HONDA INTEGRA 1998 4.G Workshop Manual

Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 581 of 1681

)37.

38.

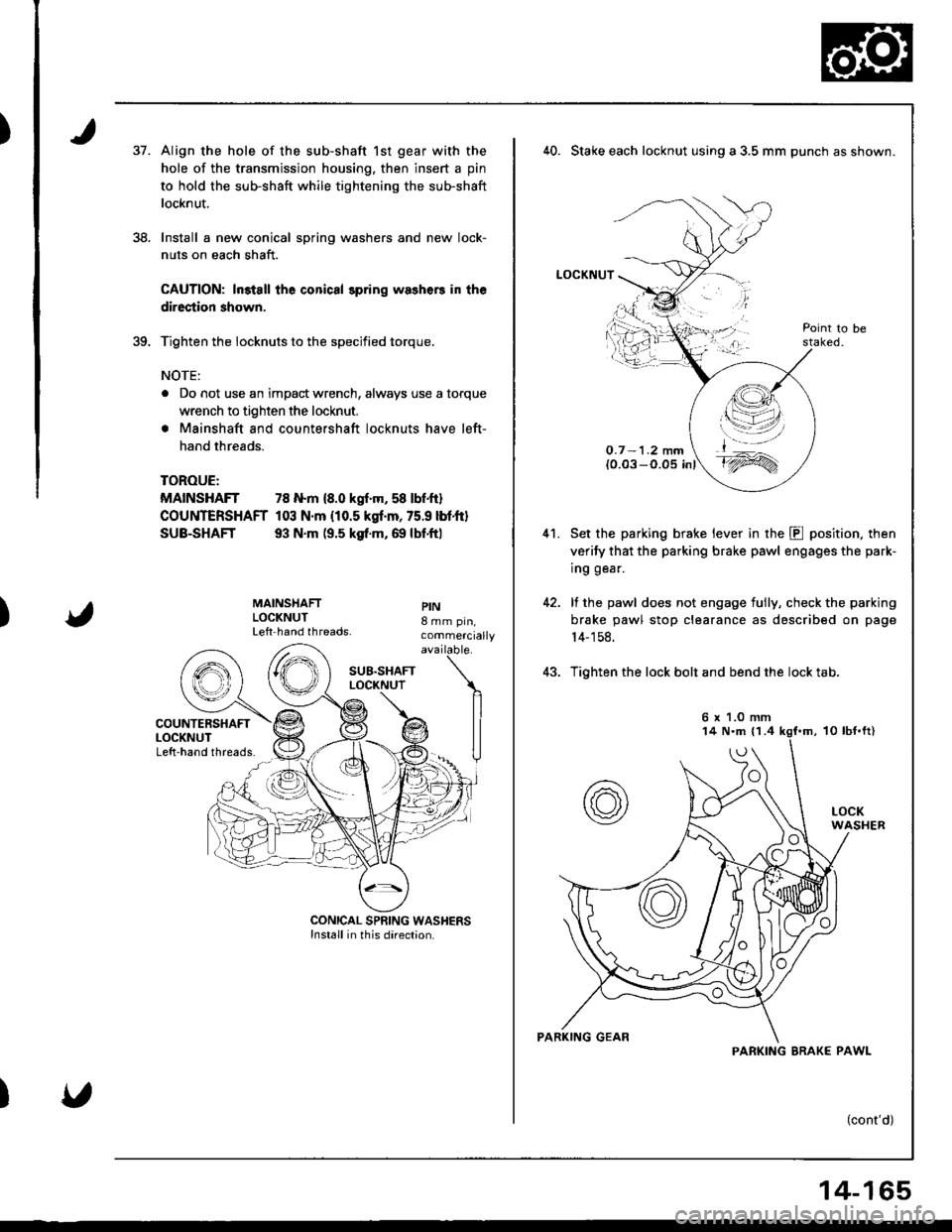

Align the hole of the sub-shaft 1st gear with the

hole of the transmission housing. then insert a pin

to hold the sub-shaft while tightening the sub-shaft

locknut.

Install a new conical spring washers and new lock-

nuts on each shaft.

CAUTION: ln3tall the conical spring washers in the

direction shown.

Tighten the iocknuts to the specified torque.

NOTE:

a Do not use an impact wrench, always use a torque

wrench to tighten the locknut.

. Mainshaft and countershaft locknuts have left-

hand threads.

TOROUE:

MAINSHAFT 78 N.m {8.0 kgf.m, 58 lbf.ft}

COUNTERSHAFT 103 N.m {10.5 kgf.m, 75.9 lbtft}

SUB-SHAFT 93 N.m (9.5 ksf.m, 69 lbf.ftl

)

MAINSHAFTLOCKNUTLeft hand threads.

PIN8 mm pin,commercially

40. Stake each locknut using a 3,5 mm punch as shown.

LOCKNUT

O.7 -1.2 mm(0.03 -O.05 inl

Set the parking brake lever in the E position. then

verify that the parking brake pawl engages the park-

ing gear.

lf the pawl does not engage tully, check the parking

brake pawl stop clearance as described on page

14- 1 58.

Tighten the lock bolt and bend the lock tab.

(cont'd)

41.

t,\--l--'-,4 l';-.-='/

t_^

t'1ry

6 x 1.0 mm

PARKING BRAK€ PAWL

14-165

Page 582 of 1681

Transmission

Reassembly lcont'd)

41.

