FORD MUSTANG 2003 Workshop Manual

MUSTANG 2003

FORD

FORD

https://www.carmanualsonline.info/img/11/56942/w960_56942-0.png

FORD MUSTANG 2003 Workshop Manual

Trending: fog light, remote start, maintenance, gas type, four wheel drive, boot, remote control

Page 1341 of 4378

INSTALLATION

Cylinder Heads

SECTION 303-

01B: Engine — 4.6L (2V) 2003 Mustang Workshop Manual Special Tool(s)

Installer, Crankshaft Vibration

Damper

303-

102 (T74P-6316- B) Installer, Front Cover Oil Seal

303-

335 (T88T-6701- A) Holding Tool, Crankshaft

303-

448 (T93P-6303- A) Spreader Bar

303-

D089 (D93P-6001- A3) Lifting Bracket Set, Engine

303-

D074 (D91P-6001- A) Strap Wrench

303-

D055 (D85L-6000- A) or

equivalent Compressor, Valve Spring

303-

567 (T97P-6565- AH) Compressor Spacer, Valve

Spring �K�l�j . 1 �b�a

252003 Mustang Workshop Manual

17. 11. 2011file:///C:/Ford/2000 - 2004/tsocache/SHEF_4464/S3B~us~en~ ...

Page 1342 of 4378

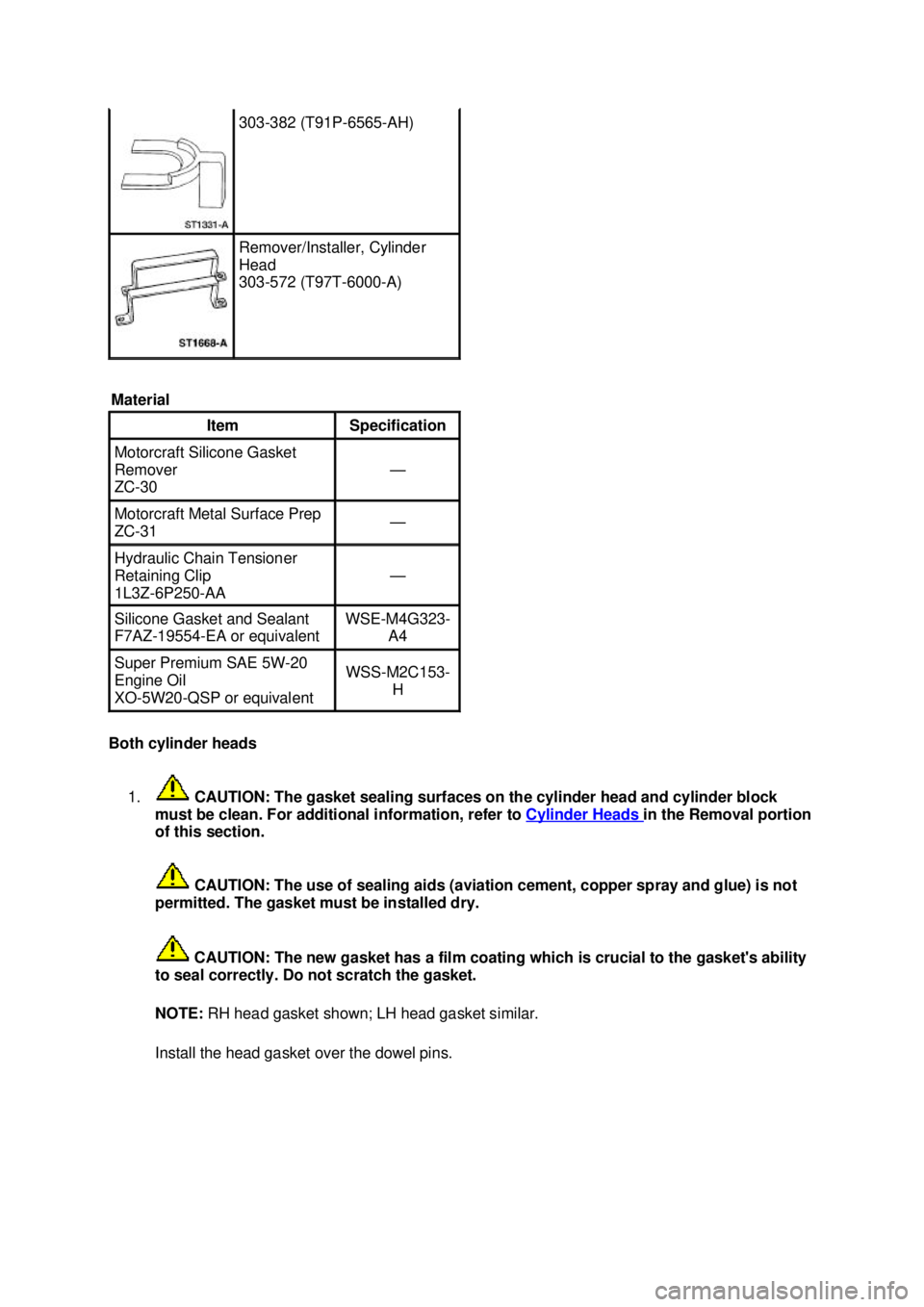

Both cylinder heads

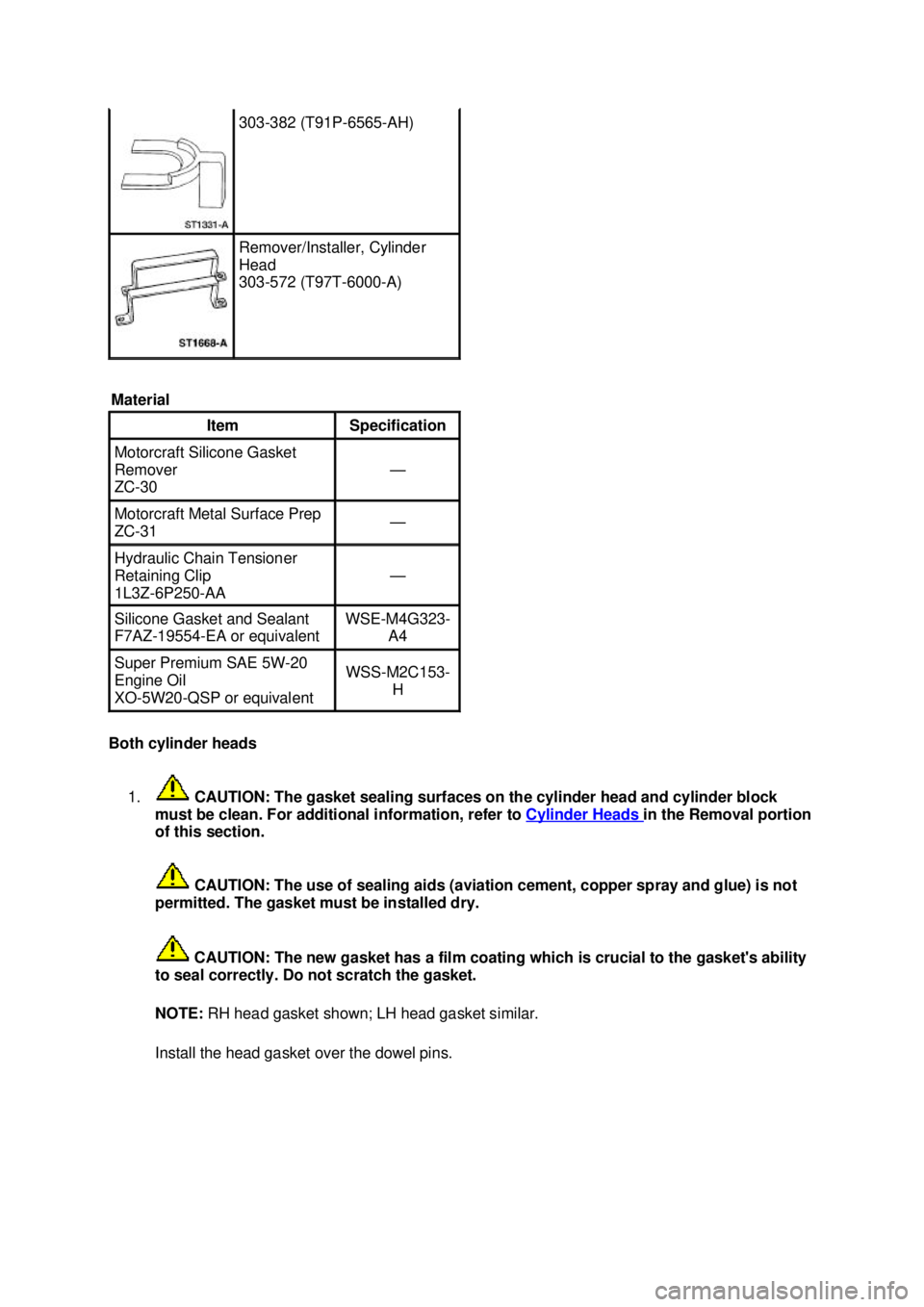

