DODGE RAM 2001 Service Repair Manual

Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 251 of 2889

(12) Add 0.254mm (0.010 in.) to the zero end play

total. This total represents the thickness of shims to

preload the new bearings when the differential is

installed.

(13) Rotate dial indicator out of the way on the

pilot stud.(14) Remove differential case and dummy bearings

from the housing.

(15) Install the pinion gear in axle housing. Install

the pinion yoke, or flange, and establish the correct

pinion rotating torque.

(16) Install differential case and Dummy Bearings

D-346 in the housing (without shims), install bearing

caps and tighten bolts snug .

(17) Seat ring gear side dummy bearing (Fig. 12).

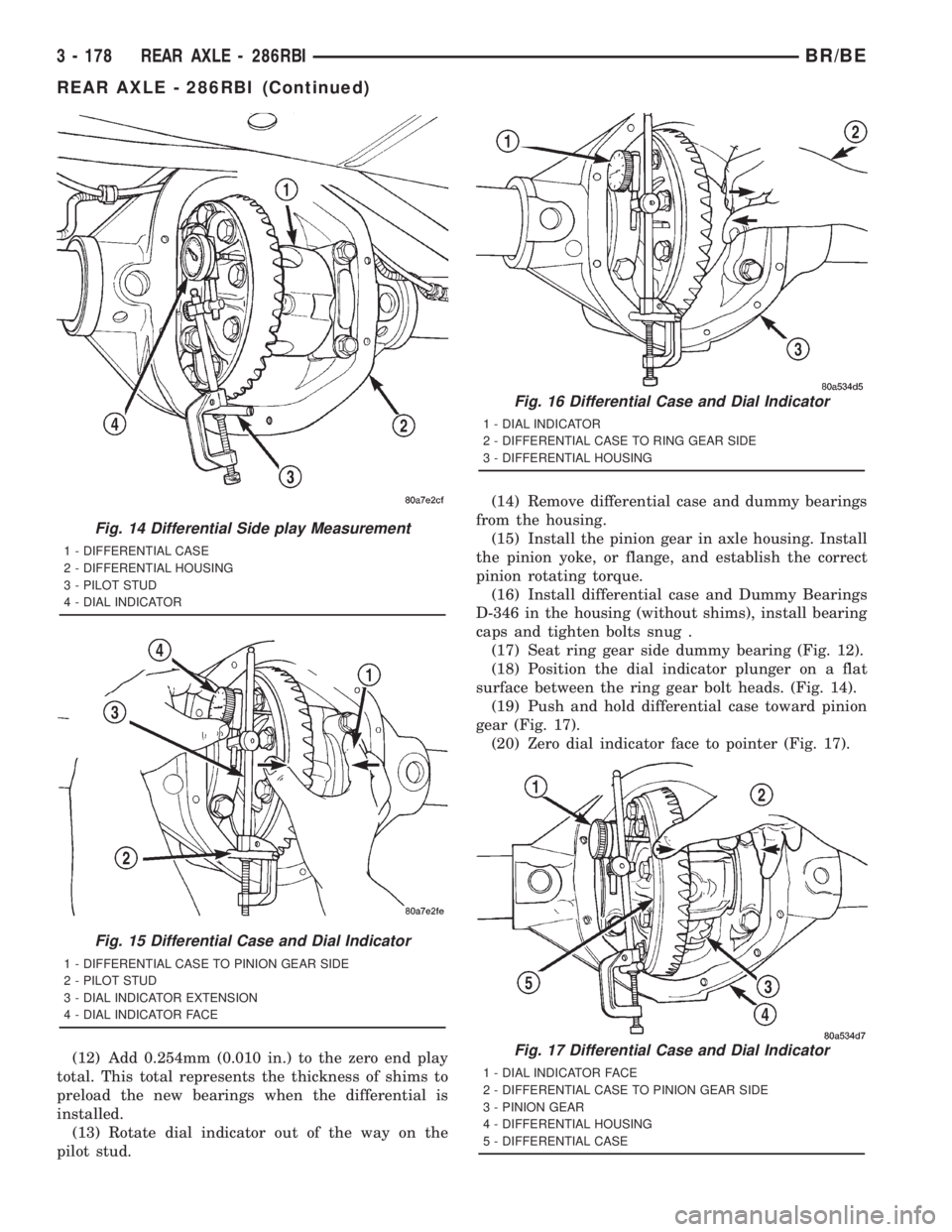

(18) Position the dial indicator plunger on a flat

surface between the ring gear bolt heads. (Fig. 14).

