FIAT TEMPRA 1988 Service And Repair Manual

Manufacturer: FIAT, Model Year: 1988, Model line: TEMPRA, Model: FIAT TEMPRA 1988Pages: 171, PDF Size: 18.05 MB

Page 141 of 171

Q Step 7: Remove the sealing ring (illustration Job

5-1,

part 2) from the locking barrel and detach the two retaining

springs. Remove the locking barrel.

Q Step 9: The magnetic locking device (illustration Job

5-1,

part 8) is removed by undoing the two retaining screws.

Q Step 10: Refitting is the reverse of removal.

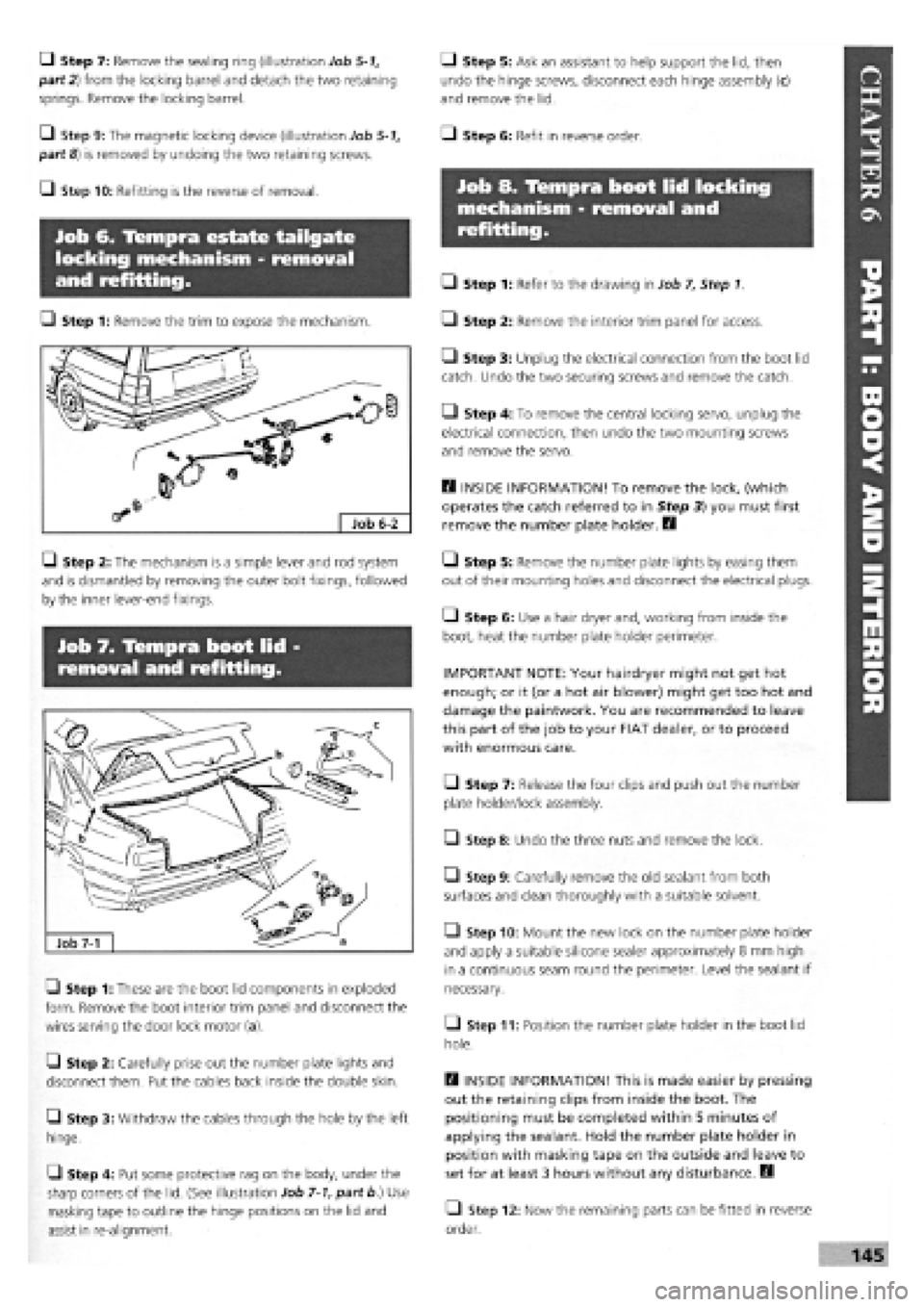

Job 6. Tempra estate tailgate

locking mechanism - removal

and refitting.

Q Step 1: Remove the trim to expose the mechanism.

G Step 2: The mechanism is a simple lever and rod system

and is dismantled by removing the outer bolt fixings, followed

by the inner lever-end fixings.

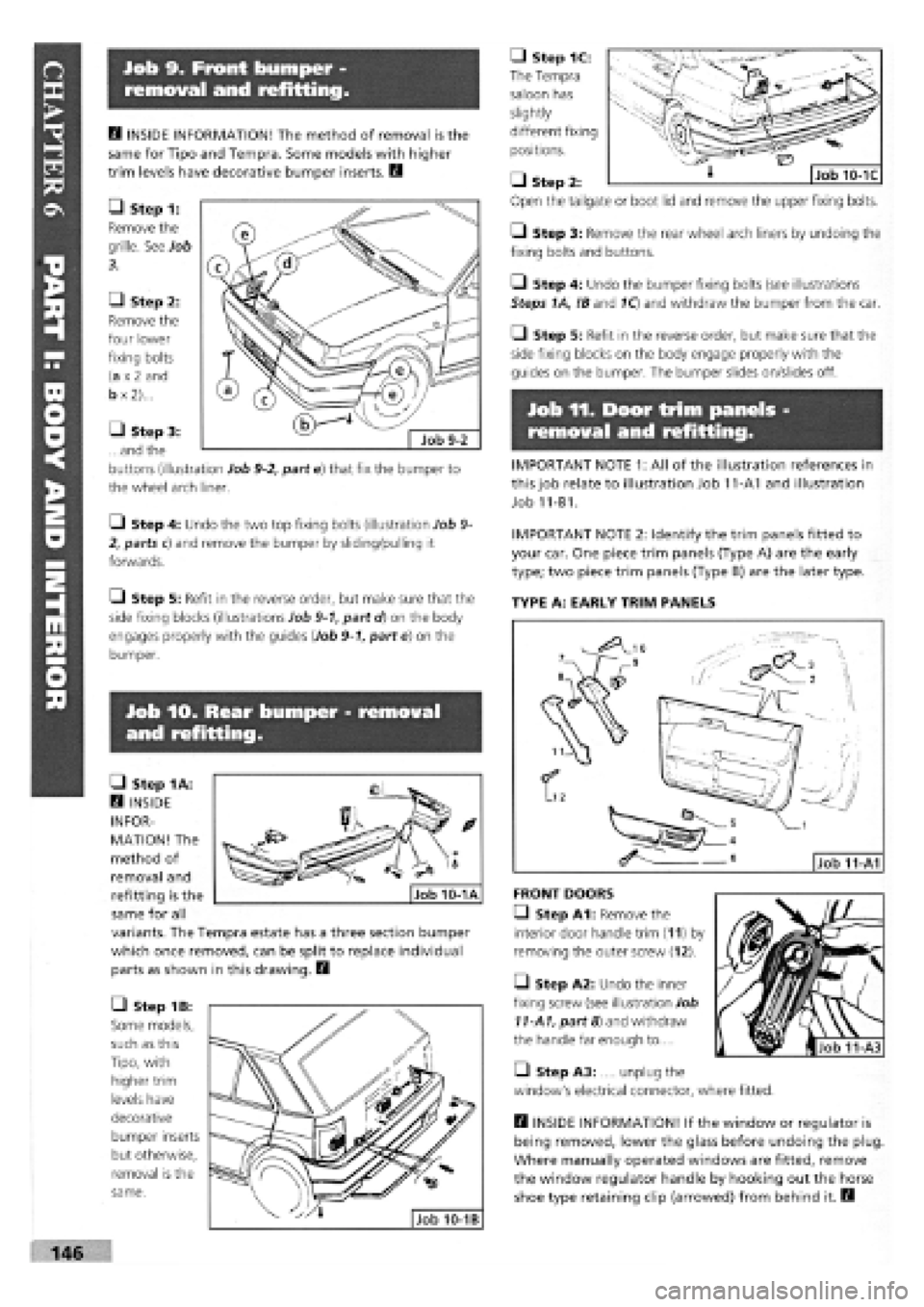

Job 7. Tempra boot lid -

removal and refitting.

