GEELY CK 2008 Workshop Manual

Manufacturer: GEELY, Model Year: 2008, Model line: CK, Model: GEELY CK 2008Pages: 392, PDF Size: 38.86 MB

Page 101 of 392

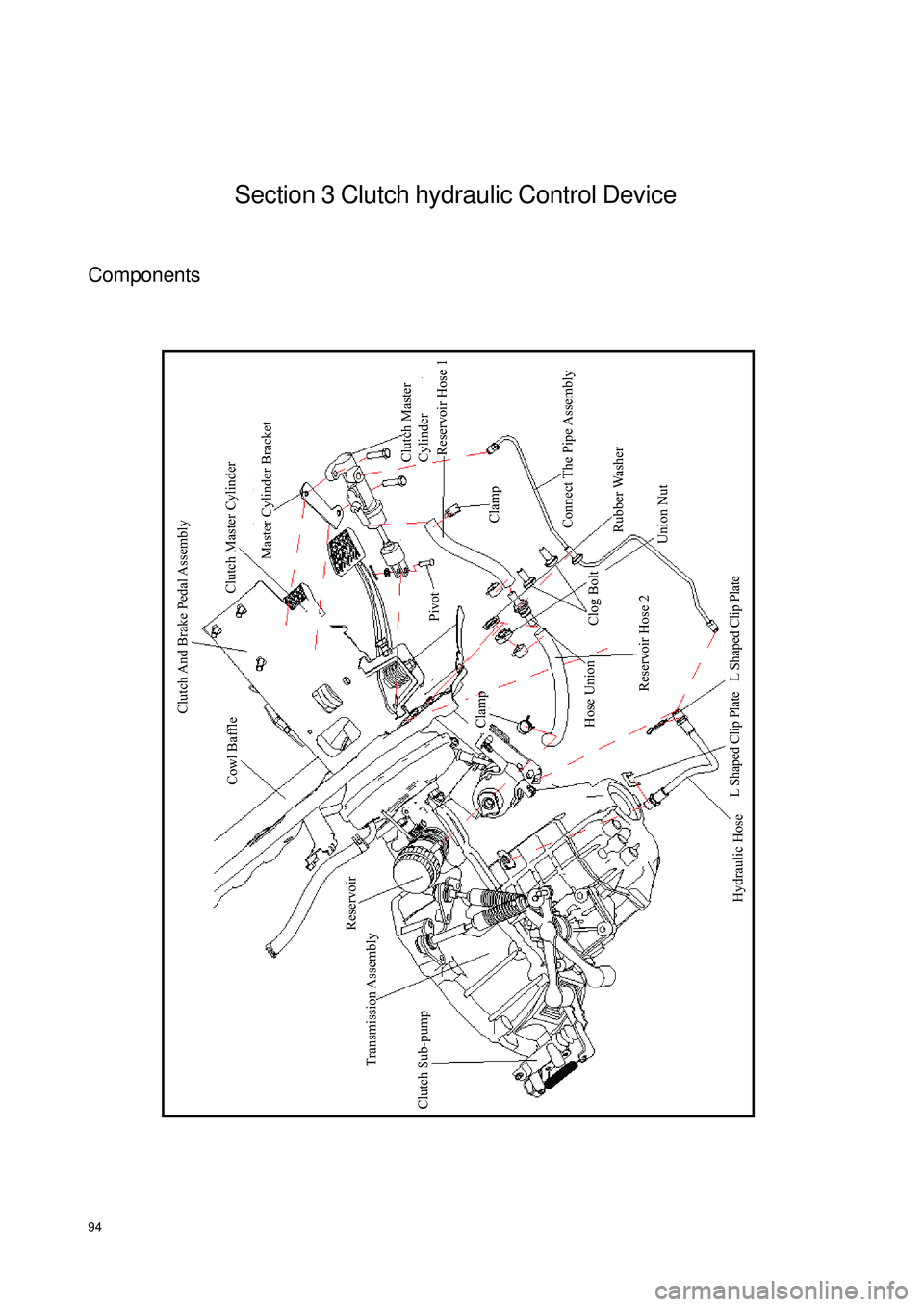

94Section 3 Clutch hydraulic Control DeviceComponents

Clutch Sub-pump

Transmission Assembly

Reservoir

Cowl Baffle

Clutch And Brake Pedal Assembly

Clutch Master Cylinder

Clutch Master

Cylinder

Master Cylinder Bracket

Clamp Clamp

Connect The Pipe Assembly

