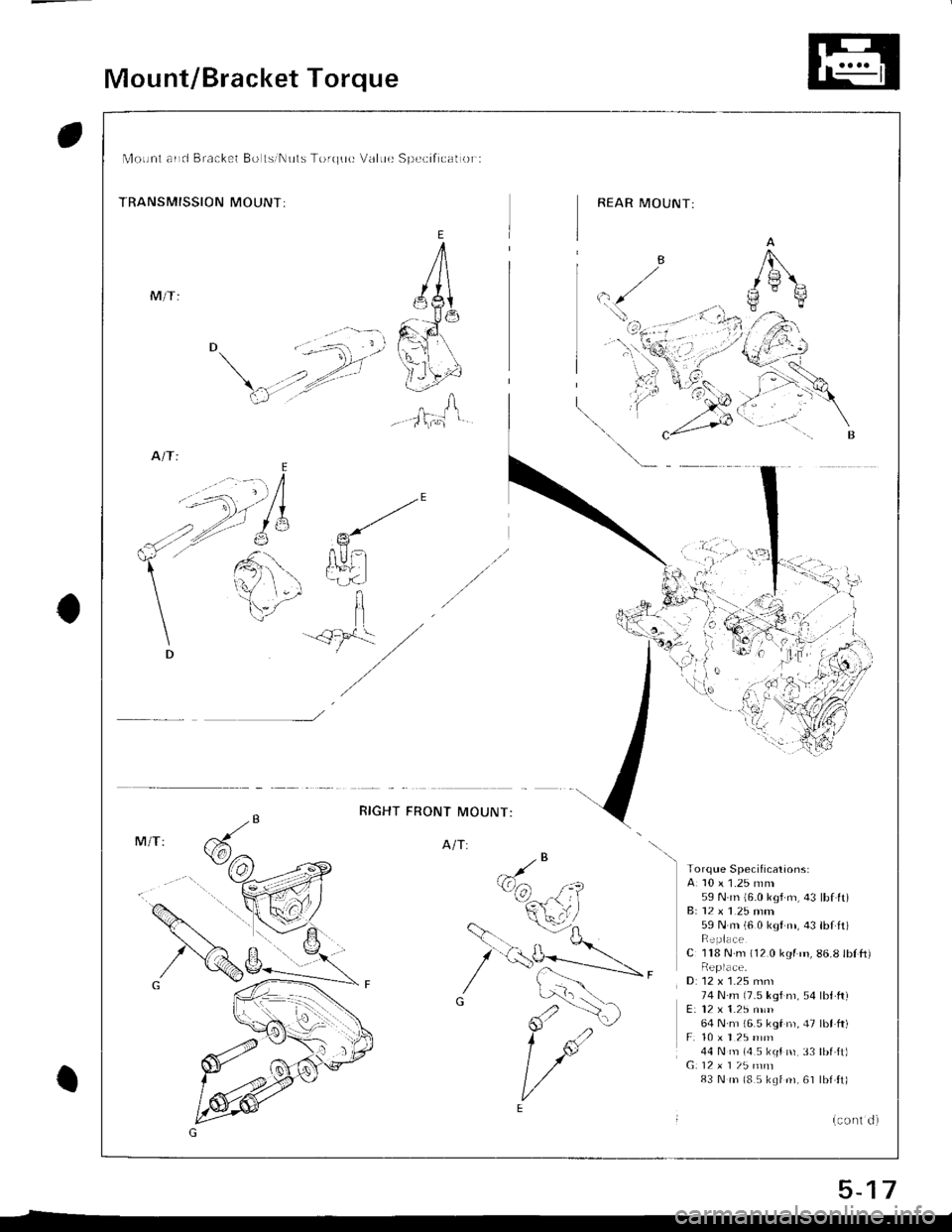

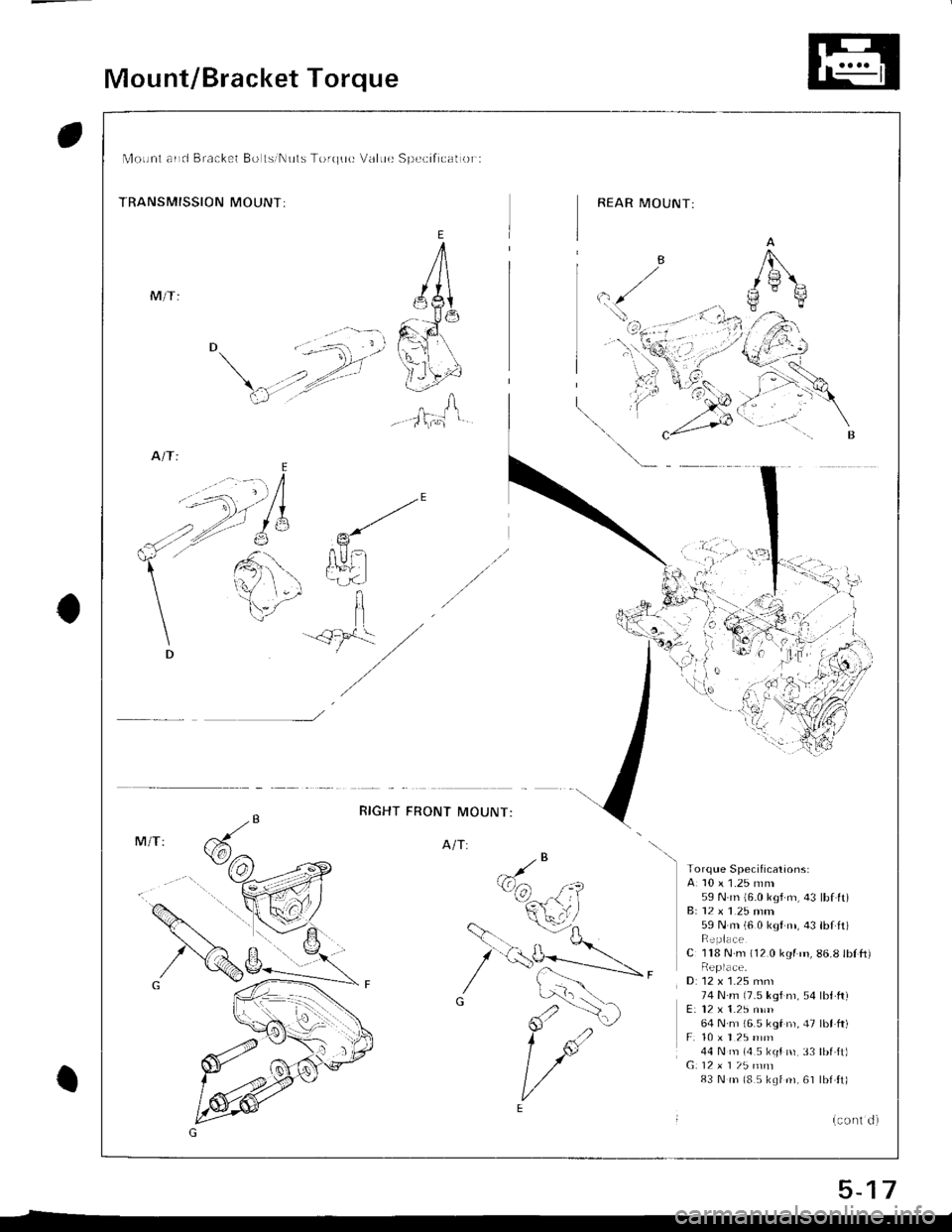

HONDA INTEGRA 1998 4.G Repair Manual

INTEGRA 1998 4.G

HONDA

HONDA

https://www.carmanualsonline.info/img/13/6069/w960_6069-0.png

HONDA INTEGRA 1998 4.G Repair Manual

Trending: Flywheel, wheelbase, USB, differential, sensor, horn, glove box

Page 51 of 1681

7

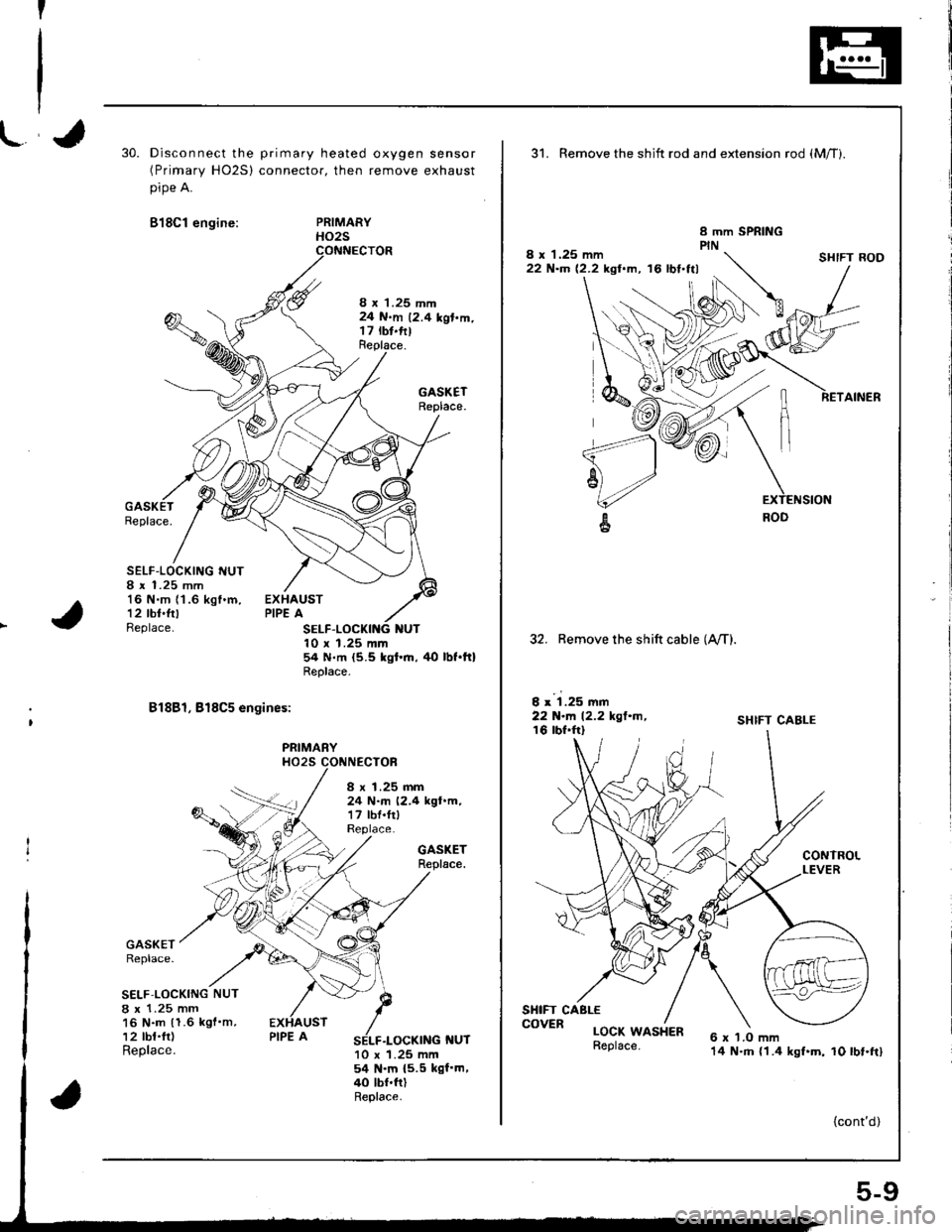

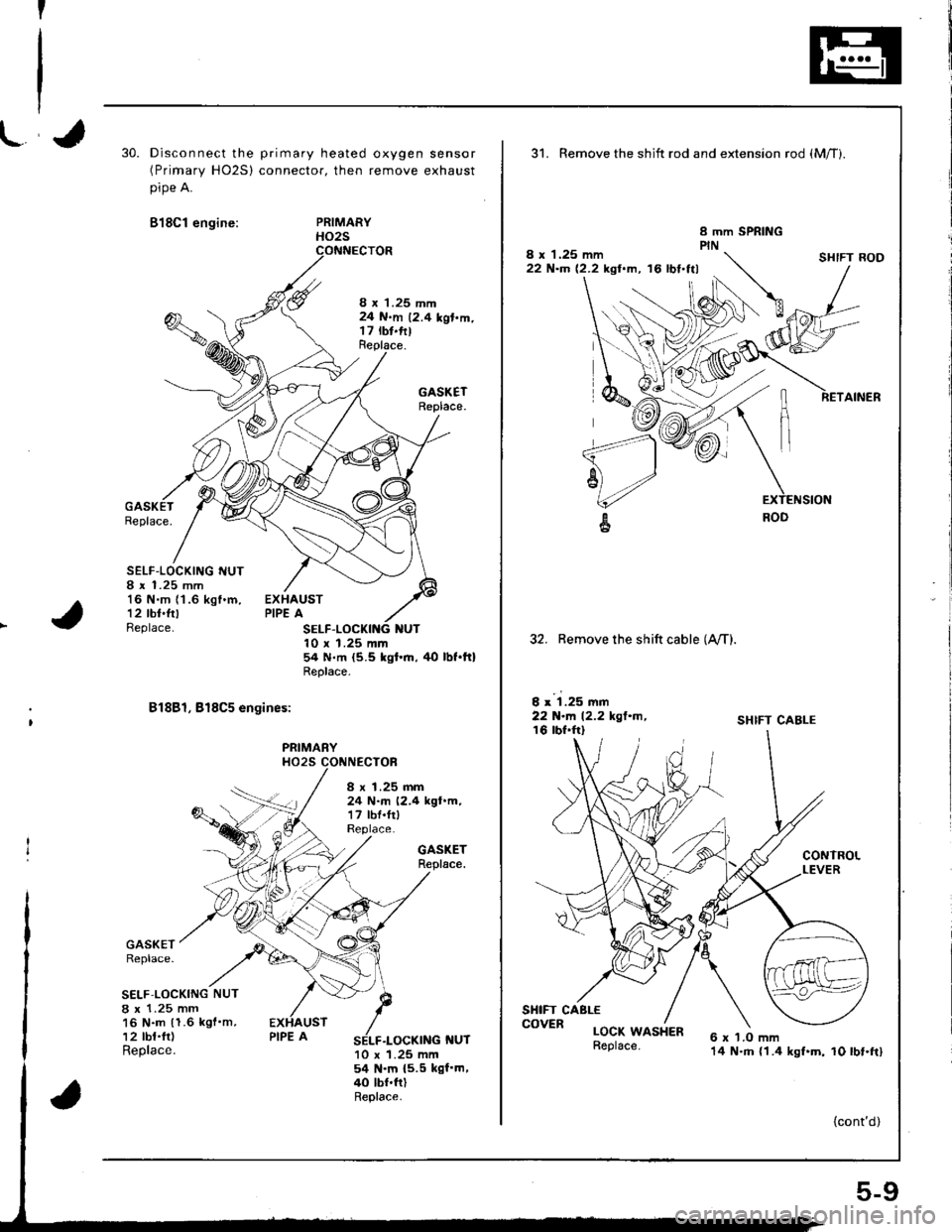

30.Disconnect the primary heated oxygen sensor(Primary HO2S) connector, then remove exhaust

pipe A.

818C1 engine:PRIMARYHO2S

8 x 1.25 mm24 N.m 12.4 kgl.m.t7 rbt.fttReplace.

GASKETReplace.

Replace.

SELF-LOCKING I{UT8 r 1.25 mm16 N.m (1 .6 kgf .m,

12 tbt.frtBeplace.

EXHAUSTPIPE A

NUT10 x 1.25 mm54 N.m {5.5 kgt'.n, tlo lbt.ft}Replace.

81881, 818C5 engines:

PRIMARYHO25 CONNECTOF

GASKETReplace.

GASKETReplace.

S€LF.LOCKING NUT

8 x 1.25 mm16 N.m (1.6 kgf'm,12 tbt.fr)Replace.f{UT10 x 1.25 mm54 N.m {5.5 kgf'm,40 lbf.ftlReplace.