Q Step 1: These are the boot lid components in exploded

form. Remove the boot interior trim panel and disconnect the

wires serving the door lock motor (a).

G Step 2: Carefully prise out the number plate lights and

disconnect them. Put the cables back inside the double skin.

Q Step 3: Withdraw the cables through the hole by the left

hinge.

L) Step 4: Put some protective rag on the body, under the

sharp corners of the lid. (See illustration Job

7-1,

part b.) Use

masking tape to outline the hinge positions on the lid and

assist in re-alignment.

Q Step 5: Ask an assistant to help support the lid, then

undo the hinge screws, disconnect each hinge assembly (c)

and remove the lid.

Q Step 6: Refit in reverse order.

Job 8. Tempra boot lid locking

mechanism - removal and

refitting.

Q Step 1: Refer to the drawing in Job 7, Step 1.

• Step 2: Remove the interior trim panel for access.

Q Step 3: Unplug the electrical connection from the boot lid

catch. Undo the two securing screws and remove the catch.

Q Step 4: To remove the central locking servo, unplug the

electrical connection, then undo the two mounting screws

and remove the servo.

Q INSIDE INFORMATION! To remove the lock, (which

operates the catch referred to in Step 3) you must first

remove the number plate holder. B

Q Step 5: Remove the number plate lights by easing them

out of their mounting holes and disconnect the electrical plugs.

Gl Step 6: Use a hair dryer and, working from inside the

boot, heat the number plate holder perimeter.

IMPORTANT NOTE: Your hairdryer might not get hot

enough; or it (or a hot air blower) might get too hot and

damage the paintwork. You are recommended to leave

this part of the job to your FIAT dealer, or to proceed

with enormous care.

• Step 7: Release the four clips and push out the number

plate holder/lock assembly.

• Step 8: Undo the three nuts and remove the lock.

Q Step 9: Carefully remove the old sealant from both

surfaces and clean thoroughly with a suitable solvent.

• Step 10: Mount the new lock on the number plate holder

and apply a suitable silicone sealer approximately 8 mm high

in a continuous seam round the perimeter. Level the sealant if

necessary.

• Step 11: Position the number plate holder in the boot lid

hole.

H INSIDE INFORMATION! This is made easier by pressing

out the retaining clips from inside the boot. The

positioning must be completed within 5 minutes of

applying the sealant. Hold the number plate holder in

position with masking tape on the outside and leave to

set for at least 3 hours without any disturbance. D

Q Step 12: Now the remaining parts can be fitted in reverse

order.

Page 142 of 171

Job 9. Front bumper -

removal and refitting.

• Step 1C:

The Tempra

saloon has

slightly

different fixing

positions.

• Step

Open the

Q Step 3: Remove the rear wheel arch liners by undoing the

fixing bolts and buttons.

• Step 4: Undo the bumper fixing bolts (see illustrations

Steps 1A, !B and 1Q and withdraw the bumper from the car.

• Step 5: Refit in the reverse order, but make sure that the

side fixing blocks on the body engage properly with the

guides on the bumper. The bumper slides on/slides off.

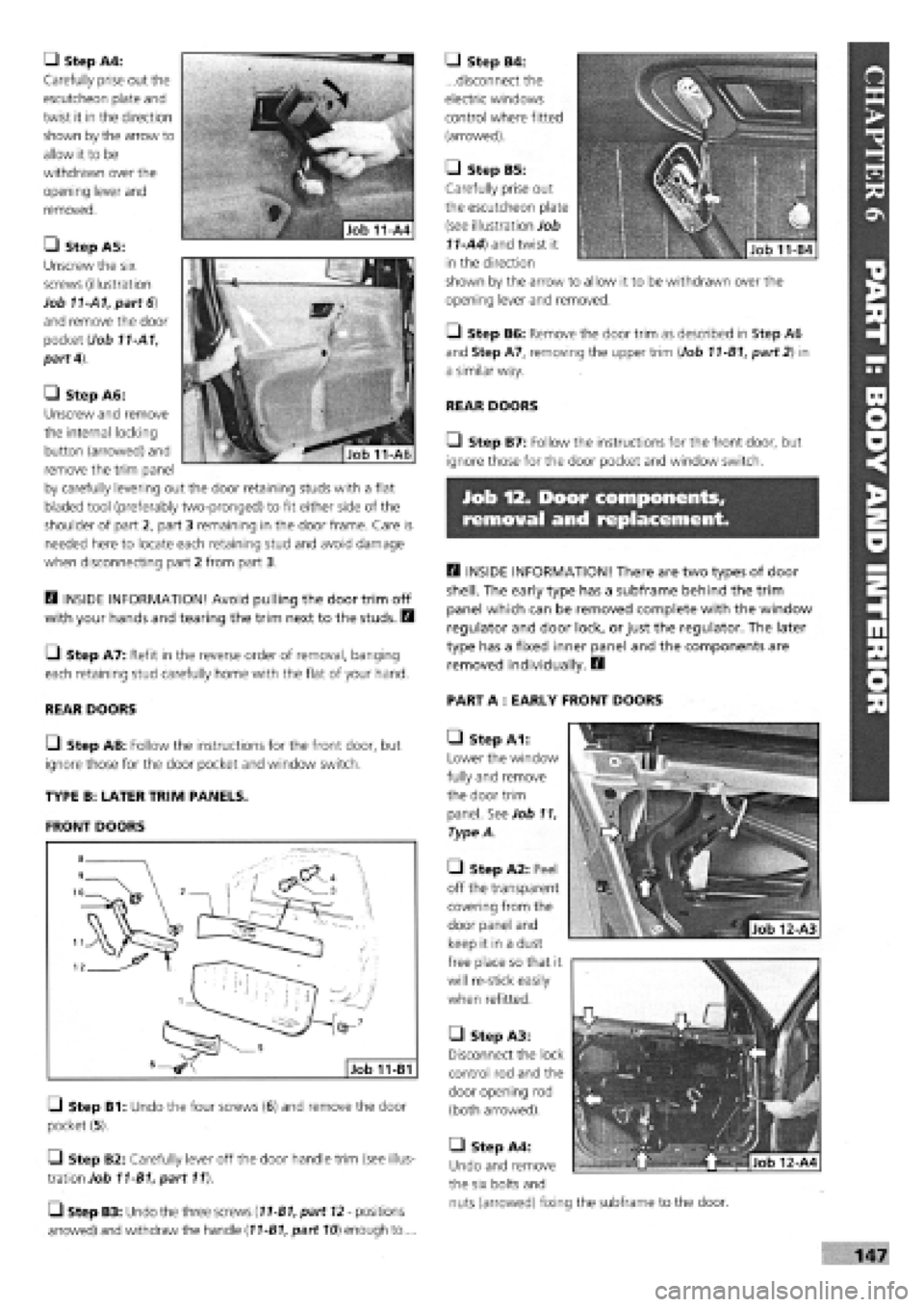

Job 11. Door trim panels -

removal and refitting.

IMPORTANT NOTE 1: All of the illustration references in

this job relate to illustration Job 11-A1 and illustration

Job 11-B1.

IMPORTANT NOTE 2: Identify the trim panels fitted to

your car. One piece trim panels (Type A) are the early

type; two piece trim panels (Type B) are the later type.

TYPE A: EARLY TRIM PANELS

Job lO. Rear bumper - removal

and refitting.

H INSIDE INFORMATION! The method of removal is the

same for Tipo and Tempra. Some models with higher

trim levels have decorative bumper inserts. B

• Step 1:

Remove the

grille. See Job

3.

• Step 2:

Remove the

four lower

fixing bolts

(a

x 2

and

b

x

2)...

• Step 3:

...and the

buttons (illustration Job

9-2,

part e) that fix the bumper to

the wheel arch liner.

Q Step 4: Undo the two top fixing bolts (illustration Job

9-

2, parts c) and remove the bumper by sliding/pulling it

forwards.

Q Step 5: Refit in the reverse order, but make sure that the

side fixing blocks (illustrations Job

9-1,

part d) on the body

engages properly with the guides (Job

9-1,

part e) on the

bumper.

