HONDA INTEGRA 1998 4.G Workshop Manual

Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 531 of 1681

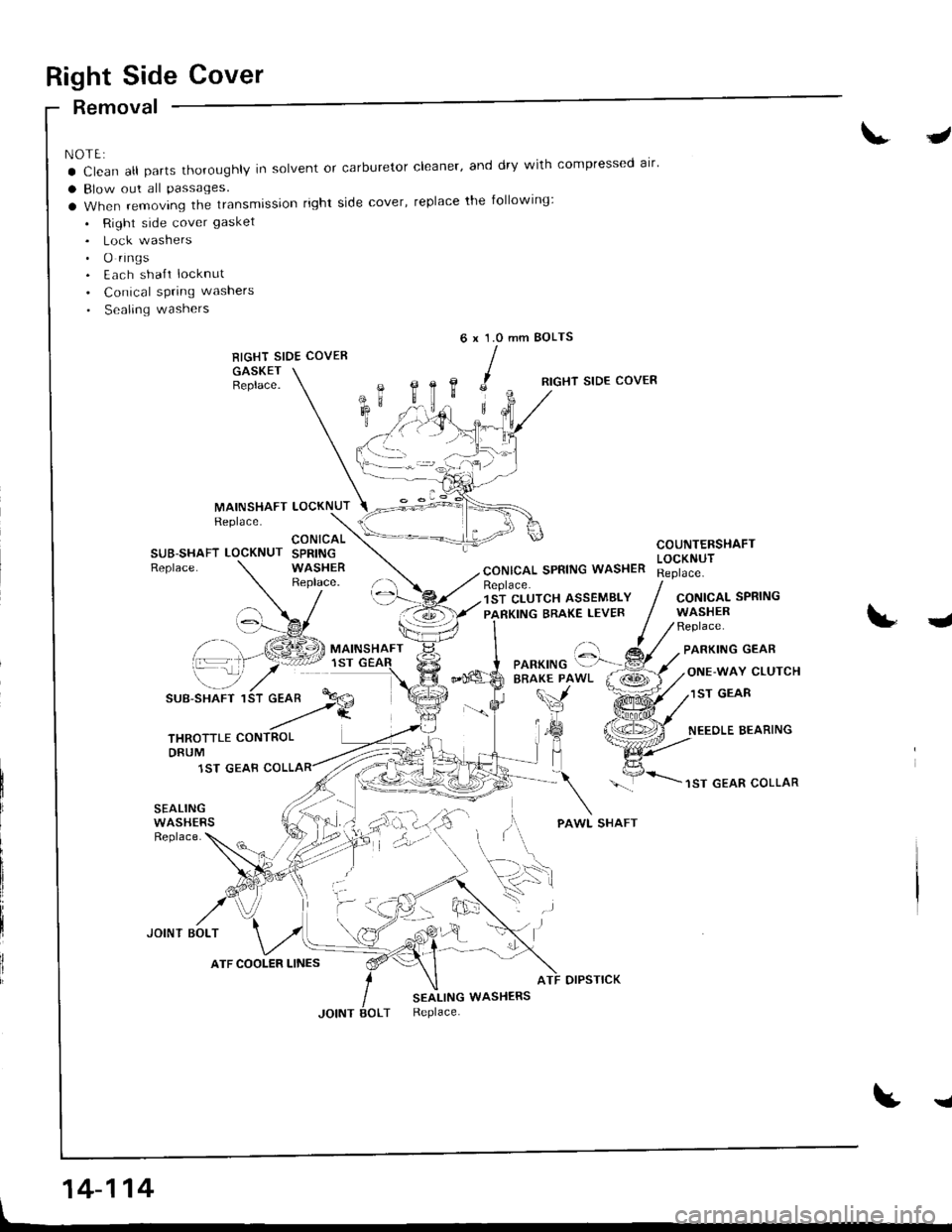

Right Side Cover

Removal

NOTE:

a Clean all parts thoroughly in solvent or carburetor cleaner' and dry with compressed alr'

a Blow out all Passages.

a When removing the transmission right side cover, replace the following:

. Right side cover gasket

. Lock washers. O rings. Each sha{t locknut

. Conical spring washers

. Sealing washers

RIGHT SIDE COVER

GASKETBeplace.

J

mm BOLTS6x1.0

,c

B,

MAINSHAFTReplace.LOCKNUT

RIGHT SIDE COVER

CONICAL SPRING WASHER

COUNTERSHAFTLOCKNUTSUB-SHAFT LOCKNUTReplace.

CONICALSPRINGWASHERReplace.Replace.1ST CLUTCH ASSEMBLY

PARKING BRAKE LEVERCONICALWASHERReplace.

SPRING

J

\-_7

SUB-SHAFT 1

PARKING GEAR

ONE-WAY CLUTCH

1ST GEAR

NEEOLE BEARING

1ST GEAR COLLAR

SEALINGWASHERSReplace.

JOINT BOLT

otPsTtcK

SEALING WASHERSReplace.

t

'::-Pf.a

THROTTLE CONTROLDRUM

1ST GEAB

ATF COOLER LINES

'. .)

