from the vehicle to allow removal of the

power brake vacuum booster. Refer to Antilock

Brake System Hydraulic Control Unit in the

Removal And Installation Section of the Antilock

Brake System Section of this service manual for the

required procedure.(9) Locate the power brake vacuum booster input

rod to brake pedal attachment under instrument

panel. Position a small screwdriver (Fig. 120) under

the center tang of the retaining clip.

CAUTION: Discard retaining clip when removed, it

is not to be reused. Replace only with a new retain-

ing clip when assembled.

(10) Rotate screwdriver (Fig. 120) enough to allow

retaining clip tang to pass over the end of the brake

pedal pin.

(11) Remove the 4 nuts attaching the power brake

vacuum booster to the dash panel (Fig. 121). The

nuts are accessible from under the instrument panel

in the area of the steering column and brake pedal

bracket.

(12) Slide power brake vacuum booster forward

until mounting studs clear dash panel, then tilt the

booster up and to the center of the vehicle to remove.

Fig. 118 Vacuum Seal Removal From Power Brake

Booster

Fig. 119 Power Brake Vacuum Booster Check Valve

Fig. 120 Input Rod Retaining Pin

Fig. 121 Power Brake Booster Mounting

PLBRAKES 5 - 45

REMOVAL AND INSTALLATION (Continued)

Page 148 of 1200

(3) Remove the rubber plug from the adjusting

hole in the brake shoe backing plate on both sides of

the vehicle.

(4)Driver (left) side park brake shoe adjust-

ment procedure.Insert a medium size screwdriver

through adjustment hole in backing plate. Position

the srewdriver against the starwheel on the park

brake shoe adjuster mechanism. Using the screw-

driver rotate the starwheeldownwarduntil a slight

drag is felt when turning the rear tire and wheel.

Then, using the screwdriver rotate the starwheel

upwardjust until the rear tire and wheel can be

rotated with no park brake shoe drag. From the

point where there is no more park brake drag rotate

the starwheelupwarda maximum of two additional

clicks. The park brake shoe to drum clearance is

know properly adjusted.

(5)Passenger (right) side park brake shoe

adjustment procedure.Insert a medium size

screwdriver through adjustment hole in backing

plate. Position the srewdriver against the starwheel

on the park brake shoe adjuster mechanism. Using

the screwdriver rotate the starwheelupwarduntil a

slight drag is felt when turning the rear tire and

wheel. Then, using the screwdriver rotate the star-

wheeldownwardjust until the rear tire and wheel

can be rotated with no park brake shoe drag. From

the point where there is no more park brake drag

rotate the starwheeldownwarda maximum of two

additional clicks. The park brake shoe to drum clear-

ance is know properly adjusted.

(6) Install the rubber plug in the adjusting hole on

the brake shoe backing plate on both sides of the

vehicle.

(7) Lower vehicle far enough to allow access the

park brake lever. The rear tires must not be on the

ground.

(8) Fully apply and release the park brakes two

times after adjusting the park brake shoes. Then

rotate both rear wheels to ensure that the park

brake shoes do not drag on the brake drum following

the application and release of the park brakes.