• Step 1A:

Q INSIDE

INFOR-

MATION! The

method of

removal and

refitting is the

same for all

variants. The Tempra estate has a three section bumper

which once removed, can be split to replace individual

parts as shown in this drawing. B

• Step 1B:

Some models,

such as this

Tipo, with

higher trim

levels have

decorative

bumper inserts

but otherwise,

removal is the

same.

FRONT DOORS

• Step A1: Remove the

interior door handle trim (11) by

removing the outer screw (12).

• Step A2: Undo the inner

fixing screw (see illustration Job

11-A1,

part 8) and withdraw

the handle far enough to....

• Step A3: .... unplug the

window's electrical connector, where fitted.

B INSIDE INFORMATION! If the window or regulator is

being removed, lower the glass before undoing the plug

Where manually operated windows are fitted, remove

the window regulator handle by hooking out the horse

shoe type retaining clip (arrowed) from behind it. B

2:

tailgate or boot lid and remove the upper fixing bolts.

MMBBMHHi 146

Page 143 of 171

Job 12. Door components,

removal and replacement.

Q Step B1: Undo the four screws

(6)

and remove the door

pocket (5).

Q Step B2: Carefully lever off the door handle trim (see illus-

tration Job 11-B1, part 11).

Q Step B3: Undo the three screws (11-B1, part 12

-

positions

arrowed) and withdraw the handle (11-B1, part 10) enough to....

• Step A4:

Carefully prise out the

escutcheon plate and

twist it in the direction

shown by the arrow to

allow it to be

withdrawn over the

opening lever and

removed.

• Step A5:

Unscrew the six

screws (illustration

Job 11-A1, part 6)

and remove the door

pocket (Job 11-A1,

part 4).

• Step A6:

Unscrew and remove

the internal locking

button (arrowed) and

remove the trim panel

by carefully levering out the door retaining studs with a flat

bladed tool (preferably two-pronged) to fit either side of the

shoulder of part 2, part 3 remaining in the door frame. Care is

needed here to locate each retaining stud and avoid damage

when disconnecting part 2 from part 3.

H INSIDE INFORMATION! Avoid pulling the door trim off

with your hands and tearing the trim next to the studs. H

C_) Step A7: Refit in the reverse order of removal, banging

each retaining stud carefully home with the flat of your hand.

REAR DOORS

Q Step A8: Follow the instructions for the front door, but

ignore those for the door pocket and window switch.

TYPE B: LATER TRIM PANELS.

FRONT DOORS

• Step B6: Remove the door trim as described in Step A6

and Step A7, removing the upper trim (Job 11-B1, part 2) in

a similar way.

REAR DOORS

• Step B7: Follow the instructions for the front door, but

ignore those for the door pocket and window switch.

the six bolts and

nuts (arrowed) fixing the subframe to the door.

H INSIDE INFORMATION! There are two types of door

shell. The early type has a subframe behind the trim

panel which can be removed complete with the window

regulator and door lock, or just the regulator. The later

type has a fixed inner panel and the components are

removed individually. B

PART A : EARLY FRONT DOORS

• Step A1:

Lower the window

fully and remove

the door trim

panel. See Job 11,

Type A.

• Step A2: Peel

off the transparent

covering from the

door panel and

keep it in a dust

free place so that it

will re-stick easily

when refitted.

• Step A3:

Disconnect the lock

control rod and the

door opening rod

(both arrowed).

• Step A4:

Undo and remove

• Step B4:

...disconnect the

electric windows

control where fitted

(arrowed).

• Step B5:

Carefully prise out

the escutcheon plate

(see illustration Job

11-A4) and twist it

in the direction

shown by the arrow to allow it to be withdrawn over the

opening lever and removed.

Page 144 of 171

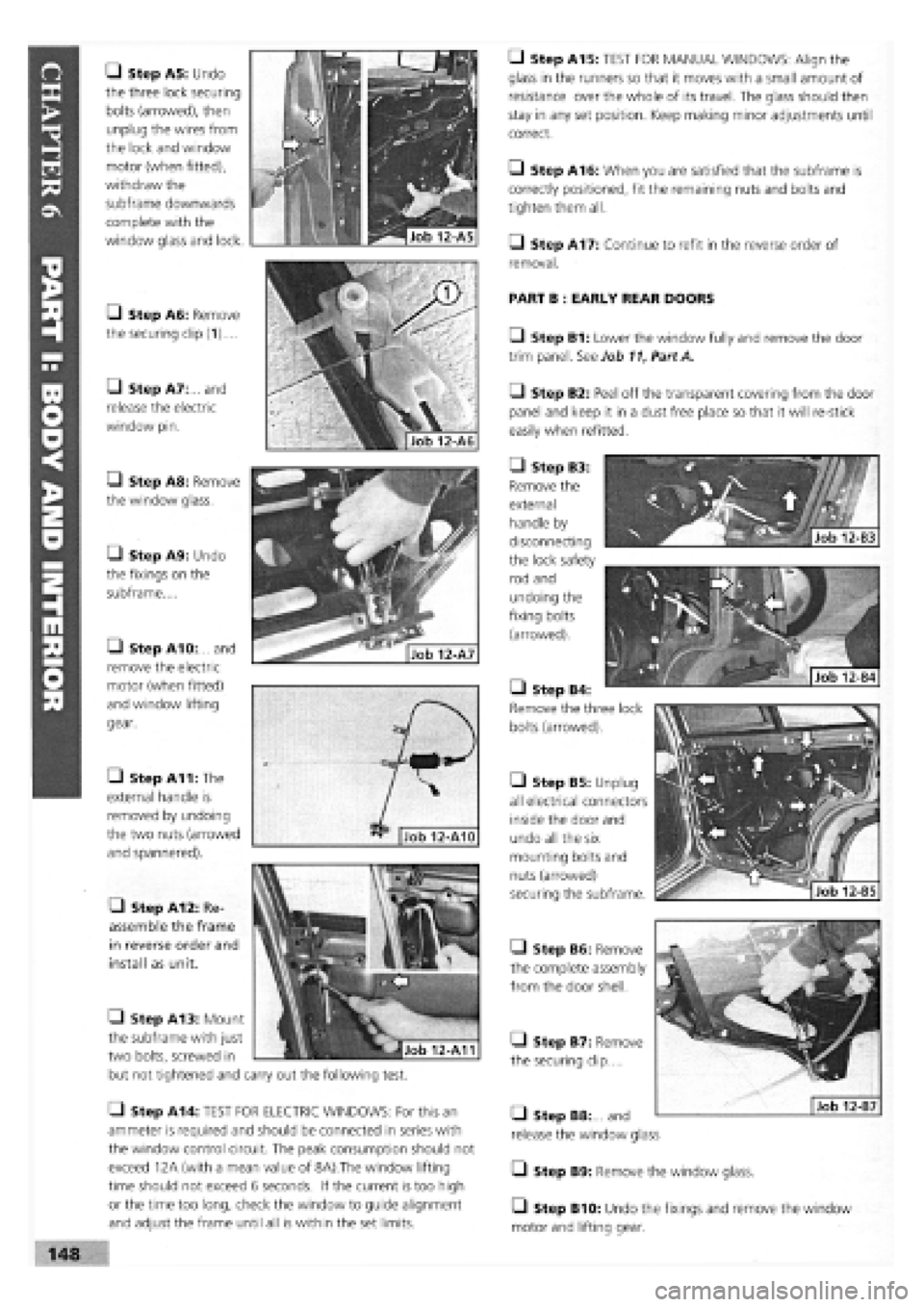

• Step A5: Undo

the three lock securing

bolts (arrowed), then

unplug the wires from

the lock and window

motor (when fitted),

withdraw the

subframe downwards

complete with the

window glass and lock.

[J Step A6: Remove

the securing clip (1)....

• Step A7: and

release the electric

window pin.

• Step A8: Remove

the window glass.

• Step A9: Undo

the fixings on the

subframe....

• Step A10:... and

remove the electric

motor (when fitted)

and window lifting

gear.

• Step A11: The

external handle is

removed by undoing

the two nuts (arrowed

and spannered).

• Step A12: Re-

assemble the frame

in reverse order and

install as unit.

• Step A13: Mount

the subframe with just

two bolts, screwed in

but not tightened and

<

out the following test.

