HONDA INTEGRA 1998 4.G Workshop Manual

INTEGRA 1998 4.G

HONDA

HONDA

https://www.carmanualsonline.info/img/13/6069/w960_6069-0.png

HONDA INTEGRA 1998 4.G Workshop Manual

Trending: seats, sunroof, immobilizer, tow bar, lock, ECO mode, CD changer

Page 561 of 1681

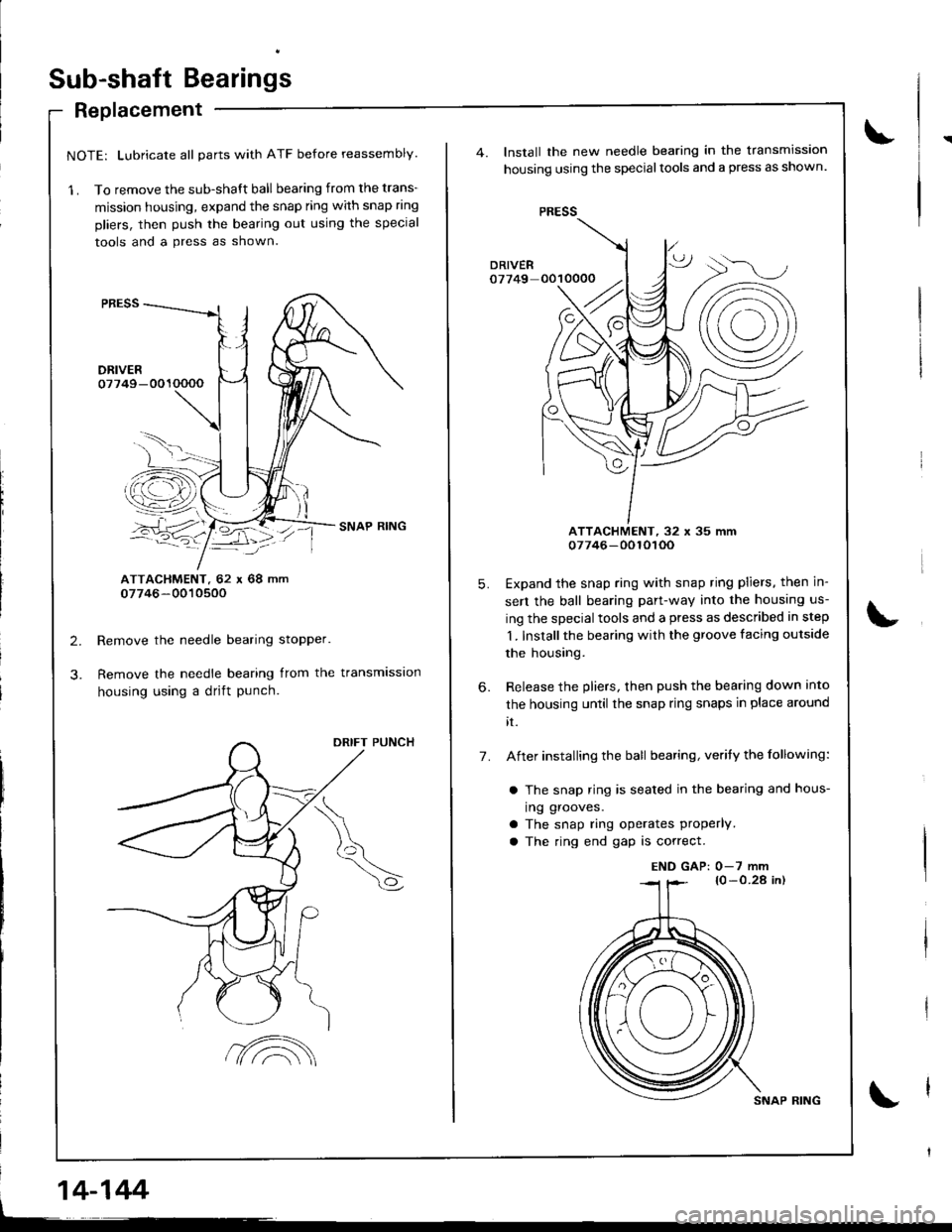

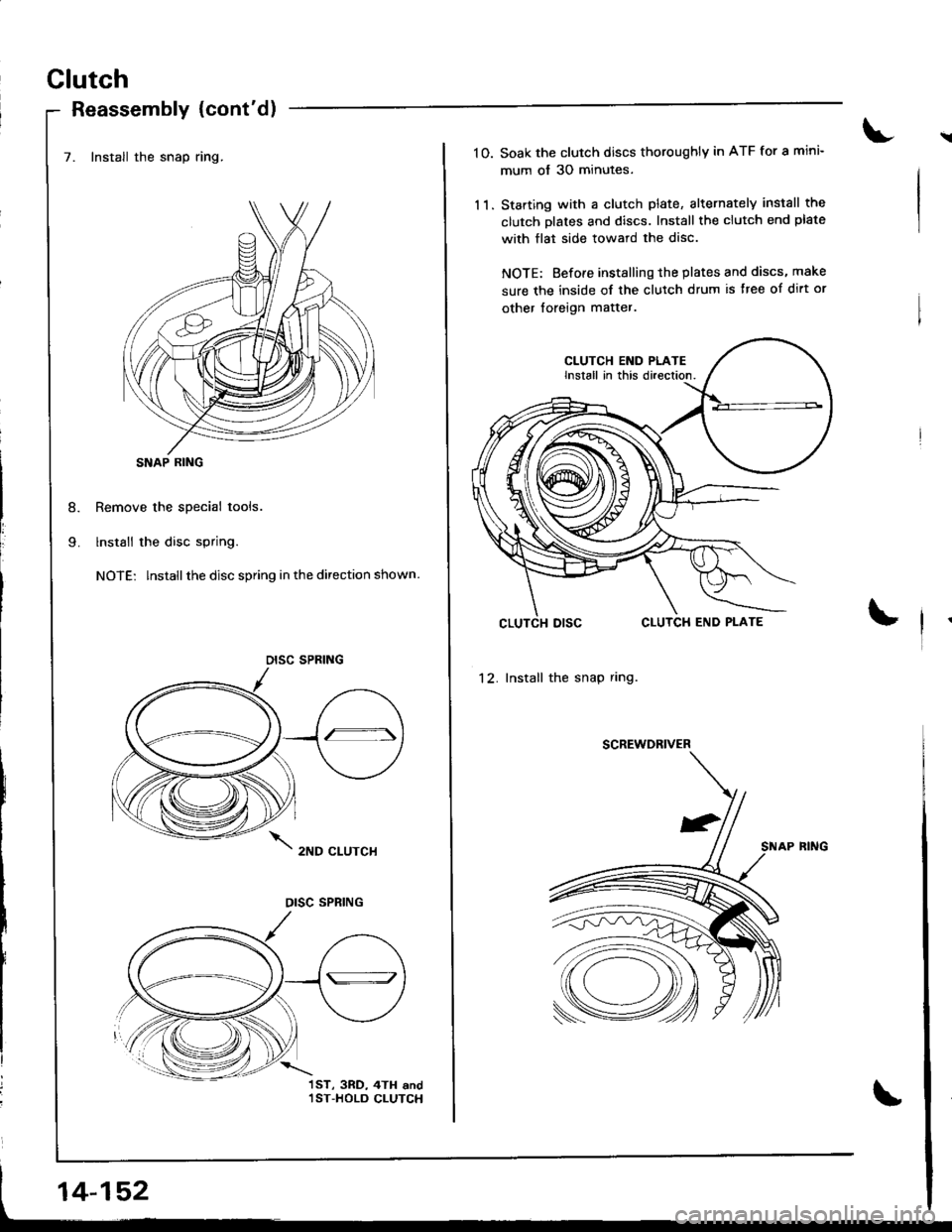

Sub-shaft Bearings

Replacement

NOTE: Lubricate all parts with ATF before reassembly.

1 . To remove the sub-shaft ball bearing from the trans-

mission housing, expand the snap ring with snap ring

pliers, then push the bearing out using the special

tools and a press as shown.

ATTACHMENT. 62 r 68 mm07746-0010500

Remove the needle bearing stopper.

Remove the needle bearing from the transmission

housing using a drift punch.

DRIFT PUNCH

L

14-144

7A

SNAP RING

Install the new needle bearing in the transmission