14-114

I

Page 532 of 1681

I

t

I

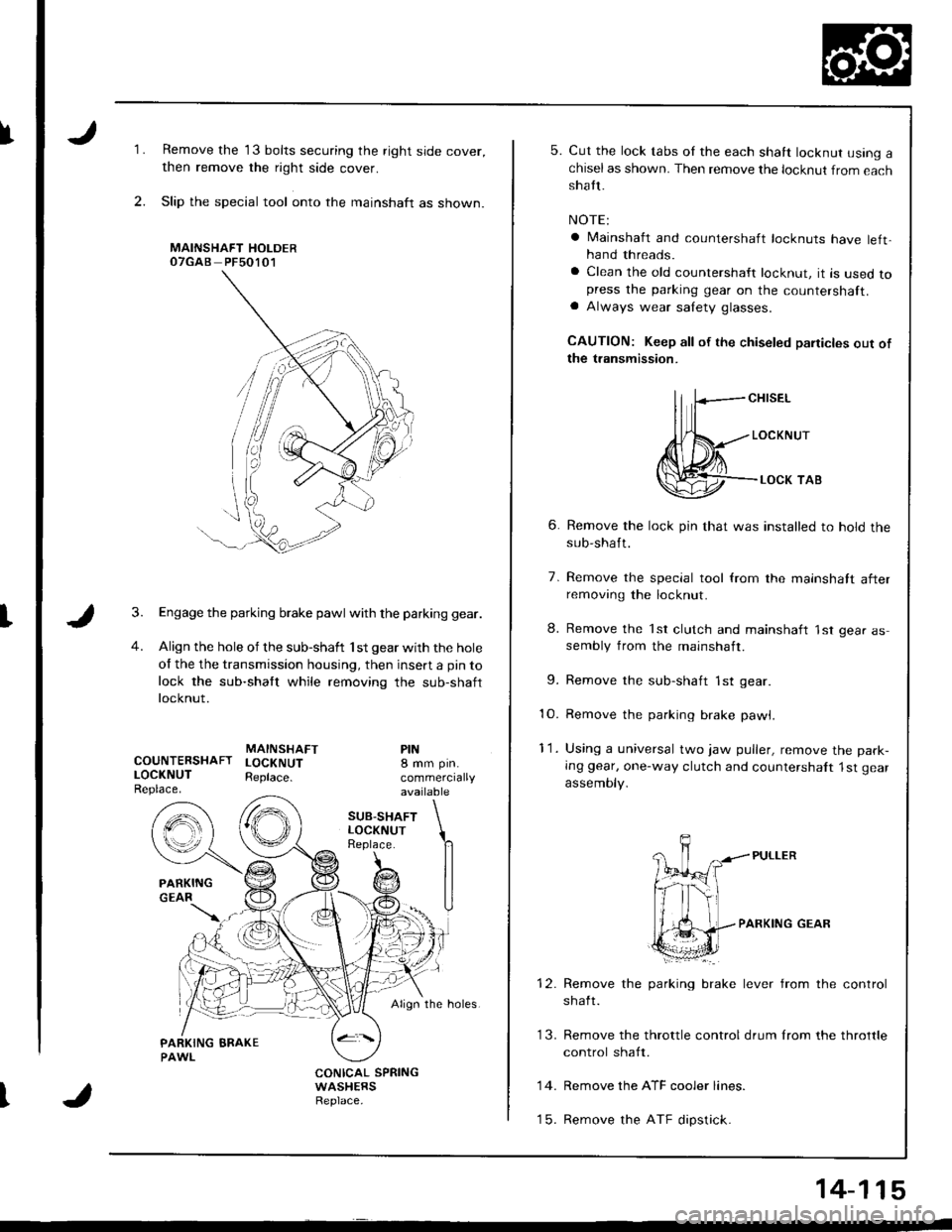

1.

2.

Remove the 13 bolts securing the right side cover,

then remove the right side cover.

Slip the special tool onto the mainshaft as shown.

MAINSHAFT HOLDEROTGAB PFsO1O1

Engage the parking brake pawl with the parking gear.

Align the hole of the sub-shaft 'lst gear with the hole

of the the transmission housing, then insert a pin to

lock the sub-shaft while removing the sub-shaft

locknut.

MAINSHAFTCOUNTERSHAFT LOCKNUTLOCKNUT Reptace.Replace.

PIN8 mm pin.

commerciallyavailable

SUB.SHAFTLOCKNUTReplace.

Align the holes.

CONICAL SPRINGWASHERSReplace.

5. Cut the lock tabs oI the each shaft locknut using achiselas shown. Then remove the locknut from eachshatt.

NOTE:

a lvlainshaft and countershaft locknuts have left,hand threads.

a Clean the old countershaft locknut, it is used topress the parking gear on the countershaft.a Always wear salety glasses.

CAUTION: Keep all of the chiseled paiticles out ofthe transmission.

ll fcH,sEL

Jl{*---,o"*",r

@--.**,o,

6. Remove the lock pin that was installed to hold thesub-shaft.

7. Remove the special tool from the mainshatt afterremoving the locknut.

8. Remove the 'lst clutch and mainshaft 'lst gear assembly from the mainshaft.

9. Remove the sub-shaft 1st gear

10. Remove the parking brake pawl,

11. Using a universal two jaw puller, remove the park-

Ing gear, one-way clutch and countershalt 1st gear

assemoty.

PARKING GEAR

brake lever from the controlRemove the parking

shaft.

Remove the ATF cooler lines.

Remove the ATF dipstick.

13. Remove the throttle control drum lrom the throttle

control shaft.

14.

t5.