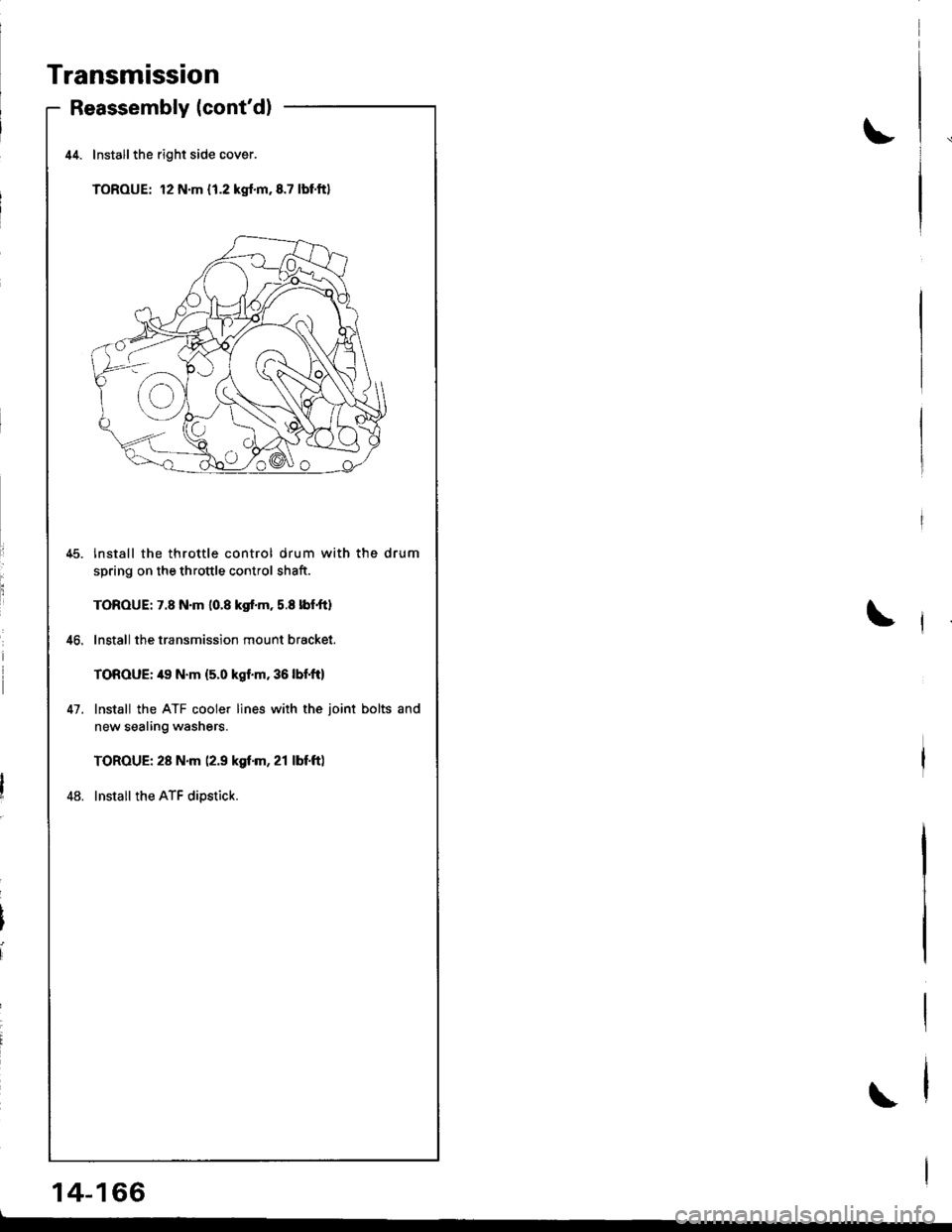

Installthe right side cover.

TOROUE: 12 N.m { 1.2 kgf.m,8.7 lbtft}

lnstall the throttle control drum with the drum

spring on the throttle control shaft.

TOROUE: 7.8 N.m 10.8 kgf.m, 5.8 lbf,ftl

Install the transmission mount bracket.

TOROUE: 49 N.m {5.0 kgf.m,36lbf,ft)

Install the ATF cooler lines with the joint bolts and

new sealing washers.

TOROUE: 28 N.m (2.9 kgf.m, 21 lbf.ft)

Install the ATF dipstick.

\

\

14-166

\

Page 583 of 1681

)

)

)

