HONDA INTEGRA 1998 4.G Workshop Manual

Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 1181 of 1681

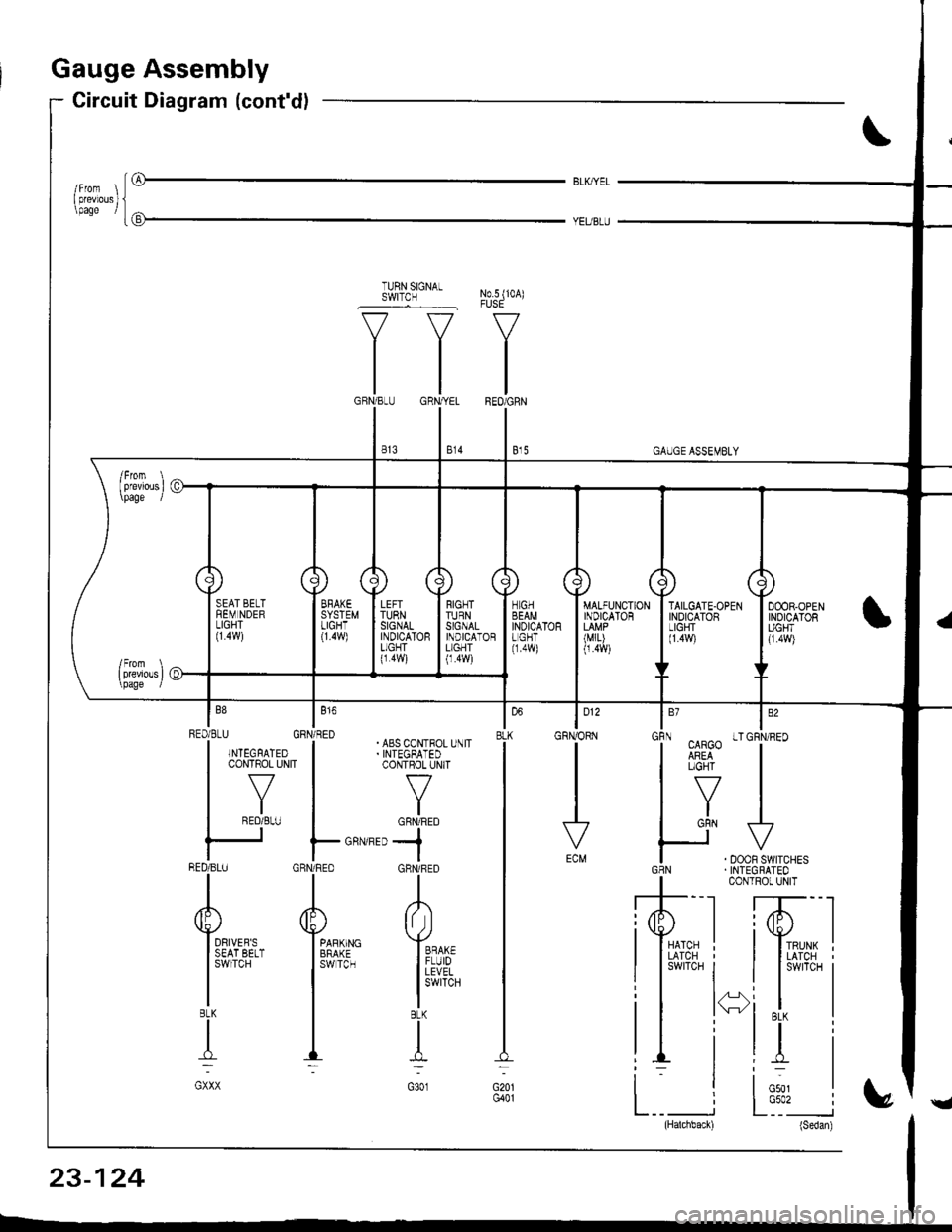

auge Assembly

Circuit Diagram (cont'dl

iG

BLK,IYEL

No.5 (10A)

V

IREO/GRN

I e,s

TURN SIGNALSWITCN

v--=v

tltl

tlGBN/BLIJ GRN,YEL

lltl

I e's I s,o

"i.uv"'T""

H^,J.**.GBN . INTEGRATEO

I coNrRor uNrT

,'T--l ffi--l

lI*ni lI*i

il i*i t i

i. li;, I

L__ i L:'�_" i(Hatchback) (Sedan)

| 012

GRNORN

vECM

louBLK

G20lG401

RIGNTTURNSIGNALINDICATORL]GHT(1.4w)

TAILGATE.OPENINDICATORLIGHT(1.4!9

RED/BLU GBN/RED| | . ABS CoN-FOL U\lTI .NTEGFATED I .INTEGBATED

|

*v^"

|

-'v*

| .roL-" I or*frro

ts Fo.''-,,-jBED/BLU GRN/RED GHNi RED

rrl

AAA

Yu'**- Y*,,r" Y**

l3$i;.?.'' 13ffi3- ll#,

| | l!i,Iib'.

TIT:-_:

GXXX G3O1

23-124

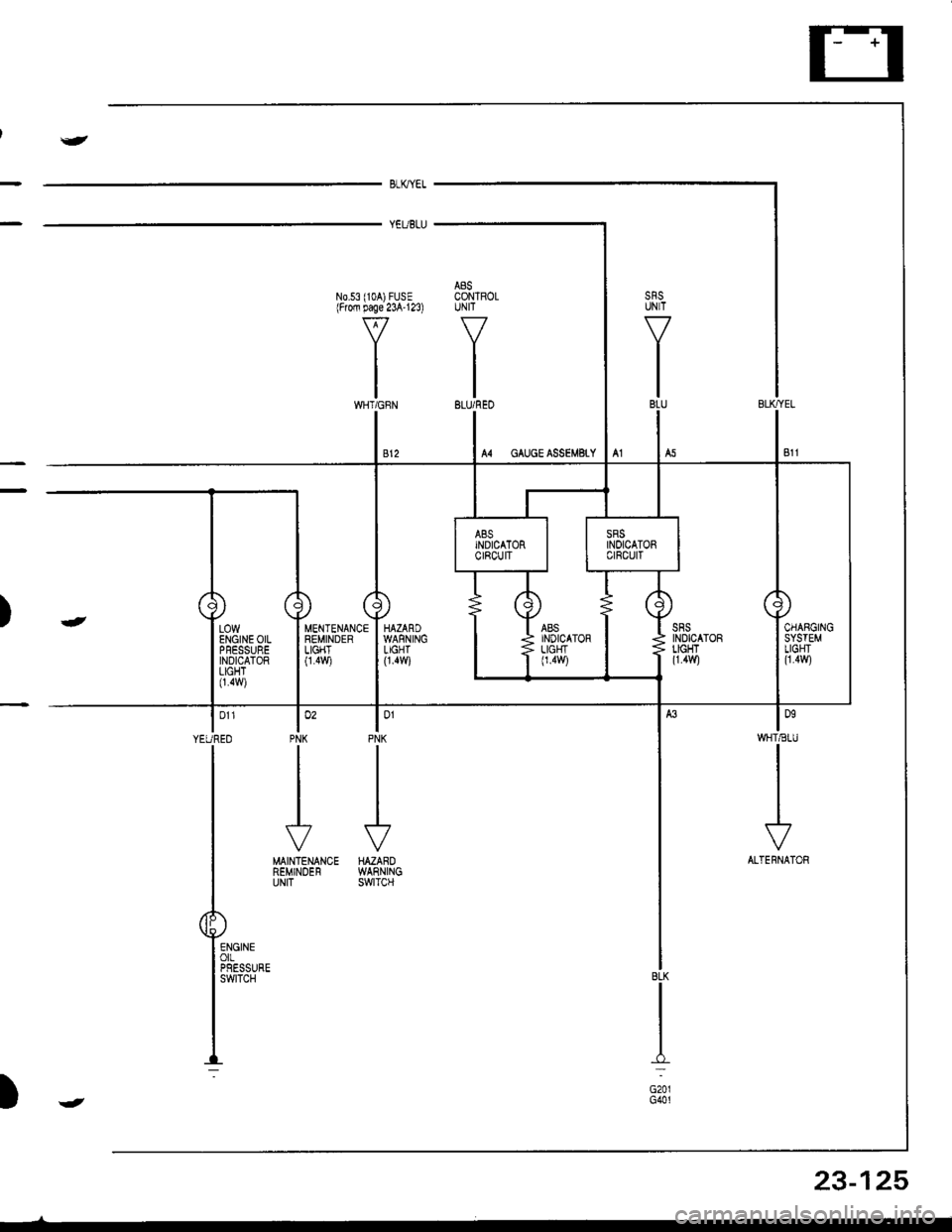

Page 1182 of 1681

J

BLKYEL

YEUBLU

A8SN0.53 (104) FUSE CONTROLlFrofi page 23A'123) UNIT

VV

II

tltlWHT/GFN BLU/REO

lonWHT€IU

I

I

I

\?

ALTERNATOR

lo'PNK

J

HAZAROWARNINGswtTcH

MENTENANCEREMINDERLIGHT0.4v,/i

lo'PNK

II

I

J

MAINTENANCEREMINDERUNIT

| 011

YEUREO

I

T

P"-:

)-

BLK

I:

G201G401

LOWENGINE OILPFESSUREINDICATORLIGHT0.4w)