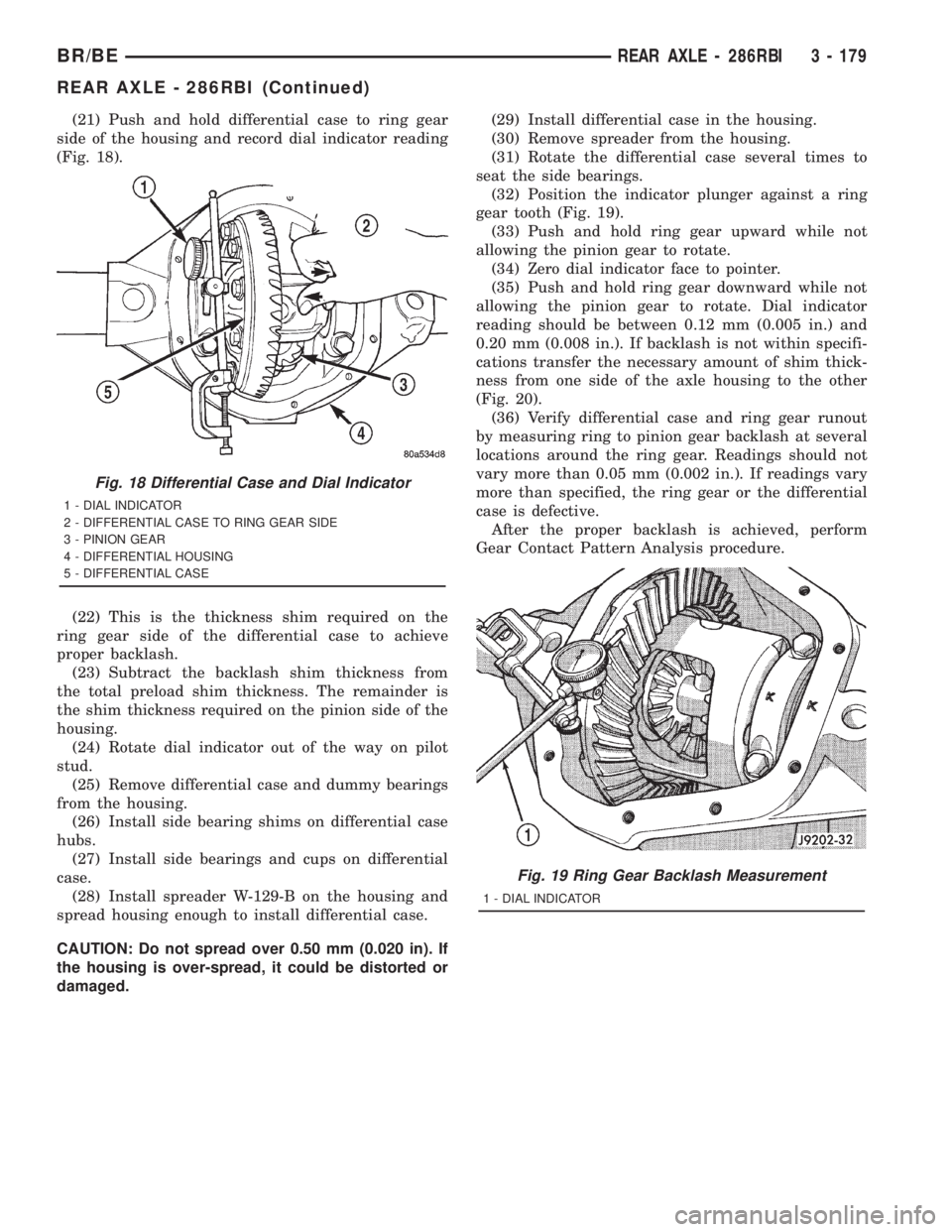

(19) Push and hold differential case toward pinion

gear (Fig. 17).

(20) Zero dial indicator face to pointer (Fig. 17).

Fig. 14 Differential Side play Measurement

1 - DIFFERENTIAL CASE

2 - DIFFERENTIAL HOUSING

3 - PILOT STUD

4 - DIAL INDICATOR

Fig. 15 Differential Case and Dial Indicator

1 - DIFFERENTIAL CASE TO PINION GEAR SIDE

2 - PILOT STUD

3 - DIAL INDICATOR EXTENSION

4 - DIAL INDICATOR FACE

Fig. 16 Differential Case and Dial Indicator

1 - DIAL INDICATOR

2 - DIFFERENTIAL CASE TO RING GEAR SIDE

3 - DIFFERENTIAL HOUSING

Fig. 17 Differential Case and Dial Indicator

1 - DIAL INDICATOR FACE

2 - DIFFERENTIAL CASE TO PINION GEAR SIDE

3 - PINION GEAR

4 - DIFFERENTIAL HOUSING

5 - DIFFERENTIAL CASE

3 - 178 REAR AXLE - 286RBIBR/BE

REAR AXLE - 286RBI (Continued)

Page 252 of 2889

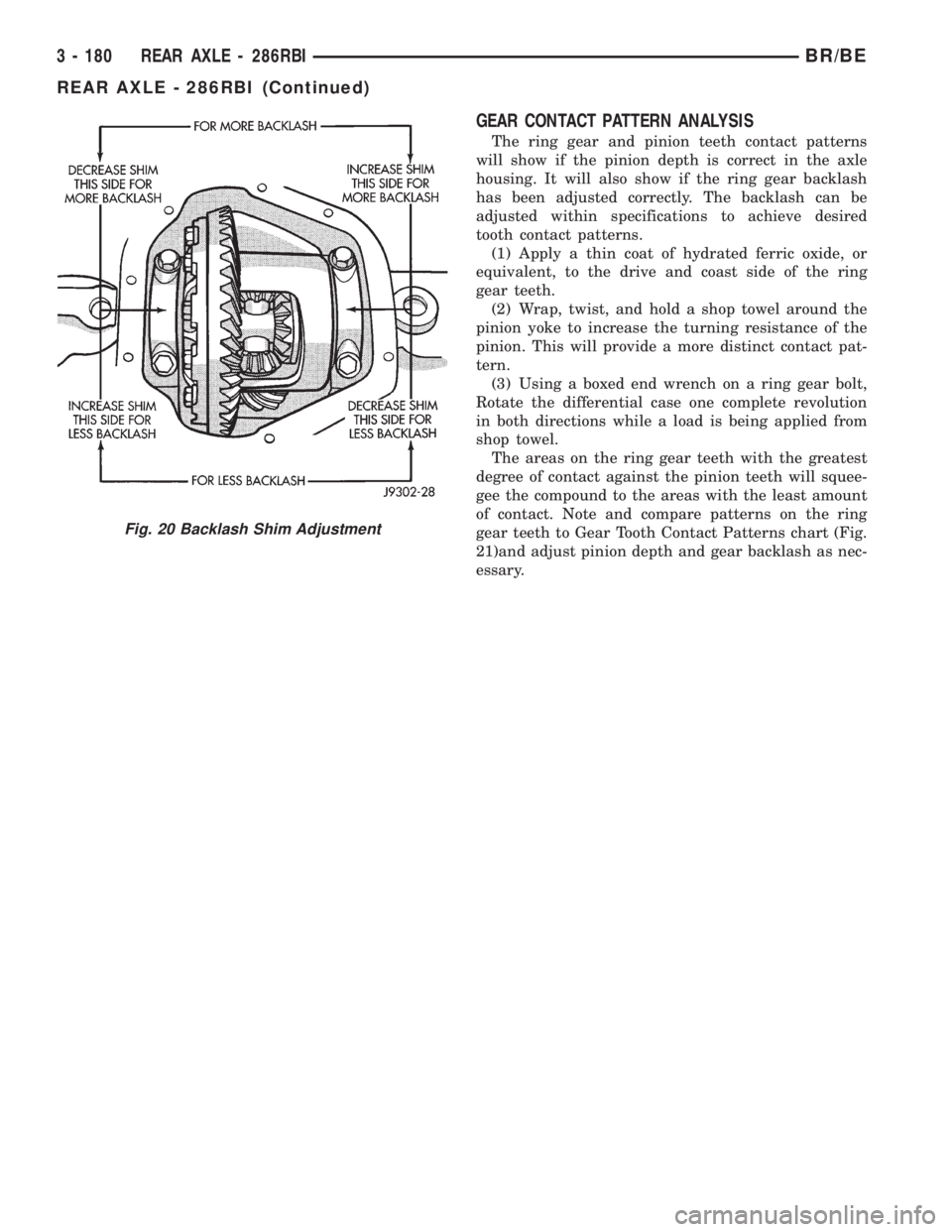

(21) Push and hold differential case to ring gear

side of the housing and record dial indicator reading

(Fig. 18).

