HONDA INTEGRA 1998 4.G Workshop Manual

Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 541 of 1681

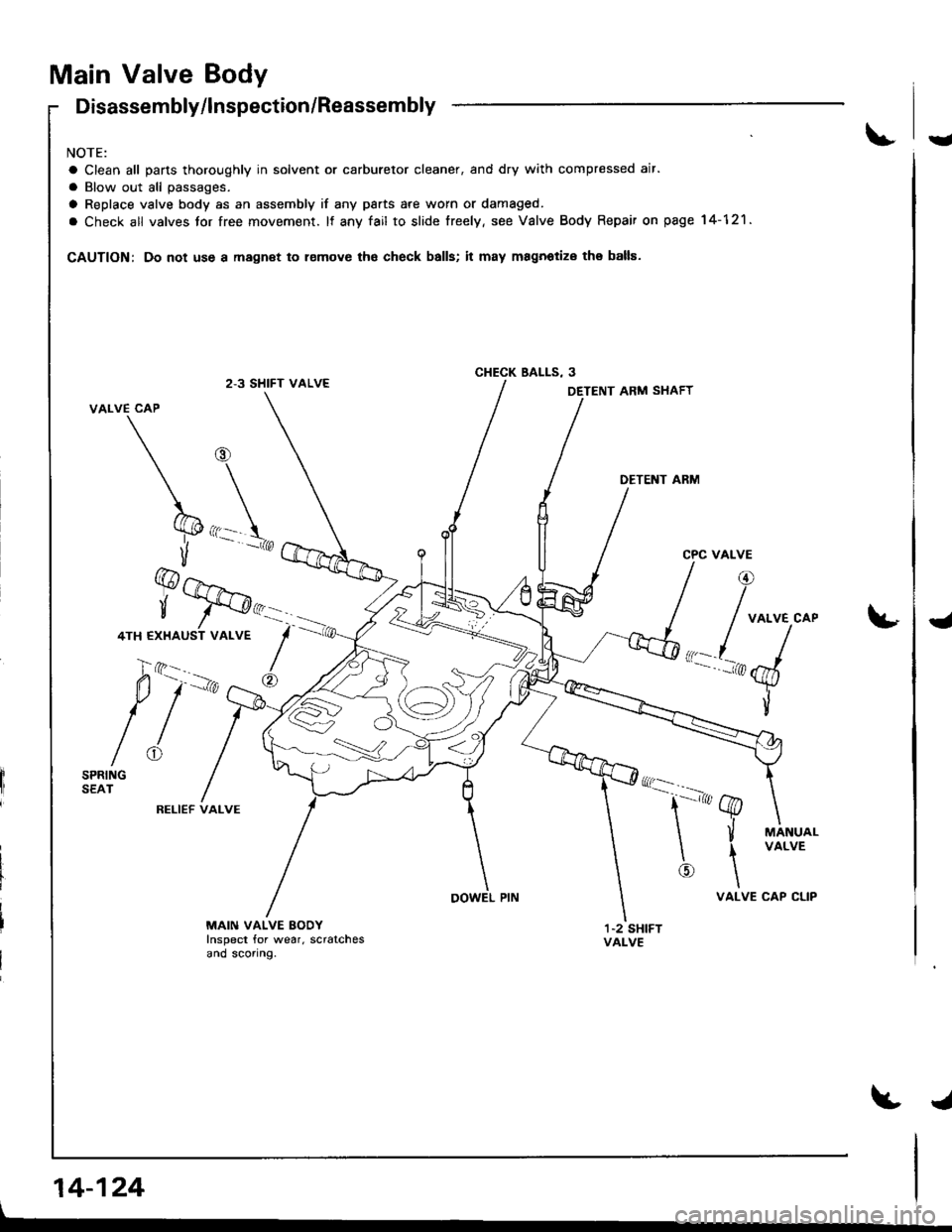

Main Valve Body

Disassembly/lnspection/Reassembly

NOTE:

a Clean all pans thoroughly in solvent or carburetor cleaner, and dry with compressed air.

a Blow out all passages.

a Replace valve body as an assembly if any psrts 8re worn or damaged.

a Check all valves tor free movement. It anv fail to slide freely, see Valve Body Repair on page 14-121.

CAUTION: Do not use a magnet to lemove tho check balls; it may magnoliz€ the balls.

2-3 SHIFT VALVECHECK BALLS. 3

14-124

ARM SHAFT

DETENT ARM

RELIEF VALVE

MAIN VALVE BODYInspect for wear. scratchesand sconng.