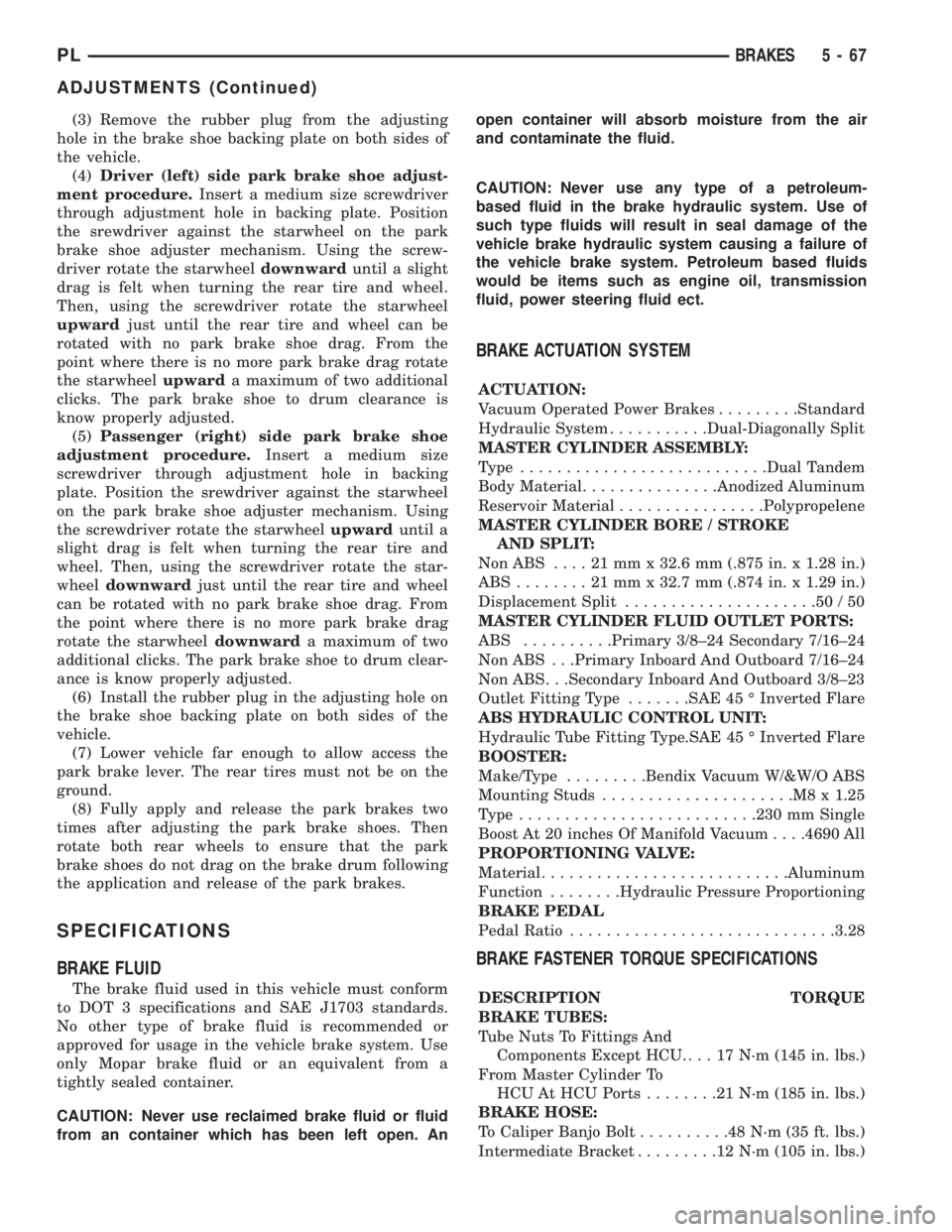

SPECIFICATIONS

BRAKE FLUID

The brake fluid used in this vehicle must conform

to DOT 3 specifications and SAE J1703 standards.

No other type of brake fluid is recommended or

approved for usage in the vehicle brake system. Use

only Mopar brake fluid or an equivalent from a

tightly sealed container.

CAUTION: Never use reclaimed brake fluid or fluid

from an container which has been left open. Anopen container will absorb moisture from the air

and contaminate the fluid.

CAUTION: Never use any type of a petroleum-

based fluid in the brake hydraulic system. Use of

such type fluids will result in seal damage of the

vehicle brake hydraulic system causing a failure of

the vehicle brake system. Petroleum based fluids

would be items such as engine oil, transmission

fluid, power steering fluid ect.

BRAKE ACTUATION SYSTEM

ACTUATION:

Vacuum Operated Power Brakes.........Standard

Hydraulic System...........Dual-Diagonally Split

MASTER CYLINDER ASSEMBLY:

Type ...........................Dual Tandem

Body Material...............Anodized Aluminum

Reservoir Material................Polypropelene

MASTER CYLINDER BORE / STROKE

AND SPLIT:

NonABS ....21mmx32.6 mm (.875 in. x 1.28 in.)

ABS........21mmx32.7 mm (.874 in. x 1.29 in.)

