HONDA INTEGRA 1998 4.G Workshop Manual

Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 571 of 1681

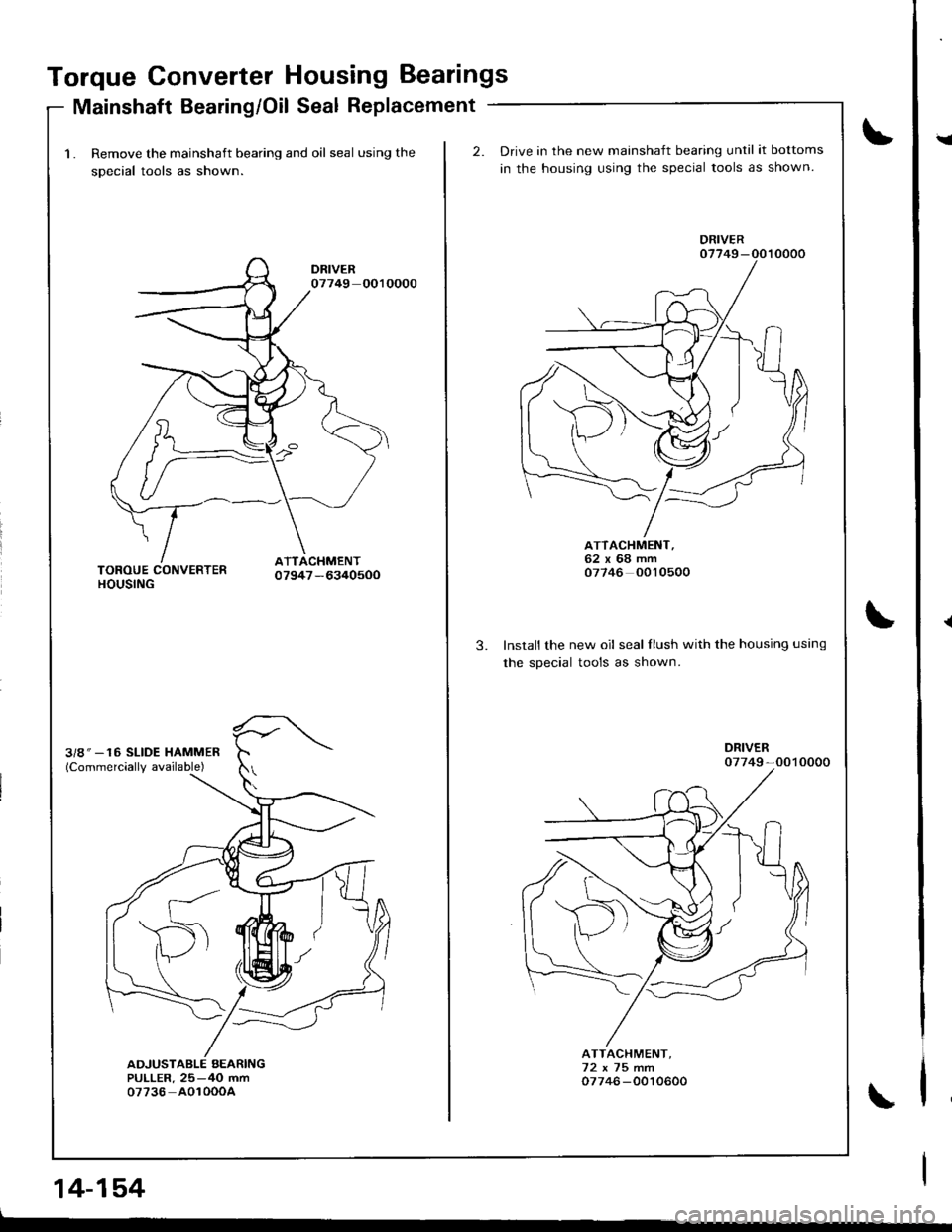

Torque Converter Housing Bearings

Mainshaft Bearing/Oil Seal Replacement

1. Remove the mainshaft bearing and oil seal using the

sDecial tools as shown.

14-154

2.Drive in the new mainshaft bearing until it bottoms

in the housing using the special tools as shown.

3.Install the new oil seal flush with the housing using

the soecial tools as shown.

ATTACHMENT,62x68mm07746 0010500

ATTACHMENT,72x75m.m07746 -0010600

I

Page 572 of 1681

Countershaft Bearing Replacement

\J

J\

\

1. Remove the countershaft bearing using the special

lools as shown.

3/8" 16 SLIDE HAMMER(Commercially available)

ADJUSTAELEBEARINGPULLER,25-40 mm07736 AO1000A

2.

3.

lnstall the ATF guide plate.

Drive the new bearing into the housing using the spe-cial tools as shown.