(22) This is the thickness shim required on the

ring gear side of the differential case to achieve

proper backlash.

(23) Subtract the backlash shim thickness from

the total preload shim thickness. The remainder is

the shim thickness required on the pinion side of the

housing.

(24) Rotate dial indicator out of the way on pilot

stud.

(25) Remove differential case and dummy bearings

from the housing.

(26) Install side bearing shims on differential case

hubs.

(27) Install side bearings and cups on differential

case.

(28) Install spreader W-129-B on the housing and

spread housing enough to install differential case.

CAUTION: Do not spread over 0.50 mm (0.020 in). If

the housing is over-spread, it could be distorted or

damaged.(29) Install differential case in the housing.

(30) Remove spreader from the housing.

(31) Rotate the differential case several times to

seat the side bearings.

(32) Position the indicator plunger against a ring

gear tooth (Fig. 19).

(33) Push and hold ring gear upward while not

allowing the pinion gear to rotate.

(34) Zero dial indicator face to pointer.

(35) Push and hold ring gear downward while not

allowing the pinion gear to rotate. Dial indicator

reading should be between 0.12 mm (0.005 in.) and

0.20 mm (0.008 in.). If backlash is not within specifi-

cations transfer the necessary amount of shim thick-

ness from one side of the axle housing to the other

(Fig. 20).

(36) Verify differential case and ring gear runout

by measuring ring to pinion gear backlash at several

locations around the ring gear. Readings should not

vary more than 0.05 mm (0.002 in.). If readings vary

more than specified, the ring gear or the differential

case is defective.

After the proper backlash is achieved, perform

Gear Contact Pattern Analysis procedure.

Fig. 18 Differential Case and Dial Indicator

1 - DIAL INDICATOR

2 - DIFFERENTIAL CASE TO RING GEAR SIDE

3 - PINION GEAR

4 - DIFFERENTIAL HOUSING

5 - DIFFERENTIAL CASE

Fig. 19 Ring Gear Backlash Measurement

1 - DIAL INDICATOR

BR/BEREAR AXLE - 286RBI 3 - 179

REAR AXLE - 286RBI (Continued)

Page 253 of 2889

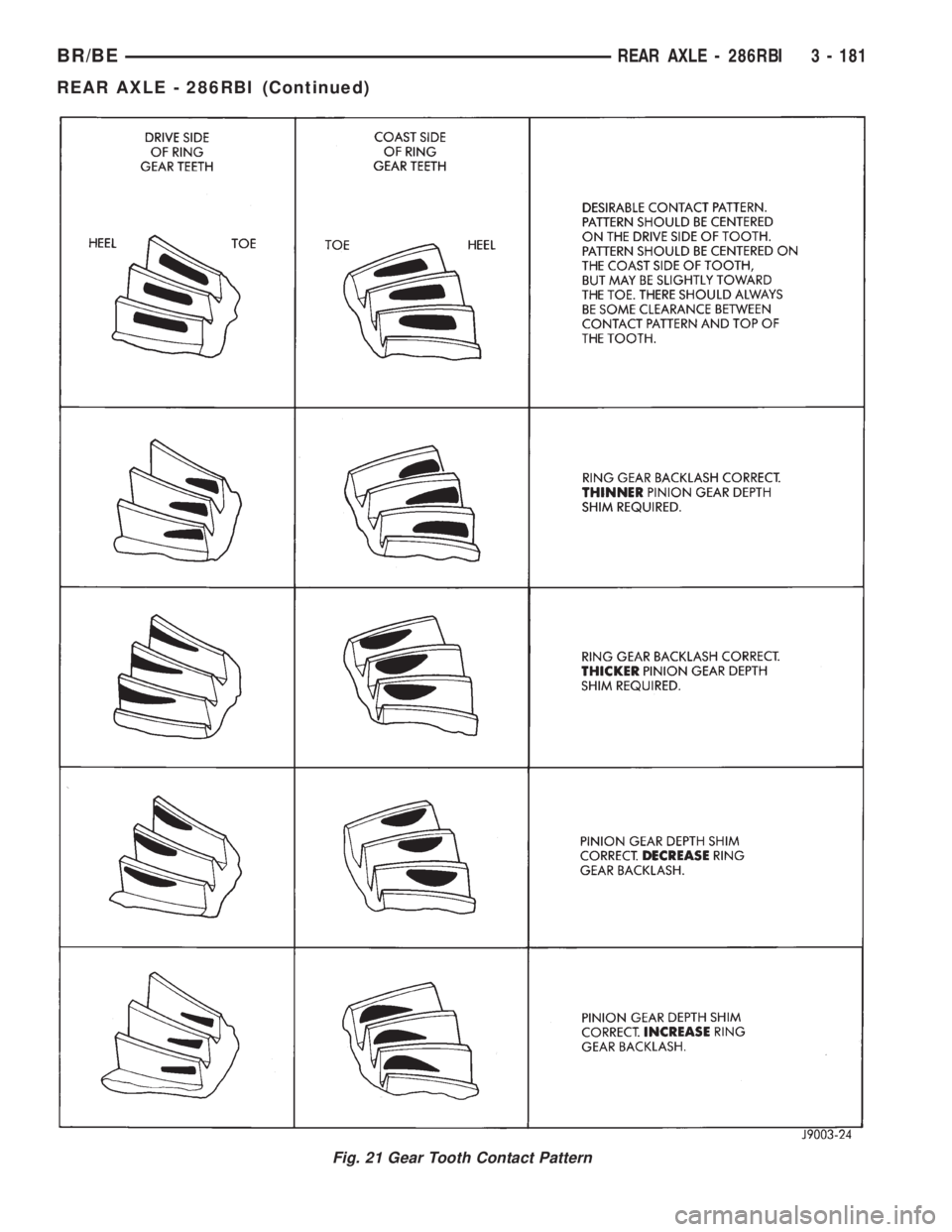

GEAR CONTACT PATTERN ANALYSIS

The ring gear and pinion teeth contact patterns

will show if the pinion depth is correct in the axle

housing. It will also show if the ring gear backlash

has been adjusted correctly. The backlash can be

adjusted within specifications to achieve desired

tooth contact patterns.

(1) Apply a thin coat of hydrated ferric oxide, or

equivalent, to the drive and coast side of the ring

gear teeth.

(2) Wrap, twist, and hold a shop towel around the

pinion yoke to increase the turning resistance of the

pinion. This will provide a more distinct contact pat-

tern.

(3) Using a boxed end wrench on a ring gear bolt,

Rotate the differential case one complete revolution

in both directions while a load is being applied from

shop towel.