Displacement Split.....................50/50

MASTER CYLINDER FLUID OUTLET PORTS:

ABS ..........Primary 3/8±24 Secondary 7/16±24

Non ABS . . .Primary Inboard And Outboard 7/16±24

Non ABS . . .Secondary Inboard And Outboard 3/8±23

Outlet Fitting Type.......SAE 45 É Inverted Flare

ABS HYDRAULIC CONTROL UNIT:

Hydraulic Tube Fitting Type.SAE 45 É Inverted Flare

BOOSTER:

Make/Type.........Bendix Vacuum W/&W/O ABS

Mounting Studs.....................M8x1.25

Type ..........................230 mm Single

Boost At 20 inches Of Manifold Vacuum. . . .4690 All

PROPORTIONING VALVE:

Material...........................Aluminum

Function........Hydraulic Pressure Proportioning

BRAKE PEDAL

Pedal Ratio.............................3.28

BRAKE FASTENER TORQUE SPECIFICATIONS

DESCRIPTION TORQUE

BRAKE TUBES:

Tube Nuts To Fittings And

Components Except HCU. . . . 17 N´m (145 in. lbs.)

From Master Cylinder To

HCU At HCU Ports........21N´m(185 in. lbs.)

BRAKE HOSE:

To Caliper Banjo Bolt..........48N´m(35ft.lbs.)

Intermediate Bracket.........12N´m(105 in. lbs.)

PLBRAKES 5 - 67

ADJUSTMENTS (Continued)