ATTACHMENT,62x68mm07746-0010500

0 0.03 mml0 -0.001 inl

a

14-155

Page 573 of 1681

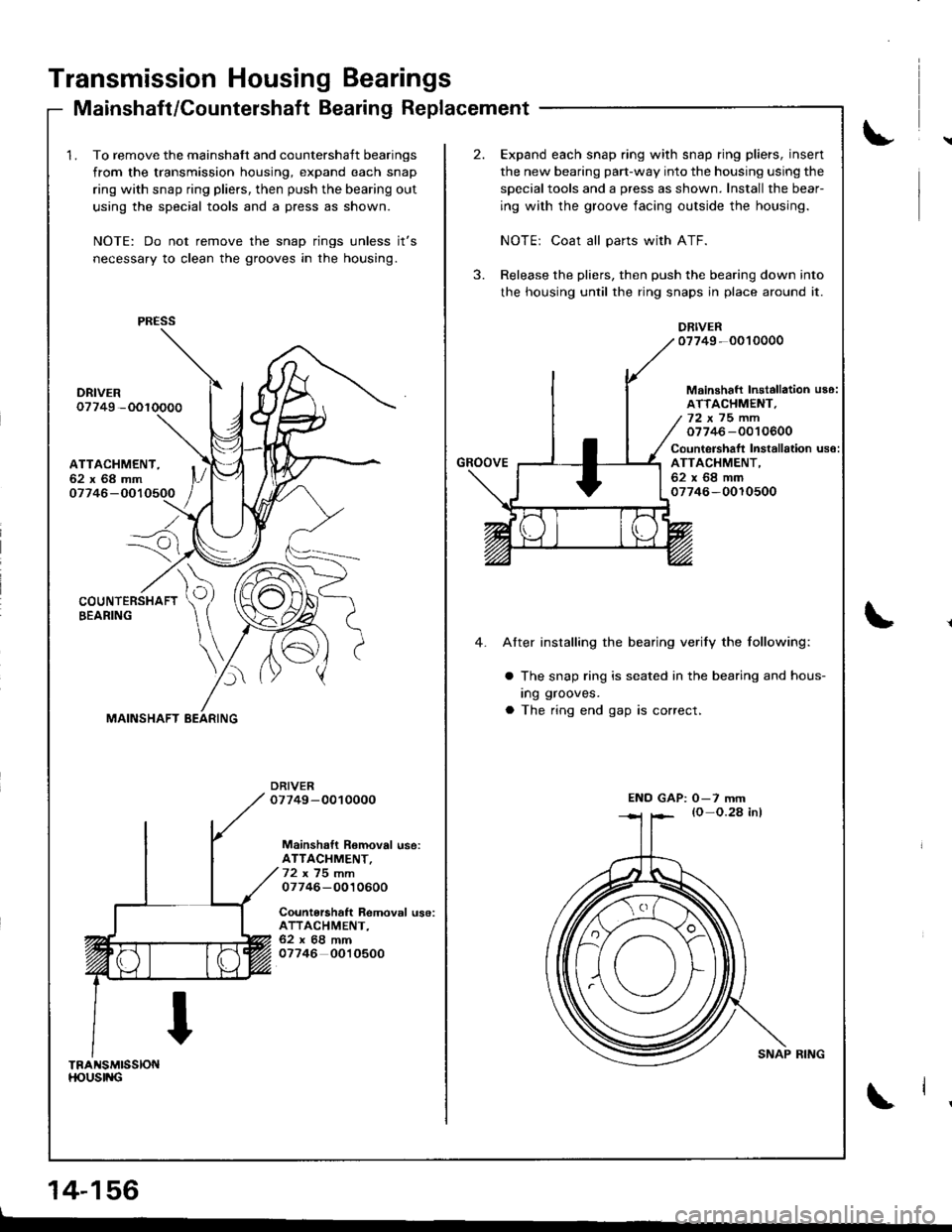

Transmission Housing Bearings

Mainshaft/Countershaft Bearing Replacement

1, To remove the mainshaft and countershaft bearings

from the transmission housing, expand each snap

ring with snap ring pliers, then push the bearing out

using the special tools and a press as shown.

NOTE: Do not remove the snap rings unless it's

necessary to clean the grooves in the housing.

DRIVER07749 -OOrOO00

ATTACHMENT,62x68mm

I07746-OO1

--_-e;

)

Mainshaft Romoval use:ATTACHMENT,

07746-0010600

Countarshaft Removal use:ATTACHMENT,62x68mm07746 0010500

TFAr{SMTSSIONT|oUSING

,,',zs>.\

/qnH

\1b22

PRESS

MAINSHAFT BEARING

2.Expand each snap ring with snap ring pliers, insert

the new bearing part-way into the housing using the

soecialtools and a oress as shown. Install the bear

ing with the groove facing outside the housing.

NOTE: Coat all parts with ATF.

Release the pliers, then push the bearing down into

the housing until the ring snaps in place around it.

DRIVER07749-0010000

Mainshafl Installation u86:ATTACHM€NT.72x75mm07746 -0010600

Countershaft Installation use:ATTACHMENT,62x68mm07746-0010500

GROOVE

4. After installing the bearing verify the following:

a The snap ring is seated in the bearing and hous-

Ing grooves.

a The ring end gap is correct.