8 x 1.25 mm24 N.m (2.4 kgt.m,17 lbf.frlReplace.

31. Remove the shift rod and extension rod {Mff).

8 x 1.25 mm22 N'm 12.2 kgl.m, '16 lbt.ttl

32. Remove the shift cable (A,/T).

I x 1.25 mm22 N-l'. 12.2 kgl.m,16 lbf.frl

SHIFT CABLE

CONTROLLEVER

6 x 'l.O mm14 N.m {1.4 kgf.m, 10 lbt.ft}

SHIFT ROD

RETAINER

SHIFT CABLE

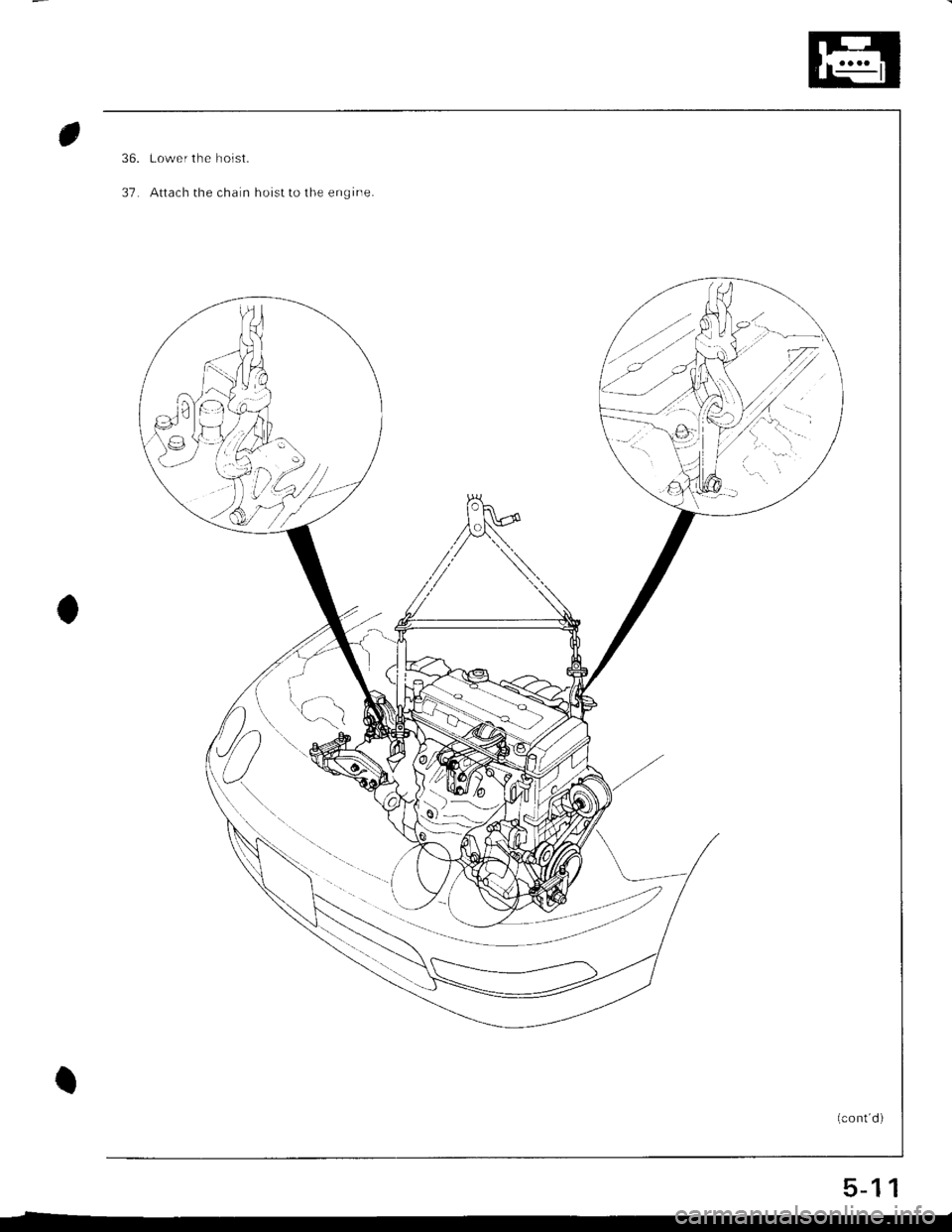

LOCK WASHER

{cont'd)