Page 150 of 1200

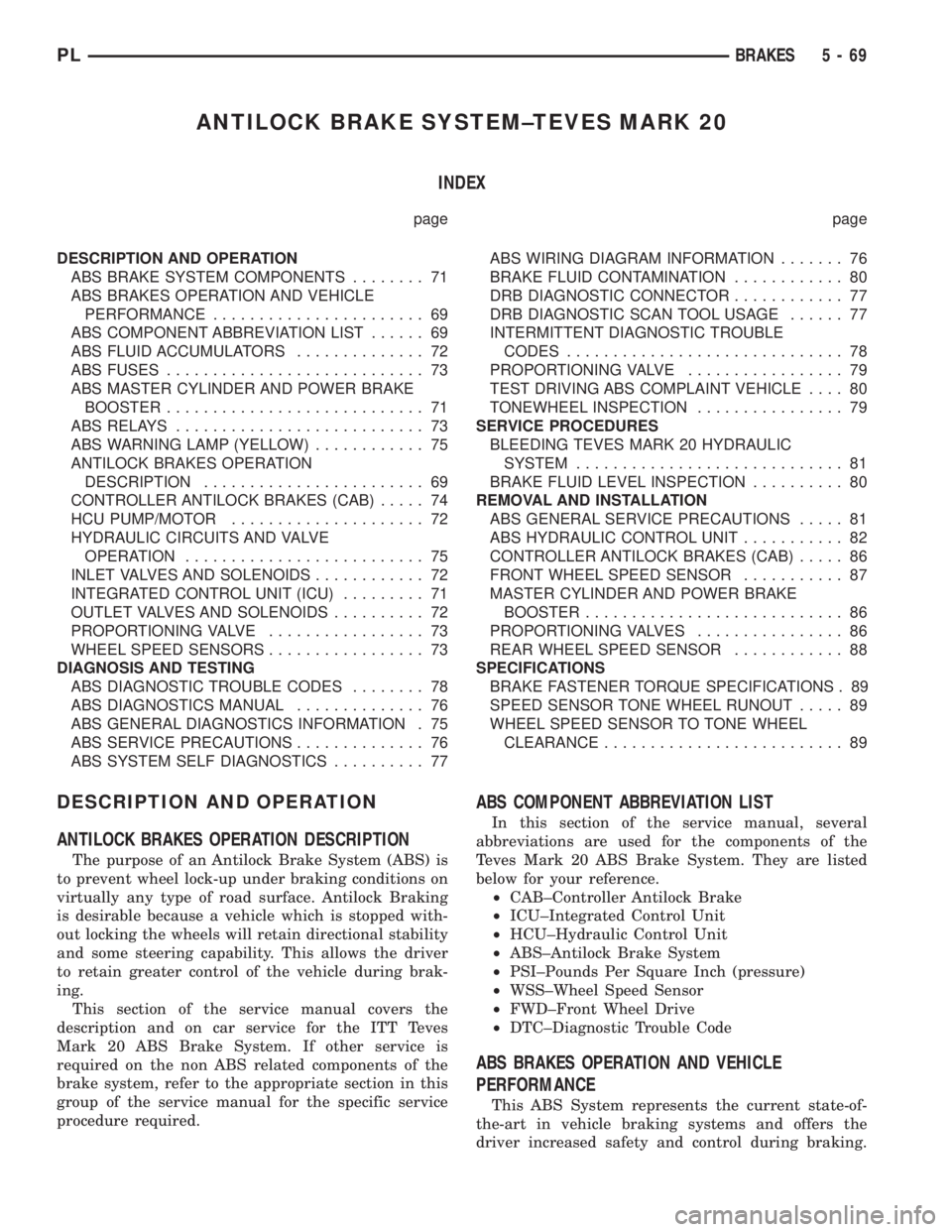

ANTILOCK BRAKE SYSTEM±TEVES MARK 20

INDEX

page page

DESCRIPTION AND OPERATION

ABS BRAKE SYSTEM COMPONENTS........ 71

ABS BRAKES OPERATION AND VEHICLE

PERFORMANCE....................... 69

ABS COMPONENT ABBREVIATION LIST...... 69

ABS FLUID ACCUMULATORS.............. 72

ABS FUSES............................ 73

ABS MASTER CYLINDER AND POWER BRAKE

BOOSTER............................ 71

ABS RELAYS........................... 73

ABS WARNING LAMP (YELLOW)............ 75

ANTILOCK BRAKES OPERATION

DESCRIPTION........................ 69

CONTROLLER ANTILOCK BRAKES (CAB)..... 74

HCU PUMP/MOTOR..................... 72

HYDRAULIC CIRCUITS AND VALVE

OPERATION.......................... 75

INLET VALVES AND SOLENOIDS............ 72

INTEGRATED CONTROL UNIT (ICU)......... 71

OUTLET VALVES AND SOLENOIDS.......... 72

PROPORTIONING VALVE................. 73

WHEEL SPEED SENSORS................. 73

DIAGNOSIS AND TESTING

ABS DIAGNOSTIC TROUBLE CODES........ 78

ABS DIAGNOSTICS MANUAL.............. 76

ABS GENERAL DIAGNOSTICS INFORMATION . 75

ABS SERVICE PRECAUTIONS.............. 76

ABS SYSTEM SELF DIAGNOSTICS.......... 77ABS WIRING DIAGRAM INFORMATION....... 76

BRAKE FLUID CONTAMINATION............ 80

DRB DIAGNOSTIC CONNECTOR............ 77

DRB DIAGNOSTIC SCAN TOOL USAGE...... 77

INTERMITTENT DIAGNOSTIC TROUBLE

CODES.............................. 78

PROPORTIONING VALVE................. 79

TEST DRIVING ABS COMPLAINT VEHICLE.... 80

TONEWHEEL INSPECTION................ 79

SERVICE PROCEDURES

BLEEDING TEVES MARK 20 HYDRAULIC

SYSTEM............................. 81

BRAKE FLUID LEVEL INSPECTION.......... 80

REMOVAL AND INSTALLATION

ABS GENERAL SERVICE PRECAUTIONS..... 81

ABS HYDRAULIC CONTROL UNIT........... 82

CONTROLLER ANTILOCK BRAKES (CAB)..... 86

FRONT WHEEL SPEED SENSOR........... 87

MASTER CYLINDER AND POWER BRAKE

BOOSTER............................ 86

PROPORTIONING VALVES................ 86

REAR WHEEL SPEED SENSOR............ 88

SPECIFICATIONS

BRAKE FASTENER TORQUE SPECIFICATIONS . 89

SPEED SENSOR TONE WHEEL RUNOUT..... 89

WHEEL SPEED SENSOR TO TONE WHEEL

CLEARANCE.......................... 89

DESCRIPTION AND OPERATION

ANTILOCK BRAKES OPERATION DESCRIPTION

The purpose of an Antilock Brake System (ABS) is

to prevent wheel lock-up under braking conditions on

virtually any type of road surface. Antilock Braking

is desirable because a vehicle which is stopped with-

out locking the wheels will retain directional stability

and some steering capability. This allows the driver

to retain greater control of the vehicle during brak-

ing.