SNAP RING

END GAP: O-7 mm

L

14-156

Page 574 of 1681

JI

JI

)

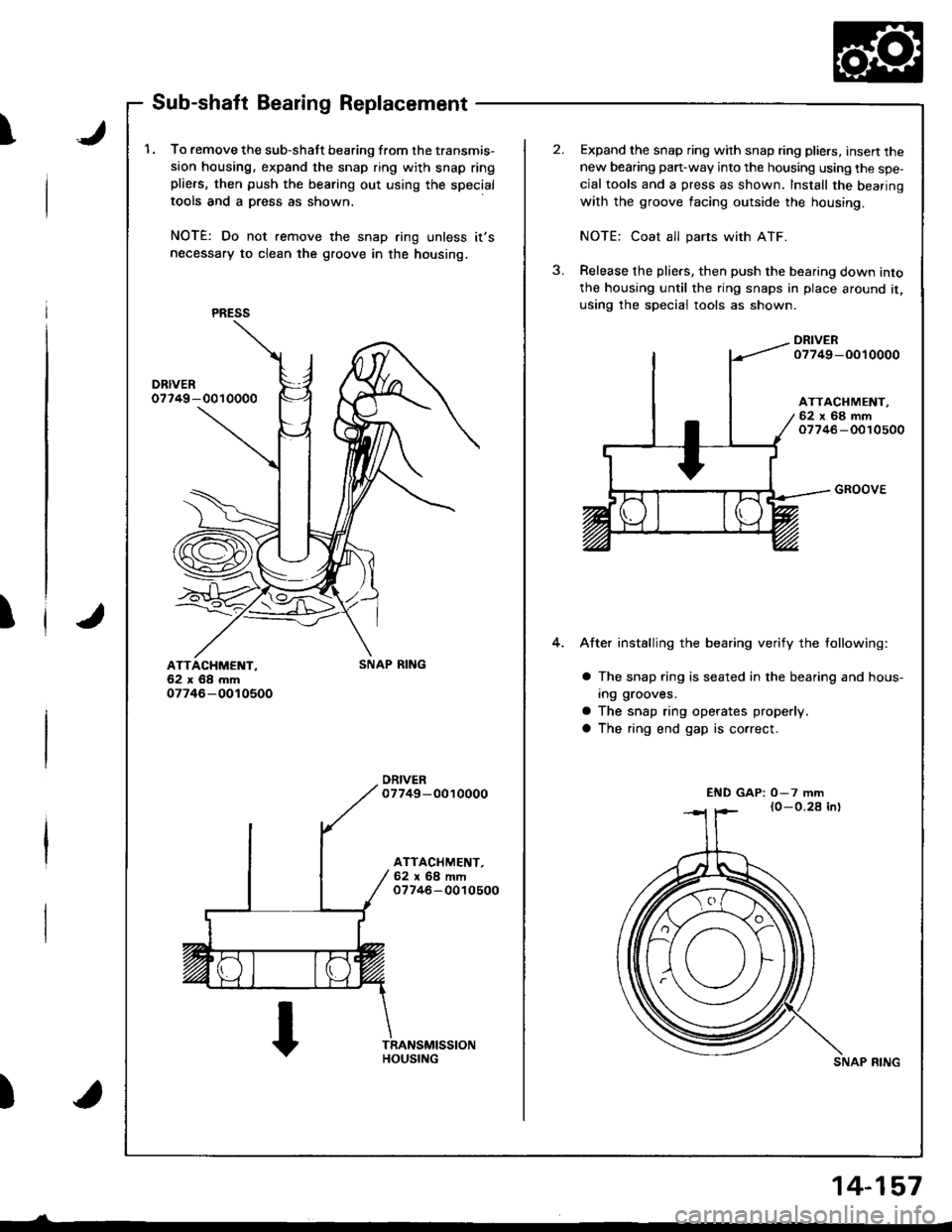

1.To remove the sub-shatt bearing from the transmis-

sion housing, expand the snap ring with snap ringplie.s, then push the bearing out using the special

tools and a Dress as shown.

NOTE: Do not remove the snap ring unless it's

necessary to clean the groove in the housing.

PRESS

ATTACHMENT-62r68mm07746-OOr 0500

SNAP RING

ATTACHMENT-62x68mm07746-0010500

Expand the snap ring with snap ring pliers, insert thenew bearing pan-way into the housing using the spe-cial tools and a press as shown. Install the bearing

with the groove facing outside the housing.

NOTE: Coat all pans with ATF.

Release the plie.s, then push the bearing down into

the housing until the ring snaps in place around it,using the special tools as shown.

DRIVER07749-OOlOO00

ATTACHMENT,62x68mm07746 -0010500

4.

GROOVE

After installing the bearing verify the following:

a The snap ring is seated in the bearing and hous-

ing grooves.

a The snap ring operates properlY

a The ring end gap is correct.