Hose Union

Reservoir Hose 2Reservoir Hose 1

Clog Bolt

Rubber Washer

Union Nut

Hydraulic Hose

L Shaped Clip Plate L Shaped Clip Plate

Pivot

Page 102 of 392

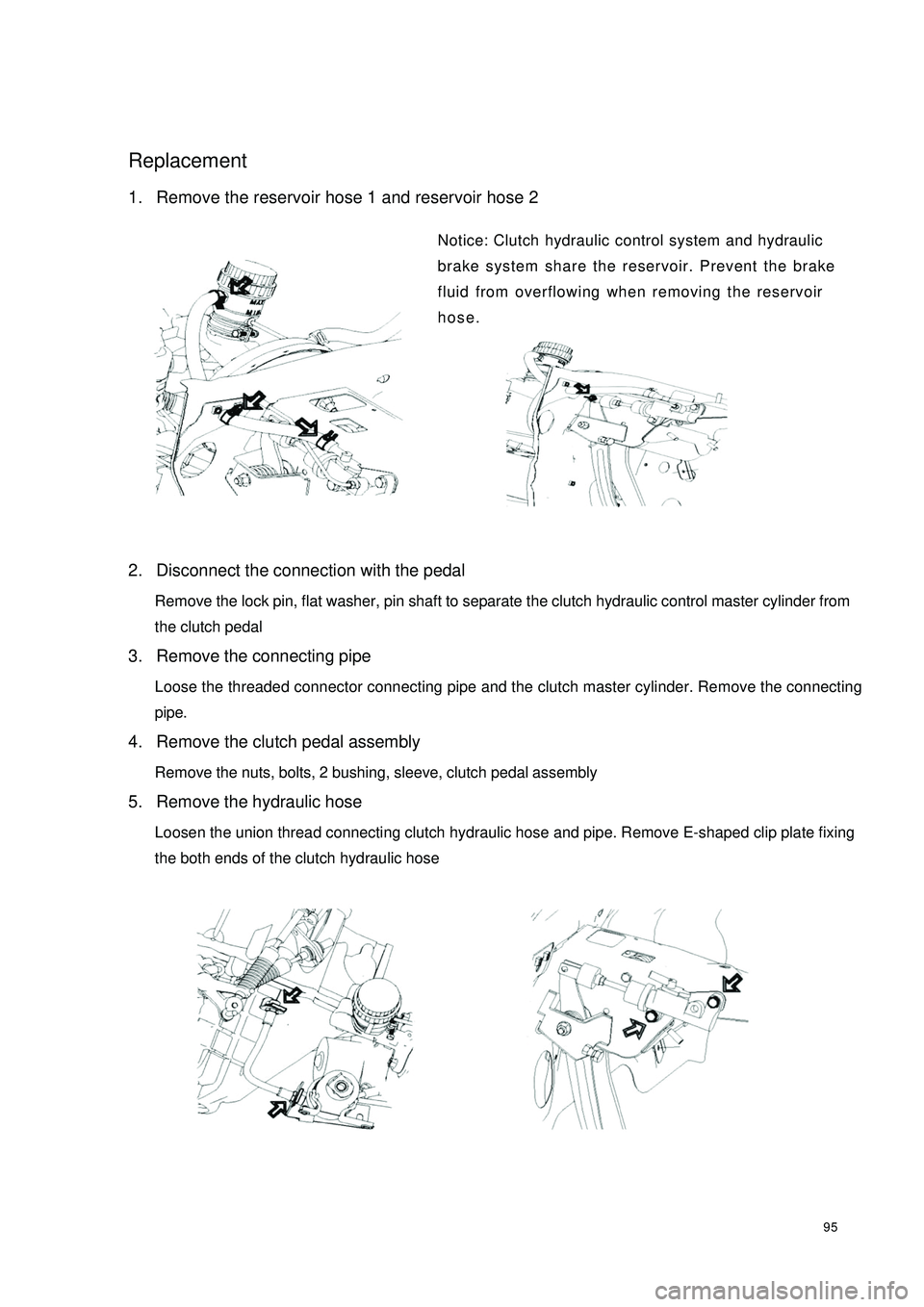

95Replacement1. Remove the reservoir hose 1 and reservoir hose 2

Notice: Clutch hydraulic control system and hydraulic

brake system share the reservoir. Prevent the brake

fluid from overflowing when removing the reservoir

hose.