23-125

)J

Page 1183 of 1681

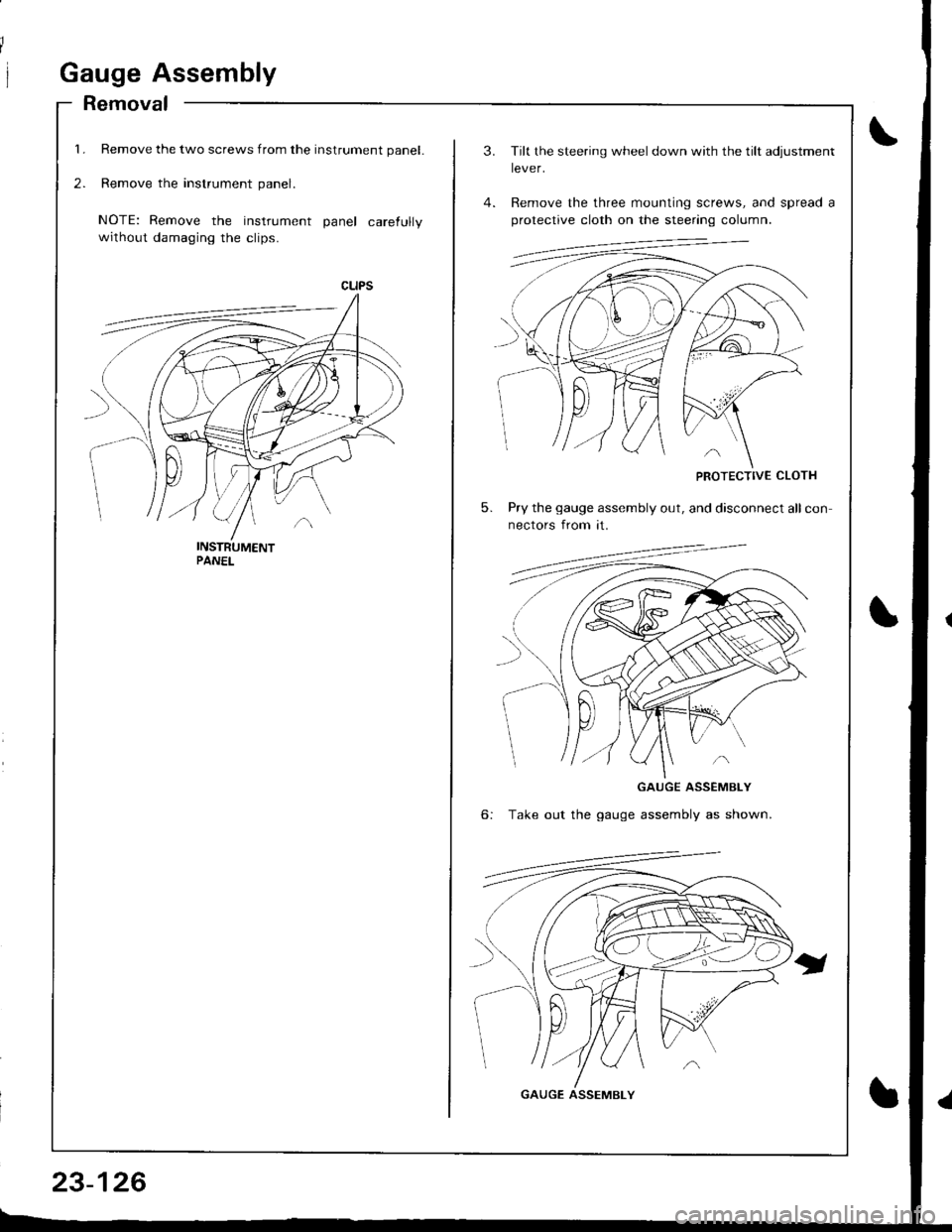

1.

2.

Gauge Assembly

Removal

Remove the two screws from the instrument panel.

Remove the instrument panel.

NOTE: Remove the instrument panel carefully

without damaging the clips.

23-126

3.

5.

Tilt the steering wheel down with the tilt adjustment

lever.

Remove the three mounting screws, and spread a

protective cloth on the steering column.

PROTECTIVE CLOTH

Pry the gauge assembly out, and disconnect all con

nectors from it.

6:

GAUGE ASSEMBLY

Take out the gauge assembly as shown.

GAUGE ASSEMBLY

Page 1184 of 1681

{

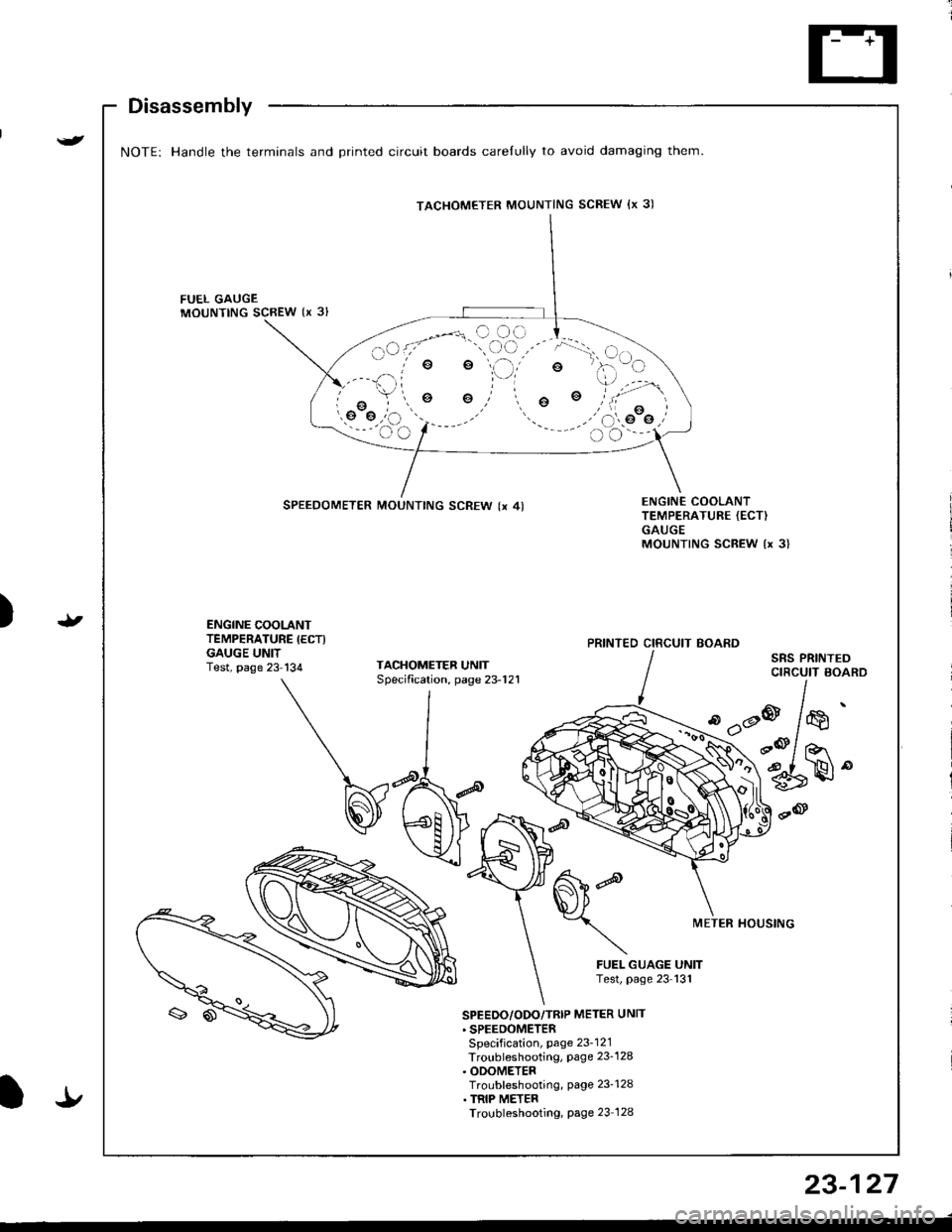

Disassembly

NOTE: Handle the terminals and Drinted circuit boards carelully to avoid damaging them.