SNAP RING

END GAP: 0-7 mm

t

14-157

Page 575 of 1681

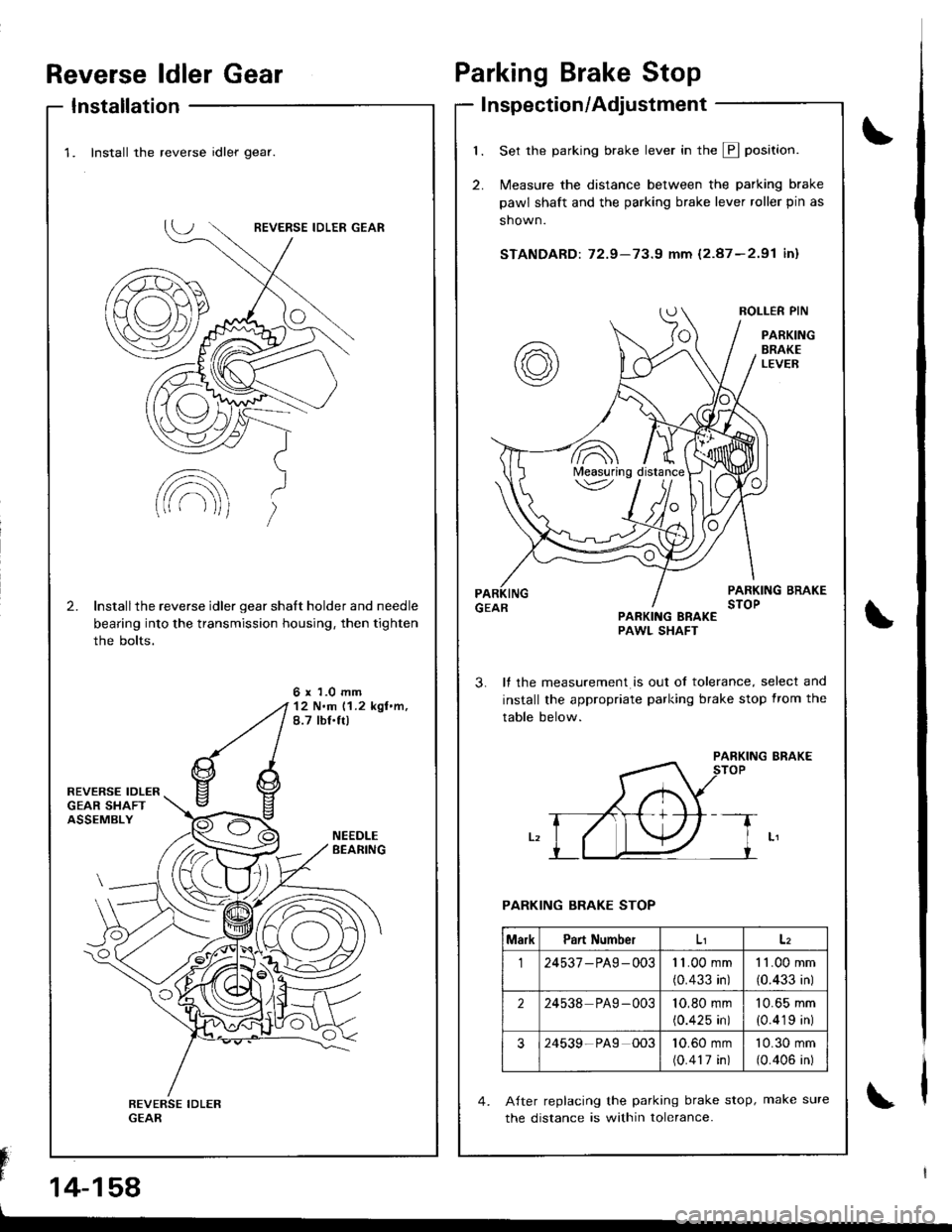

Reverse ldler Gear

Installation

Fn"

14-158

\

\

Parking Brake Stop

I nspection/Adjustment

1.

2.

Set the parking brake lever in the E position.

N4easure the distance between the parking brake

pawl shaft and the parking brake lever roller pin as

shown.

STANDARD: 72.9-73.9 mm (2.87-2.91 in)

ROLI-ER PIN

PARKINGBRAKELEVEB

PARKING BRAKESTOPPARKING BRAKEPAWL SHAFT

It the measurement is out ol tolerance, select and

install the appropriate parl

3.

PARKING ERAKE

PARKING BRAKE STOP

Atter replacing the parking brake stop, make sure

the distance is within tolerance.

'z<"

lvleasuring

MarkPart Number

l24537-PA9-00311.00mm

(0.433 in)

11.00mm

{0.433 in)

224538 PAg -00310,80 mm

{0.425 in)

10.65 mm

{0.419 in)

324539-PA9 00310.60 mm(0.417 in)

10.30 mm(0.406 in)

1. Install the reverse idler gear.

2.Installthe reverse idler gear shalt holder and needle

bearing into the transmission housing, then tighten

the bolts.

6 x 1.0 mm12 N'm 11.2 kgl.m,8.7 tbf.tt)