14-115

Page 533 of 1681

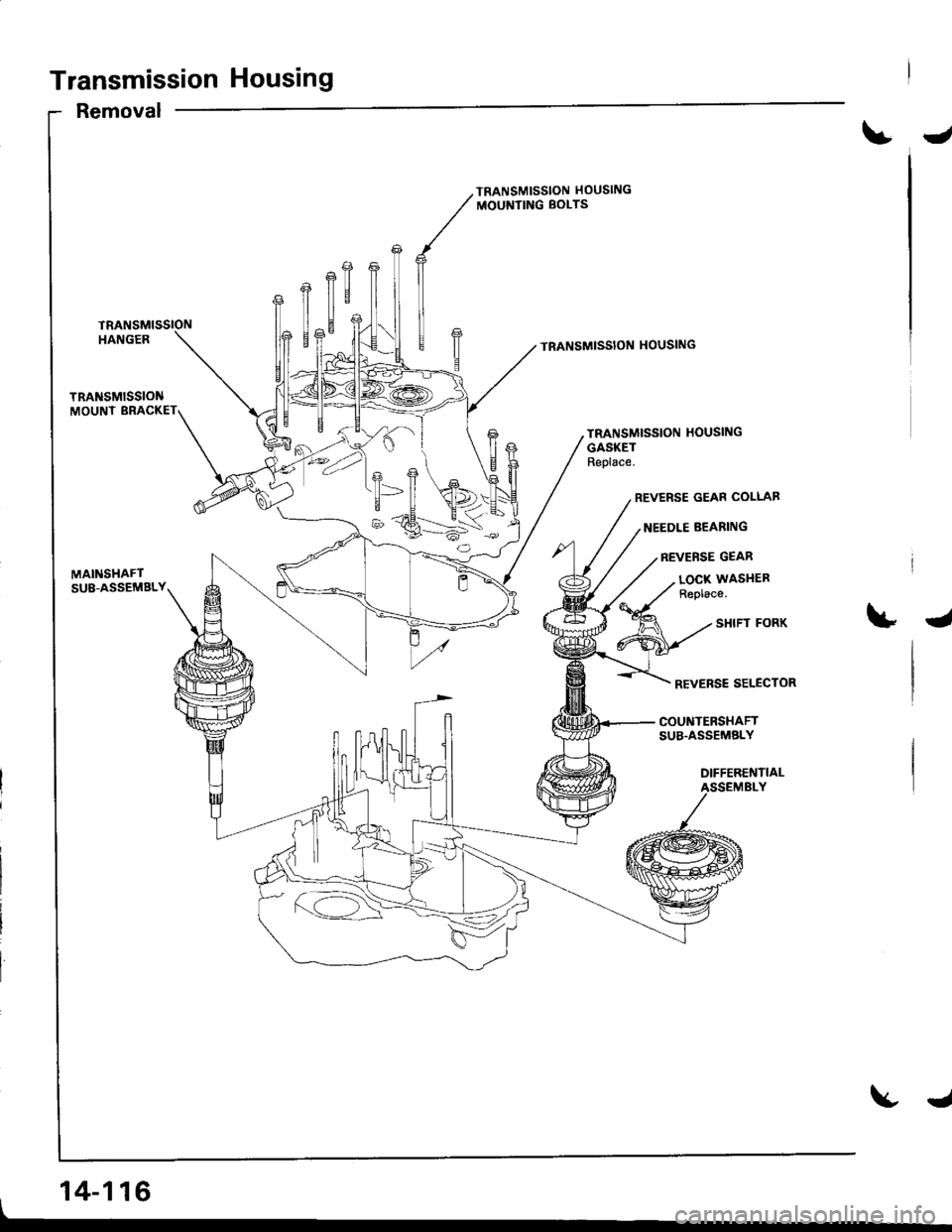

Transmission Housing

Removal

J

TRANSMISSION HOUSING

MOUNTING BOLTS

TRANSMISSION HOUSING

TRANSMISSION HOUSING

GASKETReplace.

REVERSE GEAR COLLAB

NEEDLE BEARING

REVERSE GEAR

MAINSHAFTSU8-ASSEMBLY

, 14-116

LOCX WASITEFReplace.

4

REVERSE SELECTOR

COUNTERSHAFTSUB.ASSEMELY

DIFFERENTIALASSEMBLY

J

Page 534 of 1681

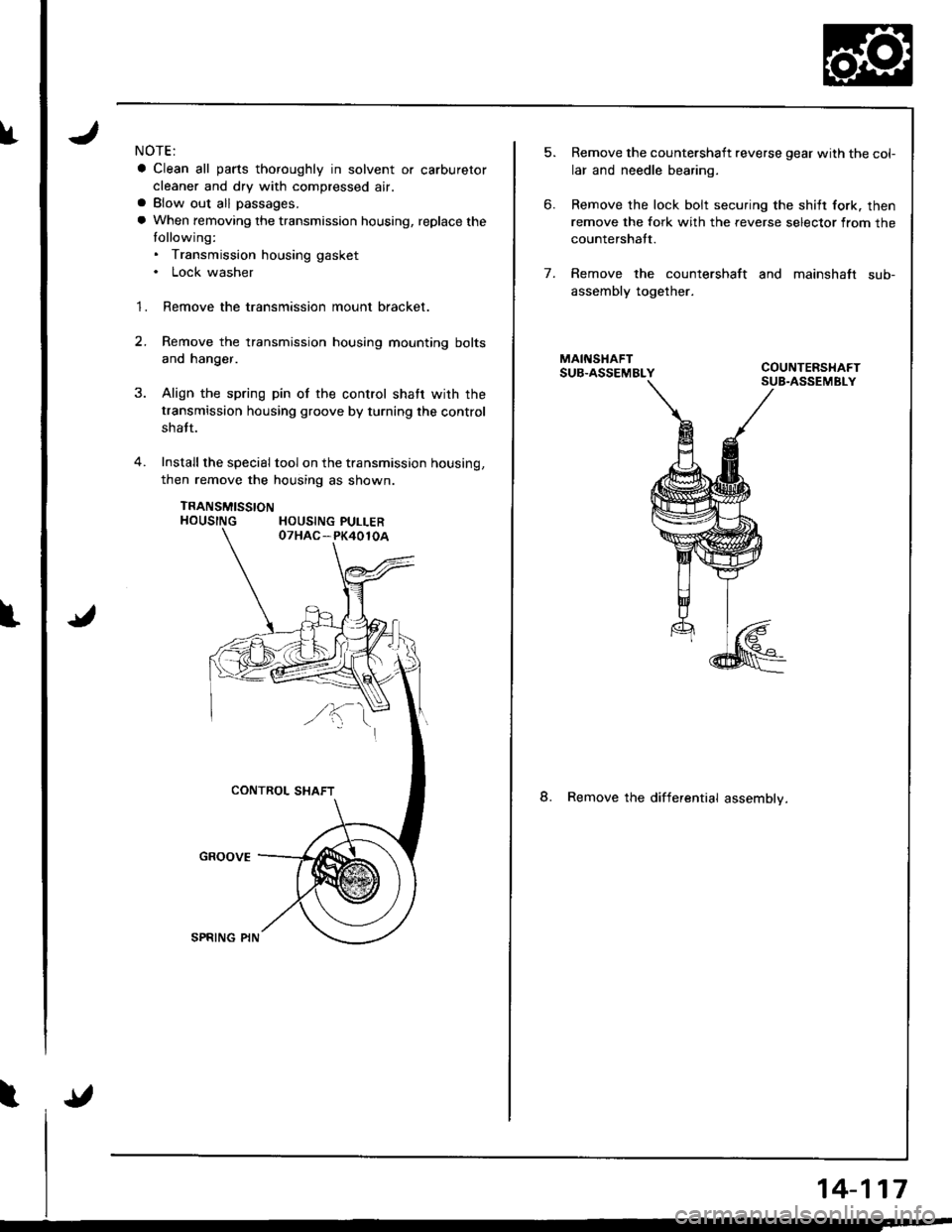

fNOTE:

a Clean all parts thoroughly in solvent or carburetor

cleaner and dry with compressed air.a Blow out all passages.

a When removing the transmission housing, replace the

tollowing:. Transmission housing gasket. Lock washer

1. Remove the transmission mount bracket.

2.Remove the transmission housing mounting bolts

and hanger.