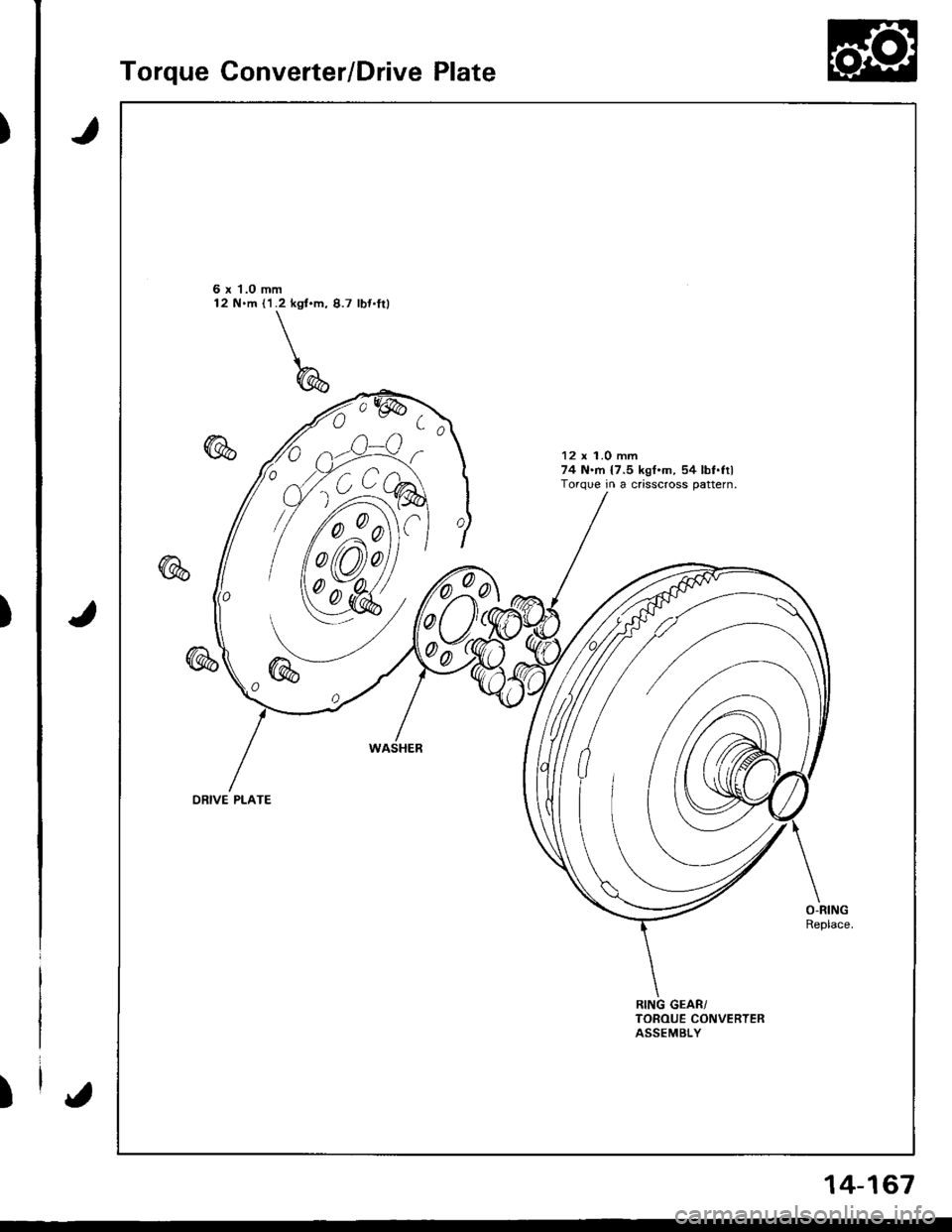

Torque Converter/Drive Plate

J

J

6 x 1.0 mm12 N.m ('l.2 kgt.m, 8.7 lbt.fil

12 x 1.0 mm74 N.rn {7.5 kgf.m, 54 lbf.filTorque in a crisscross pattern.

0

00

ORIVE PLATE

{

14-167

Page 584 of 1681

Transmission

lnstallation

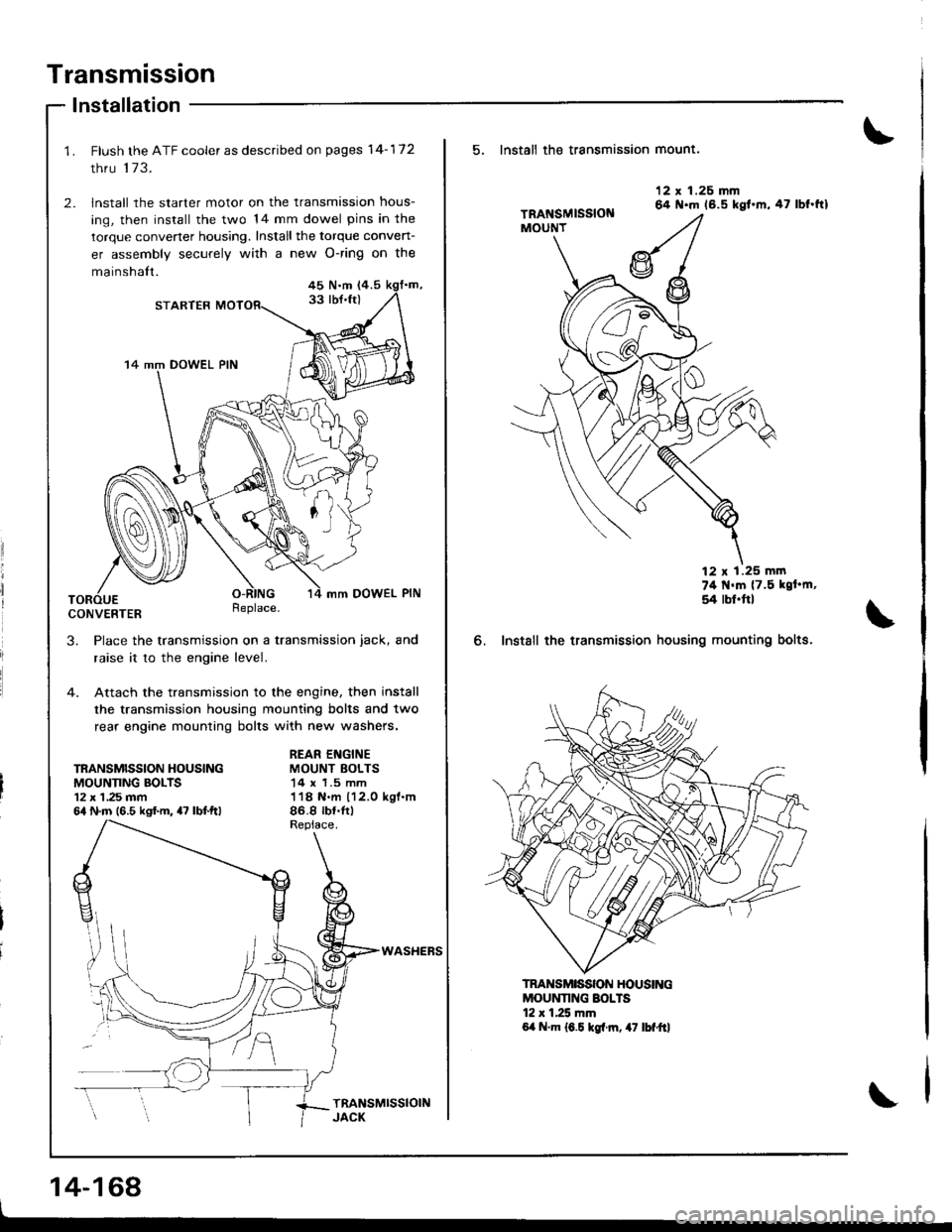

Flush the ATF cooler as described on pages 14-172

thru 173.

lnstall the starter motor on the transmission hous-

ing, then install the two 14 mm dowel pins in the

torque convener housing. Install the torque conven-

er assembly securely with a new O-ring on the

mainshalt.45 N.m (4.5

33 lbJ.ft)STARTER

14 mm DOWEL PIN

mm DOWEL PIN

CONVERTERReplace.