The areas on the ring gear teeth with the greatest

degree of contact against the pinion teeth will squee-

gee the compound to the areas with the least amount

of contact. Note and compare patterns on the ring

gear teeth to Gear Tooth Contact Patterns chart (Fig.

21)and adjust pinion depth and gear backlash as nec-

essary.

Fig. 20 Backlash Shim Adjustment

3 - 180 REAR AXLE - 286RBIBR/BE

REAR AXLE - 286RBI (Continued)

Page 254 of 2889

Fig. 21 Gear Tooth Contact Pattern

BR/BEREAR AXLE - 286RBI 3 - 181

REAR AXLE - 286RBI (Continued)

Page 255 of 2889

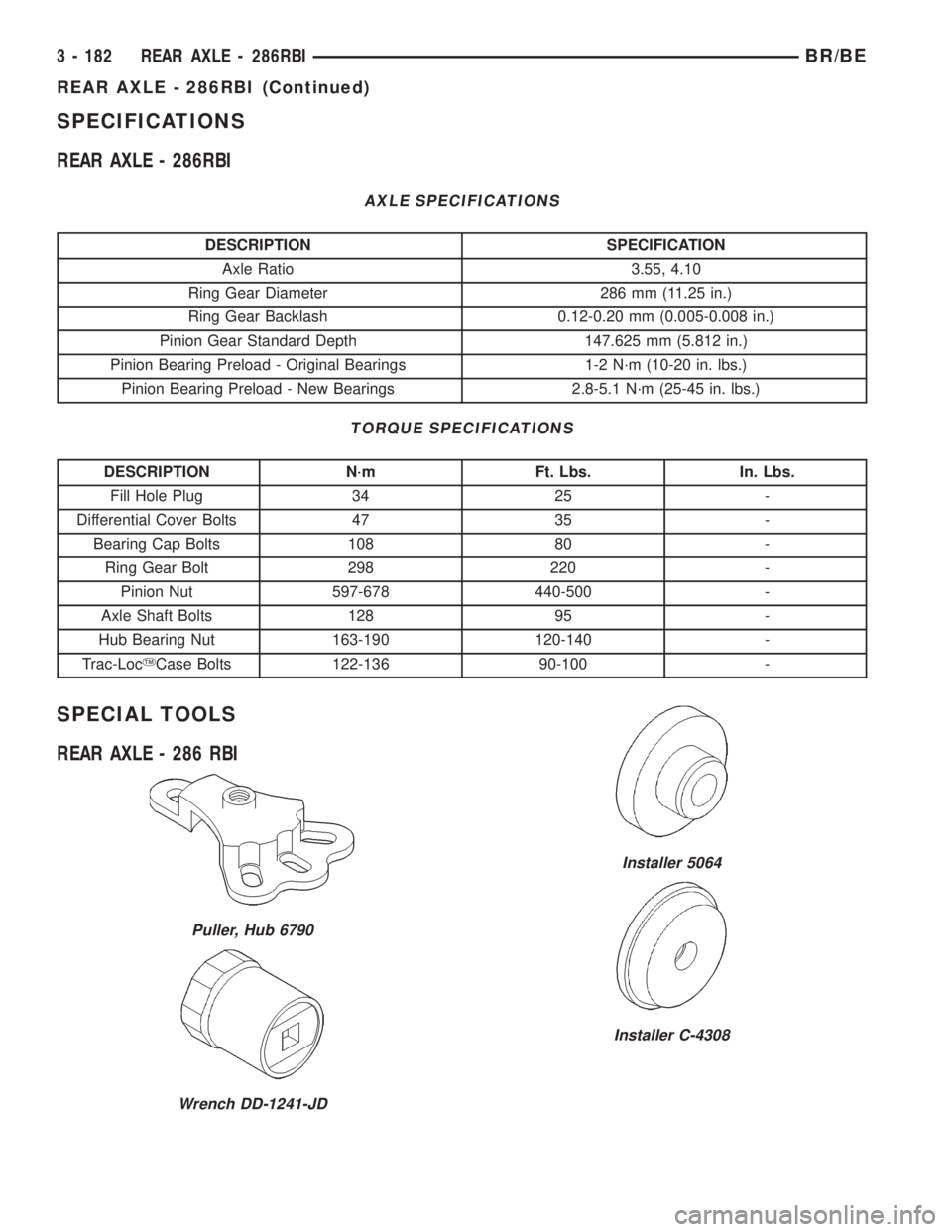

SPECIFICATIONS

REAR AXLE - 286RBI

AXLE SPECIFICATIONS

DESCRIPTION SPECIFICATION

Axle Ratio 3.55, 4.10

Ring Gear Diameter 286 mm (11.25 in.)

Ring Gear Backlash 0.12-0.20 mm (0.005-0.008 in.)

Pinion Gear Standard Depth 147.625 mm (5.812 in.)

Pinion Bearing Preload - Original Bearings 1-2 N´m (10-20 in. lbs.)

Pinion Bearing Preload - New Bearings 2.8-5.1 N´m (25-45 in. lbs.)

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Fill Hole Plug 34 25 -

Differential Cover Bolts 47 35 -

Bearing Cap Bolts 108 80 -

Ring Gear Bolt 298 220 -

Pinion Nut 597-678 440-500 -

Axle Shaft Bolts 128 95 -

Hub Bearing Nut 163-190 120-140 -

Trac-LocYCase Bolts 122-136 90-100 -

SPECIAL TOOLS

REAR AXLE - 286 RBI

Puller, Hub 6790

Wrench DD-1241-JD

Installer 5064

Installer C-4308

3 - 182 REAR AXLE - 286RBIBR/BE

REAR AXLE - 286RBI (Continued)