• Step A14: TEST FOR ELECTRIC WINDOWS: For this an

ammeter is required and should be connected in series with

the window control circuit. The peak consumption should not

exceed 12A (with a mean value of 8A).The window lifting

time should not exceed 6 seconds. If the current is too high

or the time too long, check the window to guide alignment

and adjust the frame until all is within the set limits.

• Step B5: Unplug

all electrical connectors

inside the door and

undo all the six

mounting bolts and

nuts (arrowed)

securing the subframe.

Q Step B6: Remove

the complete assembly

from the door shell.

Q Step B7: Remove

the securing clip....

• Step A15: TEST FOR MANUAL WINDOWS: Align the

glass in the runners so that it moves with a small amount of

resistance over the whole of its travel. The glass should then

stay in any set position. Keep making minor adjustments until

correct.

• Step A16: When you are satisfied that the subframe is

correctly positioned, fit the remaining nuts and bolts and

tighten them all.

Q Step A17: Continue to refit in the reverse order of

removal.

PART B : EARLY REAR DOORS

• Step B1: Lower the window fully and remove the door

trim panel. See Job

11,

Part A.

• Step B2: Peel off the transparent covering from the door

panel and keep it in a dust free place so that it will re-stick

easily when refitted.

• Step B3:

Remove the

external

handle by

disconnecting

the lock safety

rod and

undoing the

fixing bolts

(arrowed).

• Step B4:

Remove the three lock

bolts (arrowed).

• Step B8: and

release the window glass

• Step B9: Remove the window glass.

Q Step B10: Undo the fixings and remove the window

motor and lifting gear.

Page 145 of 171

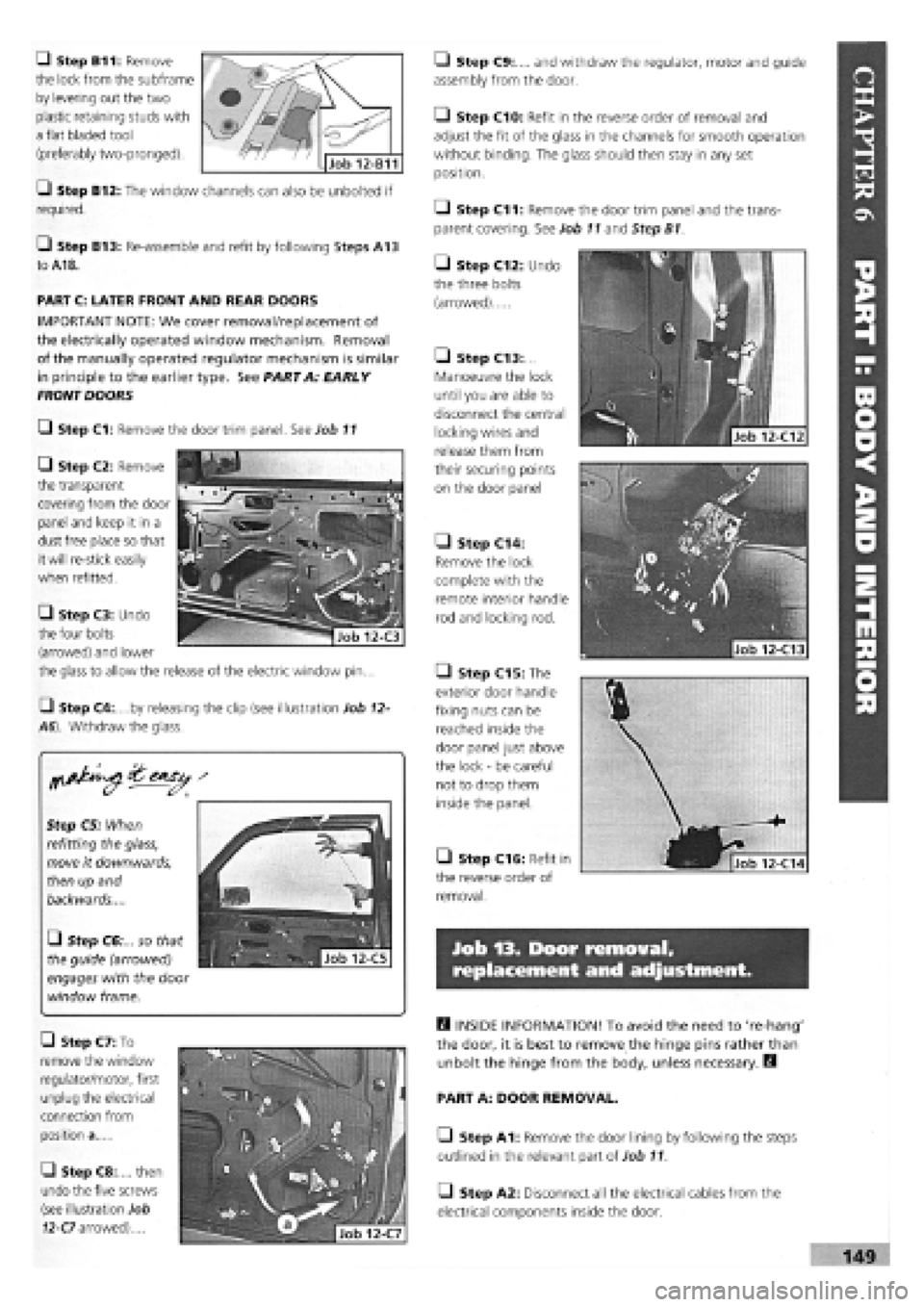

-J Step B11: Remove

the lock from the subframe

by levering out the two

plastic retaining studs with

a flat bladed tool

(preferably two-pronged).

• Step C13:...

Manoeuvre the lock

until you are able to

disconnect the central

locking wires and

release them from

their securing points

on the door panel

• Step C14:

Remove the lock

complete with the

remote interior handle

rod and locking rod.

• Step C15: The

exterior door handle

fixing nuts can be

reached inside the

door panel just above

the lock

-

be careful

not to drop them

inside the panel.

• Step C16: Refit in

the reverse order of

removal.

Q Step B12: The window channels can also be unbolted if

required.

Q Step B13: Re-assemble and refit by following Steps A13

to

A18.

PART C: LATER FRONT AND REAR DOORS

IMPORTANT NOTE: We cover removal/replacement of

the electrically operated window mechanism. Removal

of the manually operated regulator mechanism is similar

in principle to the earlier type. See PART A: EARLY

FRONTDOORS

Q Step C1: Remove the door trim panel. See Job 11

Q Step C2: Remove

the transparent

covering from the door

panel and keep it in a

dust free place so that

it will re-stick easily

when refitted.

• Step C3: Undo

the four bolts

• Step C9:.... and withdraw the regulator, motor and guide

assembly from the door.

• Step C10: Refit in the reverse order of removal and

adjust the fit of the glass in the channels for smooth operation

without binding. The glass should then stay in any set

position.

• Step C11: Remove the door trim panel and the trans-

parent covering. See Job 11 and Step B1.

• Step C12: Undo

the three bolts

(arrowed)

Step C5; When

refitting the glass,

move it downwards,

then up and

backwards....

• Step C6:... so that

the guide (arrowed)

engages with the door

window frame.

Q Step C4:....by releasing the clip (see illustration Job 12-

A6). Withdraw the glass.

(arrowed) and lower

the glass to allow the release of the electric window pin...

Job 13. Door removal,

replacement and adjustment.

• Step C7: To

remove the window

regulator/motor, first

unplug the electrical

connection from

position a

• Step C8:.... then

undo the five screws

(see illustration Job

12-C7 arrowed)....

B INSIDE INFORMATION! To avoid the need to 're-hang'

the door, it is best to remove the hinge pins rather than

unbolt the hinge from the body, unless necessary. B

PART A: DOOR REMOVAL.

LI Step A1: Remove the door lining by following the steps

outlined in the relevant part of Job 11.

• Step A2: Disconnect all the electrical cables from the

electrical components inside the door.

