HONDA INTEGRA 1998 4.G Workshop Manual

INTEGRA 1998 4.G

HONDA

HONDA

https://www.carmanualsonline.info/img/13/6069/w960_6069-0.png

HONDA INTEGRA 1998 4.G Workshop Manual

Trending: child restraint, Front bumper, automatic transmission fluid, bulb, washer fluid, Valve cover, check transmission fluid

Page 1301 of 1681

r

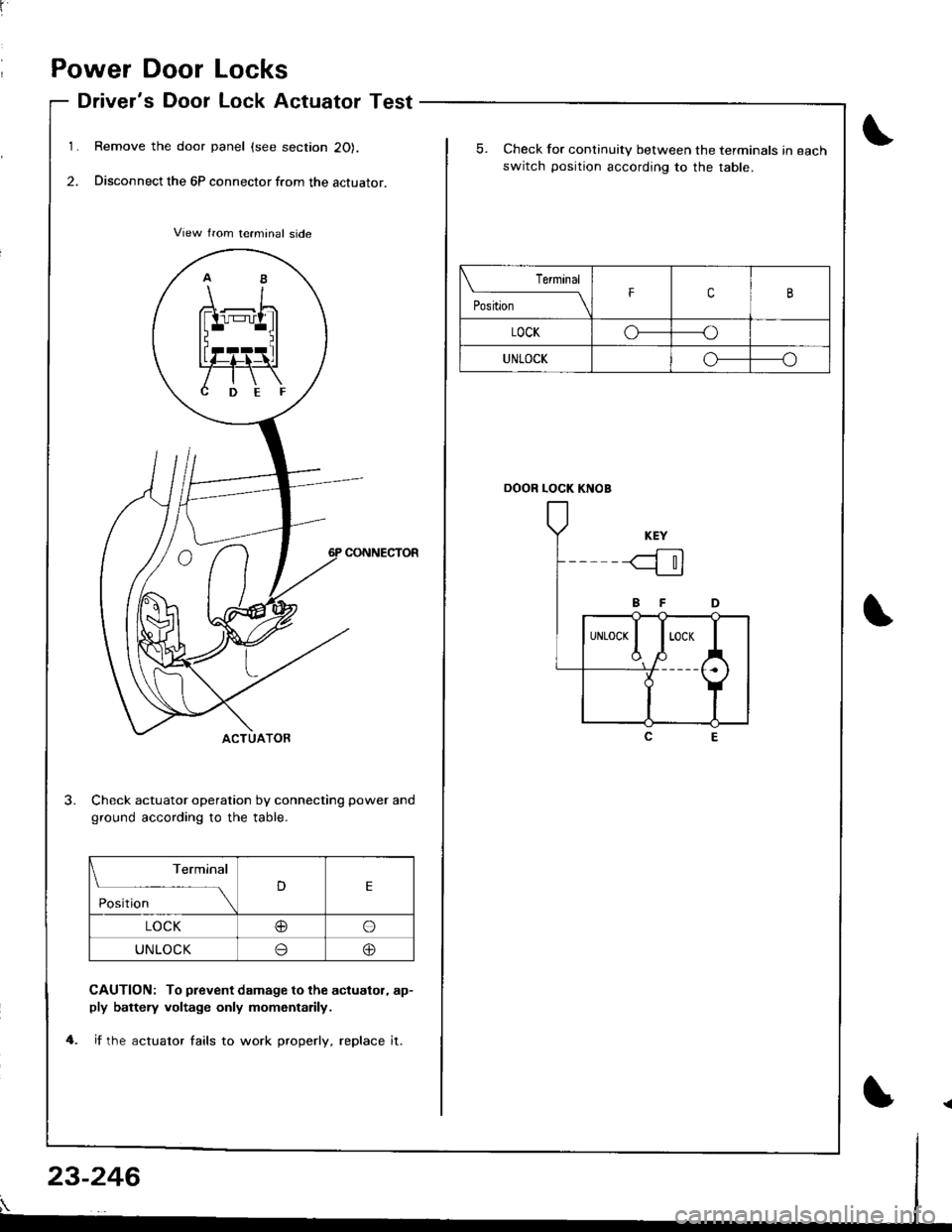

Power Door Locks

Driver's Door Lock Actuator Test

Remove the door panel (see section 20).

Disconnect the 6P connector from the actuator.

CONNECTOR

Check actuator operation by connecting power and

ground according to the table.

CAUTION: To prevent damage to the acluator, ap-ply battely voltage only momentarily.

if the actuator fails to work properly, replace it.

Terminal

DE

Position

LOCK@o

UNLOCKo@

5. Check for continuity between the terminals in each

switch position accordiog to the table.