COVER

5-9

Page 52 of 1681

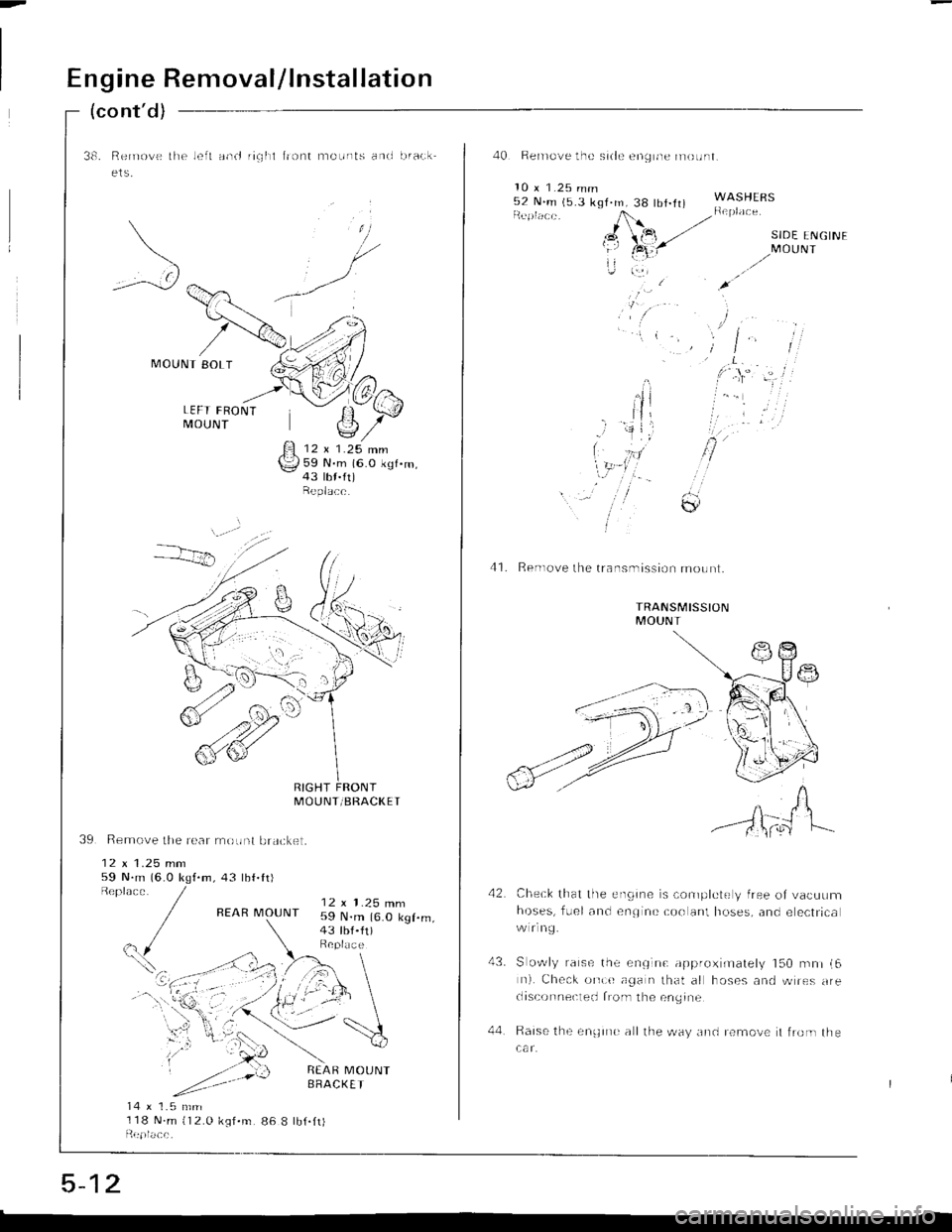

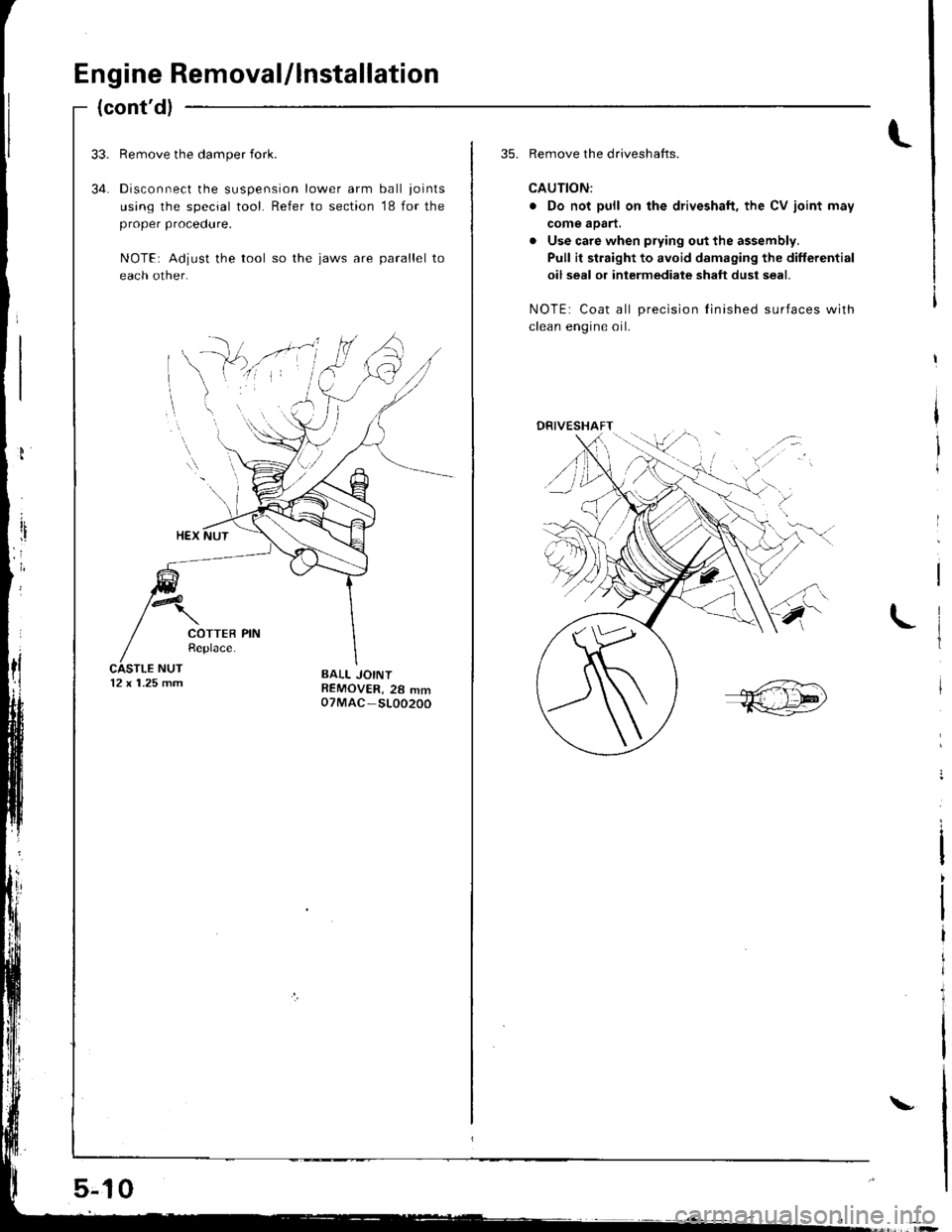

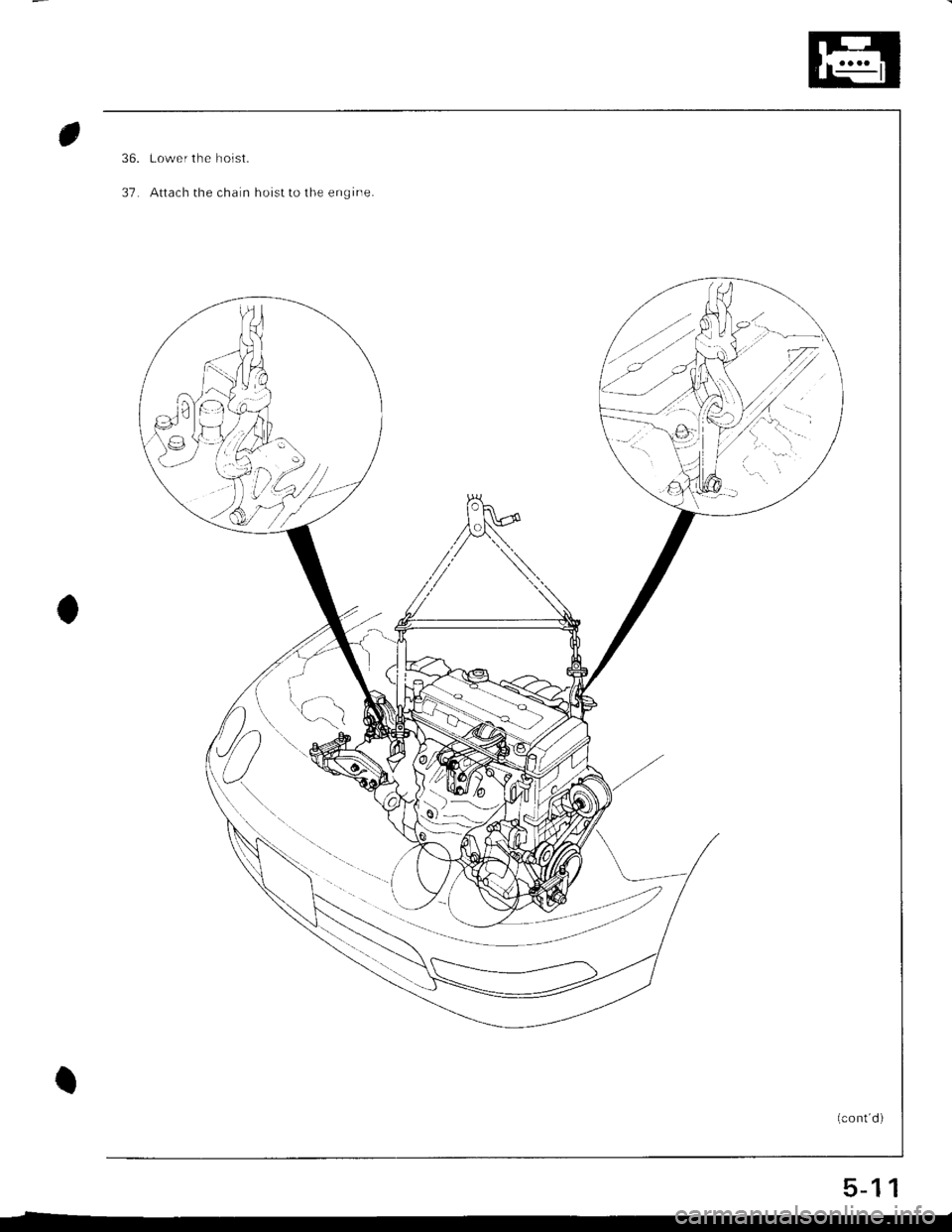

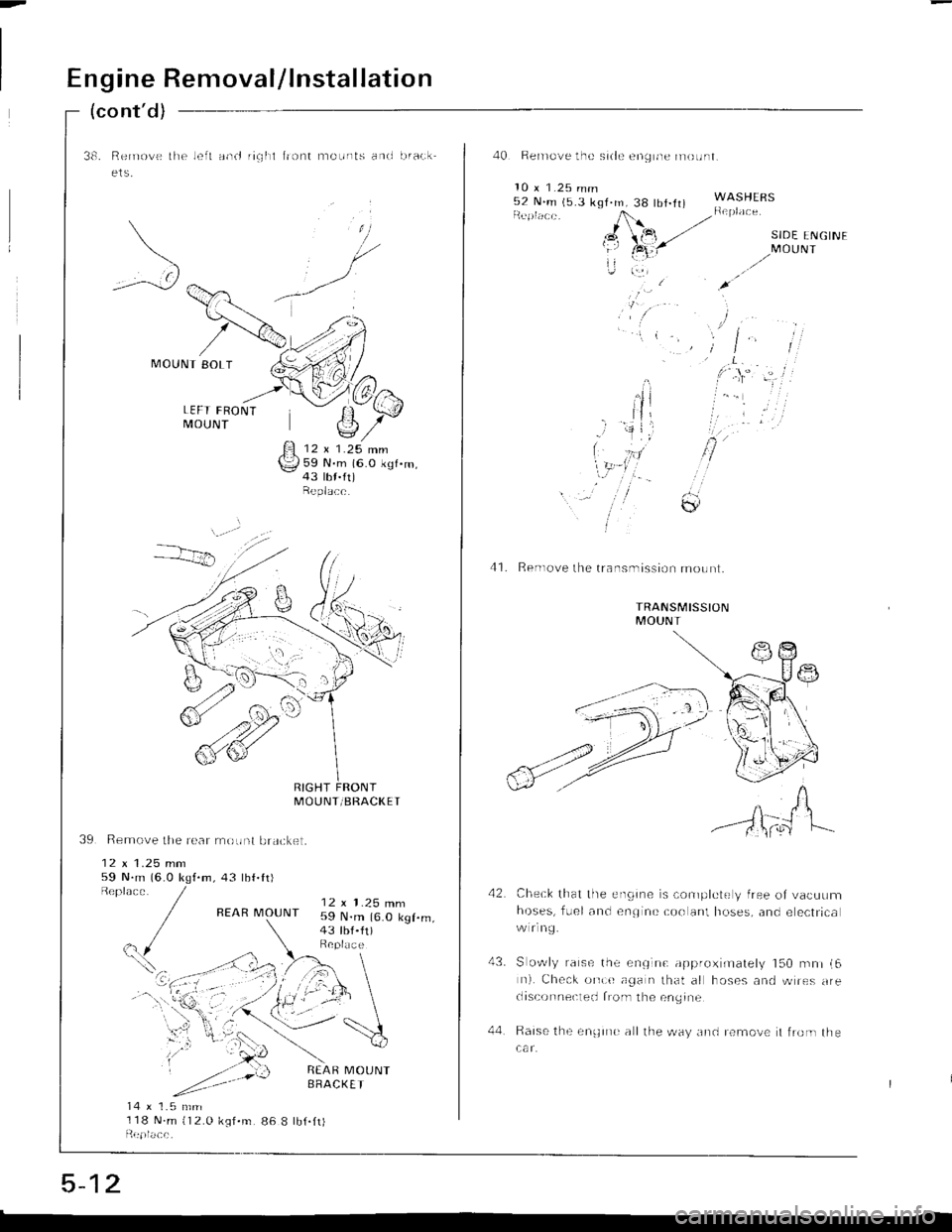

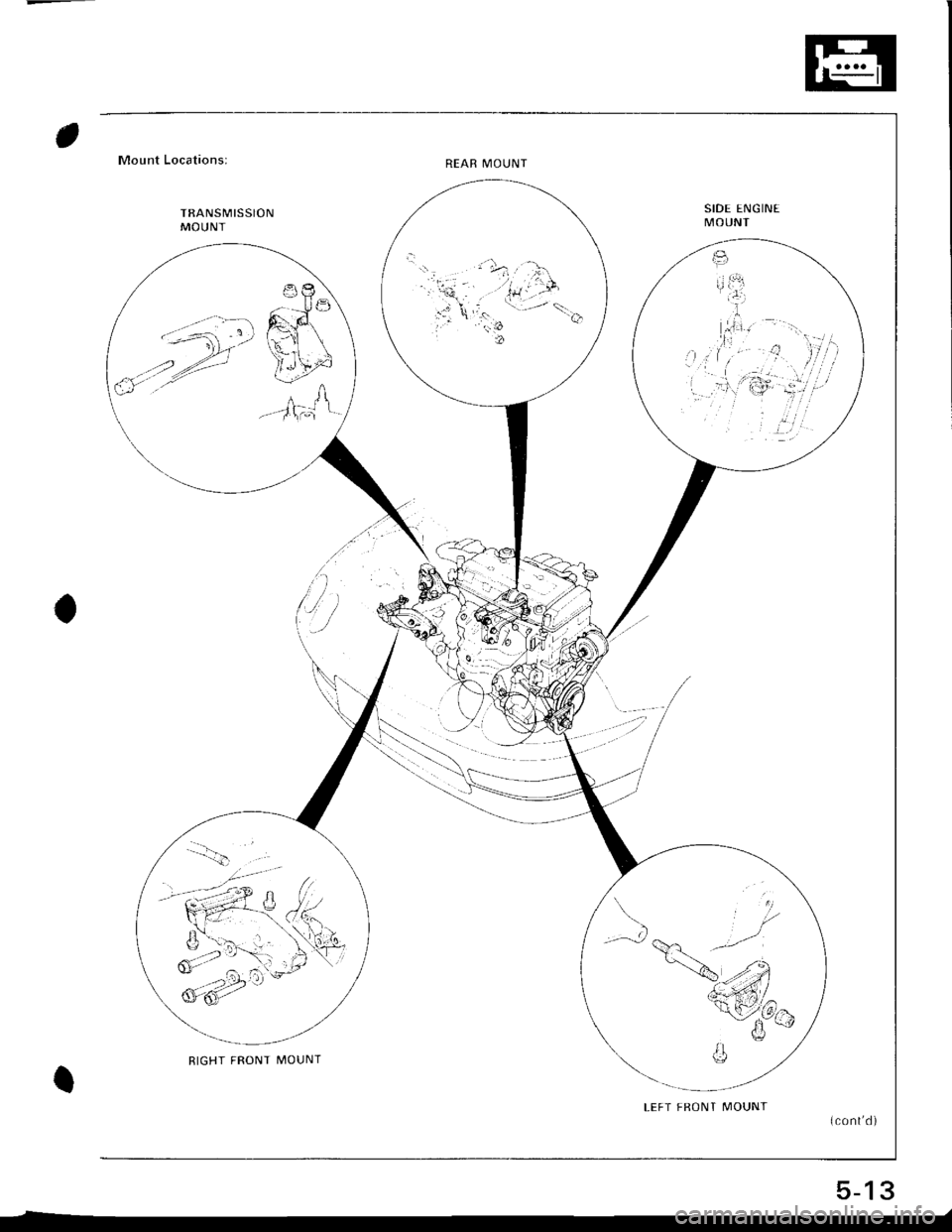

Engine Removal/lnstallation

(cont'dl