Page 256 of 2889

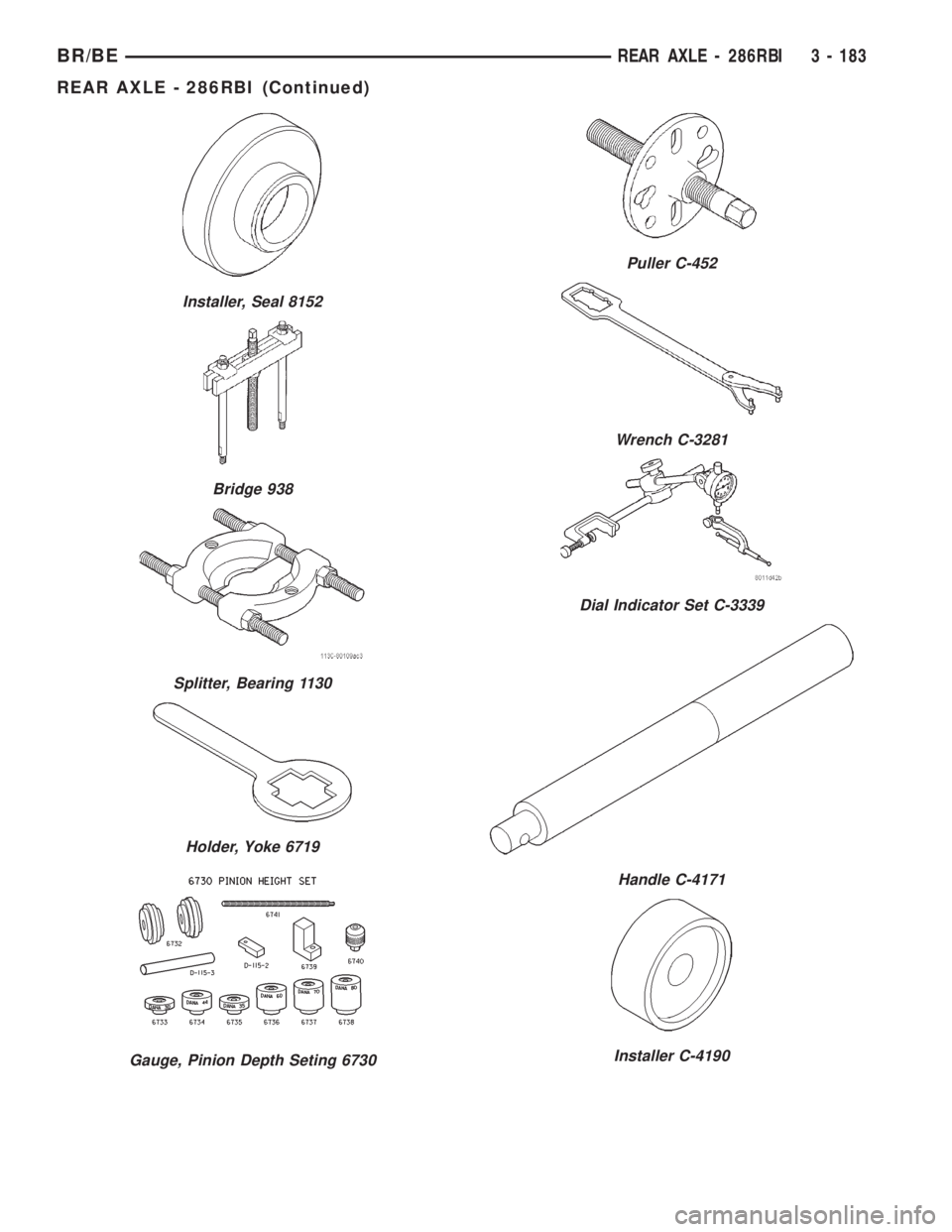

Installer, Seal 8152

Bridge 938

Splitter, Bearing 1130

Holder, Yoke 6719

Gauge, Pinion Depth Seting 6730

Puller C-452

Wrench C-3281

Dial Indicator Set C-3339

Handle C-4171

Installer C-4190

BR/BEREAR AXLE - 286RBI 3 - 183

REAR AXLE - 286RBI (Continued)

Page 257 of 2889

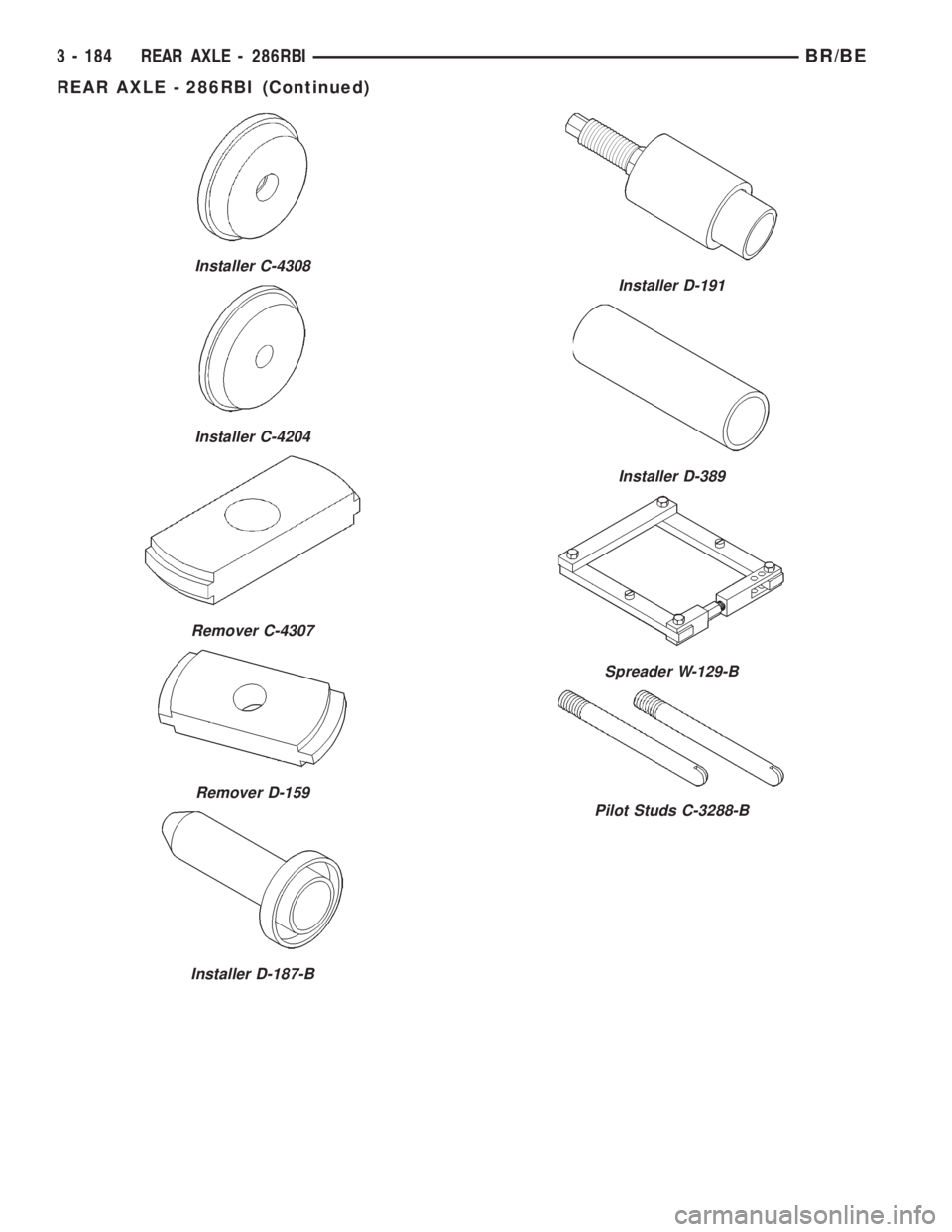

Installer C-4308

Installer C-4204

Remover C-4307

Remover D-159

Installer D-187-B

Installer D-191

Installer D-389

Spreader W-129-B

Pilot Studs C-3288-B

3 - 184 REAR AXLE - 286RBIBR/BE

REAR AXLE - 286RBI (Continued)