DOOR LOCK KNOB

Terminal

il;;-----tFcB

LOCKoo

UNLOCKo-----o

23-246

Page 1302 of 1681

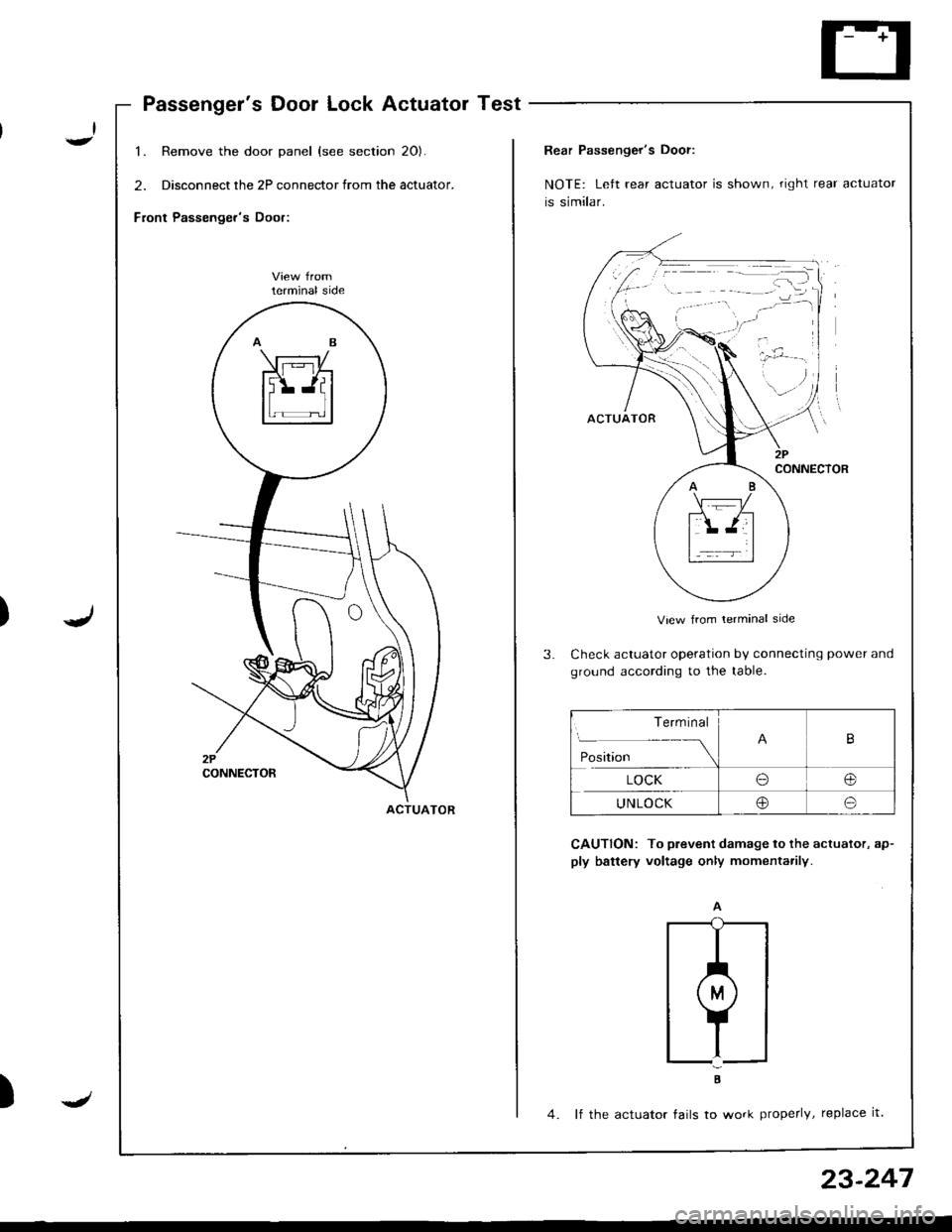

Passenger's Door Lock Actuator Test

1. Remove the door panel (see section 20).

2. Disconnect the 2P connector from the actuator.

Front Passenger's Door:

lerminal side

ACTUATOR

)J

23-247

Rear Passenger's Door:

NOTE: Left rear actuator is shown, right rear actuator

is similar.

View from lerminal side

Check actuator operation by connecting power and

ground according to the table.

CAUTION: To prevent damage to the actuator, ap-

ply battery voltage only momenta.ily.

;

4. lf the actuator tails to work properly, replace it.