1. CAUTION: The gasket sealing surfaces on the cylinder head and cylinder block

must be clean. For additional information, refer to Cylinder Heads in the Removal portion

of this section.

CAUTION: The use of sealing aids (aviation cement, copper spray and glue) is not

permitted. The gasket must be installed dry.

CAUTION: The new gasket has a film coating which is crucial to the gasket's ability

to seal correctly. Do not scratch the gasket.

NOTE: RH head gasket shown; LH head gasket similar.

Install the head gasket over the dowel pins. 303-

382 (T91P-6565- AH) Remover/Installer, Cylinder

Head

303-

572 (T97T-6000- A)

Material Item Specification

Motorcraft Silicone Gasket

Remover

ZC-

30 —

Motorcraft Metal Surface Prep

ZC-

31 —

Hydraulic Chain Tensioner

Retaining Clip

1L3Z-6P250-

AA —

Silicone Gasket and Sealant

F7AZ-

19554- EA or equivalent WSE-

M4G323-

A4 Super Premium SAE 5W-20

Engine Oil

XO- 5W20- QSP or equivalent WSS-

M2C153-

H �K�l�j . 2 �b�a

252003 Mustang Workshop Manual

17. 11. 2011file:///C:/Ford/2000 - 2004/tsocache/SHEF_4464/S3B~us~en~ ...