Align the spring pin of the control shatr wirh the

transmission housing groove by turning the control

shatt.

Install the special tool on the transmission housing,

then remove the housing as shown.

TRANSMISSTONHOUSING HOUSING PULLER

5.

6.

Remove the countershaft reverse gear with the col-

lar and needle bearing.

Remove the lock bolt securing the shilt fork. then

remove the fork with the reverse selector from the

countershatt.

Remove the countershaft and mainshaft sub-

assembly together.

8. Remove the differential assemblv.

7.

14-117

Page 535 of 1681

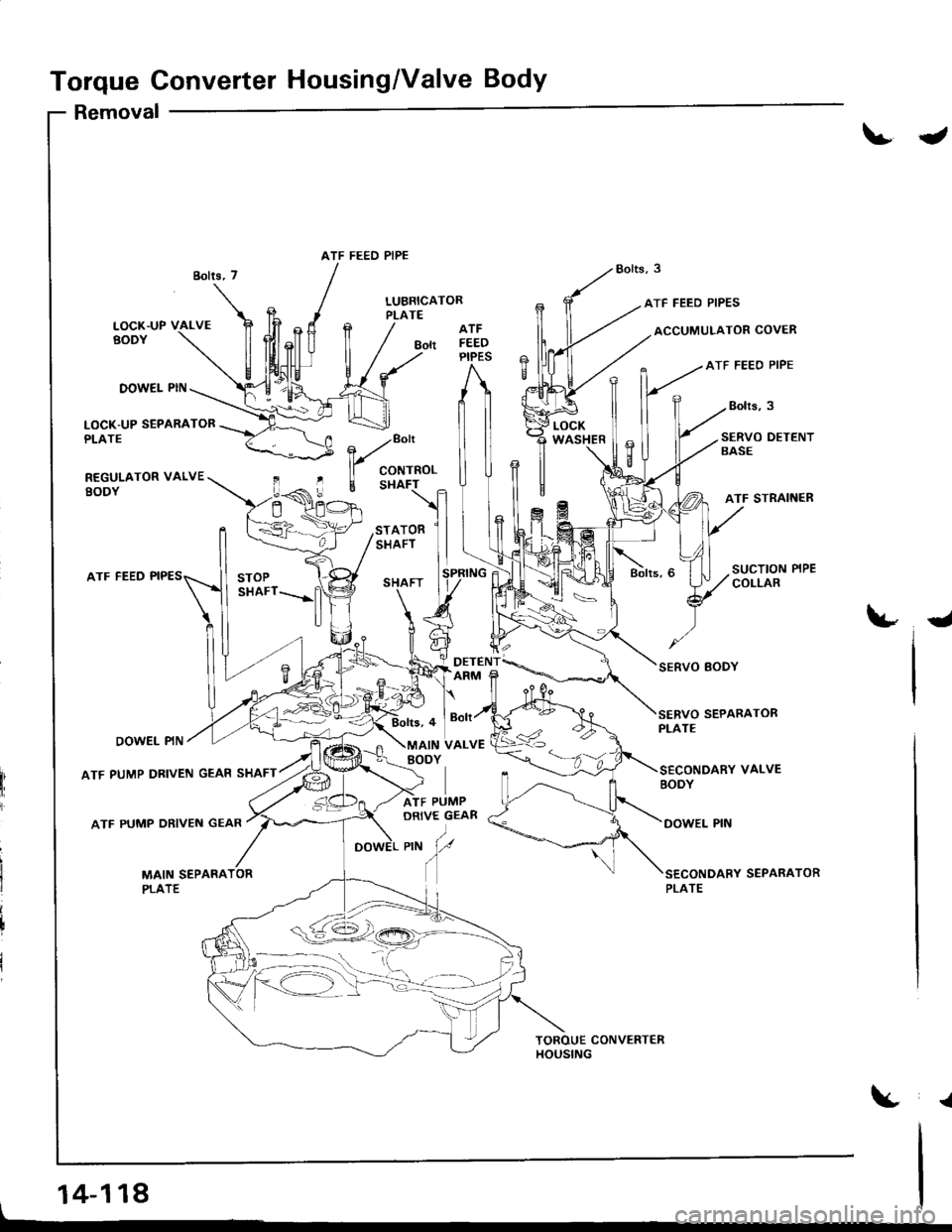

Torque Converter Housing/Valve Body

Removal

t

LUBRICATORPLATEATF FEED PIPES

ACCUMULATOR COVER

ATF FEEO PIPE

Bolrs,3

ATF

Bott FEEDPIPES

DOW€I- PIN

LOCK-UP SEPARATORPLATE

REGULATOR VALVEEODY

SERVO DETENTSASE

ATF STRAINER

LOCKWASHER

ATF FEED

DOWEL PIN

ATF PUMP DRIVEN GEAR SHAFT

ATF PUMP ORIVEN GEAR

-

SEPARATOR

.a

ATF FEED PIPE

, ./"o"

ll coNrRoL

E Sl{AF-r

ATOR

PLATE

_ro-rr!_

Page 536 of 1681

I

l"

I

J

NOTE:

a Clean all parts thoroughly in solvent or carburetor

cleaner and dry with compressed air.

a Blow out all passages.

a When removing the valve body replace the lollowing:. O-rings. Lock washers

1 . Remove the ATF feed pipes from the servo body, ser-vo detent base, accumulator cover, lock-up valve

body and main valve body.