FUEL GAUGEMOUNTING SCBEW {x 3l

e

o

SPEEDOMETER MOUNTING SCREW (x 4)ENGINE COOLANTTEMPERATURE {ECT)GAUGEMOUNTING SCREW {x 3}

t)ENGINE COOLANTTEMPERATURE IECTIGAUGE UNITTest, page 23-134TACHOMETEF UNITSpecification, page 23-121

SRS PRINTEDCIRCUIT BOARD

d'dP

METER HOUSTNG

FUEL GUAGE UNITTest, page 23 131

'

/*'

r@/ ror

6rH"

SPEEDO/ODO/TRIP METER UNTT' SPEEDOMETERSpecification, page 23-121Troubleshooting, Page 23_128. ODOMETERTroubleshooting, page 23-128. TRIP METERTroubleshooting, Page 23 128

TACHOMETER MOUNTING SCREW {x 3)

PRINTED CIRCUIT BOARD

It

23-127

Page 1185 of 1681

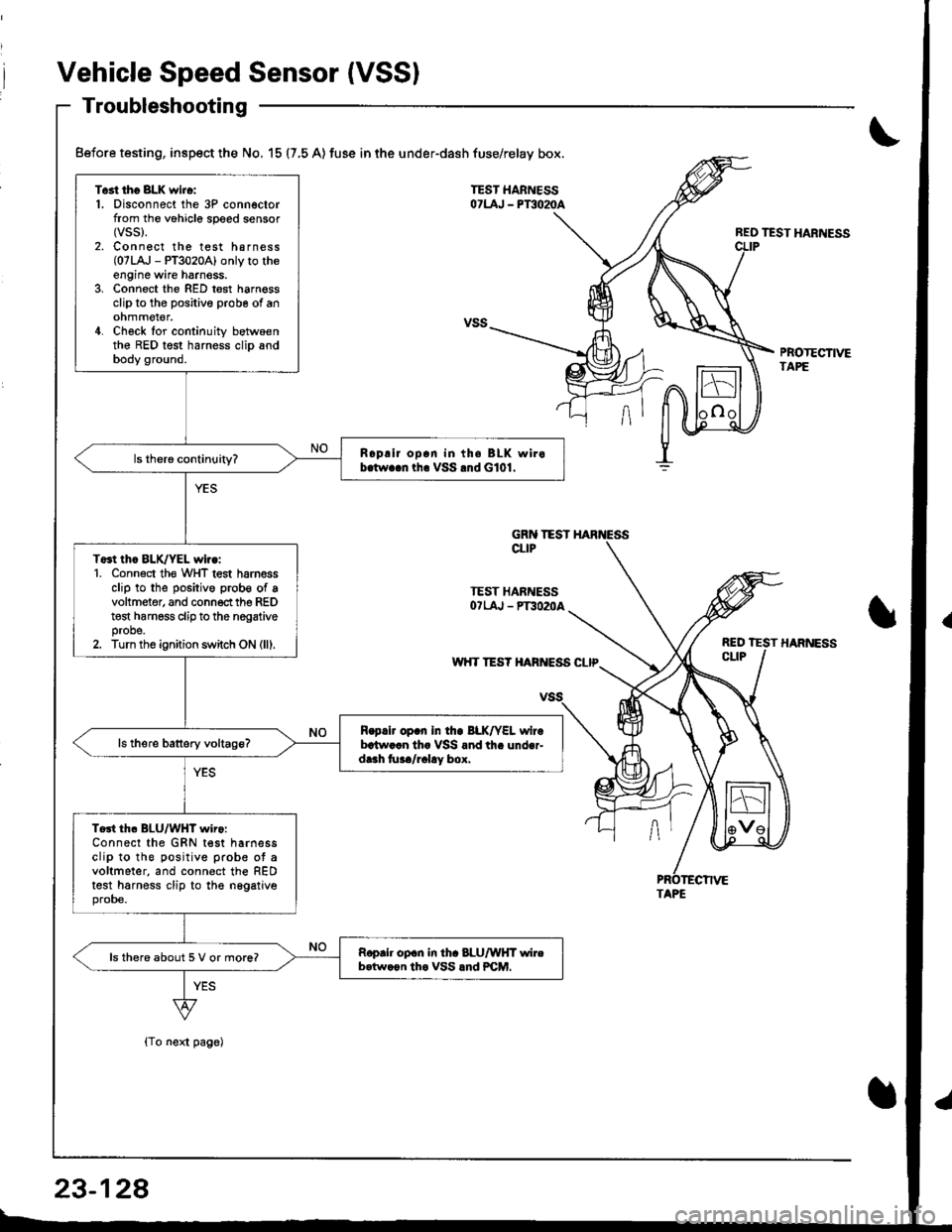

Vehicle Speed Sensor (VSSI

Troubleshooting

{To next page)

REO TEST HARNESS

PBOTECTIVETAPE

Test tho 8LK wiro:1. Disconnect the 3P connectorfrom the vohicle speed sensor(vss).

2. Connect the test harness(07LA,J - PT3020A) only to theengine wire harnoss.3, Connect the RED test harnessclip to the positive probe of anohmmel€r.4. Check for continuity betwoenthe RED test harness clip andbody ground.

Roplir op.n in th. BLK wirob.tw..n tha VSS .nd G101.

To3t thc BLK/YEL wiro:1. Conn6ct th€ WHT test harnessclip to the positive prob€ of avoltmeter, and connect the REDt€st harness clip to the nogativeprobe.2. Turn the ignition switch ON (lll.

R.p.lr op.n In tho BLK/YEL wirebrtw..n th. VSS and th. under-dr.h tu../r.l!y box.

Tort th. BLU/WHT wiro:Connect the GRN test harnessclip to the positive prob€ ot avoltmeter, and connect the REDtest harness clip to the nggatjveprobe.

Roprh op.n in th. 8LU/WHT wireb.tw.on tho VSS lnd PCM.ls there about 5 V or more?

Before testing, inspect the No. 15 (7,5 A) fuse in the under-dash fuse/relay box.