Page 1343 of 4378

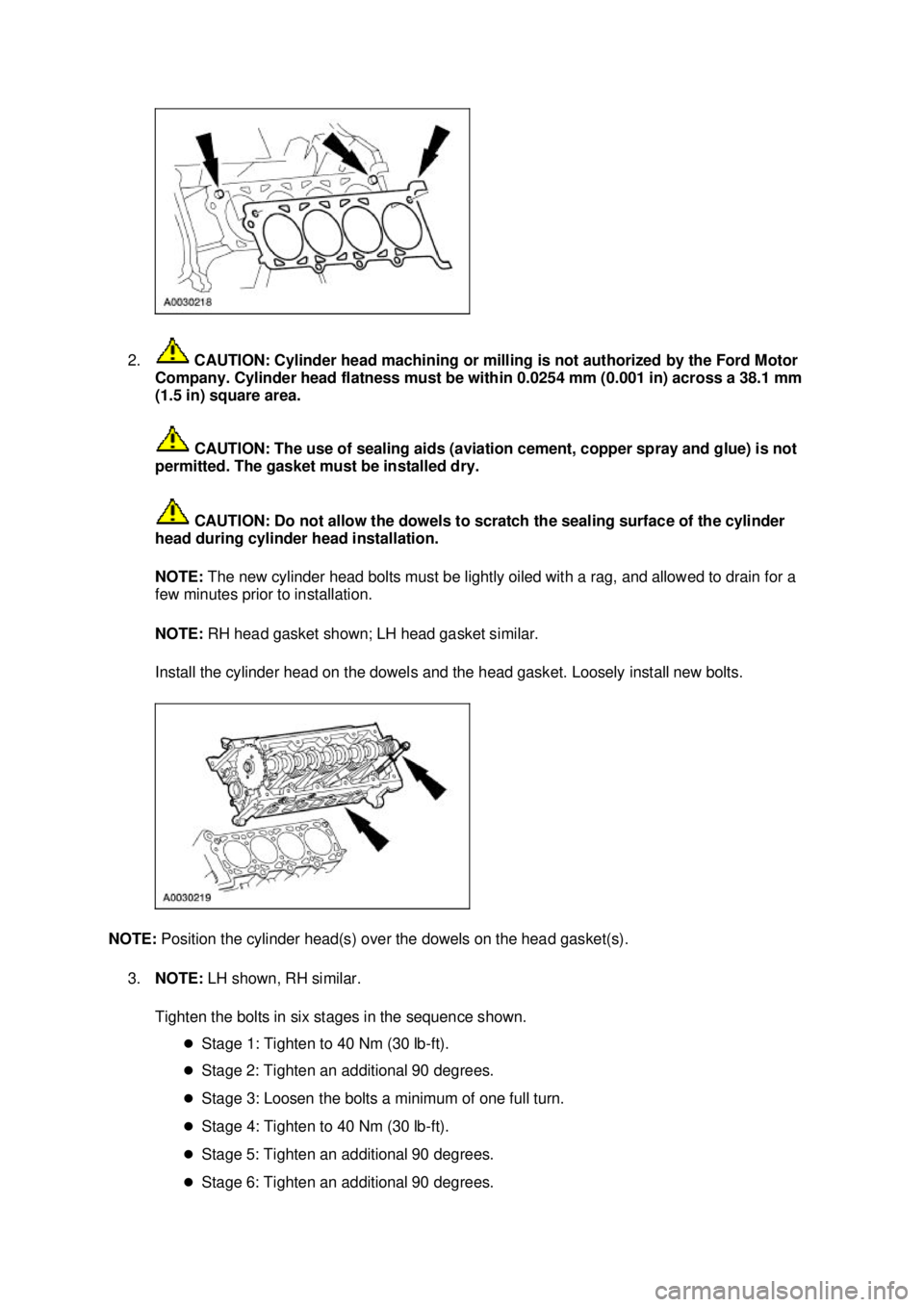

2.

CAUTION: Cylinder head machining or milling is not authorized by the Ford Motor

Company. Cylinder head flatness must be within 0.0254 mm (0.001 in) across a 38.1 mm

(1.5 in) square area.

CAUTION: The use of sealing aids (aviation cement, copper spray and glue) is not

permitted. The gasket must be installed dry.

CAUTION: Do not allow the dowels to scratch the sealing surface of the cylinder

head during cylinder head installation.

NOTE: The new cylinder head bolts must be lightly oiled with a rag, and allowed to drain for a

few minutes prior to installation.

NOTE: RH head gasket shown; LH head gasket similar.

Install the cylinder head on the dowels and the head gasket. Loosely install new bolts.

NOTE: Position the cylinder head(s) over the dowels on the head gasket(s).

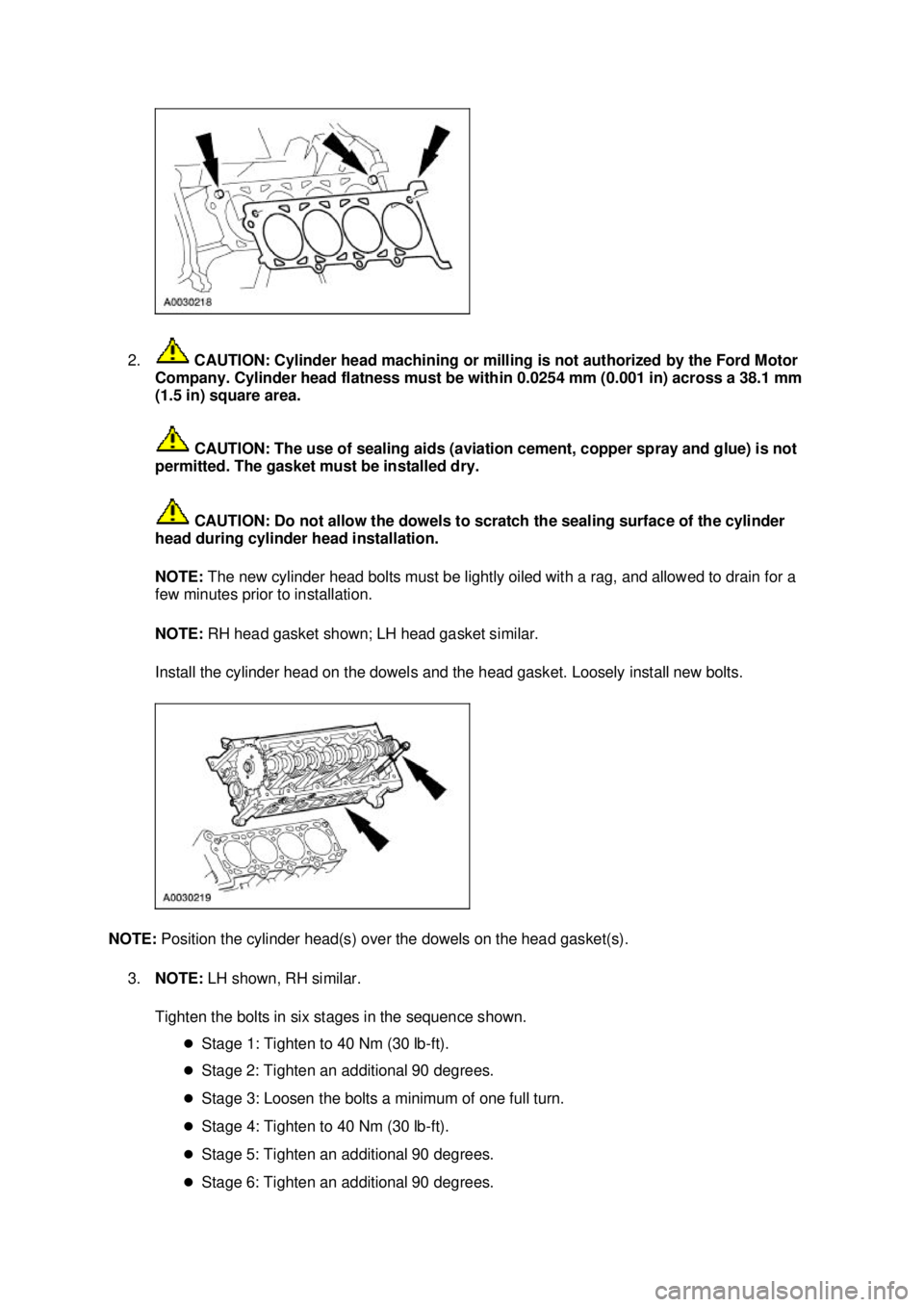

3. NOTE: LH shown, RH similar.

Tighten the bolts in six stages in the sequence shown. �zStage 1: Tighten to 40 Nm (30 lb- ft).

�z Stage 2: Tighten an additional 90 degrees.

�z Stage 3: Loosen the bolts a minimum of one full turn.

�z Stage 4: Tighten to 40 Nm (30 lb- ft).