2. Remove the three bolts securing the ATF strainer

and servo detent base, then remove the strainer

and detent base.

3. Remove the three bolts securing the accumulator

cover, then remove the accumulator cover.

4. Remove the six bolts securing the servo body. then

remove the servo body and separator plate.

5. Remove the one bolt securing the secondary valvebody, then remove lhe secondary valve body andseparator plate.

6. Remove the eight bolts securing the lubricator plate

and lock-up valve body, then remov€ th€ lubricator

plate. Iock-up valve body, and separator plate.

7. Remove the one bolt securing the regulator valve

body, then remove the regulator valve body.

8. Remove the stator shaft and stop shaft.

9. Remove the detent spring from the detent arm, then

remove the control shaft from the torque converter

housrng.

1O. Remove the detent arm and detent arm shatt from

the main valve body.

1 'l . Remove the four bolts securing the main valve body,

then remove the main valve body.

'I2. Remove the ATF pump driven gear shatt, then re-

move the ATF pump gears.

13. Remove the main separator plate with two dowel

pins.

15.

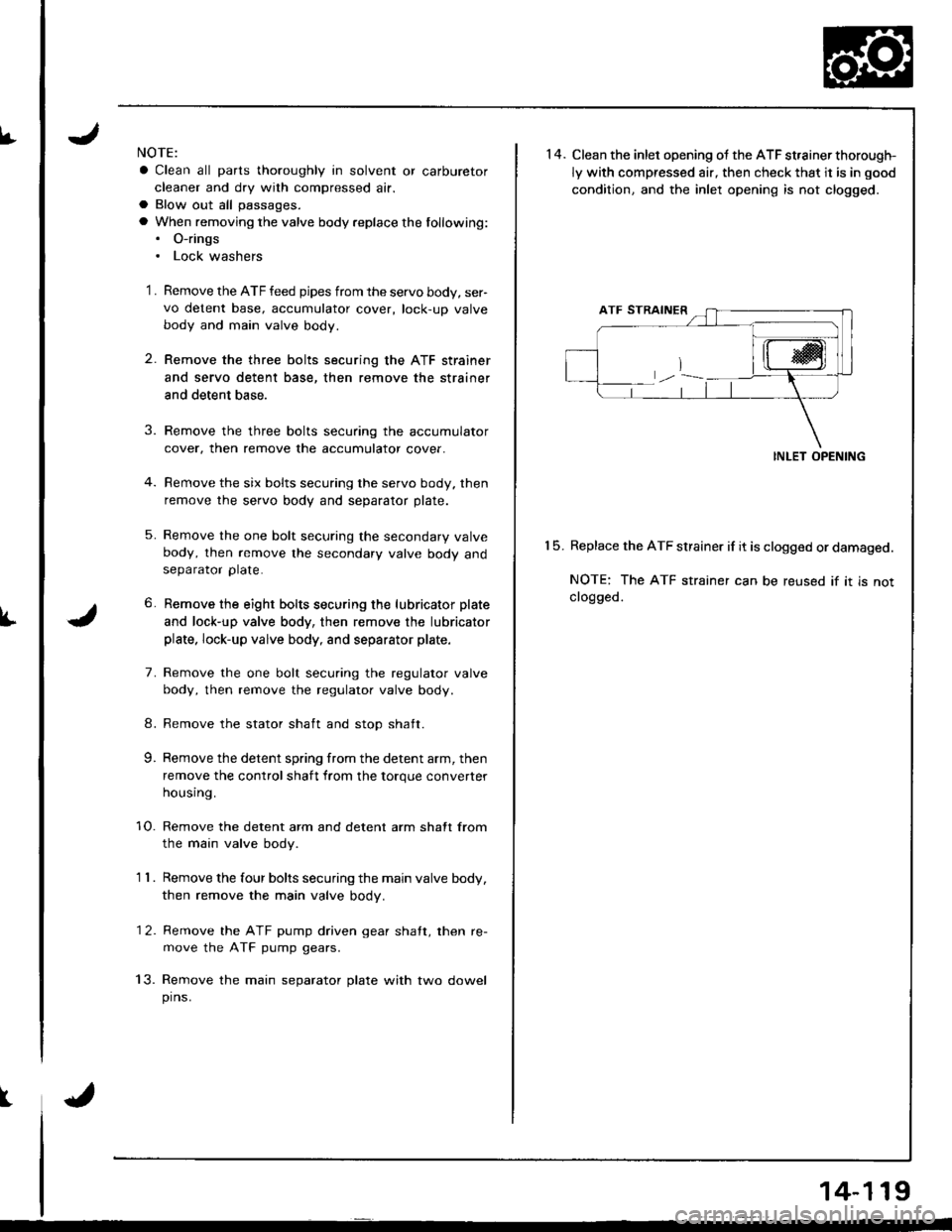

14. Clean the inlet opening ot the ATF st,ainer thorough-

ly with compressed air, then check that it is in good

condition. and the inlet opening is not clogged.

INLET OPENING

Replace the ATF strainer if it is clogged or damaged.

NOTE: The ATF strainer can be reused if it is notclogged.