2. Disconnect the connection with the pedal

Remove the lock pin, flat washer, pin shaft to separate the clutch hydraulic control master cylinder from

the clutch pedal

3. Remove the connecting pipe

Loose the threaded connector connecting pipe and the clutch master cylinder. Remove the connecting

pipe.

4. Remove the clutch pedal assembly

Remove the nuts, bolts, 2 bushing, sleeve, clutch pedal assembly

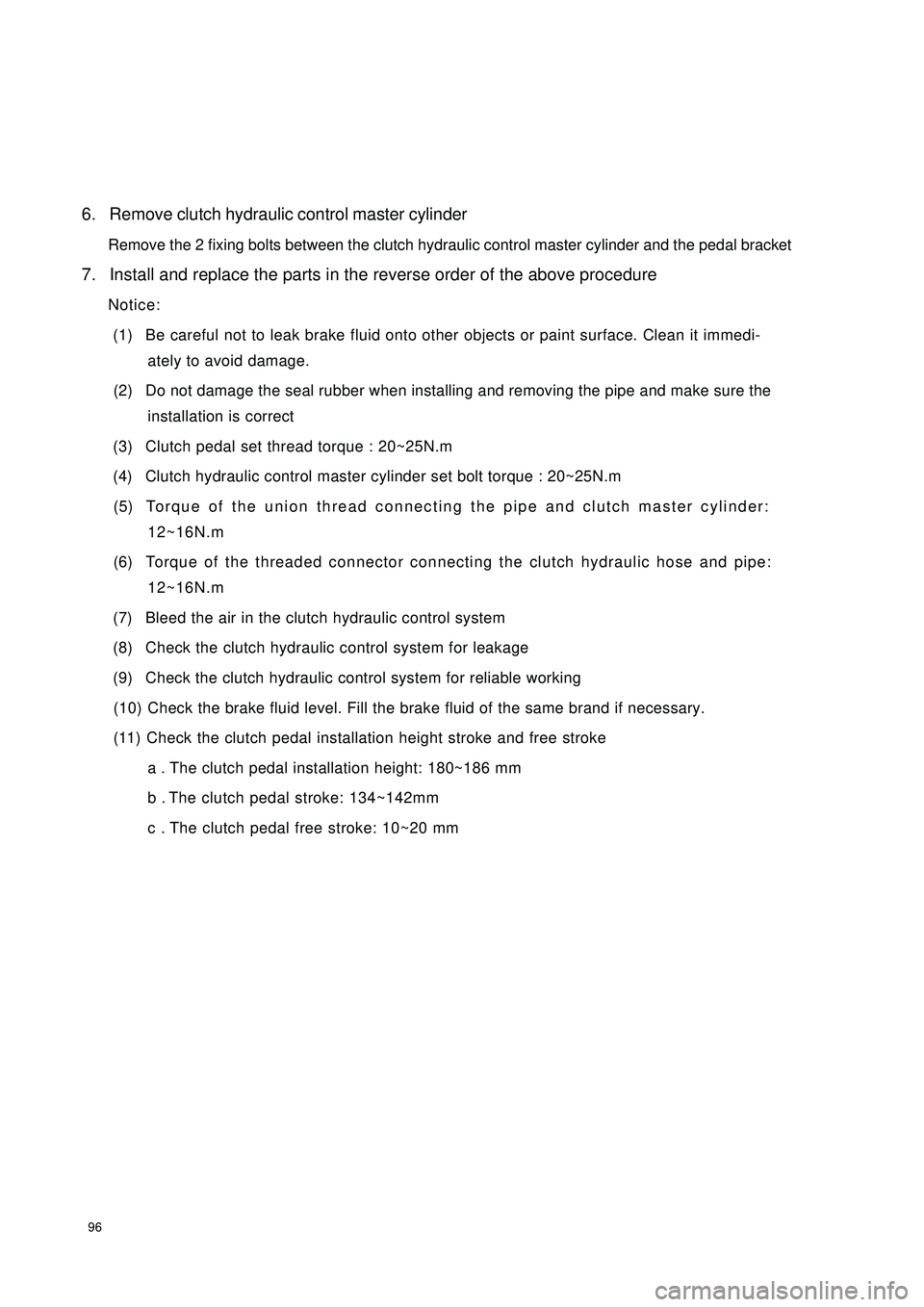

5. Remove the hydraulic hose

Loosen the union thread connecting clutch hydraulic hose and pipe. Remove E-shaped clip plate fixing

the both ends of the clutch hydraulic hose

Page 103 of 392

966. Remove clutch hydraulic control master cylinder

Remove the 2 fixing bolts between the clutch hydraulic control master cylinder and the pedal bracket

7. Install and replace the parts in the reverse order of the above procedure

Notice:

(1) Be careful not to leak brake fluid onto other objects or paint surface. Clean it immedi-

ately to avoid damage.

(2) Do not damage the seal rubber when installing and removing the pipe and make sure the

installation is correct

(3) Clutch pedal set thread torque : 20~25N.m

(4) Clutch hydraulic control master cylinder set bolt torque : 20~25N.m

(5) Torque of the union thread connecting the pipe and clutch master cylinder:

12~16N.m