�z Stage 5: Tighten an additional 90 degrees.

�z Stage 6: Tighten an additional 90 degrees. �K�l�j . 3 �b�a

252003 Mustang Workshop Manual

17. 11. 2011file:///C:/Ford/2000 - 2004/tsocache/SHEF_4464/S3B~us~en~ ...

Page 1344 of 4378

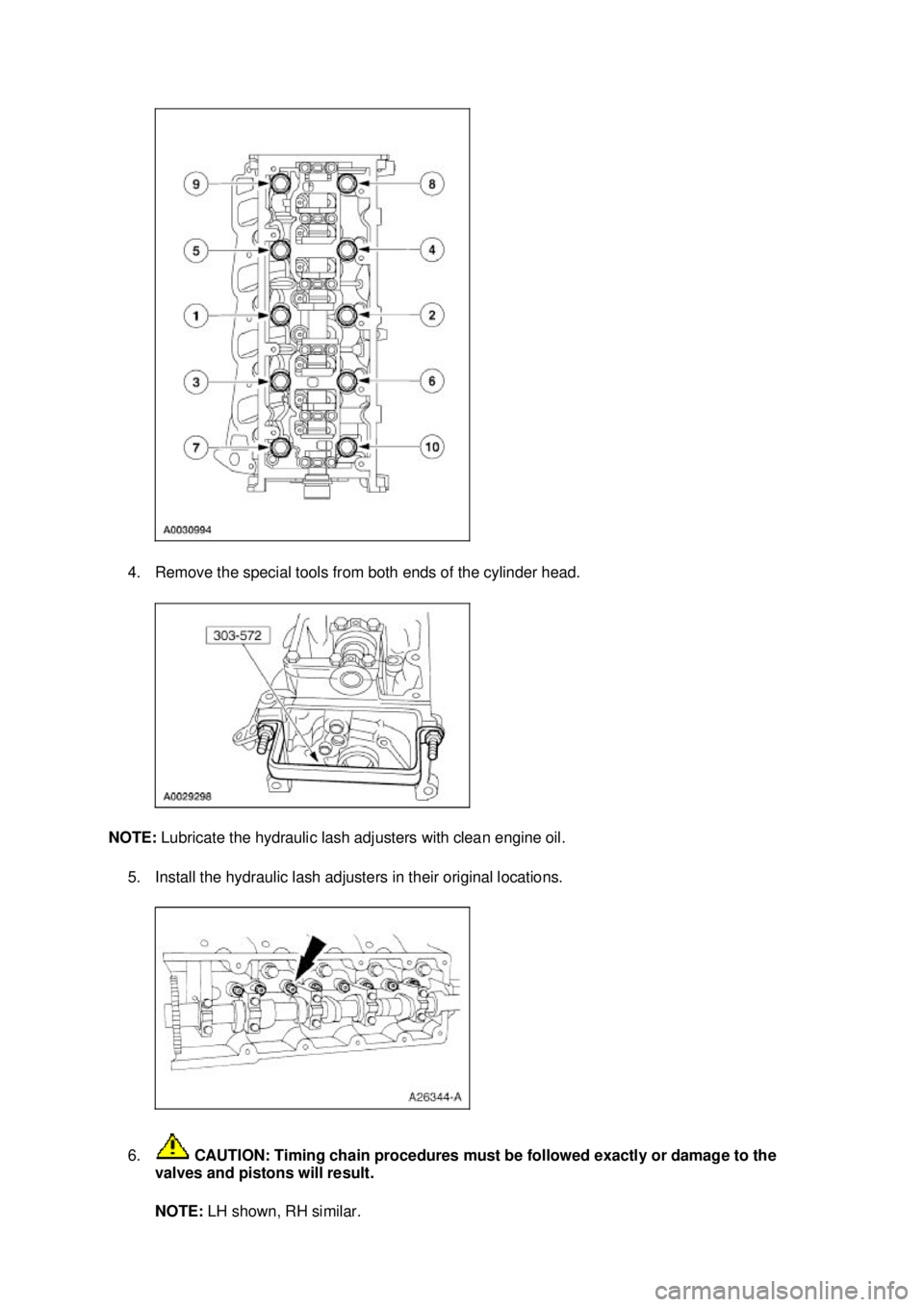

4. Remove the special tools from both ends of the cylinder head.

NOTE: Lubricate the hydraulic lash adjusters with clean engine oil.

5. Install the hydraulic lash adjusters in their original locations.

6. CAUTION: Timing chain procedures must be followed exactly or damage to the

valves and pistons will result.

NOTE: LH shown, RH similar. �K�l�j . 4 �b�a

252003 Mustang Workshop Manual

17. 11. 2011file:///C:/Ford/2000 - 2004/tsocache/SHEF_4464/S3B~us~en~ ...

