GEELY CK 2008 Repair Manual

Manufacturer: GEELY, Model Year: 2008,

Model line: CK,

Model: GEELY CK 2008

Pages: 392, PDF Size: 38.86 MB

GEELY CK 2008 Repair Manual

CK 2008

GEELY

GEELY

https://www.carmanualsonline.info/img/58/57159/w960_57159-0.png

GEELY CK 2008 Repair Manual

Trending: fuel filter, wiring diagram, door lock, jacking, heater, air suspension, wiper blades

Page 61 of 392

54Section 2 Water Pump, Thermostat and Radiator ReplacementHoist the engine from the compartment. See "Provison 20, Section 2, Chapter 2".

1. Replace water pump. See (Figure 125)

(1) Drain the coolant.

(2) Detach timing belt.

(3) Detach power steering pump assembly.

(4) Remove the oil dipstick guide.

(5) Detach water pump assembly.

(6) Install water pump assembly.

(7) The installation is in the reverse order of the removal.

2. Replace thermostat

(1) Remove thermostat (See Figure 126).

(2) Install thermostat.

a. Install a new gasket to the thermostat. See (Figure 127).

b.Align the main valve of the thermostat to the top of the

stud. Insert the thermostat into the water inlet case.

Hint:

The main valve is set at around 10°C as shown in the figure. See (Figure 128).

(3) Install inlet connector.

Figure 127 Figure 128

3. Replace radiator

(1) Open radiator cap.

(2) Open the drain valve and drain the coolant.

(3) Detach radiator water inlet hose.

(4) Detach radiator water outlet hose.Figure 125

Figure 126

Page 62 of 392

55(5) Disconnect auto-transmission oil cooler input pipe (Auto-transmission).

(6) Disconnect auto-transmission oil cooler output pipe (Auto-transmission).

(7) Remove 4 bolts from the radiator mounting bracket. See (Figure 129).

(8) Detach radiator assembly, Remove 3 bolts. Detach the fan and fan shroud. See (Figure 130).

Figure 127 Figure 128

(9) Install the cooling fan assembly

(a) Fix the reservoir assembly on the cooling fan bracket with the bolt. Torque: 16 N. m.

(b) Install the fan and fan shroud with 3 bolts. Torque: 7.5N. m.

(c) Install the cooling fan assembly to radiator assembly with 3 bolts. Torque: 16N. m.

(d) Connect the overflow pipe on the reservoir assembly and radiator assembly. Fix it with the spring

band.

(f) The installation of the radiator assembly is in the reverse order of the removal.

Page 63 of 392

56Chapter 7 Clutch

(MR7131A, MR7151A, MR7161A)Component 1 (Hydraulic Manipulation)Figure 131

Page 64 of 392

57Section 1 Clutch ReplacementHoist the engine from the compartment. See "Provison 20, Section 2, Chapter 2".