This section of the service manual covers the

description and on car service for the ITT Teves

Mark 20 ABS Brake System. If other service is

required on the non ABS related components of the

brake system, refer to the appropriate section in this

group of the service manual for the specific service

procedure required.

ABS COMPONENT ABBREVIATION LIST

In this section of the service manual, several

abbreviations are used for the components of the

Teves Mark 20 ABS Brake System. They are listed

below for your reference.

²CAB±Controller Antilock Brake

²ICU±Integrated Control Unit

²HCU±Hydraulic Control Unit

²ABS±Antilock Brake System

²PSI±Pounds Per Square Inch (pressure)

²WSS±Wheel Speed Sensor

²FWD±Front Wheel Drive

²DTC±Diagnostic Trouble Code

ABS BRAKES OPERATION AND VEHICLE

PERFORMANCE

This ABS System represents the current state-of-

the-art in vehicle braking systems and offers the

driver increased safety and control during braking.

PLBRAKES 5 - 69

Page 151 of 1200

This is accomplished by a sophisticated system of

electrical and hydraulic components. As a result,

there are a few performance characteristics that may

at first seem different but should be considered nor-

mal. These characteristics are discussed below.

NORMAL BRAKING SYSTEM FUNCTION

Under normal braking conditions, the ABS System

functions the same as a standard brake system with

a diagonally split master cylinder and conventional

vacuum assist.

ABS SYSTEM OPERATION

If a wheel locking tendency is detected during a

brake application, the brake system will enter the

ABS mode. During ABS braking, hydraulic pressure

in the four wheel circuits is modulated to prevent

any wheel from locking. Each wheel circuit is

designed with a set of electric solenoids to allow mod-

ulation, although for vehicle stability, both rear

wheel solenoids receive the same electrical signal.

During an ABS stop, the brakes hydraulic system

is still diagonally split. However, the brake system

pressure is further split into four control channels.

During antilock operation of the vehicle's brake sys-

tem the front wheels are controlled independently

and are on two separate control channels and the

rear wheels of the vehicle are controlled together.

The system can build and release pressure at each

wheel, depending on signals generated by the wheel

speed sensors (WSS) at each wheel and received at

the Controller Antilock Brake (CAB).

ABS operation is available at all vehicle speeds

above 3 to 5 mph. Wheel lockup may be perceived at

the very end of an ABS stop and is considered nor-

mal.

VEHICLE HANDLING PERFORMANCE DURING

ABS BRAKING

It is important to remember that an antilock brake

system does not shorten a vehicle's stopping distance

under all driving conditions, but does provide

improved control of the vehicle while stopping. Vehi-

cle stopping distance is still dependent on vehicle

speed, weight, tires, road surfaces and other factors.

Though ABS provides the driver with some steer-

ing control during hard braking, there are conditions

however, where the system does not provide any ben-

efit. In particular, hydroplaning is still possible when

the tires ride on a film of water. This results in the

vehicles tires leaving the road surface rendering the

vehicle virtually uncontrollable. In addition, extreme

steering maneuvers at high speed or high speed cor-

nering beyond the limits of tire adhesion to the road

surface may cause vehicle skidding, independent of

vehicle braking. For this reason, the ABS system is

termed Antilock instead of Anti-Skid.

NOISE AND BRAKE PEDAL FEEL

During ABS braking, some brake pedal movement

may be felt. In addition, ABS braking will create

ticking, popping and/or groaning noises heard by the

driver. This is normal due to pressurized fluid being

transferred between the master cylinder and the

brakes. If ABS operation occurs during hard braking,

some pulsation may be felt in the vehicle body due to

fore and aft movement of the suspension as brake

pressures are modulated.

At the end of an ABS stop, ABS will be turned off

when the vehicle is slowed to a speed of 3±4 mph.

There may be a slight brake pedal drop anytime that

the ABS is deactivated, such as at the end of the stop

when the vehicle speed is less then 3 mph or during

an ABS stop where ABS is no longer required. These

conditions will exist when a vehicle is being stopped

on a road surface with patches of ice, loose gravel or

sand on it. Also stopping a vehicle on a bumpy road

surface will activate ABS because of the wheel hop

caused by the bumps.