Page 1345 of 4378

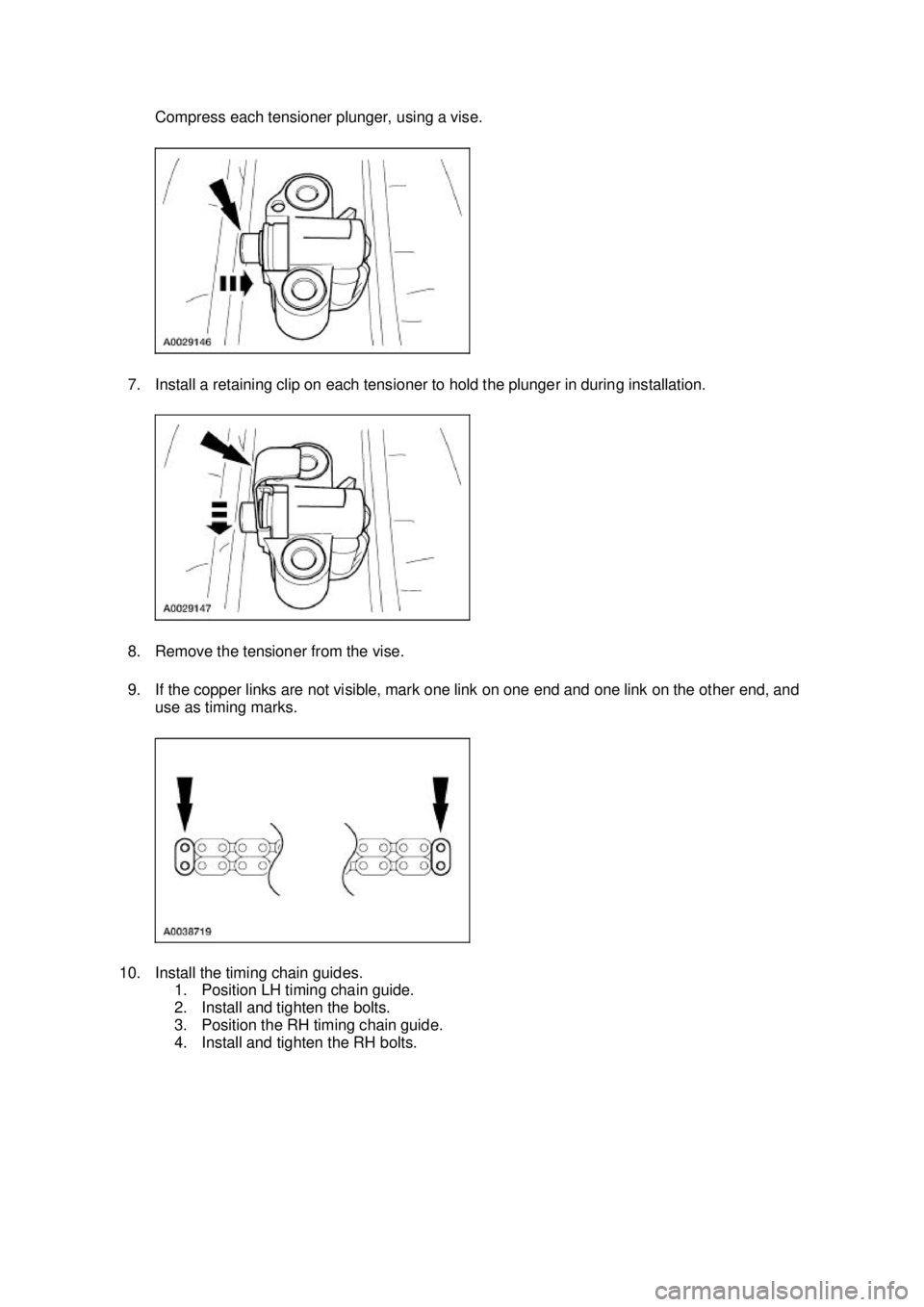

Compress each tensioner plunger, using a vise.

7. Install a retaining clip on each tensioner to hold the plunger in during installation.

8. Remove the tensioner from the vise.

9. If the copper links are not visible, mark one link on one end and one link on the other end, and use as timing marks.

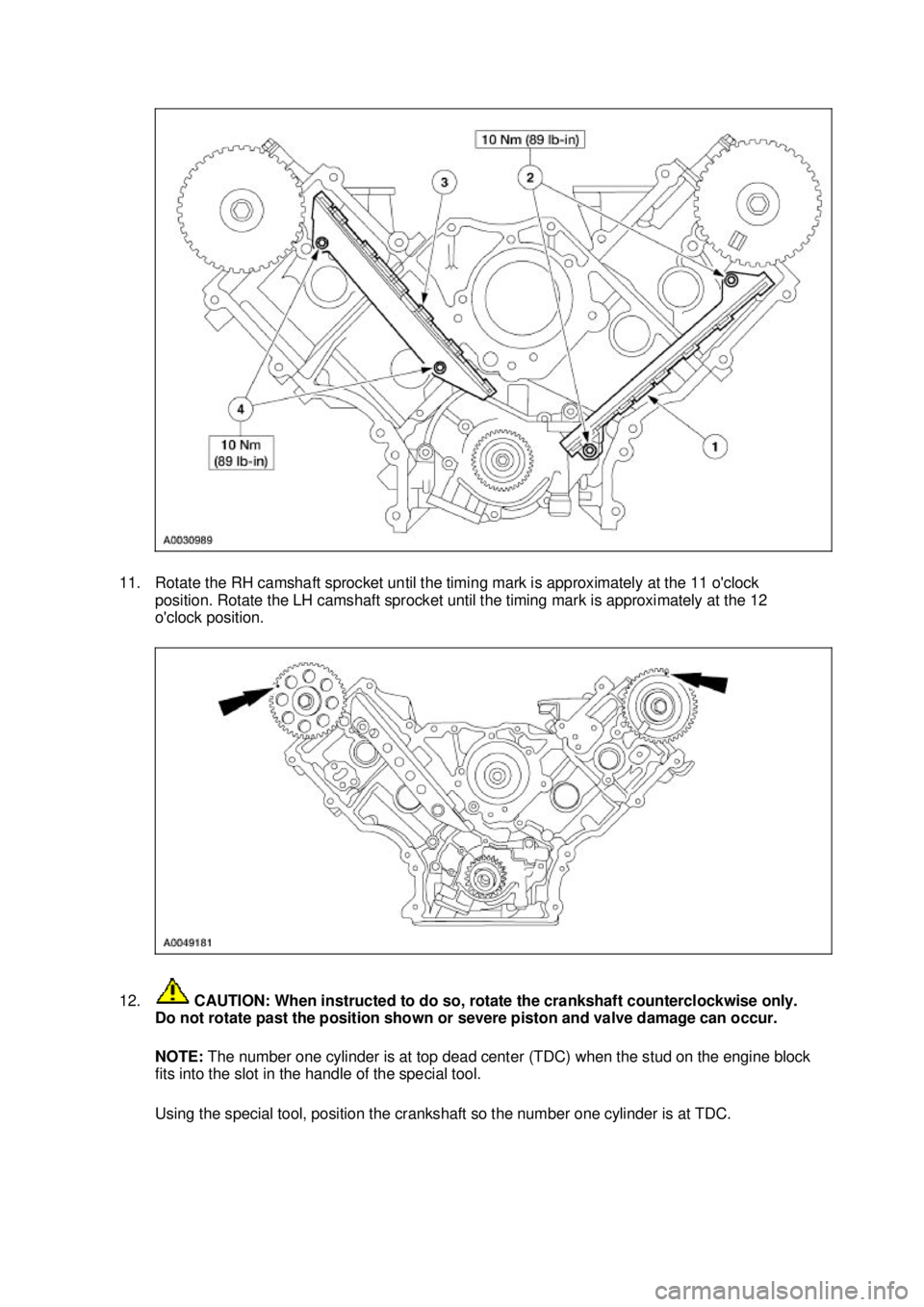

10. Install the timing chain guides. 1. Position LH timing chain guide.

2. Install and tighten the bolts.

3. Position the RH timing chain guide.

4. Install and tighten the RH bolts. �K�l�j . 5 �b�a

252003 Mustang Workshop Manual

17. 11. 2011file:///C:/Ford/2000 - 2004/tsocache/SHEF_4464/S3B~us~en~ ...