Y

I

Page 542 of 1681

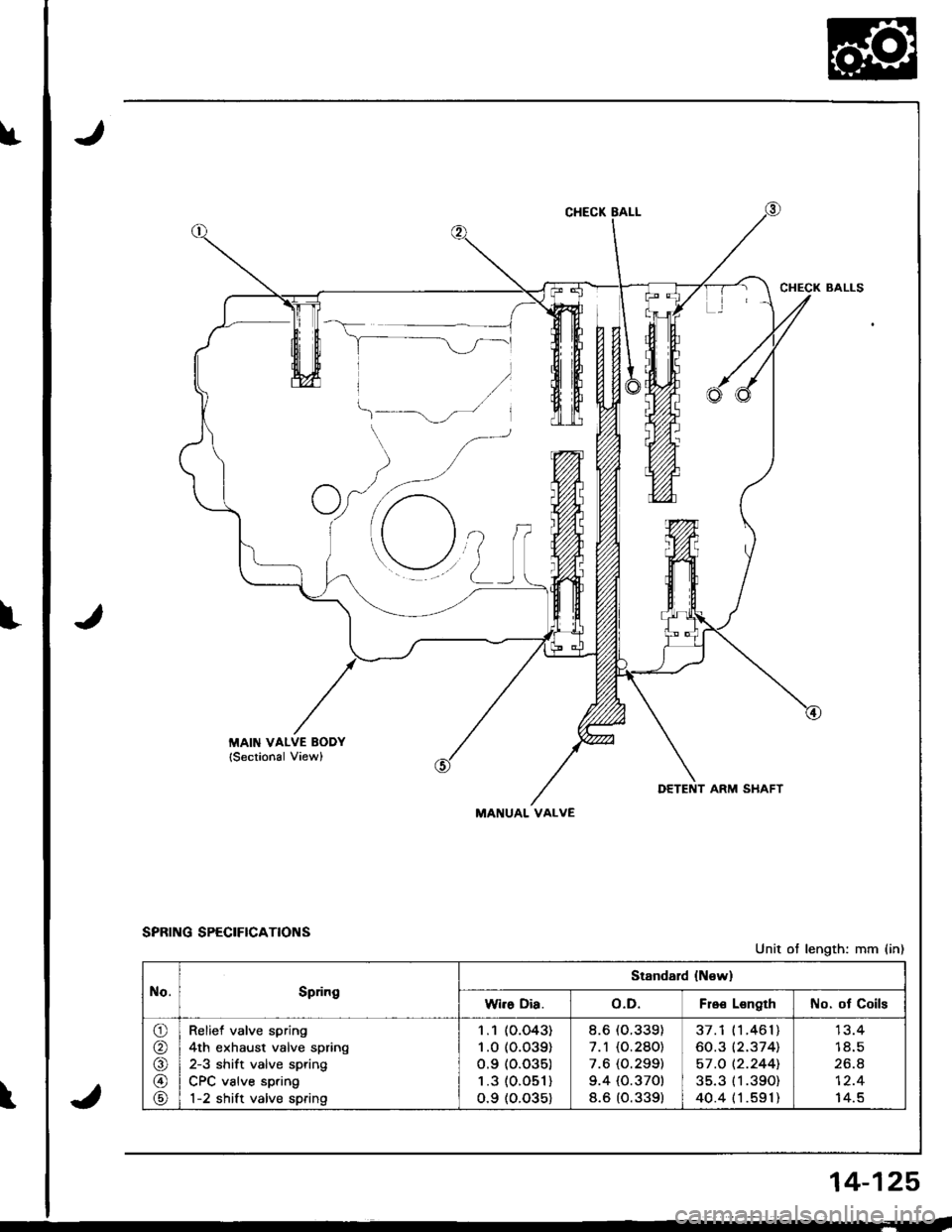

DETENT ARM SHAFT

MANUAL VALVE

SPRING SPECIFICATIONS

\

Unit ot length: mm (in)

No.Spdng

Stsndard {N€w}

Wi.s Dia.o.D.Fro€ LsngthNo. ot Coils

o

@

@

\9

Relief valve spring

4th exhaust valve spring

2-3 shift valve spring

CPC valve spring

1-2 shift valve spring

1 .1 (O.O43)

1 .0 (o.o39)

o.9 (o.o35)

1 .3 (0.O51)

o.9 (o.035)

8.6 (O.339)

7.1 (O.280)

7.6 (O.299)

9.4 {0.370)

8.6 (O.339)

37.1 (1 .461)

60.3 (2.374)

57 .O t2.244].

35.3 (1 .390)

40.4 (1 .591)

1 8.5

zo.6

14.5

14-125

Page 543 of 1681

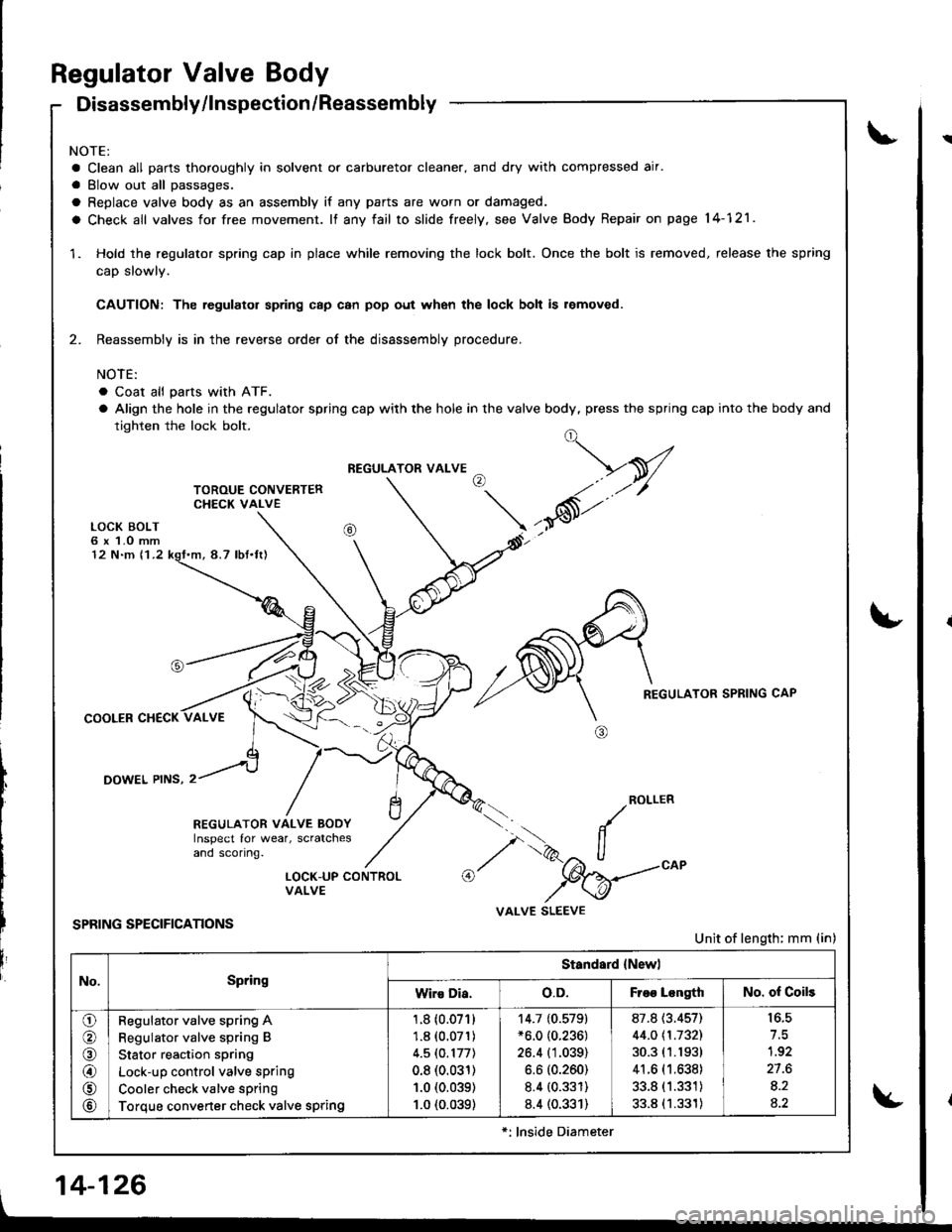

Regulator Valve Body

Disassembly/lnspection /Reassembly

NOTE:

a Clean all parts thoroughly in solvent or carburetor cleaner. and dry with compressed air.

a Blow out all passages.

a Replace valve body as an assembly if any parts are worn or damaged.

a Check all valves for free movement. lf any fail to slide freely, see Valve Body Repair on page 14-121.

1. Hold the regulator spring cap in place while removing the lock bolt. Once the bolt is removed. release the spring

cap slowly.

CAUTION: The regulator sp ng c8p can pop out when the lock bolt is r€moved.

2. Reassembly is in the reverse order of the disassembly procedure.

NOTE:

. Coat all pans with ATF.

a Align the hole in the regulator spring cap with the hole in the valve body, press the spring cap into the body and

tighten the lock bolt.

LOCK BOLT6 x 1.O mm12 N.m 11.2

COOLER CHECK

DOWEL PINS, 2

REGULATOR SPRING CAP

ROLLER

REGULATOR VALVE BODYInspect for wear, scratchesand sconng.

oi.

.. /

,/ i>, ll

,/ "W_-

VALVE SLEEVE

@LOCK-UP CONTROLVALVE

SPRING SPECIFICATIONSUnit of length; mm (in)

No.Spring

Standard {Newl

Wiro Dia.o.D.Froo LongthNo. of Coils

o

@

@

@rA

@

Regulator valve spring A

Regulator valve spring B

Stator reaction spring

Lock-up control valve sprlng

Cooler check valve spring

Torque converter check valve spring

1.8 (0.071)

1.8 (0.071)

4.5lO.177l

0.8 (0.031)

1.0 (0.039)

1.0 (0.039)

14.7 {0.579}*6.0 (0.236)

26.4 (1.039)

6.6 (0.260)

8.4 (0.331)

8.4 (0.331)

87.8 (3.457)

44.0 \1.1321

30.3 (1.1931

41.6 (1.638)

33.8 (1.331)

33.8 (1.331)

to.c

1.92

27.6

8.2

4.2

*: lnside Diameter

, 14-126

!

Page 544 of 1681

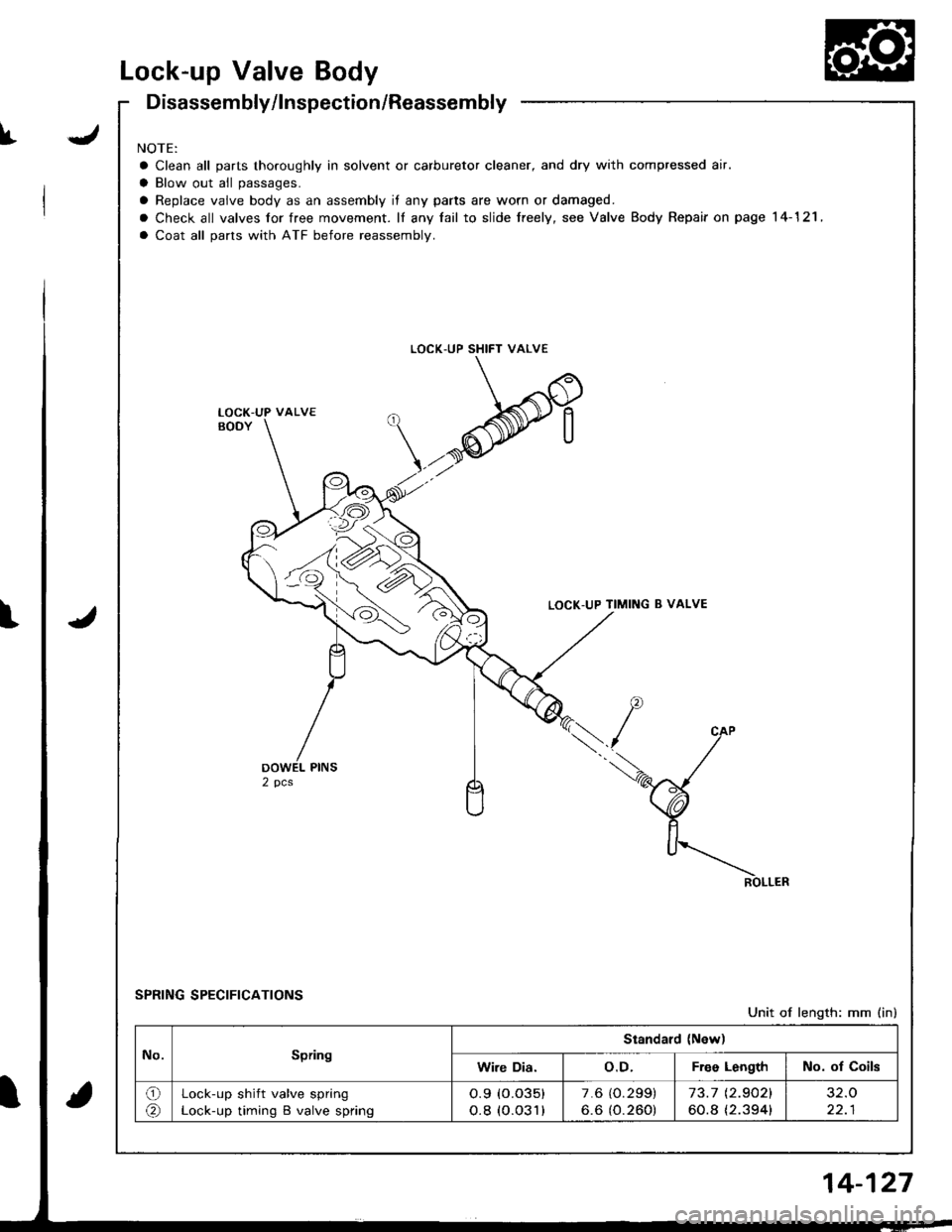

Lock-up Valve Body

JI

Disassembly/lnspection/Reassembly

NOTE:

a Clean all parts thoroughly in solvent or carburetor cleaner, and dry with compressed air.