3. Place the transmission on a transmission jack, and

raise it to the engine level.

4. Attach the transmission to the engine, then install

the transmission housing mounting bolts and two

rear engine mounting bolts with new washers.

TRANSMISSION HOUSINGMOUNNNG BOLTS12 x 1 ,25 mm64 N.m (6.5 kgf.m, 47 lbf.ftl

REAR ENGINEMOUNT BOLTS14 x 1.5 mm118 N.m 112.0 kgl.m86.8 rb{.tr)

WASHEFS

14-168

5. Install th€ transmission mount.

6. Instsll the transmission

12 x 1.26 mm64 N.m 16.5 kgt.m,47 lbf.ftl

74 t{'m {7.5 kgt'm,

54 rbl.ftl

housing mounting bolts.

MOUNNNG SOLTS12 r 1.25 mm6,t N.m 16.5 kgl.rn, 47 lbf"ftl

TRANSMISSON HOUSING

Page 585 of 1681

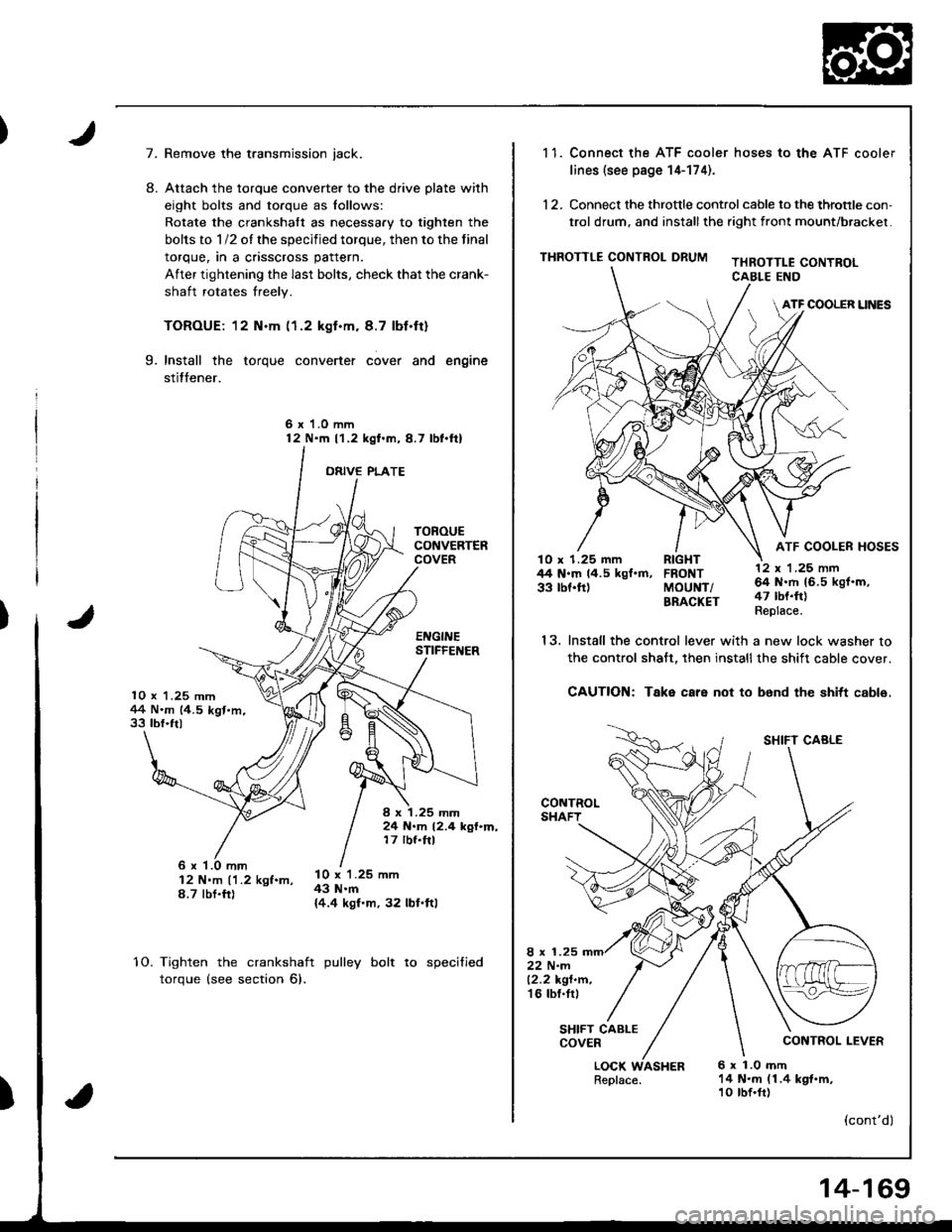

7.

10 x 1.25 mm1+4 N.m (4.5 kgt.m,33 tbf.ft)

TOROUECONVERTERCOVER

EI{GINESTIFFEI{ER

I x 1.25 mm24 N.m 12.4 kgf.m,17 rbf.ftl

8.

Remove the transmission jack.

Attach the torque converter to the drive plate with

eight bolts and torque as lollows:

Rotate the crankshatt as necessary to tighten the

bolts to 1/2 of the specified torque, then to the final

torque, in a crisscross pattern.

After tightening the last bolts, check that the crank-

shaft rotates freely.

TOROUE: 12 N.m (1.2 kgf.m. 8.7 lbf.ft)

Install the torque converter cover and engine

stitfener.

6 x 1.0 mm12 N'm l'1.2 kgl.m,8.7 lbl.ftl

ORIVE PLATE

9.

6 x '1.0 mm12 N'm ('1.2 kgf.m,8.7 tbt.fr)

l0 x 1.25 mm43 N.m{4.4 kgf.m, 32 lbl.ftl

10.Tighten the crankshaft

torque (see section 6).

pulley bolt to specified

)

1 1. Connect the ATF cooler hoses to the ATF cooler

lines (see page 14-174).