Page 1346 of 4378

11. Rotate the RH camshaft sprocket until the timing mark is approximately at the 11 o'clock

position. Rotate the LH camshaft sprocket until the timing mark is approximately at the 12

o'clock position.

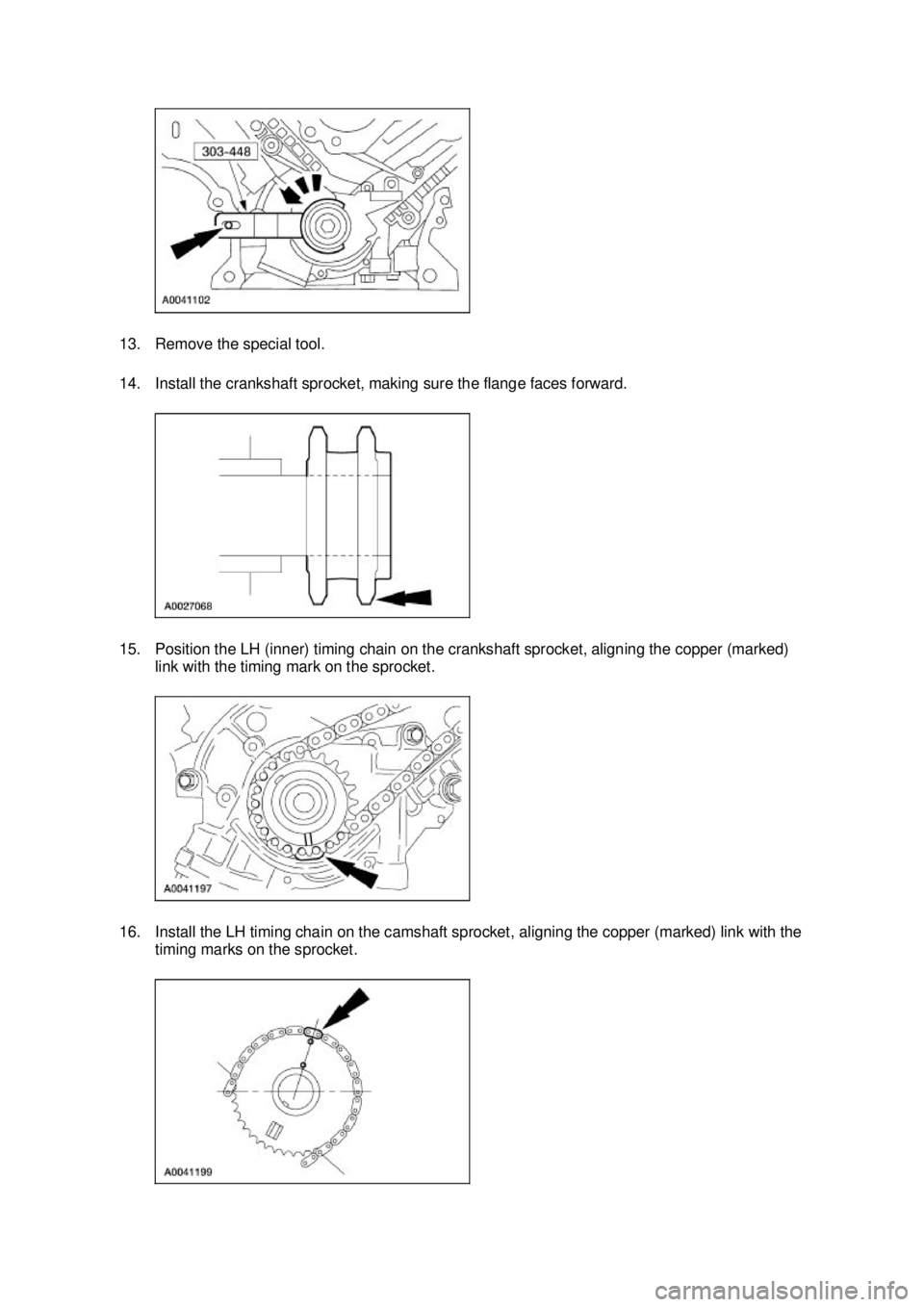

12. CAUTION: When instructed to do so, rotate the crankshaft counterclockwise only.

Do not rotate past the position shown or severe piston and valve damage can occur.

NOTE: The number one cylinder is at top dead center (TDC) when the stud on the engine block

fits into the slot in the handle of the special tool.

Using the special tool, position the crankshaft so the number one cylinder is at TDC. �K�l�j . 6 �b�a

252003 Mustang Workshop Manual

17. 11. 2011file:///C:/Ford/2000 - 2004/tsocache/SHEF_4464/S3B~us~en~ ...