a Blow out all passages.

a Replace vaive body as an assembly if any parts are worn or damaged.

o Check all valves for free movement. lf any fail to slide freely, see Valve Body Repair on page 14-121 ,

a Coat all parts with ATF before reassembly.

LOCK-UP SHIFT VALVE

LOCK-UP TIMING B VALVE

SPRING SPECIFICATIONS

Unit of length: mm (in)

LOCK-UP VALVE

No.Spring

Standard (New)

Wire Dia.o.D.Free LengthNo. of Coils

o(r\Lock-up shift valve spring

Lock-up timing B valve spring

o.9 (o.o35)

o.8 (o.o31)

7.6 (O.299)

6.6 (O.260)73.7 t2.9021

60.8 {2.394}

32.O

22.1

4-127

Page 545 of 1681

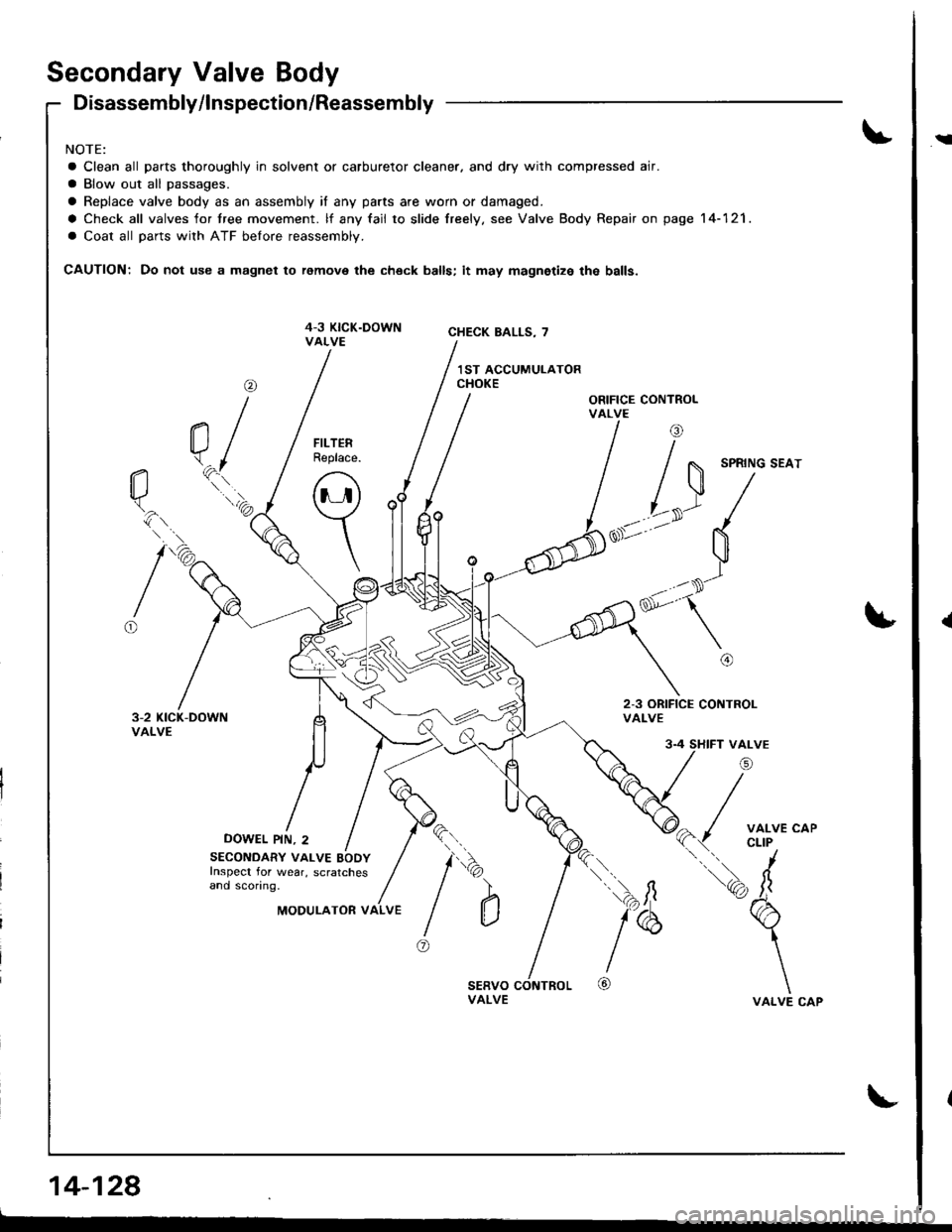

Secondary Valve Body

Disassembly/lnspection/Reassembly

NOTE:

a Clean all parts thoroughly in solvent or carburetor cleaner. and dry with compressed air.

a Blow out all passages.

a Replace valve body as an assembly if any parts are worn or damaged.

a Check all valves for tree movement. lf any fail to slide freely. see Valve Body Repair on page 14-121.

a Coat all parts with ATF belore reassembly.

CAUTION: Do not use a magnet to remove the check balls; it may magnetize the balls.

ORIFICE CONTROLVALVE

2-3 ORIFICE CONTROLVALVE

DOWEL PIN, 2

@

a/\.^fl*..'a

tio.

16

FILTERReplace.

o

\

SECONDARY VALVE BODYInspect for wear, scratchesand sconng.