\

Page 576 of 1681

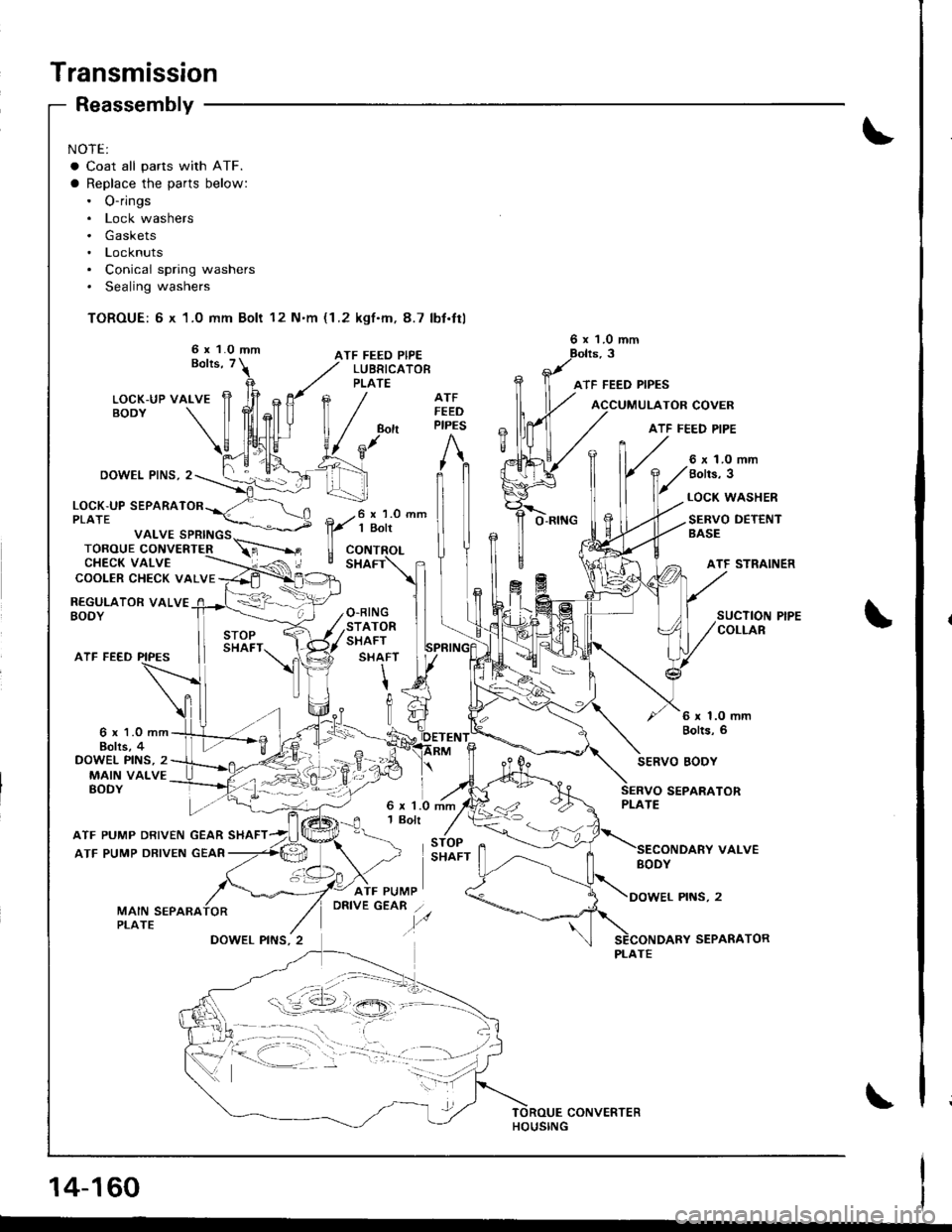

Transmission

NOTE:

a Coat all parts with ATF.

a Replace the parts below:. O-rings. Lock washers. Gaskets. Locknuts. Conical spring washers. Sealing washers

TOROUE: 6 x 1.0 mm Bolt 12 N'm (1.2 kgf.m, 8.7 lbt.ttl

6 x 1.0 mmATF FEED PIPEBolts, T

Reassembly

DOWEL PINS, 2

ATF FEED

LUBRICATOBPLATE

6 x 1.0 mm

ATF FEED PIPES

O.RINGSTATORSHAFT

SHAFT

\tIt]U

ATFFEEDPIPES

STOPSHAFT

6 x 1.0 mmBolts, 6

TOR COVER

ATF FEED PIPE

VALVE SPRINGSTOROUE CONVERTERCHECK VALVECOOLER CHECK VALVE

LOCK-UP SEPARATPLATE

REGULATOR VALVEBODY

6 x 1.0 mm8olls, 3

LOCK WASHER

SERVO DETENTBASE

ATF STRAINER

SUCTION PIPECOLLAR

6 x 1.0 mmBohs, 4DOWEL PINS, 2MAIN VALVEBODY

SERVO EODY

SEPARATOR

VALVE

PINS,2

SEPARATOR

6 x 1.0 mm1 Bolt

ATF PUMP DRIVEN GEAR SHAFT

ATF PUMP DRIVEN GEAR

GEAR /.

.,,o

{--==,.-,,..;;,,, :_ :,_11,

PLATE

14-160

CONVERTER

Page 577 of 1681

)

)