Page 258 of 2889

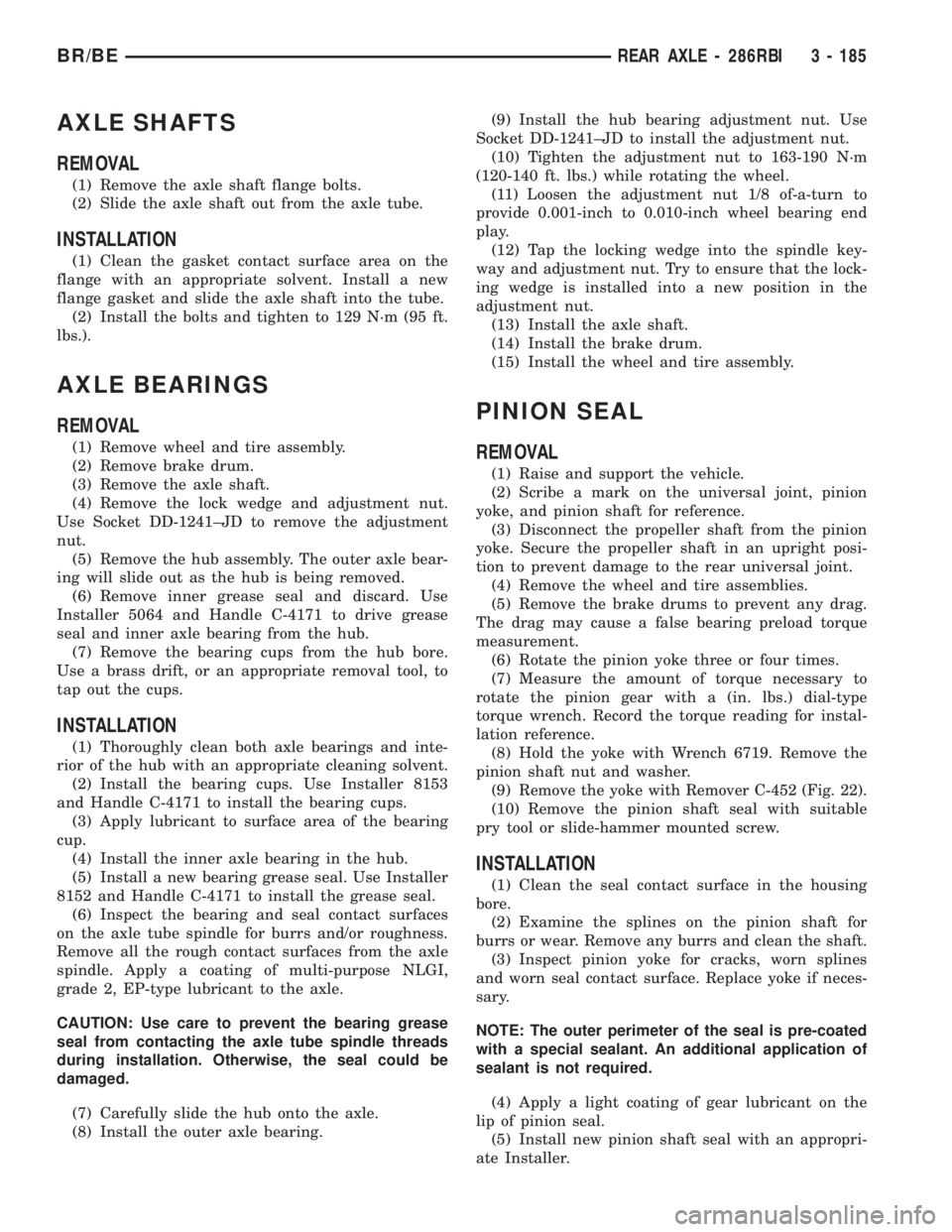

AXLE SHAFTS

REMOVAL

(1) Remove the axle shaft flange bolts.

(2) Slide the axle shaft out from the axle tube.

INSTALLATION

(1) Clean the gasket contact surface area on the

flange with an appropriate solvent. Install a new

flange gasket and slide the axle shaft into the tube.

(2) Install the bolts and tighten to 129 N´m (95 ft.

lbs.).

AXLE BEARINGS

REMOVAL

(1) Remove wheel and tire assembly.

(2) Remove brake drum.

(3) Remove the axle shaft.

(4) Remove the lock wedge and adjustment nut.

Use Socket DD-1241±JD to remove the adjustment

nut.

(5) Remove the hub assembly. The outer axle bear-

ing will slide out as the hub is being removed.

(6) Remove inner grease seal and discard. Use

Installer 5064 and Handle C-4171 to drive grease

seal and inner axle bearing from the hub.

(7) Remove the bearing cups from the hub bore.

Use a brass drift, or an appropriate removal tool, to

tap out the cups.

INSTALLATION

(1) Thoroughly clean both axle bearings and inte-

rior of the hub with an appropriate cleaning solvent.

(2) Install the bearing cups. Use Installer 8153

and Handle C-4171 to install the bearing cups.

(3) Apply lubricant to surface area of the bearing

cup.

(4) Install the inner axle bearing in the hub.

(5) Install a new bearing grease seal. Use Installer

8152 and Handle C-4171 to install the grease seal.

(6) Inspect the bearing and seal contact surfaces

on the axle tube spindle for burrs and/or roughness.

Remove all the rough contact surfaces from the axle

spindle. Apply a coating of multi-purpose NLGI,

grade 2, EP-type lubricant to the axle.

CAUTION: Use care to prevent the bearing grease

seal from contacting the axle tube spindle threads

during installation. Otherwise, the seal could be

damaged.

(7) Carefully slide the hub onto the axle.

(8) Install the outer axle bearing.(9) Install the hub bearing adjustment nut. Use

Socket DD-1241±JD to install the adjustment nut.

(10) Tighten the adjustment nut to 163-190 N´m

(120-140 ft. lbs.) while rotating the wheel.