housing using the specialtools and a press as shown.

PRESS

ATTACHMENT, 32 x 35 mm07746-0010roo

Expand the snap ring with snap ring pliers, then in-

sert the ball bearing part-way into the housing us-

ing the special tools and a press as described in step

1. Installthe bearing with the groove facing outside

the housing.

Release the pliers, then push the bearing down into

the housing until the snap ring snaps in place around

rt.

After installing the ball bearing, verity the following:

a The snap ring is sealed in the bearing and hous-

ing grooves.

a The snap ring operates Properly.a The ring end gap is correct.

5.

6.

7.

END GAP: 0-7 mm

Page 562 of 1681

I

\

T

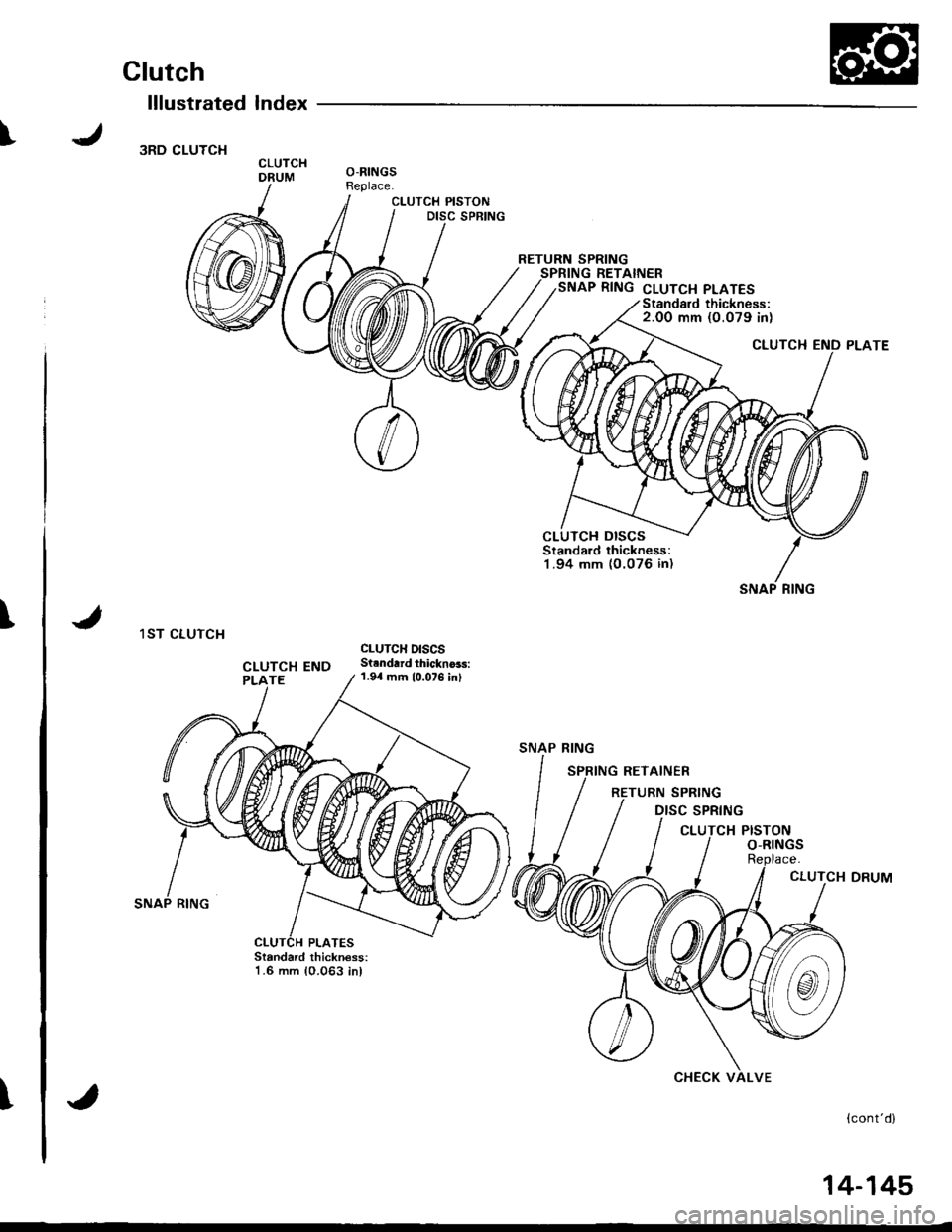

Clutch

lllustrated Index

3RD CLUTCH

1ST CLUTCH

CLUTCH PISTONDISC SPRING

CLUTCHDRUMO-RINGSReplace.