A

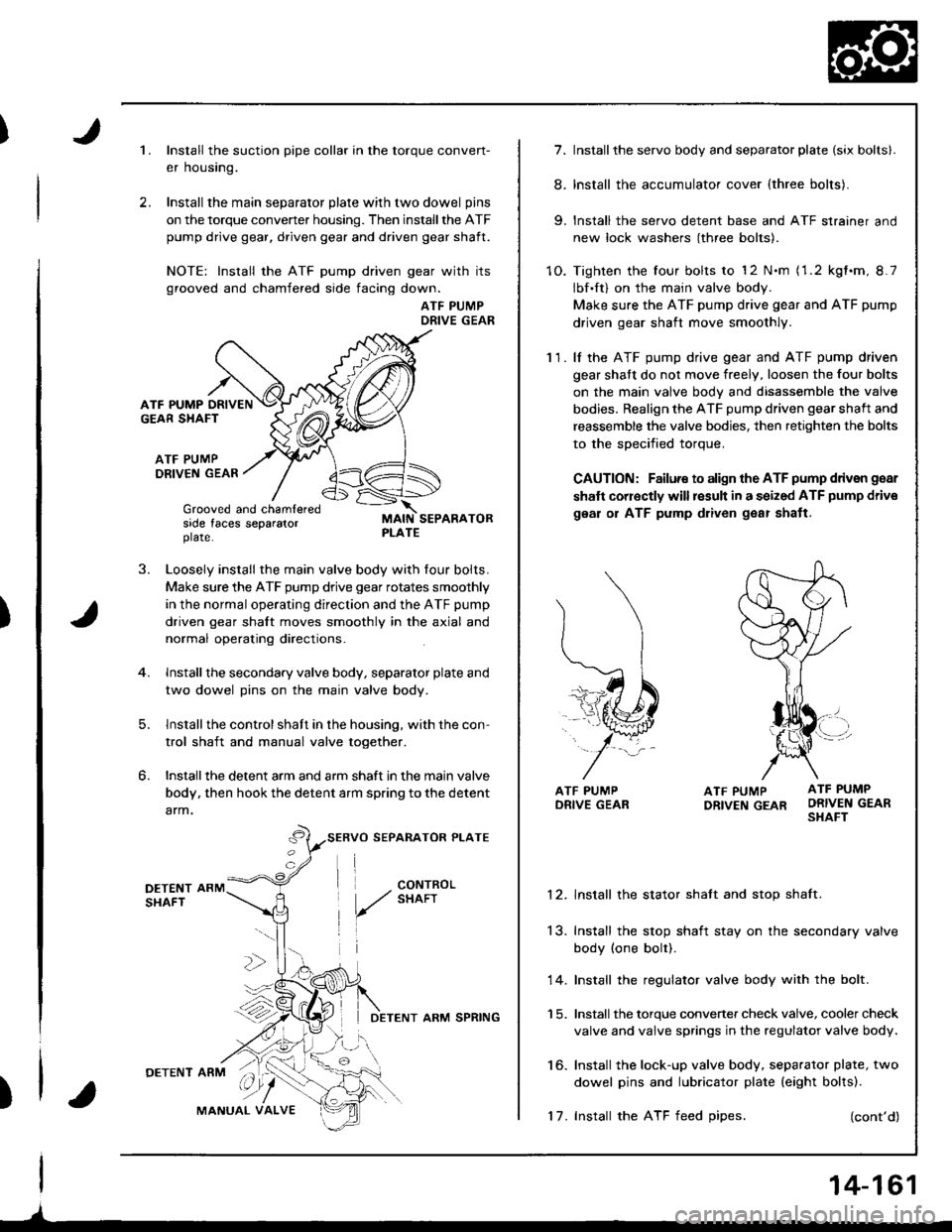

1.

ATF PUMP DRIVENGEAR SHAFT

ATF PUMPDRIV€N GEAR

J.

6

Grooved and ch6mleredside faces separatorplate.

Install the suction pipe collar in the torque conven-

er housing.

Install the main separator plate with two dowel pins

on the torque convener housing. Then install the ATF

pump drive gear, driven gear and driven gear shaft.

NOTE: Install the ATF pump driven gear with its

grooved and chamfered side facing down.

ATF PUMPDRIVE GEAR

Loosely install the main valve body with four bolts.

Make sure the ATF pump drive gear rotates smoothly

in the normal operating direction and the ATF pump

driven gear shalt moves smoothly in the axial and

normal operating directions.

Install the secondary valve body, separator plate and

two dowel pins on the main valve body.

lnstallthe control shaft in the housing, with the con-

trol shaft and manual valve together.

Installthe detent arm and arm shaft in the main valve

body, then hook the detent arm spring to the detent

arm.

SERVO SEPARATOR PLATE

I

DETENT ARM SPRING

'17. Install the ATF feed oipes.

14-161

7. Install the servo body and separator plate (six bolts|.

8. Install the accumulator cover (three bolts).

9. Install the servo detent base and ATF strainer and

new lock washers (three bolts).

1O. Tighten the four bolts to '12 N.m (1.2 kgt.m, 8.7

Ibf.ft) on the main valve body.

Make sure the ATF pump drive gear and ATF pump

driven gear shaft move smoothly.

11. lf the ATF pump drive gear and ATF pump driven

gear shaft do not move freely, loosen the four bolts

on the main valve bodv and disassemble the valve

bodies. Realign the ATF pump driven gear shaft and

reassemble the valve bodies, then retighten the bolts

to the soecified toroue.

CAUTION: Failure to align the ATF pump ddven gear

shaft corr€ctly will result in a seized ATF pump driv€

gear or ATF pump dliven g€ar shatt,

ATF PUMP ATF PUMP

DRtvEN GEAR ORIVEN GEARSHAFT

12. lnstall the stator shatt and stop shaft.

13. Inslall the stop shaft stay on the secondary valve

body (one bolt).

14. Install the regulator valve body with the bolt.

1 5. Install the torque converter check valve, cooler check

valve and valve springs in the regulator valve body.

16. Install the lock-up valve body, separator plate, two

dowel pins and lubricator plate (eight bolts).

(cont'd)