GRN TESTCLIP

TEST HARNESSOTLAJ - PT3O2OA

w'{T TES? HARIVESS CLIP

TAPE

23-128

Page 1186 of 1681

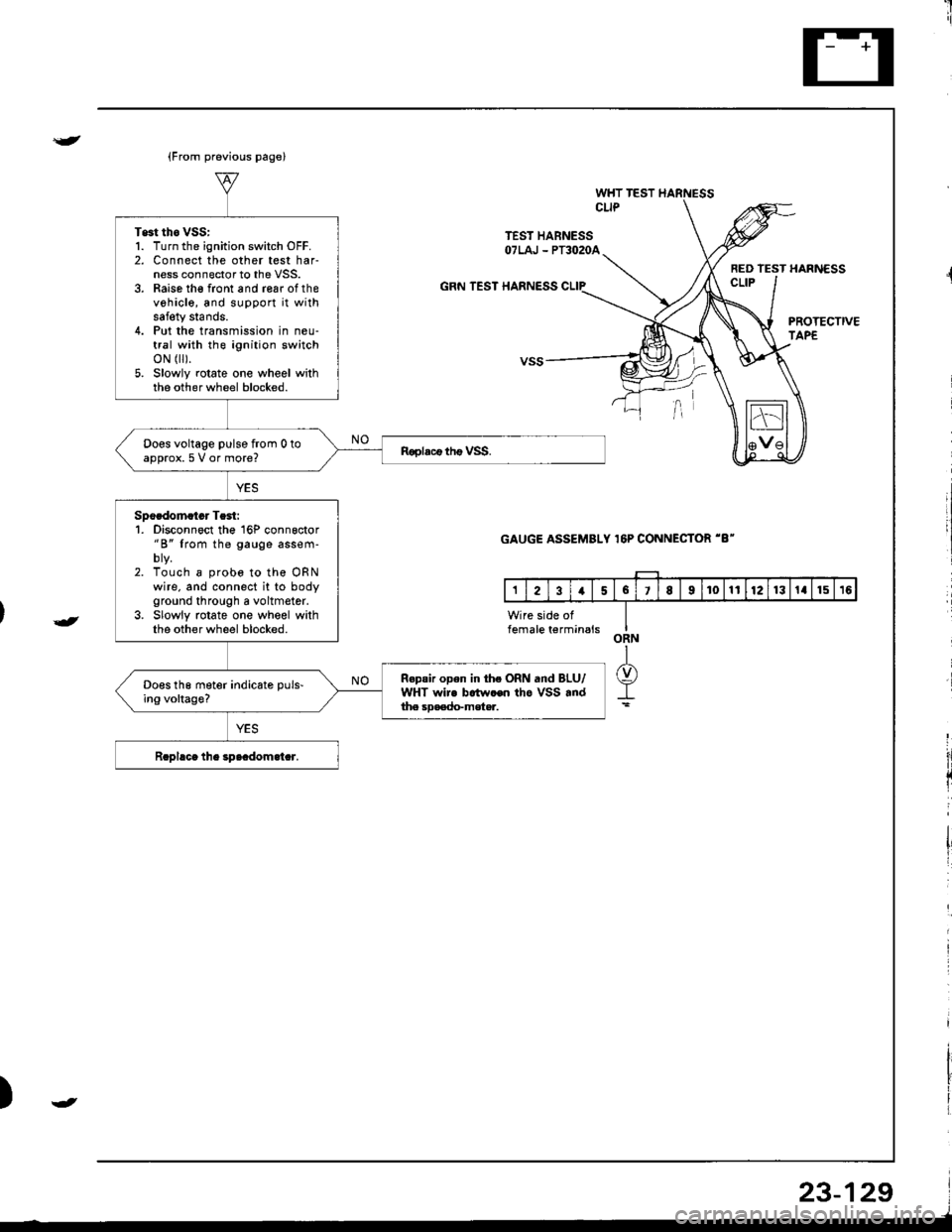

Test tho vss:1. Turn the ignition switch OFF.2. Connect the other test harness connector to the VSS.3. Raise th€ front and roar of thevehicle, and support it withsafety stands.4. Put the transmission in neu-tral with the ignition switchoN flr).5. Slowly rotate one wheel withthe other wheel blocked.

Does voltage pulse from 0 toapprox.5 V or more?

Spocdomatcr Te3t:1. Disconnoct the 16P conngctor"B" from the gauge assem-

2. Touch 8 probe to the ORNwire, and connect it to bodyground through a voltmetor.3. Slowly rotate one wheel withthe other wheel blocked.

Repair open in the ORN and BLU/WHT wire botw.en tho VSS .ndthe soa€do-mster.

Does the meter indicate puls-ing voltage?

{

{

WHT TESTCLIP

TEST HABNESSOTLAJ - PT3O2OA

FED TEST HARNESSCLIPGRN TEST HARNESS CLIP

GAUGE ASSEMBLY 16P CONNECTOR '8"