Term inal

Position

B

LOCKo@

UNLOCKoo

Page 1303 of 1681

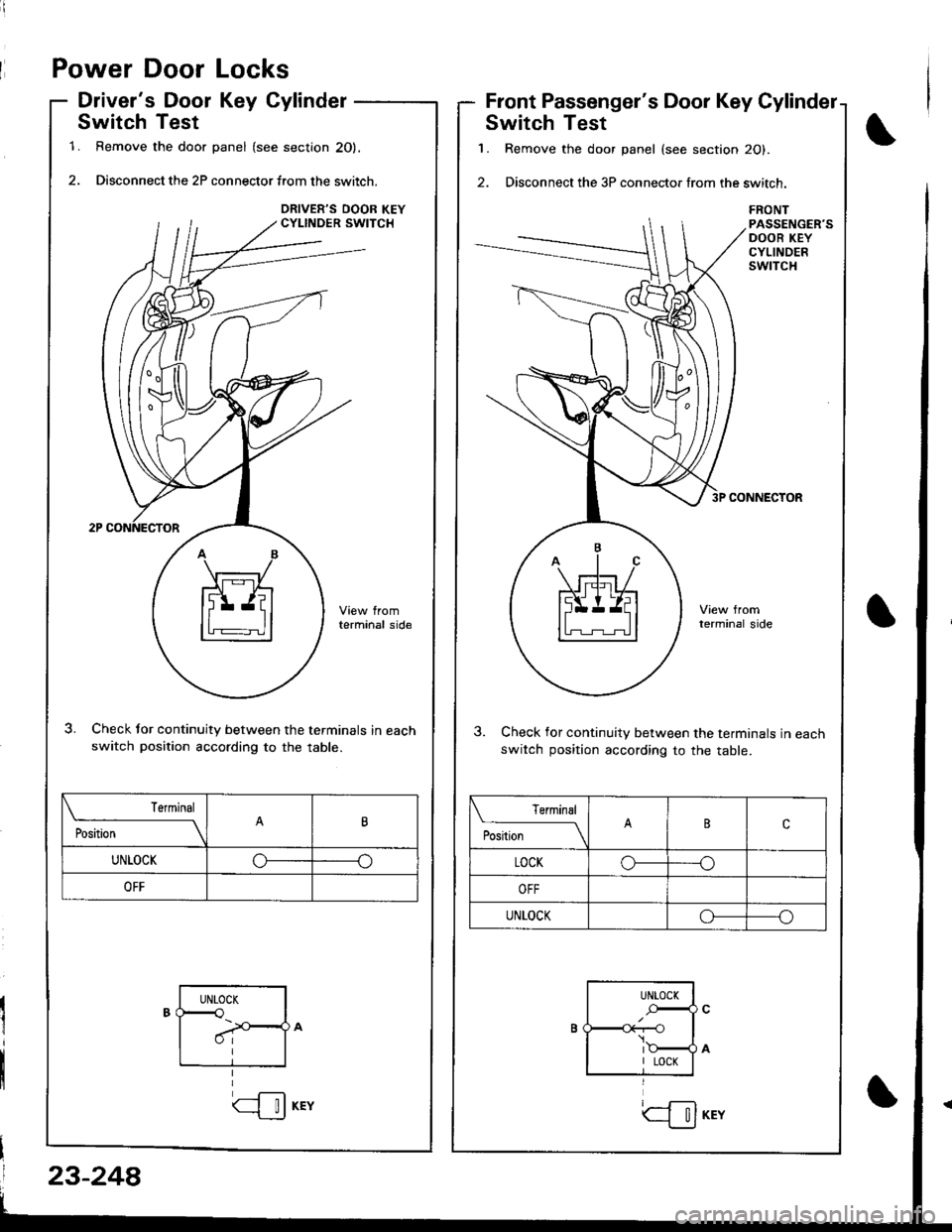

Power Door Locks

Driver's Door Key Cylinder

Switch Test

1. Remove the door panel (see section 20).

2. Disconnect the 2P connector f.om the switch.

terminal side

Check tor continuity between the terminals in eachswitch position according to the table.

Front Passenger's Door Key Cylinder

Switch Test

1. Remove the door panel (see section 20).

2. Disconnect the 3P connector from the switch.

FRONTPASSENGER'SDOOR KEYCYLINDERSwlTCH

CONNECTOR

3. Check for continuity between the terminals in eachswitch position according to the table.

Terminal

il;------__\tt

UNLOCKoo

OFF

Terminal

P**--__\c

LOCKo--o

UNLOCKoo

UNTOCK<

I

UNLOCK

r--O\:

I LOCK

23-248

(--l__!J KEYtil

Page 1304 of 1681

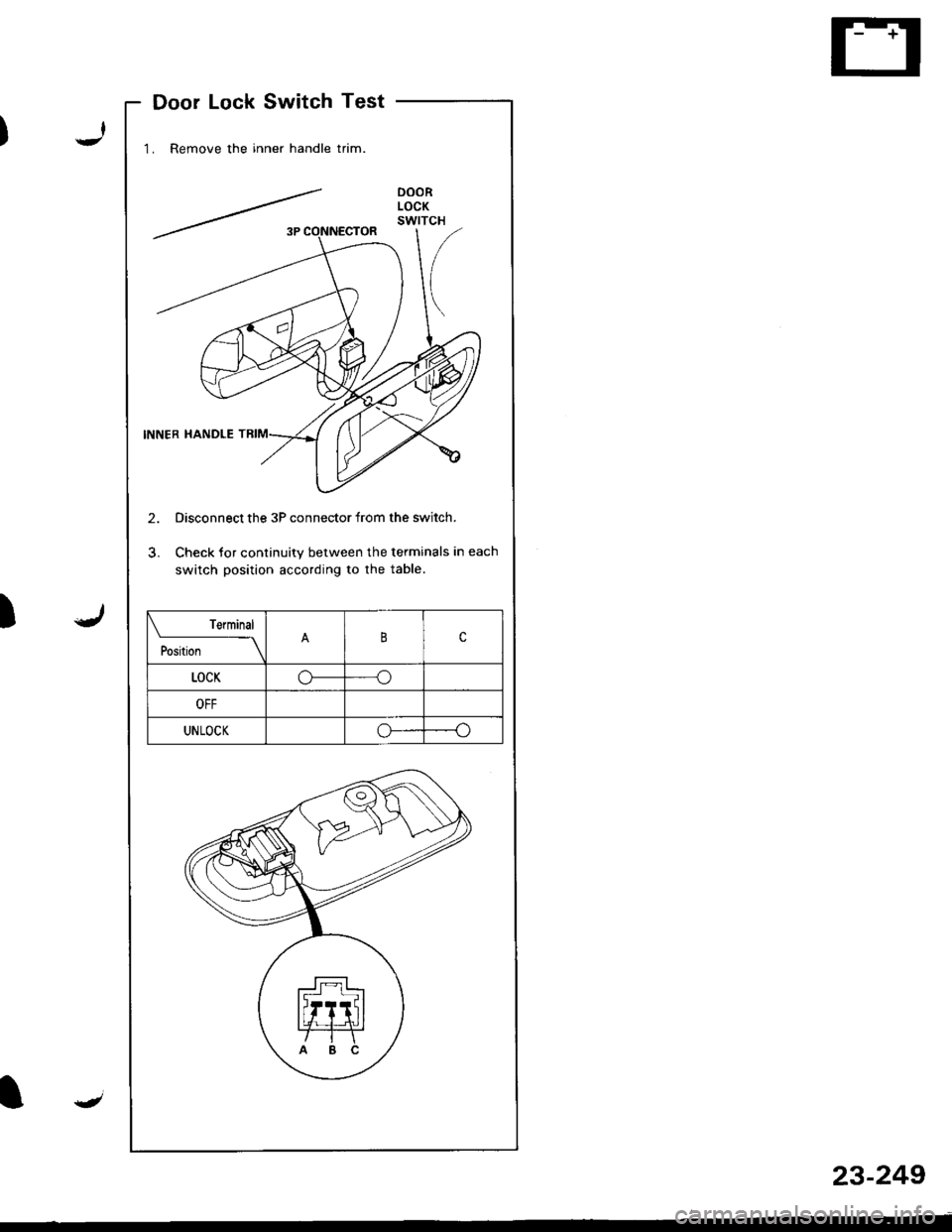

Door Lock Switch Test

1. Remove the inner handle trim.

2. Disconnect the 3P connector from the switch.

3. Check tor continuity between the terminals in each

switch position according to the table.

)

oooRLOCKswtTcH

Terminal

t"r--

-\Bc

LOCKo-----o

OFF

UNLOCKoo

4

23-249

Page 1305 of 1681

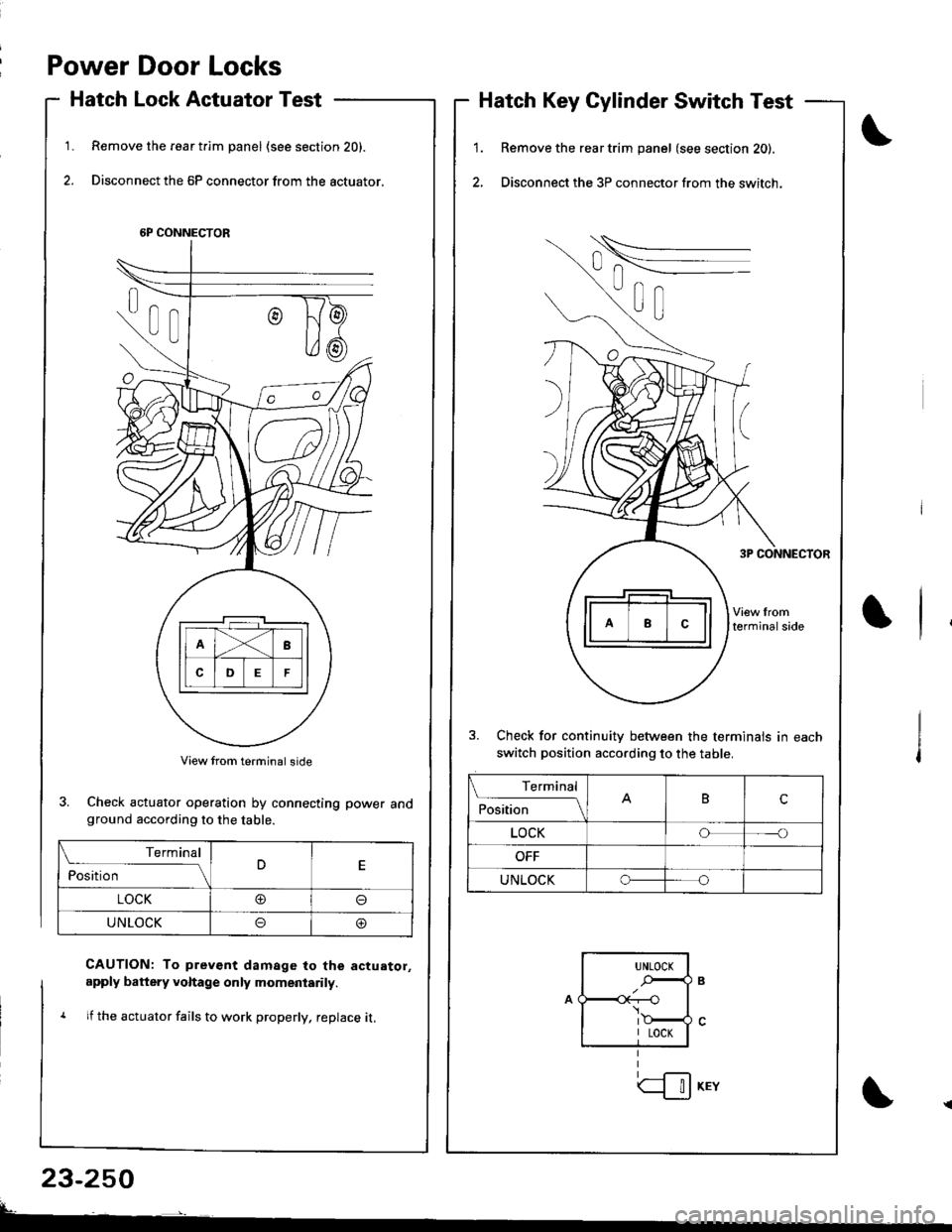

Power Door Locks

Hatch Lock Actuator Test

Remove the rear t.im panel (see section 20).