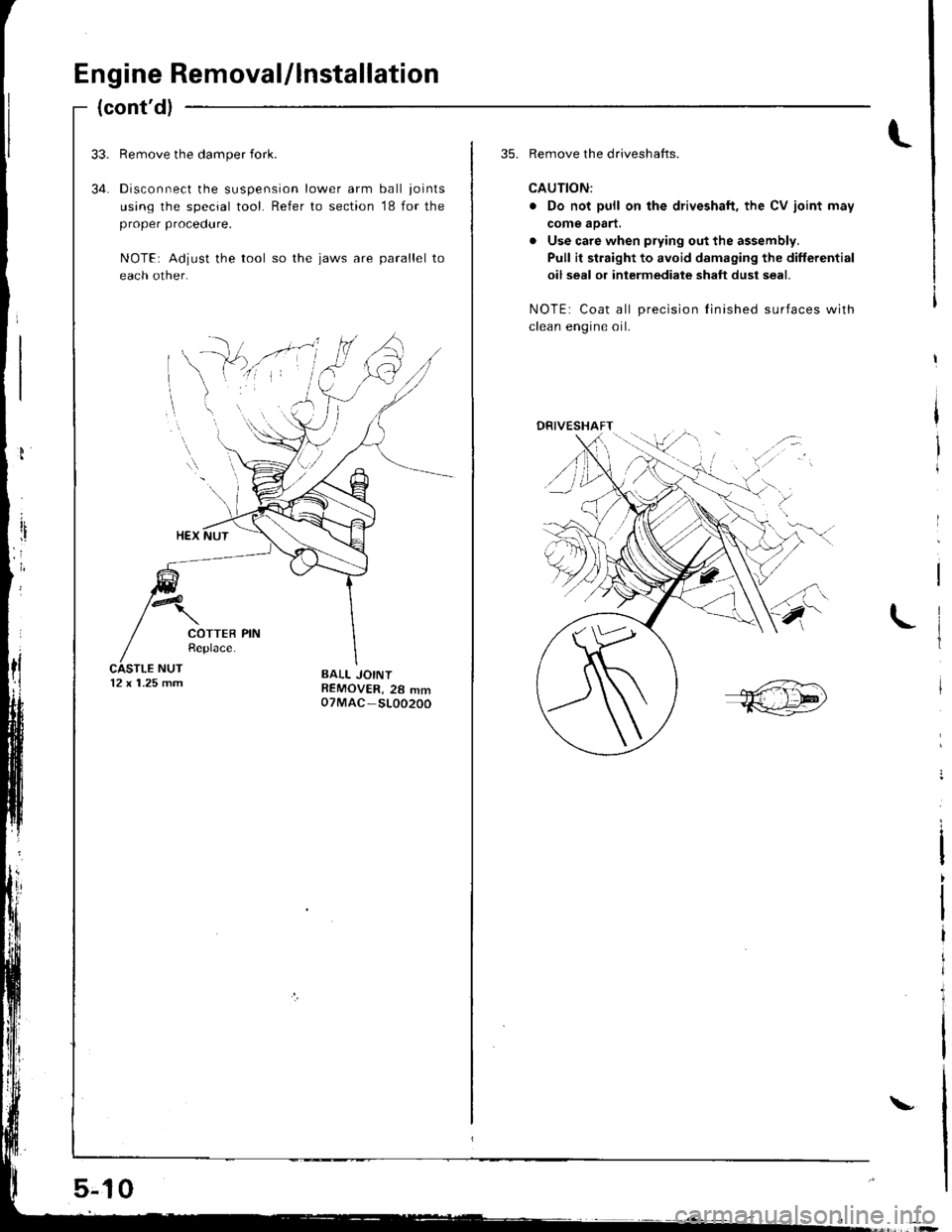

34.

Remove the damper {ork.

Disconnect the suspension lower arm ball joints

using the special tool. Refer to section '18 for the

proper procedure.

NOTE: Adjust the tool so the jaws are parallel to

each other.

12 x 1.25 mm

5-jl0

\

35. Remove the driveshafts.

CAUTION:

. Do not pull on the driveshaft, the CV joint may

come aoart.

. Use care when prying out the assembly.

Pull it straight to avoid damaging the differential

oil seal or intermediate shaft dust seal.

NOTE: Coat all precision Iinished surfaces with

clean enoine oil.

,{:

DRIVESHAFT/.-:

/

Page 53 of 1681

Page 54 of 1681

Page 55 of 1681

Page 56 of 1681

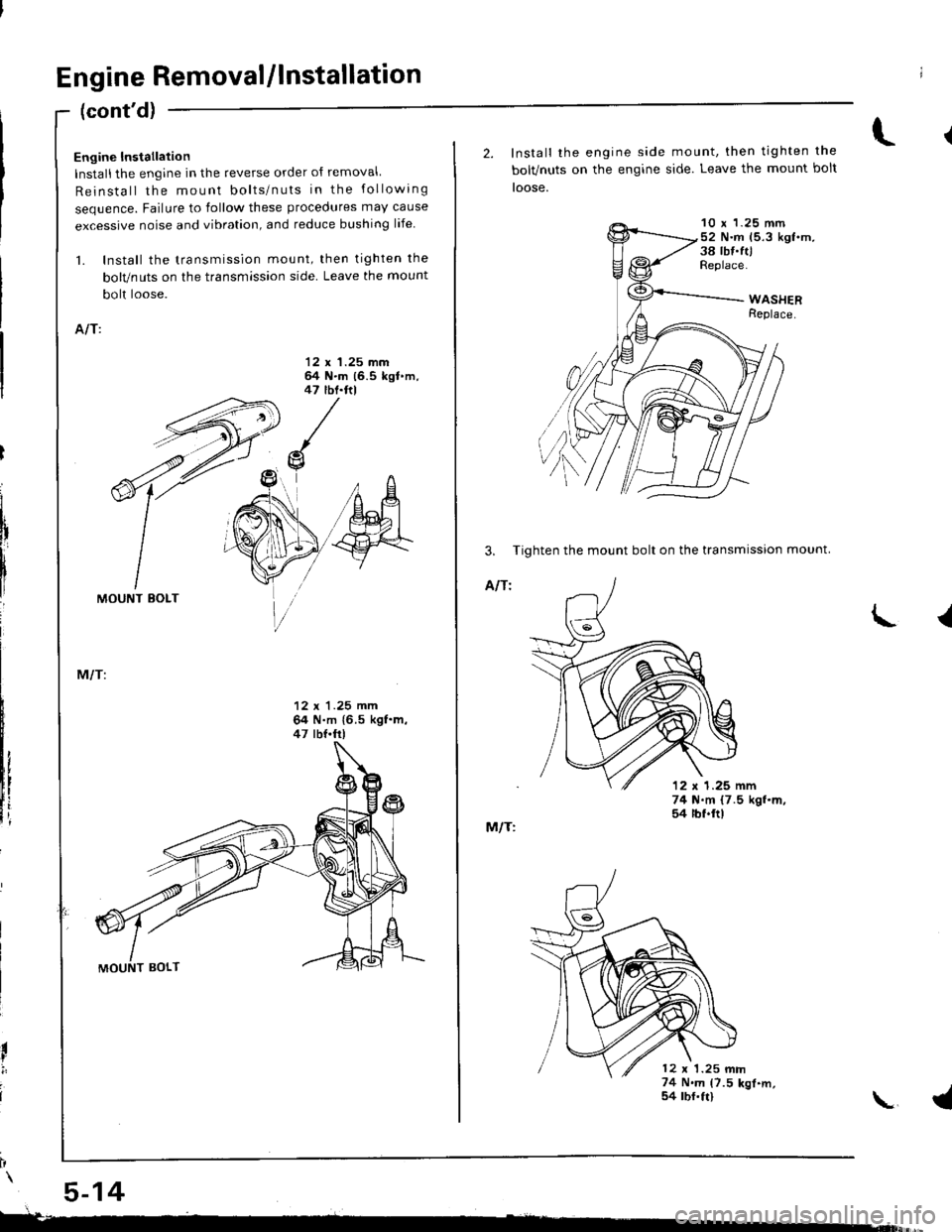

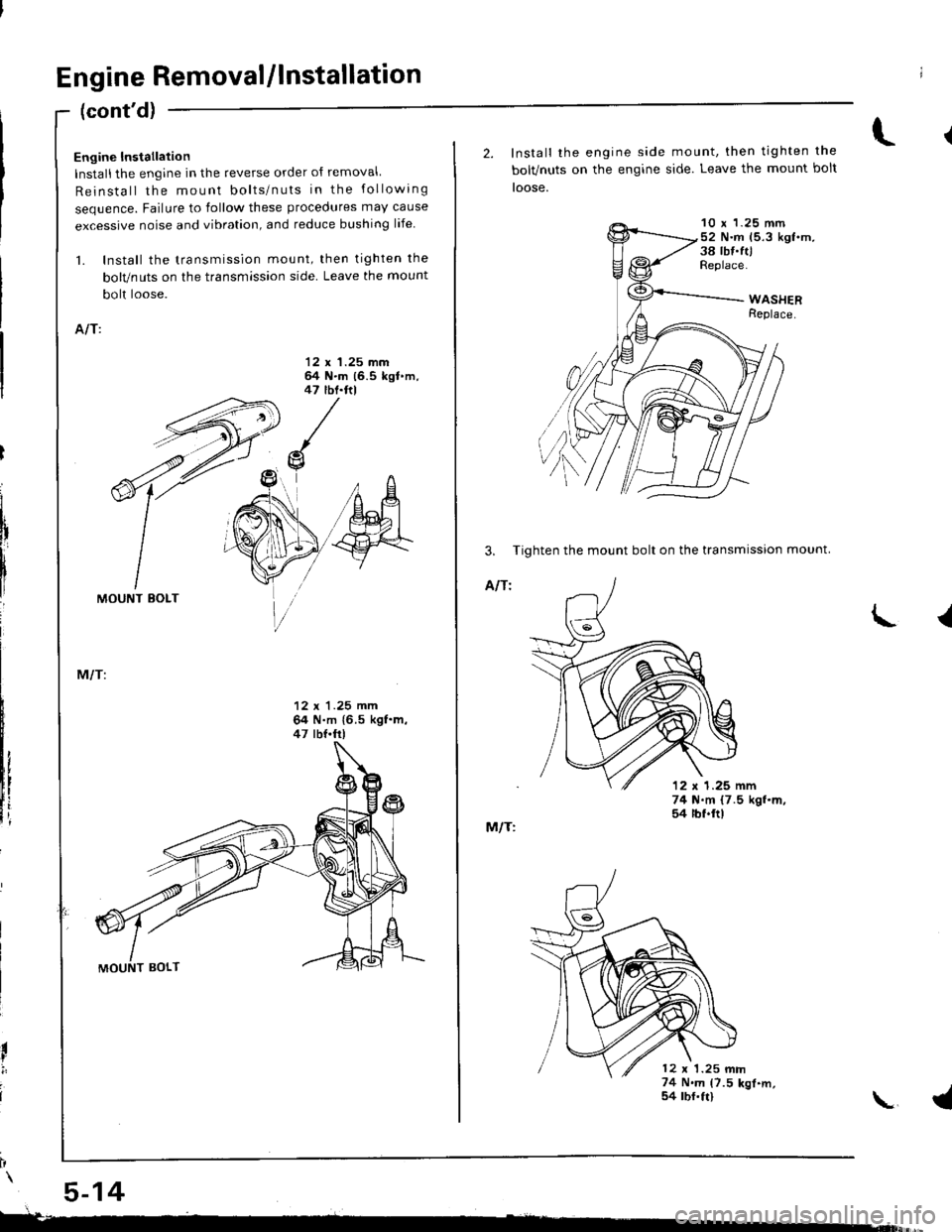

Engine Removal/lnstallation

Engine lnstallation

Installthe engine in the reverse order of removal

Reinstall the mount bolts/nuts in the following

sequence. Failure to follow these procedures may cause

excessive noise and vibration, and reduce bushing life

1. Install the transmission mount, then tighten the

bolvnuts on the tfansmlssion side. Leave the mount

bolt loose.

AIT:

'12 x 1.25 mmg N.m (6.5 kgl'm.

(cont'dl

5-14

47 thl.ftl

/o

llf

MOUNT EOLT

12 x 1.25 mm64 N.m {6.5 kgf.m,47 lbf.fr|

I

I

2. Install the engine side

bolvnuts on the engtne

toose.

M/T:

mo u nt, then tighten the

side. Leave the mount bolt

10 x 1.25 mm52 N.m 15.3 kgf.m,38 tbf.ft,Replace.

3, Tighten the mount bolt on the transmission mount.