TIRE NOISE AND MARKS

Although the ABS system prevents complete wheel

lock-up, some wheel slip is desired in order to

achieve optimum braking performance. Wheel slip is

defined as follows, 0 percent slip means the wheel is

rolling freely and 100 percent slip means the wheel is

fully locked. During brake pressure modulation,

wheel slip is allowed to reach up to 25 to30%. This

means that the wheel rolling velocity is 25 to 30%

less than that of a free rolling wheel at a given vehi-

cle speed. This slip may result in some tire chirping,

depending on the road surface. This sound should not

be interpreted as total wheel lock-up.

Complete wheel lock up normally leaves black tire

marks on dry pavement. The ABS System will not

leave dark black tire marks since the wheel never

reaches a fully locked condition. Tire marks may

however be noticeable as light patched marks.

START UP CYCLE

When the ignition is turned on, a popping sound

and a slight brake pedal movement may be noticed.

Additionally, when the vehicle is first driven off a

humming may be heard and/or felt by the driver at

approximately 20 to 40 kph (12 to 25 mph). The ABS

warning lamp will also be on for up to 5 seconds

after the ignition is turned on. All of these conditions

are a normal function of ABS as the system is per-

forming a diagnosis check.

5 - 70 BRAKESPL

DESCRIPTION AND OPERATION (Continued)

Page 152 of 1200

PREMATURE ABS CYCLING

NOTE: When working on a vehicle which has a

complaint of premature ABS cycling it may be nec-

essary to use a DRB Scan Tool to detect and verify

the condition.

There is one complaint called Premature ABS

Cycling in which neither the Red Brake Warning

Lamp nor the Amber Antilock Lamp were illumi-

nated and no fault codes were stored in the CAB.

Symptoms of Premature ABS Cycling, include click-

ing sounds from the solenoids valves, pump motor

running and pulsations in the brake pedal. This con-

dition can occur at any braking rate of the vehicle

and on any type of road surface. This creates an

additional condition which needs to be correctly

assessed when diagnosing problems with the antilock

brake system.

The following conditions are common causes that

need to be checked when diagnosing a condition of

Premature ABS Cycling. Damaged tone wheels,

incorrect tone wheels, damage to a wheel speed sen-

sor mounting boss on a steering knuckle, a loose

wheel speed sensor mounting bolt, and excessive tone

wheel runout. Also, an excessively large tone wheel

to wheel speed sensor air gap can lead to the condi-

tion of Premature ABS Cycling. Special attention is

to be given to these components when diagnosing a

vehicle exhibiting the condition of Premature ABS

Cycling. After diagnosing the defective component,

repair or replace as required.

When the component repair or replacement is com-

pleted, test drive the vehicle to verify the condition of

Premature ABS Cycling has been corrected.

ABS BRAKE SYSTEM COMPONENTS

The following is a detailed description of the Teves

Mark 20 ABS brake system components. For infor-

mation on servicing the base brake system compo-

nents, see the base Brake System section of this

Service Manual.