(11) Loosen the adjustment nut 1/8 of-a-turn to

provide 0.001-inch to 0.010-inch wheel bearing end

play.

(12) Tap the locking wedge into the spindle key-

way and adjustment nut. Try to ensure that the lock-

ing wedge is installed into a new position in the

adjustment nut.

(13) Install the axle shaft.

(14) Install the brake drum.

(15) Install the wheel and tire assembly.

PINION SEAL

REMOVAL

(1) Raise and support the vehicle.

(2) Scribe a mark on the universal joint, pinion

yoke, and pinion shaft for reference.

(3) Disconnect the propeller shaft from the pinion

yoke. Secure the propeller shaft in an upright posi-

tion to prevent damage to the rear universal joint.

(4) Remove the wheel and tire assemblies.

(5) Remove the brake drums to prevent any drag.

The drag may cause a false bearing preload torque

measurement.

(6) Rotate the pinion yoke three or four times.

(7) Measure the amount of torque necessary to

rotate the pinion gear with a (in. lbs.) dial-type

torque wrench. Record the torque reading for instal-

lation reference.

(8) Hold the yoke with Wrench 6719. Remove the

pinion shaft nut and washer.

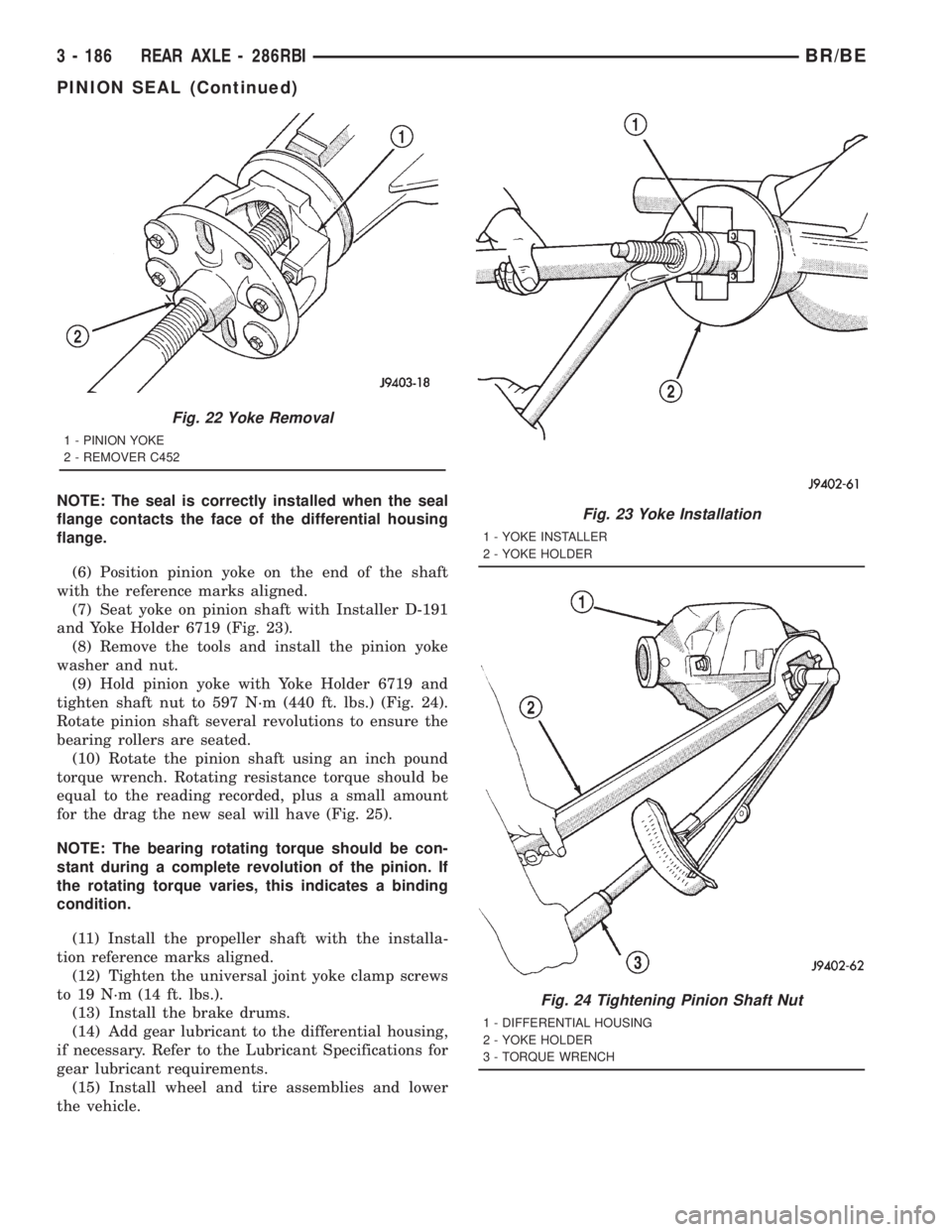

(9) Remove the yoke with Remover C-452 (Fig. 22).

(10) Remove the pinion shaft seal with suitable

pry tool or slide-hammer mounted screw.

INSTALLATION

(1) Clean the seal contact surface in the housing

bore.

(2) Examine the splines on the pinion shaft for

burrs or wear. Remove any burrs and clean the shaft.

(3) Inspect pinion yoke for cracks, worn splines

and worn seal contact surface. Replace yoke if neces-

sary.

NOTE: The outer perimeter of the seal is pre-coated

with a special sealant. An additional application of

sealant is not required.

(4) Apply a light coating of gear lubricant on the

lip of pinion seal.

(5) Install new pinion shaft seal with an appropri-

ate Installer.

BR/BEREAR AXLE - 286RBI 3 - 185

Page 259 of 2889

NOTE: The seal is correctly installed when the seal

flange contacts the face of the differential housing

flange.

(6) Position pinion yoke on the end of the shaft

with the reference marks aligned.

(7) Seat yoke on pinion shaft with Installer D-191

and Yoke Holder 6719 (Fig. 23).

(8) Remove the tools and install the pinion yoke

washer and nut.

(9) Hold pinion yoke with Yoke Holder 6719 and

tighten shaft nut to 597 N´m (440 ft. lbs.) (Fig. 24).

Rotate pinion shaft several revolutions to ensure the

bearing rollers are seated.

(10) Rotate the pinion shaft using an inch pound

torque wrench. Rotating resistance torque should be

equal to the reading recorded, plus a small amount

for the drag the new seal will have (Fig. 25).

NOTE: The bearing rotating torque should be con-

stant during a complete revolution of the pinion. If

the rotating torque varies, this indicates a binding

condition.