Disconnect the 6P connector from the actuator.

1.1.

2.

Hatch Key Cylinder Switch Test

Remove the rear trim panel (see section 20).

Disconnect the 3P connector from the switch.

3. Check for continuitv between the terminals in each

switch position according to the table.

6P CONNECTOR

3. Check actuator operation by connecting power andground according to the table.

CAUTION: To prev€nt damage to the actuator,

apply battery voltage only momeniarily.

1 lf the actuator fails to work properly, replace it,

23-250

Terminal

ilil;---tBc

LOCKoo

UNLOCKo

Terminal

ilil;-]E

LOCK@o

UNLOCKoo

UNLOCK

.-,4

I LOCK

| !J KEY

Page 1306 of 1681

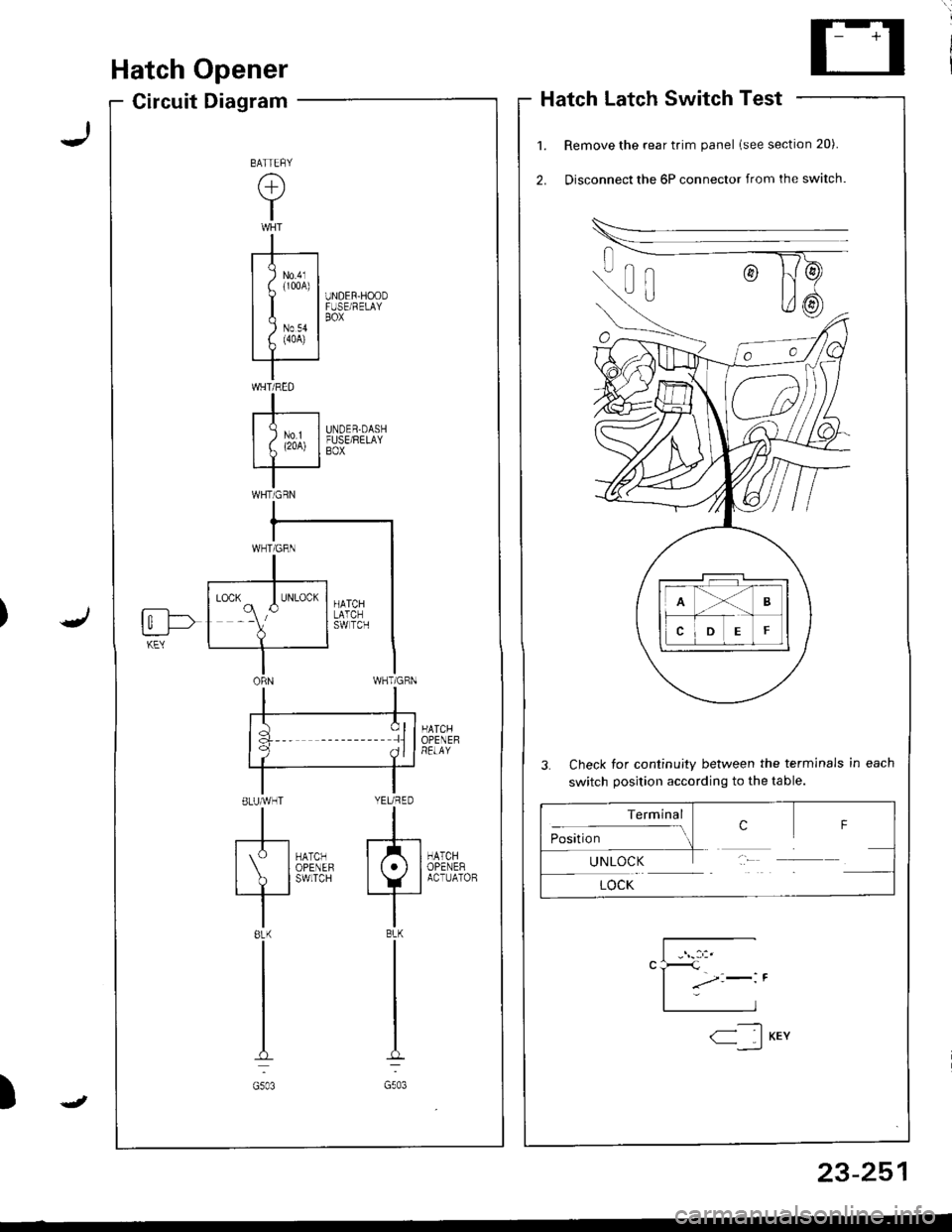

Hatch Opener

Circuit DiagramHatch Latch Switch Test

Remove the rear trim panel lsee section 20).