Page 1347 of 4378

13. Remove the special tool.

14. Install the crankshaft sprocket, making sure the flange faces forward.

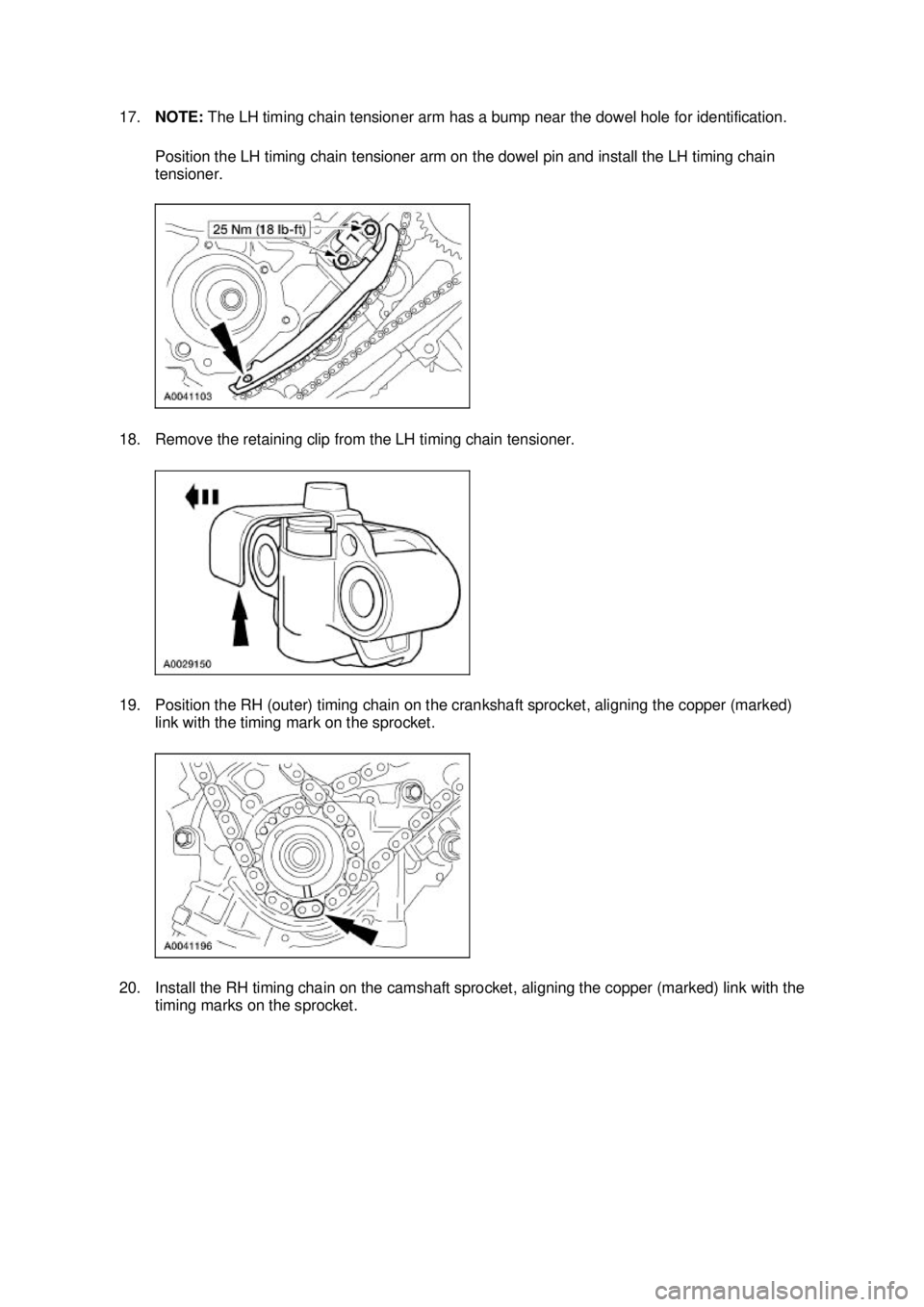

15. Position the LH (inner) timing chain on the crankshaft sprocket, aligning the copper (marked)

link with the timing mark on the sprocket.

16. Install the LH timing chain on the camshaft sprocket, aligning the copper (marked) link with the timing marks on the sprocket. �K�l�j . 7 �b�a

252003 Mustang Workshop Manual

17. 11. 2011file:///C:/Ford/2000 - 2004/tsocache/SHEF_4464/S3B~us~en~ ...

Page 1348 of 4378

17.

NOTE: The LH timing chain tensioner arm has a bump near the dowel hole for identification.

Position the LH timing chain tensioner arm on the dowel pin and install the LH timing chain

tensioner.

18. Remove the retaining clip from the LH timing chain tensioner.

19. Position the RH (outer) timing chain on the crankshaft sprocket, aligning the copper (marked) link with the timing mark on the sprocket.

20. Install the RH timing chain on the camshaft sprocket, aligning the copper (marked) link with the timing marks on the sprocket. �K�l�j . 8 �b�a

252003 Mustang Workshop Manual

17. 11. 2011file:///C:/Ford/2000 - 2004/tsocache/SHEF_4464/S3B~us~en~ ...