14-119

Page 537 of 1681

Valve Caps

Description

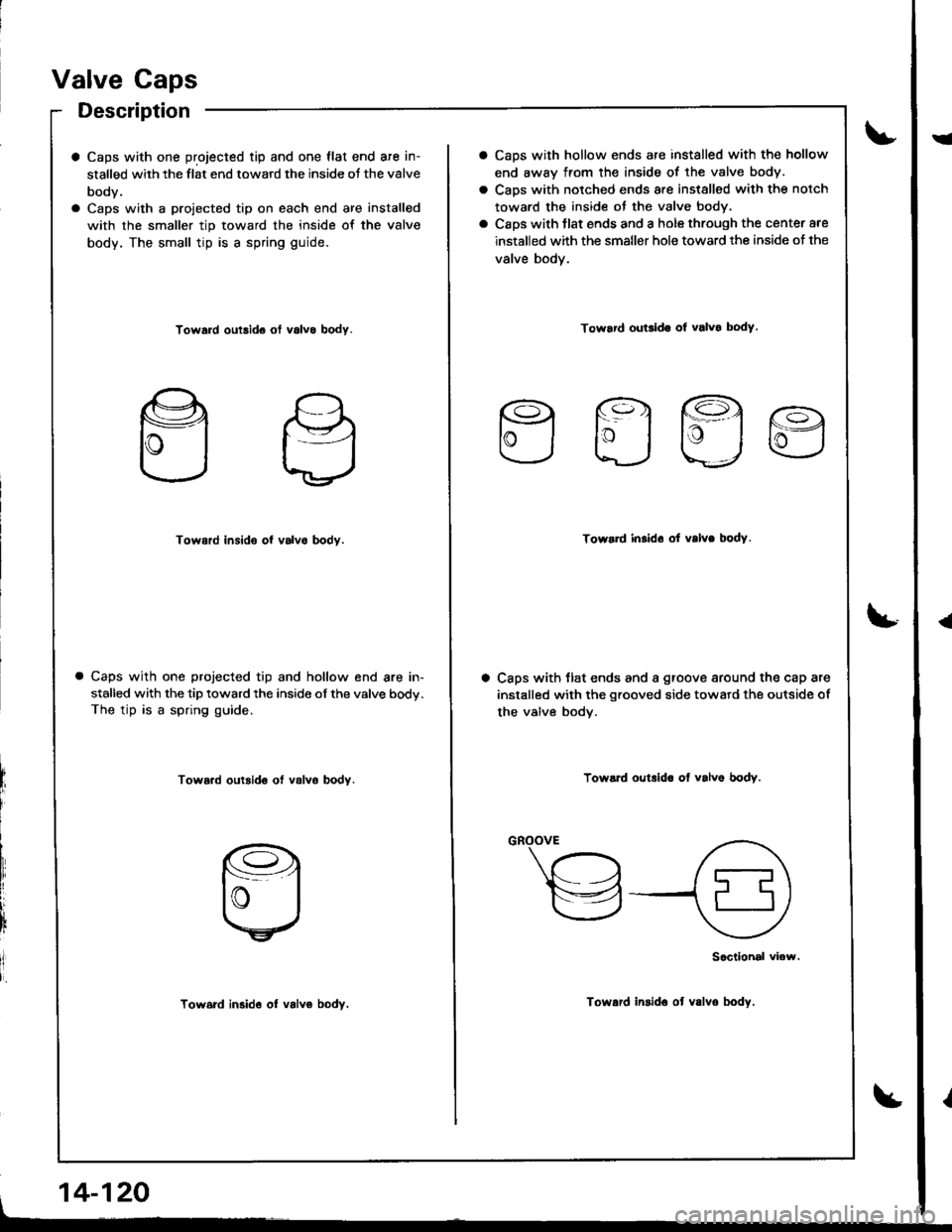

a Caps with one projected tip and one flat end are in-

stalled with the flat end toward the inside oJ the valve

body.

a Caps with a proiected tip on each end are installed

with the smaller tip toward the inside of the valve

body. The small tip is a spring guide.

Toward outsid6 ot v6lvo body.

Toward insido of valvo bodv.

Caps with one projected tip and hollow end are in-

stalled with the tip toward the inside of the valve body.

The tip is a spring guide.

Tow6.d outsid€ ot valvo bodY.

Tow6rd in3id6 ol valvo bodv.

, 14-120

CaDs with hollow ends are installed with the hollow

end away from the inside of the valve body.

Caps with notched ends are installed with the notch

toward the inside ot the valve body.

Caps with tlat ends and a hole through the center are

installed with the smaller hole toward the inside of the

valve body.

Toward ouGida ol valvo body.

Efla

Toward in.ldo ot valve bodY.

Caps with tlat ends and a groove around the cap are

installed with the grooved side toward the outside of

the valve bodv.

Toward oulrlda of valve bodv.

"-\"h

,a\

v{9

Sociiohal viow.

Toward insido ot v.lvo body.