RETURN SPRINGSPRING RETAINERSNAP RING cLUTcH PLATES

Standard thickness:1.6 mm 10.063 inl

{cont'd}

CLUTCH DISCSStandard thickness:1 .94 mm (O.076 in)

SNAP RING

CLUTCH END

SNAP RING

SPRING

CHECK VALVE

14-145�

Page 563 of 1681

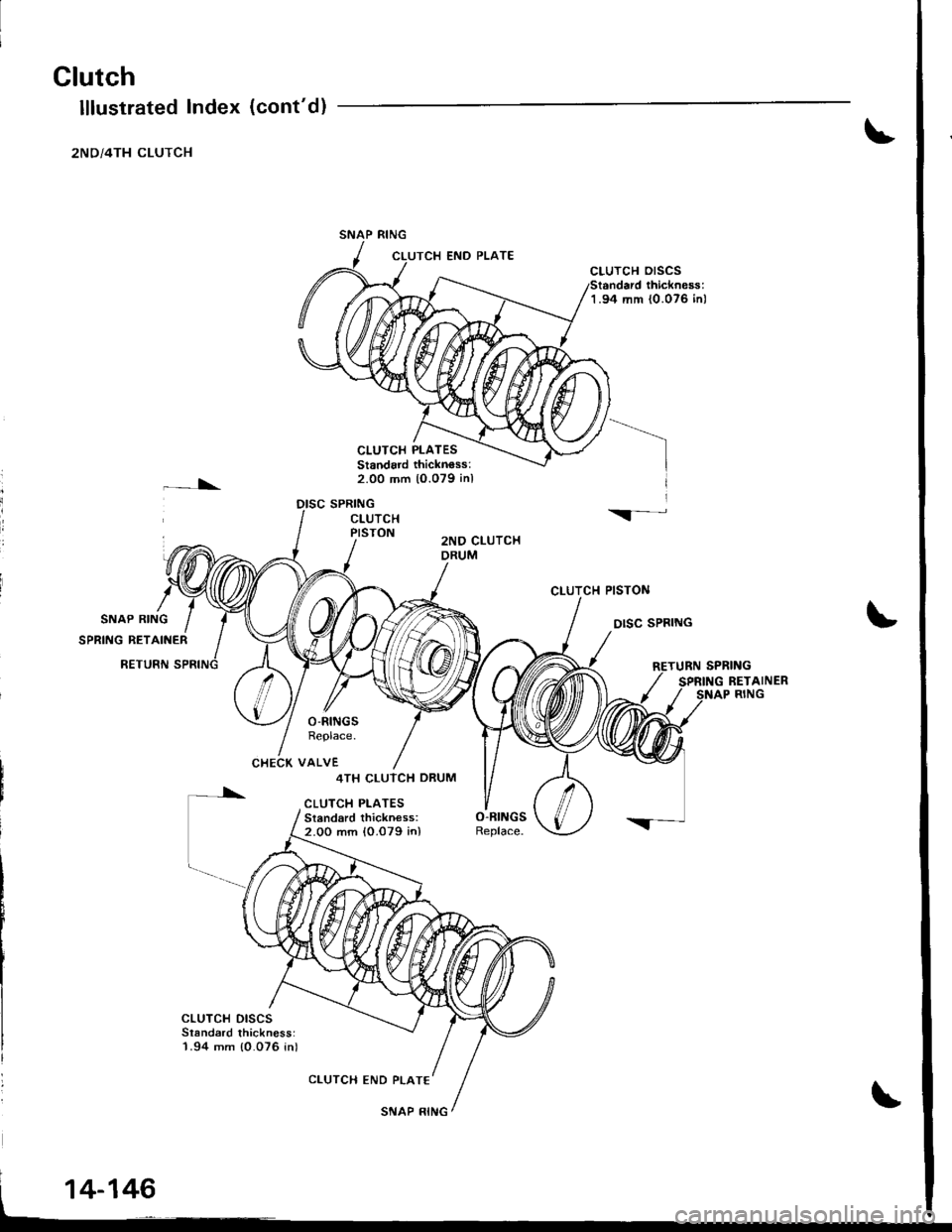

Glutch

lllustrated lndex

2ND/4TH CLUTCH

\

CLUTCH PLATESStandard thicknoss:2.00 mm 10.079 inl

DISC SPRING

CLUTCH OrSCS

1.94 rr|m {0.076 inl

CLUTCTI PISTON

DISC SPBING

(cont'd)

END PLATE

I

il

\-CLUTCHPISTON2NO CLUTCHDRUM

O-RINGSReplace.

CHECK VALVE

[*

cLuTcH DrscsSlandard thickness:1.94 mm {0.076 in)

4TH CLUTCH DRUM

CLUTCH PLATESSi.ndard thickness:2.00 mm {0.079 in)