ABS MASTER CYLINDER AND POWER BRAKE

BOOSTER

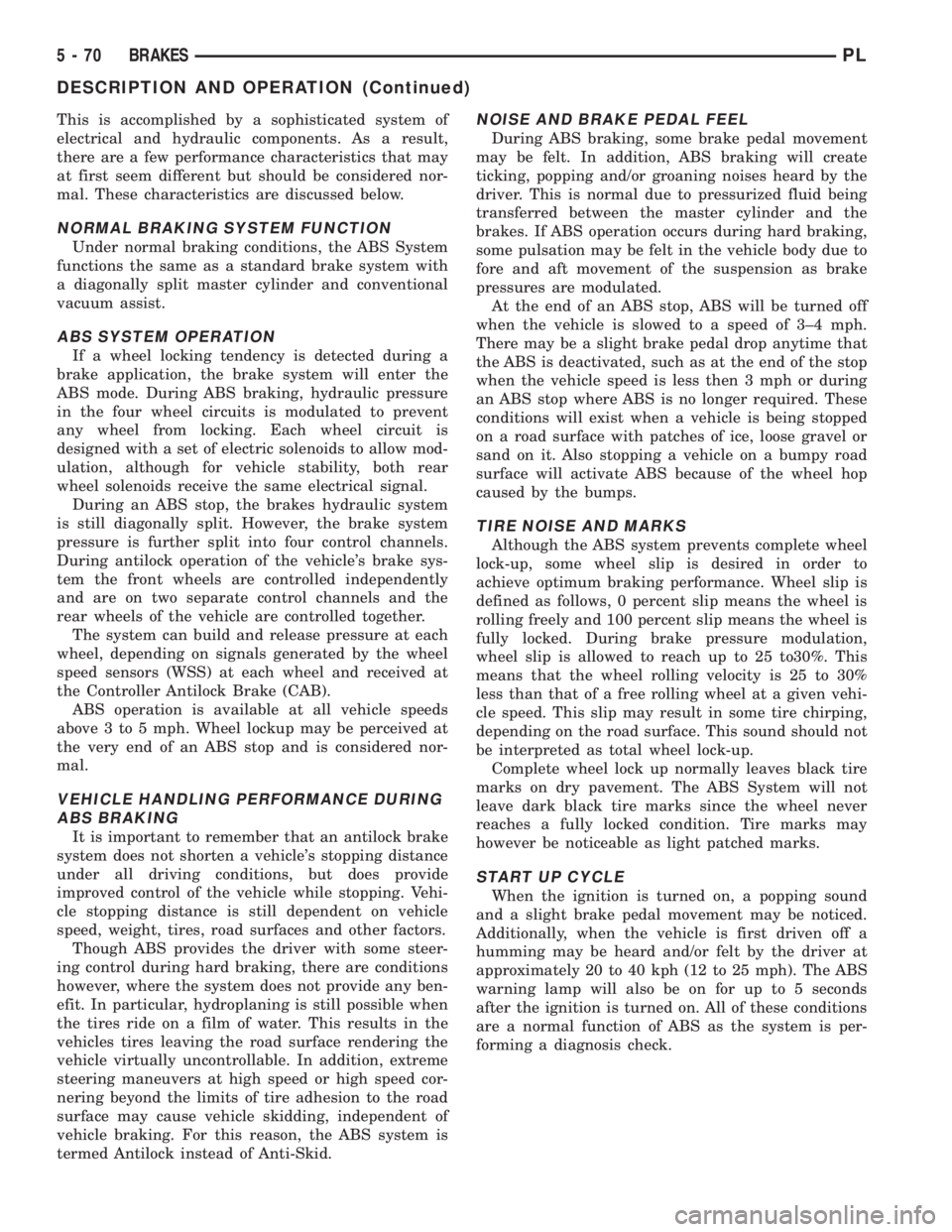

A vehicle equipped with the Teves Mark 20 ABS

uses a different master cylinder and power brake

booster (Fig. 1) then a vehicle that is not equipped

with antilock brakes. A vehicle equipped with ABS

uses a center port master cylinder while a vehicle

which is not equipped with ABS uses a compensating

port master cylinder.

The primary and secondary outlet ports on the

master cylinder go directly to the hydraulic control

unit HCU.Reference the appropriate section of this service

manual for further information on the individual

components.