Page 146 of 171

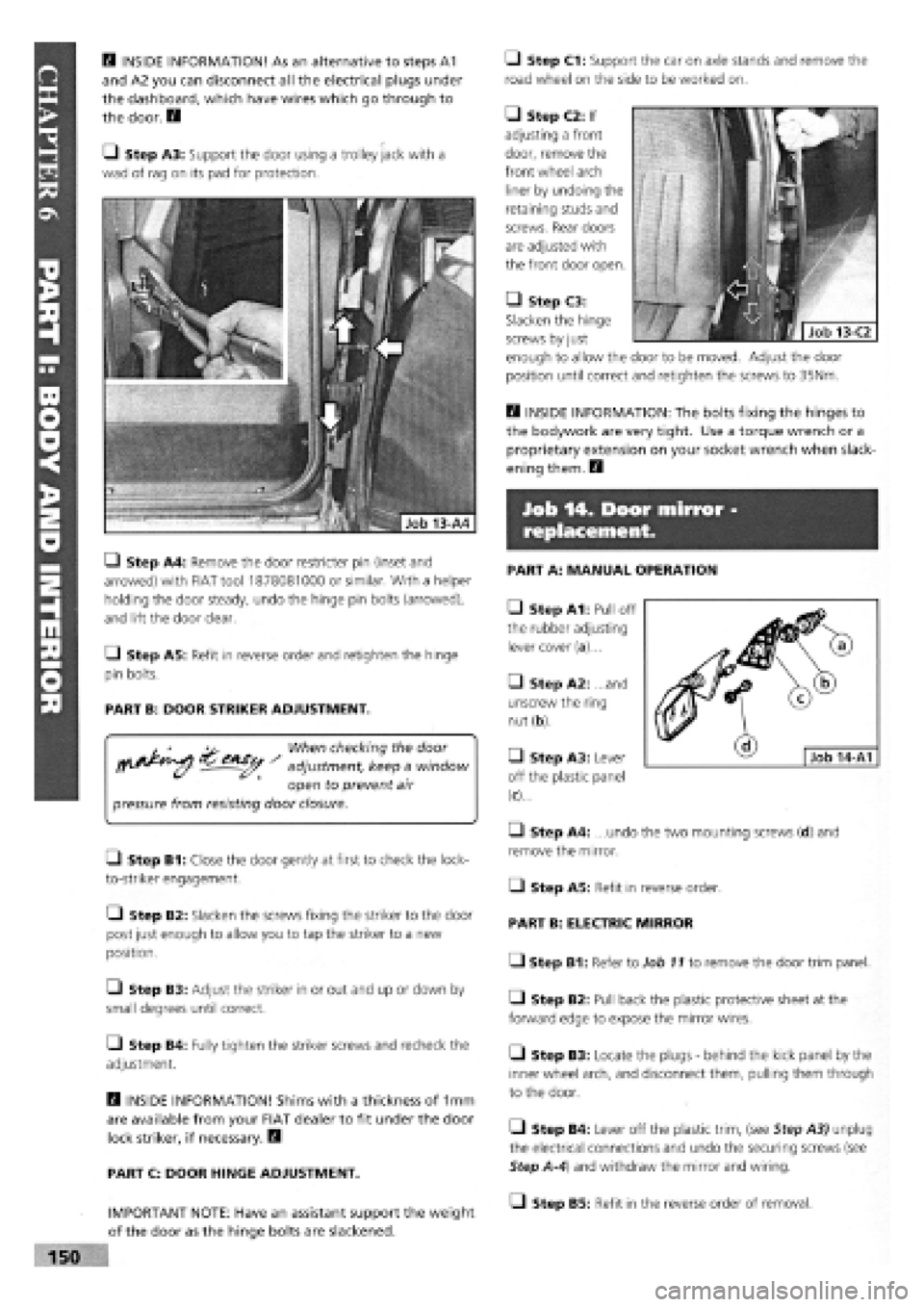

B INSIDE INFORMATION! As an alternative to steps A1

and A2 you can disconnect all the electrical plugs under

the dashboard, which have wires which go through to

the door. B

LI Step A3: Support the door using a trolley jack with a

wad of rag on its pad for protection.

LI Step A4: Remove the door restricter pin (inset and

arrowed) with FIAT tool 1878081000 or similar. With a helper

holding the door steady, undo the hinge pin bolts (arrowed),

and lift the door clear.

• Step A5: Refit in reverse order and retighten the hinge

pin bolts.

PART B: DOOR STRIKER ADJUSTMENT.

, ' -u. When checking the door

jpj^ adjustment, keep a window

open to prevent air

pressure from resisting door closure.

• Step B1: Close the door gently at first to check the lock-

to-striker engagement.

• Step B2: Slacken the screws fixing the striker to the door

post just enough to allow you to tap the striker to a new

position.

L) Step B3: Adjust the striker in or out and up or down by

small degrees until correct.

Q Step B4: Fully tighten the striker screws and recheck the

adjustment.

B INSIDE INFORMATION! Shims with a thickness of 1mm

are available from your FIAT dealer to fit under the door

lock striker, if necessary. B

PART C: DOOR HINGE ADJUSTMENT.

IMPORTANT NOTE: Have an assistant support the weight

of the door as the hinge bolts are slackened.

• Step C1: Support the car on axle stands and remove the

road wheel on the side to be worked on.

• Step C2: If

adjusting a front

door, remove the

front wheel arch

liner by undoing the

retaining studs and

screws. Rear doors

are adjusted with

the front door open.

B INSIDE INFORMATION: The bolts fixing the hinges to

the bodywork are very tight. Use a torque wrench or a

proprietary extension on your socket wrench when slack-

ening them. B

Job 14. Door mirror -

replacement.

PART A: MANUAL OPERATION

• Step A1: Pull off

the rubber adjusting

lever cover (a)...

• Step A2: and

unscrew the ring

nut (b).

• Step A3: Lever

off the plastic panel

(c)...

• Step A4: ...undo the two mounting screws (d) and

remove the mirror.

D Step A5: Refit in reverse order.

PART B: ELECTRIC MIRROR

• Step B1: Refer to Job 11 to remove the door trim panel.

• Step B2: Pull back the plastic protective sheet at the

forward edge to expose the mirror wires.

• Step B3: Locate the plugs

-

behind the kick panel by the

inner wheel arch, and disconnect them, pulling them through

to the door.

• Step B4: Lever off the plastic trim, (see Step A3) unplug

the electrical connections and undo the securing screws (see

Step A-4) and withdraw the mirror and wiring.

LI Step B5: Refit in the reverse order of removal.

• Step C3:

Slacken the hinge

screws by just

enough to allow the door to be moved. Adjust the door

position until correct and retighten the screws to 35Nm.

Page 147 of 171

Job 15. Sun roof - removal and

refitting.