CLUTCH END PLATE

14-146

SNAP RING

Page 564 of 1681

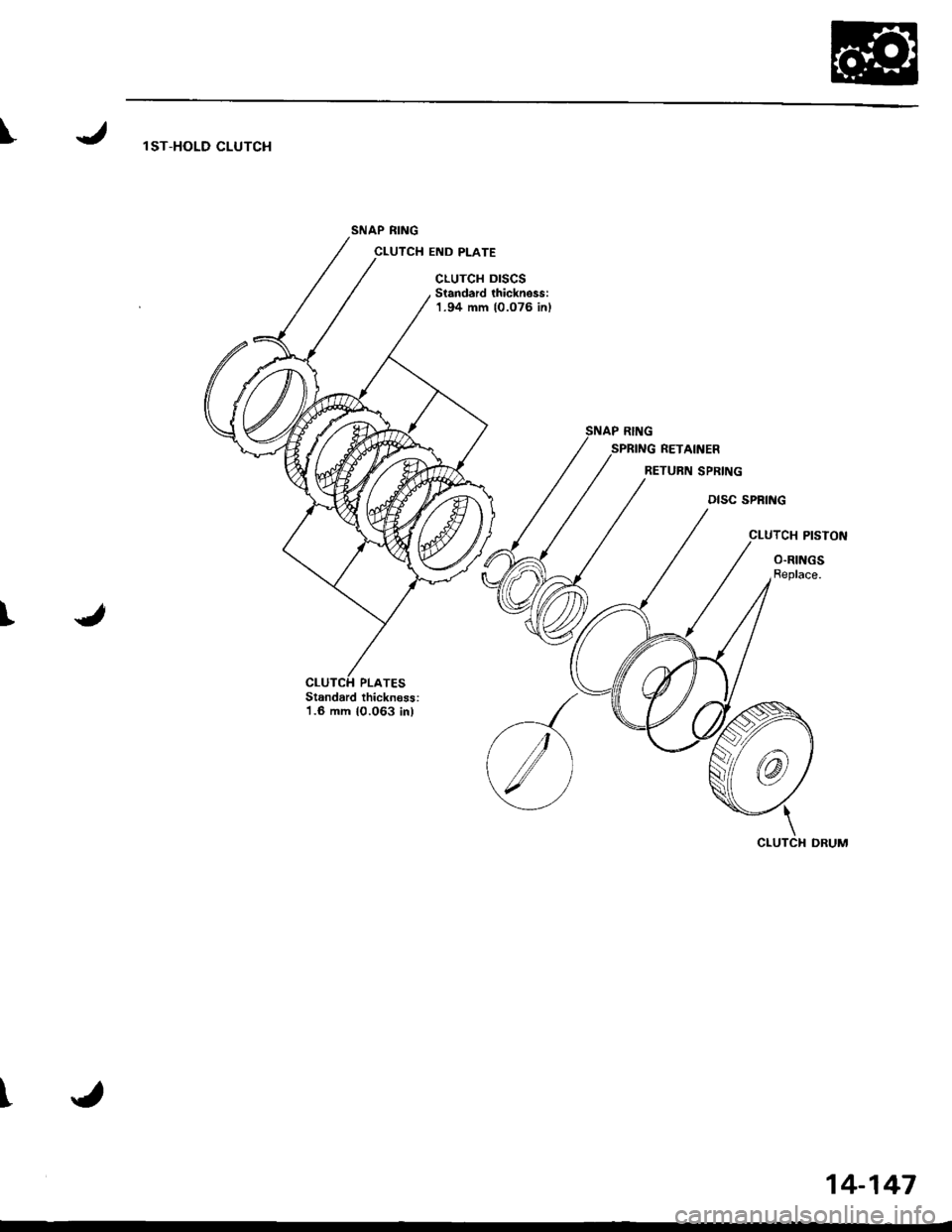

\l ST-HOLD CLUTCH

SNAP RING

CLUTCH END PLATE

cLuTcH DrscsStandard thickness:1.94 mm {0.076 inl

SPRING RETAINER

RETURN SPRING

DISC SPRING

CLUTCH PISTON

O.RINGSReplace.

t

Standard thicknoss:1.6 mm 10.063 in)

l'

14-147

Page 565 of 1681

Clutch

!

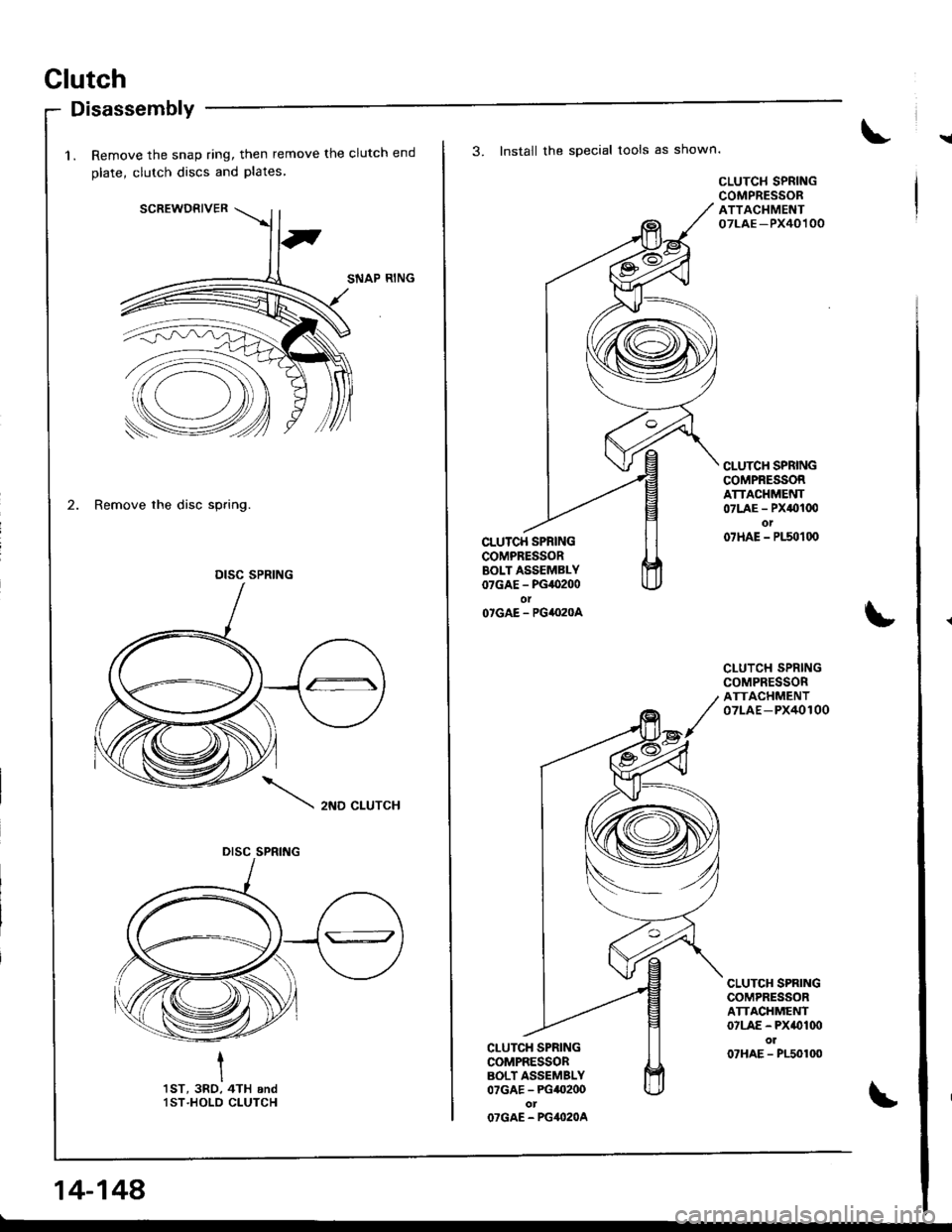

Disassembly

1. Remove the snap ring, then remove the clutch end

olate, clutch discs and Plates

SCREWDRIVER

SNAP RING

2. Remove the disc spring.

2ND CLUTCH

I

I'tsT, 3RO, 4TH andlST.HOLD CLUTCH

DISC SPRING

DISC SPRING

14-148

3. Install the special tools as shown.

CLU'CH SPRINGCOMPRESSORBOLT ASSEMBLY07GAE - PG,O200olO'GAE - PG4I}2OA

CI-UTCH SPRINGCOMPRESSORBOLT ASSEMBLY07GAE - PG40200otOTGAE - PG4O2OA

CLUTCH SPRINGCOMPRESSORATTACHMENT07LAE -PX40100

CLUTC}I SPRINGCOMPRESSORATTACHMENT07LAE - PX0100ot07HAE - P150100

CLUTCH SPRINGCOMPRESSORATTACHMENT07LAE-PX40100

CLUTCH SPRINGCOMPRESSORATTACHMENT07LAE - PX(}Iq)ol07HAE - P150100

Page 566 of 1681

I

T

)