Page 578 of 1681

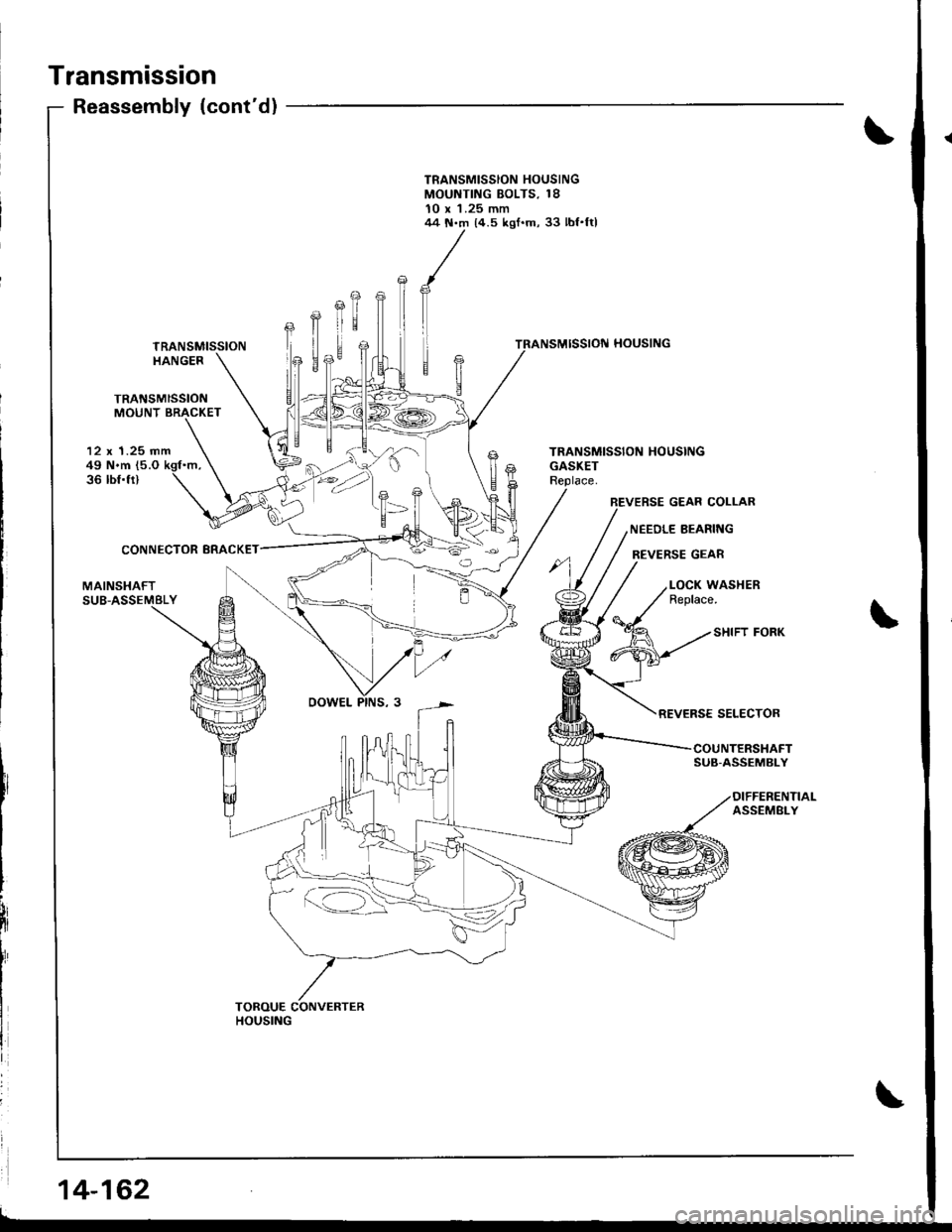

Transmission

TRANSMISSIONMOUNT BRACKET

Reassembly (cont'd)

TRANSMISSIONHANGER

Efr

E

12 x 1.25 mm49 N.m (5.O

36 tbf.fr)

CONNECTOR BRACKET

NEEDLE BEARII{G

REVERSE GEAR

MAINSHAFT

SHIFT FORK

REVERSE SELECTOR

SUB-ASSEMBLY

14-162

r=-42

TOROUE CONVERTERHOUSING

TRANSMISSION HOUSINGMOUNTING BOLTS, 1810 x 'l.25 mm44 N.m 14.5 kgf.m, 33 lbf.ftl

TRANSMISSION HOUSINGGASKET

BEVERSE GEAR COLLAR

LOCK WASHERReplace.

I

Page 579 of 1681

![HONDA INTEGRA 1998 4.G Workshop Manual 18. Install the sub-shaft assembly in the transmission

housing {see page 14-142],.

19. Install the reverse idler gear and gear shaft holder(see page 14-158).

20. Install the differential assembly in HONDA INTEGRA 1998 4.G Workshop Manual 18. Install the sub-shaft assembly in the transmission

housing {see page 14-142],.

19. Install the reverse idler gear and gear shaft holder(see page 14-158).

20. Install the differential assembly in](/img/13/6069/w960_6069-578.png)

18. Install the sub-shaft assembly in the transmission

housing {see page 14-142],.

'19. Install the reverse idler gear and gear shaft holder(see page 14-158).

20. Install the differential assembly in the torque con

verter housrng.

21. Assemble the mainshaft and countershaft sub-

assembly, then install them together in the torque

converler noustng.

22. Turn the shilt fork so the large chamlered hole is fac-

ing the fork bolt hole, then installthe shift tork with

the reverse selector and torque the lock bolt. Bend

the lock tab against the bolt head.

SHIFT FORK

23. Install the reverse gear with the collar and needte

bearing on the countershaft.

24. Align the spring pin of the control shaft with the

transmission housing groove by turning the control

shaft.

25. Place the transmission housing on the torque con-

verter housing with a new gasket and the three

dowel pins.

CONTROL

TRANSMISSION HOUSING

lnstall the transmission housing mounting bolts along

with the transmission hanger and the connector

bracket, then torque the bolts in two or more steps

in the sequence shown.

TOROUE: rt4 N'm (4.5 kgt.m, 33 lbt.lt)

TRANSMISSION

26.

LOCK WASHERReplace.