AIf l

12 x 1.25 mm

L

\

{

74 N.m 17.5 kgl.m,54 rbf.ftl

12 x 1.25 mm74 N.m (7.5 kgl.m,54 rbf.ftl

Page 57 of 1681

Page 58 of 1681

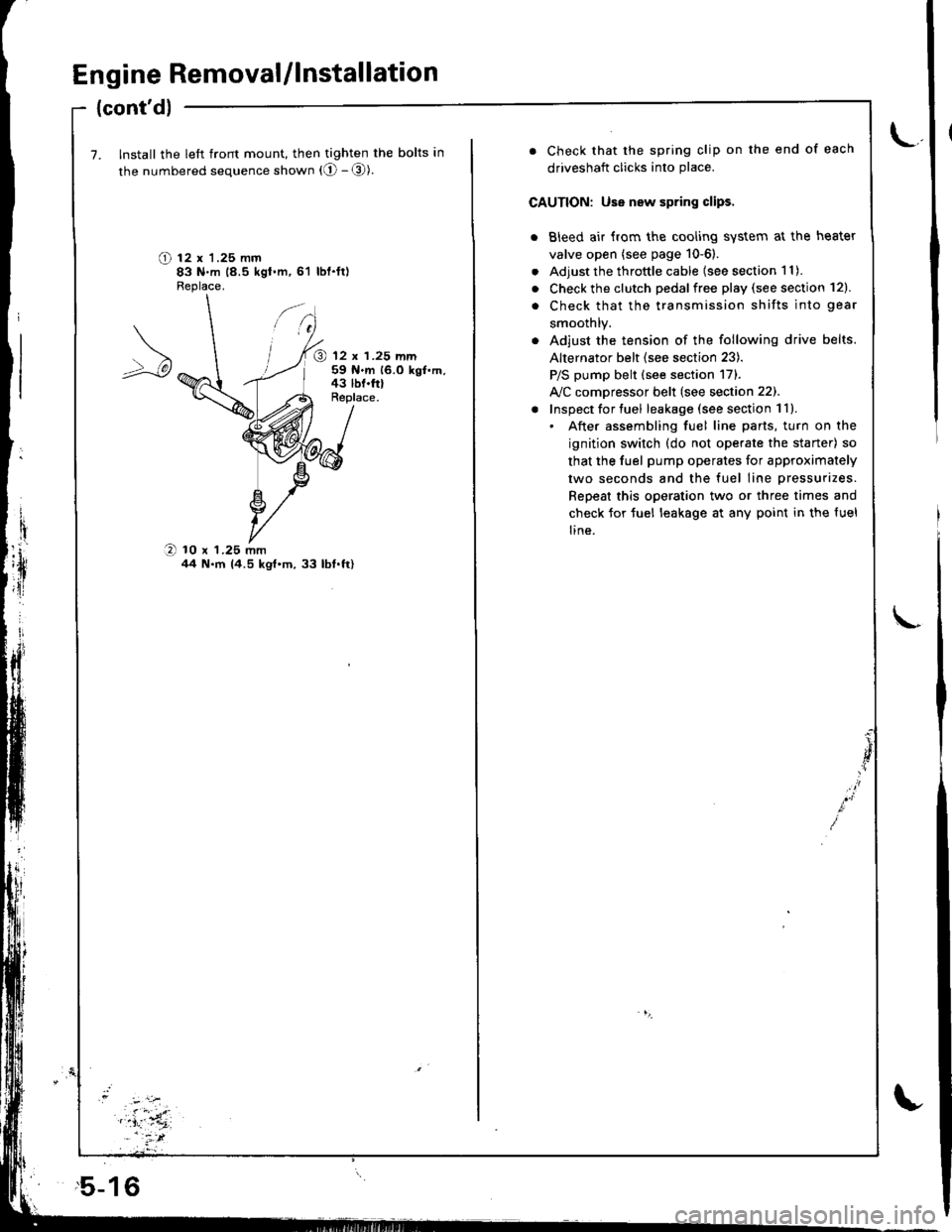

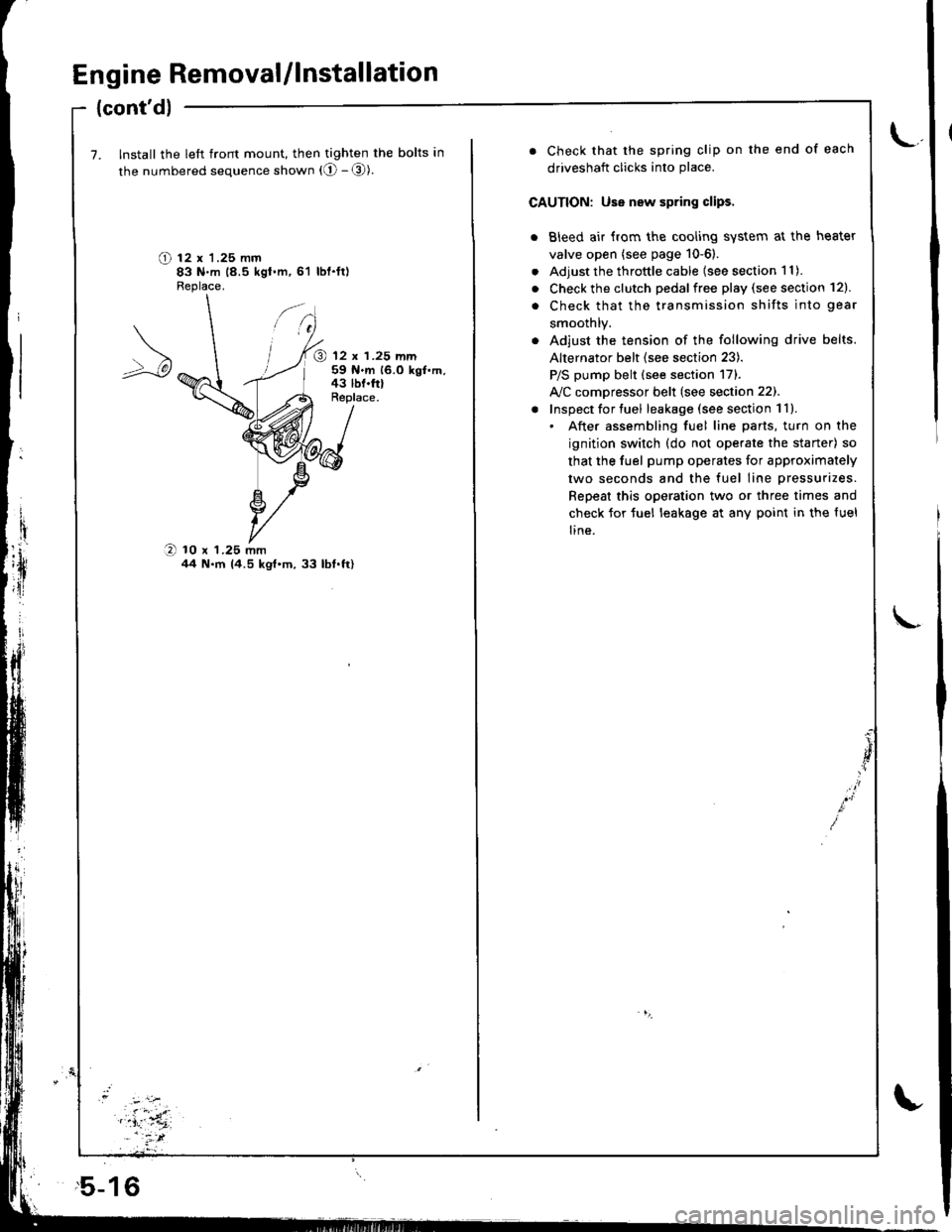

Engine Removal/lnstallation

{cont'dl

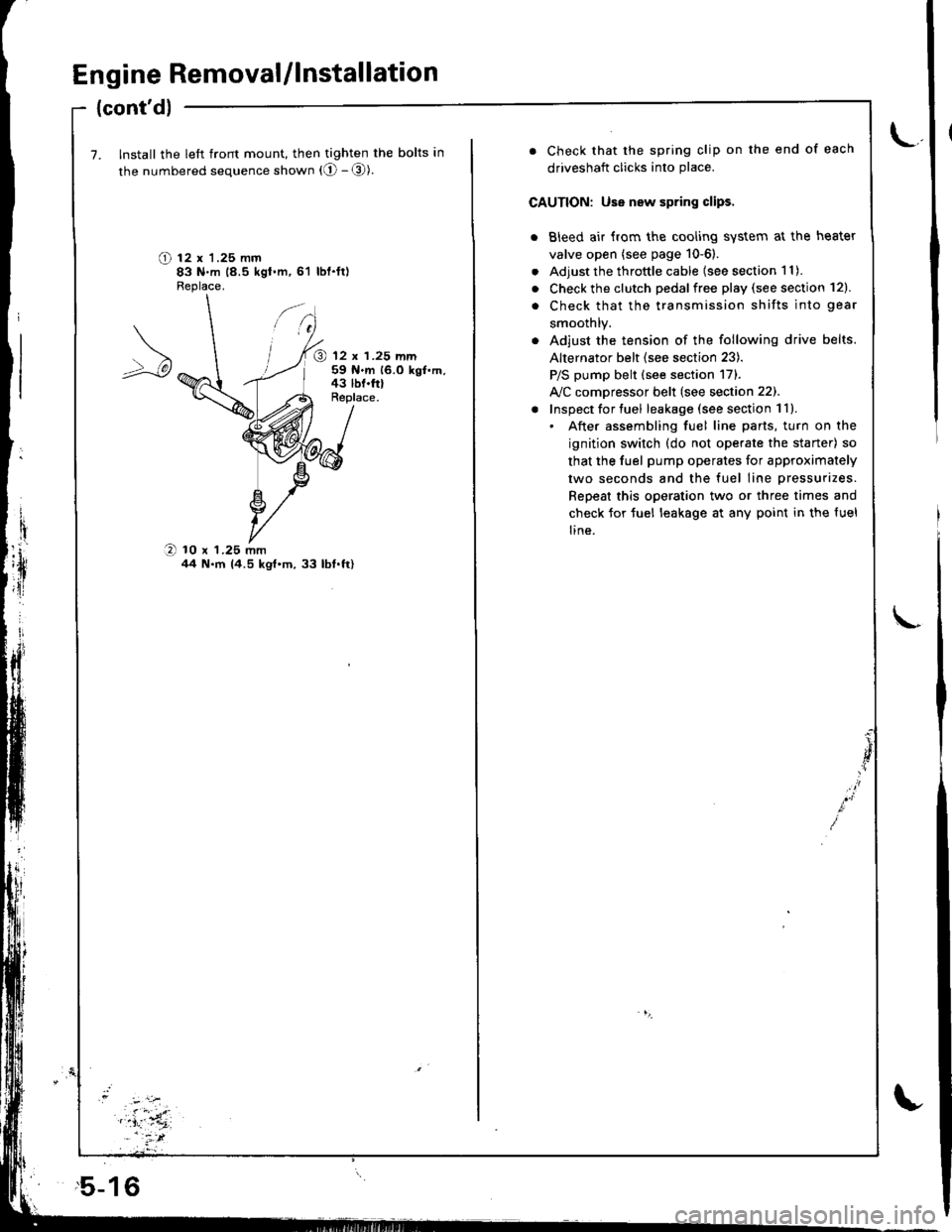

7. Install the left front mount, then tighten the bolts in

the numbered sequence shown (O - @).

O t2 x '1.25 mm83 N.m 18.5 kgt.m,61 lbl.ft)Fleplace.

@ 12 x 1.25 mm59 N.m 16.0 kgf.m,43 lbf.frlReplace.

O 10 x 1.25 mmil4 N.m 14.5 kgt'm,33 lbt.ft)

,5-16

. Check that the spring clip on the end of each

driveshaft clicks into place.

CAUTION: Use new spring clips.

. Bleed air {rom the cooling system at the heater

valve open (see page 10-6).

. Adjust the throttle cable (see section 1 1).

. Check the clutch pedalfree play (see section 12).

. Check that the transmission shifts into gear

smoothlY.

. Adjust the tension of the following drive belts.

Alternator belt {see section 23).

P/S pump belt (see section 171.

A/C comDressor belt (see section 22).

! Inspect for tuel leakage (see section 1ll.. After assembling fuel line parts, turn on the

ignition switch (do not operate the staner) so

that the fuel pump operates for approximately

two seconds and the fuel line pressurizes.

Repeat this operation two or three times and

check for tuel leakage at any point in the {uel

line.

Page 59 of 1681

Page 60 of 1681

Trending: center console, sunroof, brakes, stop start, roof, heater, immobilizer