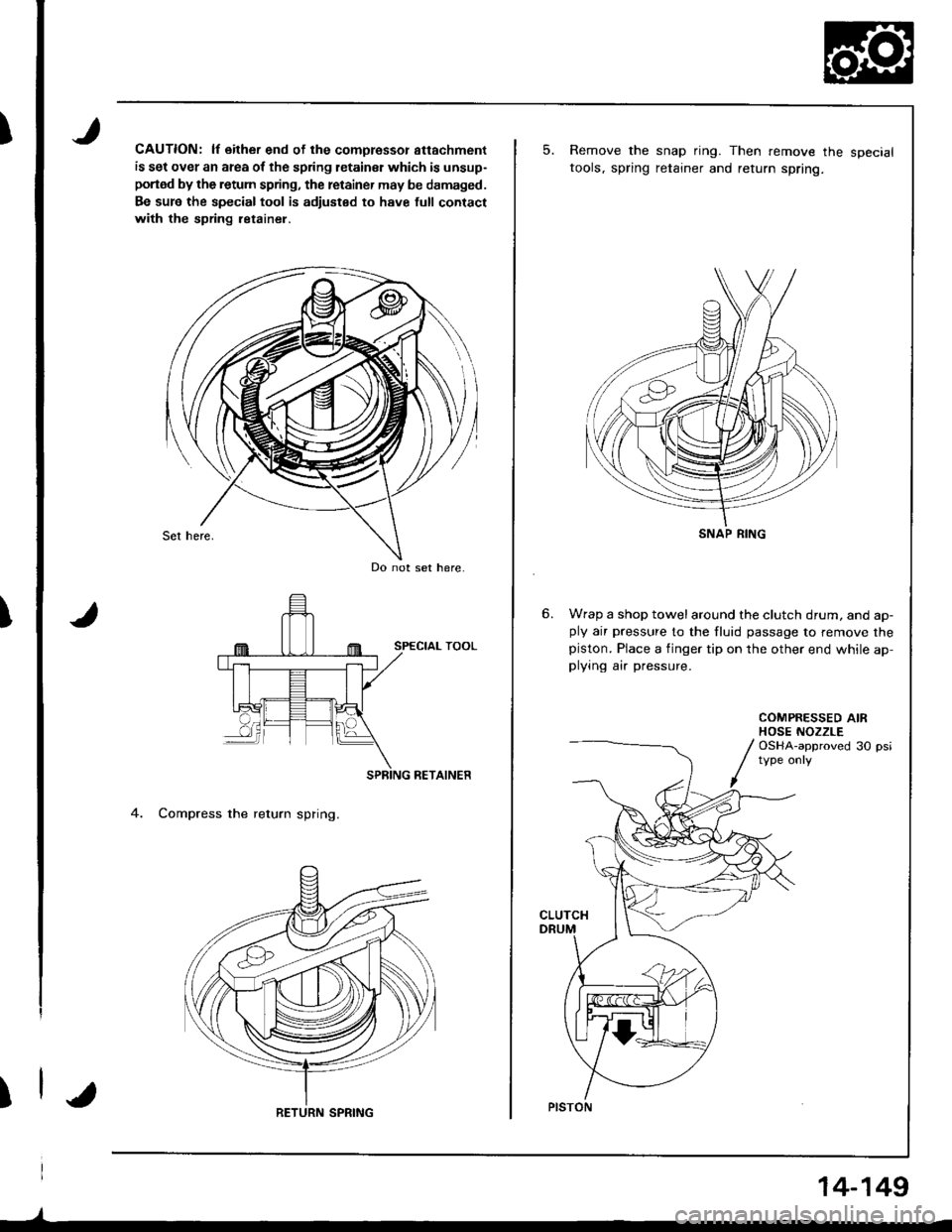

CAUTION: lf either end of the comoressor attachment

is set over an area of the spring letainsr which is unsup-

portod by the retum spring, the retainer may be damaged.

Be sur6 the special tool is adiusted to have full contact

with the spring ietainel,

RETAINER

4. Compress the return spring.

Do not set here.

RETURN SPRING

)

14-149

5.Remove the snap ring. Then remove the specialtools, spring retainer and return spring.

Wrap a shop towelaround the clutch drum, and ap-ply air pressure to the fluid passage to remove thepiston. Place a finger tip on the other end while ap,plying air pressure.

COMPRESSED AIRHOSE NOZZLEOSHA-approved 30 psi

CLUTCH

SNAP RING

PISTON

Page 567 of 1681

Glutch

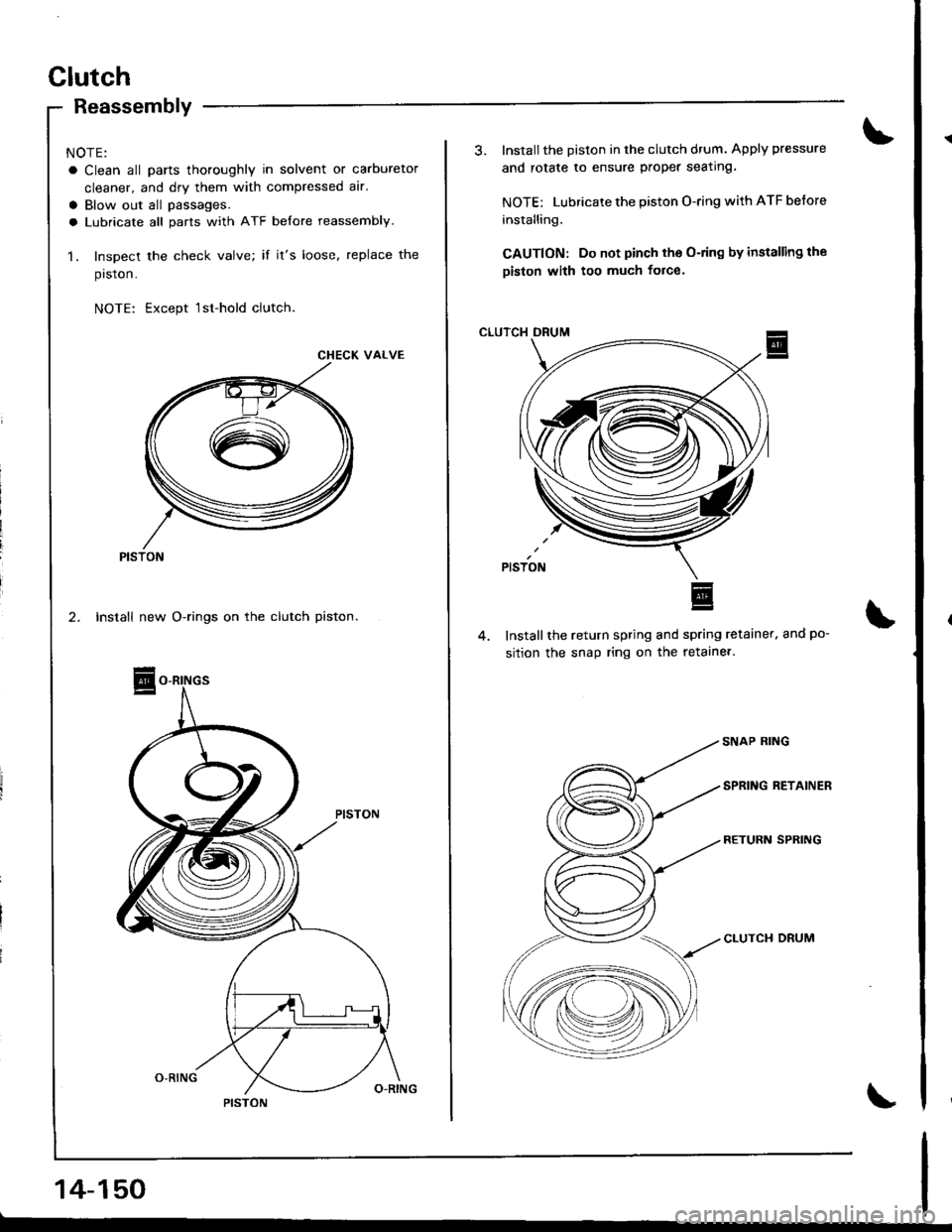

Reassembly

NOTE:

a Clean all parts thoroughly in solvent or carburetor

cleaner, and dry them with compressed alr.

a Blow out all passages.

a Lubricate all parts with ATF belore reassembly.