PART A: GENERAL

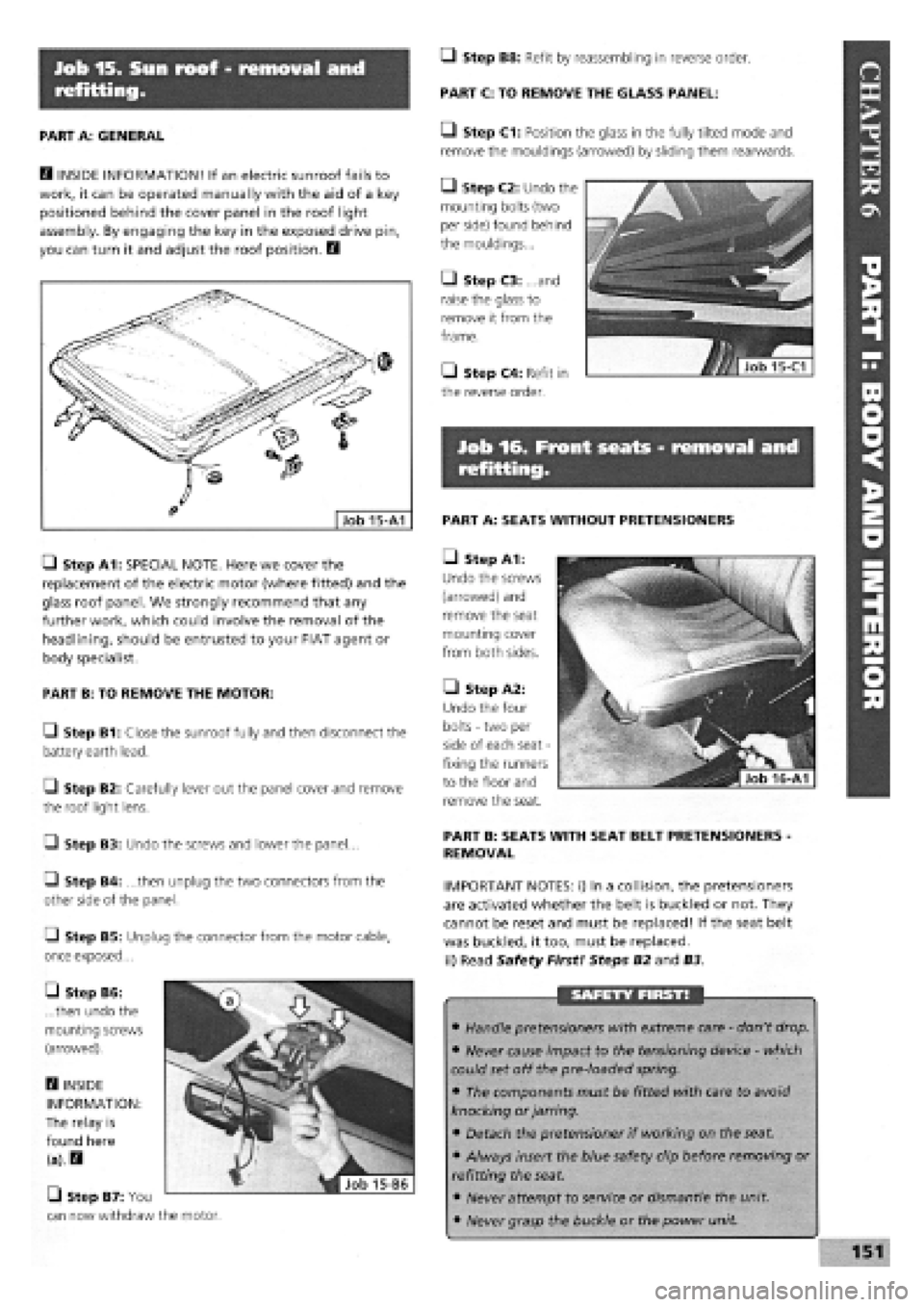

E3 INSIDE INFORMATION! If an electric sunroof fails to

work, it can be operated manually with the aid of a key

positioned behind the cover panel in the roof light

assembly. By engaging the key in the exposed drive pin,

you can turn it and adjust the roof position. Q

• Step A1: SPECIAL NOTE. Here we cover the

replacement of the electric motor (where fitted) and the

glass roof panel. We strongly recommend that any

further work, which could involve the removal of the

headlining, should be entrusted to your FIAT agent or

body specialist.

PART B: TO REMOVE THE MOTOR:

• Step B1: Close the sunroof fully and then disconnect the

battery earth lead.

Q Step B2: Carefully lever out the panel cover and remove

the roof light lens.

Q Step B3: Undo the screws and lower the panel...

G Step B4: ...then unplug the two connectors from the

other side of the panel.

O Step B5: Unplug the connector from the motor cable,

once exposed...

• Step B8: Refit by reassembling in reverse order.

PART C: TO REMOVE THE GLASS PANEL:

• Step C1: Position the glass in the fully tilted mode and

remove the mouldings (arrowed) by sliding them rearwards.

• Step C2: Undo the

mounting bolts (two

per side) found behind

the mouldings...

• Step C3: and

raise the glass to

remove it from the

frame.

• Step C4: Refit in

the reverse order.

Job 16. Front seats - removal and

refitting.

PART A: SEATS WITHOUT PRETENSIONERS

• Step A1:

Undo the screws

(arrowed) and

remove the seat

mounting cover

from both sides.

• Step A2:

Undo the four

bolts

-

two per

side of each seat

-

fixing the runners

to the floor and

remove the seat.

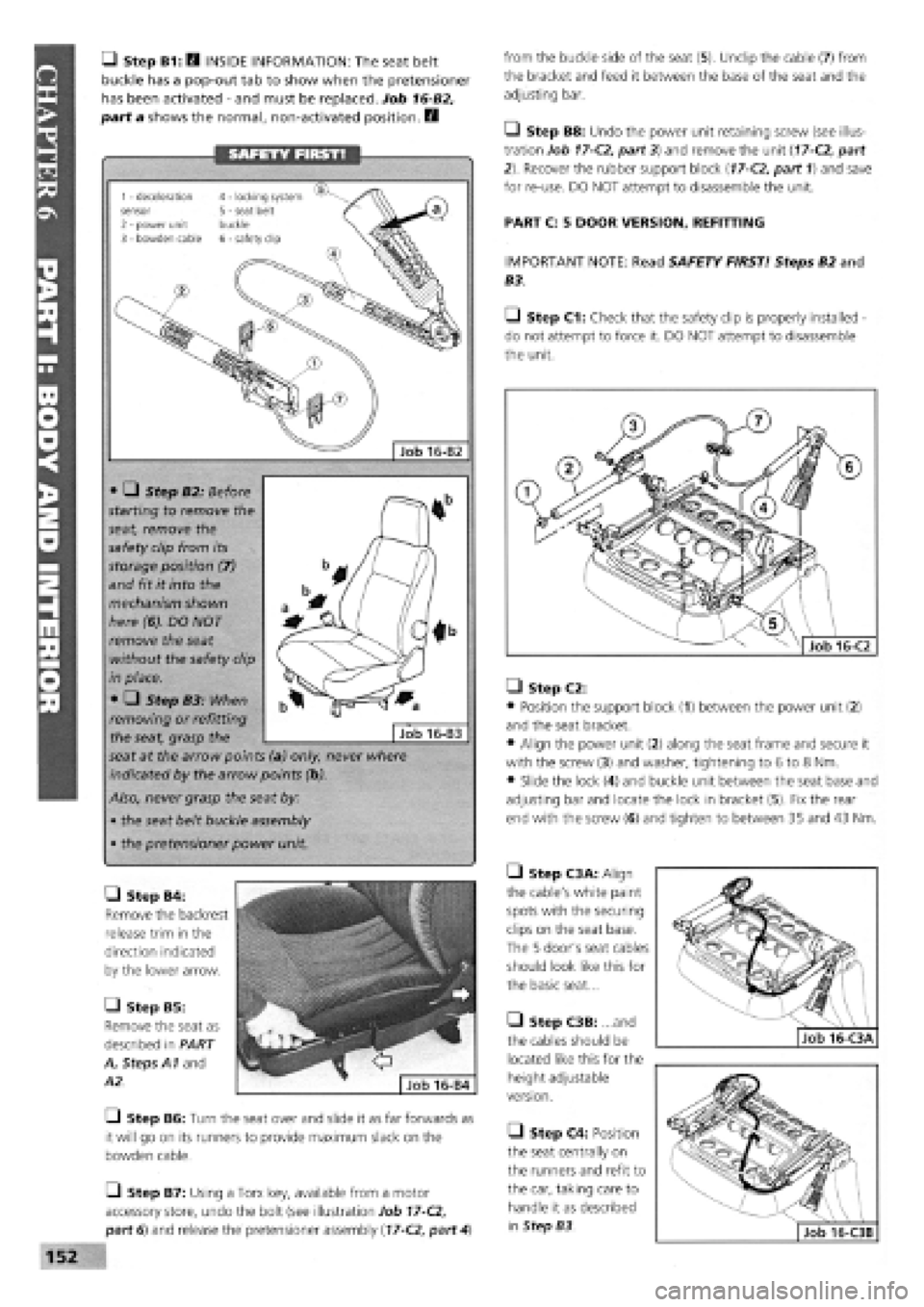

PART B: SEATS WITH SEAT BELT PRETENSIONERS -

REMOVAL

IMPORTANT NOTES: i) In a collision, the pretensioners

are activated whether the belt is buckled or not. They

cannot be reset and must be replaced! If the seat belt

was buckled, it too, must be replaced,

ii) Read Safety First! Steps B2 and B3.

he motor.

SAFETY FIRST!

• Handle pretensioners with extreme care

-

don't drop.

• Never cause impact to the tensioning device

-

which

could set off the pre-loaded spring.

• The components must be fitted with care to avoid

knocking or jarring.

• Detach the pretensioner if working on the seat.

• Always insert the blue safety clip before removing or

refitting the seat

• Never attempt to service or dismantle the unit

• Never grasp the buckle or the power unit

• Step B6:

...then undo the

mounting screws

(arrowed).

D INSIDE

INFORMATION:

The relay is

found here

(a).H

• Step B7: You

can now withdraw

Page 148 of 171

• Step B1: Q INSIDE INFORMATION: The seat belt

buckle has a pop-out tab to show when the pretensioner

has been activated

-

and must be replaced. Job 16-B2,

part a shows the normal, non-activated position. E3

from the buckle side of the seat (5). Unclip the cable (7) from

the bracket and feed it between the base of the seat and the

adjusting bar.