(11) Install the propeller shaft with the installa-

tion reference marks aligned.

(12) Tighten the universal joint yoke clamp screws

to 19 N´m (14 ft. lbs.).

(13) Install the brake drums.

(14) Add gear lubricant to the differential housing,

if necessary. Refer to the Lubricant Specifications for

gear lubricant requirements.

(15) Install wheel and tire assemblies and lower

the vehicle.

Fig. 22 Yoke Removal

1 - PINION YOKE

2 - REMOVER C452

Fig. 23 Yoke Installation

1 - YOKE INSTALLER

2 - YOKE HOLDER

Fig. 24 Tightening Pinion Shaft Nut

1 - DIFFERENTIAL HOUSING

2 - YOKE HOLDER

3 - TORQUE WRENCH

3 - 186 REAR AXLE - 286RBIBR/BE

PINION SEAL (Continued)

Page 260 of 2889

DIFFERENTIAL

REMOVAL

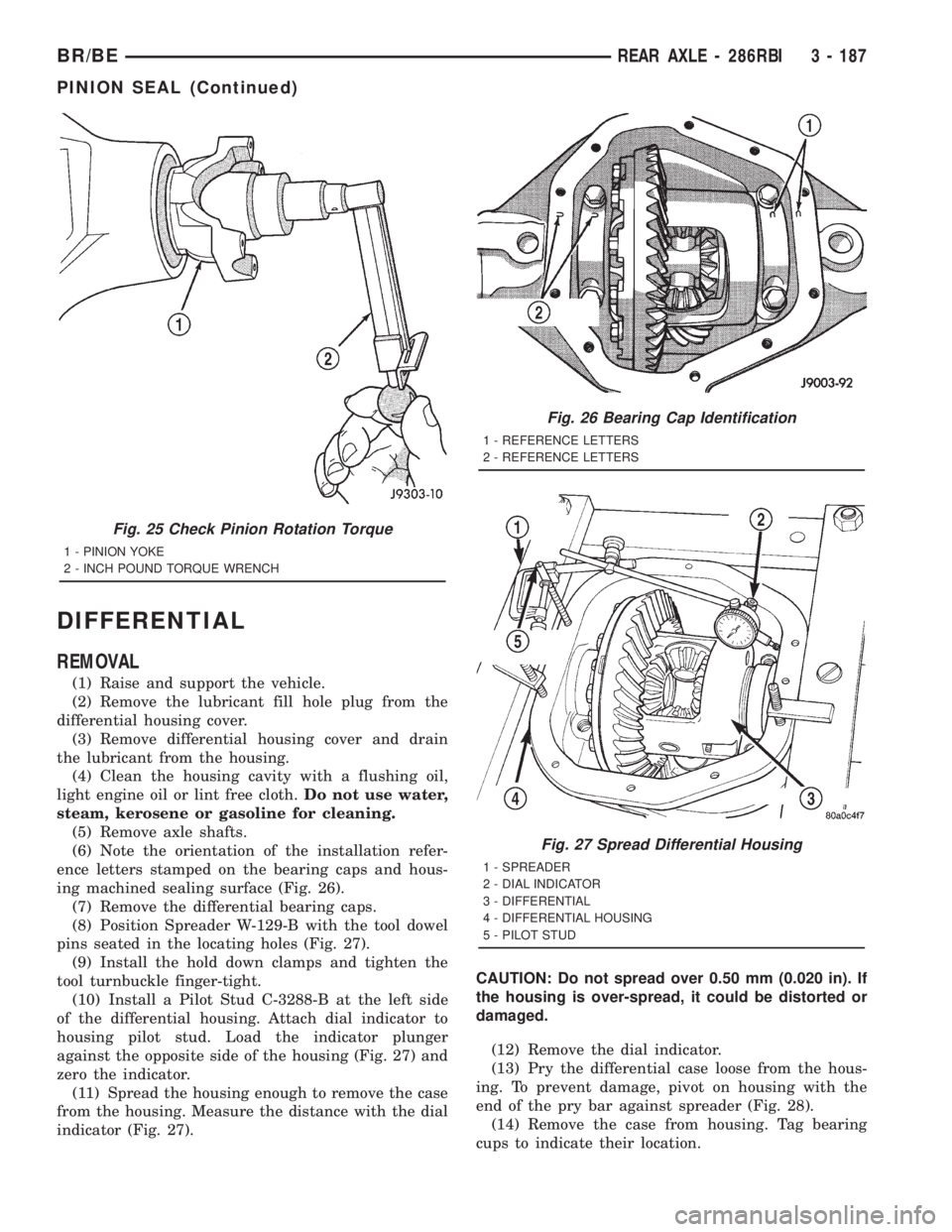

(1) Raise and support the vehicle.

(2) Remove the lubricant fill hole plug from the

differential housing cover.

(3) Remove differential housing cover and drain

the lubricant from the housing.

(4) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.Do not use water,

steam, kerosene or gasoline for cleaning.

(5) Remove axle shafts.

(6) Note the orientation of the installation refer-

ence letters stamped on the bearing caps and hous-

ing machined sealing surface (Fig. 26).

(7) Remove the differential bearing caps.

(8) Position Spreader W-129-B with the tool dowel

pins seated in the locating holes (Fig. 27).

(9) Install the hold down clamps and tighten the

tool turnbuckle finger-tight.

(10) Install a Pilot Stud C-3288-B at the left side

of the differential housing. Attach dial indicator to

housing pilot stud. Load the indicator plunger

against the opposite side of the housing (Fig. 27) and

zero the indicator.

(11) Spread the housing enough to remove the case

from the housing. Measure the distance with the dial

indicator (Fig. 27).CAUTION: Do not spread over 0.50 mm (0.020 in). If

the housing is over-spread, it could be distorted or

damaged.

(12) Remove the dial indicator.

(13) Pry the differential case loose from the hous-

ing. To prevent damage, pivot on housing with the

end of the pry bar against spreader (Fig. 28).

(14) Remove the case from housing. Tag bearing

cups to indicate their location.

Fig. 25 Check Pinion Rotation Torque

1 - PINION YOKE

2 - INCH POUND TORQUE WRENCH

Fig. 26 Bearing Cap Identification

1 - REFERENCE LETTERS

2 - REFERENCE LETTERS

Fig. 27 Spread Differential Housing

1 - SPREADER

2 - DIAL INDICATOR

3 - DIFFERENTIAL

4 - DIFFERENTIAL HOUSING

5 - PILOT STUD

BR/BEREAR AXLE - 286RBI 3 - 187

PINION SEAL (Continued)