1. Inspect the check valve; if it's loose, replace the

prston.

NOTE: Except 1sr-hold clutch

CHECK VALVE

PISTON

14-150

3. Installthe Diston in the clutch drum. Apply pressure

and rotate to ensure proper seating.

NOTE: Lubricate the piston O-ring with ATF before

installing.

CAUTION: Do not pinch tho O-ring by installing the

piston with too much force'

CLUTCH DRUM

Installthe return spring and spring retainer. and po-

sition the snap ring on the retaine..

CLUTCH DRUM

Page 568 of 1681

I

t

I

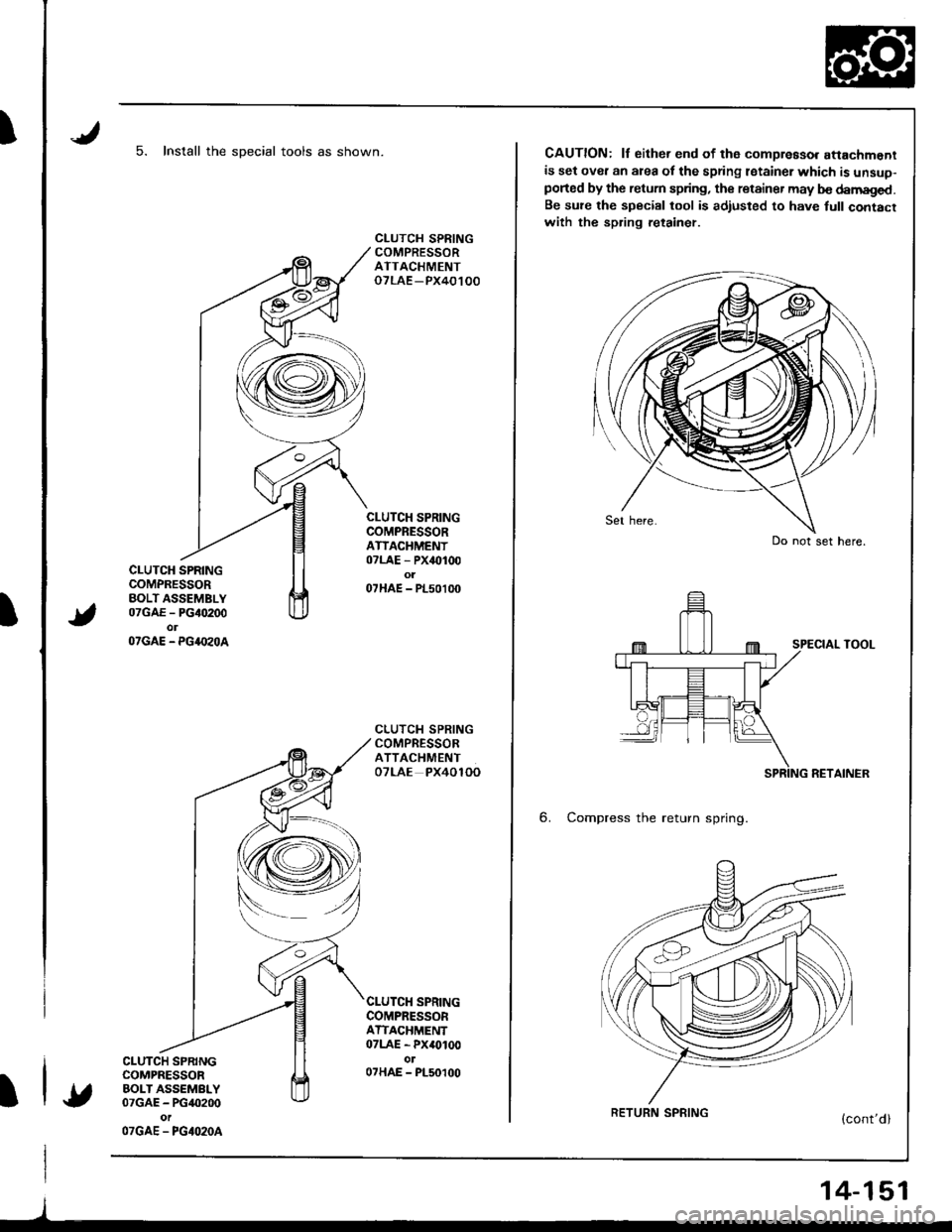

5. Install the sDecial tools as shown.

CLUTCH SPRINGCOMPRESSORBOLT ASSEMBLY07GAE - PG40200olOTGAE - PG4.I'zOA

CLUTCH SPRINGCOMPRESSORBOLT ASSEMBLY07GAE - PG40200

OTGAE - PGIO2OA

CLUTCH SPRINGCOMPRESSORATTACHMENToTLAE -PX40100

CLUTCH SPRINGCOMPRESSORATIACHMENT07LAE - PX40100o107HAE - PL50100

CLUTCH SPRINGCOMPRESSORATTACHMENTOTLAE PX4OlOO

SPRINGCOMPRESSORATTACHMENT07LAE - PX40100ol07HAE - PL50100

l

CAUTION: lf either end of th6 compreaso. attachmentis set over an area of the spring lstainer which is unsuo-ported by the retum spring, the retainer may b€ damaged.Be su?e the special tool is adiusted to have full contacrwith the spring retainer.

SPECIAL TOOL

RETAINER

6. Compress the return spring.

Do not set here.