12. Connect the throttle control cable to the throtrle con,

trol drum, and installthe right front mount/brackel.

THROTTLE CONTROL DRUMTHROTTLE CONTROLCABLE END

ATF COOLER UNES

ATF COOLER HOSESlO x 1.25 mm RIGHT44 N.m 14.5 kgf.m, FRONT33 tbf.ft) MoUNT/BRACKET

13.

LOCK WASHERReplace.6 x 1.0 mft14 N.m (1.4 kgt.m,10 tbf.fr)

12 x 'l ,25 nn64 N.rh 16.5 kgf.m,47 tbt.ft)Replace.

SHIFT CABLE

CONTROL LEVER

(cont'dl

Install the control lever with a new lock washer to

the control shalt, then installthe shift cable cover.

CAUTION: Take care not to b6nd the shitt cable.

8 x 1.2522 N-m12.2 kgt.n.'t6 tbl.tr,

SHIFT CABLECOVER

14-169

Page 586 of 1681

Transmission

Installation (cont'd)

to.

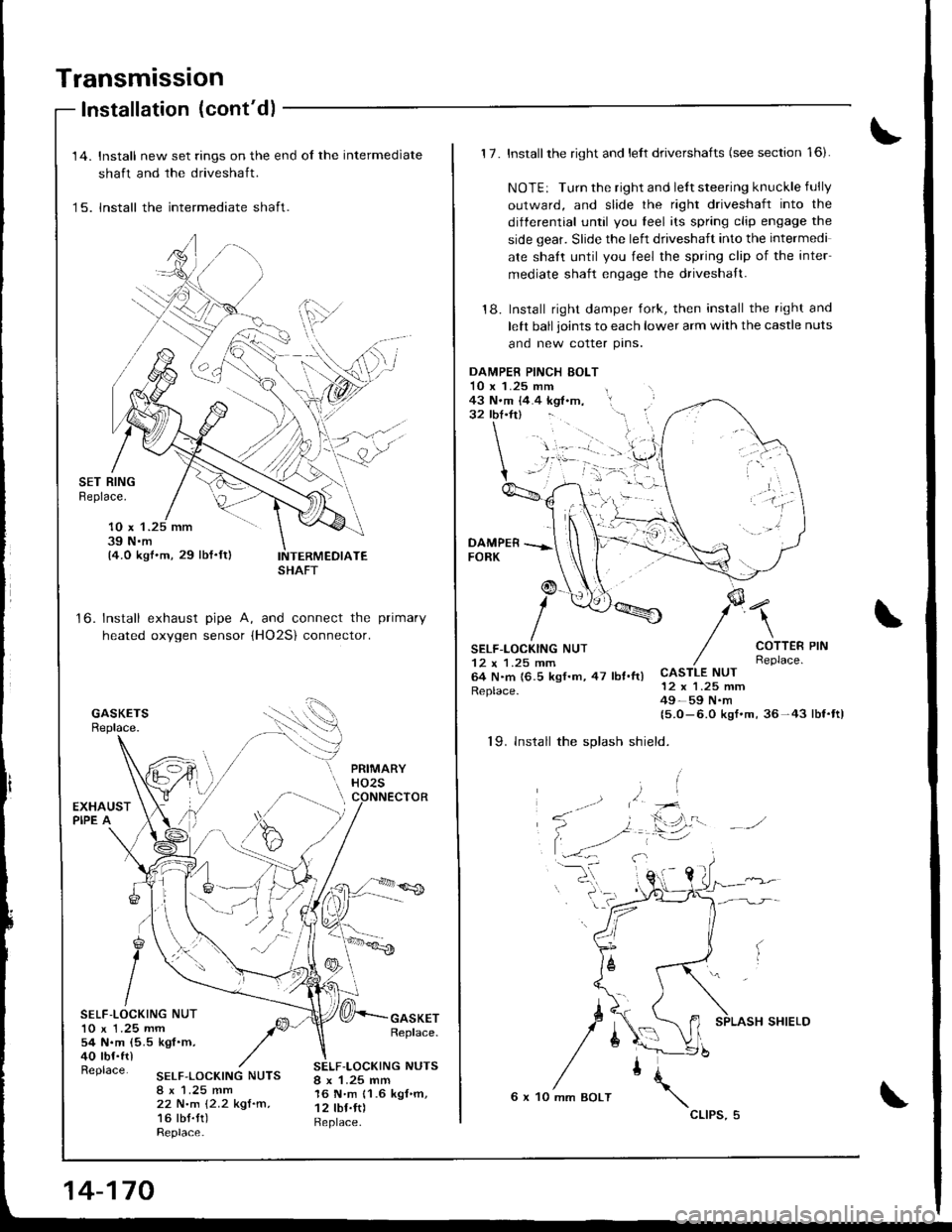

'14. Install new set rings on the end ol the intermediate

shaft and the driveshaft.

'15. lnstall the intermediate shaft.

SET RINGBeplace.

10 x 139 N.m14.0 kgf.m, 29 lbf.ft)

Install exhaust pipe A, and connect the primary

heated oxygen sensor (HO2S) connector.

g

ISELF-LOCKING NUT10 x 1.25 mm54 N.m (5.5 kgf.m,40 tbf.frlReplace.

GASKETReplace.

SELF,LOCKING NUTS8 x 1.25 mm22 N.m {2.2 kgf.m,16 tbt.tt)Replace.

SELF-LOCKING NUTS8 x 1.25 mm16 N'm 11.6 kgf.m,12 tbf.ft)Replace.

SHAFT

14-170

6 x 10 mm BOLT

cllPs,5

1 7. Install the right and lelt drivershafts (see section '16).

NOTE: Turn the right and le{t steering knuckle fully

outward, and slide the right driveshaft into the

differential until you leel its spring clip engage the

side gear. Slide the left driveshaft into the intermedi

ate shaft until you feel the spring clip of the inter

mediate shaft engage the driveshaft.