4 SHIFT VALVE

/i

( / ;fl'J'*'

tq, fr

b

\

\VALVE CAP

l"

@

\

)

@

da')

aMODULATOR VALVE

14-128

i

{

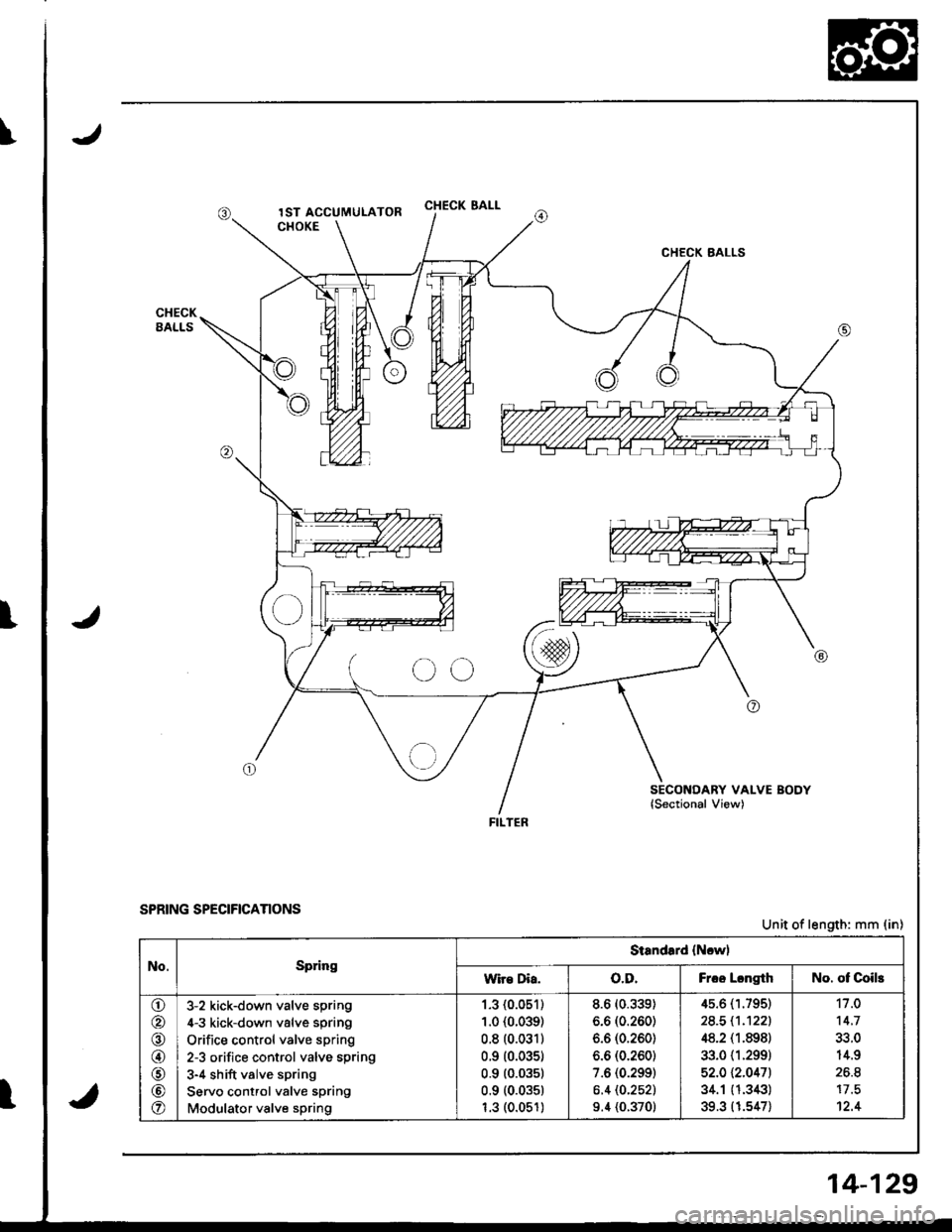

Page 546 of 1681

CHECK SALL

CHECK BALLS

SECONDARY VALVE BODYlSectional View)

FILTER

SPRING SPECIFrcANONSUnit of length: mm (in)

No.SpringStandard {Ncwl

wir€ Dia.o.D.Frcc LcngthNo. of Coils

\!-/

o

@

@

o

@

o

3-2 kick-down valve spring

4-3 kick-down valve spring

Orifice control valve spring

2-3 orifice control valve spring

3-4 shift valve spring

Servo control valve spring

Modulator valve spring

1.3 (0.051)

1.0 {0.039)

0.8 (0.031)

0.9 (0.035)

0.9 (0.03s1

0.9 (0.035)

1.3 (0.051)

8.6 (0.339)

6.6 (0.260)

6.6 (0.260)

6.6 (0.260)

7.6 (0.299)

6.4 (0.252)

9.4 (0.370)

4s.6 (1.795)

24.5 11.'t221

48.2 (1.898)

33.0 {1.299)

52.0 \2.0471

34.1 (1.343)

39.3 (1.547)