PROTECTIVETAPE

){

Page 1187 of 1681

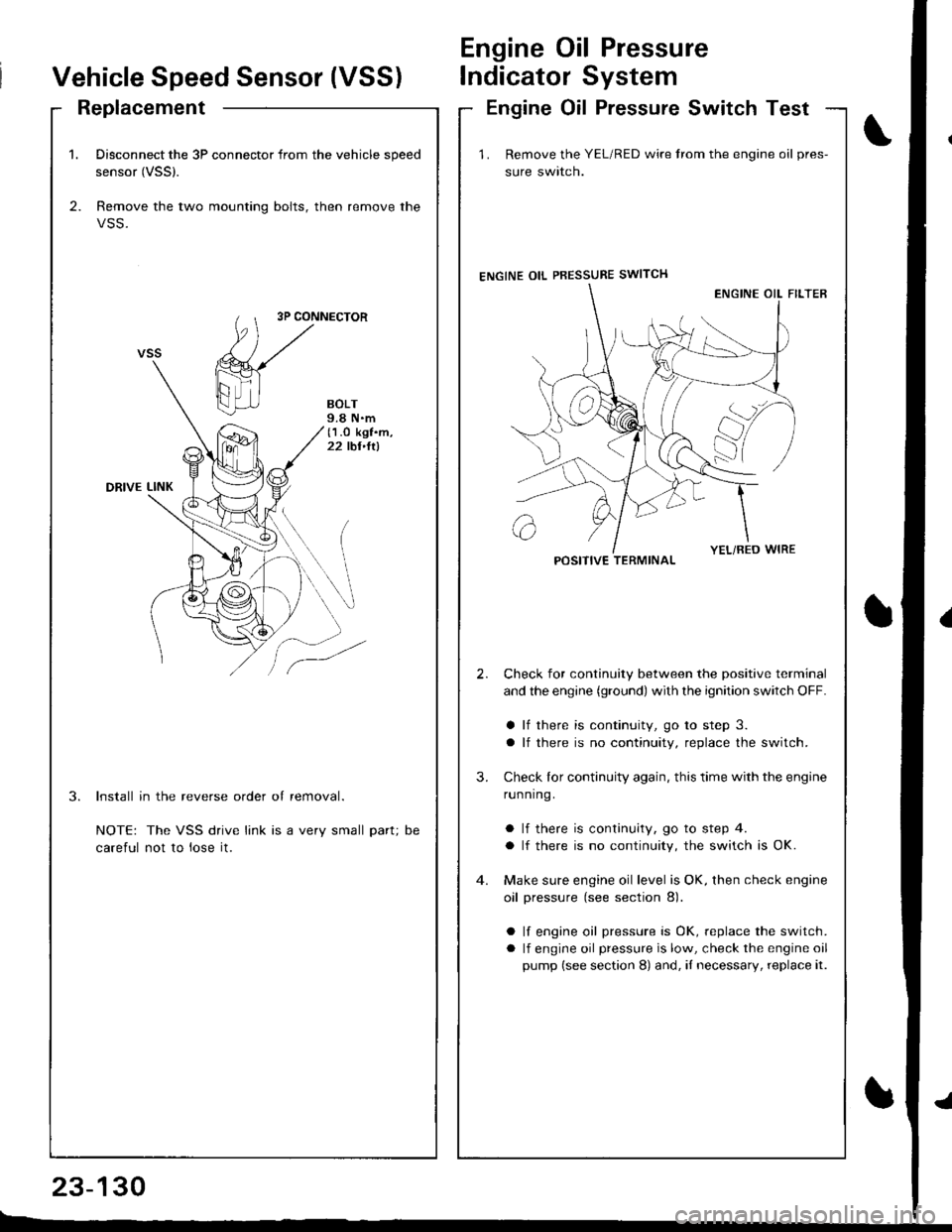

1. Disconnect the 3P connector from the vehicle speed

sensor (VSSl.

2. Remove the two mounting bolts, then remove the

VSS.

3P CONNECTOR

BOLT9.8 N.m(1.O kgf.m,22 tbt,ltl

DRIVE LINK

3.Install in the reverse order of removal.

NOTE: The VSS drive link is a very small part;

careful not to lose it.

DC

Vehicle Speed Sensor (VSS)

Engine Oil Pressure

lndicator System

ReplacementEngine Oil Pressure Switch Test

23-130

E-_

1 . Remove the YEL/RED wire trom the engine oil pres-

sure swlrcn.

ENGINE OIL PBESSURE SWITCH

Check for continuity between the positive terminal

and the engine (ground) with the ignition switch OFF.

a lf there is continuity, go to step 3.

a lf there is no continuity, replace the switch.

Check lor continuity again, this time with the engine

running.

a lf there is continuity, go to step 4.

a lf there is no continuity, the switch is OK.

Make sure engine oil level is OK, then check engine

oil pressure (see section 8).

a lf engine oil pressure is OK, replace the switch.

a lf engine oil pressure is low, check the engine oil

pump (see section 8) and, iI necessary, replace it.

2.

3.

POSITIVE TERMINAL

Page 1188 of 1681

)

{

t.t

t.!

23-131

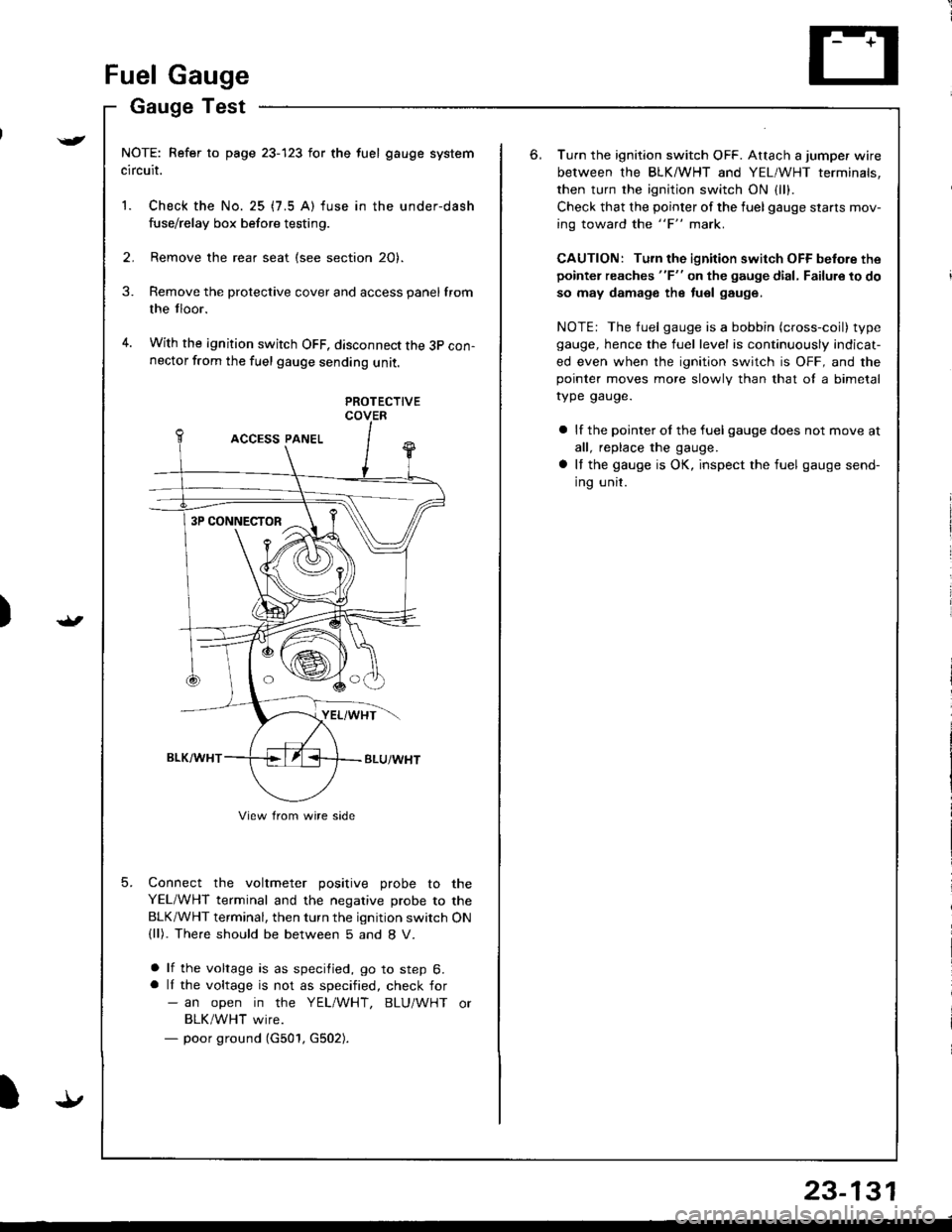

Fuel Gauge

Gauge Test

NOTE: Refer to page 23-123 for the fuel gauge system

circuit.