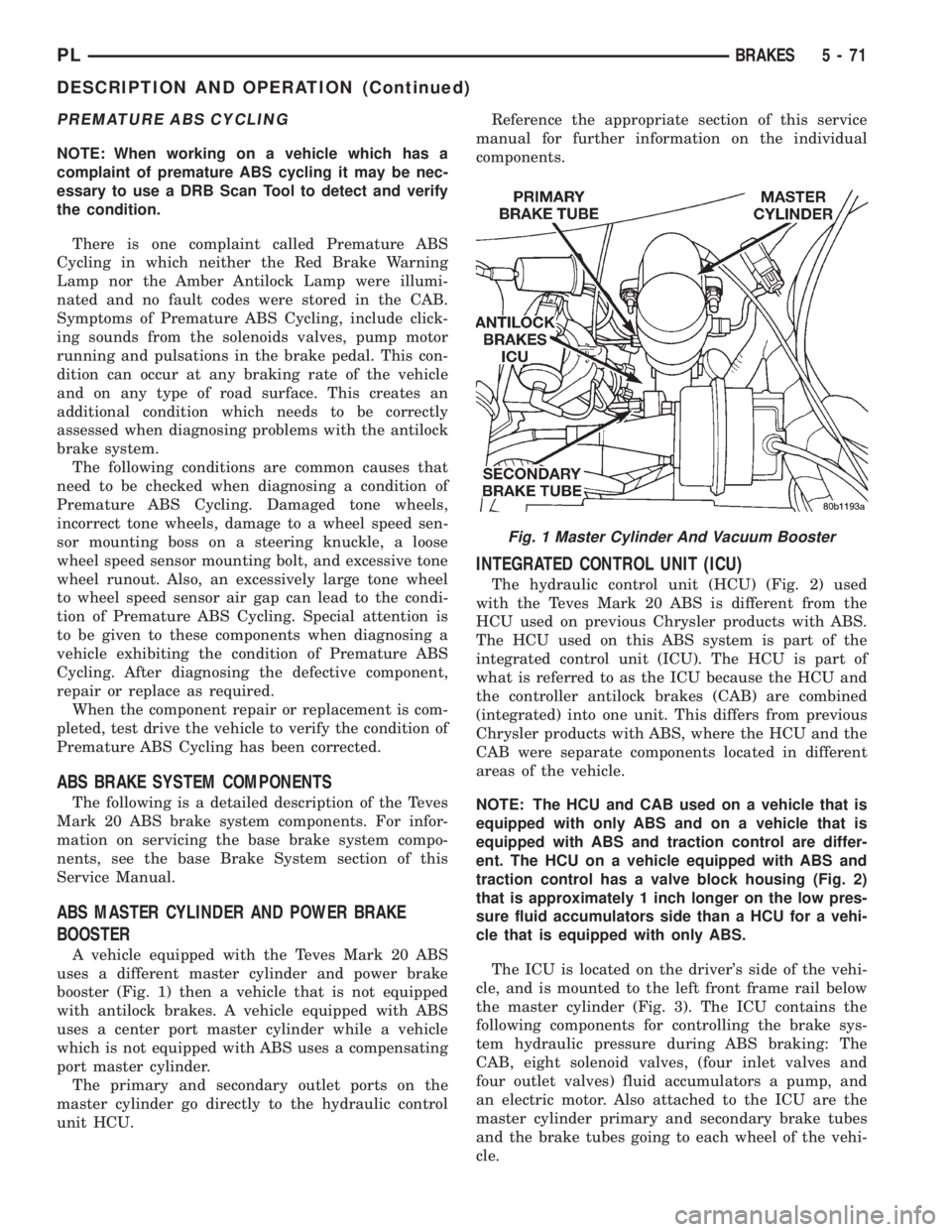

INTEGRATED CONTROL UNIT (ICU)

The hydraulic control unit (HCU) (Fig. 2) used

with the Teves Mark 20 ABS is different from the

HCU used on previous Chrysler products with ABS.

The HCU used on this ABS system is part of the

integrated control unit (ICU). The HCU is part of

what is referred to as the ICU because the HCU and

the controller antilock brakes (CAB) are combined

(integrated) into one unit. This differs from previous

Chrysler products with ABS, where the HCU and the

CAB were separate components located in different

areas of the vehicle.

NOTE: The HCU and CAB used on a vehicle that is

equipped with only ABS and on a vehicle that is

equipped with ABS and traction control are differ-

ent. The HCU on a vehicle equipped with ABS and

traction control has a valve block housing (Fig. 2)

that is approximately 1 inch longer on the low pres-

sure fluid accumulators side than a HCU for a vehi-

cle that is equipped with only ABS.

The ICU is located on the driver's side of the vehi-

cle, and is mounted to the left front frame rail below

the master cylinder (Fig. 3). The ICU contains the

following components for controlling the brake sys-

tem hydraulic pressure during ABS braking: The

CAB, eight solenoid valves, (four inlet valves and

four outlet valves) fluid accumulators a pump, and

an electric motor. Also attached to the ICU are the

master cylinder primary and secondary brake tubes

and the brake tubes going to each wheel of the vehi-

cle.

Fig. 1 Master Cylinder And Vacuum Booster

PLBRAKES 5 - 71

DESCRIPTION AND OPERATION (Continued)