11 .0

14.7

14.9

26.8

12.4

14-129

Page 547 of 1681

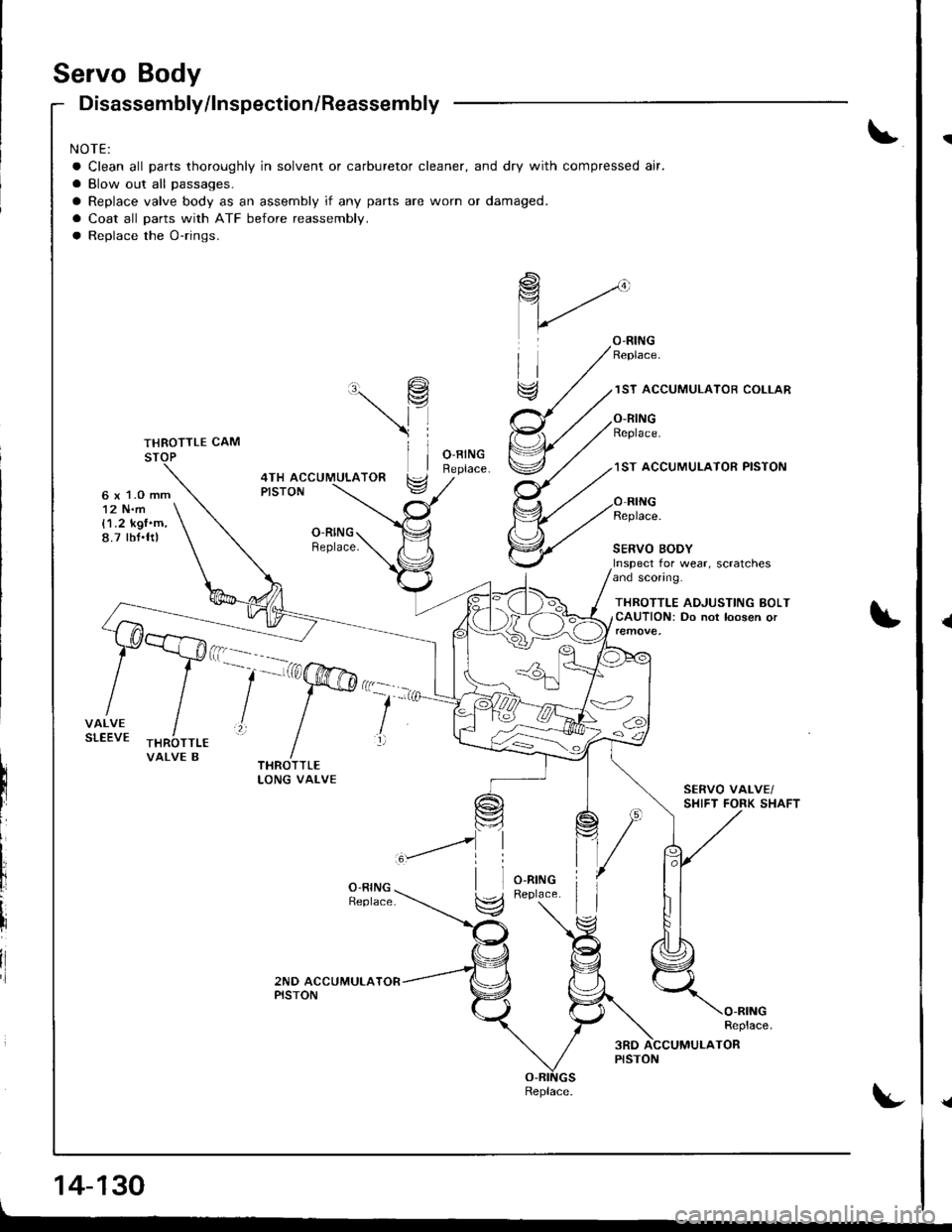

Servo Body

6 x 1.O mm12 N.m{1.2 kgf'm,8.7 tbt.ftl

Disassembly/lnspection/Reassembly

NOTE:

a Clean all parts thoroughly in solvent or carburetor cleaner, and dry with compressed air.

a Blow out all passages.

a Replace valve body as an assembly if any parts are worn or damaged.

a Coat all parts with ATF before reassembly.

a Replace the O-rings.

\9

\l

ll

1ST ACCUMULATOR COLLAR

O.RINGReplace.

1ST ACCUMUI.ATOR PISTON4TH ACCUMULATORPISTON

O.RINGReplace.

Replace.

SERVO BODYInspect for wear, scratchesand sconng.

THROTTLE ADJUSTING BOLTCAUTION: Do not loosen or

VALVE B

--'-'a@':

lll

li

il

14-130

Replace.