I

{

Page 538 of 1681

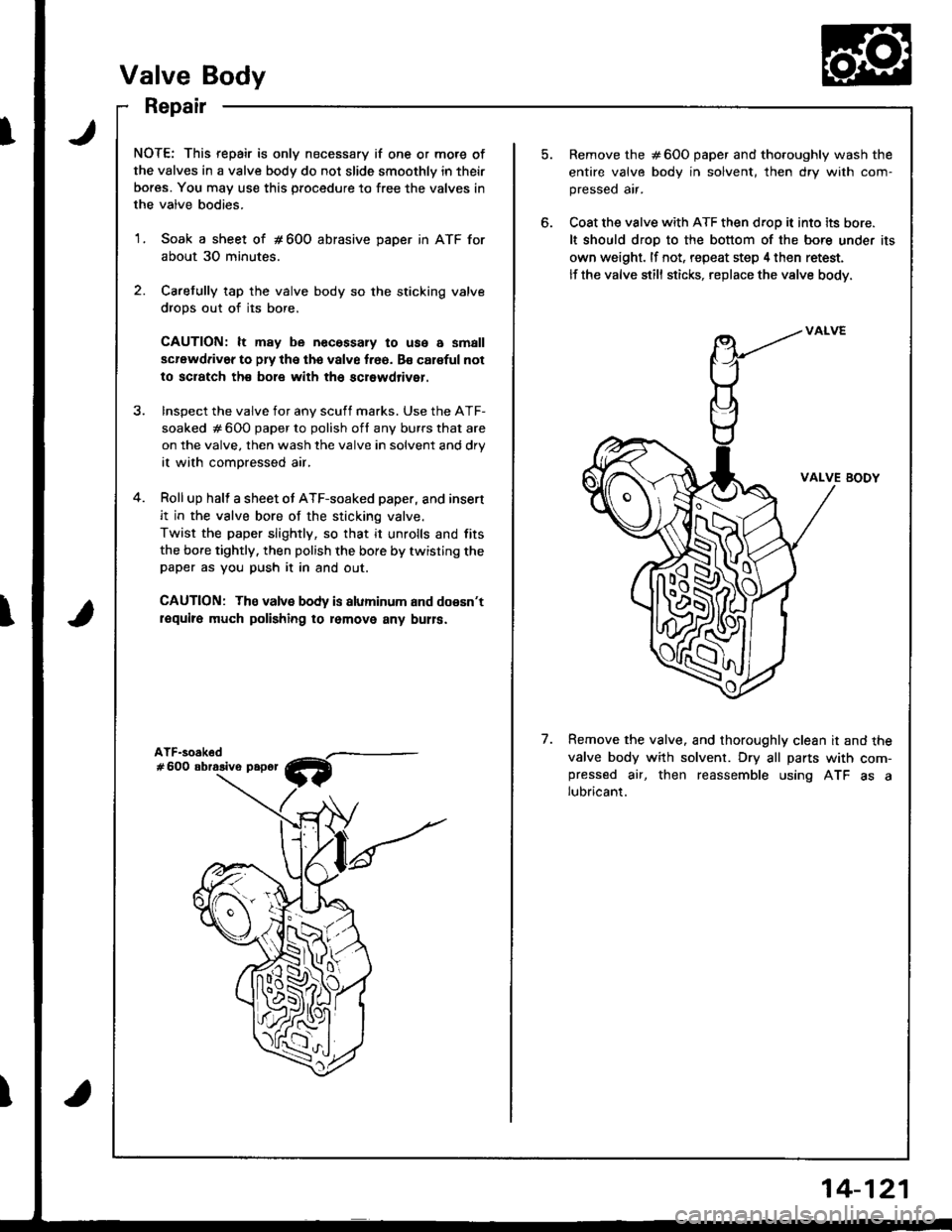

NOTE: This repair is only necessary if one or more of

the valves in a valve body do not slide smoothly in their

bores. You may use this procedure to free the valves in

the valve bodies.

1. Soak a sheet of # 600 abrasive DaDer in ATF for

about 30 minutes.

2. Caretully tap the valve body so the sticking valve

drops out of its bore.

CAUTION: lt may be necessary to use a small

scrawdriv6r to pry the the valve f.66. Bs caloful not

to sciatch th€ bole with th6 scrowdriver.

Remove the #600 paper and tho.oughly wash the

entire valve body in solvent, th€n dry with com-

pressed air.

Coat the valve with ATF then droD it into its bore.

It should droD to the bottom of the bore under its

own weight. lf not, repeat step 4 then retest.

lf the valve still sticks, replace the valve body.

InsDect the valve for anv scuff marks. Use the ATF-

soaked # 600 paper to polish ofl any burrs that are

on the valve. then wash the valve in solvent and drV

it with compressed air,

Roll up halt a sheet ot ATF-soaked paper, and insert

it in the valve bore of the sticking valve.

Twist the paper slightly, so that it unrolls and fits

the bore tightly. then polish the bore by twisting thepaper as you push it in and out.

CAUTION: The valvs body is aluminum and doesn't

require much polishing ro lomovo any bulla.

VALVE BODY

7.Remove the valve. and thoroughly clean it and the

valve body with solvent. Dry all parts with com-pressed air, then reassemble using ATF as alubricant.

Valve Body

Repair

14-121

Page 539 of 1681

Valve

Assembly

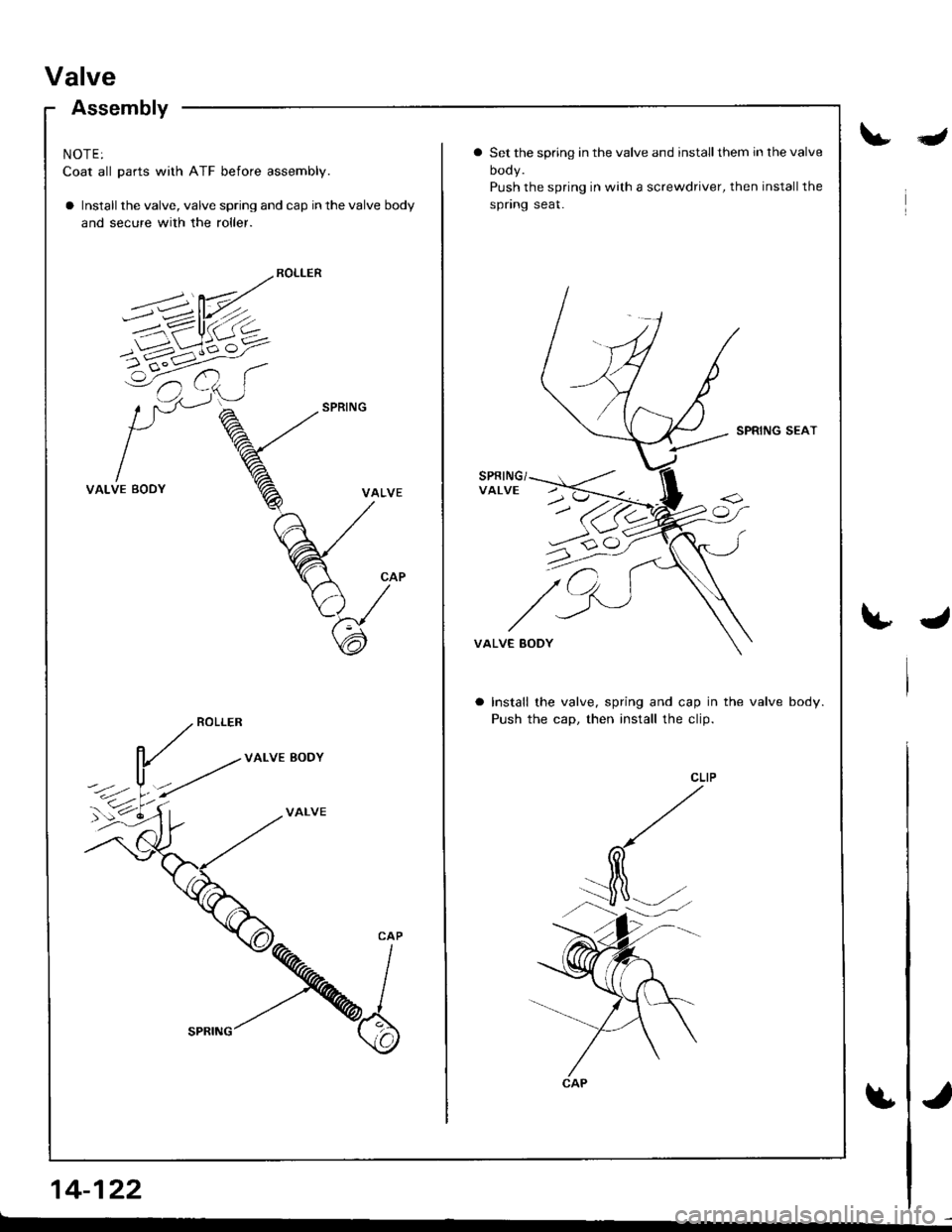

NOTE:

Coat all parts with ATF before assembly.

a Install the valve, valve spring and cap in the valve body

and secure with the roller.