Disconnect the 6P connector from the switch.

3. Check for continuity between the terminals in each

switch position according to the table.

HATCHOPENEHRELAY

HATCHOPENERACTUATOB

UNDER-HOODFUSE/RELAYBOX

UNDER.DASHFUSE/RELAYBOX

la :llf q ^ll

ELUMHT YEURED

tl

[S-l*0,., f/tl| IoPENEF lt.l I

I ? l'*n'" +_i

tl8LK BLK

tl

tl

tt.:

G503 G503

BATTEFY

(+)

Y

I

-r--t

I I lm,1

uI| )Nov II f. (4oA) |rT '

IWHT/RED

I-r----| )ur II L (2oA) I

IWHTiGRN

fi--l->t_:___J-KEY

Terminal

:- ..- crosrUon-1UNLOCK

LOCK

F

23-251

-----t1< IKEY--,_)

J

Page 1307 of 1681

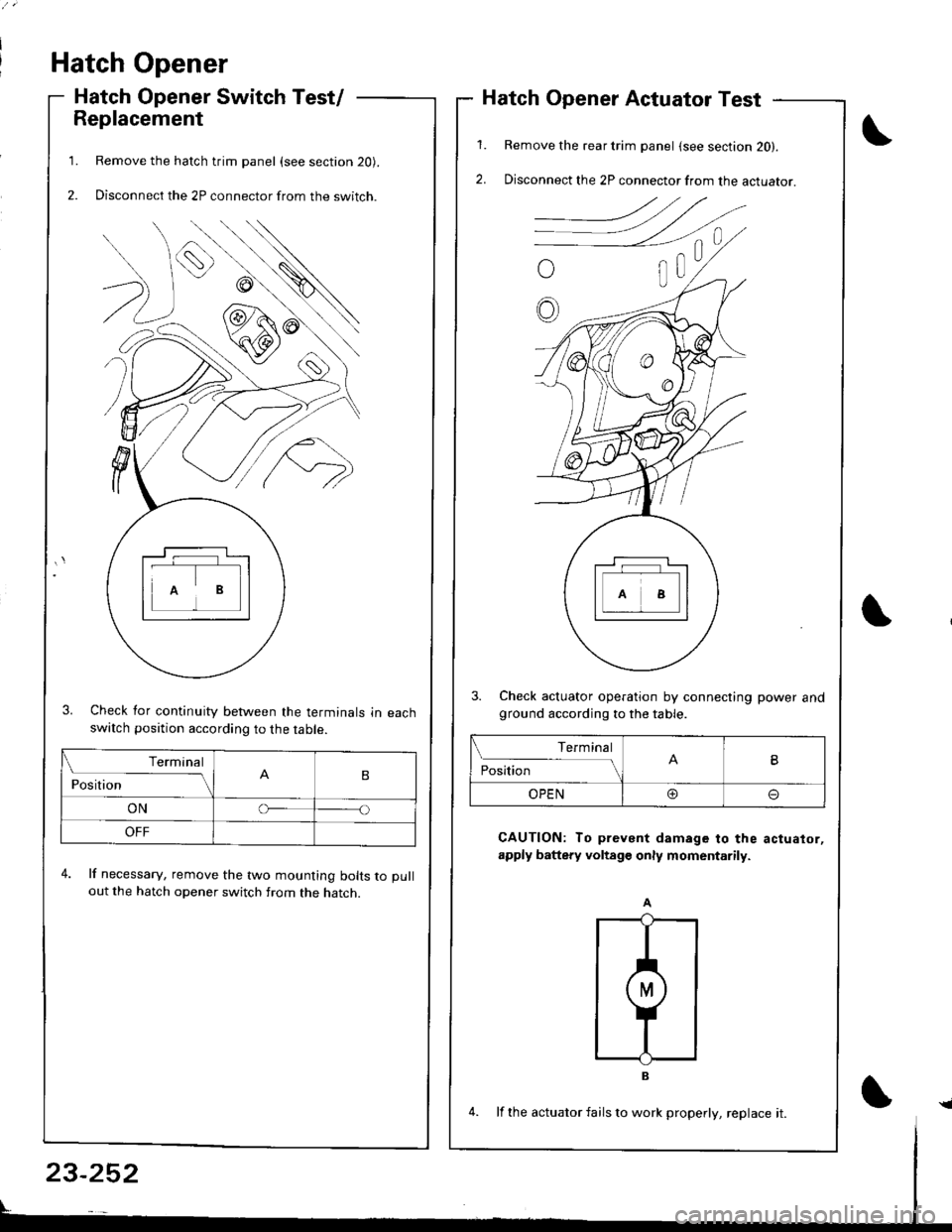

Hatch Opener

Hatch Opener Switch Test/

Replacement

Remove the hatch trim panel (see section 20).

Disconnect the 2P connector from the switch.

3. Check for continuity between the terminals in eachswatch position according to the table.

4. lf necessary, remove the two mounting bolts to pull

out the hatch opener switch from the hatch.

1.

2.

1.

2.

Hatch Opener Actuator Test

Remove the rear trim panel (see section 20).

Disconnect the 2P connector from the actuator.