6 x 1.0 mm4 t{.m(1.4 kgf.m, 10

e

Large chamfered hole

/ -'K\,,

a

14-163

Page 580 of 1681

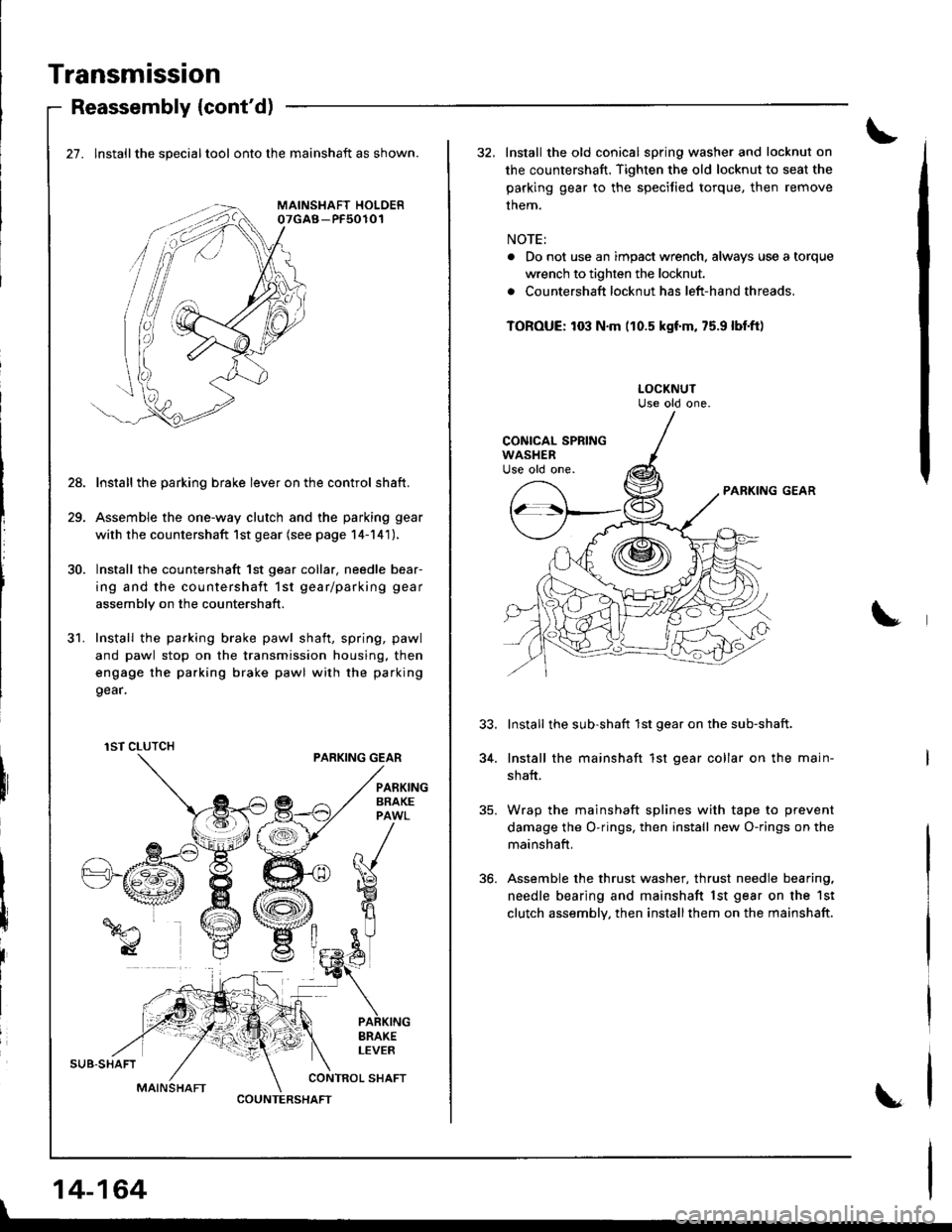

Transmission

SUB.SHAFT

MAINSHAFT

Reassembly {cont'd)

27. lnstallthe specialtool onto the mainshaft as shown.

Install the parking brake lever on the control shaft.

Assemble the one-way clutch and the parking gear

with the countershaft 1st gear (see page 14-141),

Install the countershaft 1st gear collar. needle bear-

ing and the countershaft 1st gear/parking gear

assembly on the countershaft.

Install the parking brake pawl shaft, spring, pawl

and pawl stop on the transmission housing. then

engage the parking brake pawl with the parking

9ear.

PARKING GEAR

28.

31.

I

I

iIBRAKELEVER

CONTROL SHAFT

1ST CLUTCH

COUNTERSHAFT

|

14-164

32, Install the old conical spring washer and locknut on

the countershaft. Tighten the old locknut to seat the

parking gear to the speciJied torque, then remove

them.

NOTE:

. Do not use an impact wrench, always use a torque

wrench to tighten the locknut.

. Countershaft locknut has left-hand threads,

TOROUE: to3 N.m (10.5 kgf'm, 75.9 lbl.ft)

PARKING GEAR

Install the sub-shaft 1st gear on the sub-shaft.

Install the mainshaft 1st gear collar on the main-

shaft.

Wrap the mainshaft splines with tape to prevent

damage the O-rings, then install new O-rings on the

mainshaft,

Assemble the thrust washer, thrust needle bearing,

needle bearing and mainshaft lst gear on the 1st

clutch assembly, then installthem on the mainshaft.

34.