Q Step B8: Undo the power unit retaining screw (see illus-

tration Job

17-C2,

part 3) and remove the unit

(17-C2,

part

2). Recover the rubber support block

(17-C2,

part 1) and save

for re-use. DO NOT attempt to disassemble the unit.

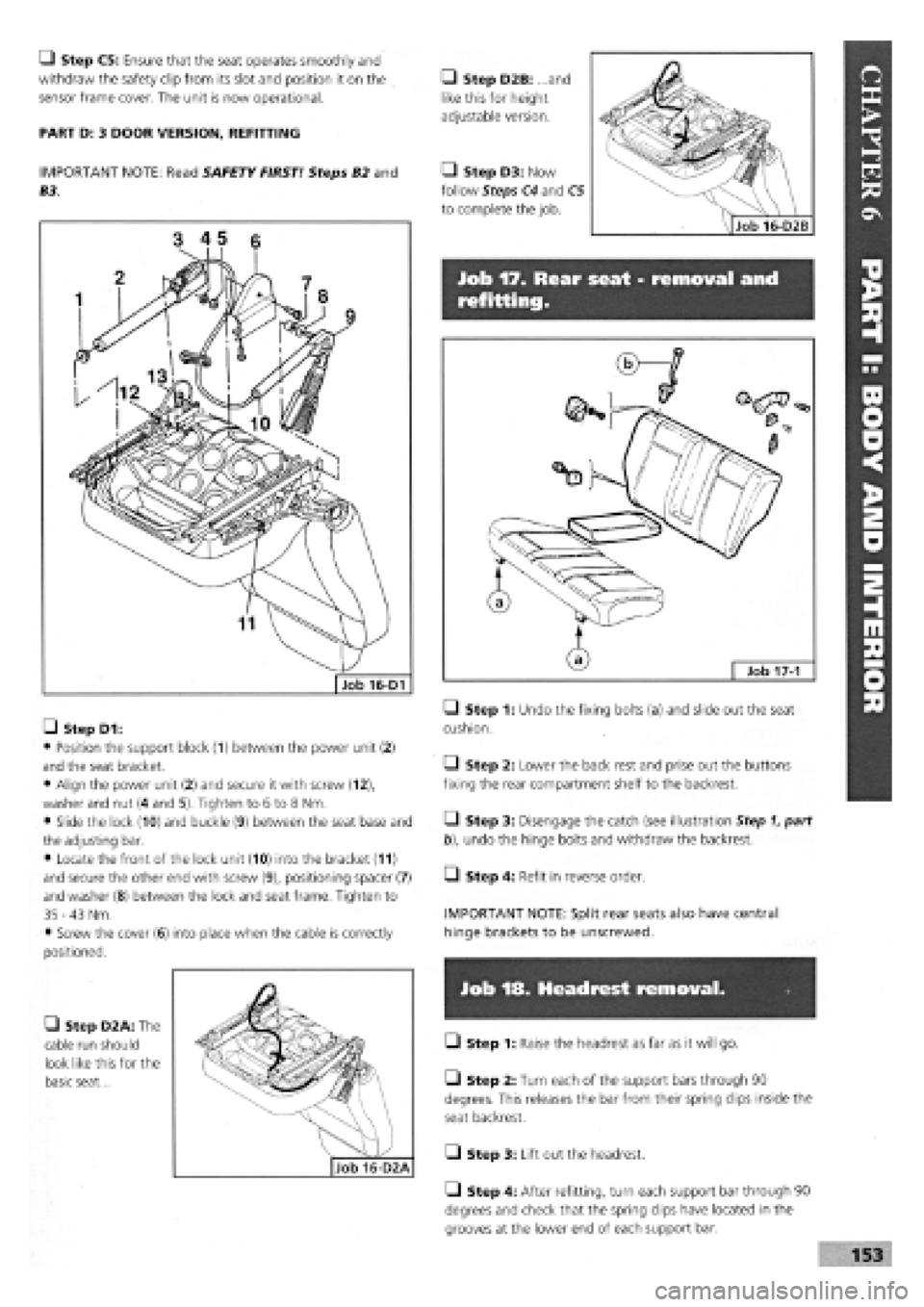

PART C: 5 DOOR VERSION, REFITTING

IMPORTANT NOTE: Read SAFETY FIRST! Steps B2 and

B3.

Q Step C1: Check that the safety clip is properly installed -

do not attempt to force it. DO NOT attempt to disassemble

the unit.

• Step B4:

Remove the backrest

release trim in the

direction indicated

by the lower arrow.

• Step B5:

Remove the seat as

described in PART

A, Steps A1 and

A2.

—I Step B6: Turn the seat over and slide it as far forwards as

it will go on its runners to provide maximum slack on the

bowden cable.

O Step B7: Using a Torx key, available from a motor

accessory store, undo the bolt (see illustration Job

17-C2,

part 6) and release the pretensioner assembly

(17-C2,

part

4)

• Step C2:

• Position the support block (1) between the power unit (2)

and the seat bracket.

• Align the power unit (2) along the seat frame and secure it

with the screw (3) and washer, tightening to 6 to 8 Nm.

• Slide the lock (4) and buckle unit between the seat base and

adjusting bar and locate the lock in bracket (5). Fix the rear

end with the screw (6) and tighten to between 35 and 43 Nm.

• Step C3A: Align

the cable's white paint

spots with the securing

clips on the seat base.

The 5 door's seat cables

should look like this for

the basic seat...

• Step C3B: ...and

the cables should be

located like this for the

height adjustable

version.

• Step C4: Position

the seat centrally on

the runners and refit to

the car, taking care to

handle it as described

in Step B3.

SAFETY FIRST!

• • Step B2: Before

starting to remove the

seat, remove the

safety clip from its

storage position (7)

and fit it into the

mechanism shown

here (6). DO NOT

remove the seat

without the safety clip

in place.

• • Step B3: When

removing or refitting

the seat, grasp the

seat at the arrow points (a) only, never where

indicated by the arrow points (b).

Also, never grasp the seat by:

• the seat belt buckle assembly

• the pretensioner power unit.

Job 16-B3

• •

Job 16-B2

1 - deceleration sensor 2 - power unit 3 - bowden cable

4 - locking system 5 - seat belt buckle 6 - safety clip

Page 149 of 171

Job 17. Rear seat - removal and

refitting.

Job 16-D1

Q Step C5: Ensure that the seat operates smoothly and

withdraw the safety clip from its slot and position it on the

sensor frame cover. The unit is now operational.

PART D: 3 DOOR VERSION, REFITTING

IMPORTANT NOTE: Read SAFETY FIRST! Steps B2 and

B3.

• Step D2B: .. and

like this for height

adjustable version.

• Step D3: Now

follow Steps C4 and C5

to complete the job.

• Step D1:

• Position the support block (1) between the power unit (2)

and the seat bracket.

• Align the power unit (2) and secure it with screw (12),

washer and nut (4 and 5). Tighten to 6 to 8 Nm.

• Slide the lock (10) and buckle (9) between the seat base and

the adjusting bar.

• Locate the front of the lock unit (10) into the bracket (11)

and secure the other end with screw (9), positioning spacer (7)

and washer

(8)

between the lock and seat frame. Tighten to

35 -43

Nm.

• Screw the cover

(6)

into place when the cable is correctly

positioned.

• Step D2A: The

cable run should

look like this for the

basic seat...

• Step 1: Undo the fixing bolts (a) and slide out the seat

cushion.

Q Step 2: Lower the back rest and prise out the buttons

fixing the rear compartment shelf to the backrest.

• Step 3: Disengage the catch (see illustration Step 1, part

b), undo the hinge bolts and withdraw the backrest.

Q Step 4: Refit in reverse order.

IMPORTANT NOTE: Split rear seats also have central

hinge brackets to be unscrewed.

Job 18. Headrest removal.

• Step 1: Raise the headrest as far as it will go.

• Step 2: Turn each of the support bars through 90

degrees. This releases the bar from their spring clips inside the

seat backrest.

Q Step 3: Lift out the headrest.

Q Step 4: After refitting, turn each support bar through 90

degrees and check that the spring clips have located in the

grooves at the lower end of each support bar.