1. Remove manual transaxle assembly

2. Remove the clutch release fork. See (Figure 132)

3. Detach clutch release fork boot.

4. Detach clutch release bearing

5. Detach clutch release bearing fixed clamp

6. Remove clutch fork pivot pin

7. Align the clutch cover to the mark on the flywheel. Detach clutch cover. See (Figure 133)

8. Remove clutch plate

9. Check and remove clutch plate assembly. See (Figure 134)

10. Check clutch cover. See (Figure 135)

Depth wear: A: 0.6mm

Width wear: B: 5mm

Figure 132 Figure 133

Figure 134 Figure 135

Page 65 of 392

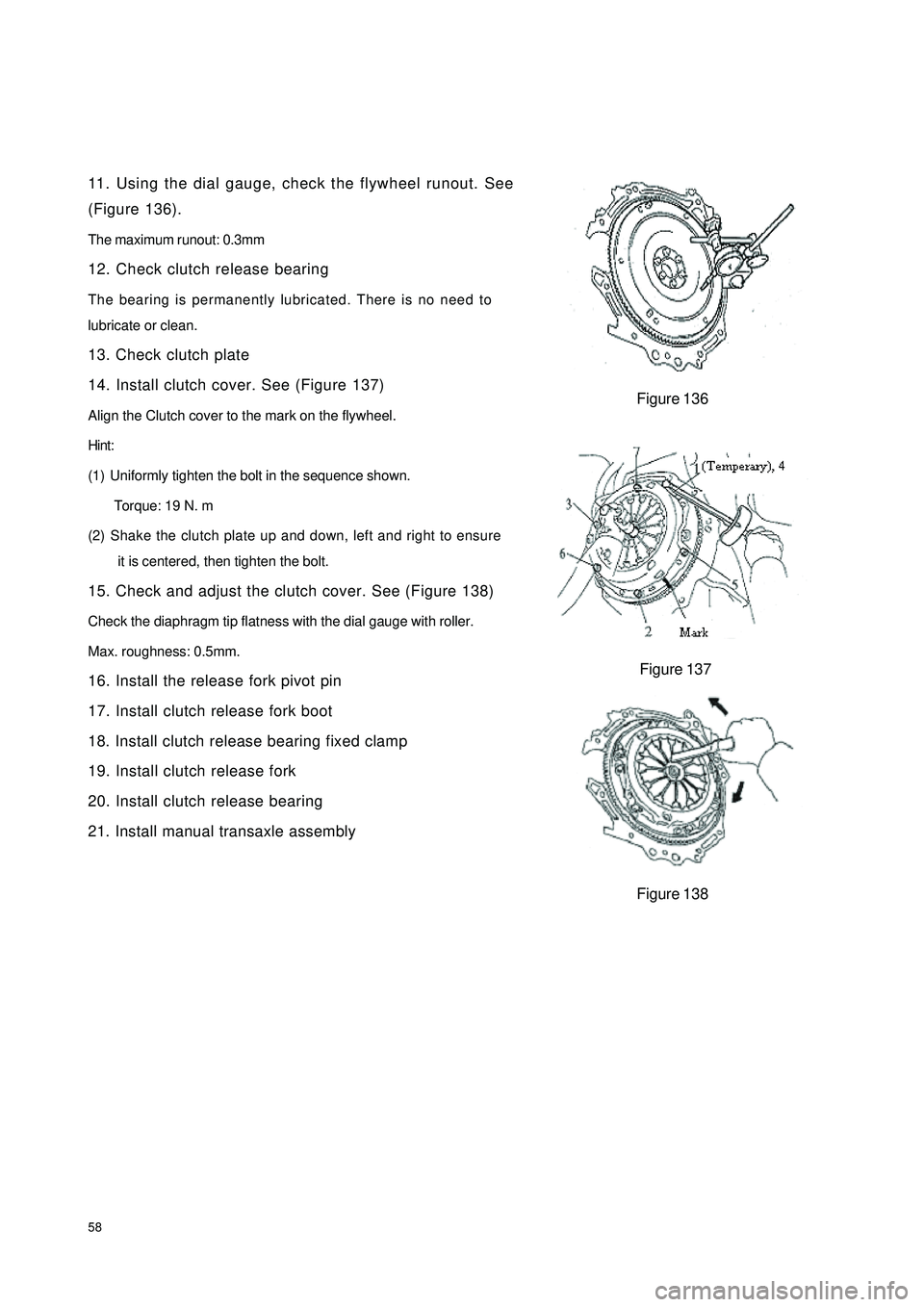

5811. Using the dial gauge, check the flywheel runout. See

(Figure 136).

The maximum runout: 0.3mm

12. Check clutch release bearing

The bearing is permanently lubricated. There is no need to

lubricate or clean.