3. Check actuator operation by connecting power andground according to the table.

CAUTION: To prevent damage to the actuator,

apply battery voltage only momentarily.

Terminal

PositionB

ONo

OFF

Terminal

PositionB

OPEN@o

23-252

4. lf the actuator fails to work properly, replace it.{

Page 1308 of 1681

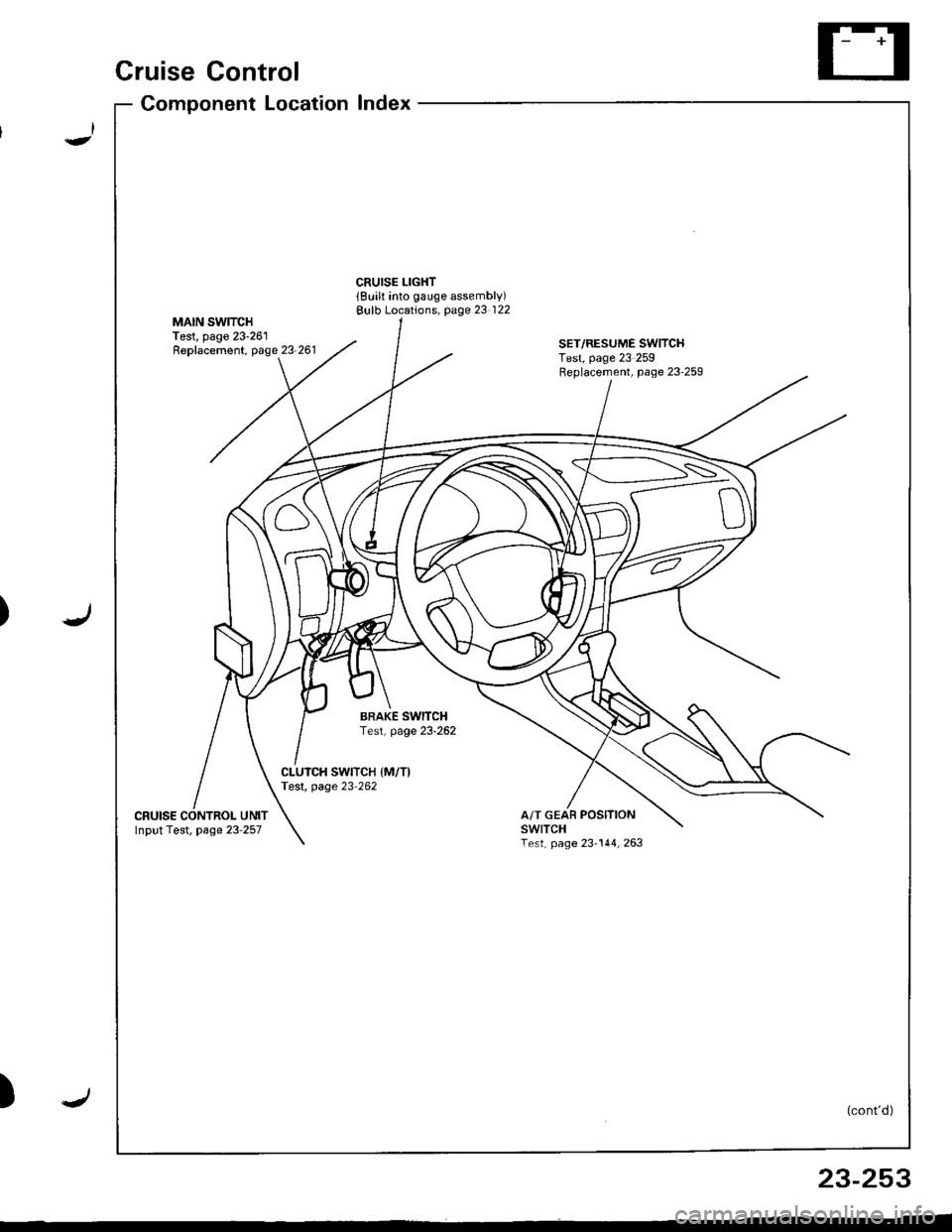

Cruise Control

)

Component LocationIndex

CRUISE LIGHT{Built into gauge assembly)Bulb Locations, page 23 122MAIN SWITCHTest, page 23-261Replacement, page 23-261SET/RESUME SWITCHTest, page 23 259Feplacement, page 23'259

BRAKE SwlTCHTest, page 23-262

CLUICH SWITCH IM/T)Test, page 23 262

cRutsEA/T GEAR POSITIONswtTcHTest, page 23-144,263Input Test, page 23 257

(cont'd)