Page 1349 of 4378

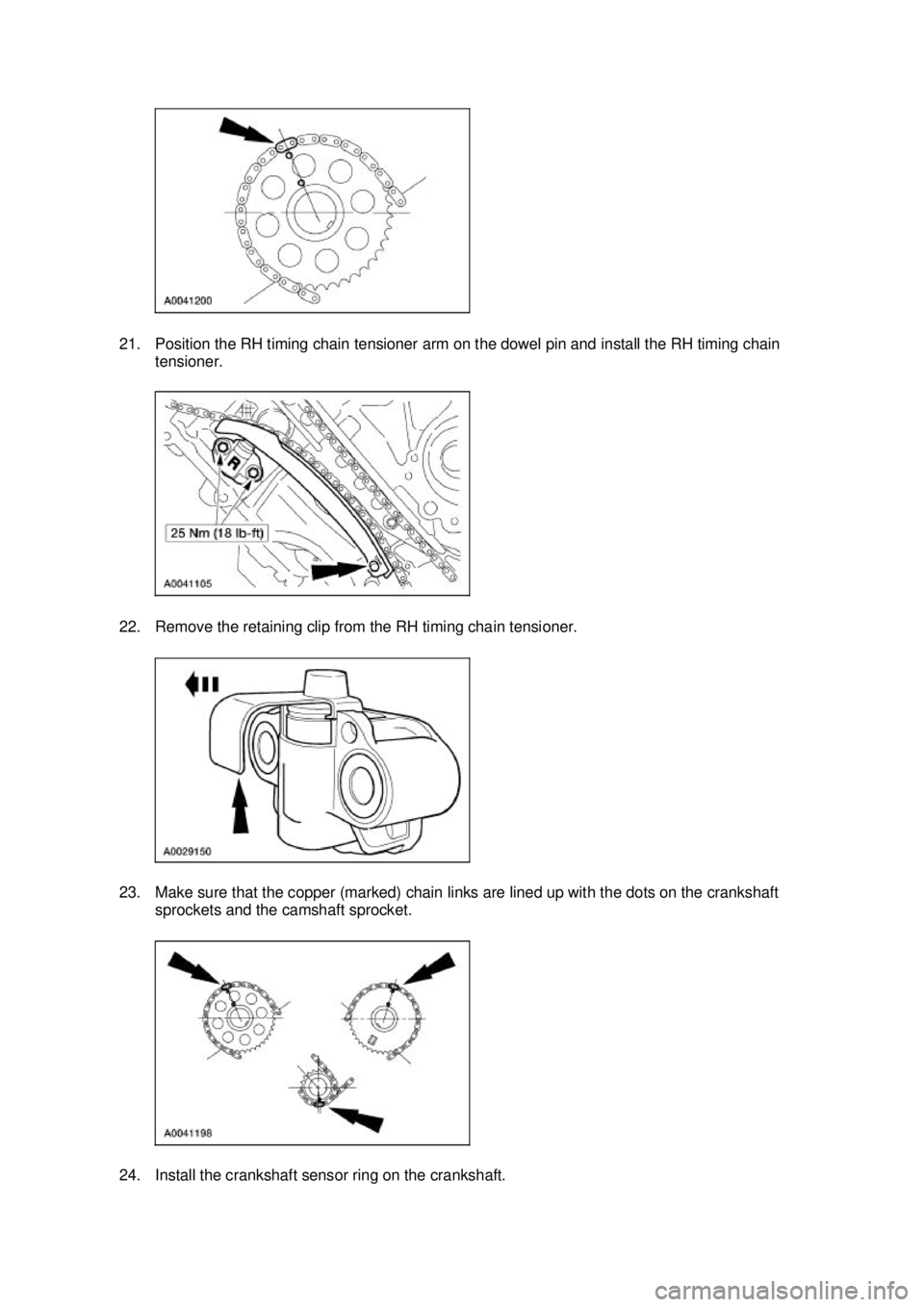

21. Position the RH timing chain tensioner arm on the dowel pin and install the RH timing chain

tensioner.

22. Remove the retaining clip from the RH timing chain tensioner.

23. Make sure that the copper (marked) chain links are lined up with the dots on the crankshaft sprockets and the camshaft sprocket.

24. Install the crankshaft sensor ring on the crankshaft. �K�l�j . 9 �b�a

252003 Mustang Workshop Manual

17. 11. 2011file:///C:/Ford/2000 - 2004/tsocache/SHEF_4464/S3B~us~en~ ...

Page 1350 of 4378

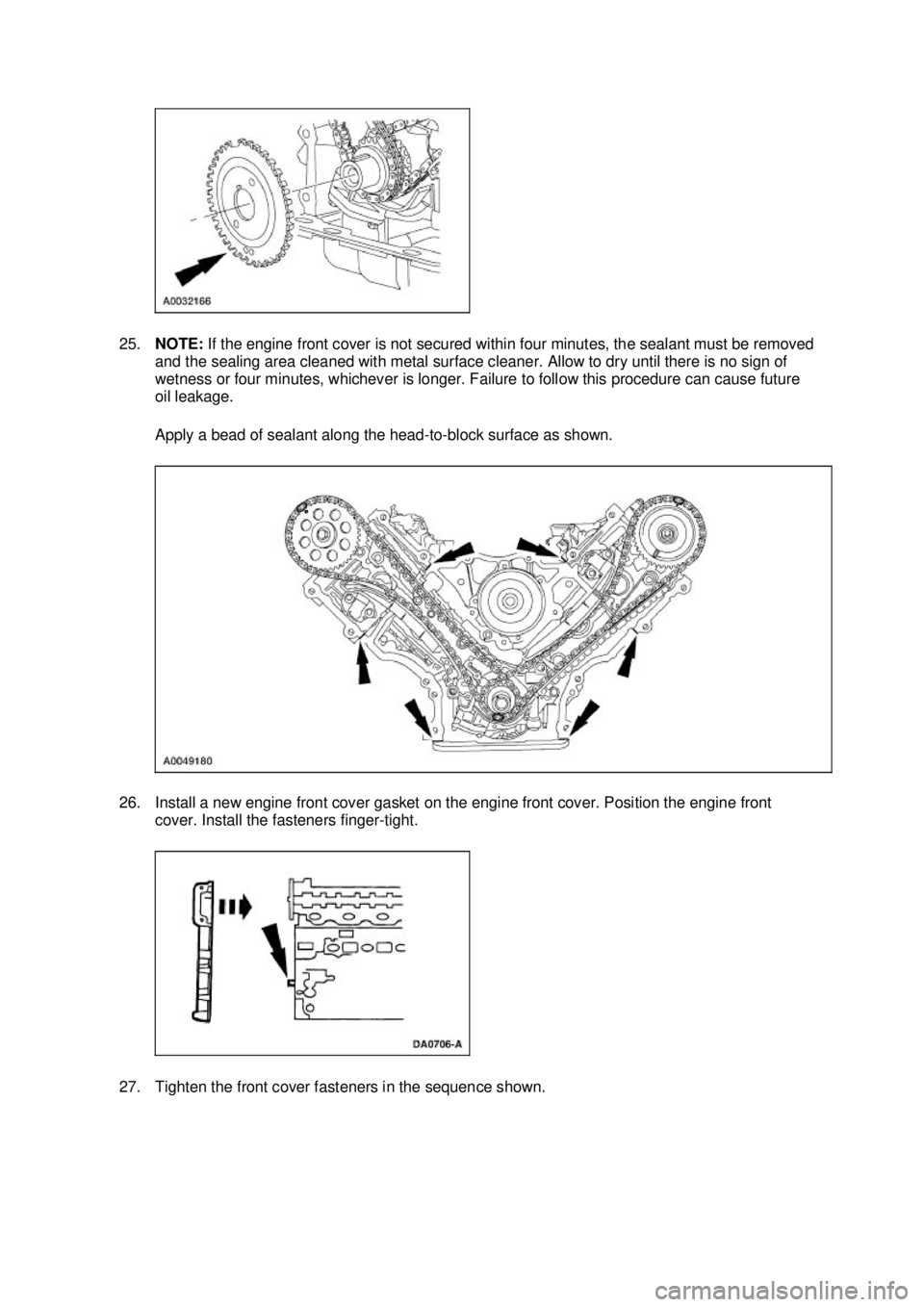

25.

NOTE: If the engine front cover is not secured within four minutes, the sealant must be removed

and the sealing area cleaned with metal surface cleaner. Allow to dry until there is no sign of

wetness or four minutes, whichever is longer. Failure to follow this procedure can cause future

oil leakage.

Apply a bead of sealant along the head- to-block surface as shown.

26. Install a new engine front cover gasket on the engine front cover. Position the engine front cover. Install the fasteners finger- tight.

27. Tighten the front cover fasteners in the sequence shown. �K�l�j . 10 �b�a

252003 Mustang Workshop Manual

17. 11. 2011file:///C:/Ford/2000 - 2004/tsocache/SHEF_4464/S3B~us~en~ ...

Trending: oil capacity, brake, drain bolt, key fob, service interval, jacking, child restraint