(6) Torque of the threaded connector connecting the clutch hydraulic hose and pipe:

12~16N.m

(7) Bleed the air in the clutch hydraulic control system

(8) Check the clutch hydraulic control system for leakage

(9) Check the clutch hydraulic control system for reliable working

(10)Check the brake fluid level. Fill the brake fluid of the same brand if necessary.

(11) Check the clutch pedal installation height stroke and free stroke

a . The clutch pedal installation height: 180~186 mm

b . The clutch pedal stroke: 134~142mm

c . The clutch pedal free stroke: 10~20 mm

Page 104 of 392

97Chapter 4 Propeller ShaftSection 1 Propeller ShaftPropeller shaft is constant velocity propeller shaft, consisting of tripod constant velocity universal joint and

Rzeppa constant velocity univeral joint, where the tripod one is on the differential side and the Rzeppa one is

on the wheel side.Structure

Symptom TableThe table below is helpful to find the cause of the problem. The numbers indicate the priority of the likely

cause of the problem. Check each part in order. Repair or replace these parts or assemblies if necessary.Symptom Inspe c tion A re a

1.

R ze ppa C onsta nt ve loc ity unive rsa l joint (w orn)

2.

Tripod c onsta nt ve loc ity unive rsa l joint (w orn) NoiseRzeppa TypeTripod TypeRzeppa Constant Velocity Joint Tripod Constant Velocity Joint