RETURN SPRING

14-151

Page 569 of 1681

Clutch

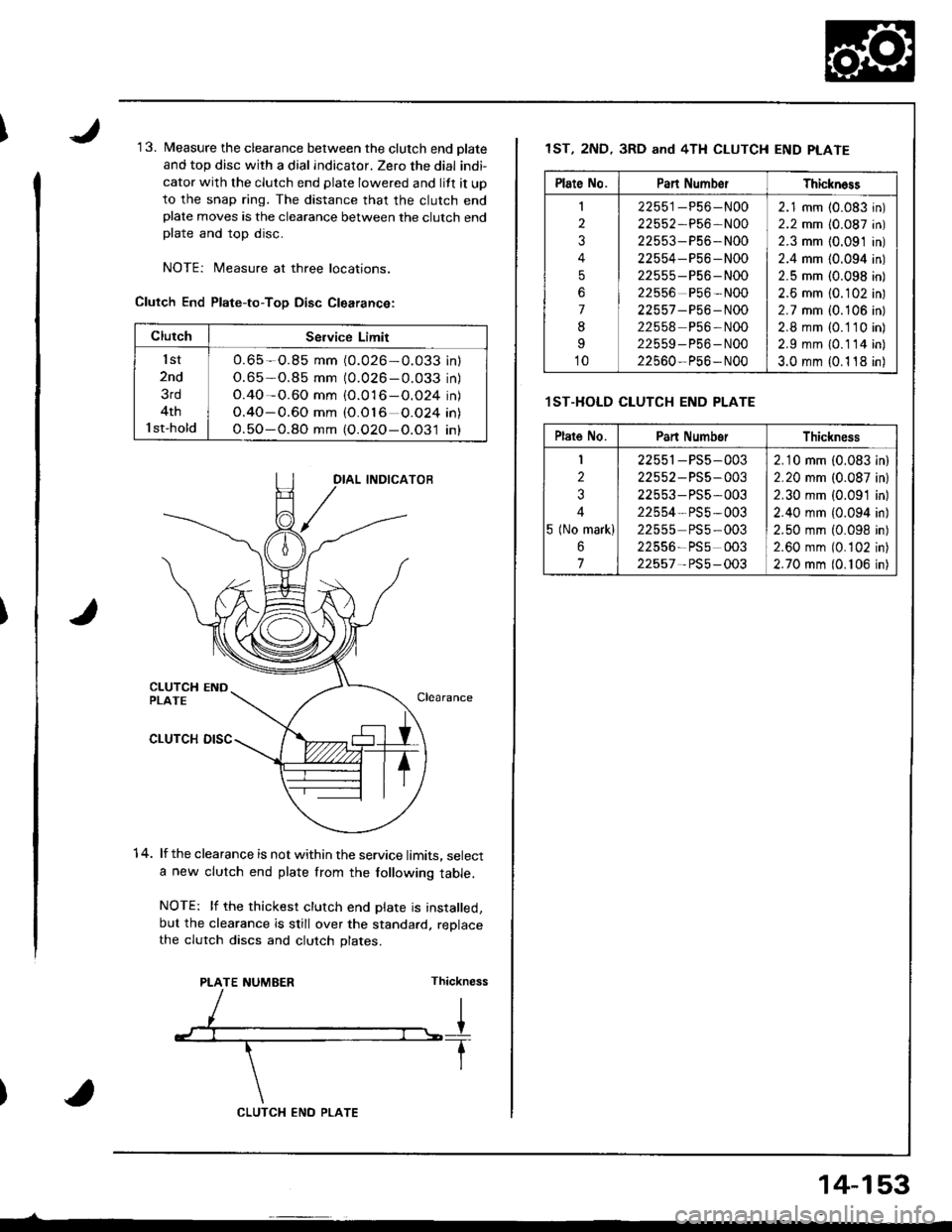

Reassembly {cont'd)

7. Install the snap ring.

Remove the special tools.

lnstall the disc spring.

NOTE: lnstallthe disc spring in the direction shown.

2ND CLUTCH

j

I

SNAP RING

DISC SPRING

OISC SPRING

1ST, 3RD, 4TH and,IST-HOLD CLUTCH

14-152

\10. Soak the clutch discs thoroughly in ATF for a mini-

mum of 30 minutes.

11. Starting with a clutch plate, alternatelY install the

clutch Dlates and discs. Install the clutch end plate

with flat side toward the disc.

NOTE: Before installinq the plates and discs, make

sure the inside of the clutch drum is ttee of dirt or

other loreign matter.

CLUTCH END PLATEInstall in this direction.