Page 150 of 171

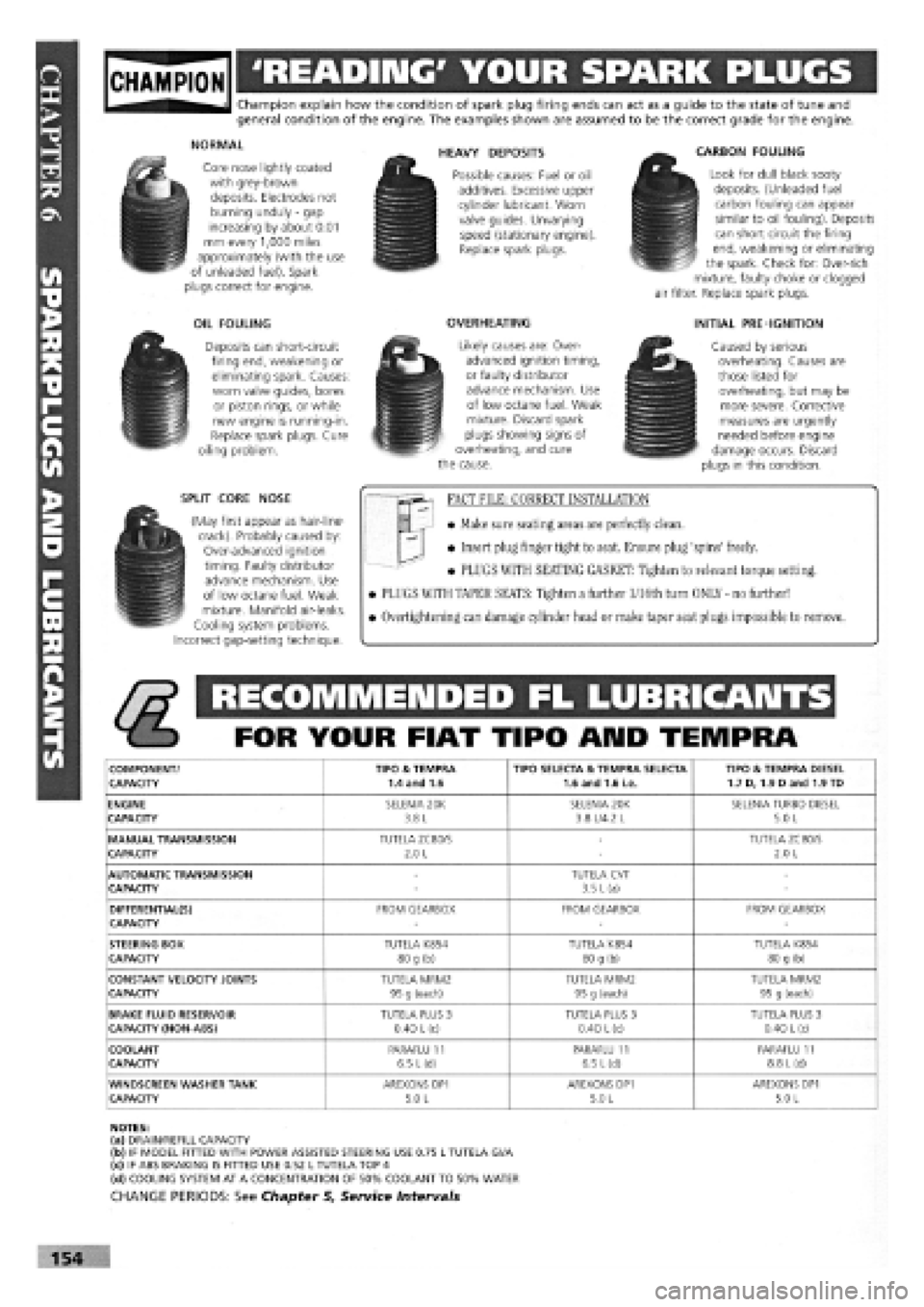

gjpjgjjl 'READING' YOUR SPARK PLUGS

Champion explain how the condition of spark plug firing ends can act as a guide to the state of tune and general condition of the engine. The examples shown are assumed to be the correct grade for the engine.

NORMAL

Core nose lightly coated with grey-brown deposits. Electrodes not burning unduly

-

gap increasing by about 0.01 mm every 1,000 miles approximately (with the use of unleaded fuel). Spark plugs correct for engine.

OIL FOULING

Deposits can short-circuit firing end, weakening or eliminating spark. Causes: worn valve guides, bores or piston rings, or while new engine is running-in. Replace spark plugs. Cure oiling problem.

SPLIT CORE NOSE

(May first appear as hair-line-crack). Probably caused by: Over-advanced ignition timing. Faulty distributor advance mechanism. Use of low octane fuel. Weak mixture. Manifold air-leaks. Cooling system problems. Incorrect gap-setting technique.

HEAVY DEPOSITS

Possible causes: Fuel or oil additives. Excessive upper cylinder lubricant. Worn valve guides. Unvarying speed (stationary engine). Replace spark plugs.

OVERHEATING

Likely causes are: Over-advanced ignition timing, or faulty distributor advance mechanism. Use of low octane fuel. Weak mixture. Discard spark plugs showing signs of overheating, and cure the cause.

CARBON FOULING

Look for dull black sooty deposits. (Unleaded fuel carbon fouling can appear similar to oil fouling). Deposits can short circuit the firing end, weakening or eliminating the spark. Check for: Over-rich mixture, faulty choke or clogged air filter. Replace spark plugs.

INITIAL PRE-IGNITION

Caused by serious overheating. Causes are those listed for overheating, but may be more severe. Corrective measures are urgently needed before engine damage occurs. Discard plugs in this condition.

FACT FILE: CORRECT INSTALLATION

• Make sure seating areas are perfectly clean.

• Insert plug finger tight to seat. Ensure plug 'spins' freely.

• PLUGS WITH SEATING GASKET: Tighten to relevant torque setting.

• PLUGS WITH TAPER SEATS: Tighten a further l/16th turn ONLY - no further!

• Overtightening can damage cylinder head or make taper seat plugs impossible to remove.

RECOMMENDED FL LUBRICANTS

FOR YOUR FIAT TIPO ARID TEMPRA

COMPONENT/ TIPO & TEMPRA TIPO SELECTA & TEMPRA SELECTA TIPO & TEMPRA DIESEL CAPACITY 1.4 and 1.6 1.6 and 1.6 i.e. 1.7 D, 1.9 Dand 1.9 TD

ENGINE SELENIA 20K SELENIA 20K SELENIA TURBO DIESEL CAPACITY 3.8 L 3.8 L/4.2 L 5.0 L

MANUAL TRANSMISSION TUTELA ZC80/S -TUTELA ZC80/S CAPACITY 2.0 L -2.0 L

AUTOMATIC TRANSMISSION -TUTELA CVT -CAPACITY -3.5 L (a) -

DIFFERENTIAL(S) FROM GEARBOX FROM GEARBOX FROM GEARBOX CAPACITY ---

STEERING BOX TUTELA K854 TUTELA K854 TUTELA K854 CAPACITY 80 g (b) 80 g (b) 80 g (b)

CONSTANT VELOCITY JOINTS TUTELA MRM2 TUTELA MRM2 TUTELA MRM2 CAPACITY 95 g (each) 95 g (each) 95 g (each)

BRAKE FLUID RESERVOIR TUTELA PLUS 3 TUTELA PLUS 3 TUTELA PLUS 3 CAPACITY (NON-ABS) 0.40

L

(c) 0.40 L (c) 0.40

L

(c)

COOLANT PARAFLU 11 PARAFLU 11 PARAFLU 11 CAPACITY 6.5 L(d) 6.5 L(d) 8.8

L

(d)

WINDSCREEN WASHER TANK AREXONS DP1 AREXONS DP1 AREXONS DP1 CAPACITY 5.0 L 5.0 L 5.0 L

NOTES: (a) DRAIN/REFILL CAPACITY (b) IF MODEL FITTED WITH POWER ASSISTED STEERING USE 0.75 L TUTELA Gl/A (c) IF ABS BRAKING IS FITTED USE 0.52 L TUTELA TOP 4 (d) COOLING SYSTEM AT A CONCENTRATION OF 50% COOLANT TO 50% WATER

CHANGE PERIODS: See Chapter 5, Service Intervals

154