'18. Install right damper fork, then insrall the right and

lett ball joints to each lower arm with the castle nuts

and new cotter prns.

\

COTTERReplace.CASTLE NUT12 x 1.25 mm49-59 N.m15.0- 6.0 kgf.m,36-43 lbl.tt)

19. lnstall the splash shield.

DAMPEB PINCH EOLT10 x 1.25 mm43 N.m {4.4 kgf .m, l.32 lb{.tr} - '- i

:'g

SELF-LOCKING NUT12 x 1.25 mm64 N.m {6.5 kgf.m,47 lbt.ftlReplace.

PIN

SHIELD

Page 587 of 1681

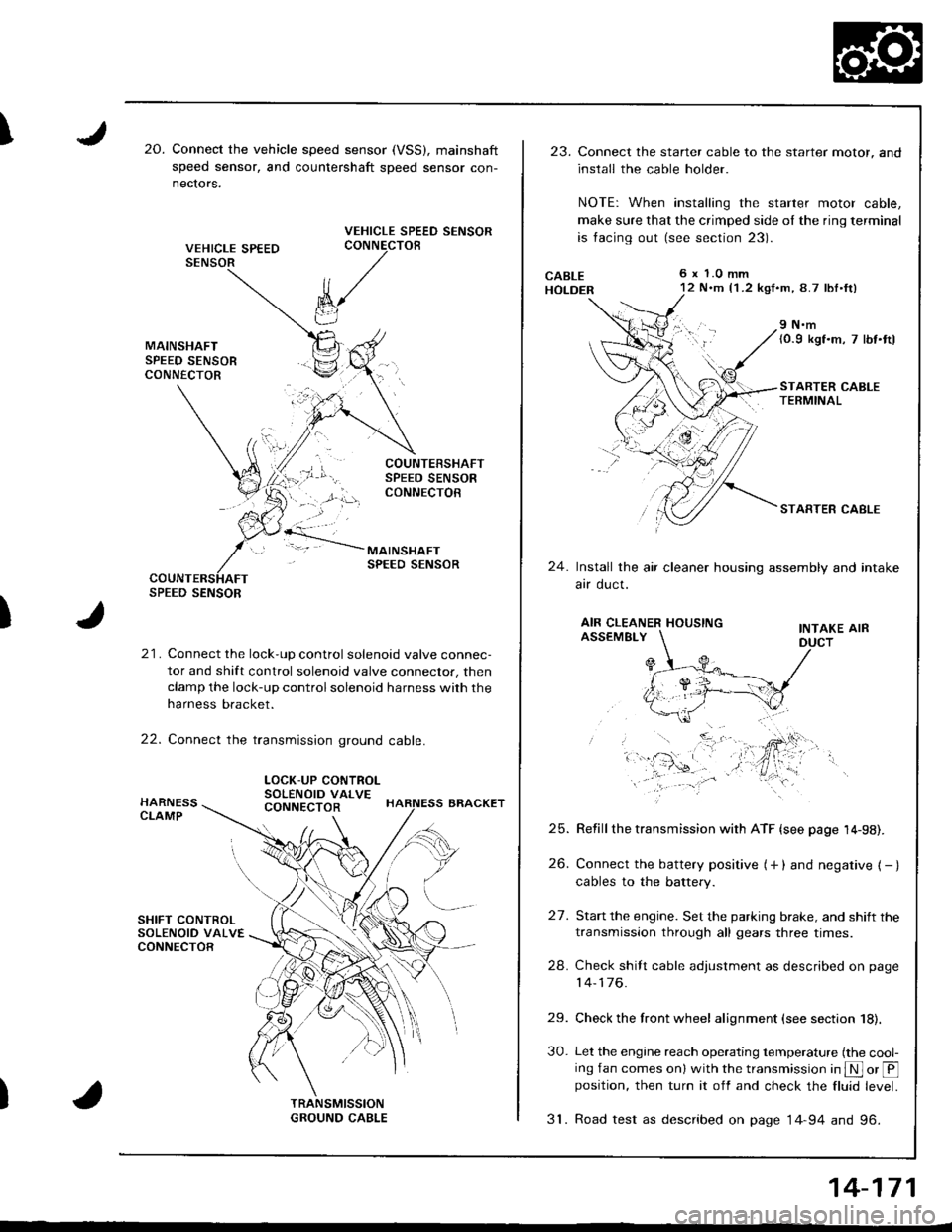

I20.Connect the vehicle speed sensor (VSS), mainshaft

speed sensor, and countershaft sDeed sensor con-

nectors.

VEHICLE SPEED SENSORCONNECTOB

)

k/

t"J

21. Connect the lock-up control solenoid valve connec-

tor and shift control solenoid valve conneclor, then

clamp the lock-up control solenoid harness with the

harness bracket.

22. Connect the transmission ground cable.

SPEED SENSOR

LOCK-UP CONTROLSOLENOID VALVECONNECTOR

23.Connect the starter cable to the starter motor, and

install the cable holder.

NOTE: When installing the starter motor cable,

make sure that the crimped side ol the ring terminal

is facing out (see section 23).

6 x 1.0 mm12 N.m {1 .2 kgf.m, 8.7 lbl.ft)

9 N.m(0.9 kgf.m, 7 lbt.ttl

STARTER CABLETERMINAL

STARTER CABLE

24.Install the air cleaner housing assembly and intake

arr oucl.

AIR CLEANER HOUSINGINTAKE AIRASSEMBLY

27.

Refill the transmission with ATF {see page 14-98).

Connect the battery positive (+ ) and negative { - }cables to the battery.

Start the engine. Set the parking brake, and shift the

transmission through all gears three times.

Check shilt cable adjustment as described on page

14-176.

Check the front wheel alignment (see section 18).

Let the engine reach operating temperature (the cool-ing fan comes onl with the transmission in S or @position, then turn it off and check the fluid level.

31. Road test as described on page 14-94 and 96.

25.

26.

24.

29.

30.