1. Check the No. 25 (7.5 A) fuse in the under-dash

fuse/relay box before testing.

2. Remove the rear seat (see section 20).

Remove the protective cover and access panel from

the tloor.

With the ignition switch OFF, disconnect the 3p con-nector from the fuel gauge sending unit.

3.

4.

5.

PROTECTIVECOVER

Connect the voltmeter positive probe to the

YEL/WHT terminal and the negative probe to the

BLK/WHT terminal, then turn the ignition switch ON(ll). The.e should be between 5 and 8 V.

a lf the voltage is as specified, go to step 6.a lI the voltage is not as specified, check for- an open in the YEL/WHT, BLU/WHT or

BLK/WHT wire.- poor ground (G501, G502).

3P CONNECTOR

View from wire side

6.Turn the ignition switch OFF. Attach a jumper wire

between the BLKMHT and YEL/WHT terminals,

then turn the ignition switch ON {1.,.

Check that the pointer of the fuel gauge starls mov-

ing toward the "F" mark.

CAUTION: Turn the ignition switch OFF before the

pointer reaches "F" on the gauge dial, Failure to do

so may damage the tuel gauge.

NOTE: The fuel gauge is a bobbin (cross-coil) type

gauge, hence the fuel level is continuously indicat-

ed even when the ignition switch is OFF, and thepointer moves more slowlv than that ol a bimetal

rype gauge.

a lf the pointer ol the fuel gauge does not move at

all, replace the gauge.

a It the gauge is OK, inspect the fuel gauge send-

ing unit.

Page 1189 of 1681

Fuel Gauge

Sending Unit Test/Replacement

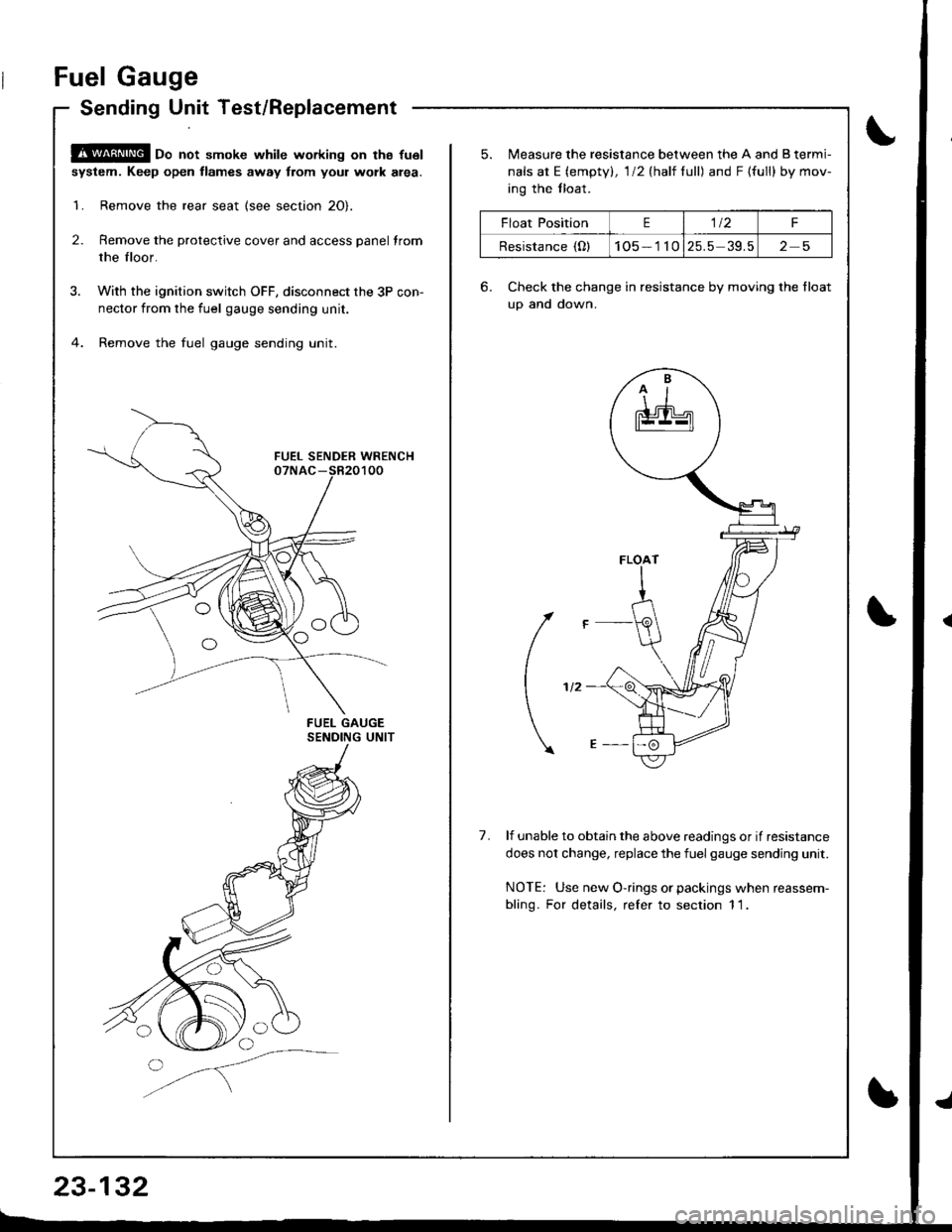

@oo not smoke while working on tha fu6l

system. Keep open llames away trom youl work alea.