{

{a

Page 548 of 1681

I

t

t

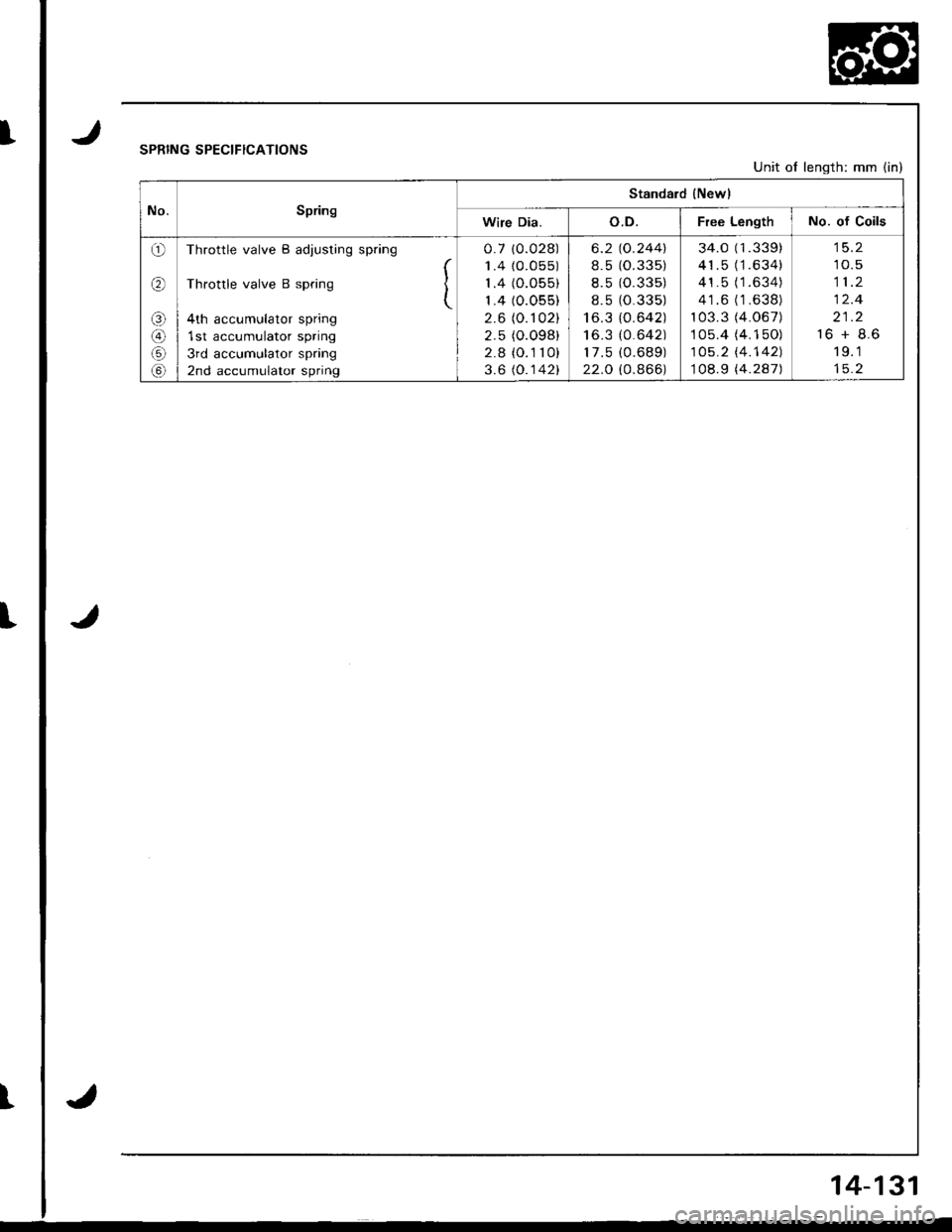

JSPRING SPECIFICATIONS

J

Unit of length: mm (in)

No.Spring

Standard {Newl

Wire Dia.o.D.Free LengthNo. of Coils

o

(r\

o

@

Throttle valve B adjusting spring

Throttle valve B spring I(

4th accumulator spring

1st accumulator spring

3rd accumulator spring

2nd accumulator spring

0.7 10.028)

1.4 {0.055)

1.4 (O.055)

1.4 (0.055)

2.6 (0. r 02)

2.5 (O.098)

2.8 (O.1 10)

3.6 (O.142)

6.2

8.5

8.5

8.5

I o_J

I o.J

17 .5

22.O

"o.244\

1o.33 5)

10.33 5)

1o.33 5)

lo.642)

lo.6421

10.68 9)

lo.866)

34.0 (1.339)

41.5 (1.634)

41.5 (1.634)

41.6 ('1 .638)

103.3 (4.067)

1 05.4 (4. 1 50)

105.2 l'4.142)

108.9 (4.287)

10.5

11.2

12.4

21.2

16 + 8.6

19.1

J

14-131

Page 549 of 1681

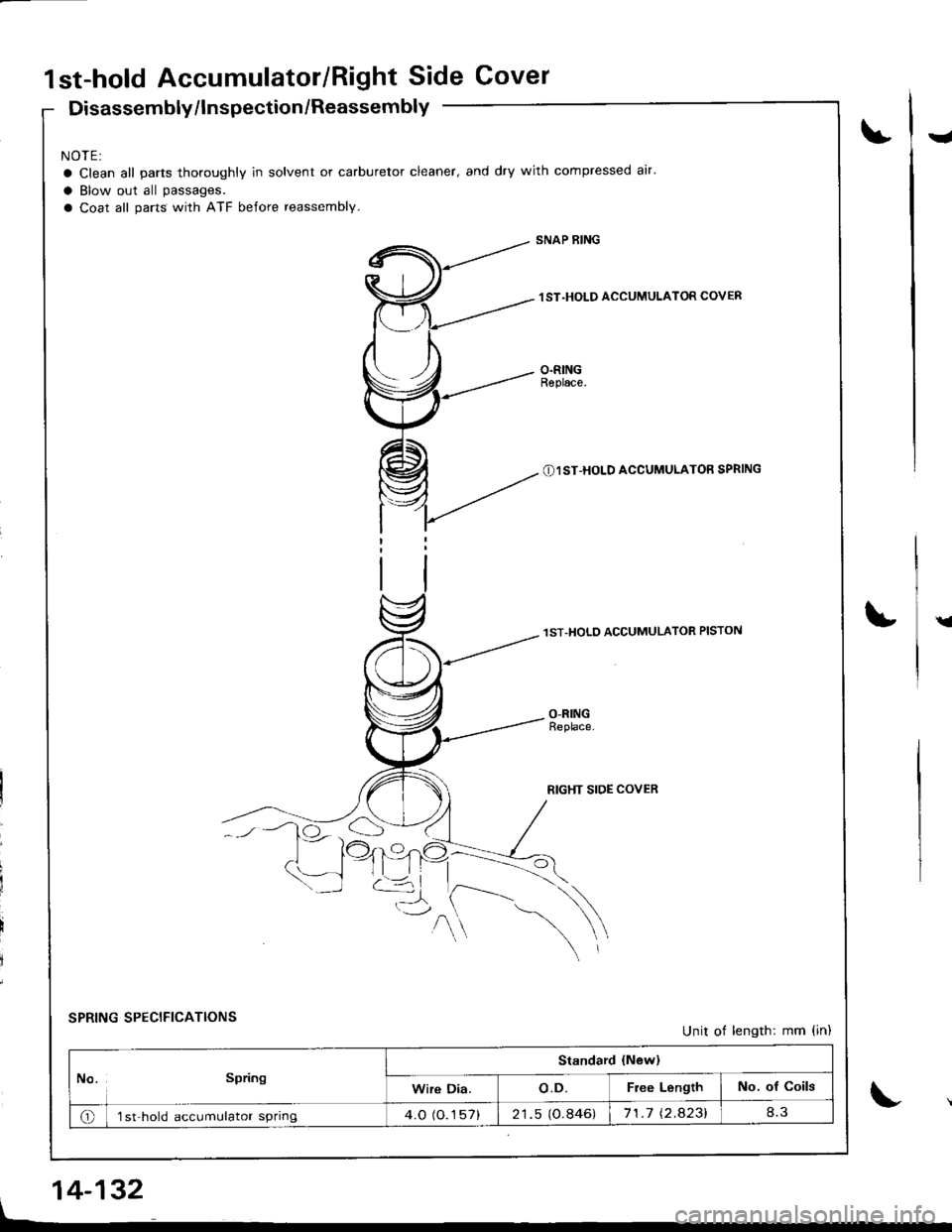

1st-hold Accumulator/Right Side Cover

Disassembly/lnspection /Reassembly

NOTE:

a Clean all parts thoroughly ln solvent or carburetor cleaner, and dry with compressed air.

a Blow out all passages.

a Coat all parts with ATF before reassembly.

rl

SNAP RING

lST.HOLD ACCUMULATOR COVER

O.RINGRephce.