14-171

Page 588 of 1681

Transmission

Cooler Flushing

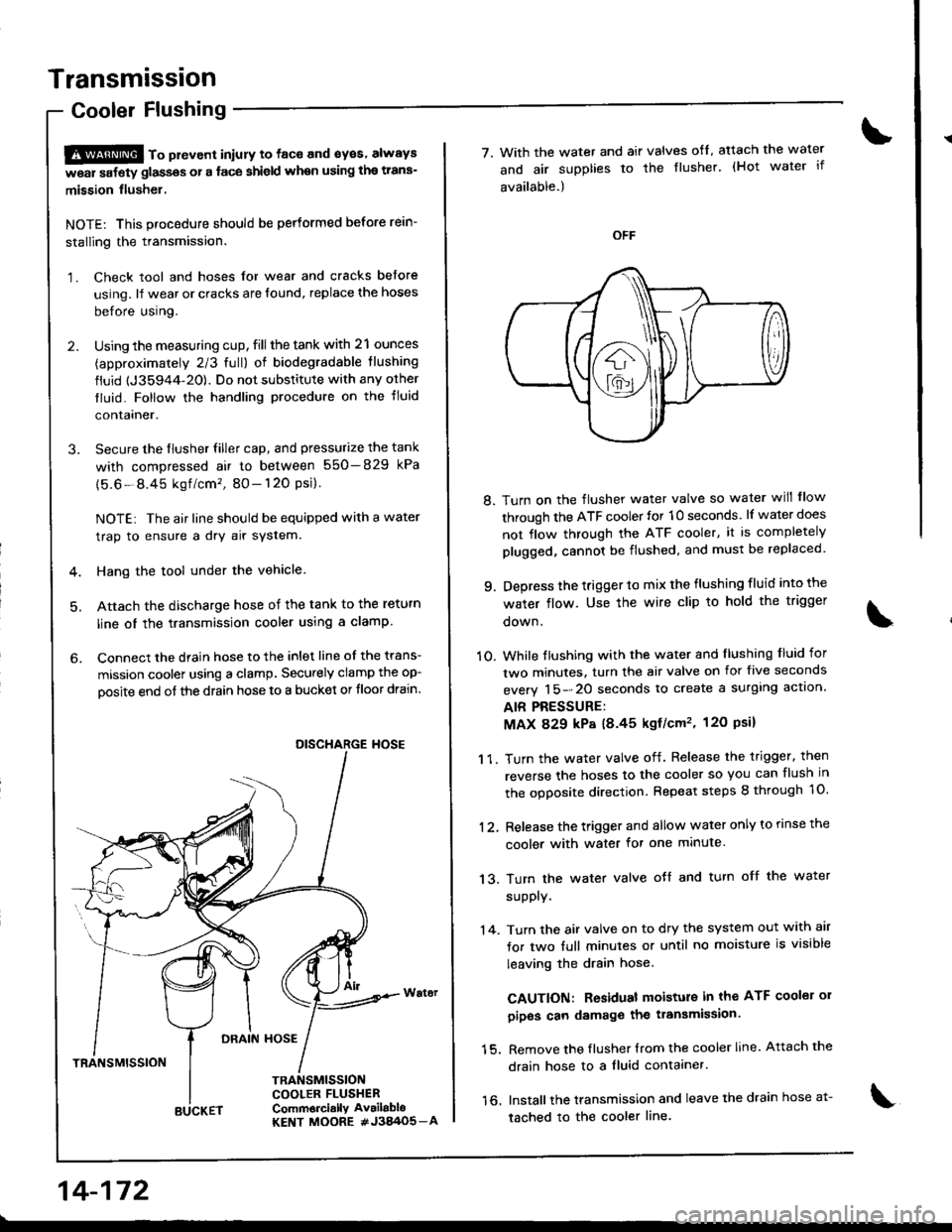

S@ to pttvont iniury to face and syes' always

w6ar safety glassos or a face shield when using the trans-

mission flusher.

NOTE: This procedure should be performed before rein-

stalling the transmission.

1. Check tool and hoses for wear and cracks before

using. lf wear or cracks are found, replace the hoses

before using.

2. Using the measuring cup, fill the tank with 21 ounces

(approximately 2/3 full) of biodegradable tlushing

fluid {J35944-20). Do not substitute with any orher

tluid. Follow the handling procedure on the tluid

contalner.

3. Secure the flusher filler cap, and pressurize the tank

with compressed air to between 550-829 kPa

{5.6-8.45 kgf /cm'�, 80- 120 Psi}.

NOTE: The air line should be equipped with a water

trap to ensure a dry air system.

4. Hang the tool under the vehicle

5. Attach the discharge hose of the tank to the return

line oI the transmission cooler using a clamp

6. Connect the drain hose to the inlet line of the trans-

mission coolel using a clamp. Securely clamp the op-

oosite end of the drain hose to a bucket or tloor drain.

DRAIN HOSE

TRANSMISSION

TRANSMISSIONCOOLER FLUSHERComm6rci.llY Av.ilabloKENT MOORE #J3A/O5_A

DISCHARGE HOSE

14-172

BUCKET

7. With the water and air valves ofl, atach the water

and air supplies to the flusher. (Hot water if

available.)

8. Turn on the flusher water valve so water will flow

through the ATF cooler for 10 seconds. lf water does

not flow through the ATF cooler, it is completely

plugged, cannot be flushed, and must be replaced

9. Depress the trigger to mix the flushing fluid into the

water flow. Use the wire clip to hold the trigger

oown.

1O. While tlushing with the water and llushing f luid for

two minutes. turn the air valve on for five seconds

everv 15-20 seconds to create a surglng actlon.

AIR PRESSURE:

MAX 829 kP8 18.45 kgf/cm'�, 120 Psil

1 1. Turn the water valve off. Release the trigger. then

reverse the hoses to the cooler so you can flush in

the ooDosite direction. Repeat steps 8 through 1O.

12, Release the trigger and allow water only to rinse the

cooler with water for one minute.

13. Turn the water valve oJf and turn off the water

supply.