23-253

Page 1309 of 1681

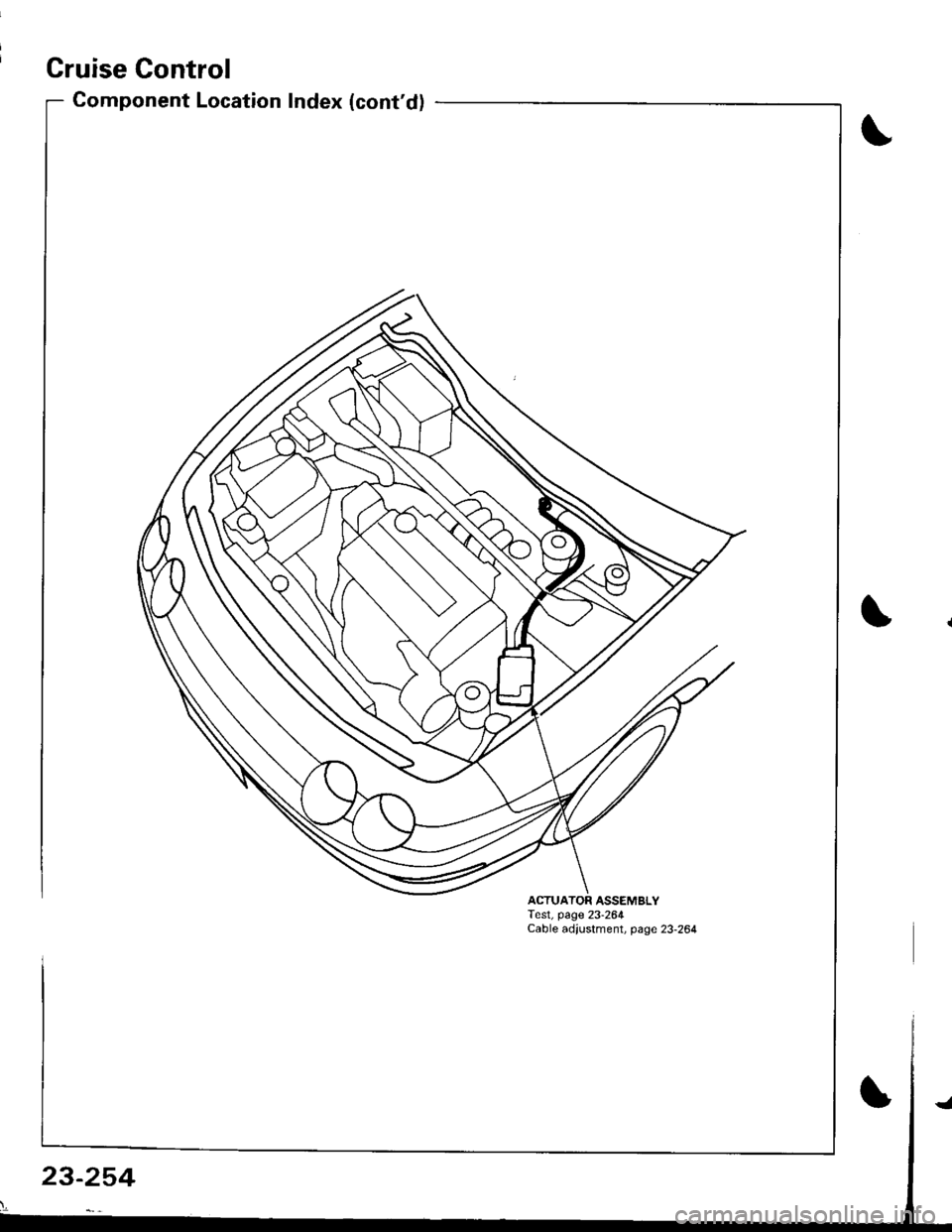

Cruise Control

Component Location Index (cont'd)

ACTUATOR ASSEMBLYTest, page 23-264Cable adjustment, page 23-264

23-254

Page 1310 of 1681

Circuit Diagram

J

WNT/BLK +WHT

BLKYEL YEL/8LU

CABLEREEL

SET/BESUME1 SW]TCH

J

IGNITONCONTROLMODULE(cM)

LT

B lA

i,"'YlDGBY

c

IT GRN/RED LTGRN/BLK

BLK

I

:

:2013401

III

I

VEHICLE SPEEDSENSOR (VSS)

M/T: CLLTCH SWITCH \A/T:A,TGEARPostT oN swrc!(oN E].tr tr

8LK 8LK

lltl-0-_L-- --

G301 G2AlG401

UNDER-HOOD FUSEiFELAY BOXUNDEF DASH FUSEi RELAY BOX

lNDICATORL]GHT(0.91W)

BLU/RED

23-255

:?:'

ACC : ACCELERATIONOEC iDECELERATION

Trending: warning, oil viscosity, transmission oil, c503, radio, oil dipstick, bulb

![HONDA INTEGRA 1998 4.G Workshop Manual Circuit Diagram

J

WNT/BLK +WHT

BLKYEL YEL/8LU

CABLEREEL

SET/BESUME1 SW]TCH

J

IGNITONCONTROLMODULE(cM)

LT

B lA

i,"YlDGBY

c

IT GRN/RED LTGRN/BLK

BLK

I

:

:2013401

III

I

VEHICLE SPEEDSENSOR (VSS)

M/T: CL HONDA INTEGRA 1998 4.G Workshop Manual Circuit Diagram

J

WNT/BLK +WHT

BLKYEL YEL/8LU

CABLEREEL

SET/BESUME1 SW]TCH

J

IGNITONCONTROLMODULE(cM)

LT

B lA

i,"YlDGBY

c

IT GRN/RED LTGRN/BLK

BLK

I

:

:2013401

III

I

VEHICLE SPEEDSENSOR (VSS)

M/T: CL](/img/13/6069/w960_6069-1309.png)