12. Install the snap ring.

SCREWDRIVER

SNAP FING

Page 570 of 1681

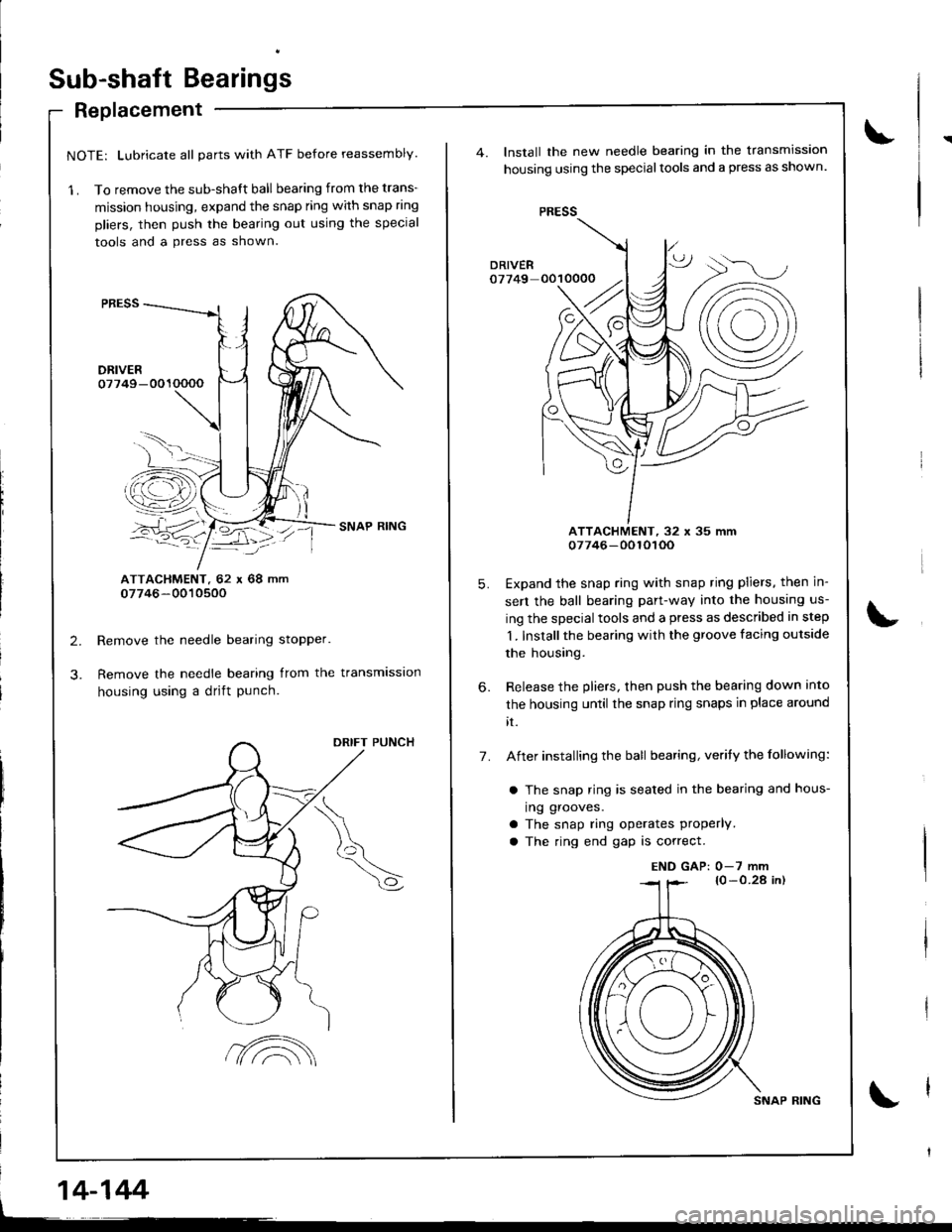

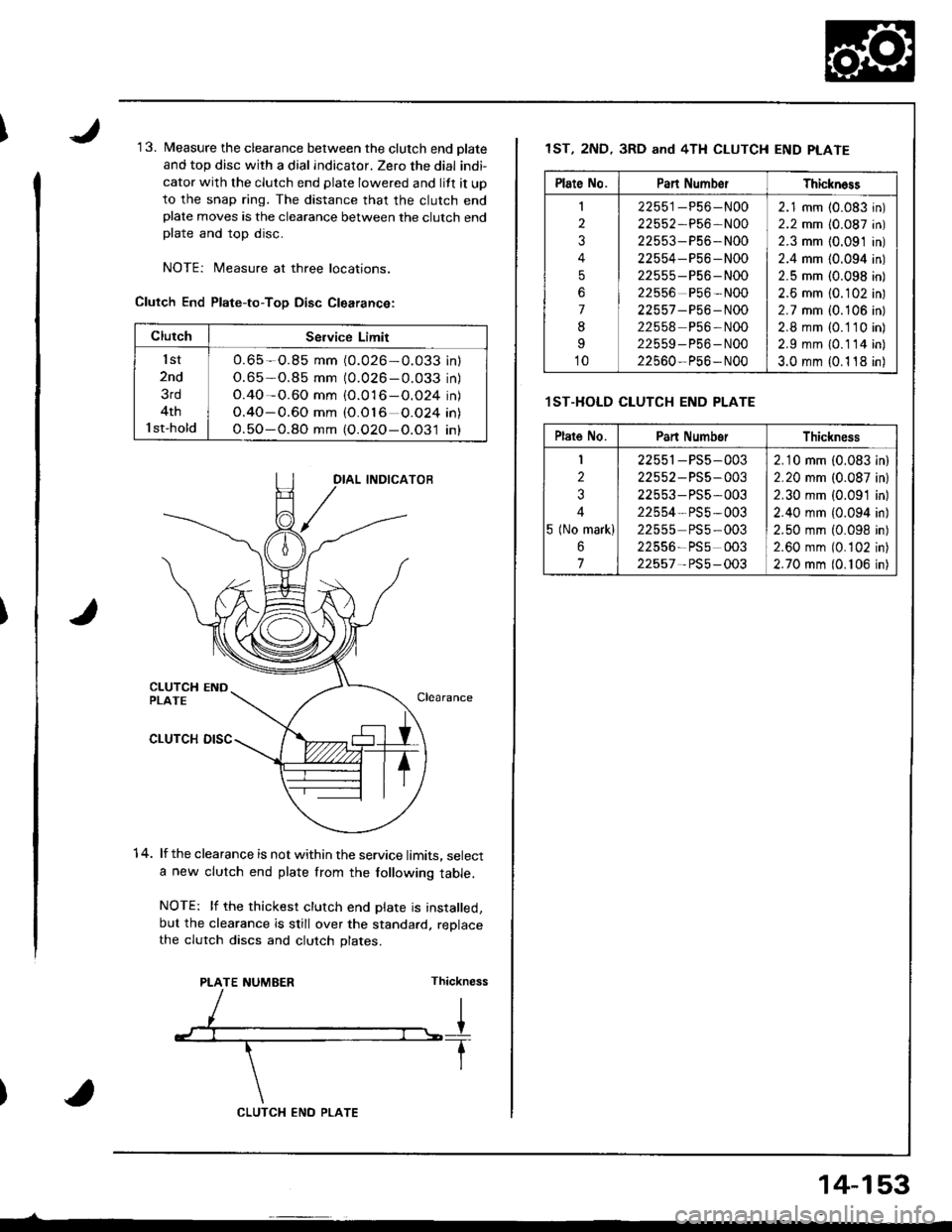

1 3. Measure the clearance between the clutch end olate

and top disc with a dial indicator. Zero the dial indi-

cator with the clutch end plate lowered and lift it up

to the snap ring. The distance that the clutch endplate moves is the clearance between the clutch endplate and top disc.

NOTEi Measure at three locations.

Clutch End Plate-to-ToD Disc Clearance:

1 4. lf the clearance is not within the service limits, selecta new clutch end plate from the following table.

NOTE: lf the thickest clutch end plate is installed,but the clearance is still over the standard. replacethe clutch discs and clutch plates.

PLATE NUMEERThickness

ClutchSeNice Limit

lst

2nd

3rd

4th

l st-hold

O.65 -O.85 mm (0.026-O.033 inl

O.65-0.85 mm (0.026 - 0.033 in)

O.40-0.60 mm {O.016-O.O24 in)

O.40-0.60 mm (O.O16 O.O24 in\

O.5O-O.8O mm (O.O2O-O.O31 in)

CLUTCX ENO PLATE

14-153

1ST, 2ND, 3RD and 4TH CLUTCH END PLATE

.lST.HOLD CLUTCH END PLATE

Plate No.Pan Numb€rThickn6ss

I

2

3

4

5

6

7

8

I

10

22551-P56-N00

22552,P56-N00

22553-P56-N00

22554-P56 -N00

22555 -P56- N00

22556 P56 -N00

22557 -P56 - N00

22558 P56-N00

22559-P56-N00

22560-P56- N00

2.1 mm (0.083 in)

2.2 mm (0.087 in)

2.3 mm {0.091 in)

2.4 mm (0.094 in)

2.5 mm (0.098 in)

2.6 mm {0.102 in)

2.7 mm i0.106 in)

2.8 mm (0. 1 10 in)

2.9 mm {0.114 in)

3.0 mm {0.1 18 in)

Plate No.Pan NumborThickness

I

2

3

4

5 (No mark)

6

7

22551-PS5-003

22552 - PS5-003

22553- PS5,003

22554- PS5 -003

22555 PS5-003

22556-PSs 003

22557- PS5-003

2.10 mm (0.083 in)

2.20 mm (0.087 inl

2.30 mm {0.091 in)

2.40 mm {0.094 in)

2.50 mm (0.098 in)

2.60 mm (0.102 in)

2.70 mm (0. 106 in)

Trending: fuel pressure, light, oil temperature, child seat, Ground location, oil dipstick, ZC engine