(N1 ST-HOLD ACCUMULATOR SPRING

lST.HOLO ACCUMULATOR PISTON

RIGHT SIDE COVER

ra

\

SPRING SPECIFICATIONS

O

--l

Unit of length: mm {in)

No. Spring

Standard {New}

Wire Dia.o.D.Free LengthNo. of coils

o'lst hold accumulator spring4.O (O.1 57)21.5 (O.846)71.7 t2.a23l

L

14-132

Page 550 of 1681

\

\

\

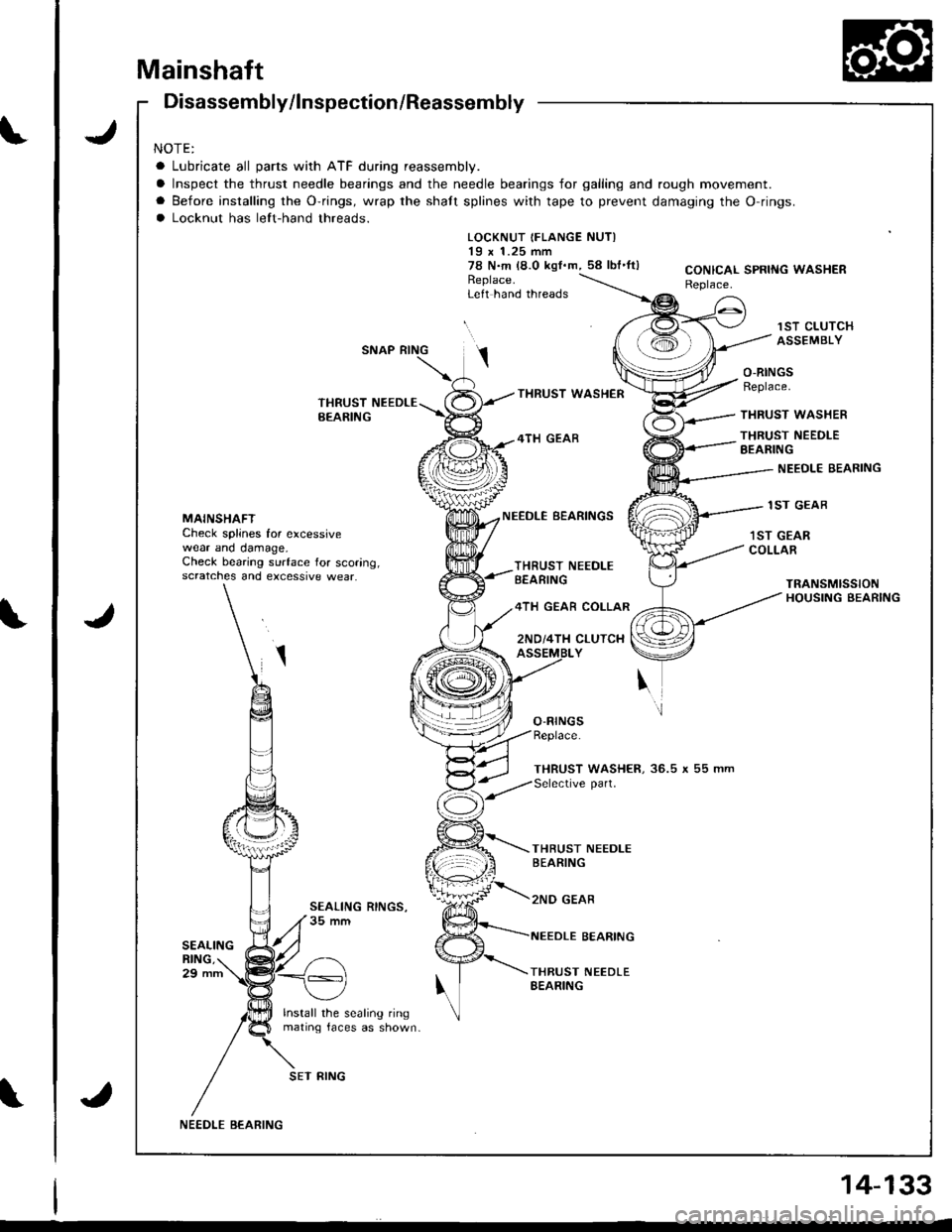

Mainshaft

J

J

Disassembly/lnspection/Reassembly

NOTE:

a Lubricate all parts with ATF during reassembly.

a Inspect the thrust needle bearings and the needle bearings for galling and rough movement.

a Before installing the O-rings, wrap the shatt splines with tape to prevent damaging the O-rings.

a Locknut has left-hand threads.

LOCKNUT IFLANGE NUTI19 x 1.25 mm78 N.m (a.0 kgf.m, 58 lbl'ltlReplace.Left hand threads

THRUST WASI{€R

4TH GEAR

CONICAL SPRING WASHERReplace.

1ST CLUTCHASSEMBLY

O-RINGSReplace.

THRUST WASHER

THRUST NEEDLEEEARING

NEEDLE EEARING

1ST GEABMAINSHAFTCheck splines for excessivewear ano oamage,Check bearing surface for scoring,scratches and excessive wear.

NEEDLE BEARINGS

THRUST NEEDI-EBEARING

4TH GEAR COLLAR

2ND/4TH CLUTCH

BEARING

THRUST NEEDLEBEARING

lST GEARCOLLAR

O-RINGSReplace.

THRUST WASHER, 36.5 x 55 mmSelective part.

THBUST NEEDLEBEARING

2ND GEAR

lnstall the sealing ringmating laces as shown-

SET FING

NE€DLE BEARING

J

14-133