13. Check clutch plate

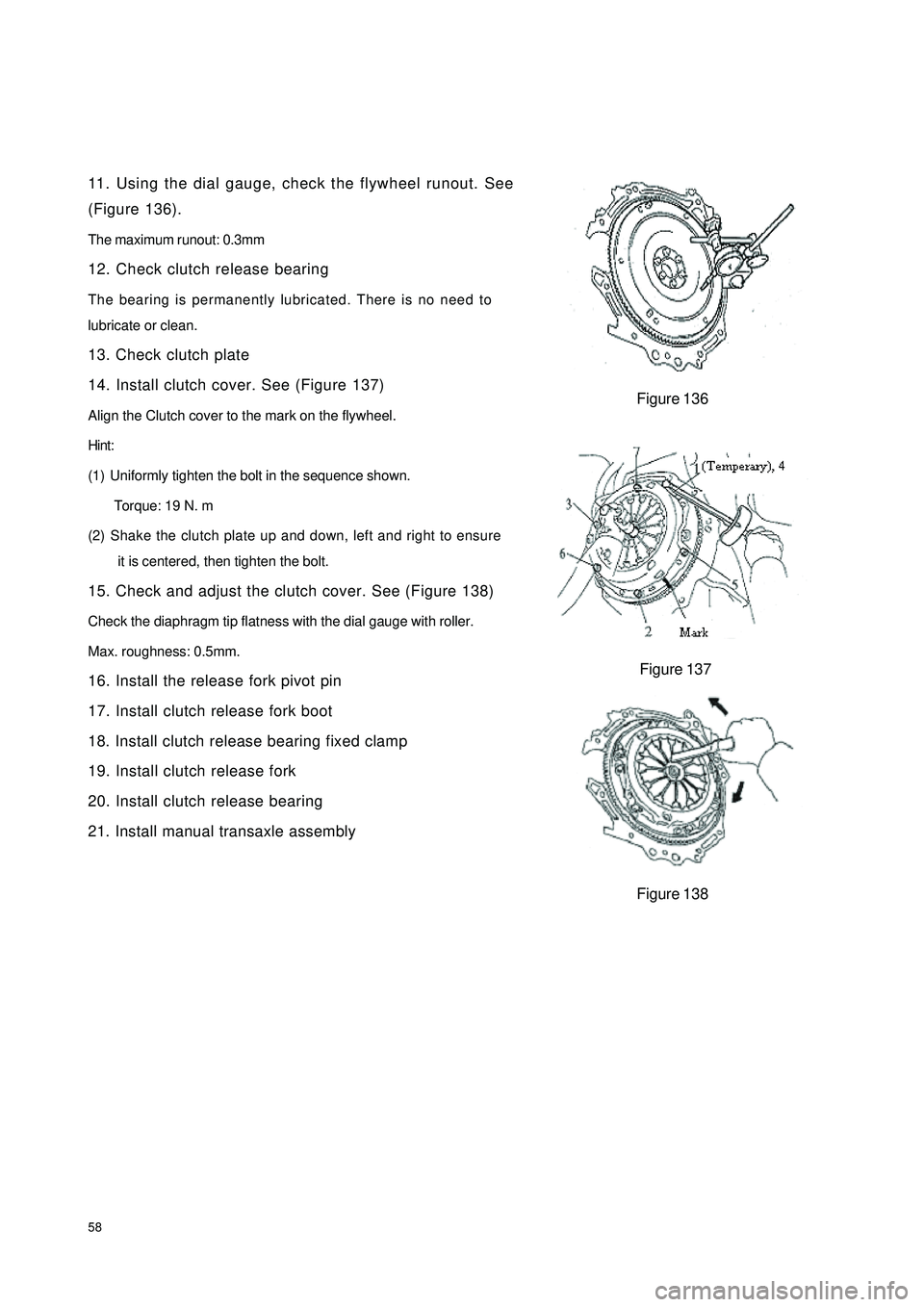

14. Install clutch cover. See (Figure 137)

Align the Clutch cover to the mark on the flywheel.

Hint:

(1) Uniformly tighten the bolt in the sequence shown.

Torque: 19 N. m

(2) Shake the clutch plate up and down, left and right to ensure

it is centered, then tighten the bolt.

15. Check and adjust the clutch cover. See (Figure 138)

Check the diaphragm tip flatness with the dial gauge with roller.

Max. roughness: 0.5mm.

16. Install the release fork pivot pin

17. Install clutch release fork boot

18. Install clutch release bearing fixed clamp

19. Install clutch release fork

20. Install clutch release bearing

21. Install manual transaxle assemblyFigure 136

Figure 137

Figure 138

Page 66 of 392

59Chapter 8 Maunal Transaxle Assembly

(MR7131A, MR7151A, MR7161A)Component 1Figure 139

Page 67 of 392

60Section 1 Manual Transaxle Replacement1. Open the engine hood

2. Remove the battery

3. Remove clutch cylinder sub-assembly. See (Figure 140)

4. Detach transmission shift cable assembly. See (Figure 141)

5. Remove the connector and turn on the back-up lamp switch connector.

6. Disconnect vehicle speed sensor

Disconnect vehicle speed sensor connector.

7. Detach the front exhaust pipe

8. Drain transmission oil

9. Detach left & right front wheel hub nut

10. Detach left & right front wheel speed sensor (ABS)

11. Detach front balance rod

12. Detach left & right tie-rod with ball stud pin

13. Detach front balance rod

14. Detach left & right lower swing arm

15. Detach left & right front propeller assembly

16. Hoist the engine from compartment. See "Provision 20, Section 2, Chapter 2"

17. Detach starter assembly

18. Detach engine mounting bracket

19. Detach manual transaxle assembly

20. Install engine mounting bracket

21. Install manual transaxle assembly

22. Connect engine vibration insulating cushions

23. Install starter assembly

24. Install left & right front propeller assembly

25. Connect left & right lower swing arm

26. Connect left & right tie-rod with ball stud pin

27. Connect front balance rod

28. Connect left & right front speed sensor (ABS)

29. Installleft & right front shaft nut

30. Install front exhaust pipe

31. Connect speedometer sensor connector.

32. Connect back-up lamp switch connector.

33. Connect transmission shift cable assembly. See (Figure 141)

34. Install clutch sub-pump assembly. See (Figure 140)Figure 140

Figure 141

Page 68 of 392

61Section 2 Vehicle Speed Sensor Replacement1. Disconnect vehicle speed sensor. See (Figure 142)

2. Remove bolt and vehicle speed sensor.

3. Install vehicle speed sensor. See (Figure 142)

4. Connect vehicle speed sensor connector. See (Figure 143)

Figure 142 Figure 143

Page 69 of 392

62Section 3 Transmission Case Oil Seal1. Remove transmission case oil seal. See (Figure 144)

2. Install transmission case oil seal. See (Figure 145)

Notice:

Be careful not to damage oil seal lip.

Figure 144 Figure 145

Page 70 of 392

63Section 4 Transaxle Case Oil Seal Replacement1. Using special tool, remove transaxle case oil seal. See (Figure 146)

2. Install transaxle case oil seal. See (Figure 147)

Figure 144 Figure 145

Trending: AUX, brake sensor, clock, headlights, reset, roof, fuel filter