1. Case 2.Steel Ball 3.Rzeppa

4.Inner Star Race 5.Semi-shaft1.Case 2.Tripod Assembly

3.Semi-shaft

Page 105 of 392

98Components 1. Rzeppa Constant velocity universal joint2. Snap ring

3 . Clip Band

4. Rzeppa Type Constant velocity universal joint boot

5 . Band

6. Shaft

7 . Band

8. Tripod constant velocity universal joint boot

9 . Band

10. Snap ring

11. Tripod constant velocity universal joint

12. Snap ring

Page 106 of 392

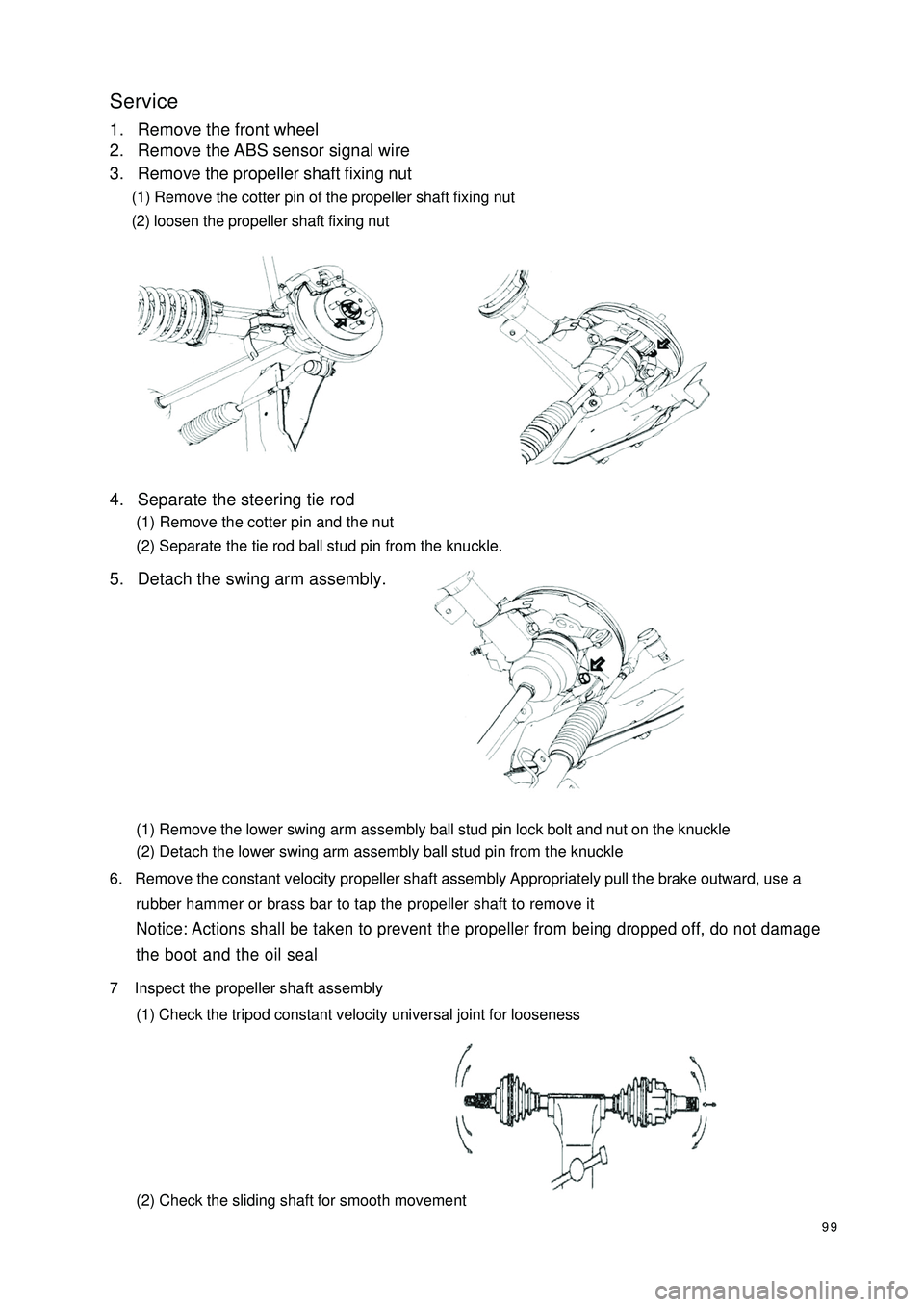

99Service1. Remove the front wheel

2. Remove the ABS sensor signal wire

3. Remove the propeller shaft fixing nut

(1) Remove the cotter pin of the propeller shaft fixing nut

(2) loosen the propeller shaft fixing nut

4. Separate the steering tie rod

(1) Remove the cotter pin and the nut

(2) Separate the tie rod ball stud pin from the knuckle.

5. Detach the swing arm assembly.

(1) Remove the lower swing arm assembly ball stud pin lock bolt and nut on the knuckle

(2) Detach the lower swing arm assembly ball stud pin from the knuckle

6. Remove the constant velocity propeller shaft assembly Appropriately pull the brake outward, use a

rubber hammer or brass bar to tap the propeller shaft to remove itNotice: Actions shall be taken to prevent the propeller from being dropped off, do not damage

the boot and the oil seal7 Inspect the propeller shaft assembly

(1) Check the tripod constant velocity universal joint for looseness

(2) Check the sliding shaft for smooth movement

Page 107 of 392

100(3) Check the Rzeppa Constant velocity universal joint for looseness

(4) Check the boot for damage

Notice: Check that the propeller shaft assembly is placed horizontal.