VALVE BODY

VALVE

14-122

Ia Set the spring in the valve and installthem in the valve

oooy.

Push the spring in with a screwdriver, then installthe

spnng seat.

SPRING SEAT

VALVE EODY

Install the valve, spring and cap in the valve body.

Push the cap, then install the clip.

Page 540 of 1681

ATF Pump

Inspection

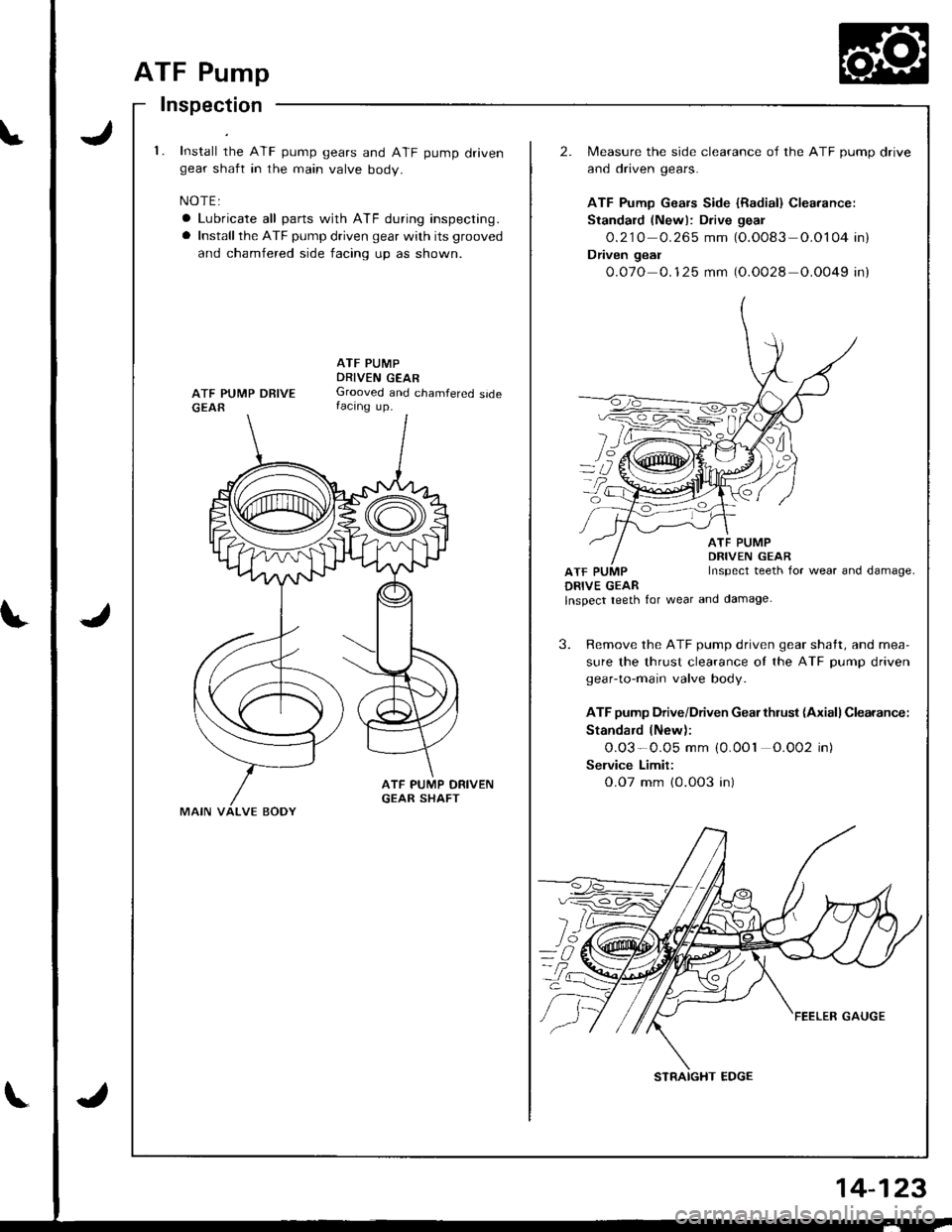

't.Install the ATF pump gears and ATF pump drivengear shaft in the main valve body.

NOTE:

a Lubricate all parts with ATF during inspecting.

a Installthe ATF pump driven gear with its grooved

and chamfered side facing up as shown.

2.Measure the side clearance of the ATF pump drive

and driven gears.

ATF Pump Gears Side {Radial} Clearance:

Standald (Newl: Drive geal

O.21O 0.265 mm (O.O083 O.O104 in)

Dfiven geal

0.07O 0.1 25 mm (O.O028 O.0049 in)

ATF PUMPDRIVEN GEARGrooved and chamfered sidefacing up.

ATF PUMPDRIVE GEAR

ATF PUMPDRIVEN GEARInspect teeth for wear and damage,

lnspect teeth for wear and damage-

3. Remove the ATF pump driven gear shatt, and mea-

sure the thrust clearance oI the ATF pump driven

gear-to-main valve body.

ATF pump Drive/Driven Gearthlust (Axiall Clearance:

Standard lNew):

0.O3-0.05 mm (0.0O1 0.002 in)

Selvice Limit:

O.O7 mm {0.003 in)

STRAIGHT EDGE

14-'|,23