'14. Turn the air valve on to dry the system out with air

for two full minutes or until no moisture is visible

leaving the drain hose.

CAUTION: Residual moisture in the ATF coolei 01

pipos can damage the transmission.

15. Remove the flusher {rom the cooler line. Attach the

drain hose to a fluid contaaner.

16. Installthe transmission and leave the drain hose a1-

tached to the cooler line.

Page 589 of 1681

![HONDA INTEGRA 1998 4.G Workshop Manual 17. Make sure the transmission is in E] position.

Fill the transmission with ATF, and run the engineJor 30 seconds or until approximately one quart isdischarged.

18. Remove the drain hose, and reconn HONDA INTEGRA 1998 4.G Workshop Manual 17. Make sure the transmission is in E] position.

Fill the transmission with ATF, and run the engineJor 30 seconds or until approximately one quart isdischarged.

18. Remove the drain hose, and reconn](/img/13/6069/w960_6069-588.png)

17. Make sure the transmission is in E] position.

Fill the transmission with ATF, and run the engineJor 30 seconds or until approximately one quart isdischarged.

'18. Remove the drain hose, and reconnect the coolerreturn hose to the transmission.

19. Refillthe tiansmission with ATF to the propef level.

FILLER CAP

TOOL MAINTENANCE

1. Empty and rinse after each use. Fill the can withwater and pressurize the can. Flush the dischargeline to ensure that the unit is clean.

2. lf discharge liquid does not foam, the orifice may beblocked.

3, To clean, disconnect the plumbing from the tank atthe large coupling nut,

4. Remove the in-line filter trom the discharge side andclean if necessary.

5. The fluid oritice is located behind the filter.

Clean it with the pick stored in the bottom of the tankhandle or blow it clean with air. Securely reassem-

ble all parts.

COUPLING NUT

FILTER

\

IO-RINGORIFICE

14-173

Page 590 of 1681

ATF Cooler Hoses

Connection

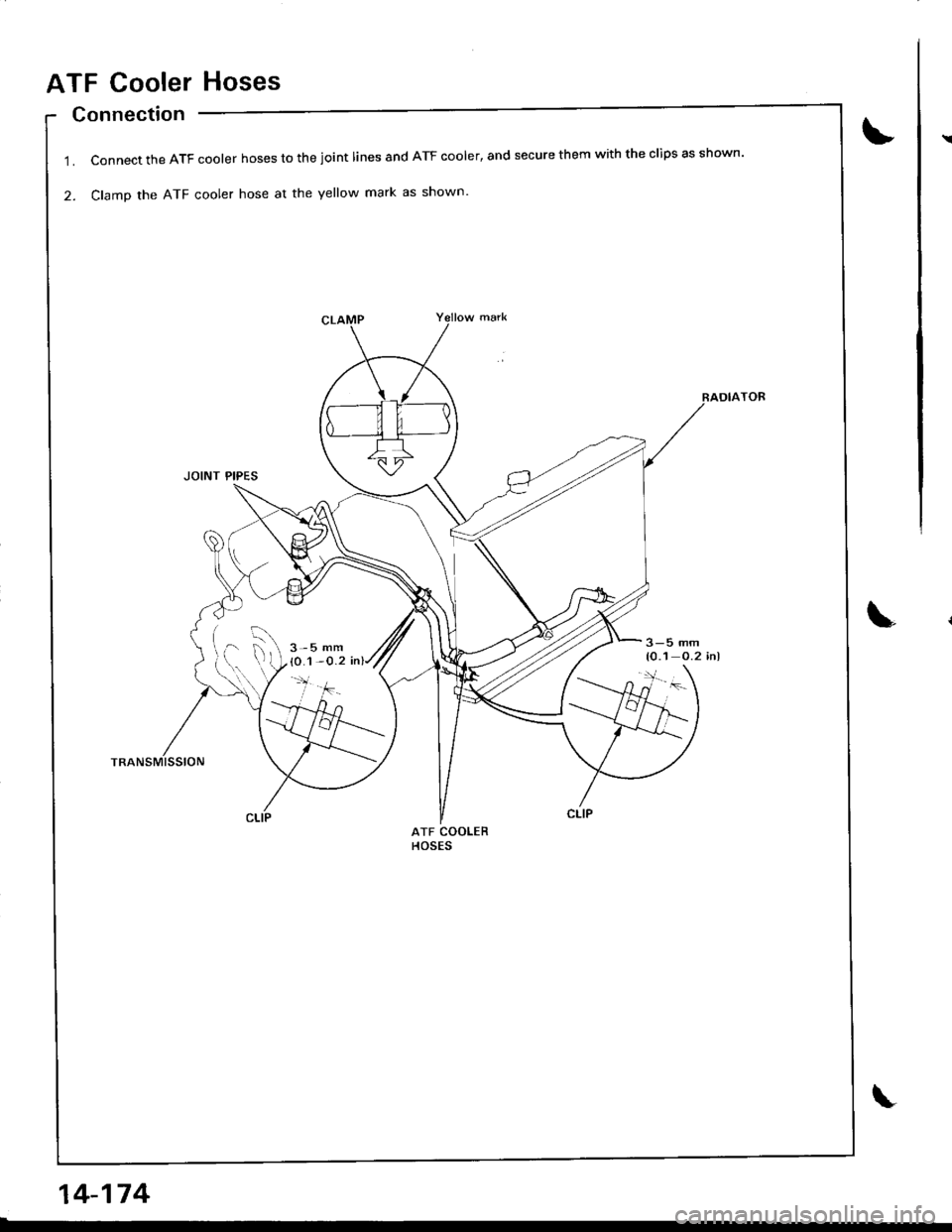

Connect the ATF cooler hoses to the joint lines and ATF cooler, and secure them with the clips as shown'

ClamD the ATF cooler hose at the yellow mark as shown'

JOINT PIPES

TRANSMISSION

1.

2.

ATF COOLERHOSES

/' \, 3-5mm

\..'.'i211..'-,"'"

14-174