8. Disassemble the tripod constant velocity universal joint boot Use screwdriver to loose the tripod constant

velocity universal joint boot band, remove the boot

Notice: Replace the band if it is distorted

9. Disassembly the tripod constant velocity universal joint

(1) Remove the old grease

(2) Use the mark pen to place a matchmark on the inboard and outboard joint

Notice: Do not punch the marks

(3) Remove the outboard knuckle

(4) Use snap ring pliers to remove the snap ring

(5) Use mark pen to place matchmarks on the tripod ball joint and outboard joint

(6) Use brass bar and hammer to remove the tripod ball joint

Notice: Do not tap the rollerMarkBrass BarMark

Page 108 of 392

10110. Remove the snap ring on the spline shaft end of the tripod constant velocity joint

Notice: Do not damage the snap ring, or it shall be replaced

11.Disassemble the Rzeppa Constant velocity universal joint boot Use screwdriver to loosen the

Rzeppa Constant velocity universal joint boot band, remove the boot

Notice: Replace the band if it is distorted

12. Disassemble the Rzeppa Constant velocity universal joint

(1) Remove the old grease

(2) Use the mark pen to make a matchmark on the inboard and outboard joint

Notice: Do not punch the marks

13. Installation is in the reverse order of removal procedure

Notice:

(1) Apply proper amount of long life grease as specified when assembling the tripod

velocity universal joint and Rzeppa Constant velocity universal joint, and then

assemble it according to the matchmark.(2) Keep both sides of the spline shaft clean, the boot intact and the band assembled into place(3) The tripod constant velocity joint spline shaft and the differential shall be assembled into place, with the snap ring opening facing down, use rubber hammer to tap it

appropriately when necessary

(4) Propeller shaft attaching nut torque: 145~155N.m, install the cotter pin

(5) Steering knuckle lower swing arm assembly ball stud pin retaining bolt and nut

torque: 80~90N.m

(6) Tie rod ball stud pin attaching nut torque:27~39N.m, install the cotter pin

Page 109 of 392

102(7) Install front wheel, wheel nut torque: 95~115N.m

(8) Make sure that the propeller shafts for 1.3L engine and 1.5L engine are not interchanged

at the time of replacement

(9) Check the ABS sensor signal, check and adjust the front wheel alignment if necessary.