1. Remove the rear seat {see section 2O}.

2. Remove the protective cover and access panel trom

the floor.

3. With the ignition switch OFF, disconnect the 3P con-

nector from the fuel gauge sending unit.

4. Remove the fuel gauge sending unit.

o

23-132

Float PositionE1t2F

Resistance (Ol105 - 1 1025.5 39.525

5. lreasure the resistance between the A and B termi-

nals at E (empty), l/2(half full) andF{full} bymov-

ing the tloat.

6. Check the change in resistance by moving the float

uo and down.

(

1.lf unable to obtain the above readings or if resistance

does not change, replace the fuel gauge sending unit.

NOTE: Use new O-rings or packings when reassem-

bling. For details, refer to section 1 1.

Page 1190 of 1681

I

Seat Belt Reminder

SystemLow Fuel lndicator

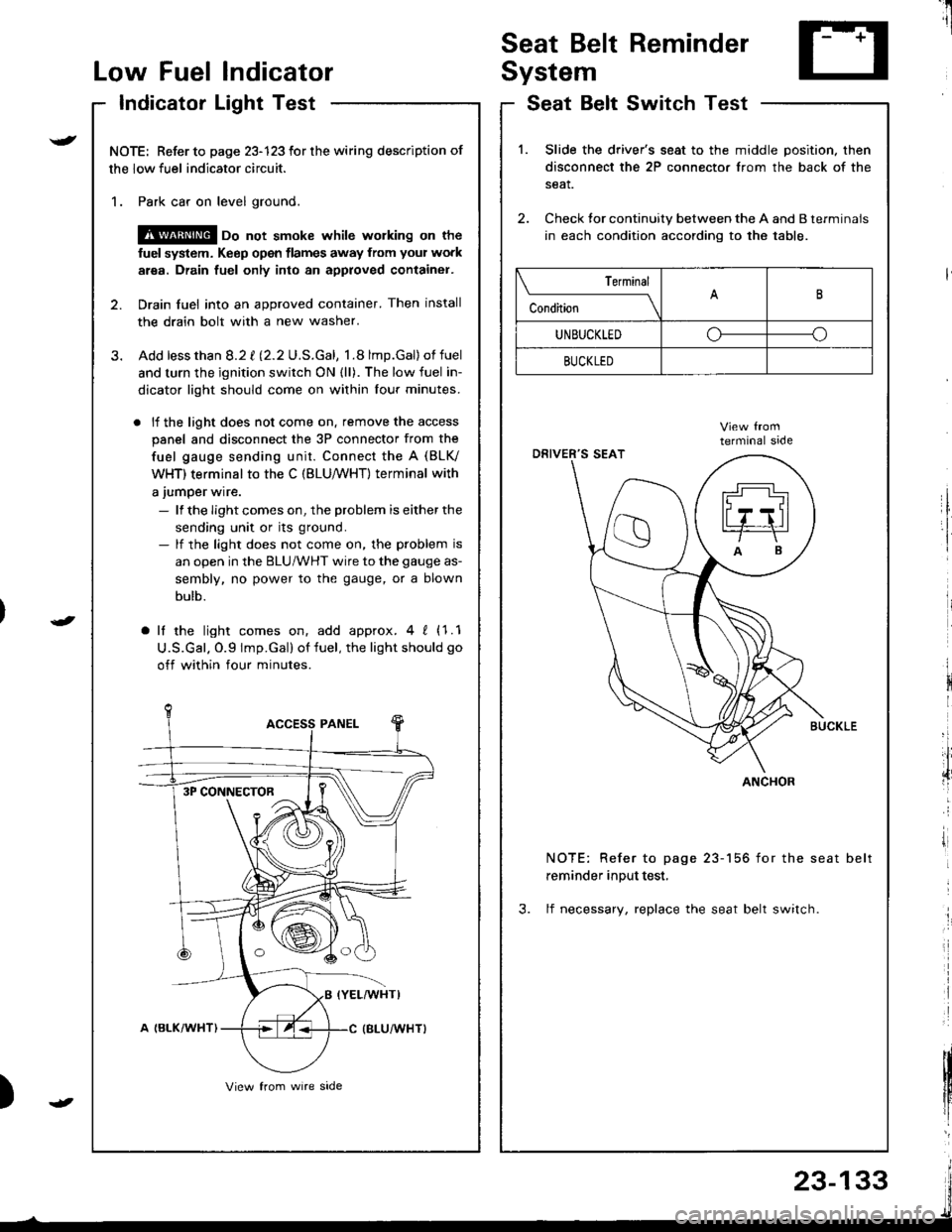

Indicator Light Test

NOTE: Refer to page 23-123 for the wiring description of

the low fuel indicator circuit.

1. Park car on level ground.

@ oo not smoke whilc wolking on the

fuel system. Keep open tlames away from your work

area. Drain fuel only into an approved container.

2. Drain fuel into an approved container. Then install

the drain bolt with a new washer.

3. Add lessthan 8.2 t l2.2U.S.Gal, 1.8 lmp.Gal)of fuel

and turn the ignition switch ON {ll). The low fuel in-

dicator light should come on within lour minutes.

. lf the light does not come on. remove the access

panel and disconnect the 3P connector from the

fuel gauge sending unit. Connect the A (BLV

WHT) terminal to the C (BLU,/WHT) terminal with

a jumper wire.

- lf the Iight comes on, the problem is either the

sending unit or its ground.- lf the light does not come on, the problem is

an open in the BLU/WHT wire to the gauge as-

sembly, no power to the gauge, or a blown

bulb.

a lf the light comes on, add approx.4 ! (1.1

U.S.Gal. O.9 lmp.Gal) of fuel, the light should go

off within four minutes.

I

i

)

SeatSwitchTestBelt

1.Slide the driver's seat to the middle position. then

disconnect the 2P connector from the back of the

seat.

Check tor continuity between the A and B terminals

in each condition according to the table.

NOTE: Refer to page 23-156 for the seat belt

reminder input test,

3. lf necessary, replace the seat belt switch.

Terminal

c""dil----lB

UNBUCKLEDoo

BUCKLED

ANCHOR3P CONNECTOR

23-133