Page 110 of 392

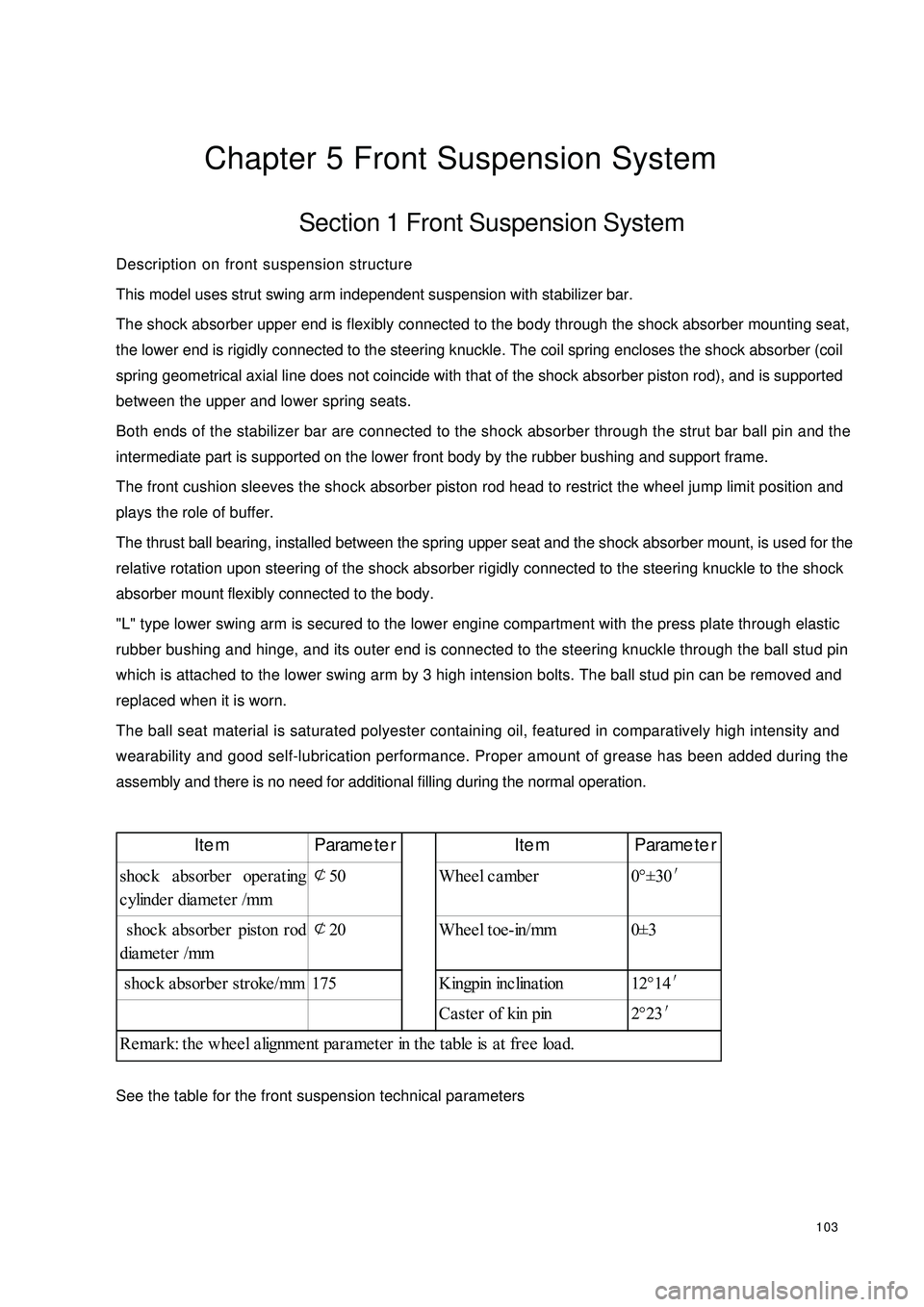

103Chapter 5 Front Suspension SystemSection 1 Front Suspension SystemDescription on front suspension structure

This model uses strut swing arm independent suspension with stabilizer bar.

The shock absorber upper end is flexibly connected to the body through the shock absorber mounting seat,

the lower end is rigidly connected to the steering knuckle. The coil spring encloses the shock absorber (coil

spring geometrical axial line does not coincide with that of the shock absorber piston rod), and is supported

between the upper and lower spring seats.

Both ends of the stabilizer bar are connected to the shock absorber through the strut bar ball pin and the

intermediate part is supported on the lower front body by the rubber bushing and support frame.

The front cushion sleeves the shock absorber piston rod head to restrict the wheel jump limit position and

plays the role of buffer.

The thrust ball bearing, installed between the spring upper seat and the shock absorber mount, is used for the

relative rotation upon steering of the shock absorber rigidly connected to the steering knuckle to the shock

absorber mount flexibly connected to the body.

"L" type lower swing arm is secured to the lower engine compartment with the press plate through elastic

rubber bushing and hinge, and its outer end is connected to the steering knuckle through the ball stud pin

which is attached to the lower swing arm by 3 high intension bolts. The ball stud pin can be removed and

replaced when it is worn.

The ball seat material is saturated polyester containing oil, featured in comparatively high intensity and

wearability and good self-lubrication performance. Proper amount of grease has been added during the

assembly and there is no need for additional filling during the normal operation.

See the table for the front suspension technical parametersItem Parameter Item Parameter

shoc k a bsorbe r ope ra ting

cylinder diameter /mm¢

50 Wheel camber 0°±30′

shoc k a bsorbe r piston rod

diameter /mm¢

20 Wheel toe-in/mm 0±3

shoc k a bsorbe r stroke /mm 175 Kingpin inc lina tion 12°14′

Ca ste r of kin pin 2°23′

Remark: the wheel alignment parameter in the table is at free load.